The Role of Friction Stir Processing Travel Speed on the Microstructure Evolution and Mechanical Performance of As-Cast Hypoeutectic Al-5Si Alloy

Abstract

1. Introduction

2. Materials and Methods

2.1. Casting Process

2.2. Chemical Composition Analysis

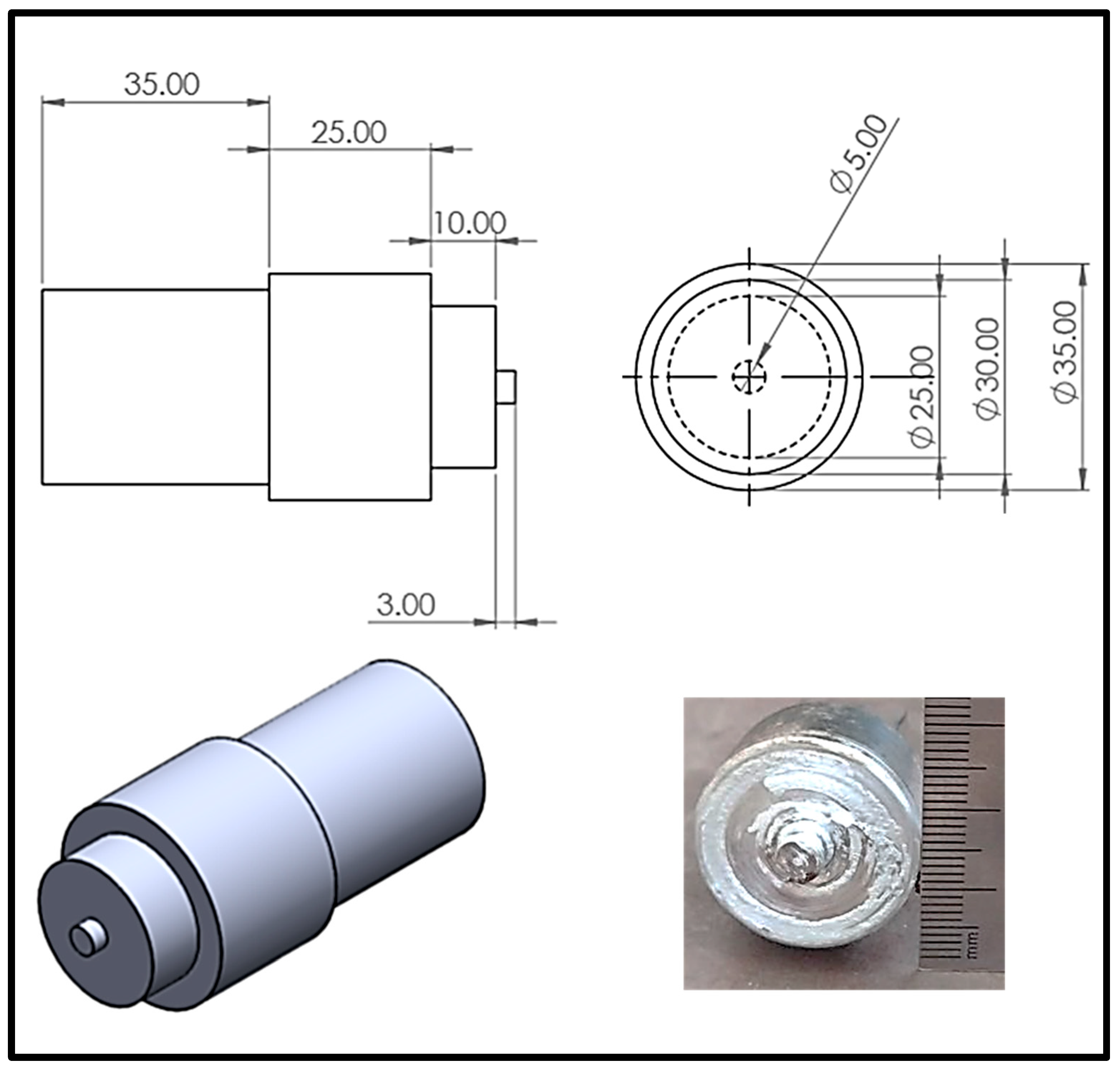

2.3. Friction Stir Processing (FSP)

2.4. Sample Preparation for Microstructure, Mechanical, and Wear Testing

3. Results and Discussion

3.1. Top Surface Features of Friction Stir Processed Specimens

3.2. Microstructure Characterization

3.3. Mechanical Properties of the As-Cast and the FSPed Al-5Si Alloy

3.3.1. Tensile Properties

3.3.2. Microhardness

3.3.3. Impact

3.3.4. Wear Behavior

4. Conclusions

- Friction stir processing (FSP) significantly modifies the microstructure and enhances the mechanical properties of as-cast Al-5Si alloy, with the most pronounced improvements generally observed at lower travel speeds. For instance, at a travel speed of 26 mm/min the hardness improved by up to 39%, ultimate tensile strength (UTS) by up to 51%, impact energy by up to 197%, and wear resistance by up to 64% compared to the as-cast state.

- FSP results in a significant reduction in α-Al grain size. The as-cast Al-5Si alloy exhibited a coarse grain size of 26.24 ± 4.79 µm. Following FSP, the α-Al grain sizes were notably refined to 12.46 ± 1.59 µm, 9.55 ± 1.51 µm, 7.87 ± 1.38 µm, and 7.75 ± 1.34 µm for travel speeds of 26, 33, 42, and 52 mm/min, respectively.

- Compared to the as-cast alloy, which exhibits a heterogeneous coarse structure and poor tensile properties (YS of 57 MPa, UTS of 108.7 MPa, and strain at fracture of 3.6%), FSP significantly enhances the UTS and strain at fracture of Al-5Si alloys, particularly at lower travel speeds (26 and 33 mm/min). The sample processed at 26 mm/min achieved the highest UTS (164.5 MPa) and strain at fracture (10.2%), primarily due to porosity elimination and the breakdown/dispersion of the dendrite arm structure and