Tribological Behavior of SPS-Prepared Al-Matrix–ZrO2-Nanofiber Composites with Graphene Nanoplatelets Solid-Lubricating Surface Films

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

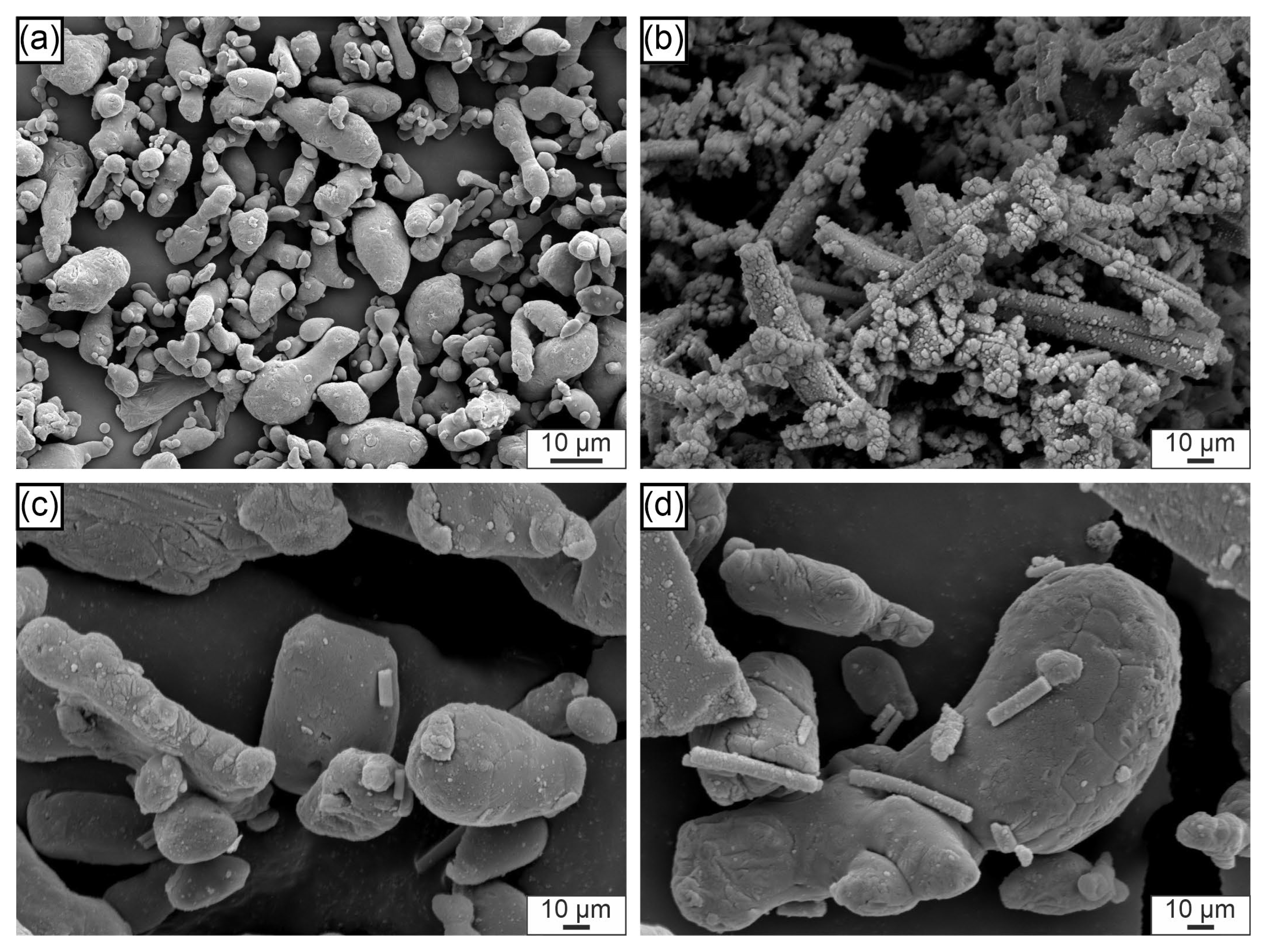

3.1. Starting Powders

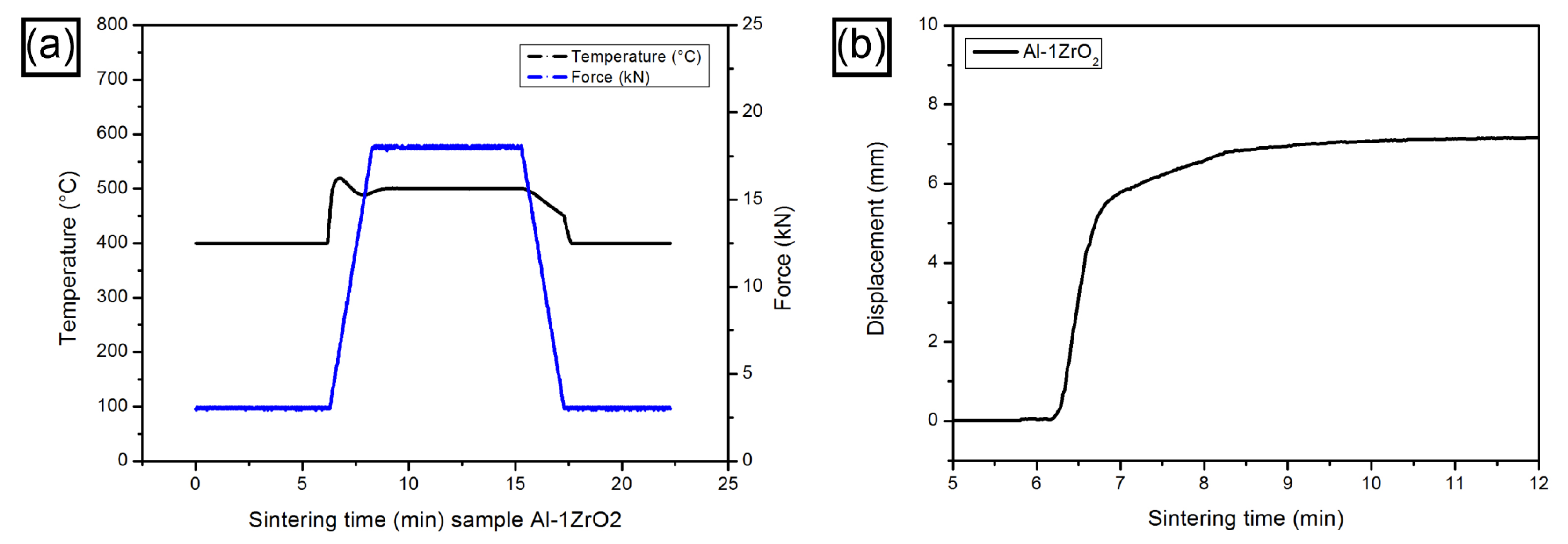

3.2. Sintering Regime

3.3. Density

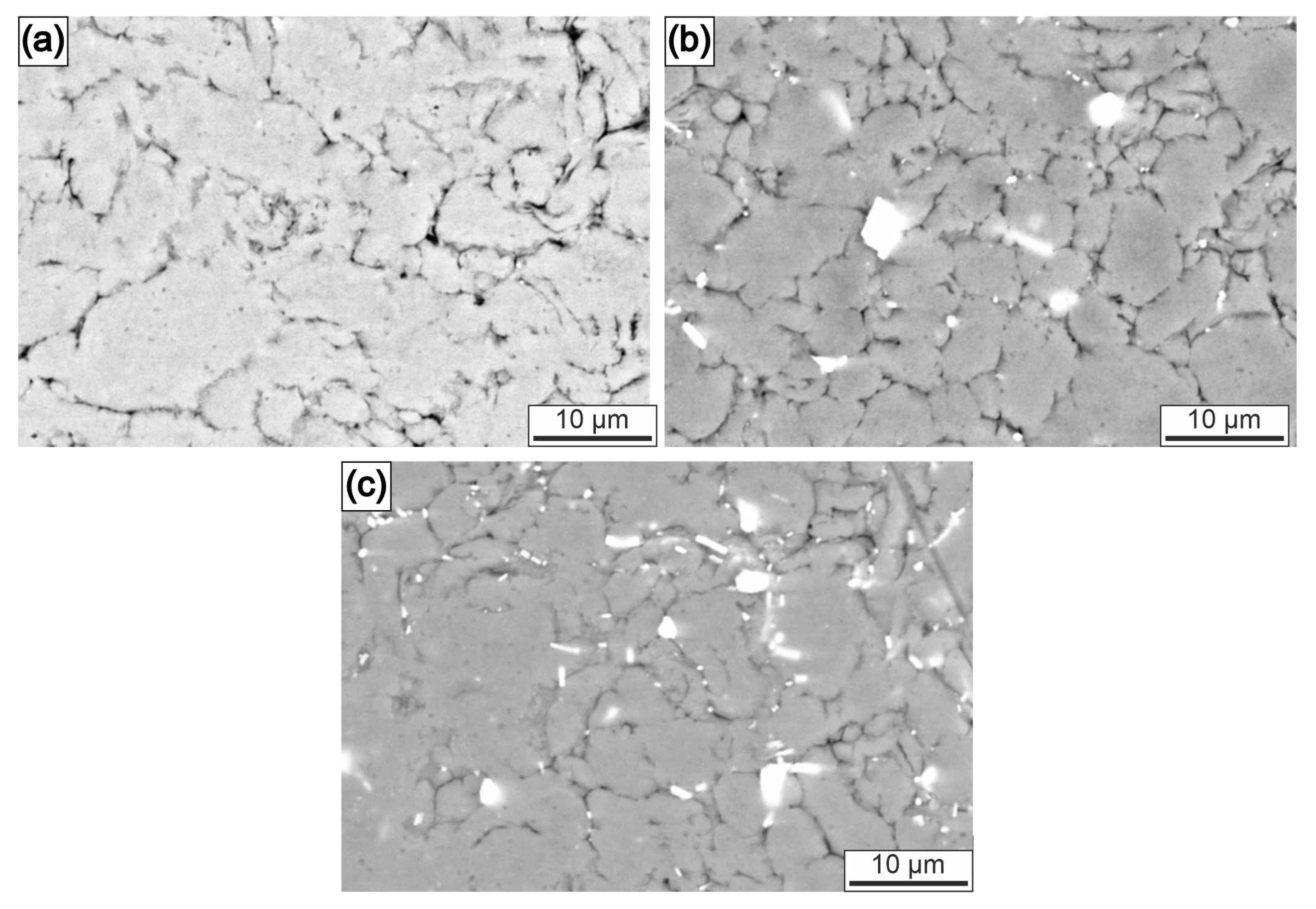

