Preparation of GRCop-42 Cu Alloy by Laser-Directed Energy Deposition: Role of Laser Power on Densification, Microstructure, and Mechanical Properties

Abstract

1. Introduction

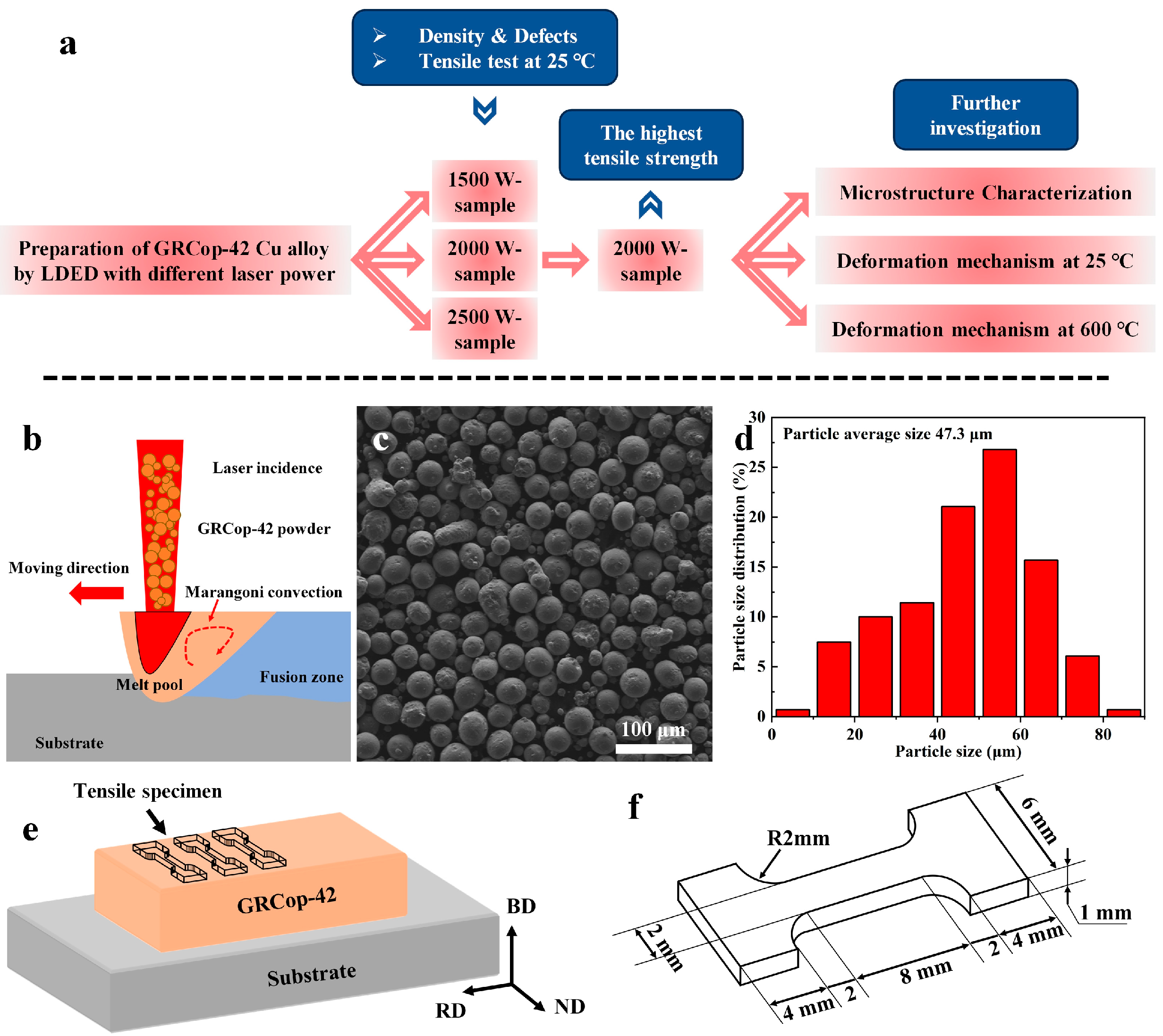

2. Materials and Methods

2.1. Materials

2.2. Experimental Procedure

2.3. Experimental Characterization

3. Result

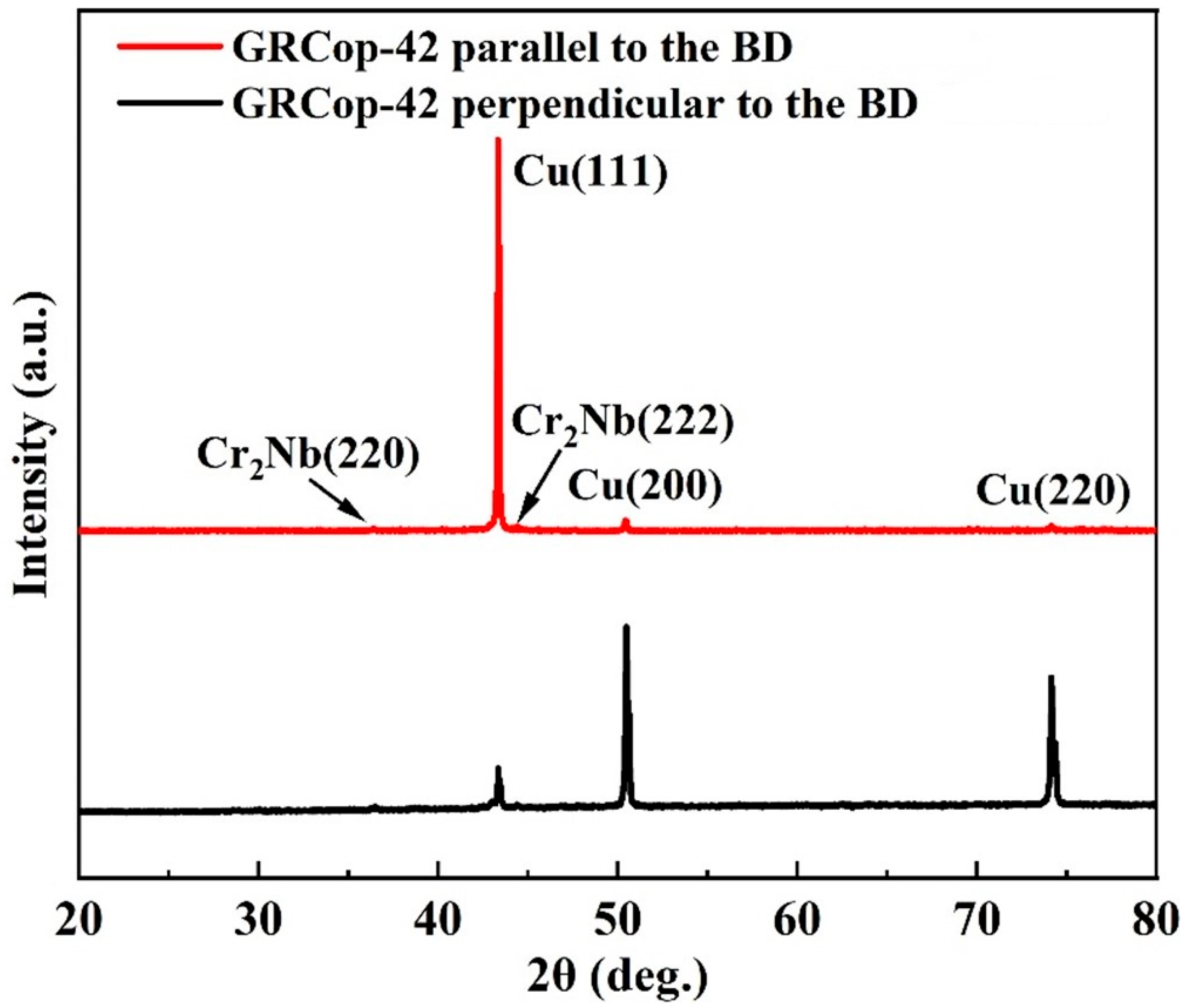

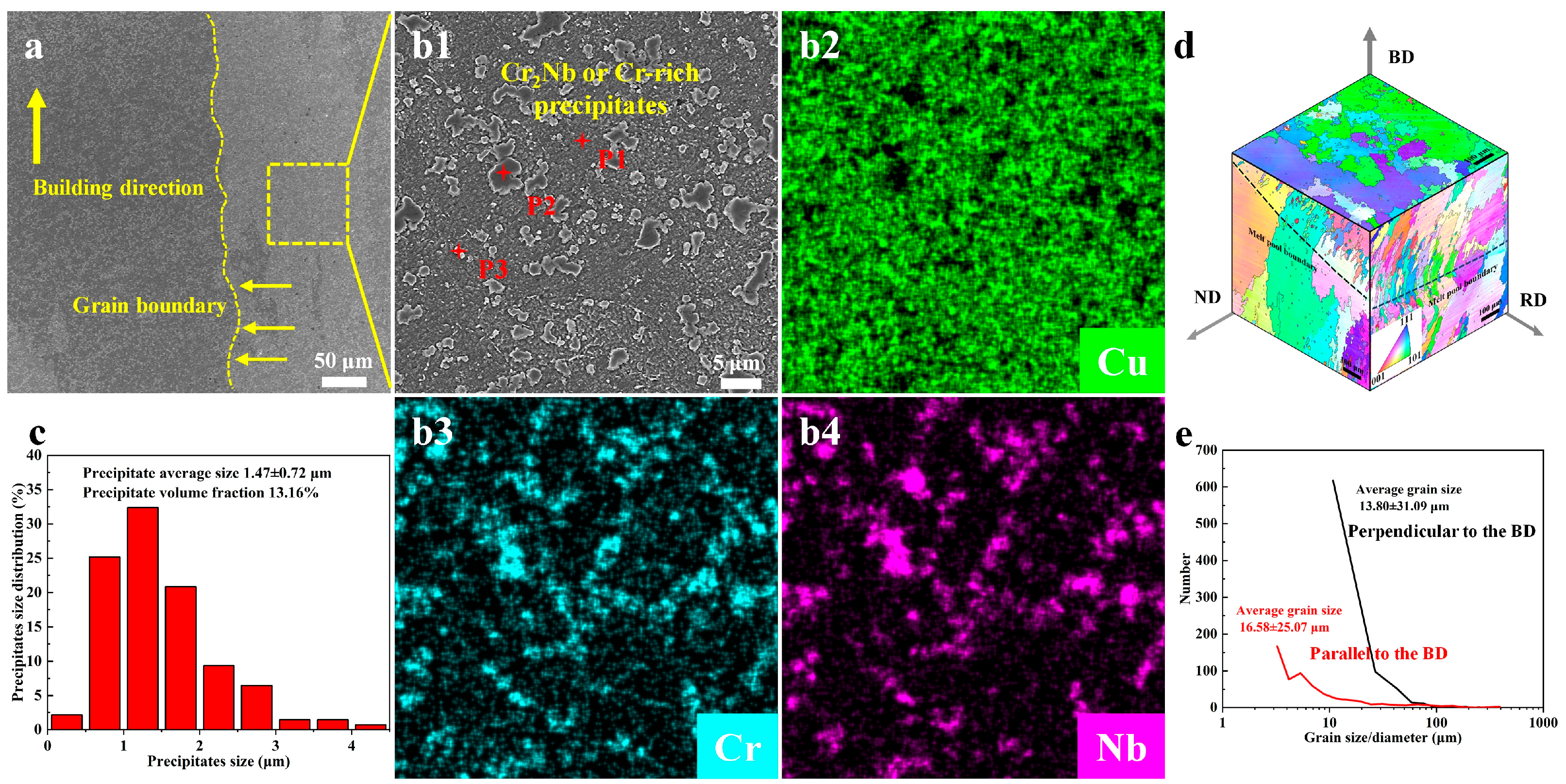

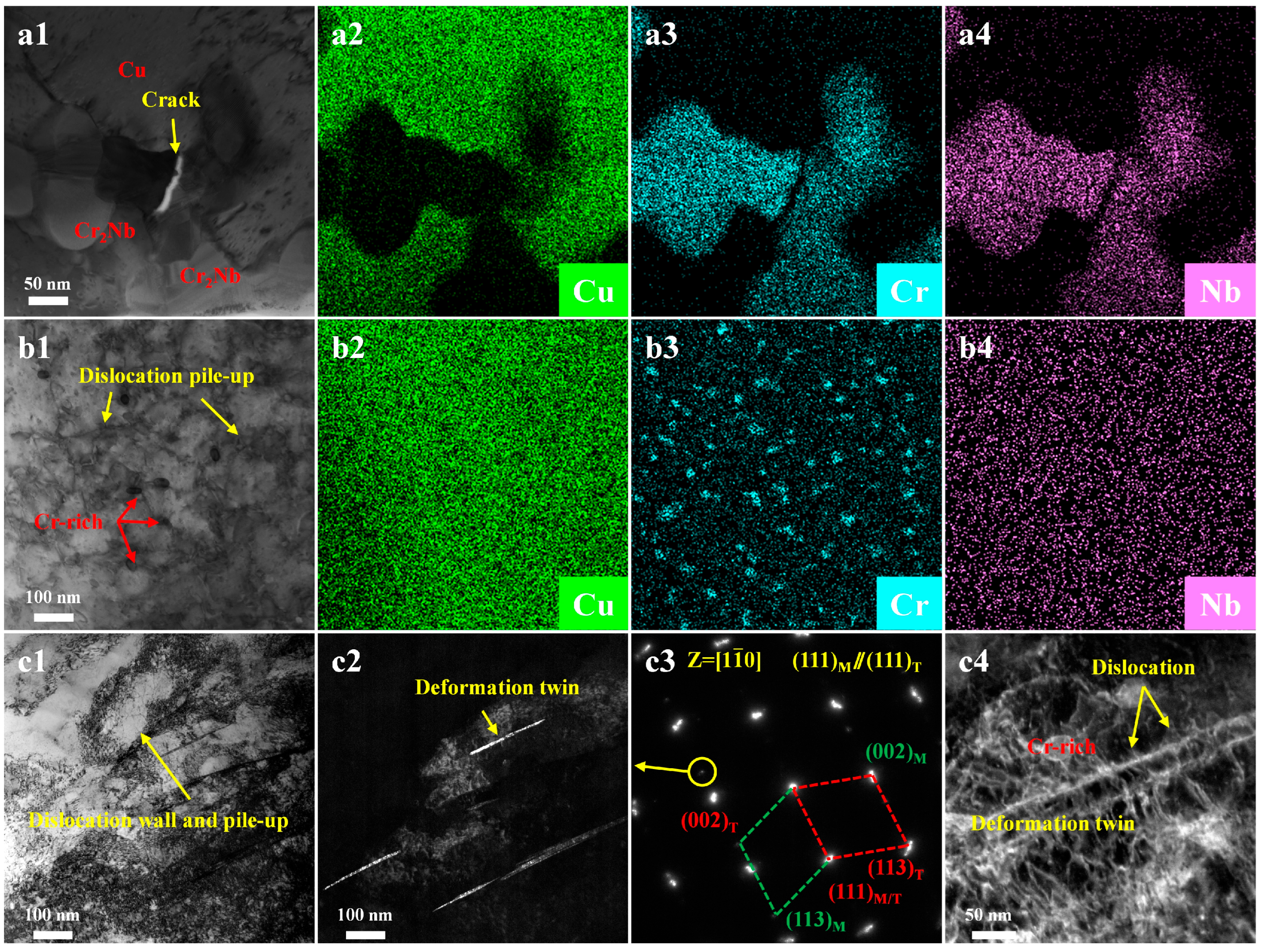

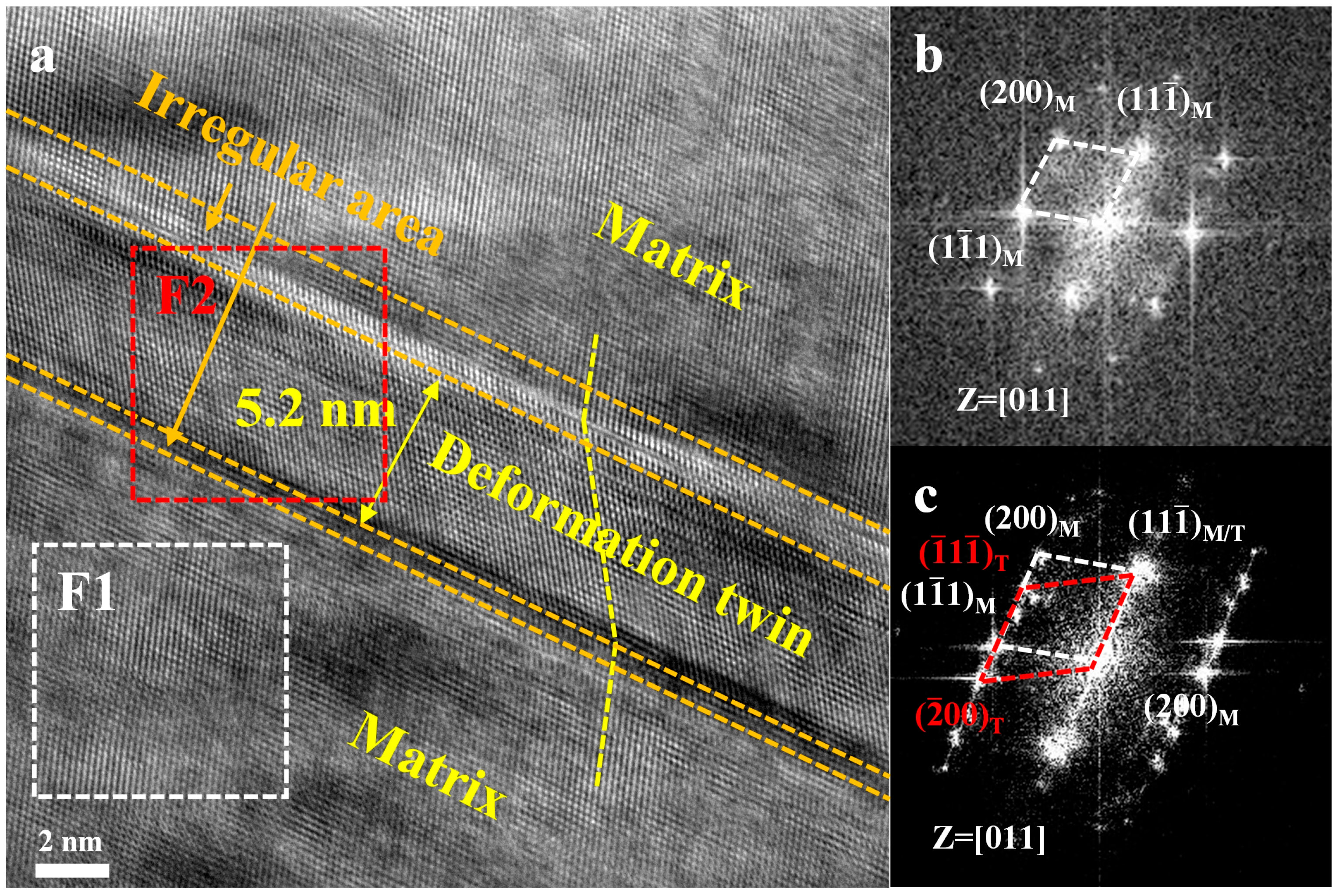

3.1. Effects of Laser Powers on Microstructure