eutectic Si-phase. While higher travel speeds (42 and 52 mm/min) still showed improvement (e.g., UTS of 131.2 MPa and strain at fracture of 10% at 52 mm/min), the enhancement was less pronounced than at lower speeds. FPS improves the toughness of Al-5Si alloys at all travel speeds, and the impact energy reached its highest value of 12.5 ± 0.57 J at a travel speed of 26 compared to 4.2 ± 1 J for the as-cast state, indicating a predominantly ductile fracture mode.

- Analysis of tensile and impact fracture surfaces confirmed changes in failure mechanisms. The as-cast Al-5Si alloy primarily exhibited brittle fracture, characterized by flat faced regions and limited plastic deformation. In contrast, the FSPed alloy, especially at a travel speed of 26 mm/min, showed a predominantly ductile fracture mode with numerous deep, equiaxed dimples, consistent with improved toughness. At the highest processing travel speed of 52 mm/min, a mixed mode fracture (combining ductile dimples and brittle cleavage facets) was observed.

- The wear resistance of the Al-5Si alloy was significantly enhanced by FSP. The wear rate of the as-cast Al-5Si alloy was 9.23 ± 1.2 × 10−6 g/m, which is substantially higher than that of all FSPed materials. The lowest wear rate, indicating the highest wear resistance, was achieved at a travel speed of 26 mm/min (3.31 ± 0.8 × 10−6 g/m). While FSP generally improved wear resistance, the wear rate progressively increased with higher travel speeds, reaching 4.63 ± 0.9 × 10−6 g/m at 33 mm/min, 5.29 ± 0.7 × 10−6 g/m at 42 mm/min, and 8.6 ± 0.9 × 10−6 g/m at 52 mm/min. This trend highlights the optimal balance of microstructural refinement and heat input at lower travel speeds for superior wear performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jeong, C.; Kang, C.-S.; Cho, J.-I.; Oh, I.-H.; Kim, Y.-C. Effect of microstructure on mechanical properties for A356 casting alloy. Int. J. Cast Met. Res. 2008, 21, 193–197. [Google Scholar] [CrossRef]

