Machine Learning Unveils the Impacts of Key Elements and Their Interaction on the Ambient-Temperature Tensile Properties of Cast Titanium Aluminides Employing SHAP Analysis

Abstract

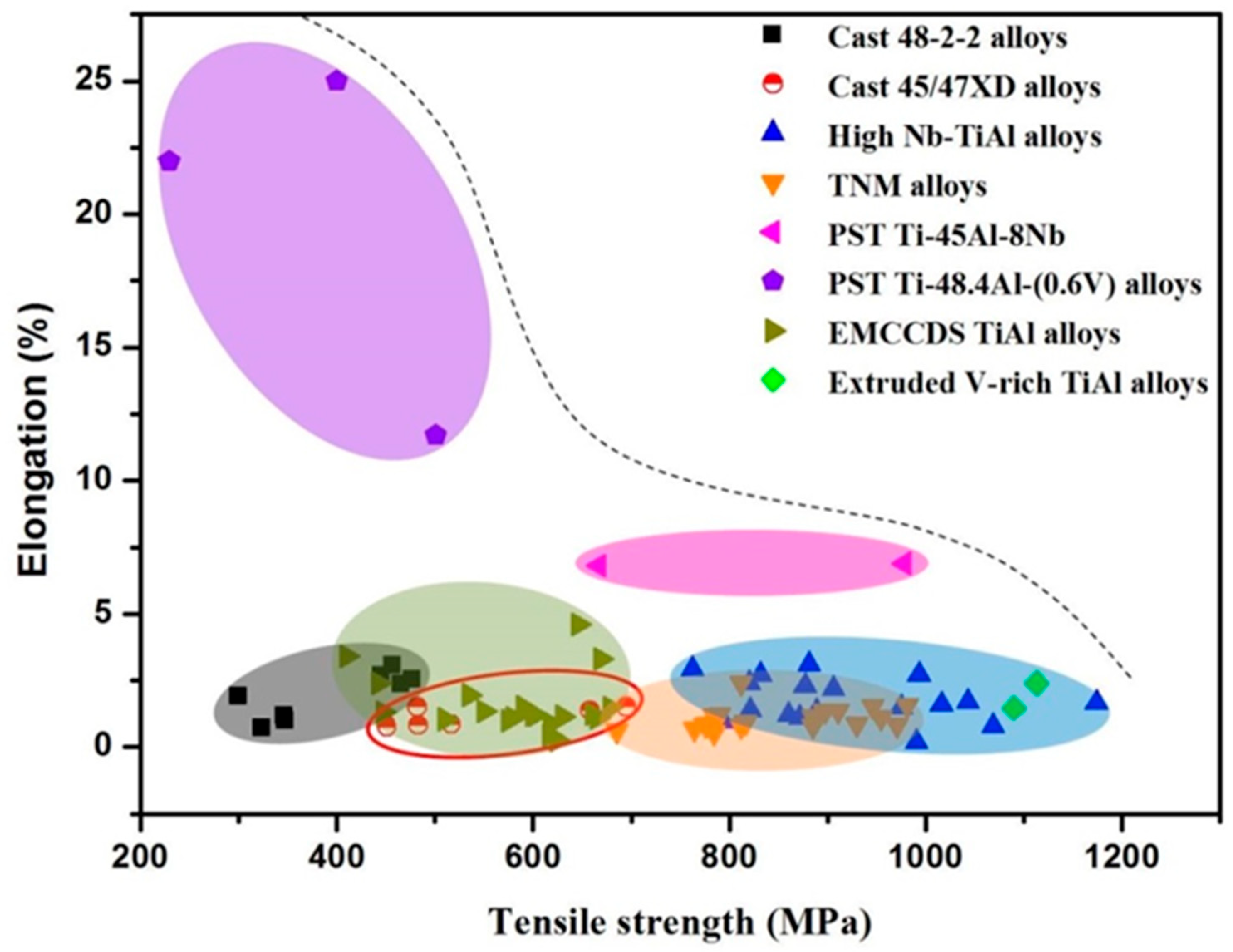

1. Introduction

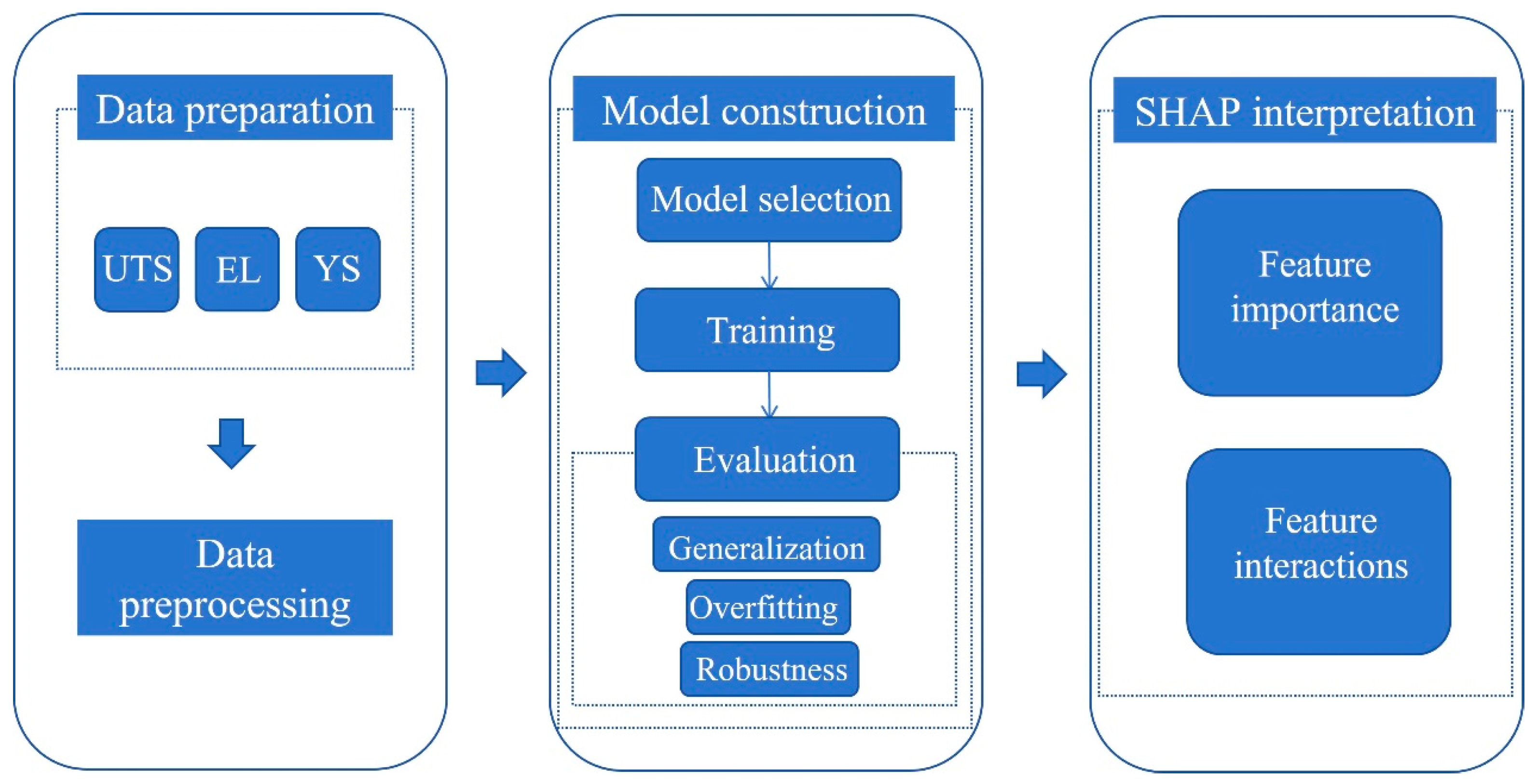

2. Methods

2.1. Data Preparation

2.2. Model Construction

2.3. Model Interpretation Tool

3. Results

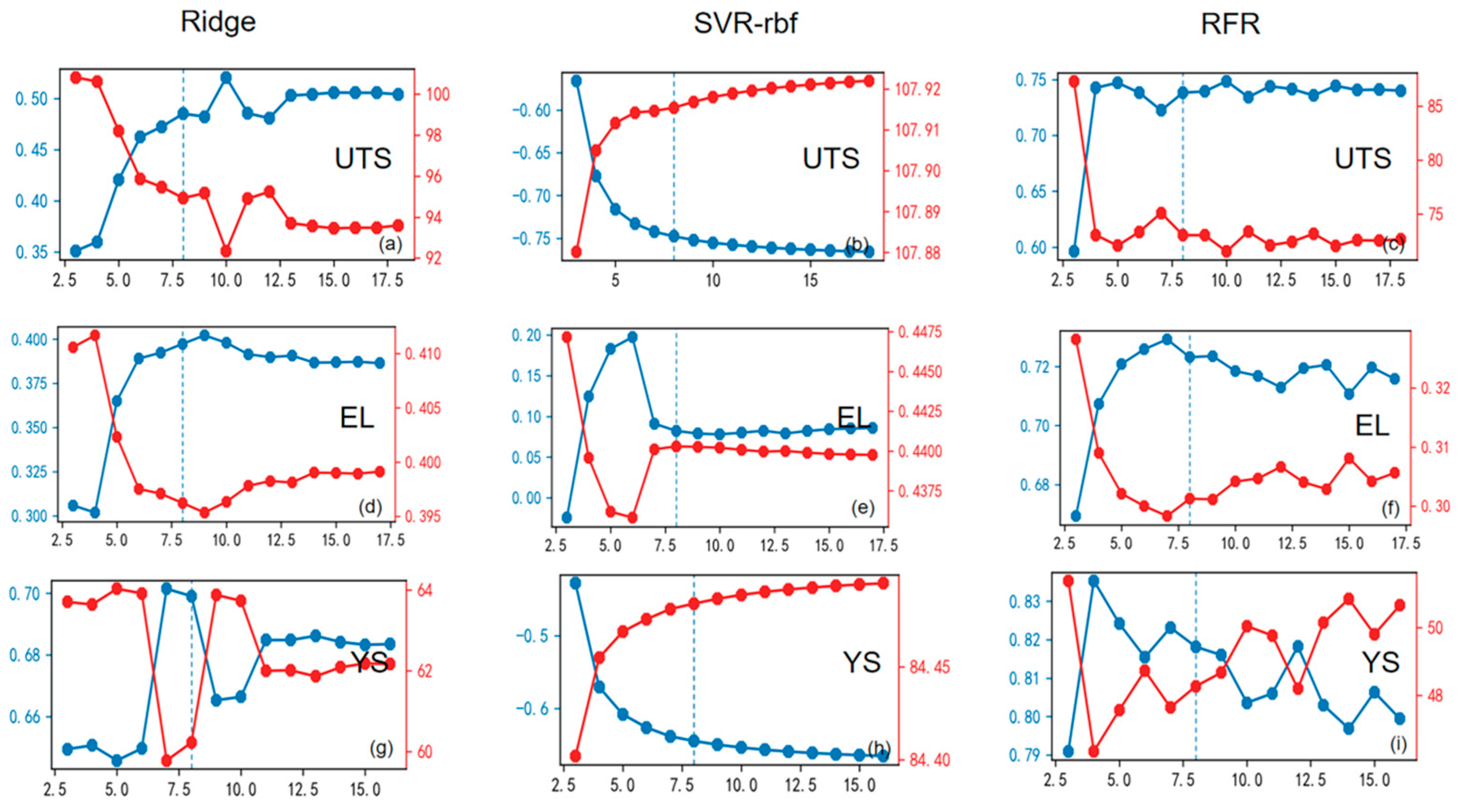

3.1. Model Selection

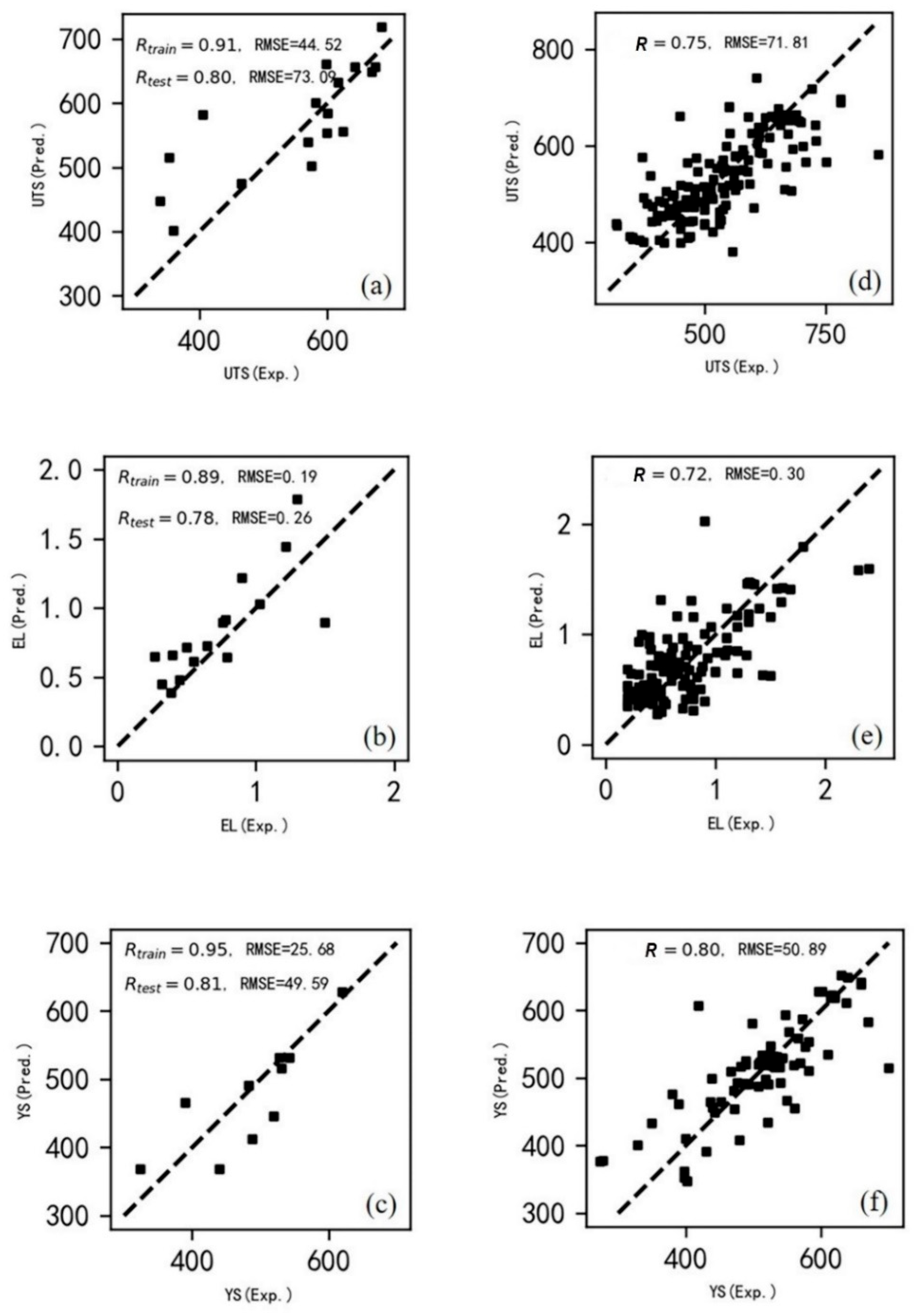

3.2. Model Construction and Evaluation

3.3. Model Interpretation

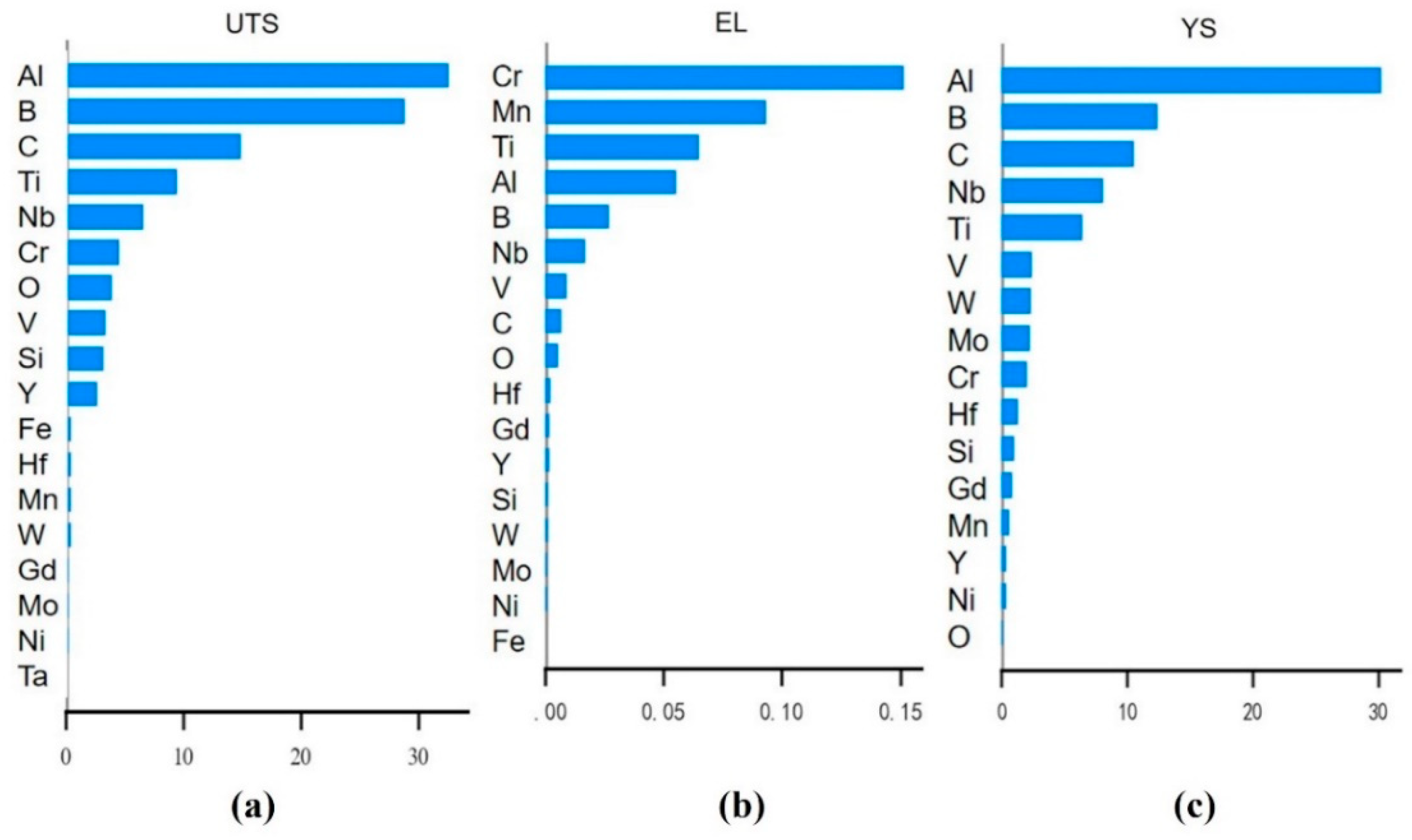

3.3.1. Feature Importance

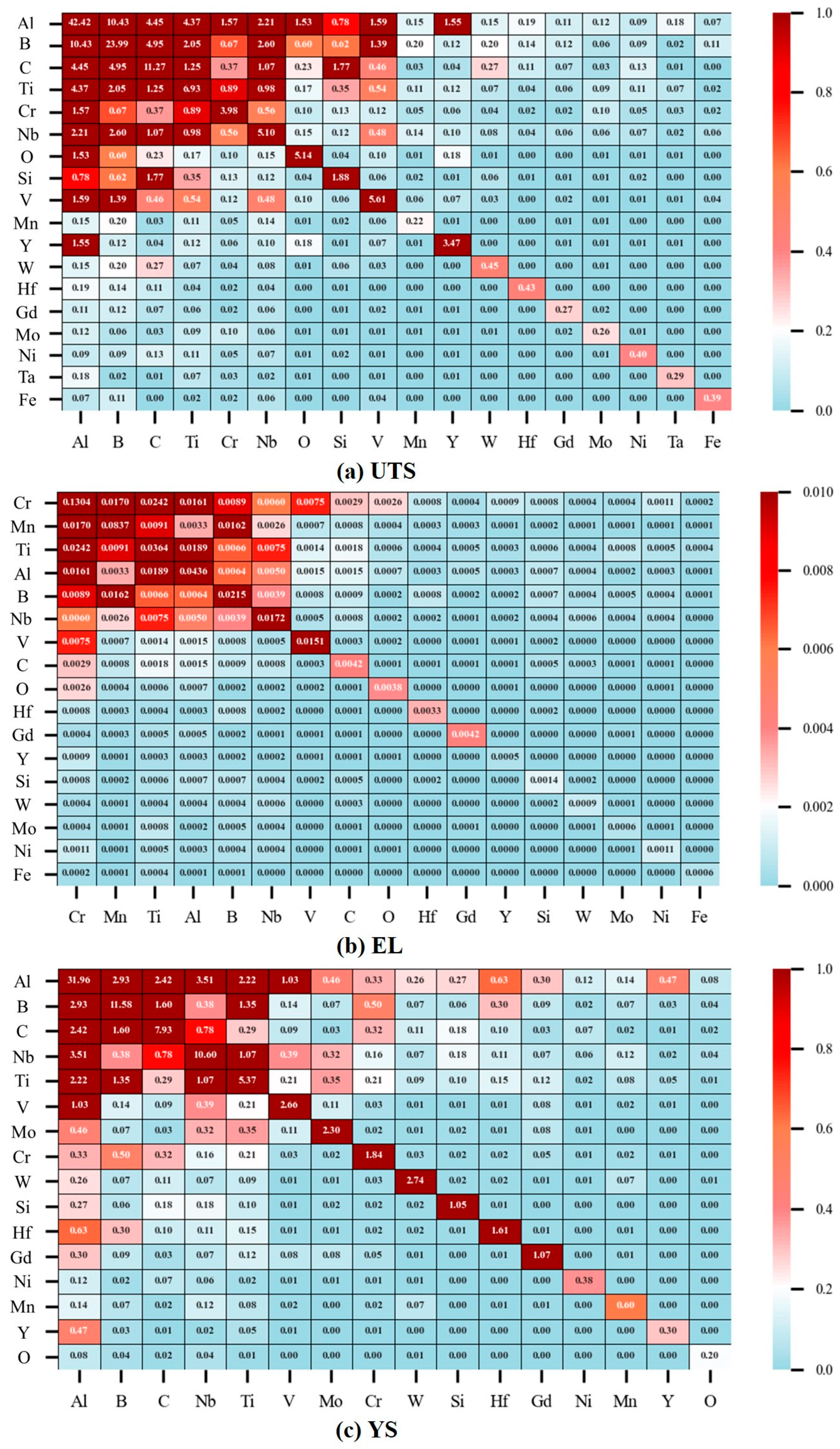

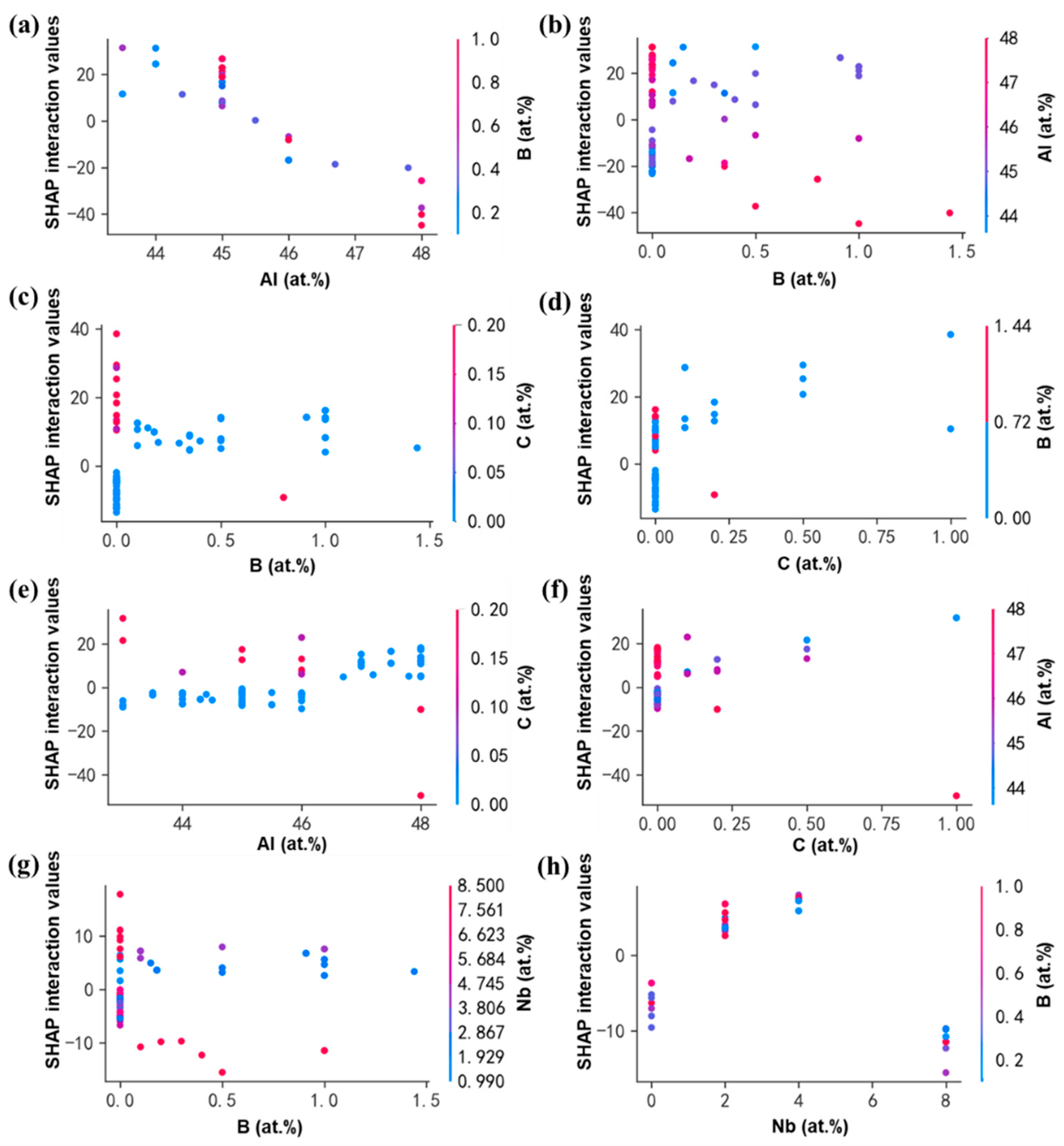

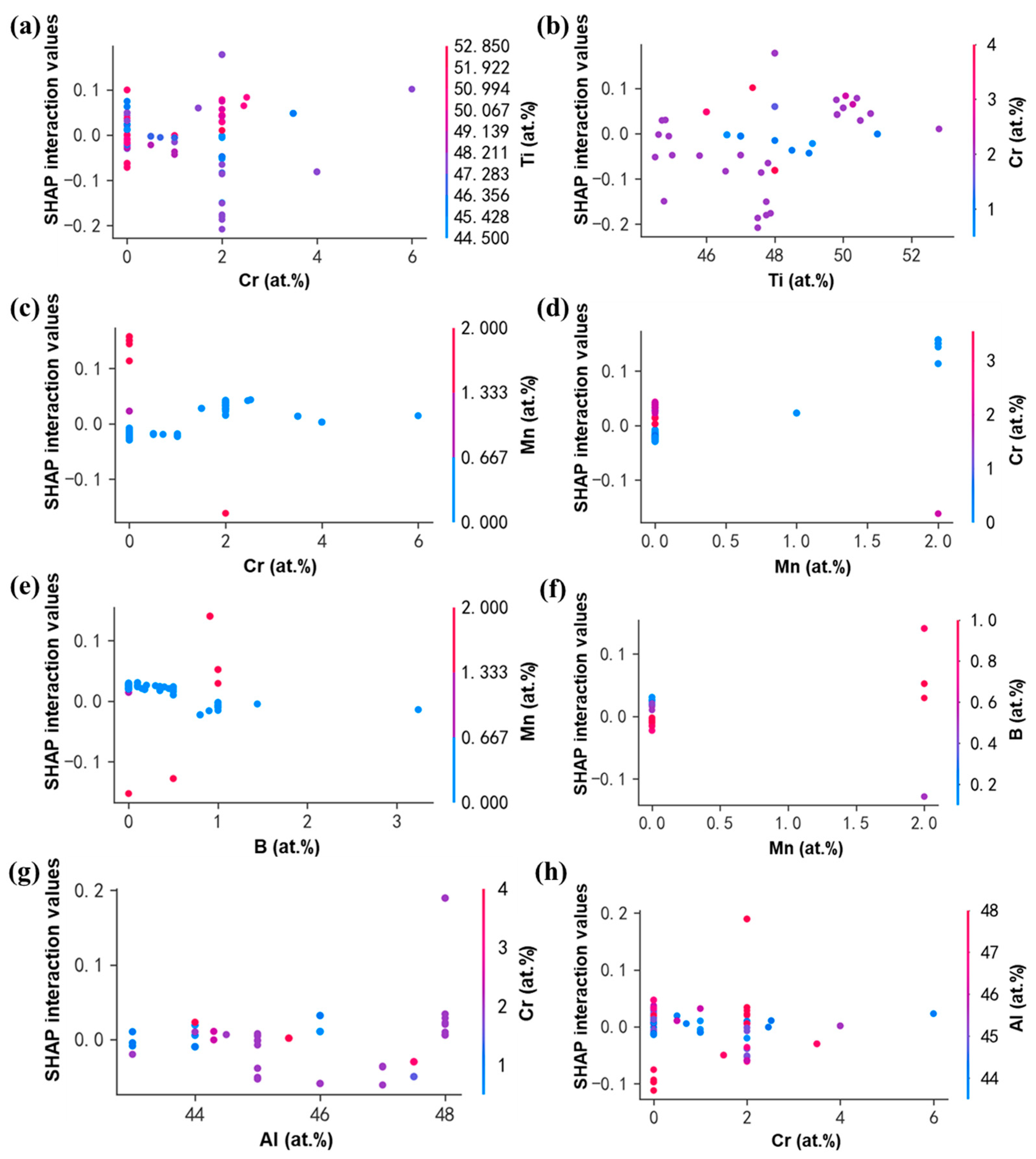

3.3.2. Feature Interaction

4. Discussion