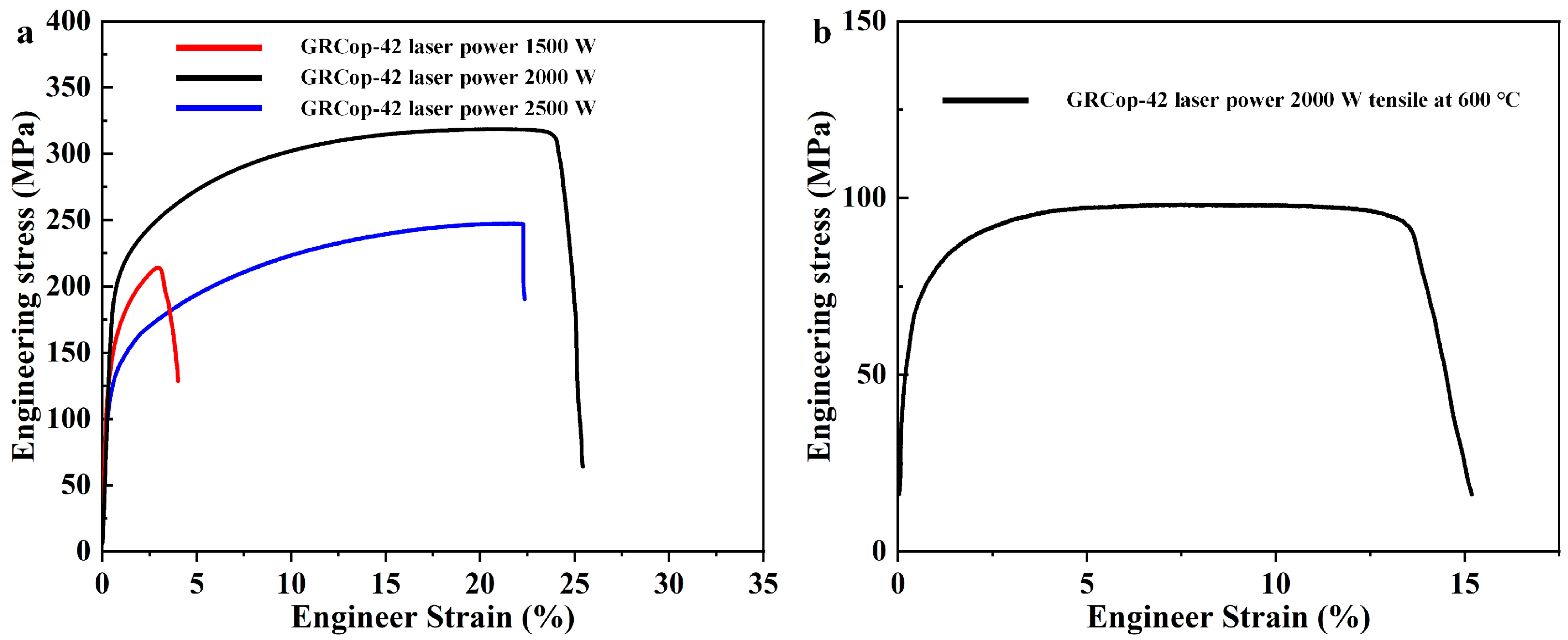

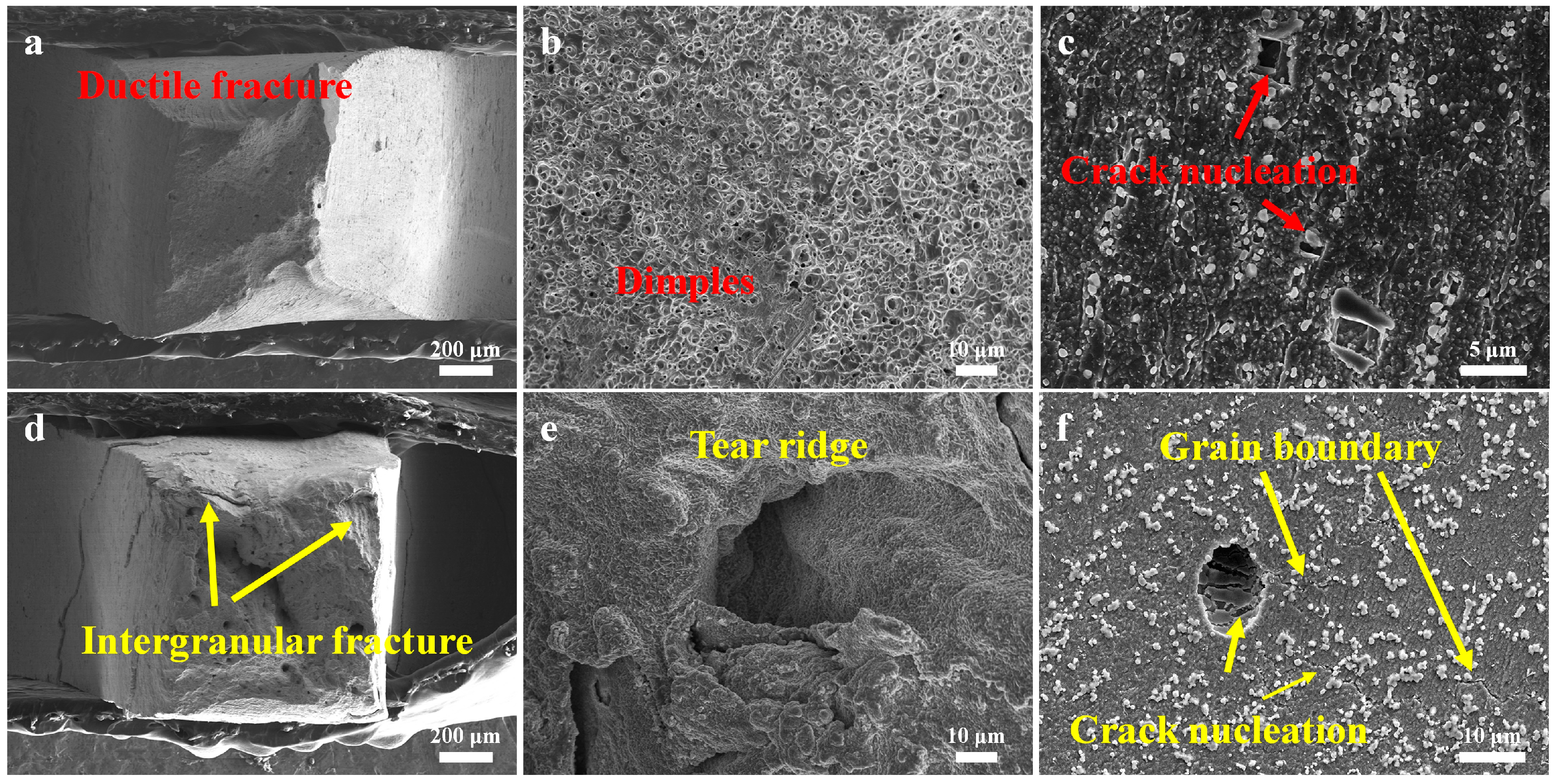

3.2. Tensile Behaviors

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Liu, M.; Kumar, A.; Bukkapatnam, S.; Kuttolamadom, M. A Review of the Anomalies in Directed Energy Deposition (DED) Processes & Potential Solutions—Part Quality & Defects. Procedia Manuf. 2021, 53, 507–518. [Google Scholar] [CrossRef]

- Zhao, W.; Sun, Y.; Che, P.; Ning, Z.; Fan, H.; Yang, H.; Sun, J.; Liaw, P.K.; Ngan, A.H.W.; Huang, Y. The columnar to equiaxed transition of CoCrNi