- Kang, M.; Kwon, H.; Byon, E.; Lee, E. Anti-corrosion and wear performance of Al-Si coating deposited by wire arc spray for marine applications. J. Adv. Mar. Eng. Technol. 2023, 47, 175–186. [Google Scholar] [CrossRef]

- Alzahrani, B.; El-Sayed Seleman, M.M.; Ahmed, M.M.Z.; Elfishawy, E.; Ahmed, A.M.; Touileb, K.; Jouini, N.; Habba, M.I. The applicability of die cast A356 alloy to additive friction stir deposition at various feeding speeds. Materials 2021, 14, 6018. [Google Scholar] [CrossRef]

- Bohlooli, V.; Shabani Mahalli, M.; Boutorabi, S. Effect of ablation casting on microstructure and casting properties of A356 aluminium casting alloy. Acta Metall. Sin. 2013, 26, 85–91. [Google Scholar] [CrossRef]

- Wang, Q. Microstructural effects on the tensile and fracture behavior of aluminum casting alloys A356/357. Metall. Mater. Trans. A 2003, 34, 2887–2899. [Google Scholar] [CrossRef]

- Merlin, M.; Timelli, G.; Bonollo, F.; Garagnani, G.L. Impact behaviour of A356 alloy for low-pressure die casting automotive wheels. J. Mater. Process. Technol. 2009, 209, 1060–1073. [Google Scholar] [CrossRef]

- Jiang, W.; Fan, Z.; Liu, D.; Liao, D.; Dong, X.; Zong, X. Correlation of microstructure with mechanical properties and fracture behavior of A356-T6 aluminum alloy fabricated by expendable pattern shell casting with vacuum and low-pressure, gravity casting and lost foam casting. Mater. Sci. Eng. A 2013, 560, 396–403. [Google Scholar] [CrossRef]

- Nafisi, S.; Ghomashchi, R. Grain refining of conventional and semi-solid A356 Al–Si alloy. J. Mater. Process. Technol. 2006, 174, 371–383. [Google Scholar] [CrossRef]

- Kolahdooz, A.; Dehkordi, S.A. Effects of important parameters in the production of Al-A356 alloy by semi-solid forming process. J. Mater. Res. Technol. 2019, 8, 189–198. [Google Scholar] [CrossRef]

- Nafisi, S.; Ghomashchi, R. Effects of modification during conventional and semi-solid metal processing of A356 Al-Si alloy. Mater. Sci. Eng. A 2006, 415, 273–285. [Google Scholar] [CrossRef]

- Jamaati, R.; Amirkhanlou, S.; Toroghinejad, M.R.; Niroumand, B. Significant improvement of semi-solid microstructure and mechanical properties of A356 alloy by ARB process. Mater. Sci. Eng. A 2011, 528, 2495–2501. [Google Scholar] [CrossRef]

- Khosravi, H.; Eslami-Farsani, R.; Askari-Paykani, M. Modeling and optimization of cooling slope process parameters for semi-solid casting of A356 Al alloy. Trans. Nonferrous Met. Soc. China 2014, 24, 961–968. [Google Scholar] [CrossRef]

- Chou, S.; Trask, M.; Danovitch, J.; Wang, X.; Choi, J.; Brochu, M. Pulsed laser powder bed fusion additive manufacturing of A356. Mater. Charact. 2018, 143, 27–33. [Google Scholar] [CrossRef]