4.1. Analysis of Feature Importance

4.2. Analysis of Feature Interaction

5. Conclusions

- (1)

- By comparing the RMSE and R of the LOOCV across various algorithms, including the Ridge, the SVR-rbf, and the RFR, within the training set, it was found that the RFR model emerged as the superior choice, boasting a higher R and a lower RMSE.

- (2)

- To assess the performance of the developed RFR model and mitigate the risk of overfitting, LOOCV was performed concurrently on the training set. It was revealed that the discrepancy in R values between the independent test set and the LOOCV on the training set was about 0.05, suggesting that all three well-trained models for UTS, EL, and YS exhibit relatively good predictive capabilities.

- (3)

- The RT UTS of cast TiAl alloys was mainly influenced by Al, B, C, Ti, Nb elements and so on, where the positive elements for UTS mainly included B, C, Nb, O, and Y, while the negative elements mainly contained Al, Ti, Cr, V, Si, and Fe. The RT EL of cast TiAl alloys was mainly influenced by Cr, Mn, Ti, Al, B elements and so on, where the positive elements for EL mainly included Cr, Mn, Al, and V, while the negative elements mainly contained Nb and C. The RT YS of cast TiAl alloys was mainly influenced by Al, B, C, Nb, Ti elements and so on, where the positive elements for YS mainly included B, C, and Nb, while the negative elements mainly contained Al, Ti, V, W, and Mo.

- (4)

- The highly probable interaction direction between two different elements on the RT tensile properties of cast TiAl alloys was basically unveiled by analyses of the SHAP dependence plots. Such