medium-entropy alloy fabricated by laser directed energy deposition. Mater. Des. 2024, 237, 112538. [Google Scholar] [CrossRef]

- Hu, Z.; Zhao, Y.; Zhan, X.; Xu, J.; Ma, Z. The immiscible W/Cu composites with heterostructures and excellent bond strength prepared by additively manufactured transient liquid-phase direct bonding: Experiments and simulations. Compos. Part B 2025, 291, 111981. [Google Scholar] [CrossRef]

- Hu, Z.; Qian, Z.; Yan, Z.; Shi, G.; Qiao, Z.; Li, S.; Zhan, X.; Ma, Z. Synchronized construction of metallurgical bonding and mechanical interlocking interface in immiscible W/CuCrZr functional gradient material by additive manufacturing. Scr. Mater. 2025, 260, 116599. [Google Scholar] [CrossRef]

- Zhang, D.; Sun, S.; Qiu, D.; Gibson, M.A.; Dargusch, M.S.; Brandt, M.; Qian, M.; Easton, M. Metal Alloys for Fusion-Based Additive Manufacturing. Adv. Eng. Mater. 2018, 20, 1700952. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Tang, X.; Chen, X.; Sun, F.; Liu, P.; Zhou, H.; Fu, S. The current state of CuCrZr and CuCrNb alloys manufactured by additive manufacturing: A review. Mater. Des. 2022, 224, 111419. [Google Scholar] [CrossRef]