- Carneiro, V.H.; Rawson, S.; Puga, H.; Withers, P. Macro-, meso-and microstructural characterization of metallic lattice structures manufactured by additive manufacturing assisted investment casting. Sci. Rep. 2021, 11, 4974. [Google Scholar] [CrossRef]

- Fan, H.; Witvrouw, A.; Wolf-Monheim, F.; Souschek, R.; Yang, S. Effects of substrate surface treatments on hybrid manufacturing of AlSi7Mg using die casting and selective laser melting. J. Mater Sci. Technol. 2023, 156, 142–156. [Google Scholar] [CrossRef]

- Mehmood, A.; Shah, M.; Sheikh, N.A.; Qayyum, J.A.; Khushnood, S. Grain refinement of ASTM A356 aluminum alloy using sloping plate process through gravity die casting. Alex. Eng. J. 2016, 55, 2431–2438. [Google Scholar] [CrossRef]

- Lin, J.-H.; Zhao, H.-D.; Huang, J.-M. Spatial interfacial heat transfer and surface characteristics during gravity casting of A356 alloy. Trans. Nonferrous Met. Soc. China 2019, 29, 43–50. [Google Scholar] [CrossRef]

- Ceschini, L.; Morri, A.; Morri, A.; Pivetti, G. Predictive equations of the tensile properties based on alloy hardness and microstructure for an A356 gravity die cast cylinder head. Mater. Des. 2011, 32, 1367–1375. [Google Scholar] [CrossRef]

- Huang, L.; Du, X.; Zhuang, Q.; Huang, C.; Li, J. Effect of alloying elements Mg and Cu on the modification of eutectic silicon in hypoeutectic Al–Si alloys. Metals 2023, 13, 1995. [Google Scholar] [CrossRef]

- Gursoy, O.; Timelli, G. Lanthanides: A focused review of eutectic modification in hypoeutectic Al–Si alloys. J. Mater. Res. Technol. 2020, 9, 8652–8666. [Google Scholar] [CrossRef]

- Callegari, B.; Lima, T.N.; Coelho, R.S. The influence of alloying elements on the microstructure and properties of Al-Si-based casting alloys: A review. Metals 2023, 13, 1174. [Google Scholar] [CrossRef]

- Hegde, S.; Prabhu, K.N. Modification of eutectic silicon in Al–Si alloys. J. Mater. Sci. 2008, 43, 3009–3027. [Google Scholar] [CrossRef]

- Fracchia, E.; Gobber, F.S.; Rosso, M. Effect of alloying elements on the Sr modification of Al-Si cast alloys. Metals 2021, 11, 342. [Google Scholar] [CrossRef]

- Ding, W.; Gou, L.; Hu, L.; Zhang, H.; Zhao, W.; Ma, J.; Qiao, J.; Li, X. Modification of eutectic Si in hypoeutectic Al-Si alloy with novel Al-3Ti-4.35 La master alloy. J. Alloys Compd. 2022, 929, 167350. [Google Scholar] [CrossRef]

- Jiang, D.; Yu, J. Simultaneous refinement and modification of the eutectic Si in hypoeutectic Al–Si alloys achieved via the addition of SiC nanoparticles. J. Mater. Res. Technol. 2019, 8, 2930–2943. [Google Scholar] [CrossRef]

- Al-Helal, K.; Stone, I.; Fan, Z. Simultaneous primary Si refinement and eutectic modification in hypereutectic Al–Si alloys. Trans. Indian Inst. Met. 2012, 65, 663–667. [Google Scholar] [CrossRef]

- Manani, S.; Pradhan, A. Effects of melt thermal treatment on cast Al-Si alloys: A review. Mater. Today Proc. 2022, 62, 6568–6572. [Google Scholar] [CrossRef]

- Samuel, A.; Garza-Elizondo, G.; Doty, H.; Samuel, F. Role of modification and melt thermal treatment processes on the microstructure and tensile properties of Al–Si alloys. Mater. Des. 2015, 80, 99–108. [Google Scholar] [CrossRef]

