Comparative Study on the Microstructure and Simulation of High-Speed and Conventional Fe-Based Laser-Cladding Coatings

Abstract

1. Introduction

2. Cladding Experiment

2.1. Substrates and Materials

2.2. Experimental Equipment

2.3. Test and Characterization Methods

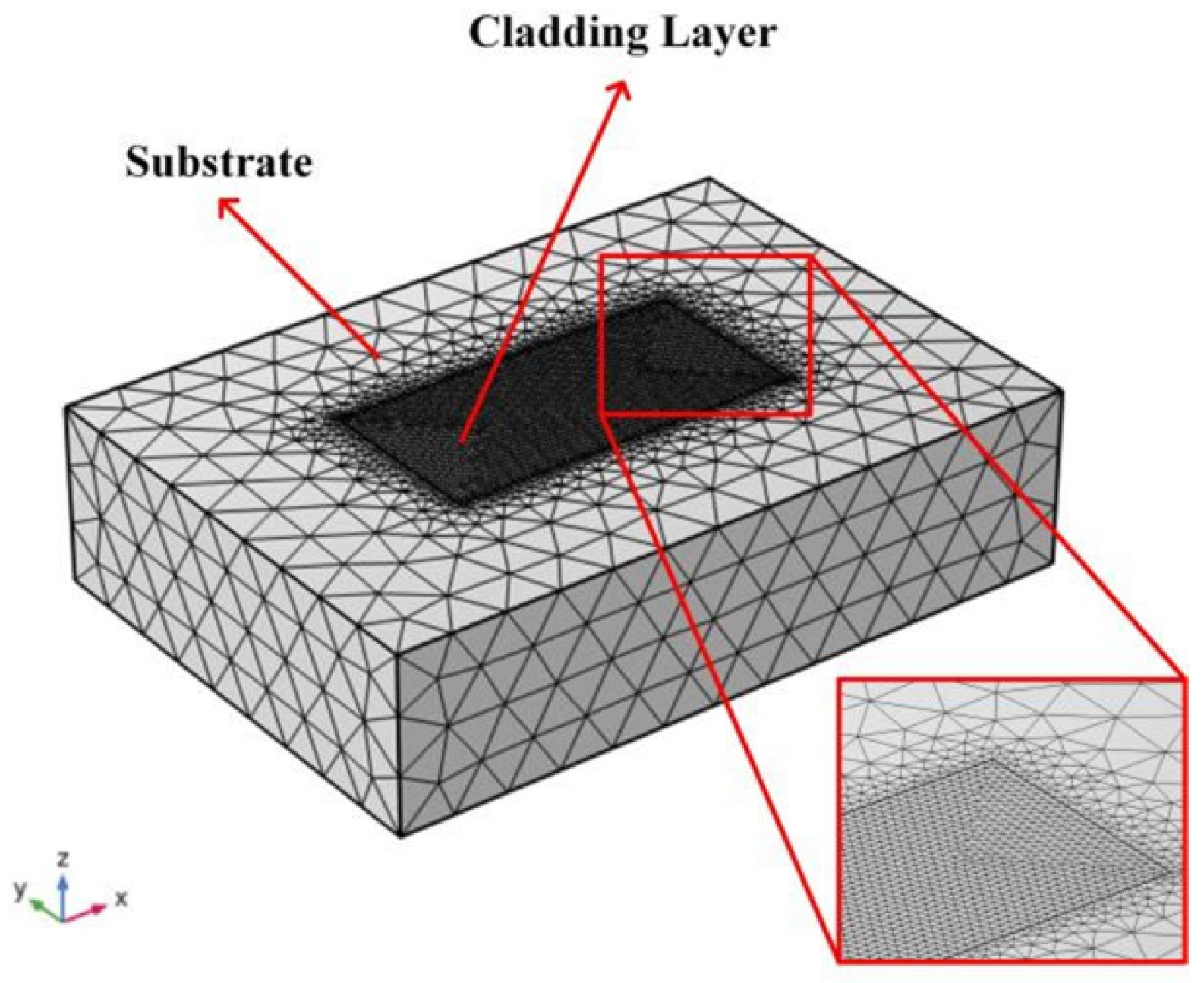

3. Laser Cladding Temperature Field Simulation