- Demeneghi, G.; Barnes, B.; Gradl, P.; Ellis, D.; Mayeur, J.R.; Hazeli, K. Directed energy deposition GRCop-42 copper alloy: Characterization and size effects. Mater. Des. 2022, 222, 111035. [Google Scholar] [CrossRef]

- Hazeli, K.; June, D.; Anantwar, P.; Babamiri, B.B. Mechanical behavior of additively manufactured GRCop-84 copper alloy lattice structures. Addit. Manuf. 2022, 56, 102928. [Google Scholar] [CrossRef]

- Gradl, P.R.; Protzb, C.S.; Ellisc, D.L.; Greened, S.E. Progress in Additively Manufactured Copper-Alloy GRCop-84, GRCop-42, and Bimetallic Combustion Chambers for Liquid Rocket Engines. In Proceedings of the 70th International Astronautical Congress (IAC), Washington, DC, USA, 21–25 October 2019. [Google Scholar]

- Pan, Y.; Guo, Q.; Hu, Z.; Wei, C.; Ding, R.; Liu, C.; Ma, Z.; Liu, Y. The role of the post-heat treatment on the Cr-based precipitates and related room temperature mechanical properties of the sintered Nb-lean Cu–Cr–Nb alloy. J. Mater. Res. Technol. 2024, 28, 2420–2429. [Google Scholar] [CrossRef]

