Unveiling the Strengthening and Ductility Mechanisms of a CoCr0.4NiSi0.3 Medium-Entropy Alloy at Cryogenic Temperatures

Abstract

1. Introduction

2. Experimental

3. Results and Discussion

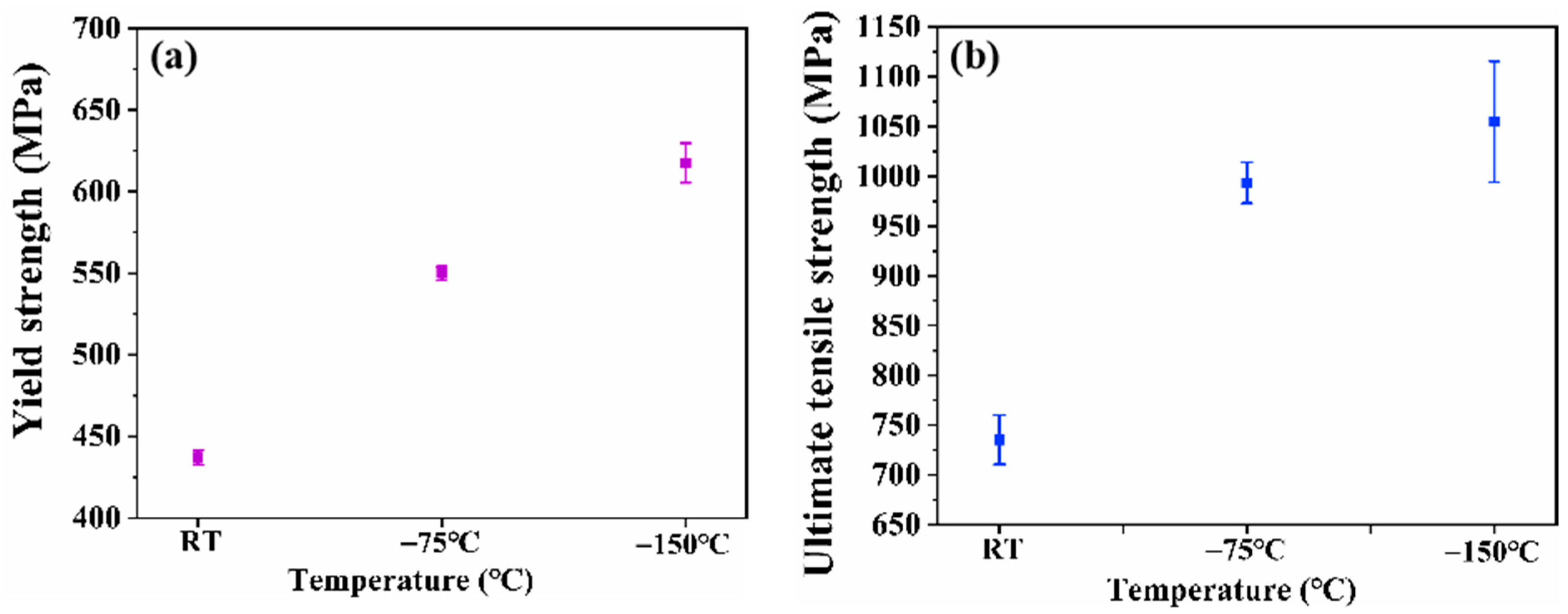

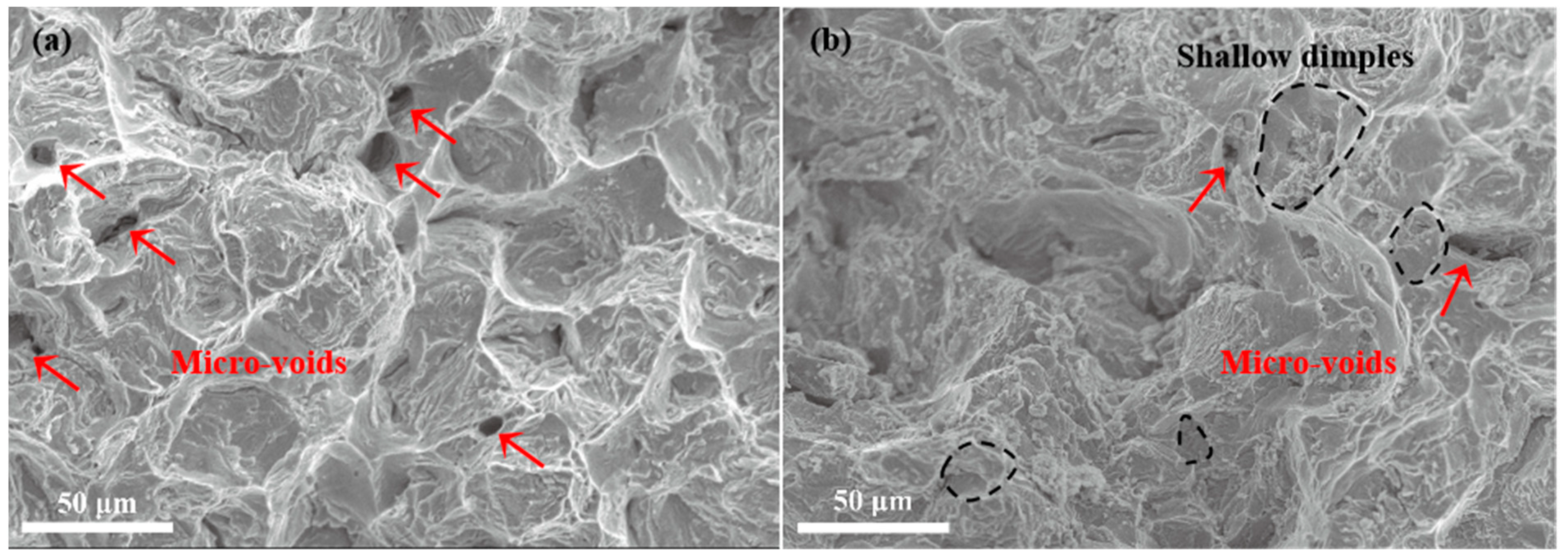

3.1. The Mechanical Properties

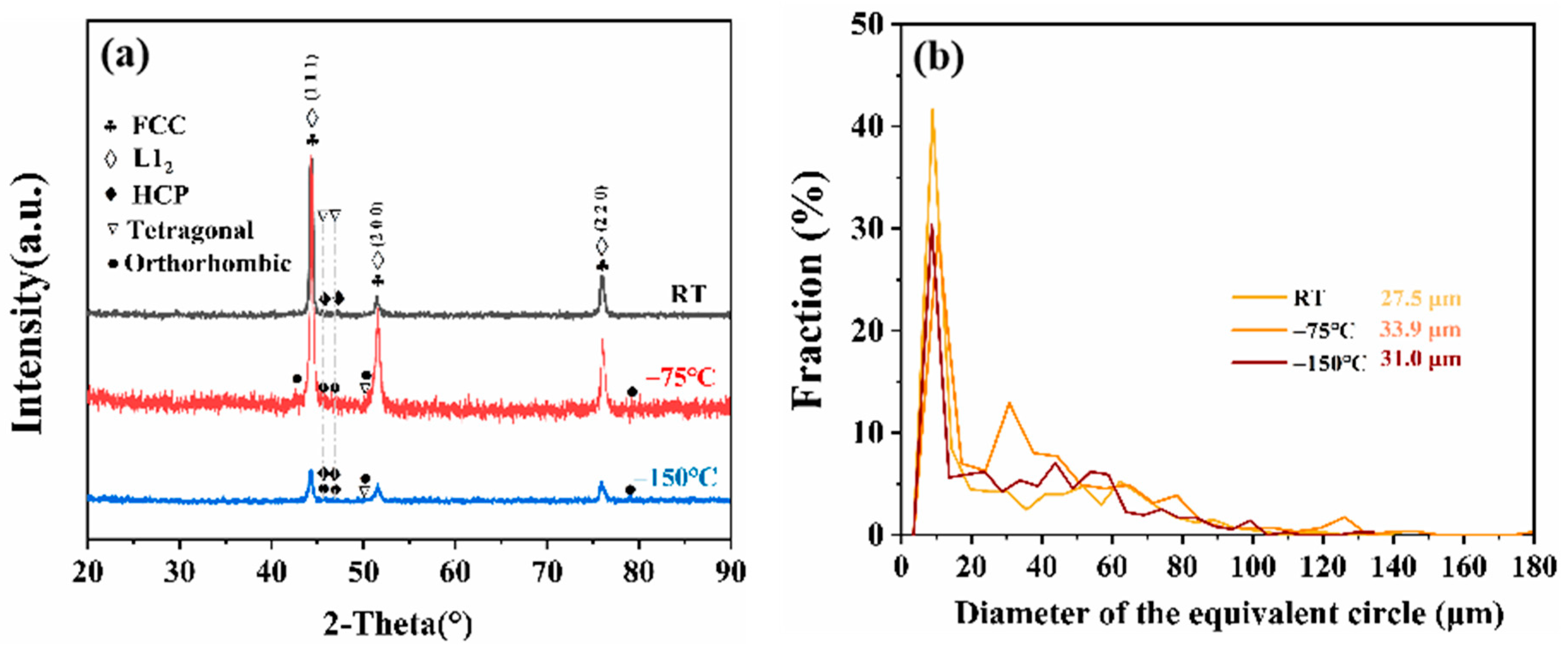