as, when the Al content is less than about 45.5 at%, the interaction between Al and B elements is usually positive for the UTS; when the Cr content is more than about 1 at%, the interaction between Cr and Mn elements is generally positive for the EL; when the Al content is 44–46 at%, the interactions between Al and B, as well as between Al and C elements, are generally positive for the YS.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Appel, F.; Clemens, H.; Fischer, F.D. Modeling concepts for intermetallic titanium aluminides. Prog. Mater. Sci. 2016, 81, 55–124. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, D.; Liu, S.; Ding, H.; Yuan, S. Hot deformation characterization of lamellar Ti-43Al-2Si alloy fabricated by cold crucible continuous casting. J. Alloys Compd. 2016, 688, 542–552. [Google Scholar] [CrossRef]

- Liu, S.; Ding, H.; Guo, J.; Zhang, H.; Chen, Z.; Wang, Q.; Chen, R.; Fu, H. Rapid Cellular Crystal Growth of TiAl-Based Intermetallic without Peritectic Reaction by Melt-Quenching in Ga–In Liquid. Cryst. Growth Des. 2017, 17, 1716–1728. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, D.; Liu, S.; Ding, H.; Yuan, S. Effect of microstructures on hot compression behavior of a Ti-43Al-2Si alloy fabricated by cold crucible continuous casting. Mater. Charact. 2018, 144, 424–430. [Google Scholar] [CrossRef]

- Liu, S.; Ding, H.; Chen, R.; Guo, J.; Fu, H. Microstructural evolution and mechanical properties of a Cr-rich β-solidifying TiAl-based alloy prepared by electromagnetic cold crucible continuous casting. Mater. Sci. Eng. A 2020, 798, 140205. [Google Scholar] [CrossRef]