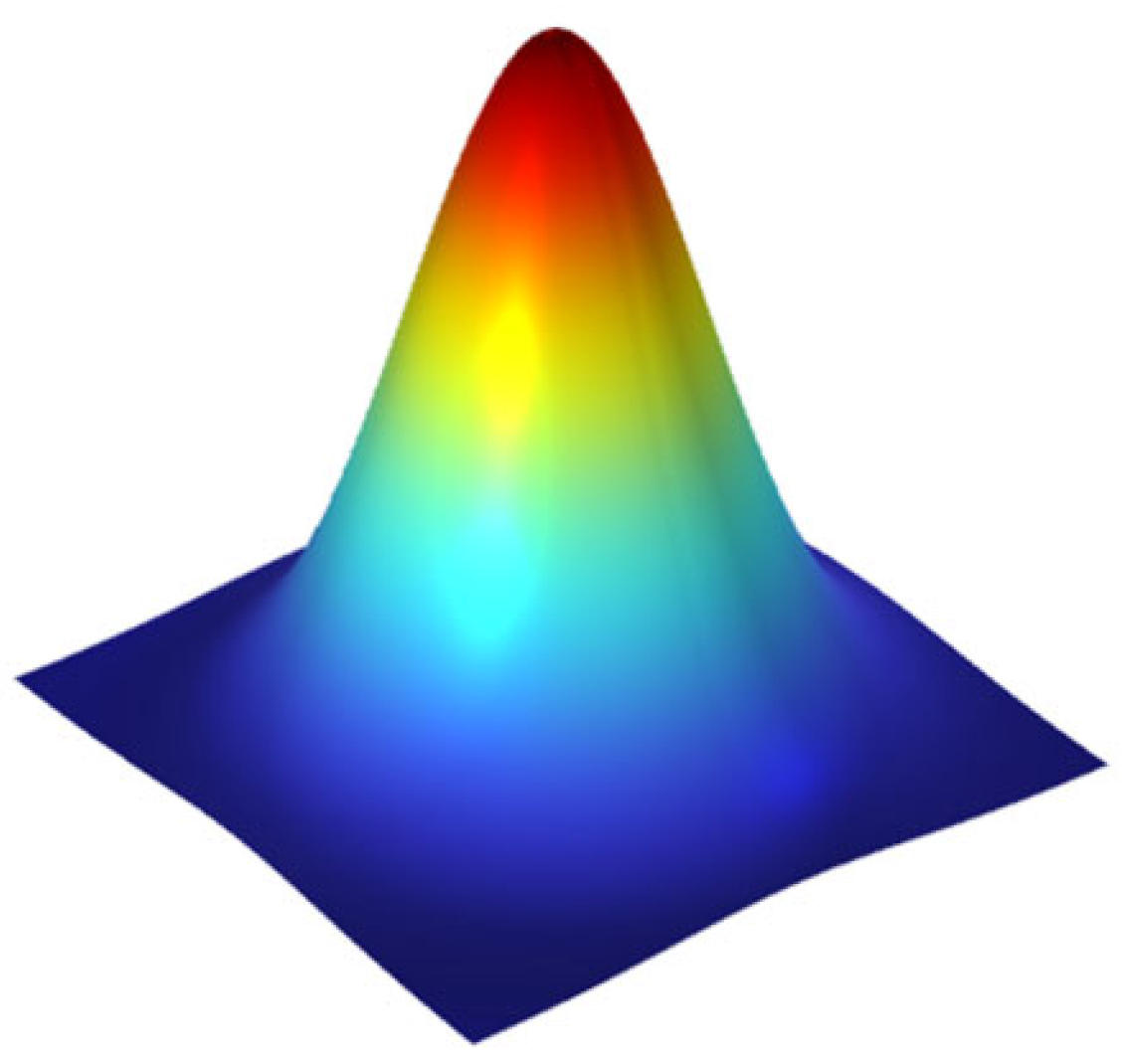

Heat Transfer Model with Phase Change and Heat Source Modeling

4. Results and Discussion

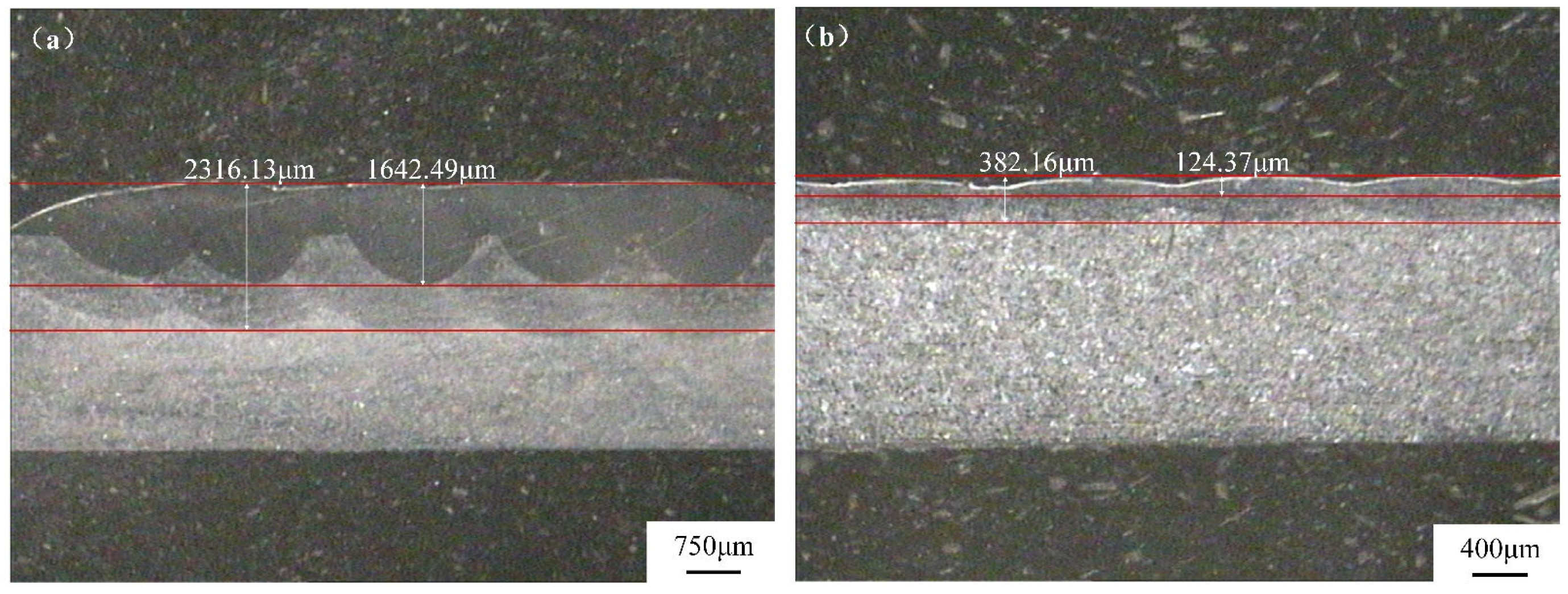

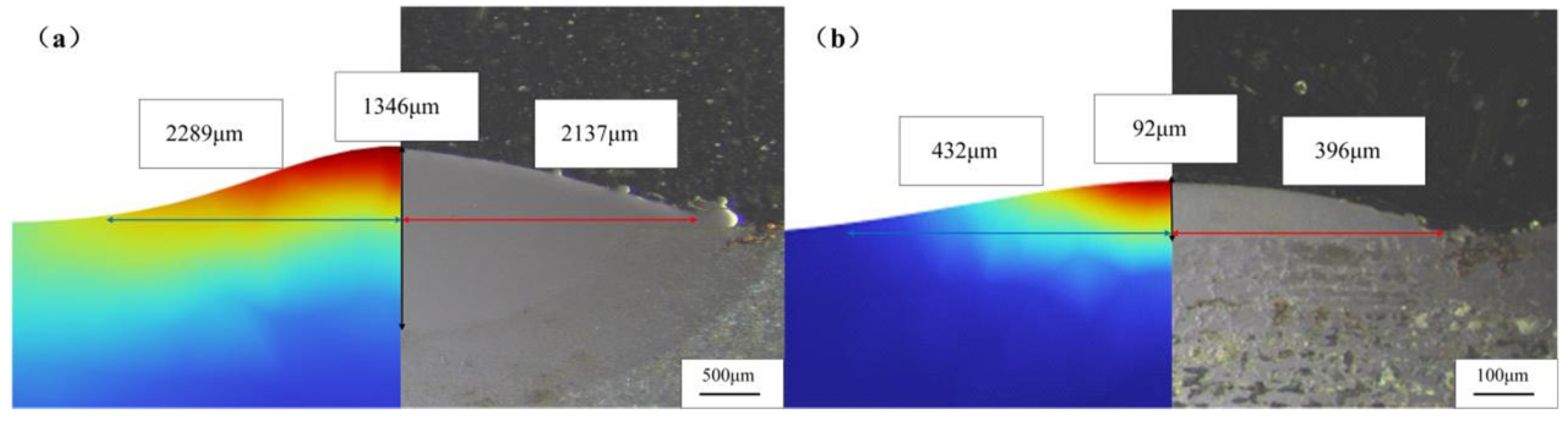

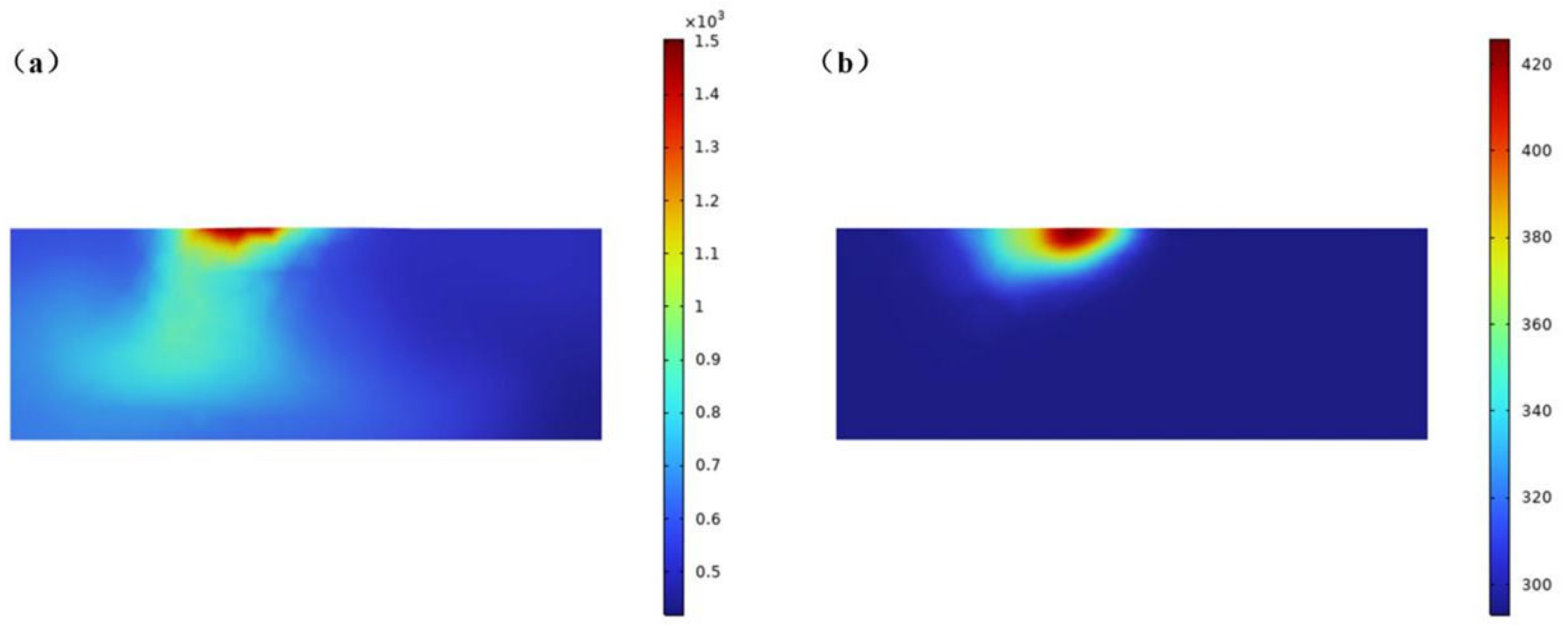

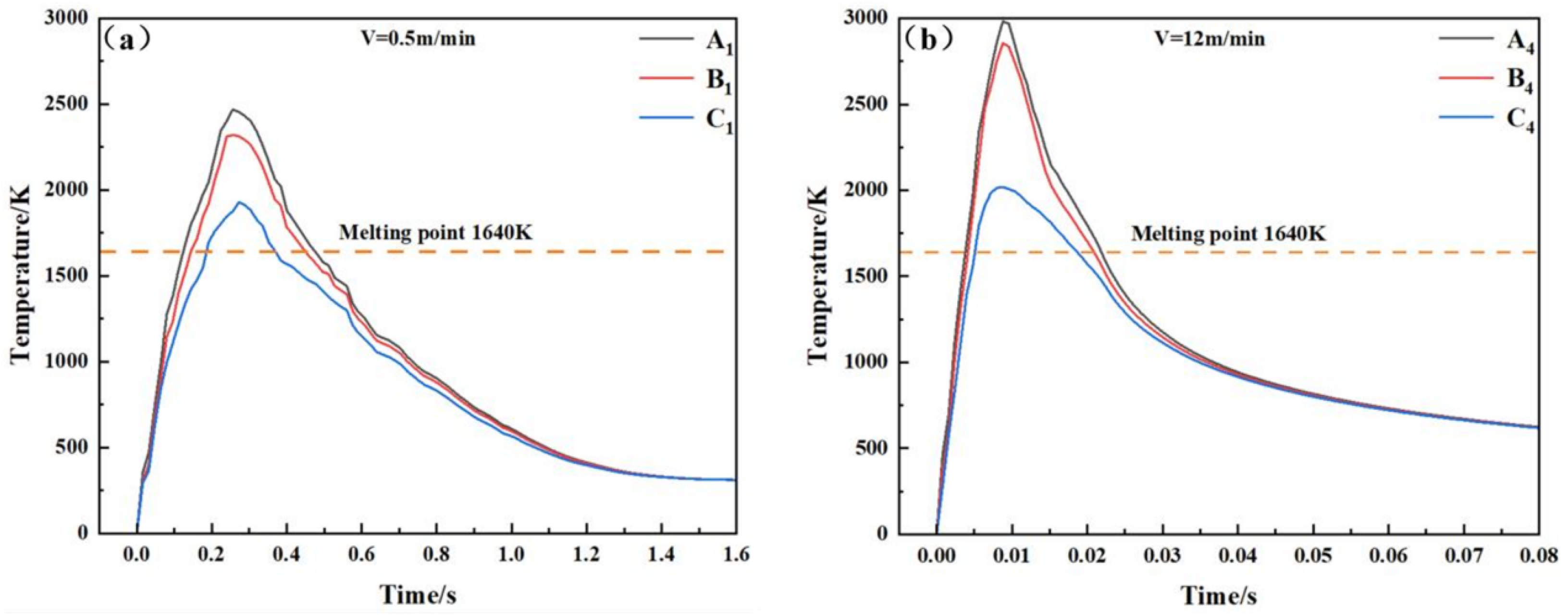

4.1. Numerical Simulation of Coating Temperature Field