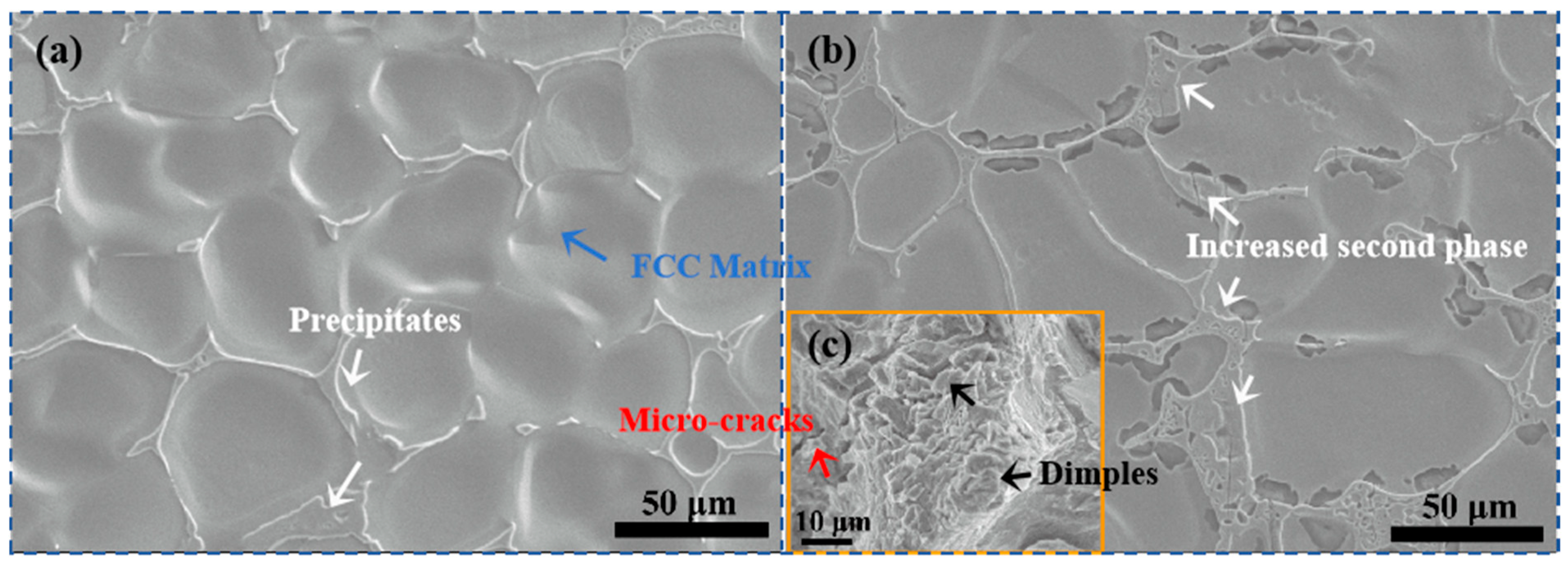

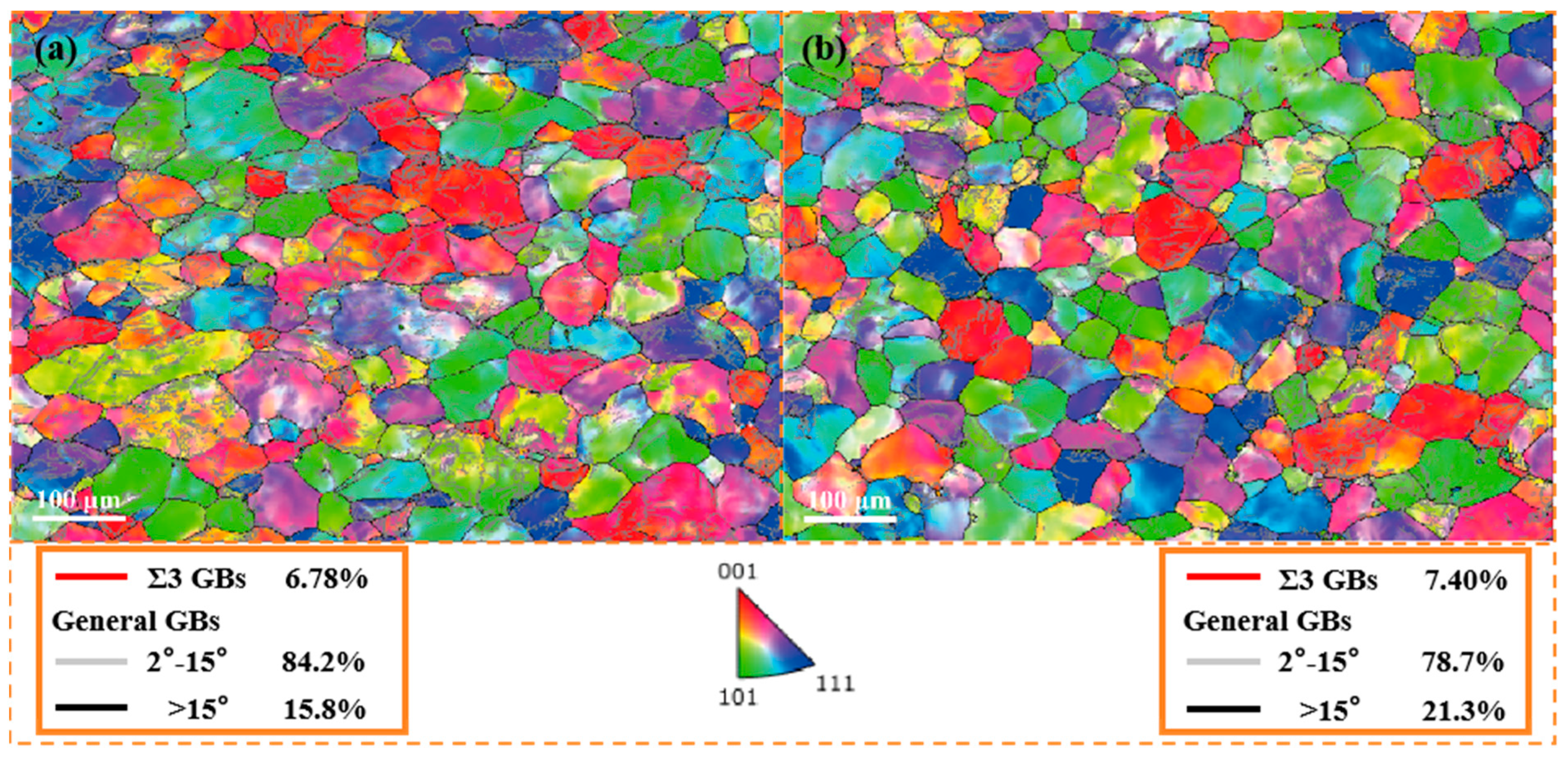

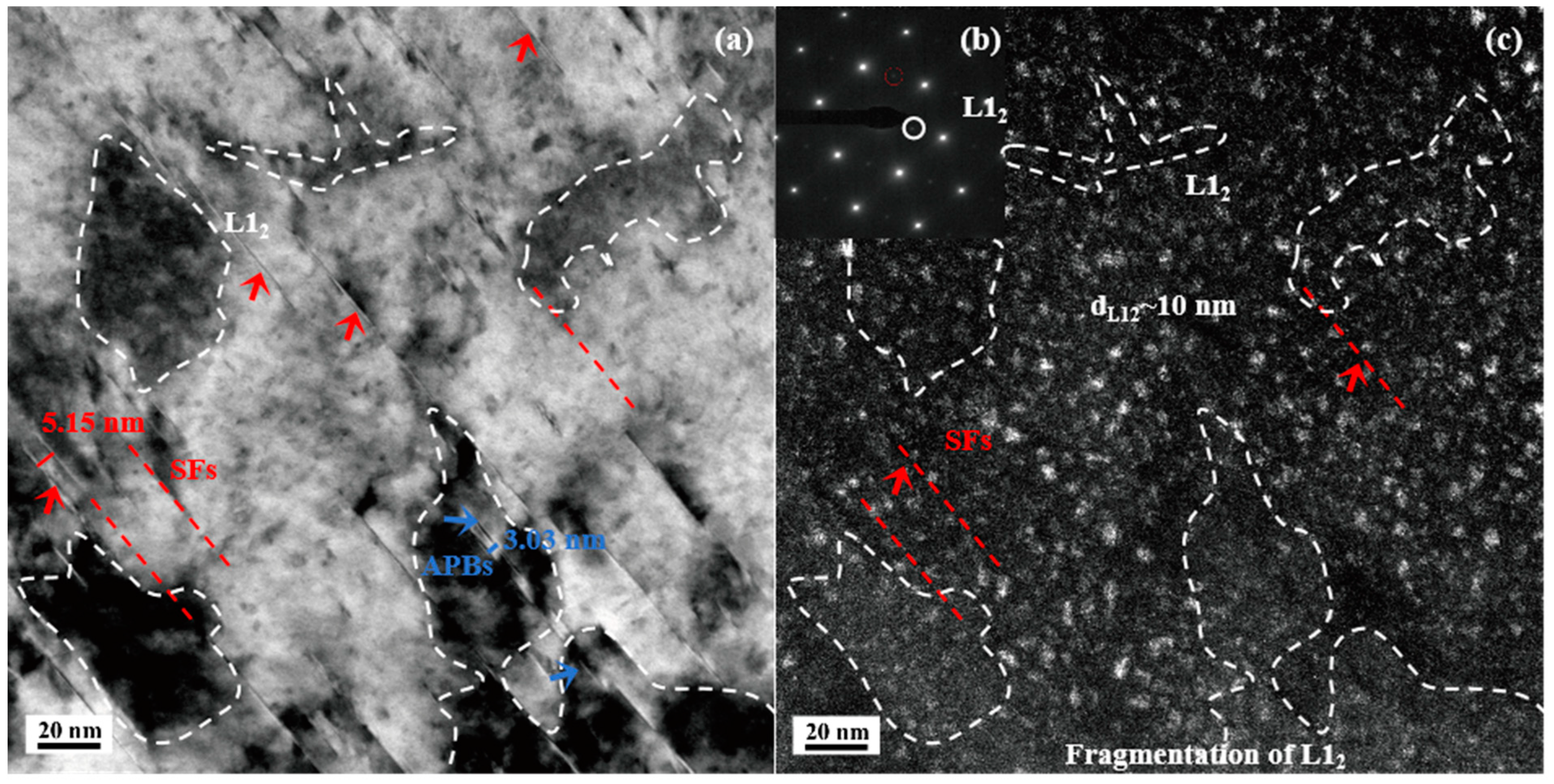

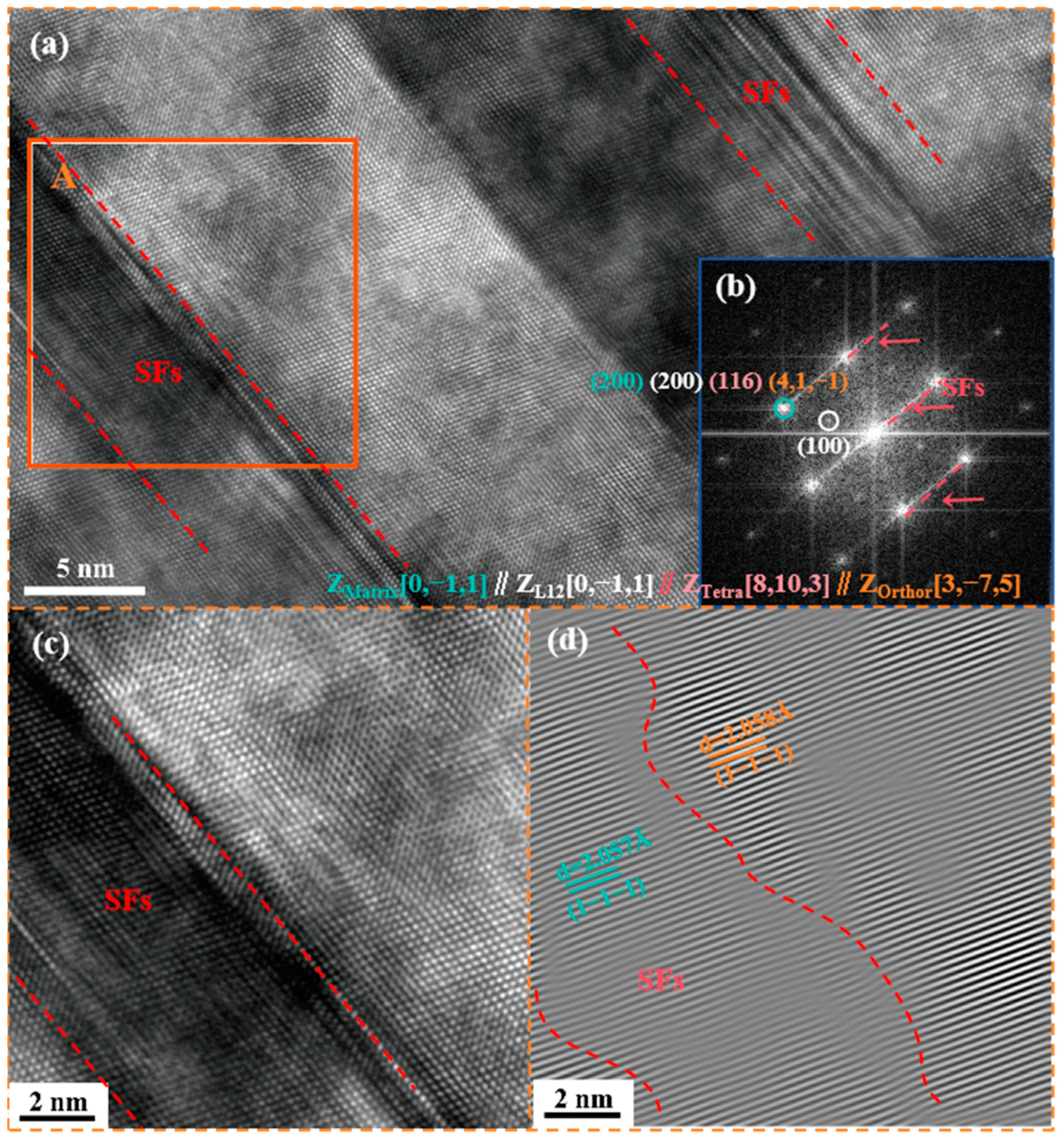

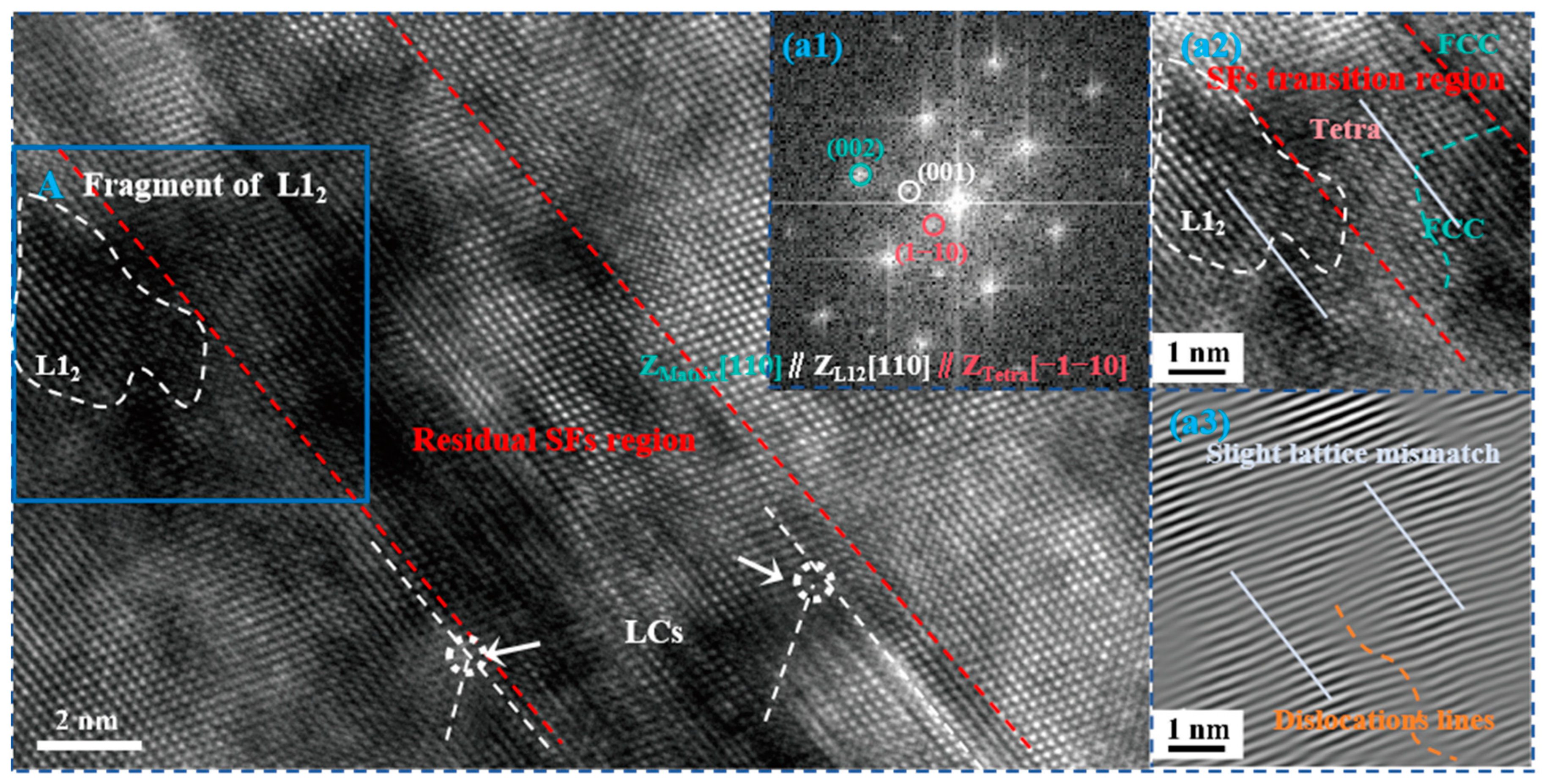