- Xu, C.; Yang, Y.; Wang, H.; Jiang, Q. Effects of modification and heat-treatment on the abrasive wear behavior of hypereutectic Al–Si alloys. J. Mater. Sci. 2007, 42, 6331–6338. [Google Scholar] [CrossRef]

- Shabestari, S.; Shahri, F. Influence of modification, solidification conditions and heat treatment on the microstructure and mechanical properties of A356 aluminum alloy. J. Mater. Sci. 2004, 39, 2023–2032. [Google Scholar] [CrossRef]

- Pan, T.-A.; Tzeng, Y.-C. Impact of Sr and La Modification and Post-Heat Treatment on Microstructural Evolution and Thermal Conductivity of Hypoeutectic Al-Si Alloys. J. Alloys Compd. 2025, 1032, 181114. [Google Scholar] [CrossRef]

- Ma, X.; Pan, Y.; Chen, L.; Hua, H.; Hou, J.; Zhao, Y. Effects of Cu and Mg alloying and low-temperature aging on microstructure characteristics and mechanical properties of heat treatment-free cast Al-Si-Cu-Mg alloys. J. Mater. Res. Technol. 2025, 36, 7081–7093. [Google Scholar] [CrossRef]

- Sahu, B.P.; Andani, M.T.; Ghosh, A.; Wang, J.; Misra, A. Crystallography and Interface Structures in As-Arc Melted and Laser Surface-Remelted Aluminum–Silicon Alloys with and without Strontium Addition. Crystals 2024, 14, 283. [Google Scholar] [CrossRef]

- Bashir, N.; Iqbal, A. Characterizing Laser-Modified Microstructures and Electrical and Mechanical Properties of Al-15.3% Si (wt.%) Alloys. J. Mater. Eng. Perform. 2024, 33, 2196–2208. [Google Scholar] [CrossRef]

- Babalou, R.; Azarbarmas, M.; Prashanth, K.G. Heat treatment and laser shock peening of AlSi10Mg alloy produced by selective laser melting: Microstructure, hardness and residual stress analysis. Mater. Today Commun. 2025, 45, 112408. [Google Scholar] [CrossRef]

- Snopiński, P.; Yu, T.; Zhang, X.; Jensen, D.J. Effect of multi-pass shot peening on the microstructure of LPBF AlSi10Mg alloy. In Proceedings of the 44th Risø International Symposium on Materials Science (RISO 2024), Roskilde, Denmark, 2–6 September 2024; p. 012039. [Google Scholar] [CrossRef]

- Asharsheikh, B.; Daneshifar, M.H.; Jabbareh, M.A. Effect of Friction Stir Processing on the Microstructure and Mechanical Properties of Iron-Bearing A356 Cast Aluminum Alloy. Int. J. Met. 2025, 1–12. [Google Scholar] [CrossRef]

- Wais, A.M.H.; Salman Ahmed, J.M.; Al-Roubaiy, O. Influence of friction stir processing on mechanical properties and the microstructure of aluminum-silicon cast alloys. Jordan J. Mech. Ind. Eng. 2025, 19, 203–214. [Google Scholar] [CrossRef]

- Singh, K.; Hussain, M.I.; Pancholi, V.; Kashyap, B.P. Effect of friction stir processing on grain refinement and superplastic properties of binary Al-8 wt.% Si to Al-30 wt.% Si alloys. Philos. Mag. 2025, 105, 229–260. [Google Scholar] [CrossRef]

- Traiano, D.; do Nascimento Rosa, S.; Lourençato, L.A.; Sánchez Roca, A.; Sánchez Orozco, M.C.; Carvajal Fals, H.D. Multiresponse optimization applied to friction-stir processing to enhance wear and corrosion performance in Al–Si alloys. Discov. Appl. Sci. 2024, 6, 643. [Google Scholar] [CrossRef]