- Liu, S.; Ding, H.; Chen, R.; Guo, J.; Fu, H. Evolution of rapidly grown cellular microstructure during heat treatment of TiAl-based intermetallic and its effect on micromechanical properties. Intermetallics 2021, 132, 107166. [Google Scholar] [CrossRef]

- Liu, S.; Luo, Y.; Ding, H.; Chen, R.; Guo, J.; Fu, H. Improved Fracture Toughness of Polycrystalline γ-TiAl-Based Intermetallic Alloys with a Favorable Deformation Mechanism of Twinning. Adv. Eng. Mater. 2022, 24, 2101710. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, S.; Sun, Z.; Liu, B.; Wang, L.; Wang, Y.; Liu, Y. Microstructural evolution during annealing of a powder metallurgical TiAl–Nb composite and its effect on mechanical properties. J. Mater. Res. Technol. 2023, 25, 3654–3669. [Google Scholar] [CrossRef]

- Bewlay, B.P.; Nag, S.; Suzuki, A.; Weimer, M.J. TiAl alloys in commercial aircraft engines. Mater. High Temp. 2016, 33, 549–559. [Google Scholar] [CrossRef]

- Janschek, P. Wrought TiAl Blades. Mater. Today Proc. 2015, 2, S92–S97. [Google Scholar] [CrossRef]

- Bewlay, B.P.; Weimer, M.; Kelly, T.; Suzuki, A.; Subramanian, P.R. The Science, Technology, and Implementation of TiAl Alloys in Commercial Aircraft Engines. MRS Online Proc. Libr. (OPL) 2013, 1516, 49–58. [Google Scholar] [CrossRef]

- Yang, R. Advances and challenges of TiAl base alloys. Acta Metall. Sin. 2015, 51, 129–147. [Google Scholar]

- Liu, B.G.; Liu, L.H.; Xing, W.D.; Liu, R.C.; Yang, R.; Withey, P.A.; Zhu, J.; Yu, R. Structural stability and the alloying effect of TiB polymorphs in TiAl alloys. Intermetallics 2017, 90, 97–102. [Google Scholar] [CrossRef]

- Duan, B.; Yang, Y.; He, S.; Feng, Q.; Mao, L.; Zhang, X.; Jiao, L.; Lu, X.; Chen, G.; Li, C. History and development of γ-TiAl alloys and the effect of alloying elements on their phase transformations. J. Alloys Compd. 2022, 909, 164811. [Google Scholar] [CrossRef]

- Musi, M.; Graf, G.; Clemens, H.; Spoerk-Erdely, P. Alloying Elements in Intermetallic γ-TiAl Based Alloys–A Review on Their Influence on Phase Equilibria and Phase Transformations. Adv. Eng. Mater. 2024, 26, 2300610. [Google Scholar] [CrossRef]

- Sun, F.-S.; Cao, C.-X.; Yan, M.-G.; Kim, S.-E.; Tailee, Y. Alloying mechanism of beta stabilizers in a TiAl alloy. Metall. Mater. Trans. A 2001, 32, 1573–1589. [Google Scholar] [CrossRef]

- Jin, Y.; Wang, J.N.; Yang, J.; Wang, Y. Microstructure refinement of cast TiAl alloys by β solidification. Scr. Mater. 2004, 51, 113–117. [Google Scholar] [CrossRef]

- Imayev, R.M.; Imayev, V.M.; Oehring, M.; Appel, F. Alloy design concepts for refined gamma titanium aluminide based alloys. Intermetallics 2007, 15, 451–460. [Google Scholar] [CrossRef]

- Han, J.; Xiao, S.; Tian, J.; Chen, Y.; Xu, L.; Wang, X.; Jia, Y.; Du, Z.; Cao, S. Grain refinement by trace TiB2 addition in conventional cast TiAl-based alloy. Mater. Charact. 2015, 106, 112–122. [Google Scholar] [CrossRef]

- Cui, N.; Wang, X.-P.; Kong, F.-T.; Chen, Y.-Y.; Zhou, H.-T. Microstructure and properties of a beta-solidifying TiAl-based alloy with different refiners. Rare Met. 2016, 35, 42–47. [Google Scholar] [CrossRef]

- Zhang, K.; Hu, R.; Lei, T.; Yang, J. Refinement of massive γ phase with enhanced properties in a Ta containing γ-TiAl-based alloys. Scr. Mater. 2019, 172, 113–118. [Google Scholar] [CrossRef]

- Chapman, J.; Ramprasad, R. Nanoscale Modeling of Surface Phenomena in Aluminum Using Machine Learning Force Fields. J. Phys. Chem. C 2020, 124, 22127–22136. [Google Scholar] [CrossRef]

- Morgan, D.; Jacobs, R. Opportunities and Challenges for Machine Learning in Materials Science. Annu. Rev. Mater. Res. 2020, 50, 71–103. [Google Scholar] [CrossRef]

- Moosavi, S.M.; Jablonka, K.M.; Smit, B. The Role of Machine Learning in the Understanding and Design of Materials. J. Am. Chem. Soc. 2020, 142, 20273–20287. [Google Scholar] [CrossRef]

- Lee, K.; Hong, C.; Lee, E.-H.; Yang, W. Comparison of Artificial Intelligence Methods for Prediction of Mechanical Properties. IOP Conf. Ser. Mater. Sci. Eng. 2020, 967, 012031. [Google Scholar] [CrossRef]

- Bhandari, U.; Rafi, M.R.; Zhang, C.; Yang, S. Yield strength prediction of high-entropy alloys using machine learning. Mater. Today Commun. 2021, 26, 101871. [Google Scholar] [CrossRef]

- Liao, H.; Zhao, B.; Suo, X.; Wang, Q. Prediction models for macro shrinkage of aluminum alloys based on machine learning algorithms. Mater. Today Commun. 2019, 21, 100715. [Google Scholar] [CrossRef]

- Xinyu, C.; Yingbo, Z.; Jiaheng, L.; Hui, C. Composition design of 7XXX aluminum alloys optimizing stress corrosion cracking resistance using machine learning. Mater. Res. Express 2020, 7, 046506. [Google Scholar] [CrossRef]

- Hart, G.L.W.; Mueller, T.; Toher, C.; Curtarolo, S. Machine learning for alloys. Nat. Rev. Mater. 2021, 6, 730–755. [Google Scholar] [CrossRef]

- Rickman, J.M.; Balasubramanian, G.; Marvel, C.J.; Chan, H.M.; Burton, M.-T. Machine learning strategies for high-entropy alloys. J. Appl. Phys. 2020, 128, 221101. [Google Scholar] [CrossRef]

- Kaufmann, K.; Vecchio, K.S. Searching for high entropy alloys: A machine learning approach. Acta Mater. 2020, 198, 178–222. [Google Scholar] [CrossRef]