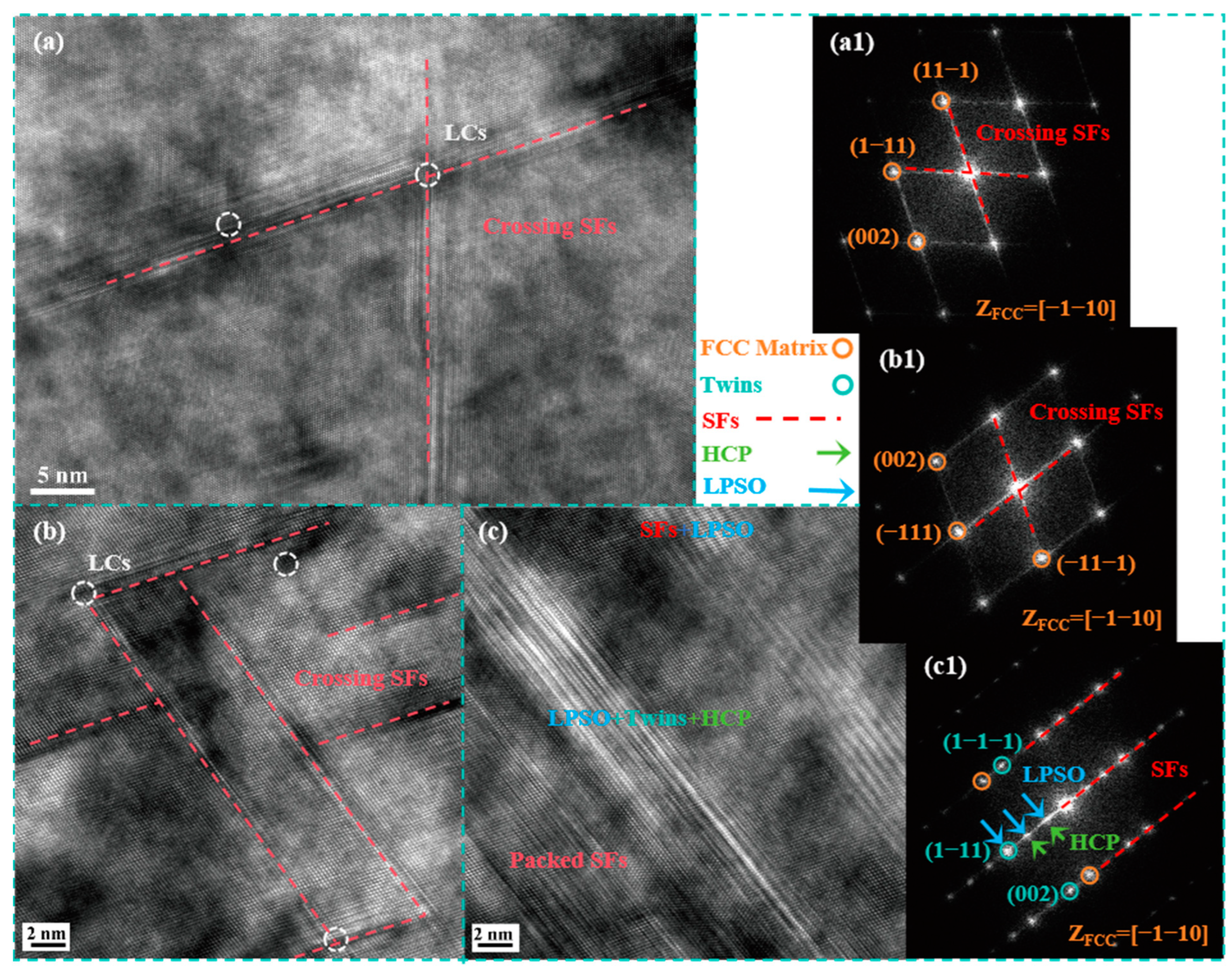

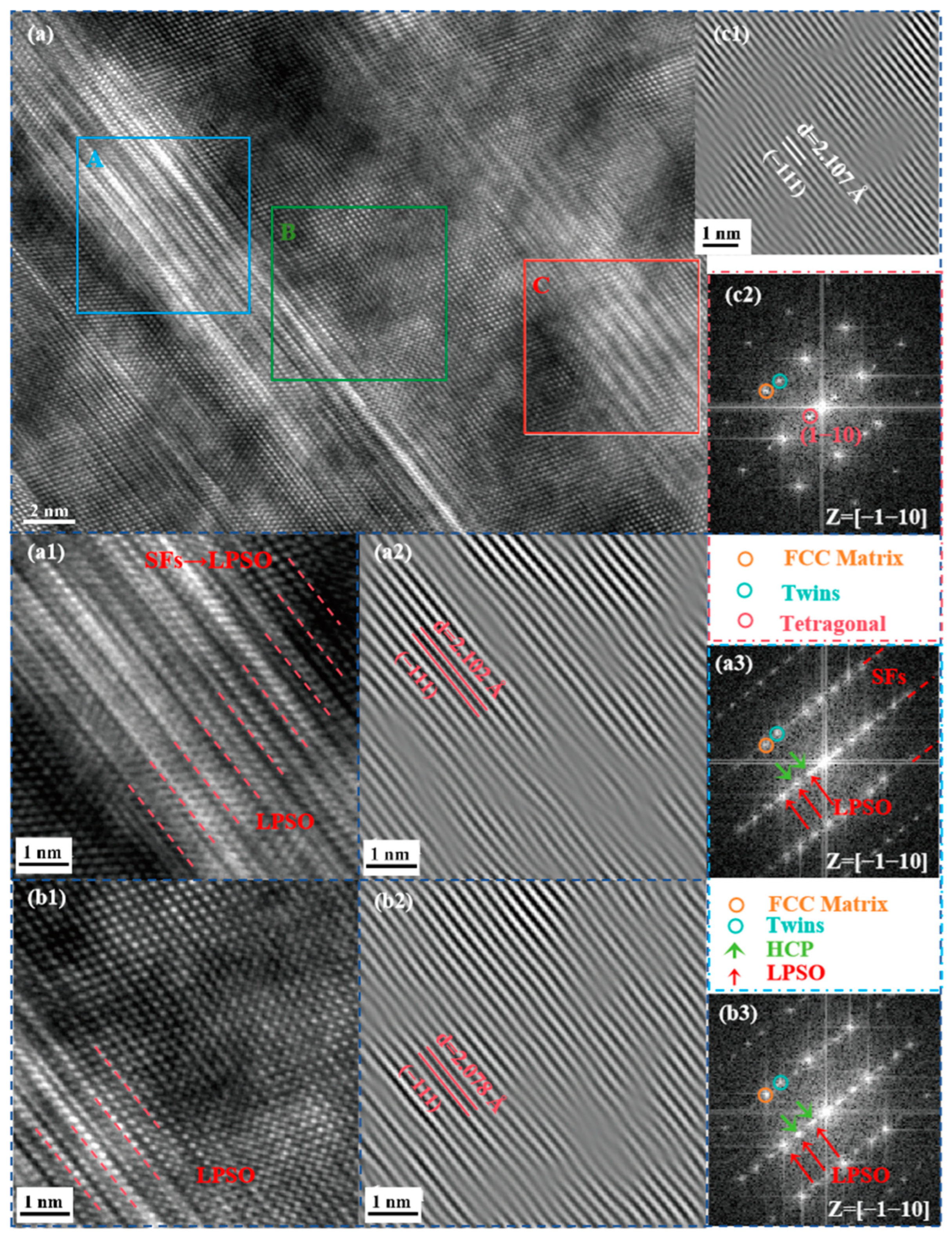

3.2. Microstructure Evolution

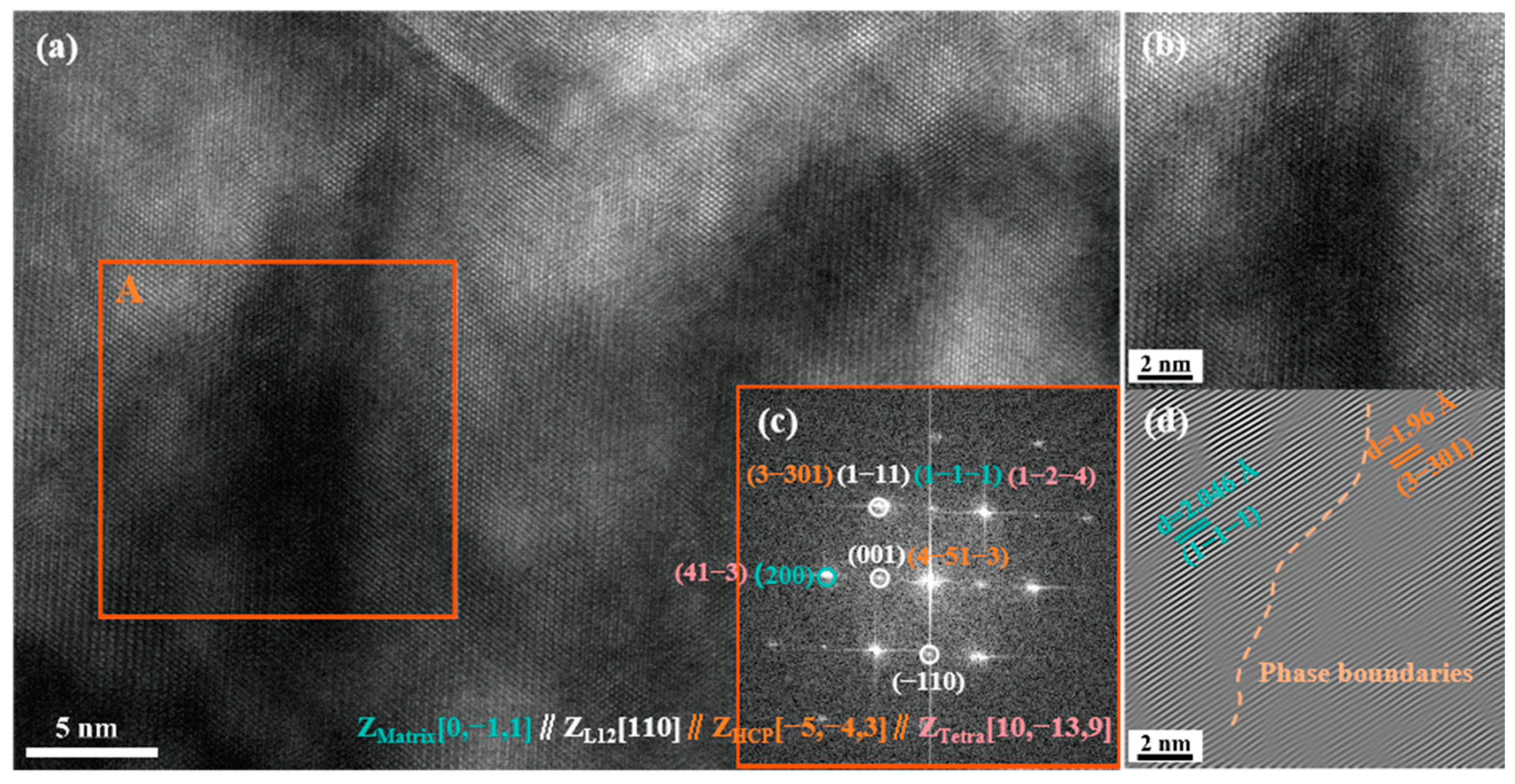

3.3. Mechanism of Cryogenic Tensile Deformation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, J.; Guo, X.; Lin, Q.; He, Z.; An, X.; Li, L.; Liaw, P.K.; Liao, X.; Yu, L.; Lin, J.; et al. Excellent ductility and serration feature of metastable CoCrFeNi high-entropy alloy at extremely low temperatures. Sci. China Mater. 2018, 62, 853–863. [Google Scholar] [CrossRef]