- Meenia, S.; Khan, F.; Babu, S.; Immanuel, R.; Panigrahi, S.; Ram, G.J. Particle refinement and fine-grain formation leading to enhanced mechanical behaviour in a hypo-eutectic Al–Si alloy subjected to multi-pass friction stir processing. Mater. Charact. 2016, 113, 134–143. [Google Scholar] [CrossRef]

- Singh, S.K.; Immanuel, R.; Babu, S.; Panigrahi, S.; Ram, G.J. Influence of multi-pass friction stir processing on wear behaviour and machinability of an Al-Si hypoeutectic A356 alloy. J. Mater. Process. Technol. 2016, 236, 252–262. [Google Scholar] [CrossRef]

- Charandabi, F.K.; Jafarian, H.R.; Mahdavi, S.; Javaheri, V.; Heidarzadeh, A. Modification of microstructure, hardness, and wear characteristics of an automotive-grade Al-Si alloy after friction stir processing. J. Adhes. Sci. Technol. 2021, 35, 2696–2709. [Google Scholar] [CrossRef]

- Bates, W.P.; Patel, V.; Rana, H.; Andersson, J.; De Backer, J.; Igestrand, M.; Fratini, L. Properties augmentation of cast hypereutectic Al–Si alloy through friction stir processing. Met. Mater. Int. 2023, 29, 215–228. [Google Scholar] [CrossRef]

- Cheng, W.; Liu, C.; Ge, Z. Optimizing the mechanical properties of Al–Si alloys through friction stir processing and rolling. Mater. Sci. Eng. A 2021, 804, 140786. [Google Scholar] [CrossRef]

- Elfishawy, E.; Ahmed, M.M.Z.; El-Sayed Seleman, M.M. Additive Manufacturing of Aluminum Using Friction Stir Deposition. In Proceedings of the TMS 2020 149th Annual Meeting & Exhibition Supplemental Proceedings, San Diego, CA, USA, 23–27 February 2020; Minerals, Metals & Materials Society, Ed.; The Minerals, Metals & Materials Series. Springer: Cham, Switzerland, 2020. [Google Scholar]

- El-Eraki, B.; El-Sissi, A.; Khafagi, S.; Nada, H. Process parameters optimization for producing AA6061/(Al2O3, Gr and Al2O3 + Gr) surface composites by friction stir processing. In Proceedings of the International Conference on Aerospace Sciences and Aviation Technology, Cairo, Egypt, 9–11 April 2019; pp. 1–13. [Google Scholar] [CrossRef]

- El-Sayed Seleman, M.M.; Alateyah, A.I.; Mahmoud, E.A.E.; Elsoeudy, R.; Ahmed, M.M.Z.; Hafez, K.M.; El-Garaihy, W.H.; AS, A. Friction stir welding of 2507 super-duplex stainless steel: Feasibility of butt joint groove filling at different process parameters. Adv. Mater. Process. Technol. 2024, 1–23. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Jouini, N.; Alzahrani, B.; El-Sayed Seleman, M.M.; Jhaheen, M. Dissimilar friction stir welding of AA2024 and AISI 1018: Microstructure and mechanical properties. Metals 2021, 11, 330. [Google Scholar] [CrossRef]

- Maqbool, A.; Lone, N.F.; Khan, N.Z.; Siddiquee, A.N.; Chen, D. Exceptional tensile strength-ductility synergy in friction stir processed Mg-Y-Nd-Zr alloy achieved through bimodal grain size distribution. Mater. Sci. Eng. A 2025, 919, 147521. [Google Scholar] [CrossRef]

- Lone, N.F.; Bajaj, D.; Gangil, N.; Abidi, M.H.; Chen, D.; Arora, A.; Siddiquee, A.N. Implementing high entropy alloy synthesis via friction stir processing: Simultaneous solid-state alloying and ultra-refinement of copper. Vacuum 2024, 222, 113042. [Google Scholar] [CrossRef]

