Comparison of Durability and Gamma-Ray Shielding Performance of High-Velocity Oxygen Fuel Tungsten Carbide-Based Coatings on Cold-Rolled Steel Surface

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Coating Procedure

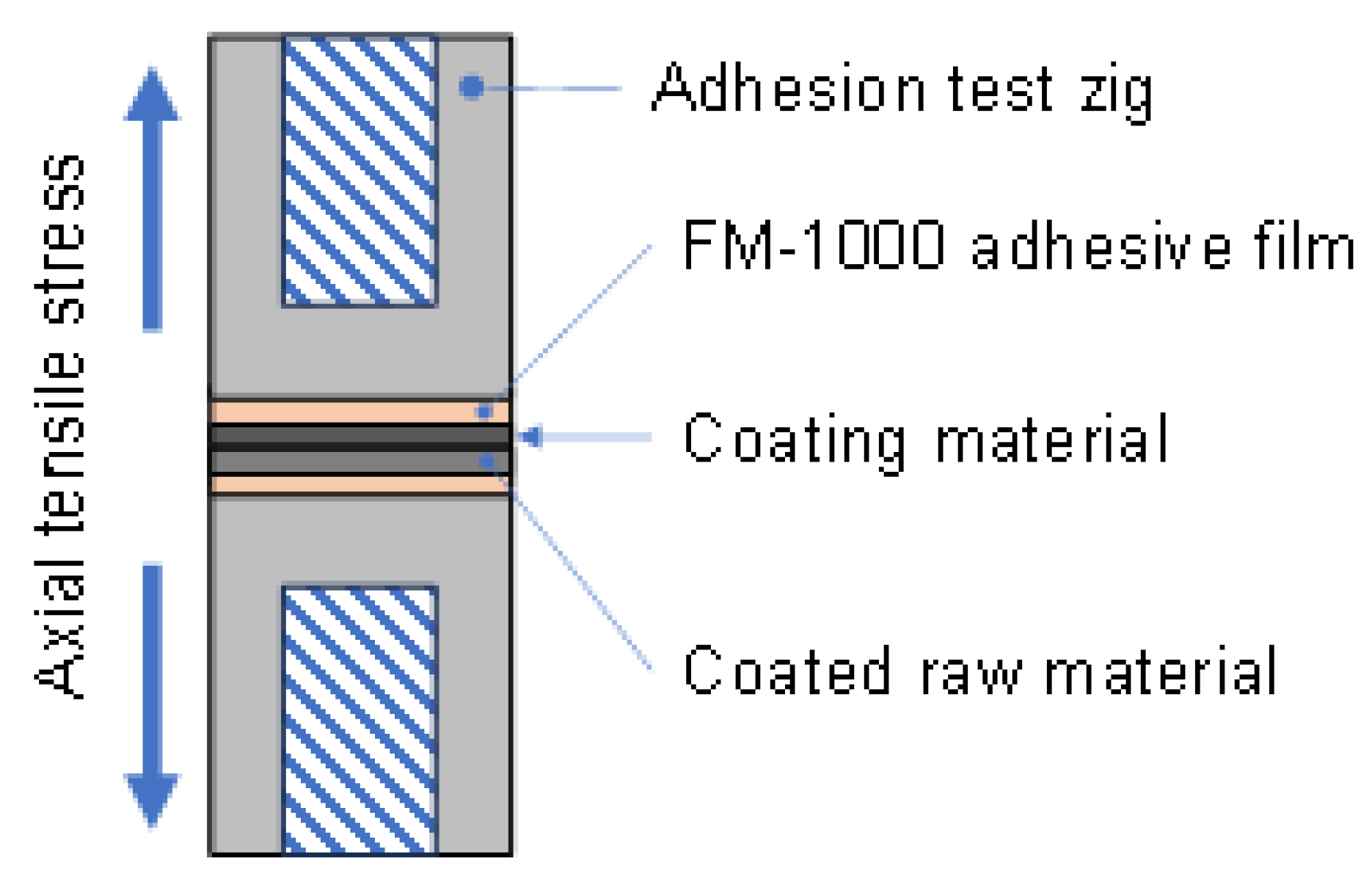

2.2. Microstructural and Mechanical Characterization

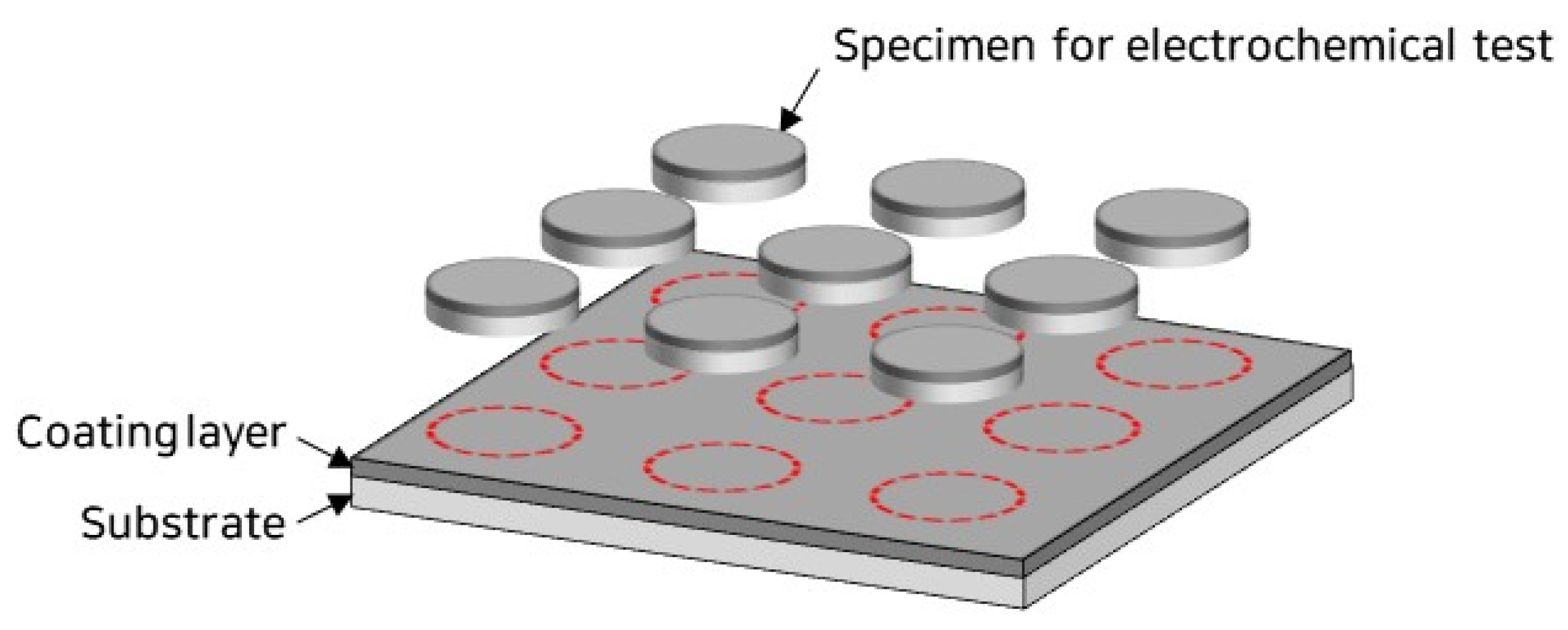