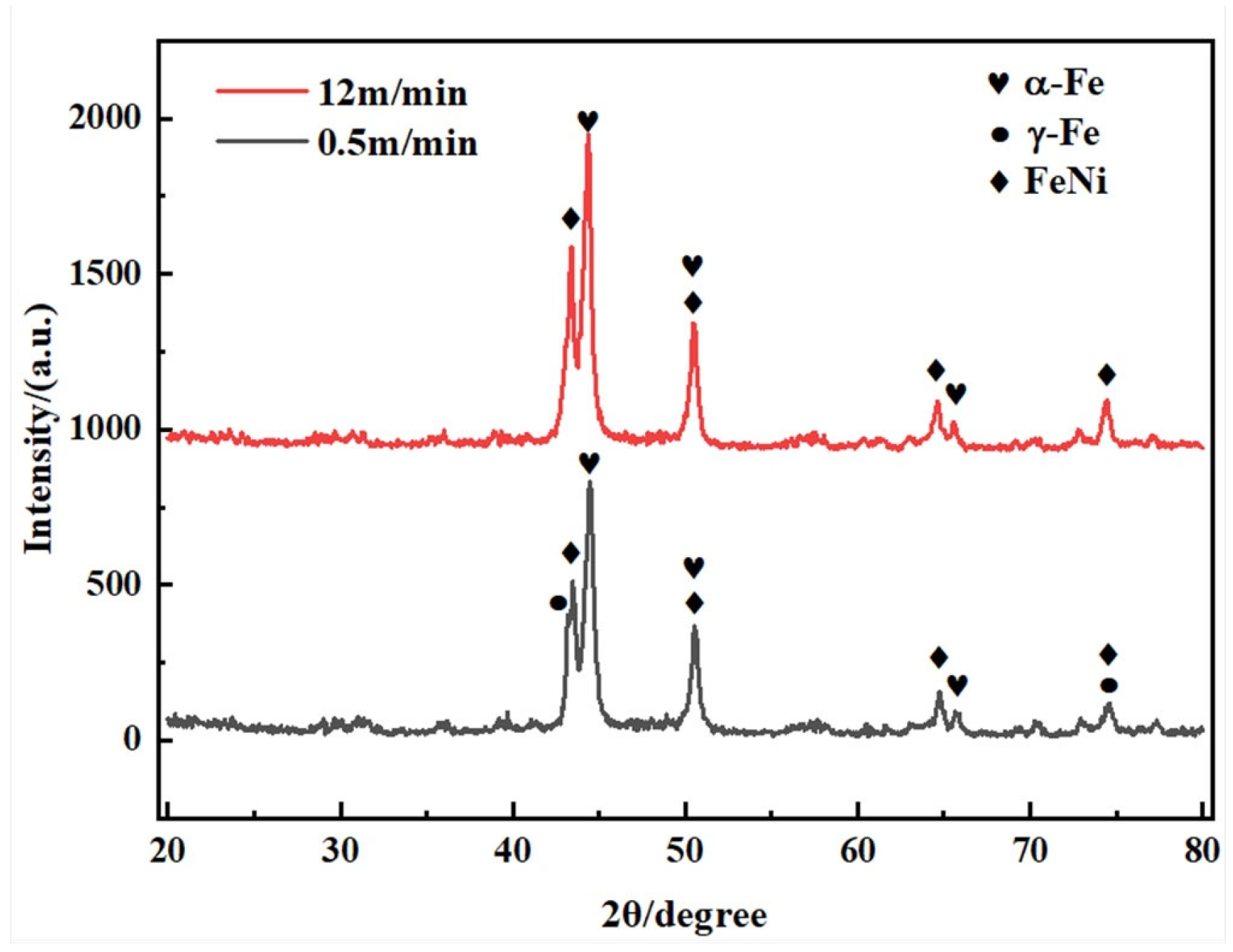

4.2. Phase Constitution

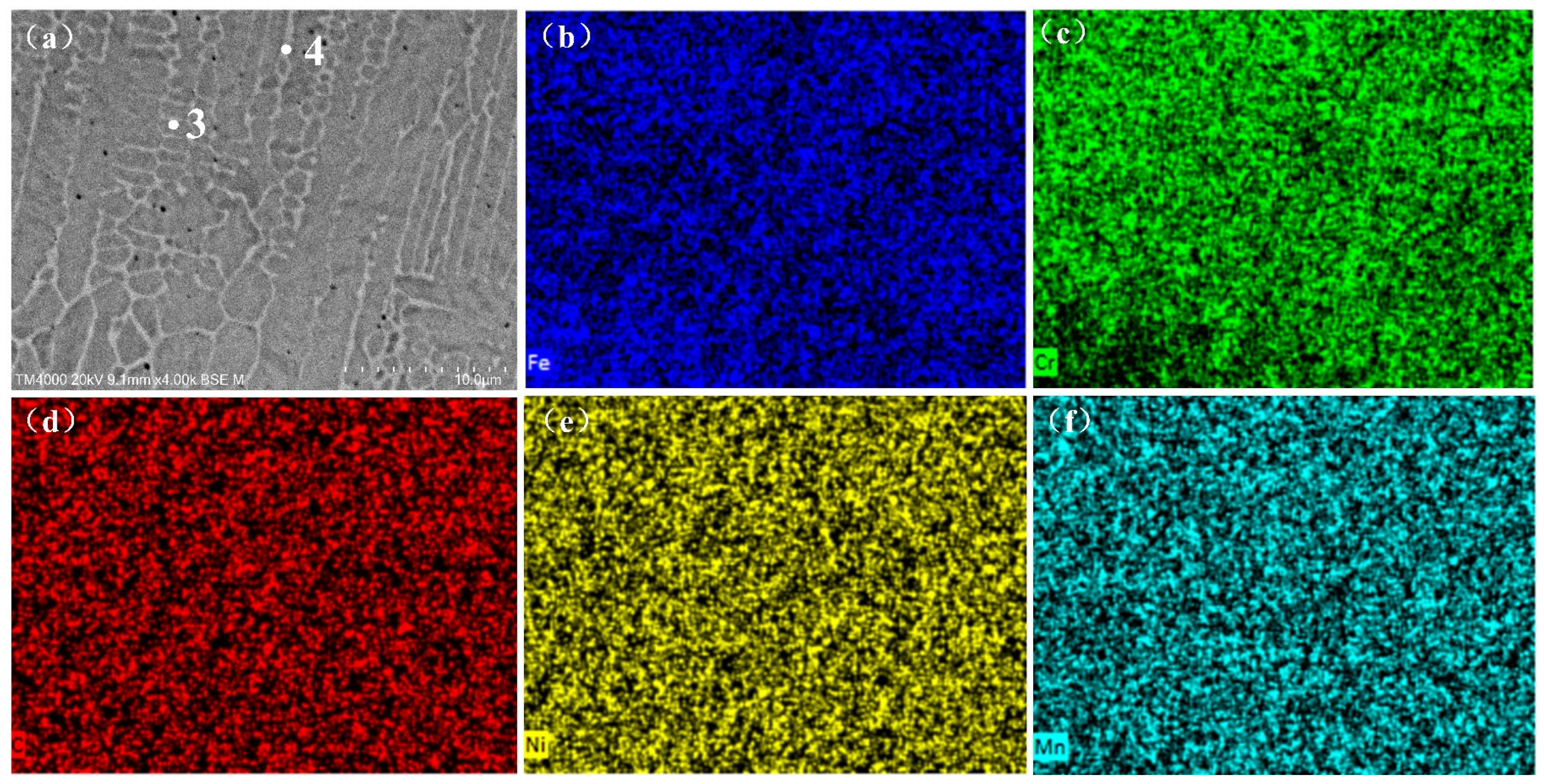

4.3. Microstructure

4.4. Hardness of Coating

5. Conclusions

- The phase composition of conventional laser-cladding coatings is primarily α-Fe solid solution, γ-Fe, and FeNi. Owing to the extremely high cooling rates in high-speed laser cladding, γ-Fe rapidly transforms into α-Fe, resulting in no residual γ-Fe. The other phases remain the same as in conventional laser cladding, with no new phases emerging. The high cooling rate in high-speed laser cladding leads to significant formation of supersaturated α-Fe, causing the diffraction angle of α-Fe in high-speed laser-cladding coatings to be smaller than that in conventional laser cladding.