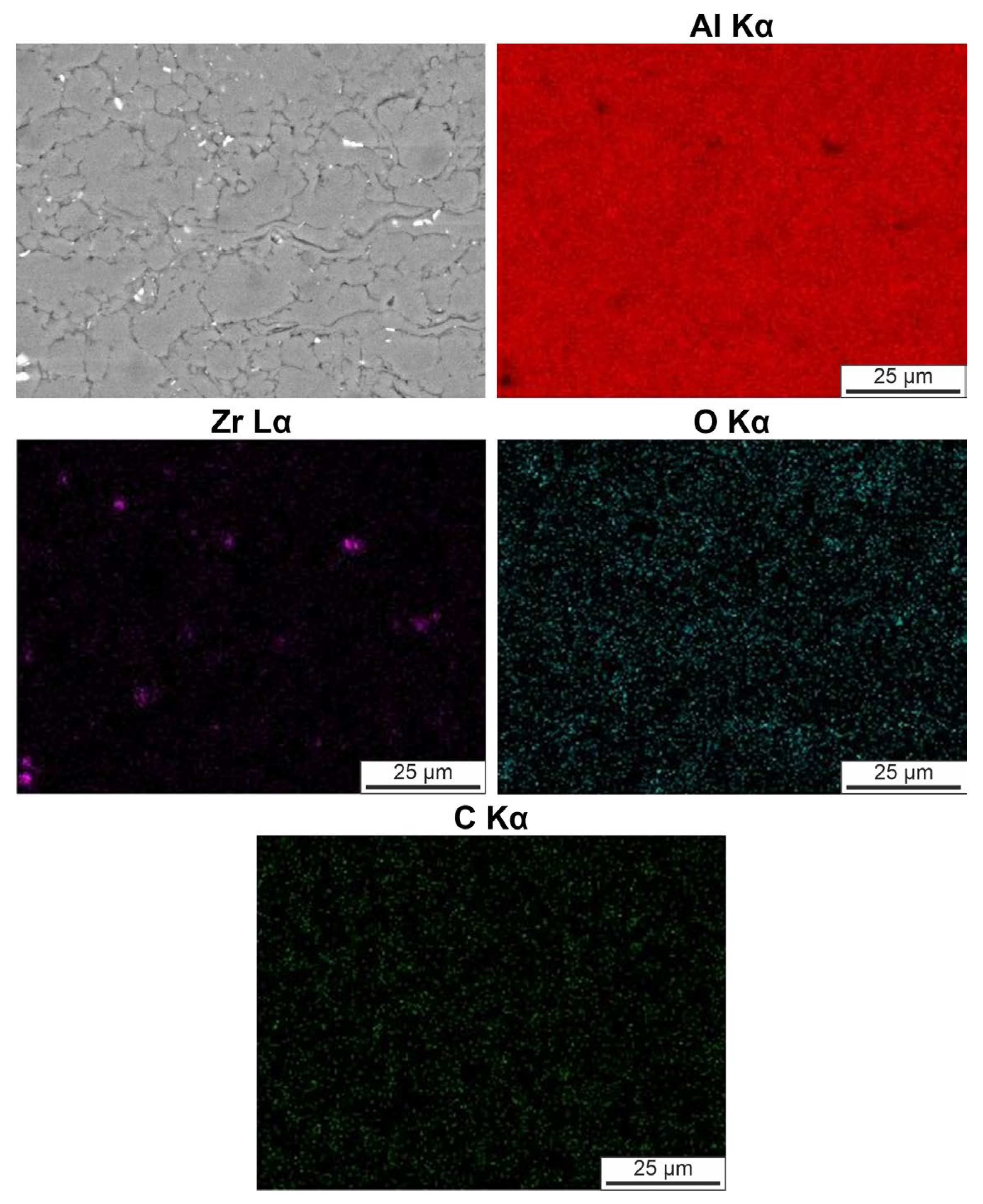

3.4. Microstructures

3.5. Mechanical Properties

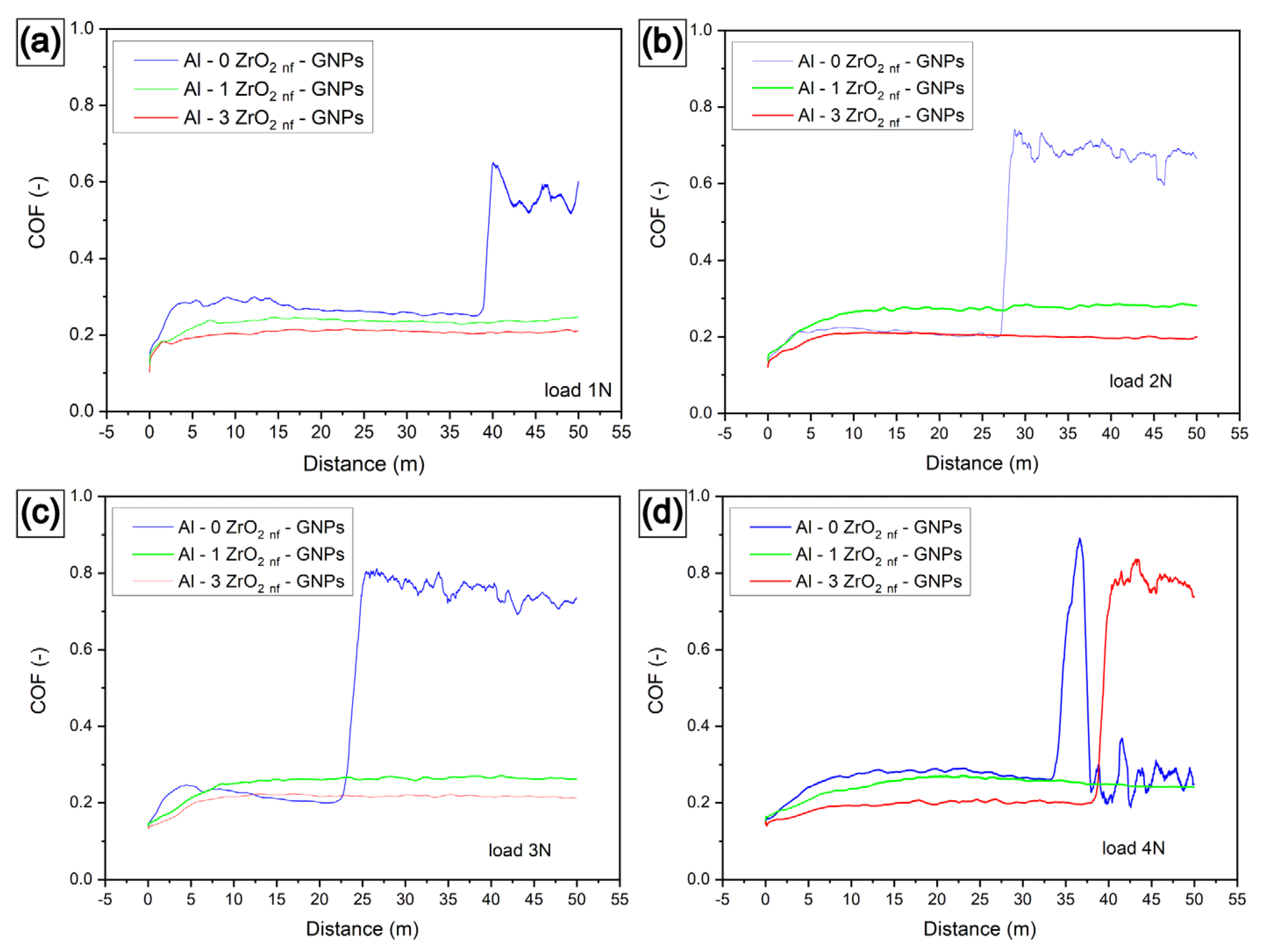

3.6. Coefficient of Friction

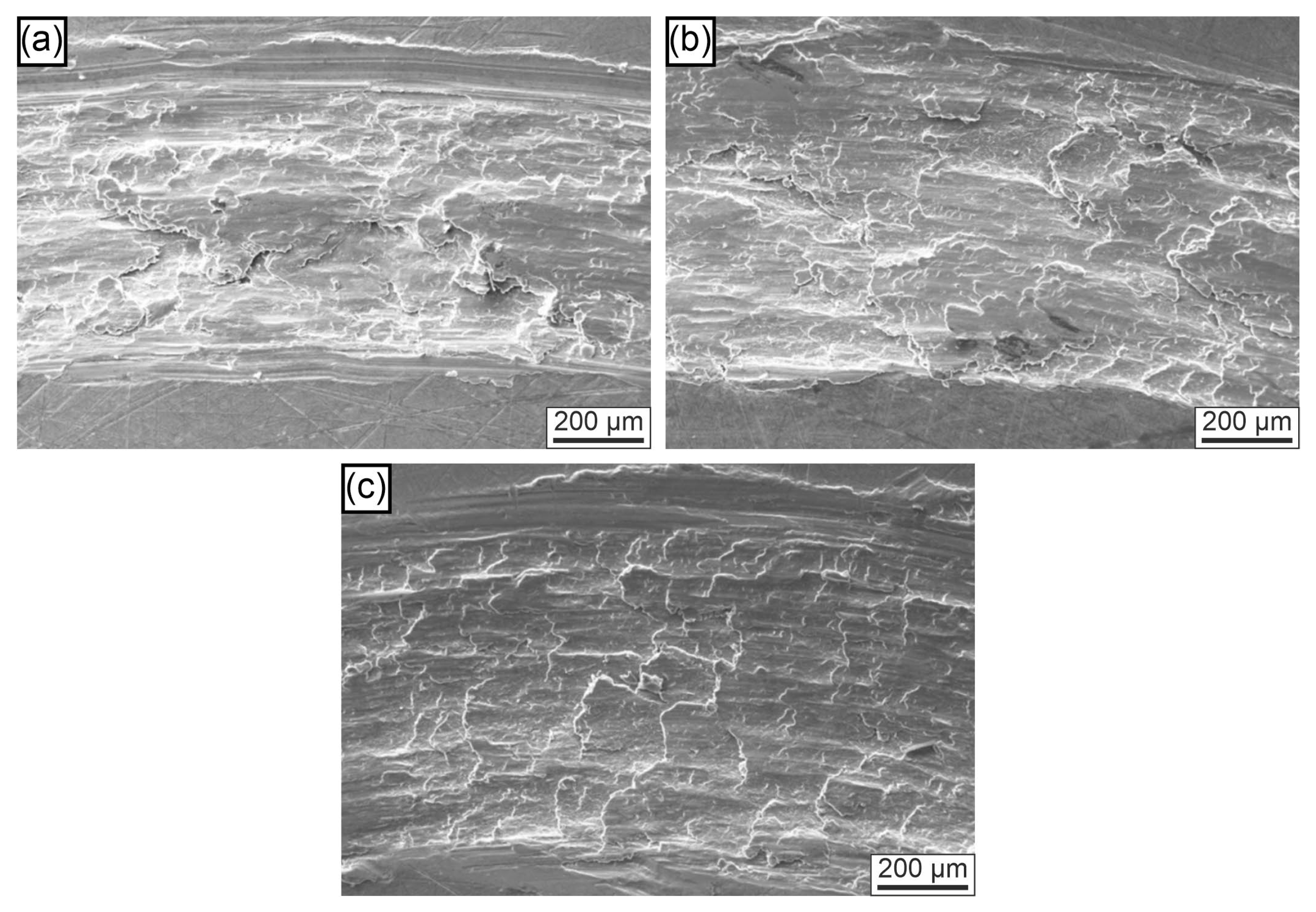

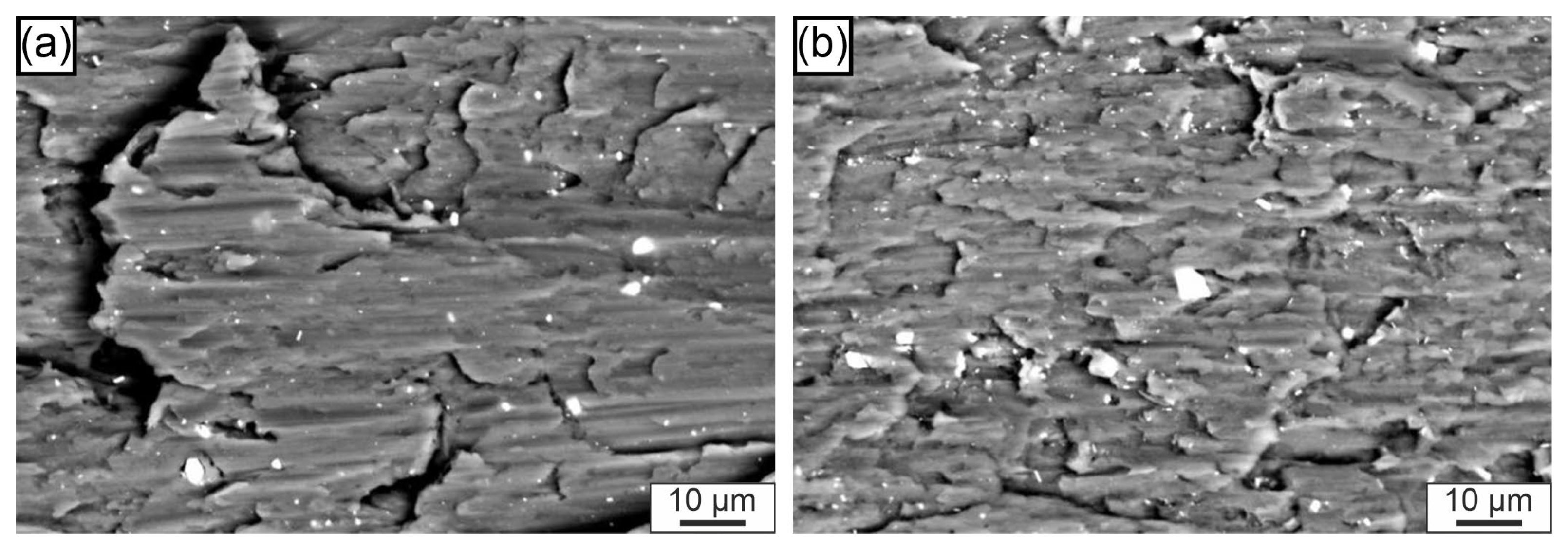

3.7. Wear Analysis

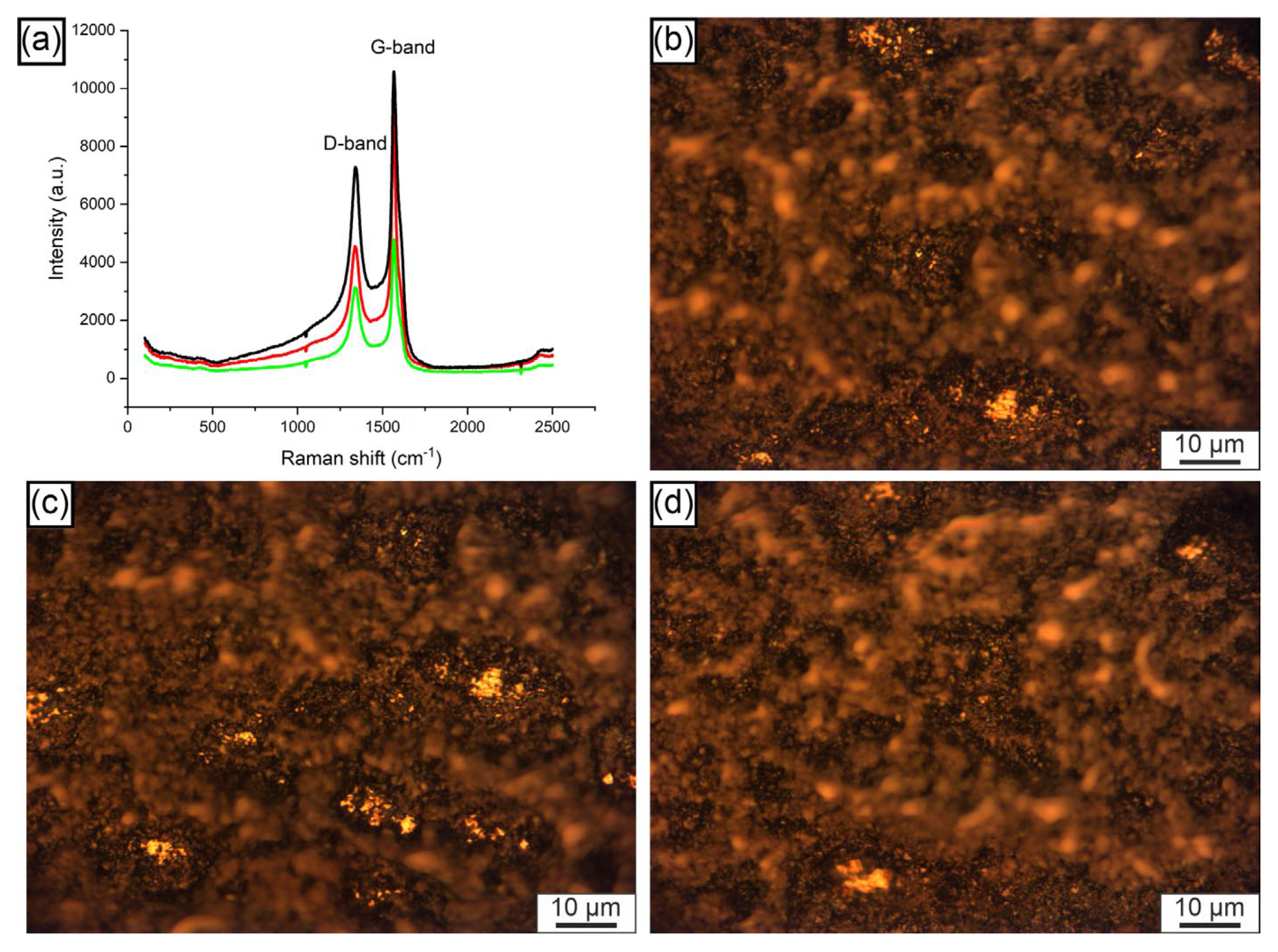

3.8. Wear Mechanisms

4. Conclusions

- (1)