- Preis, J.; Wang, Z.; Howard, J.; Lu, Y.; Wannenmacher, N.; Shen, S.; Paul, B.K.; Pasebani, S. Effect of laser power and deposition sequence on microstructure of GRCop42—Inconel 625 joints fabricated using laser directed energy deposition. Mater. Des. 2024, 241, 112944. [Google Scholar] [CrossRef]

- Zhao, R.; Li, L.; Nie, Z.; Ma, Z.; Guo, Q. Effects of pre-heating induced interfacial diffusion on microstructure and related mechanical properties of direct laser metal deposited Inconel 625 superalloy on a Cu-Cr-Zr substrate. Mater. Sci. Eng. A 2025, 920, 147551. [Google Scholar] [CrossRef]

- Landes, S.; Suresh, T.; Prasad, A.; Letcher, T.; Gradl, P.; Ellis, D. Investigation of additive manufactured GRCop-42 alloy developed by directed energy deposition methods. In Proceedings of the ASME 2020 International Mechanical Engineering Congress and Exposition, Portland, OR, USA, 16–19 November 2020. [Google Scholar]

- Kini, A.R.; Maischner, D.; Weisheit, A.; Ponge, D.; Gault, B.; Jägle, E.A.; Raabe, D. In-situ synthesis via laser metal deposition of a lean Cu–3.4Cr–0.6Nb (at%) conductive alloy hardened by Cr nano-scale precipitates and by Laves phase micro-particles. Acta Mater. 2020, 197, 330–340. [Google Scholar] [CrossRef]

- Holzwarth, U.; Stamm, H. The precipitation behaviour of ITER-grade Cu–Cr–Zr alloy after simulating the thermal cycle of hot isostatic pressing. J. Nucl. Mater. 2000, 279, 31–45. [Google Scholar] [CrossRef]

- Suresh, T.; Landes, S.; Letcher, T.; Prasad, A.; Ellis, D. Nanomechanical Characterization of Additive Manufactured GRCop-42 Alloy Developed by Directed Energy Deposition Methods. In Proceedings of the ASME 2020 International Mechanical Engineering Congress and Exposition, Portland, OR, USA, 16–19 November 2020. [Google Scholar]

- de Groh, H.C.; Ellis, D.L.; Loewenthal, W.S. Comparison of GRCop-84 to Other Cu Alloys with High Thermal Conductivities. J. Mater. Eng. Perform. 2008, 17, 594–606. [Google Scholar] [CrossRef]

- Seltzman, A.H.; Wukitch, S.J. Fracture characteristics and heat treatment of laser powder bed fusion additively manufactured GRCop-84 copper. Mater. Sci. Eng. A 2021, 827, 141690. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, G.; Zhang, P.; Xu, J.; Zhang, X.; Gao, H.; Xie, H.; Xu, S.; Zhao, J.; Li, P.; et al. Dispersoid inhomogeneity induced HDI effects in the dispersion-strengthened GRCop-42 alloy without typical hetero-structures. Mater. Sci. Eng. A 2025, 923, 147737. [Google Scholar] [CrossRef]

- Li, W.Y.; Guo, X.P.; Verdy, C.; Dembinski, L.; Liao, H.L.; Coddet, C. Improvement of microstructure and property of cold-sprayed Cu–4at.%Cr–2at.%Nb alloy by heat treatment. Scr. Mater. 2006, 55, 327–330. [Google Scholar] [CrossRef]

- Hao, Z.; He, Z.; Nie, Z.; Li, J.; Ma, Z.; Guo, Q. Effects of residual Laves phase on microstructural evolution and mechanical properties of wire arc additive manufactured GH4169 Ni-based superalloy. Mater. Sci. Eng. A 2024, 914, 147175. [Google Scholar] [CrossRef]

- Li, L.; Liu, C.; Ma, Z.; Guo, Q. Microstructure and mechanical properties of Stellite 6 alloy coating metallurgically bonded to 304 stainless steel by DED-LB technology. J. Mater. Sci. 2024, 59, 20012–20027. [Google Scholar] [CrossRef]

- Hu, Z.; Ma, Z.; Yu, L.; Liu, Y. Functionally graded materials with grain-size gradients and heterogeneous microstructures achieved by additive manufacturing. Scr. Mater. 2023, 226, 115197. [Google Scholar] [CrossRef]

- Zhang, K.; Chen, Y.; Marussi, S.; Fan, X.; Fitzpatrick, M.; Bhagavath, S.; Majkut, M.; Lukic, B.; Jakata, K.; Rack, A.; et al. Pore evolution mechanisms during directed energy deposition additive manufacturing. Nat. Commun. 2024, 15, 1715. [Google Scholar] [CrossRef] [PubMed]

- Ellis, D.; Gray, H.; Nathel, M. Aerospace Structural Materials Handbook Supplement GRCop-84; Cindas Llc.: West Lafayette, IN, USA, 2001. [Google Scholar]