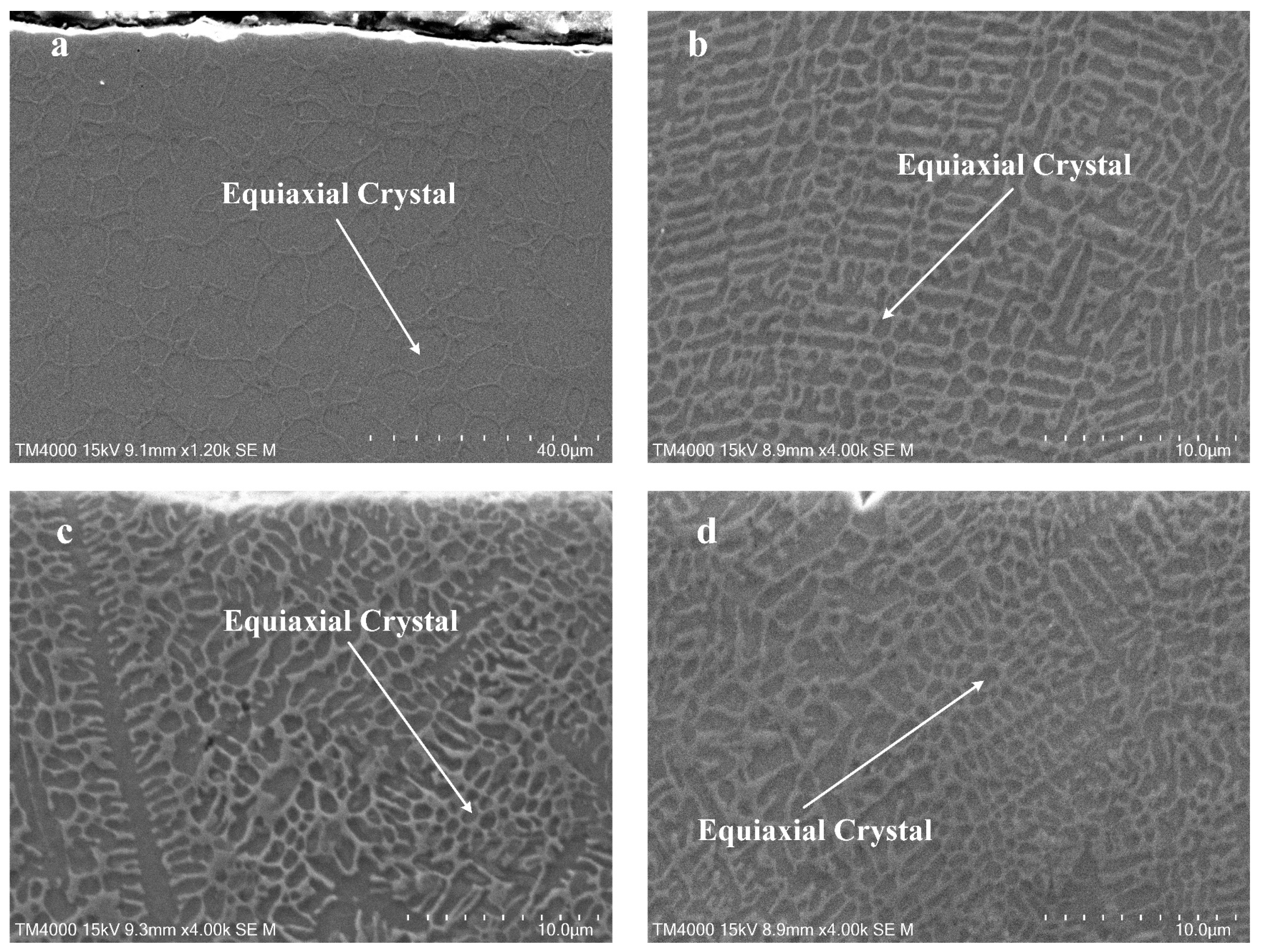

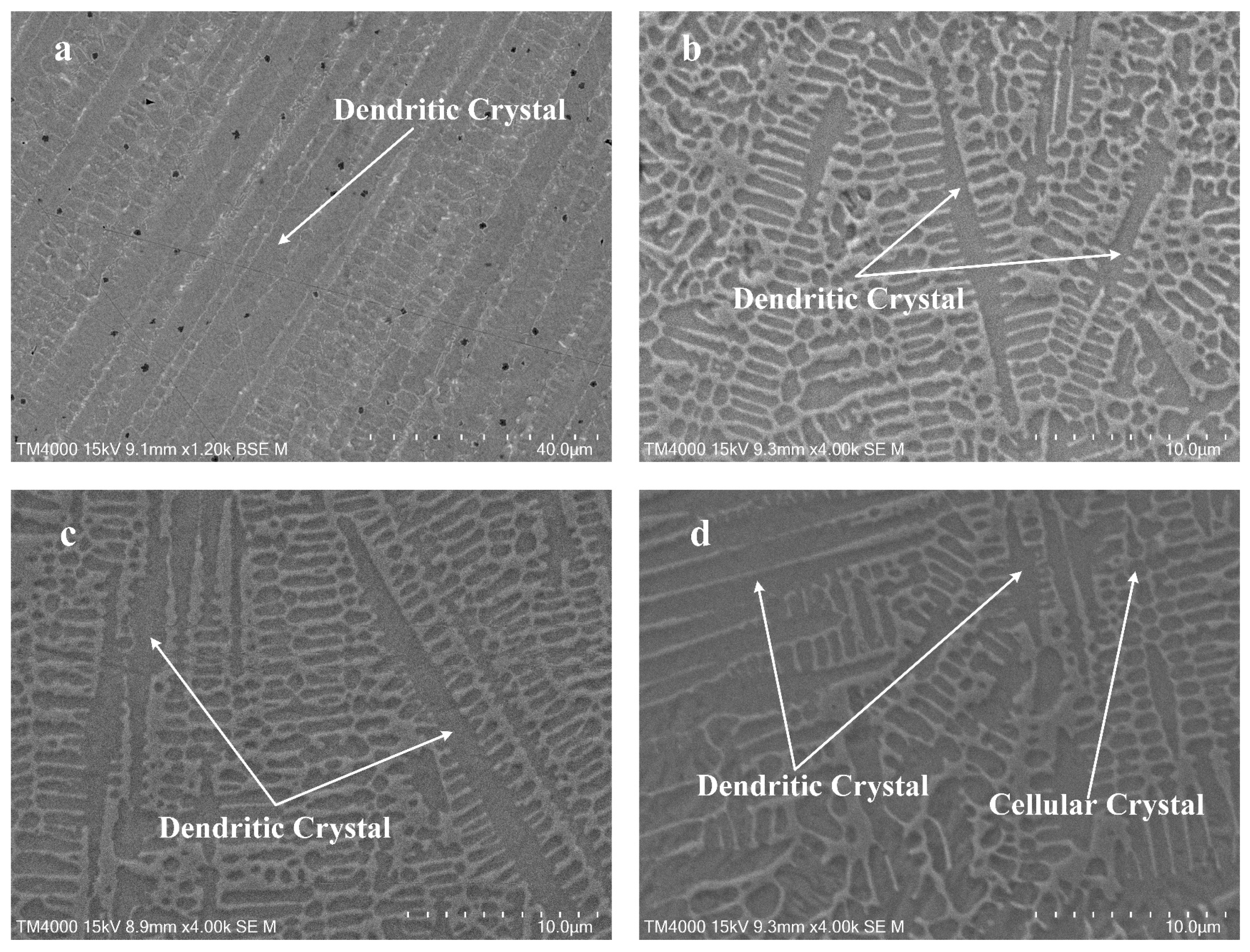

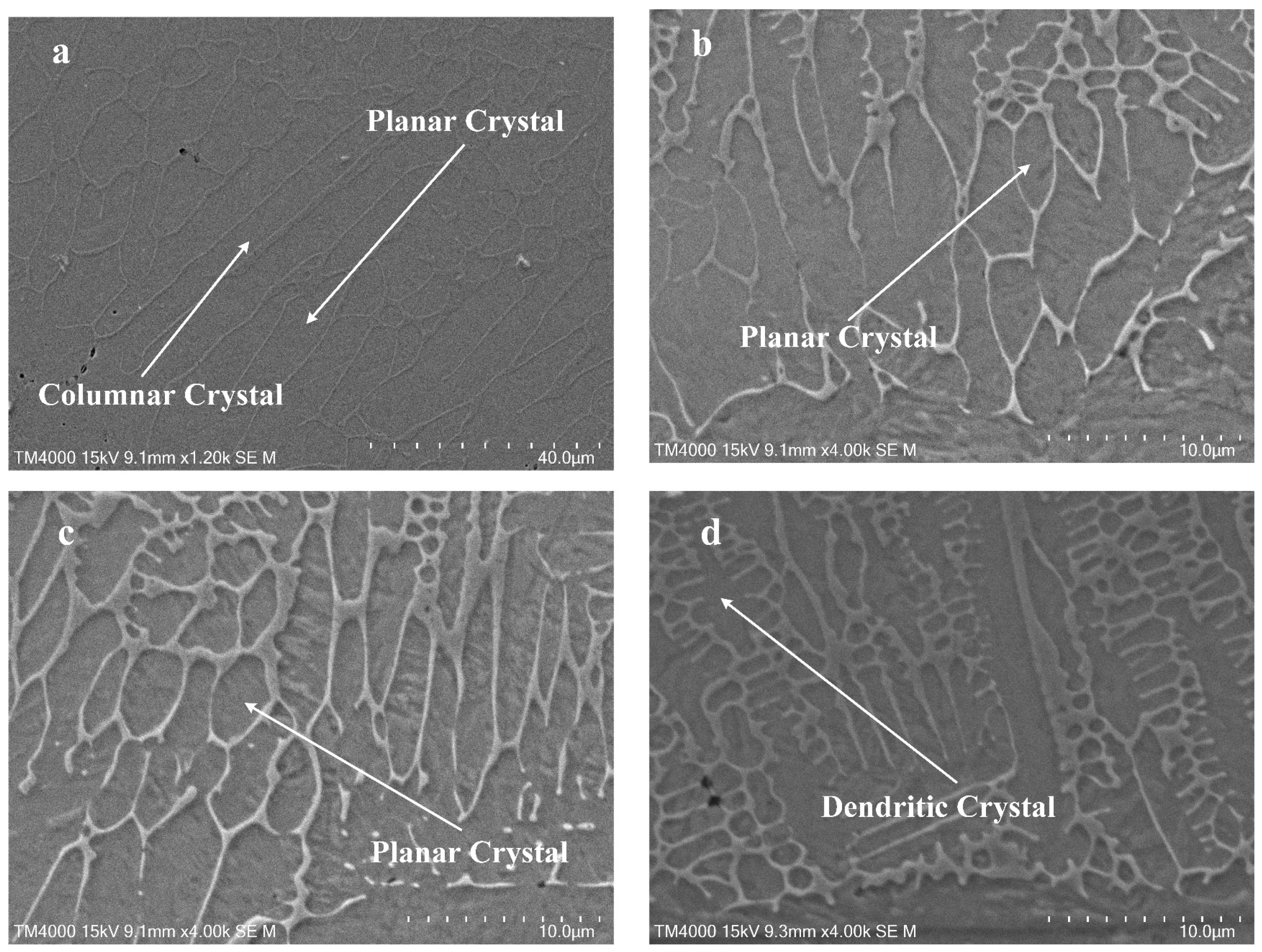

- In both the conventional and high-speed cladding processes, the evolution of the microstructural morphology remained relatively consistent: the surface of the coating primarily consisted of equiaxed crystals, the middle of the coating featured dendritic structures, and the bottom of the coating was characterized by planar crystals and large columnar crystals. The grain size in high-speed laser cladding is significantly smaller than that in conventional laser cladding.

- The hardness of both the conventional and high-speed laser-cladding coatings was significantly higher than that of the substrates. The average hardness of conventional laser-cladding coatings is 406 HV0.5, while the average hardness of high-speed laser-cladding coatings reaches 779 HV0.5 at a speed of 12 m/min. The solidification rate of high-speed laser cladding is several tens of times greater than that of conventional laser cladding. Consequently, the hardness of high-speed laser-cladding coatings is nearly twice that of conventional laser cladding, and the hardness of the coatings increases with cladding speed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Haldar, B.; Saha, P. Identifying defects and problems in laser cladding and suggestions of some remedies for the same. Mater. Today Proc. 2018, 5, 13090–13101. [Google Scholar] [CrossRef]

- Comakli, R.; Balci, C.; Copur, H.; Tumac, D. Experimental studies using a new portable linear rock cutting machine and verification for disc cutters. Tunn. Undergr. Space Technol. 2021, 108, 103702. [Google Scholar] [CrossRef]