- Wen, C.; Zhang, Y.; Wang, C.; Xue, D.; Bai, Y.; Antonov, S.; Dai, L.; Lookman, T.; Su, Y. Machine learning assisted design of high entropy alloys with desired property. Acta Mater. 2019, 170, 109–117. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, T.; Ju, W.; Shi, S. Materials discovery and design using machine learning. J. Mater. 2017, 3, 159–177. [Google Scholar] [CrossRef]

- Hu, M.; Tan, Q.; Knibbe, R.; Xu, M.; Jiang, B.; Wang, S.; Li, X.; Zhang, M.-X. Recent applications of machine learning in alloy design: A review. Mater. Sci. Eng. R Rep. 2023, 155, 100746. [Google Scholar] [CrossRef]

- Kwak, S.; Kim, J.; Ding, H.; Xu, X.; Chen, R.; Guo, J.; Fu, H. Machine learning prediction of the mechanical properties of γ-TiAl alloys produced using random forest regression model. J. Mater. Res. Technol. 2022, 18, 520–530. [Google Scholar] [CrossRef]

- Kwak, S.; Kim, J.; Ding, H.; Xu, X.; Chen, R.; Guo, J.; Fu, H. Using multiple regression analysis to predict directionally solidified TiAl mechanical property. J. Mater. Sci. Technol. 2022, 104, 285–291. [Google Scholar] [CrossRef]

- Kwak, S.; Kim, J.; Ding, H.; Liang, H.; Chen, R.; Guo, J.; Fu, H. Prediction improvement of compressive strength and strain of directionally solidified TiAl alloy based on training data size adjustment. J. Mater. Res. Technol. 2024, 30, 5017–5027. [Google Scholar] [CrossRef]

- Mangalathu, S.; Hwang, S.-H.; Jeon, J.-S. Failure mode and effects analysis of RC members based on machine-learning-based SHapley Additive exPlanations (SHAP) approach. Eng. Struct. 2020, 219, 110927. [Google Scholar] [CrossRef]

- Wang, D.; Thunéll, S.; Lindberg, U.; Jiang, L.; Trygg, J.; Tysklind, M. Towards better process management in wastewater treatment plants: Process analytics based on SHAP values for tree-based machine learning methods. J. Environ. Manag. 2022, 301, 113941. [Google Scholar] [CrossRef]

- Yang, Y.; Yuan, Y.; Han, Z.; Liu, G. Interpretability analysis for thermal sensation machine learning models: An exploration based on the SHAP approach. Indoor Air 2022, 32, 12984. [Google Scholar] [CrossRef]

- Lundberg, S.M.; Lee, S.-I. A Unified Approach to Interpreting Model Predictions. In Proceedings of the 31st Conference on Neural Information Processing Systems (NIPS 2017), Long Beach, CA, USA, 4–9 December 2017. [Google Scholar]

- Hu, D. Effect of composition on grain refinement in TiAl-based alloys. Intermetallics 2001, 9, 1037–1043. [Google Scholar] [CrossRef]

- Tian, W.H.; Nemoto, M. Effect of carbon addition on the microstructures and mechanical properties of γ-TiAl alloys. Intermetallics 1997, 5, 237–244. [Google Scholar] [CrossRef]

- Wang, Q.; Ding, H.; Zhang, H.; Chen, R.; Guo, J.; Fu, H. Variations of microstructure and tensile property of γ-TiAl alloys with 0–0.5 at% C additives. Mater. Sci. Eng. A 2017, 700, 198–208. [Google Scholar] [CrossRef]

- Liu, Z.C.; Lin, J.P.; Li, S.J.; Chen, G.L. Effects of Nb and Al on the microstructures and mechanical properties of high Nb containing TiAl base alloys. Intermetallics 2002, 10, 653–659. [Google Scholar] [CrossRef]

- Ding, H.; Nie, G.; Chen, R.; Guo, J.; Fu, H. Influence of oxygen on microstructure and mechanical properties of directionally solidified Ti–47Al–2Cr–2Nb alloy. Mater. Des. 2012, 41, 108–113. [Google Scholar] [CrossRef]

- Zhong, H.; Yang, Y.; Li, J.; Wang, J.; Zhang, T.; Li, S.; Zhang, J. Influence of oxygen on microstructure and phase transformation in high Nb containing TiAl alloys. Mater. Lett. 2012, 83, 198–201. [Google Scholar] [CrossRef]

- Li, B.H.; Chen, Y.Y.; Hou, Z.Q.; Kong, F.T. Microstructure and mechanical properties of as-cast Ti–43Al–9V–0.3Y alloy. J. Alloys Compd. 2009, 473, 123–126. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Li, B.H.; Kong, F.T. Microstructural refinement and mechanical properties of Y-bearing TiAl alloys. J. Alloys Compd. 2008, 457, 265–269. [Google Scholar] [CrossRef]

- Huang, S.-C.; Hall, E.L. The effects of Cr additions to binary TiAl-base alloys. Metall. Trans. A 1991, 22, 2619–2627. [Google Scholar] [CrossRef]

- Hamzah, E.; Kanniah, M.; Harun, M. Effect of chromium addition on microstructure, tensile properties and creep resistance of as-cast Ti-48Al alloy. J. Mater. Sci. 2007, 42, 9063–9069. [Google Scholar] [CrossRef]

- Nishikiori, S.; Matsuda, K.; Nakagawa, Y.G. Microstructural effects on tensile properties of cast TiAl–Fe–V–B alloy. Mater. Sci. Eng. A 1997, 239–240, 592–599. [Google Scholar] [CrossRef]

- Knaislová, A.; Novák, P.; Cabibbo, M.; Jaworska, L.; Vojtěch, D. Development of TiAl–Si Alloys—A Review. Materials 2021, 14, 1030. [Google Scholar] [CrossRef] [PubMed]

- Klein, T.; Rashkova, B.; Holec, D.; Clemens, H.; Mayer, S. Silicon distribution and silicide precipitation during annealing in an advanced multi-phase γ-TiAl based alloy. Acta Mater. 2016, 110, 236–245. [Google Scholar] [CrossRef]

- Liu, S.; Ding, H.; Zhang, H.; Chen, R.; Guo, J.; Fu, H. High-density deformation nanotwin induced significant improvement in the plasticity of polycrystalline γ-TiAl-based intermetallic alloys. Nanoscale 2018, 10, 11365–11374. [Google Scholar] [CrossRef]

- Liu, S.; Ding, H.; Chen, R.; Guo, J.; Fu, H. Remarkable improvement in tensile strength of a polycrystalline γ-TiAl-based intermetallic alloy by deformation nanotwins. Mater. Sci. Eng. A 2021, 823, 141692. [Google Scholar] [CrossRef]

- Wang, Q.; Ding, H.; Zhang, H.; Chen, R.; Guo, J.; Fu, H. Influence of Mn addition on the microstructure and mechanical properties of a directionally solidified γ-TiAl alloy. Mater. Charact. 2018, 137, 133–141. [Google Scholar] [CrossRef]