- Tang, L.; Guo, Q.; Li, C.; Ding, R.; Liu, Y. Precipitation and tensile behaviors of Allvac 718Plus superalloy during long-term thermal exposure. Mater. Sci. Eng. A 2024, 896, 146221. [Google Scholar] [CrossRef]

- Tang, L.; Guo, Q.; Li, C.; Liu, C.; Liu, Y. Precipitation sequences in rapidly solidified Allvac 718Plus alloy during solution treatment. J. Mater. Sci. Technol. 2022, 128, 180–194. [Google Scholar] [CrossRef]

- Hu, Z.; Du, Z.; Yang, Z.; Yu, L.; Ma, Z. Preparation of Cu–Cr–Zr alloy by selective laser melting: Role of scanning parameters on densification, microstructure and mechanical properties. Mater. Sci. Eng. A 2022, 836, 142740. [Google Scholar] [CrossRef]

- Wang, G.; Ouyang, H.; Fan, C.; Guo, Q.; Li, Z.; Yan, W.; Li, Z. The origin of high-density dislocations in additively manufactured metals. Mater. Res. Lett. 2020, 8, 283–290. [Google Scholar] [CrossRef]

- Turnage, S.A.; Rajagopalan, M.; Darling, K.A.; Garg, P.; Kale, C.; Bazehhour, B.G.; Adlakha, I.; Hornbuckle, B.C.; Williams, C.L.; Peralta, P.; et al. Anomalous mechanical behavior of nanocrystalline binary alloys under extreme conditions. Nat. Commun. 2018, 9, 2699. [Google Scholar] [CrossRef]

- Hornbuckle, B.C.; Koju, R.K.; Kennedy, G.; Jannotti, P.; Lorenzo, N.; Lloyd, J.T.; Giri, A.; Solanki, K.; Thadhani, N.N.; Mishin, Y.; et al. Direct observation of deformation and resistance to damage accumulation during shock loading of stabilized nanocrystalline Cu-Ta alloys. Nat. Commun. 2024, 15, 9135. [Google Scholar] [CrossRef]

- Hu, Z.; Gan, B.; Tan, J.; Wu, J.; Chen, S.; Dong, J.; Ma, Z. The enhancement of laser absorptivity and properties in laser powder bed fusion manufactured Cu-Cr-Zr alloy by employing Y2O3 coated powder as precursor. J. Alloys Compd. 2022, 927, 167111. [Google Scholar] [CrossRef]

| Material | Cu | Cr | Nb | O | N | C | S |

|---|---|---|---|---|---|---|---|

| GRCop-42 powder | Bal. | 3.24 | 2.76 | 0.035 | 0.001 | 0.0029 | 0.0012 |

| Parameters | Value |

|---|---|

| Laser power (W) | 1500/2000/2500 |

| Scanning speed (mm/s) | 15 |

| Laser beam spot diameter (mm) | 3.2 |

| Hatch width (mm) | 1.6 |

| Powder feed rate (g/min) | 8.4 |

| Protective gas flow rate (L/min) | 15 |

| Point ID | Cu | Cr | Nb |

|---|---|---|---|

| P1 | 99.25 | - | 0.75 |

| P2 | 51.13 | 9.83 | 39.03 |

| P3 | 10.57 | 84.22 | 5.21 |

| Samples | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| GRCop-42 laser power 1500 W | 201 ± 10.4 | 213 ± 17.5 | 4.00 ± 1.4 |

| GRCop-42 laser power 2000 W | 236 ± 5.1 | 319 ± 6.5 | 25.42 ± 1.9 |

| GRCop-42 laser power 2500 W | 164 ± 6.2 | 247 ± 7.8 | 22.34 ± 2.5 |

| GRCop-42 laser power 2000 W at 600 °C | 89 ± 2.7 | 98 ± 3.1 | 15.83 ± 1.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Han, P.; Sun, H.; Zhao, Y. Preparation of GRCop-42 Cu Alloy by Laser-Directed Energy Deposition: Role of Laser Power on Densification, Microstructure, and Mechanical Properties. Crystals 2025, 15, 547. https://doi.org/10.3390/cryst15060547

Liu C, Han P, Sun H, Zhao Y. Preparation of GRCop-42 Cu Alloy by Laser-Directed Energy Deposition: Role of Laser Power on Densification, Microstructure, and Mechanical Properties. Crystals. 2025; 15(6):547. https://doi.org/10.3390/cryst15060547

Chicago/Turabian StyleLiu, Chao, Ping Han, Hongwei Sun, and Yun Zhao. 2025. "Preparation of GRCop-42 Cu Alloy by Laser-Directed Energy Deposition: Role of Laser Power on Densification, Microstructure, and Mechanical Properties" Crystals 15, no. 6: 547. https://doi.org/10.3390/cryst15060547

APA StyleLiu, C., Han, P., Sun, H., & Zhao, Y. (2025). Preparation of GRCop-42 Cu Alloy by Laser-Directed Energy Deposition: Role of Laser Power on Densification, Microstructure, and Mechanical Properties. Crystals, 15(6), 547. https://doi.org/10.3390/cryst15060547