- Manoj, A.; Saurabh, A.; Narala, S.K.R.; Saravanan, P.; Natu, H.P.; Verma, P.C. Surface modification of grey cast iron by laser cladding for automotive brake disc application. Wear 2023, 532–533, 205099. [Google Scholar] [CrossRef]

- Agrawal, A.K.; Chattopadhyaya, S.; Murthy, V.M.S.R.; Legutko, S.; Krolczyk, G. A novel method of laser coating process on worn-out cutter rings of tunnel boring machine for eco-friendly reuse. Symmetry 2020, 12, 471. [Google Scholar] [CrossRef]

- Zhang, D.; Li, Z.; Fan, H.; Rui, H.; Gao, F. Microstructure and tribological properties of Fe-based laser cladding layer on nodular cast iron for surface remanufacturing. Coatings 2021, 11, 974. [Google Scholar] [CrossRef]

- Li, Y.; Shi, Y. Microhardness, wear resistance, and corrosion resistance of AlxCrFeCoNiCu high-entropy alloy coatings on aluminum by laser cladding. Opt. Laser Technol. 2021, 134, 106632. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Q.; Zhang, L.; Chen, D.X.; Jin, H.; Li, J.D.; Zhang, J.W. Microstructure, wear and electrochemical behaviors of laser cladding Fe-based coatings with various molybdenum contents. Mater. Res. Express 2022, 9, 026504. [Google Scholar] [CrossRef]

- Schopphoven, T.; Gasser, A.; Wissenbach, K.; Poprawe, R. Investigations on ultra-high-speed laser material deposition as alternative for hard chrome plating and thermal spraying. J. Laser Appl. 2016, 28, 022501. [Google Scholar] [CrossRef]

- Ren, Y.; Li, L.; Zhou, Y.; Wang, S. In situ synthesized VC reinforced Fe-based coating by using extreme high-speed laser cladding. Mater. Lett. 2022, 315, 131962. [Google Scholar] [CrossRef]

- Ding, Y.; Bi, W.; Zhong, C.; Wu, T.; Gui, W. A comparative study on microstructure and properties of ultra-high-speed laser cladding and traditional laser cladding of Inconel625 coatings. Materials 2022, 15, 6400. [Google Scholar] [CrossRef]