- Liu, L.-X.; Pan, J.; Zhang, P.-C.; Guo, R.; Xu, J.-Y.; Liu, L. Tensile and impact behavior of 3D-printed (FeCoNi)86Al7Ti7 high entropy alloy at ambient and cryogenic temperatures. Mater. Des. 2024, 242, 113020. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Liu, W.H.; Wu, Y.; He, J.Y.; Nieh, T.G.; Lu, Z.P. Grain growth and the hall–petch relationship in a high-entropy FeCrNiCoMn alloy. Scr. Mater. 2013, 68, 526–529. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhý, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef]

- Laplanche, G.; Kostka, A.; Horst, O.M.; Eggeler, G.; George, E.P. Microstructure evolution and critical stress for twinning in the CrMnFeCoNi high-entropy alloy. Acta Mater. 2016, 118, 152–163. [Google Scholar] [CrossRef]

- Jo, Y.H.; Jung, S.; Choi, W.M.; Sohn, S.S.; Kim, H.S.; Lee, B.J.; Kim, N.J.; Lee, S. Cryogenic strength improvement by utilizing room-temperature deformation twinning in a partially recrystallized vcrmnfeconi high-entropy alloy. Nat. Commun. 2017, 8, 15719. [Google Scholar] [CrossRef]

- Zhang, Z.; Sheng, H.; Wang, Z.; Gludovatz, B.; Zhang, Z.; George, E.P.; Yu, Q.; Mao, S.X.; Ritchie, R.O. Dislocation mechanisms and 3D twin architectures generate exceptional strength-ductility-toughness combination in CrCoNi medium-entropy alloy. Nat. Commun. 2017, 8, 14390. [Google Scholar] [CrossRef] [PubMed]

- Magalhães, D.C.; Kliauga, A.M.; Ferrante, M.; Sordi, V.L. Plastic deformation of FCC alloys at cryogenic temperature: The effect of stacking-fault energy on microstructure and tensile behaviour. J. Mater. Sci. 2017, 52, 7466–7478. [Google Scholar] [CrossRef]

- Huang, S.; Li, W.; Lu, S.; Tian, F.; Shen, J.; Holmström, E.; Vitos, L. Temperature dependent stacking fault energy of FeCrCoNiMn high entropy alloy. Scr. Mater. 2015, 108, 44–47. [Google Scholar] [CrossRef]

- Laplanche, G.; Kostka, A.; Reinhart, C.; Hunfeld, J.; Eggeler, G.; George, E.P. Reasons for the superior mechanical properties of medium-entropy CrCoNi compared to high-entropy CrMnFeCoNi. Acta Mater. 2017, 128, 292–303. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Thurston, K.V.; Bei, H.; Wu, Z.; George, E.P.; Ritchie, R.O. Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nat. Commun. 2016, 7, 10602. [Google Scholar] [CrossRef] [PubMed]

- Chang, H.; Zhang, T.W.; Ma, S.G.; Zhao, D.; Xiong, R.L.; Wang, T.; Li, Z.Q.; Wang, Z.H. Novel si-added CrCoNi medium entropy alloys achieving the breakthrough of strength-ductility trade-off. Mater. Des. 2021, 197, 109202. [Google Scholar] [CrossRef]

- Tai, C.L.; You, J.D.; Chen, J.J.; Liang, S.C.; Chung, T.F.; Yang, Y.L.; Ii, S.; Ohmura, T.; Zheng, X.; Chen, C.Y.; et al. In-situ transmission electron microscopy investigation of the deformation mechanism in CoCrNi and cocrnisi0.3 nanopillars. Scr. Mater. 2025, 255, 116405. [Google Scholar] [CrossRef]

- Guo, S.; Ng, C.; Lu, J.; Liu, C.T. Effect of valence electron concentration on stability of FCC or BCC phase in high entropy alloys. J. Appl. Phys. 2011, 109, 103505. [Google Scholar] [CrossRef]

- Zhang, D.D.; Wang, H.; Zhang, J.Y.; Xue, H.; Liu, G.; Sun, J. Achieving excellent strength-ductility synergy in twinned NiCoCr medium-entropy alloy via Al/Ta co-doping. J. Mater. Sci. Technol. 2021, 87, 184–195. [Google Scholar] [CrossRef]

- Wang, L.X.; Xiang, S.; Tan, Y.B.; Shi, W.; Liu, F.; Cai, Y.Q.; Ji, X.M. The Design of Appropriate Si Content Overcomes the Strength-Ductility Trade-off in Dual-Phase High Entropy Alloy. J. Alloys Compd. 2024, 1004, 175738. [Google Scholar] [CrossRef]

- Lopes, J.G.; Shen, J.; Maawad, E.; Agrawal, P.; Schell, N.; Mishra, R.S.; Oliveira, J.P. Time-resolved evolution of the deformation mechanisms in a TRIP/TWIP Fe50Mn30Co10Cr10 high entropy during tensile loading probed with synchrotron X-ray diffraction. Int. J. Plast. 2024, 179, 104048. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, H.; Chen, L.; Li, F.; Zhang, W.; Zhou, G.; Zhang, H.; Geng, N. Investigation of the Hot Deformation Behavior and Mechanism of a Medium-Entropy CoCr0.4NiSi0.3 Alloy. Crystals 2024, 14, 3. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, L.; Zhang, W.; Zhao, H.; Li, F. Thermomechanically induced phase separation at elevated temperatures in a CoCr0.4NiSi0.3 medium-entropy alloy. J. Mater. Res. Technol. 2025, 34, 1908–1920. [Google Scholar] [CrossRef]

- Gao, X.; Liu, J.; Fu, W.; Huang, Y.; Ning, Z.; Zhang, Z.; Sun, J.; Chen, W. Strong and ductile CoCrFeNi high-entropy alloy microfibers at ambient and cryogenic temperatures. Mater. Des. 2023, 233, 112250. [Google Scholar] [CrossRef]