- Al-1 wt.% ZrO2 nanofiber and Al-3 wt.% ZrO2 nanofiber composite materials were successfully prepared using SPS. Microstructural analysis showed that the addition of 1–3 wt.% ZrO2 nanofibers to the aluminum matrix led to visible grain refinement and the formation of a homogeneously distributed ZrO2 phase. Performed EDS analyses confirmed uniform distribution of the reinforcement ZrO2 phase. However, the both produced composites showed visible clustering of ZrO2 particles.

- (2)

- The application of a GNP-derived tribofilm to pure aluminum is insufficient to ensure favorable tribological performance. The soft aluminum matrix does not provide adequate mechanical support for the tribofilm, which fails under applied load, resulting in a high and unstable coefficient of friction.

- (3)

- The incorporation of short ZrO2 nanofibers into the aluminum matrix significantly enhances the load-bearing capacity and resistance to plastic deformation. The hard ceramic fibers act as a structural phase that stabilizes the surface and facilitates the formation of a stable and effective GNP-derived tribofilm, leading to a dramatic reduction in the coefficient of friction.

- (4)

- Under increased load, reinforcement content becomes critical. While both composites perform similarly at 1–3 N, at 4 N the Al-1 wt.% ZrO2 nanofiber composite maintains a low and stable coefficient of friction for the entire 50 m, whereas the Al-3 wt.% ZrO2 nanofiber composite shows tribofilm failure and a sudden coefficient of friction rise after ~35 m, consistent with nanofiber clustering that disrupts tribofilm continuity.