- Xu, Y.F.; Sun, Y.N.; Wang, G.J.; Gui, Y.L. Microstructure and Properties of Iron-Based Alloys Coatings Prepared by High-Speed Laser Cladding. Chin. J. Lasers 2021, 48, 222–230. [Google Scholar]

- Lv, H.; Liu, Y.; Chen, H.; Zhang, W.; Lv, S.; He, D. Temperature field simulation and microstructure evolution of Fe-based coating processed by extreme high-speed laser cladding for re-manufacturing locomotive axle. Surf. Coat. Technol. 2023, 464, 129529. [Google Scholar] [CrossRef]

- Ye, X.; Wang, J.; Ying, Q.; Planche, M.P.; Liao, H.; Suo, X. Melting behavior of in-flight particles in ultra-high speed laser cladding. J. Mater. Res. Technol. 2023, 24, 7047–7057. [Google Scholar] [CrossRef]

- Cho, C.; Zhao, G.; Kwak, S.Y.; Kim, C.B. Computational mechanics of laser cladding process. J. Mater. Process. Technol. 2004, 153–154, 494–500. [Google Scholar] [CrossRef]

- Qi, H.; Mazumder, J.; Ki, H. Numerical simulation of heat transfer and fluid flow in coaxial laser cladding process for direct metal deposition. J. Appl. Phys. 2006, 100, 024903. [Google Scholar] [CrossRef]

- Zhou, J.L.; Cheng, Y.H.; Chen, H.; Ma, K.; Wan, Y.X.; Yang, J.Y. Strengthening mechanisms and high-temperature oxidation properties of laser-clad TaNbZrTi refractory high entropy alloy coatings. J. Mater. Sci. 2023, 58, 16822–16840. [Google Scholar] [CrossRef]

- Bedenko, D.V.; Kovalev, O.B. Modelling of heat and mass transfer in the laser cladding during direct metal deposition. Thermophys. Aeromechanics 2013, 20, 251–261. [Google Scholar] [CrossRef]

- Shen, C.; Li, C.; Guo, Y.; Liu, C.; Zhang, X.; Feng, X. Modeling of temperature distribution and clad geometry of the molten pool during laser cladding of TiAlSi alloys. Opt. Laser Technol. 2021, 142, 107277. [Google Scholar] [CrossRef]

- Yang, M.; Wu, G.; Li, X.; Zhang, S.; Wang, H.; Huang, J. Influence of heat source model on the behavior of laser cladding pool. J. Laser Appl. 2023, 35, 022006. [Google Scholar] [CrossRef]

- Lou, L.Y.; Liu, K.C.; Jia, Y.J.; Ji, G.; Wang, W.; Li, C.J.; Li, C.X. Microstructure and properties of lightweight Al0. 2CrNbTiV refractory high entropy alloy coating with different dilutions deposited by high-speed laser cladding. Surf. Coat. Technol. 2022, 447, 128873. [Google Scholar] [CrossRef]

- Hu, Z.; Li, Y.; Lu, B.; Tan, N.; Cai, L.; Yong, Q. Effect of WC content on microstructure and properties of high-speed laser cladding Ni-based coating. Opt. Laser Technol. 2022, 155, 108449. [Google Scholar] [CrossRef]

- Guo, B.; Zhou, J.; Zhang, S.; Zhou, H.; Pu, Y.; Chen, J. Phase composition and tribological properties of Ti–Al coatings produced on pure Ti by laser cladding. Appl. Surf. Sci. 2007, 253, 9301–9310. [Google Scholar] [CrossRef]

- Luo, K.Y.; Xu, X.; Zhao, Z.; Zhao, S.S.; Cheng, Z.G.; Lu, J.Z. Microstructural evolution and characteristics of bonding zone in multilayer laser cladding of Fe-based coating. J. Mater. Process. Technol. 2019, 263, 50–58. [Google Scholar] [CrossRef]

- Yang, J.; Bai, B.; Ke, H.; Cui, Z.; Liu, Z.; Zhou, Z.; Xu, H.; Xiao, J.; Liu, Q.; Li, H. Effect of metallurgical behavior on microstructure and properties of FeCrMoMn coatings prepared by high-speed laser cladding. Opt. Laser Technol. 2021, 144, 107431. [Google Scholar] [CrossRef]

- Zhong, M.; Liu, W.; Yao, K.; Goussain, J.C.; Mayer, C.; Becker, A. Microstructural evolution in high power laser cladding of Stellite 6+WC layers. Surf. Coat. Technol. 2002, 157, 128–137. [Google Scholar] [CrossRef]

- Peng, R.F.; Zhang, M.; Li, Y.H.; Yu, Y.L.; Guan, Y.C.; Tan, Z.L. Microstructural development and wear properties analyses of Fe-based coatings on bainitic steel by laser cladding. J. Iron Steel Res. Int. 2022, 29, 687–697. [Google Scholar] [CrossRef]

- Du, J.L.; Deng, W.W.; Xu, X.; Wu, Y.J.; Luo, K.Y.; Zhang, H.M.; Lu, J.Z. Improvement of microstructure and performance of an extreme-high-speed laser cladding CoCrFeMnNi coating through laser shock peening. J. Alloys Compd. 2024, 1002, 175520. [Google Scholar] [CrossRef]

- Paydas, H.; Mertens, A.; Carrus, R.; Lecomte-Beckers, J.; Tchuindjang, J.T. Laser cladding as repair technology for Ti–6Al–4V alloy: Influence of building strategy on microstructure and hardness. Mater. Des. 2015, 85, 497–510. [Google Scholar] [CrossRef]

- Zhang, Q.; Han, B.; Li, M.; Chen, Z.; Hu, C.; Jia, C. Comparison of CoCrFeNi coatings prepared via high-speed laser cladding and normal laser cladding on microstructure and properties. Intermetallics 2023, 153, 107795. [Google Scholar] [CrossRef]

- Lian, G.; Zhao, C.; Zhang, Y.; Feng, M.; Jiang, J. Investigation into micro-hardness and wear resistance of 316L/SiC composite coating in laser cladding. Appl. Sci. 2020, 10, 3167. [Google Scholar] [CrossRef]

- Qiao, Y.; Huang, J.; Huang, D.; Chen, J.; Liu, W.; Wang, Z.; Zhibin, Z. Effects of laser scanning speed on microstructure, microhardness, and corrosion behavior of laser cladding Ni45 coatings. J. Chem. 2020, 2020, 1438473. [Google Scholar] [CrossRef]

- Yang, Z.; Jian, Y.; Chen, Z.; Qi, H.; Huang, Z.; Huang, G.; Xing, J. Microstructure, hardness and slurry erosion-wear behaviors of high-speed laser cladding Stellite 6 coatings prepared by the inside-beam powder feeding method. J. Mater. Res. Technol. 2022, 19, 2596–2610. [Google Scholar] [CrossRef]