- Li, L.; Song, K.; Gao, Q.; Zhou, C.; Liu, X.; Wang, Y.; Bai, X.; Cao, C. Enhancing strength-ductility synergy of CoCrNi-based medium-entropy alloy through coherent L12 Nanoprecipitates and grain boundary precipitates. Acta Metall. Sin. (Engl. Lett.) 2023, 37, 78–88. [Google Scholar] [CrossRef]

- Gao, L.; Wu, Y.; An, N.; Chen, J.; Liu, X.; Bai, R.; Hui, X. Nanoscale L12 phase precipitation induced superb ambient and high temperature mechanical properties in Ni-Co-Cr-Al System high-entropy superalloys. Mater. Sci. Eng. A 2024, 898, 145995. [Google Scholar] [CrossRef]

- Karpstein, N.; Lenz, M.; Bezold, A.; Wu, M.; Neumeier, S.; Spiecker, E. Reliable identification of the complex or superlattice nature of intrinsic and extrinsic stacking faults in the L12 phase by high-resolution imaging. Acta Mater. 2023, 260, 119284. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, W.; Chen, L.; Li, F.; Zhao, H.; Wang, X.; Zhou, G. Microstructure and texture evolution of a dynamic compressed medium-entropy CoCr0.4NiSi0.3 alloy. Crystals 2023, 13, 1390. [Google Scholar] [CrossRef]

- Yuan, J.L.; Wang, Z.; Jin, X.; Han, P.D.; Qiao, J.W. L12-strengthened heterostructure high-entropy alloys with ultra-high strength over a wide temperature range. Mater. Sci. Eng. A 2022, 853, 143712. [Google Scholar] [CrossRef]

- Rae, C.M.F.; Reed, R.C. Primary creep in Single Crystal Superalloys: Origins, mechanisms and effects. Acta Mater. 2007, 55, 1067–1081. [Google Scholar] [CrossRef]

- Wang, S.; Chen, S.; Jia, Y.; Hu, Z.; Huang, H.; Yang, Z.; Dong, A.; Zhu, G.; Wang, D.; Shu, D.; et al. FCC-L12 ordering transformation in equimolar feconiv multi-principal element alloy. Mater. Des. 2019, 168, 107648. [Google Scholar] [CrossRef]

- Yamamoto, M.; Fukuda, T.; Kakeshita, T.; Takahashi, K. Orthorhombic martensite formed in L12-Type Fe3Pt Invar alloy. J. Alloys Compd. 2013, 577, S503–S506. [Google Scholar] [CrossRef]

- Eberhart, M.E.; O’Handley, R.C.; Johnson, K.H. Molecular-orbital models of structural phase transformations in crystalline and amorphous cobalt alloys. Phys. Rev. B Condens. Matter Mater. Phys. 1984, 29, 1097–1100. [Google Scholar] [CrossRef]

- Hope, D.A.O.; Cheetham, A.K. A low-temperature powder neutron diffraction study of the antiferromagnetic phase of MnxCo1−XO. J. Solid State Chem. 1988, 72, 42–51. [Google Scholar] [CrossRef]

- Jiang, F.; Chen, S.; Zhang, H.; Wang, X.; Di, Y.; Liu, E.; Li, T.; Deng, L.; Zhu, X.; Huang, D. Correction to: First-principles study on the jahn-teller distortion in trigonal bipyramidal coordinated LiFe1−xMxBO3 (M=Mn, Co, and Ni) compounds. J. Solid State Electrochem. 2020, 25, 637. [Google Scholar] [CrossRef]

- Molnár, D.; Engberg, G.; Li, W.; Vitos, L. Deformation properties of austenitic stainless steels with different stacking fault energies. Mater. Sci. Forum 2018, 941, 190–197. [Google Scholar] [CrossRef]

- Mahato, B.; Shee, S.K.; Sahu, T.; Ghosh Chowdhury, S.; Sahu, P.; Porter, D.A.; Karjalainen, L.P. An effective stacking fault energy viewpoint on the formation of extended defects and their contribution to strain hardening in a Fe-Mn-Si-Al twinning-induced plasticity steel. Acta Mater. 2015, 86, 69–79. [Google Scholar] [CrossRef]

- Van Swygenhoven, H.; Derlet, P.M.; Hasnaoui, A. Atomic mechanism for dislocation emission from nanosized grain boundaries. Phys. Rev. B 2002, 66, 024101. [Google Scholar] [CrossRef]

- Meng, M.; Zhang, H.; Gao, Z.; Lei, G.; Yu, J. Effect of aging treatment on the precipitation transformation and age hardening of Mg-Gd-Y-Zn-Zr alloy. J. Magnes. Alloys 2023, 11, 4628–4643. [Google Scholar] [CrossRef]

- Li, D.; Zeng, X.; Dong, J.; Zhai, C. Influence of heat treatment on microstructure and mechanical properties of Mg-10Gd-3Y-1.2Zn-0.4Zr alloy. Trans. Nonferrous Met. Soc. China 2008, 18, s117–s121. [Google Scholar] [CrossRef]

| Co | Cr | Ni | Si |

|---|---|---|---|

| 40.13 | 14.16 | 39.97 | 5.74 |

| Test Temperature | YS | UTS | EF |

|---|---|---|---|

| RT | 437.0 ± 4.2 | 825.0 ± 17.0 | 13.5% ± 4.9% |

| −75 °C | 550.0 ± 4.2 | 993.5 ± 20.5 | 21.5% ± 2.8% |

| −150 °C | 617.5 ± 12.0 | 1055.0 ± 60.8 | 21.0% ± 4.9% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Zhang, L.; Chen, X. Unveiling the Strengthening and Ductility Mechanisms of a CoCr0.4NiSi0.3 Medium-Entropy Alloy at Cryogenic Temperatures. Crystals 2025, 15, 170. https://doi.org/10.3390/cryst15020170

Zhang L, Zhang L, Chen X. Unveiling the Strengthening and Ductility Mechanisms of a CoCr0.4NiSi0.3 Medium-Entropy Alloy at Cryogenic Temperatures. Crystals. 2025; 15(2):170. https://doi.org/10.3390/cryst15020170

Chicago/Turabian StyleZhang, Li, Lingwei Zhang, and Xiang Chen. 2025. "Unveiling the Strengthening and Ductility Mechanisms of a CoCr0.4NiSi0.3 Medium-Entropy Alloy at Cryogenic Temperatures" Crystals 15, no. 2: 170. https://doi.org/10.3390/cryst15020170

APA StyleZhang, L., Zhang, L., & Chen, X. (2025). Unveiling the Strengthening and Ductility Mechanisms of a CoCr0.4NiSi0.3 Medium-Entropy Alloy at Cryogenic Temperatures. Crystals, 15(2), 170. https://doi.org/10.3390/cryst15020170