- (5)

- Overall, the Al-1 wt.% ZrO2 nanofiber composite exhibits the best performance across the tested conditions, combining the most stable low coefficient of friction with the highest wear resistance. The 3 wt.% composite ranks second, matching 1 wt.% at 1–3 N but losing stability at 4 N, while pure sintered aluminum performs worst.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Polmear, I.; St John, D.; Nie, J.-F.; Qian, M. Light Alloys: From Traditional Alloys to Nanocrystals, 5th ed.; Butterworth-Heinemann: Oxford, UK, 2017; ISBN 978-0-08-099431-4. [Google Scholar]

- Anderson, K.; Weritz, J.; Kaufman, J.G. (Eds.) ASM Handbook, Volume 2A: Aluminum Science and Technology; ASM International: Materials Park, OH, USA, 2018. [Google Scholar]

- Rohatgi, P.; Weiss, D.; Srivatsan, T.S.; Ghaderi, O.; Zare, M. Solidification Processing of Aluminum Alloy Metal Matrix Composites for Use in Transportation Applications. Metall. Mater. Trans. A 2024, 55, 4867–4881. [Google Scholar] [CrossRef]

- Miracle, D.B.; Donaldson, S.L. ASM Handbook, Volume 21: Composites; ASM International: Materials Park, OH, USA, 2001. [Google Scholar]

- Claussen, N. Fracture Toughness of Al2O3 with an Unstabilized ZrO2 Dispersed Phase. J. Am. Ceram. Soc. 1976, 59, 49–51. [Google Scholar] [CrossRef]

- Kozlovskiy, A.L.; Konuhova, M.; Borgekov, D.B.; Popov, A.I. Study of irradiation temperature effect on radiation-induced polymorphic transformation mechanisms in ZrO2 ceramics. Opt. Mater. 2024, 156, 115994. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, X.; Wang, L.; Zhang, J.; Liu, R.; Sun, Q.; Ye, X.; Ma, X. Fabrication and Applications of Ceramic-Based Nanofiber Materials Service in High-Temperature Harsh Conditions—A Review. Gels 2023, 9, 208. [Google Scholar] [CrossRef]

- Ammal, M.A.; Sudha, J. Microstructural Evolution & Mechanical Properties of ZrO2/GNP and B4C/GNP reinforced AA6061 Friction Stir Processed Surface Composites—A Comparative study. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2022, 237, 1149–1160. [Google Scholar]

- Parveen, A.; Chauhan, N.R.; Suhaib, M. Mechanical and Tribological Behaviour of Al-ZrO2 Composites: A Review. In Advances in Engineering Design; Prasad, A., Gupta, S., Tyagi, R., Eds.; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2019. [Google Scholar]

- Omori, M. Sintering, consolidation, reaction and crystal growth by the spark plasma system (SPS). Mater. Sci. Eng. A 2000, 287, 183–188. [Google Scholar] [CrossRef]

- Munir, Z.A.; Anselmi-Tamburini, U.; Ohyanagi, M. The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method. J. Mater. Sci. 2006, 41, 763–777. [Google Scholar] [CrossRef]

- Orrù, R.; Licheri, R.; Locci, A.M.; Cincotti, A.; Cao, G. Consolidation/synthesis of materials by electric current activated/assisted sintering. Mater. Sci. Eng. R Rep. 2009, 63, 127–287. [Google Scholar] [CrossRef]

- Vintila, R.; Charest, A.; Drew, R.A.L.; Brochu, M. Synthesis and consolidation via spark plasma sintering of nanostructured Al-5356/B4C composite. Mater. Sci. Eng. A 2011, 528, 4395–4407. [Google Scholar] [CrossRef]

- Rangrej, S.; Pandya, S.; Menghani, J. Effects of reinforcement additions on properties of aluminium matrix composites—A review. Mater. Today Proc. 2021, 44, 637–641. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Graphene: A new emerging lubricant. Mater. Today 2014, 17, 31–42. [Google Scholar] [CrossRef]

- Ge, X.; Chai, Z.; Shi, Q.; Liu, Y.; Wang, W. Graphene superlubricity: A review. Friction 2023, 11, 1953–1973. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, S.; Shi, Q.; Ge, X.; Wang, W. Graphene-Family Lubricant Additives: Recent Developments and Future Perspectives. Lubricants 2022, 10, 215. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, X.; Fan, Y.; Liu, J.; Xie, L.; Jiang, C.; Xiao, X.; Wu, P.; You, X. Microstructure and Properties of Aluminum–Graphene–SiC Matrix Composites after Friction Stir Processing. Materials 2024, 17, 979. [Google Scholar] [CrossRef]

- Poudel, S.; Bajwa, R.; Xia, Y.; Khan, Z.; Zhang, Y.; Zhu, Y. Tribological properties of Al–GNP composites at elevated temperature. Friction 2024, 12, 1028–1041. [Google Scholar] [CrossRef]

- Hasan, M.S.; Wong, T.; Rohatgi, P.K.; Nosonovsky, M. Analysis of the friction and wear of graphene-reinforced aluminum metal matrix composites using machine learning models. Tribol. Int. 2022, 170, 107527. [Google Scholar] [CrossRef]

- Marcinauskas, L.; Ratautaitė, K.; Kavaliauskas, Ž.; Žunda, A.; Kėželis, R.; Aikas, M. Influence of Graphite and Zirconia Addition on the Tribological Properties of Plasma-Sprayed Alumina Coatings. Coatings 2024, 14, 978. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Mishchenko, A.; Carvalho, A.; Neto, A.H.C. 2D Materials and van der Waals Heterostructures. Science 2016, 353, aac9439. [Google Scholar] [CrossRef]

- Acar, Ç.G.; Žunda, A. Tribological Aspects of Graphene and Its Derivatives. Lubricants 2025, 13, 232. [Google Scholar] [CrossRef]

- Balcı, Ö.; Ağaoğulları, D.; Gökçe, H.; Duman, İ.; Öveçoğlu, M.L. Influence of TiB2 particle size on the microstructure and properties of Al matrix composites prepared via mechanical alloying and pressureless sintering. J. Alloys Compd. 2014, 586, S78–S84. [Google Scholar] [CrossRef]