- Huang, S.-C.; Hall, E.L. Characterization of the effect of vanadium additions to TiAl base alloys. Acta Metall. Mater. 1991, 39, 1053–1060. [Google Scholar] [CrossRef]

- Tetsui, T. Effects of high niobium addition on the mechanical properties and high-temperature deformability of gamma TiAl alloy. Intermetallics 2002, 10, 239–245. [Google Scholar] [CrossRef]

- Fang, H.; Chen, R.; Yang, Y.; Su, Y.; Ding, H.; Guo, J.; Fu, H. Role of graphite on microstructural evolution and mechanical properties of ternary TiAl alloy prepared by arc melting method. Mater. Des. 2018, 156, 300–310. [Google Scholar] [CrossRef]

- Liu, C.T.; Maziasz, P.J. Microstructural control and mechanical properties of dual-phase TiAl alloys. Intermetallics 1998, 6, 653–661. [Google Scholar] [CrossRef]

- Chu, W.-Y.; Thompson, A.W. Effects of grain size on yield strength in TiAl. Scr. Metall. Mater. 1991, 25, 641–644. [Google Scholar]

- Zhang, W.J.; Appel, F. Effect of Al content and Nb addition on the strength and fault energy of TiAl alloys. Mater. Sci. Eng. A 2002, 329–331, 649–652. [Google Scholar] [CrossRef]

| Elements | Ti | Al | Cr | Nb | B | C | V | Ni | Mn | Fe | Mo | W | Hf | Si | Y | O | Ta | Gd |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Content (at%) | Bal. | 43–48 | 0–6 | 0–8.5 | 0–3.24 | 0–1 | 0–9 | 0–0.25 | 0–2 | 0–1.3 | 0–2 | 0–2 | 0–4 | 0–1.3 | 0–0.3 | 0–0.45 | 0–1 | 0–0.2 |

| Number | 163 | 163 | 83 | 147 | 59 | 26 | 20 | 8 | 26 | 4 | 18 | 14 | 5 | 27 | 9 | 6 | 2 | 5 |

| (a) | ||||||||||||||||||

| Elements | Ti | Al | Cr | Nb | B | C | V | Ni | Mn | Mo | W | Hf | Si | Y | O | Gd | ||

| Content (at%) | Bal. | 43–48 | 0–4 | 0–8 | 0–1 | 0–0.5 | 0–9 | 0–0.2 | 0–2 | 0–2 | 0–2 | 0–4 | 0–0.5 | 0–0.3 | 0–0.15 | 0–0.2 | ||

| Number | 93 | 93 | 28 | 86 | 51 | 9 | 9 | 5 | 27 | 8 | 8 | 7 | 19 | 4 | 2 | 5 | ||

| (b) | ||||||||||||||||||

| Elements | Ti | Al | Cr | Nb | B | C | V | Ni | Mn | Fe | Mo | W | Hf | Si | Y | O | Gd | |

| Content (at%) | Bal. | 43–48 | 0–6 | 0–8 | 0–3.24 | 0–1 | 0–9 | 0–0.25 | 0–2 | 0–1.3 | 0–2 | 0–2 | 0–4 | 0–1.3 | 0–0.3 | 0–0.45 | 0–0.2 | |

| Number | 155 | 155 | 78 | 141 | 68 | 22 | 18 | 3 | 24 | 4 | 15 | 14 | 7 | 24 | 8 | 5 | 5 | |

| (c) | ||||||||||||||||||

| Mechanical Properties | ||||

|---|---|---|---|---|

| UTS | 0.91 | 44.80 | 0.80 | 66.75 |

| YS | 0.94 | 27.3 | 0.80 | 45.8 |

| EL | 0.89 | 0.19 | 0.77 | 0.32 |

| Metrics of Tensile Property | Key Chemical Elements | 90% Confidence Interval of Mean |SHAP Values| |

|---|---|---|

| UTS | Al | [18.150, 53.778] |

| B | [14.521, 47.786] | |

| EL | Cr | [0.078, 0.232] |

| Mn | [0.046, 0.138] | |

| YS | Al | [20.999, 50.279] |

| B | [4.534, 30.850] |

| Metrics of Tensile Property | Key Chemical Elements | 90% Confidence Interval of Mean |SHAP Interaction Value| |

|---|---|---|

| UTS | Al-B | [4.300, 13.957] |

| B-C | [1.797, 6.870] | |

| EL | Cr-Ti | [0.010, 0.040] |

| Ti-Al | [0.006, 0.032] | |

| YS | Al-Nb | [1.054, 6.954] |

| Al-B | [0.748, 4.377] |

| UTS | EL | YS | |||

|---|---|---|---|---|---|

| Element Pair | Mean |SHAP Interaction Value| | Element Pair | Mean |SHAP Interaction Value| | Element Pair | Mean |SHAP Interaction Value| |

| Al-B | 10.43 | Cr-Ti | 0.0242 | Al-Nb | 3.51 |

| B-C | 4.95 | Ti-Al | 0.0189 | Al-B | 2.93 |

| Al-C | 4.45 | Cr-Mn | 0.017 | Al-C | 2.42 |

| Al-Ti | 4.37 | Mn-B | 0.0162 | Al-Ti | 2.22 |

| B-Nb | 2.60 | Cr-Al | 0.0161 | B-C | 1.6 |

| Al-Nb | 2.21 | Mn-Ti | 0.0091 | B-Ti | 1.35 |

| B-Ti | 2.05 | Cr-B | 0.0089 | Nb-Ti | 1.07 |

| C-Si | 1.77 | Cr-V | 0.0075 | Al-V | 1.03 |

| Al-V | 1.59 | Ti-Nb | 0.0075 | C-Nb | 0.78 |

| Al-Cr | 1.57 | Ti-B | 0.0066 | B-Cr | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Liang, L. Machine Learning Unveils the Impacts of Key Elements and Their Interaction on the Ambient-Temperature Tensile Properties of Cast Titanium Aluminides Employing SHAP Analysis. Crystals 2025, 15, 468. https://doi.org/10.3390/cryst15050468

Liu S, Liang L. Machine Learning Unveils the Impacts of Key Elements and Their Interaction on the Ambient-Temperature Tensile Properties of Cast Titanium Aluminides Employing SHAP Analysis. Crystals. 2025; 15(5):468. https://doi.org/10.3390/cryst15050468

Chicago/Turabian StyleLiu, Shiqiu, and Li Liang. 2025. "Machine Learning Unveils the Impacts of Key Elements and Their Interaction on the Ambient-Temperature Tensile Properties of Cast Titanium Aluminides Employing SHAP Analysis" Crystals 15, no. 5: 468. https://doi.org/10.3390/cryst15050468

APA StyleLiu, S., & Liang, L. (2025). Machine Learning Unveils the Impacts of Key Elements and Their Interaction on the Ambient-Temperature Tensile Properties of Cast Titanium Aluminides Employing SHAP Analysis. Crystals, 15(5), 468. https://doi.org/10.3390/cryst15050468