- Lone, N.F.; Bajaj, D.; Gangil, N.; Khan, T.; Abidi, M.H.; Al-Ahmari, A.; Siddiquee, A.N. Multi principal element alloy particle reinforced metal matrix composites: Synthesis, microstructure, and mechanical aspects. Manuf. Lett. 2023, 36, 46–51. [Google Scholar] [CrossRef]

- Maqbool, A.; Lone, N.F.; Ahmad, T.; Khan, N.Z.; Siddiquee, A.N. Effect of hybrid reinforcement and number of passes on microstructure, mechanical and corrosion behavior of WE43 Mg alloy based metal matrix composite. J. Manuf. Process. 2023, 89, 170–181. [Google Scholar] [CrossRef]

- Besekar, A.; Kathiresan, M.; Jose Immanuel, R. Friction stir processing of recycled titanium reinforced A356 composite developed through stir casting. Trans. Indian Inst. Met. 2024, 77, 3037–3043. [Google Scholar] [CrossRef]

- Cheremnov, A.; Chumaevskii, A.; Knyazhev, E.; Kolubaev, E. Effect of multipass friction stir processing on structure formation, mechanical and tribological properties of CuSn6 copper alloy. Russ. Phys. J. 2024, 67, 2049–2055. [Google Scholar] [CrossRef]

- Ralls, A.M.; Kasar, A.K.; Menezes, P.L. Friction stir processing on the tribological, corrosion, and erosion properties of steel: A review. J. Manuf. Mater. Process. 2021, 5, 97. [Google Scholar] [CrossRef]

- Ghasemi-Kahrizsangi, A.; Kashani-Bozorg, S.F. Microstructure and mechanical properties of steel/TiC nano-composite surface layer produced by friction stir processing. Surf. Coat. Technol. 2012, 209, 15–22. [Google Scholar] [CrossRef]

- Aldajah, S.; Ajayi, O.; Fenske, G.; David, S. Effect of friction stir processing on the tribological performance of high carbon steel. Wear 2009, 267, 350–355. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Eid, R.G.; Zawrah, M. Production of AA1050/silica fume composite by bobbin tool-friction stir processing: Microstructure, composition and mechanical properties. CIRP J. Manuf. Sci. Technol. 2022, 38, 801–812. [Google Scholar] [CrossRef]

- Elshaghoul, Y.G.; El-Sayed Seleman, M.M.; Bakkar, A.; Elnekhaily, S.A.; Albaijan, I.; Ahmed, M.M.Z.; Abdel-Samad, A.; Reda, R. Additive friction stir deposition of AA7075-T6 alloy: Impact of process parameters on the microstructures and properties of the continuously deposited multilayered parts. Appl. Sci. 2023, 13, 10255. [Google Scholar] [CrossRef]

- Ma, Z.; Sharma, S.; Mishra, R. Microstructural modification of as-cast Al-Si-Mg alloy by friction stir processing. Metall. Mater. Trans. A 2006, 37, 3323–3336. [Google Scholar] [CrossRef]

- Jiang, H.; Liu, C.; Yang, Z.; Li, Y.; Huang, H.; Qin, F. Effect of friction stir processing on the microstructure, damping capacity, and mechanical properties of Al-Si alloy. J. Mater. Eng. Perform. 2019, 28, 1173–1179. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Eid, R.G.; Albaijan, I.; Touileb, K. The influence of tool pin geometry and speed on the mechanical properties of the bobbin tool friction stir processed AA1050. Materials 2022, 15, 4684. [Google Scholar] [CrossRef]

- Adi, S.S.; Malik, V.R. Friction stir processing of aluminum machining waste: Carbon nanostructure reinforcements for enhanced composite performance—A comprehensive review. Mater. Manuf. Process. 2025, 40, 285–334. [Google Scholar] [CrossRef]