- Singh, V.; Joung, D.; Zhai, L.; Das, S.; Khondaker, S.I.; Seal, S. Graphene Based Materials: Past, Present and Future. Prog. Mater. Sci. 2011, 56, 1178–1271. [Google Scholar] [CrossRef]

- Manu, R.B.; Gupta, A.; Jayatissa, A.H. Tribological Properties of 2D Materials and Composites—A Review of Recent Advances. Materials 2021, 14, 1630. [Google Scholar] [CrossRef]

- Liu, Q.; Ke, L.; Liu, F.; Huang, C.; Xing, L. Microstructure and mechanical property of multi-walled carbon nanotubes reinforced aluminum matrix composites fabricated by friction stir processing. Mater. Des. 2013, 45, 343–348. [Google Scholar] [CrossRef]

- Hall, E.O. The Deformation and Ageing of Mild Steel: III Discussion of Results. Proc. Phys. Soc. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Zhang, J.-D.; Zhang, L.; Ma, H.-z. Effect of ZrO2 additions on the microstructure, mechanical and wear properties of ZrO2/7075 aluminium alloy composite. Mater. Today Commun. 2023, 37, 107437. [Google Scholar] [CrossRef]

- Kumar, G.; Rao, C.; Selvaraj, N. Mechanical and Tribological Behavior of Particulate Reinforced Aluminum Metal Matrix Composites—A review. J. Miner. Mater. Charact. Eng. 2011, 10, 59–91. [Google Scholar]

- Sahin, Y. Wear behaviour of aluminium alloy and its composites reinforced by SiC particles using statistical analysis. Mater. Des. 2003, 24, 95–103. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, X.; Sun, H.; Zhang, Y.; Fang, Y.; Shu, R. Microstructure and mechanical properties of bioinspired laminated Al matrix hybrid reinforced with B4C and graphene nanoplatelets. Mater. Charact. 2022, 193, 112307. [Google Scholar] [CrossRef]

- Devaganesh, S.; Kumar, P.K.D.; Venkatesh, N.; Balaji, R. Study on the mechanical and tribological performances of hybrid SiC-Al7075 metal matrix composites. J. Mater. Res. Technol. 2020, 9, 3759–3766. [Google Scholar] [CrossRef]

- Kumar, N.; Irfan, G. A review on tribological behaviour and mechanical properties of Al/ZrO2 metal matrix nano composites. Mater. Today Proc. 2021, 38, 2649–2657. [Google Scholar] [CrossRef]

- Lee, C.; Li, Q.; Kalb, W.; Liu, X.Z.; Berger, H.; Carpick, R.W.; Hone, J. Frictional Characteristics of Atomically Thin Sheets. Science 2010, 328, 76–80. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, A.S.; Aljebreen, O.S.; Hakeem, A.S.; Laoui, T.; Patel, F.; Baig, M.M.A. Tribological Behavior of Aluminum Hybrid Nanocomposites Reinforced with Alumina and Graphene Oxide. Materials 2022, 15, 865. [Google Scholar] [CrossRef] [PubMed]

- Lin, F.; Wang, J.; Wu, H.; Jia, F.; Lu, Y.; Ren, M.; Yang, M.; Chen, Z.; Jiang, Z. Synergistic effects of TiC and graphene on the microstructure and tribological properties of Al matrix composites. Adv. Powder Technol. 2021, 32, 3635–3649. [Google Scholar] [CrossRef]

- Liu, Y.; Ge, X.; Li, J. Graphene lubrication. Appl. Mater. Today 2020, 20, 100662. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Puchý, V.; Sedlák, R.; Vojtko, M.; Podobová, M.; Petruš, O.; Čiripová, L.; Falat, L. Tribological Behavior of SPS-Prepared Al-Matrix–ZrO2-Nanofiber Composites with Graphene Nanoplatelets Solid-Lubricating Surface Films. Crystals 2025, 15, 971. https://doi.org/10.3390/cryst15110971

Puchý V, Sedlák R, Vojtko M, Podobová M, Petruš O, Čiripová L, Falat L. Tribological Behavior of SPS-Prepared Al-Matrix–ZrO2-Nanofiber Composites with Graphene Nanoplatelets Solid-Lubricating Surface Films. Crystals. 2025; 15(11):971. https://doi.org/10.3390/cryst15110971

Chicago/Turabian StylePuchý, Viktor, Richard Sedlák, Marek Vojtko, Mária Podobová, Ondrej Petruš, Lucia Čiripová, and Ladislav Falat. 2025. "Tribological Behavior of SPS-Prepared Al-Matrix–ZrO2-Nanofiber Composites with Graphene Nanoplatelets Solid-Lubricating Surface Films" Crystals 15, no. 11: 971. https://doi.org/10.3390/cryst15110971

APA StylePuchý, V., Sedlák, R., Vojtko, M., Podobová, M., Petruš, O., Čiripová, L., & Falat, L. (2025). Tribological Behavior of SPS-Prepared Al-Matrix–ZrO2-Nanofiber Composites with Graphene Nanoplatelets Solid-Lubricating Surface Films. Crystals, 15(11), 971. https://doi.org/10.3390/cryst15110971