- Zhou, L.; Ma, G.; Wang, H.; Wang, W.; Mou, H.; XianYong, Z.; Zhao, H.; Li, Y.; Tan, N. High-speed laser cladded Ni-based cermet coating with high ceramic phase content derived from core-shell structured powder. Surf. Coat. Technol. 2024, 489, 131110. [Google Scholar] [CrossRef]

| C | Mn | Si | Cr | Ni | Cu | P | S |

|---|---|---|---|---|---|---|---|

| 0.42~0.50 | 0.50~0.80 | 0.17~0.37 | ≤0.25 | ≤0.25 | ≤0.25 | ≤0.040 | ≤0.045 |

| C | B | Si | Cr | Ni | Mo | Fe |

|---|---|---|---|---|---|---|

| 0.3 | 0.8 | 1 | 15.4 | 2.1 | 1.3 | Bal |

| No. | Laser Power (W) | Cladding Speed (m/min) | Powder Feeding Rate (g/min) | Overlap Rate (%) | |

|---|---|---|---|---|---|

| Conventional laser cladding | 1 | 2000 | 0.5 | 18.18 | 25 |

| High-speed laser cladding | 2 | 2000 | 8 | 18.18 | 25 |

| 3 | 2000 | 10 | 18.18 | 25 | |

| 4 | 2000 | 12 | 18.18 | 25 |

| Temperature (K) | 473 | 673 | 873 | 1073 | 1273 | 1473 |

|---|---|---|---|---|---|---|

| Specific heat (J/gK) | 0.49 | 0.53 | 0.58 | 0.64 | 0.72 | 0.86 |

| Thermal conductivity (W/(m·k)) | 42.90 | 41.72 | 39.52 | 37.04 | 34.48 | 32.10 |

| Temperature (K) | 473 | 673 | 873 | 1073 | 1273 | 1473 |

|---|---|---|---|---|---|---|

| Specific heat (J/gK) | 0.55 | 0.58 | 0.61 | 0.63 | 0.66 | 0.75 |

| Thermal conductivity (W/(m·k)) | 11.23 | 12.01 | 12.75 | 13.55 | 14.26 | 15.0 |

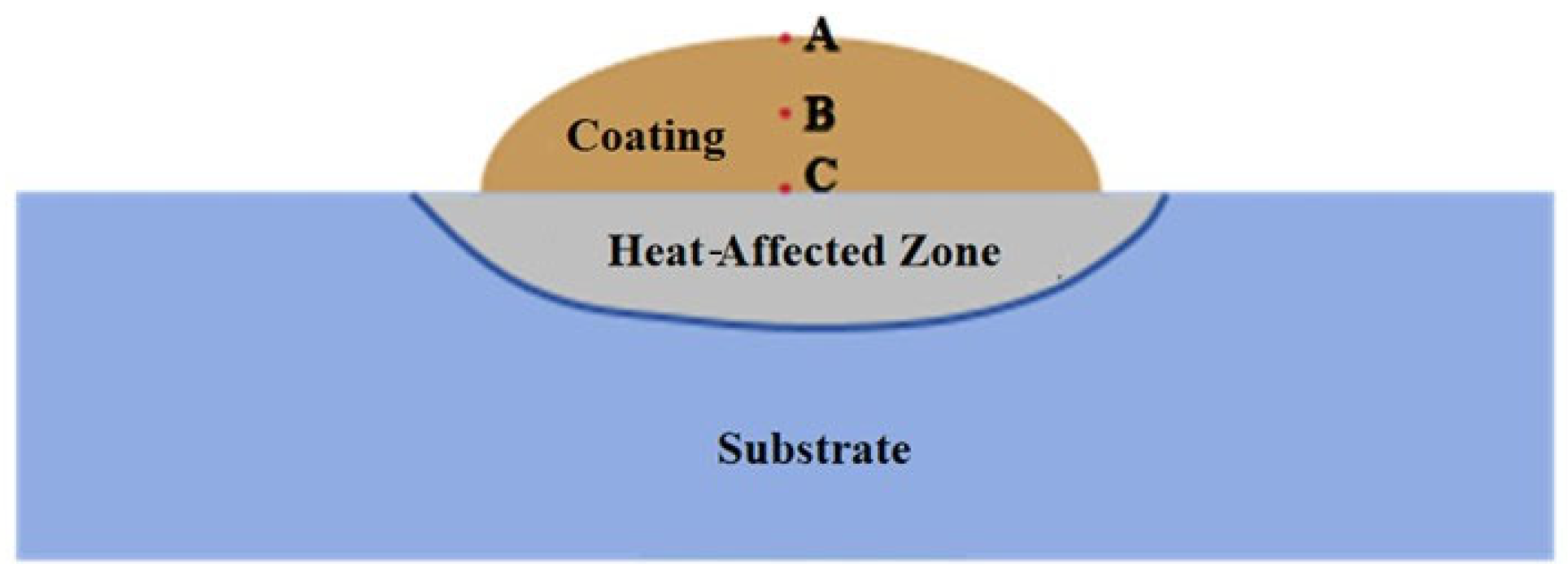

| Point | Conventional Laser Cladding | High-Speed Laser Cladding | ||||

|---|---|---|---|---|---|---|

| A1 | B1 | C1 | A4 | B4 | C4 | |

| G (K/mm) | 0.98 × 103 | 1.48 × 103 | 1.76 × 103 | 1.43 × 103 | 2.74 × 103 | 4.36 × 103 |

| R (mm/s) | 5.84 | 3.82 | 1.83 | 24.7 | 12.6 | 4.3 |

| G/R (Ks/mm2) | 171 | 388 | 961 | 58 | 196 | 1014 |

| G×R (K/s) | 5.72 × 103 | 5.67 × 103 | 3.22 × 103 | 3.53 × 105 | 3.45 × 105 | 1.84 × 105 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, C.; Ding, S.; Xue, X.; Li, M.; Yan, J.; Wang, S.; Wang, D.; Zhang, X.; Chen, S.; Yang, L.; et al. Comparative Study on the Microstructure and Simulation of High-Speed and Conventional Fe-Based Laser-Cladding Coatings. Crystals 2025, 15, 545. https://doi.org/10.3390/cryst15060545

Guo C, Ding S, Xue X, Li M, Yan J, Wang S, Wang D, Zhang X, Chen S, Yang L, et al. Comparative Study on the Microstructure and Simulation of High-Speed and Conventional Fe-Based Laser-Cladding Coatings. Crystals. 2025; 15(6):545. https://doi.org/10.3390/cryst15060545

Chicago/Turabian StyleGuo, Chuan, Shouwen Ding, Xiaoqiang Xue, Mingzhong Li, Jingwang Yan, Shubin Wang, Dandan Wang, Xiaotong Zhang, Shuisheng Chen, Liuhua Yang, and et al. 2025. "Comparative Study on the Microstructure and Simulation of High-Speed and Conventional Fe-Based Laser-Cladding Coatings" Crystals 15, no. 6: 545. https://doi.org/10.3390/cryst15060545

APA StyleGuo, C., Ding, S., Xue, X., Li, M., Yan, J., Wang, S., Wang, D., Zhang, X., Chen, S., Yang, L., Liu, Z., & Guo, S. (2025). Comparative Study on the Microstructure and Simulation of High-Speed and Conventional Fe-Based Laser-Cladding Coatings. Crystals, 15(6), 545. https://doi.org/10.3390/cryst15060545