- Naumov, A.A.; Safi, S.V.; Safi, S.M. Advances in friction stir processing of aluminum 2024: A review of nanoparticle-reinforced surface composites. Int. J. Adv. Manuf. Technol. 2025, 137, 3141–3164. [Google Scholar] [CrossRef]

- Guru, P.; Khan, F.; Panigrahi, S.; Ram, G.J. Enhancing strength, ductility and machinability of a Al–Si cast alloy by friction stir processing. J. Manuf. Process. 2015, 18, 67–74. [Google Scholar] [CrossRef]

- Cui, G.; Ni, D.; Ma, Z.; Li, S. Effects of friction stir processing parameters and in situ passes on microstructure and tensile properties of Al-Si-Mg casting. Metall. Mater. Trans. A 2014, 45, 5318–5331. [Google Scholar] [CrossRef]

- Alidokht, S.A.; Abdollah-Zadeh, A.; Soleymani, S.; Saeid, T.; Assadi, H. Evaluation of microstructure and wear behavior of friction stir processed cast aluminum alloy. Mater. Charact. 2012, 63, 90–97. [Google Scholar] [CrossRef]

- Soleymanpour, M.; Aval, H.J.; Jamaati, R. Manufacturing of high-toughness Al–Si alloy by rolling and friction stir processing: Effect of traverse speed. CIRP J. Manuf. Sci. Technol. 2022, 37, 19–36. [Google Scholar] [CrossRef]

- John Baruch, L.; Raju, R.; Balasubramanian, V.; Rao, A.; Dinaharan, I. Influence of multi-pass friction stir processing on microstructure and mechanical properties of die cast Al–7Si–3Cu aluminum alloy. Acta Metall. Sin. 2016, 29, 431–440. [Google Scholar] [CrossRef]

- Kumar, H.; Prasad, R.; Kumar, P. Microstructural and mechanical Characterization of friction stir processed A356 alloy. J. Phys. Conf. Ser. 2024, 2837, 012023. [Google Scholar] [CrossRef]

| Element | Si% | Fe% | Cr% | Mn% | Zn% | Cu% | Ni% | Mg% | Al% |

|---|---|---|---|---|---|---|---|---|---|

| Percentage (%) | 5 | 0.72 | 0.03 | 0.02 | 0.06 | 0.01 | 0.019 | 0.05 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El-Eraki, B.; Shalaby, M.F.Y.; El-Sissy, A.; Eisa, A.; Ataya, S.; El-Sayed Seleman, M.M. The Role of Friction Stir Processing Travel Speed on the Microstructure Evolution and Mechanical Performance of As-Cast Hypoeutectic Al-5Si Alloy. Crystals 2025, 15, 546. https://doi.org/10.3390/cryst15060546

El-Eraki B, Shalaby MFY, El-Sissy A, Eisa A, Ataya S, El-Sayed Seleman MM. The Role of Friction Stir Processing Travel Speed on the Microstructure Evolution and Mechanical Performance of As-Cast Hypoeutectic Al-5Si Alloy. Crystals. 2025; 15(6):546. https://doi.org/10.3390/cryst15060546

Chicago/Turabian StyleEl-Eraki, Basma, Mahmoud F. Y. Shalaby, Ahmed El-Sissy, Abeer Eisa, Sabbah Ataya, and Mohamed M. El-Sayed Seleman. 2025. "The Role of Friction Stir Processing Travel Speed on the Microstructure Evolution and Mechanical Performance of As-Cast Hypoeutectic Al-5Si Alloy" Crystals 15, no. 6: 546. https://doi.org/10.3390/cryst15060546

APA StyleEl-Eraki, B., Shalaby, M. F. Y., El-Sissy, A., Eisa, A., Ataya, S., & El-Sayed Seleman, M. M. (2025). The Role of Friction Stir Processing Travel Speed on the Microstructure Evolution and Mechanical Performance of As-Cast Hypoeutectic Al-5Si Alloy. Crystals, 15(6), 546. https://doi.org/10.3390/cryst15060546