2.3. Electrochemical Corrosion Test

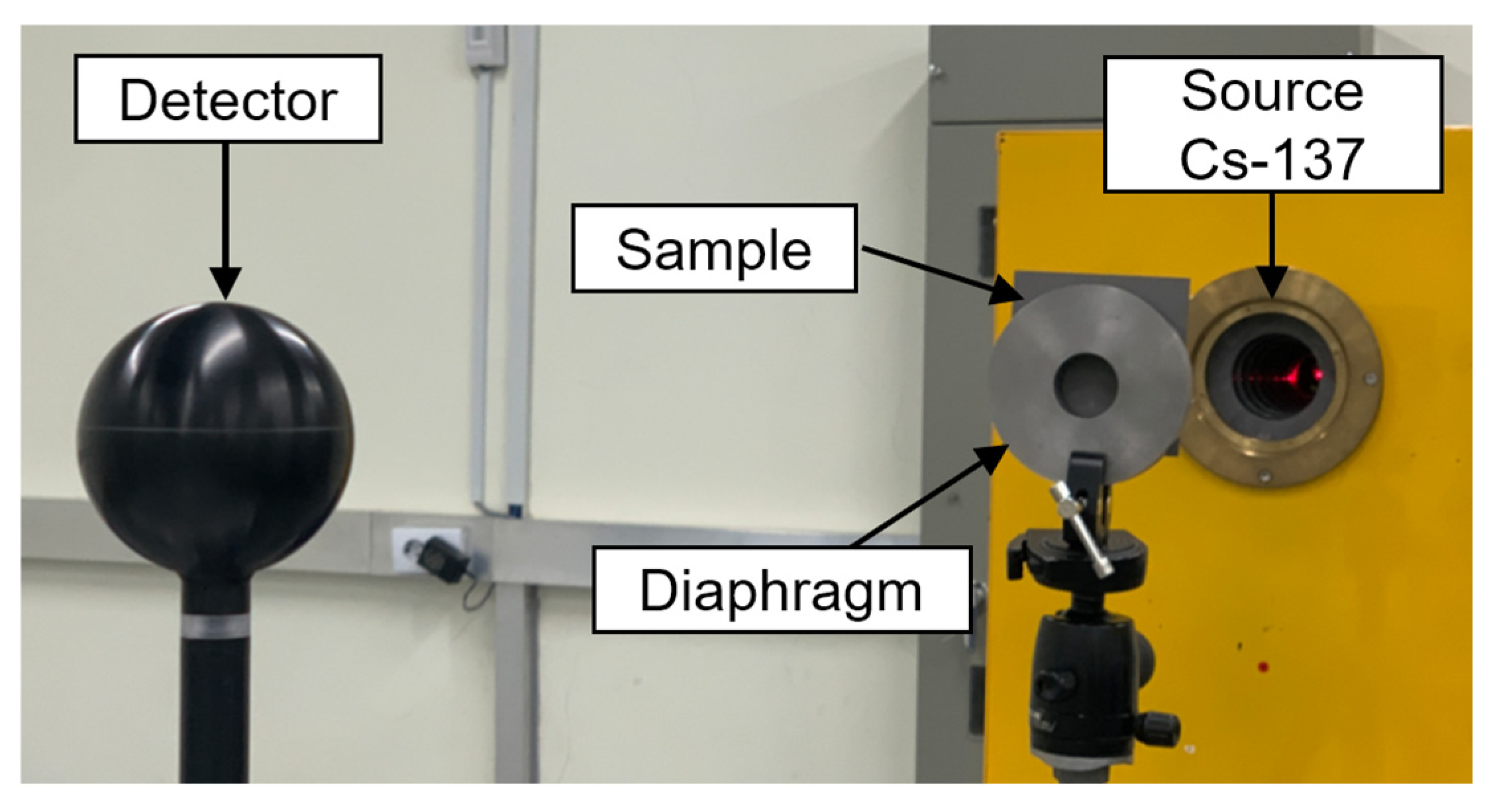

2.4. Gamma-Ray Shielding Test

3. Results and Discussion

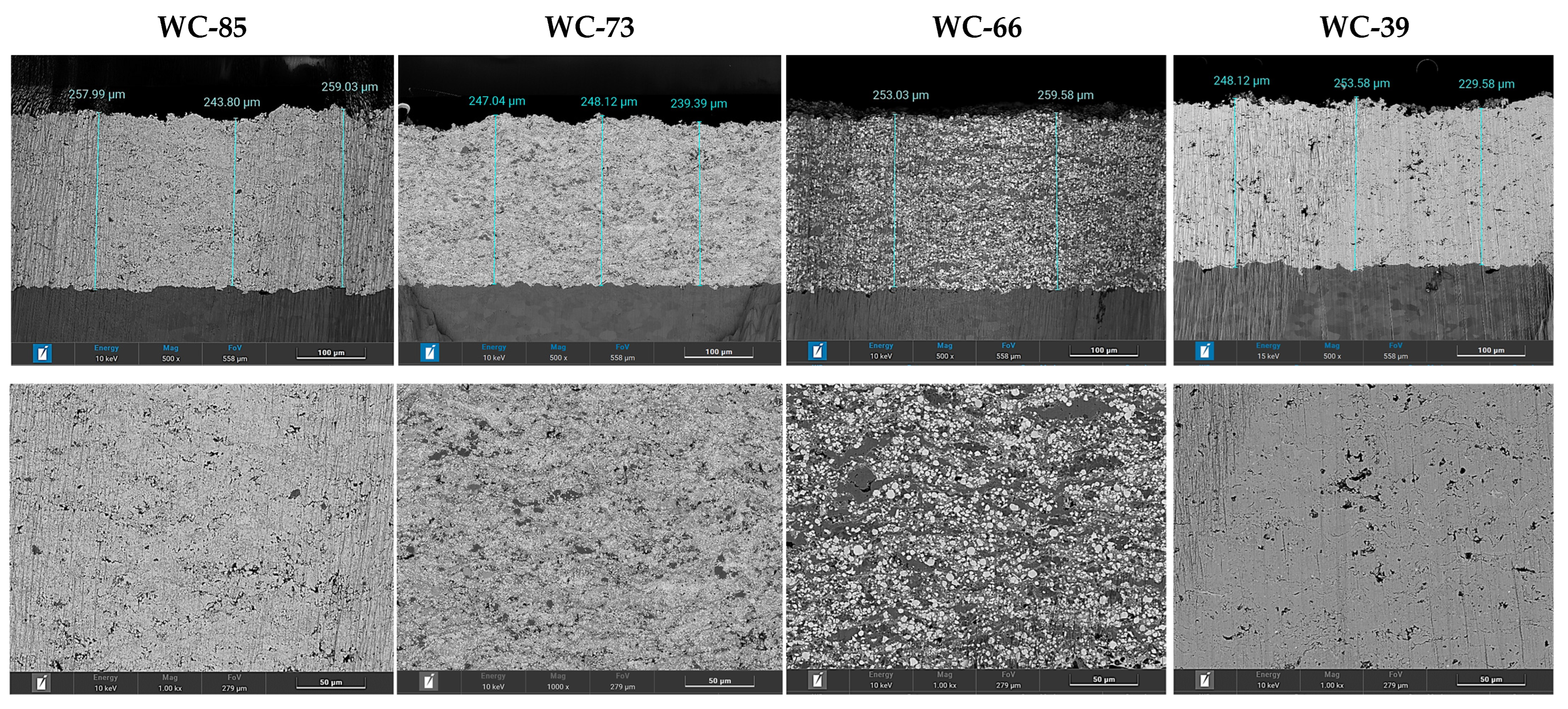

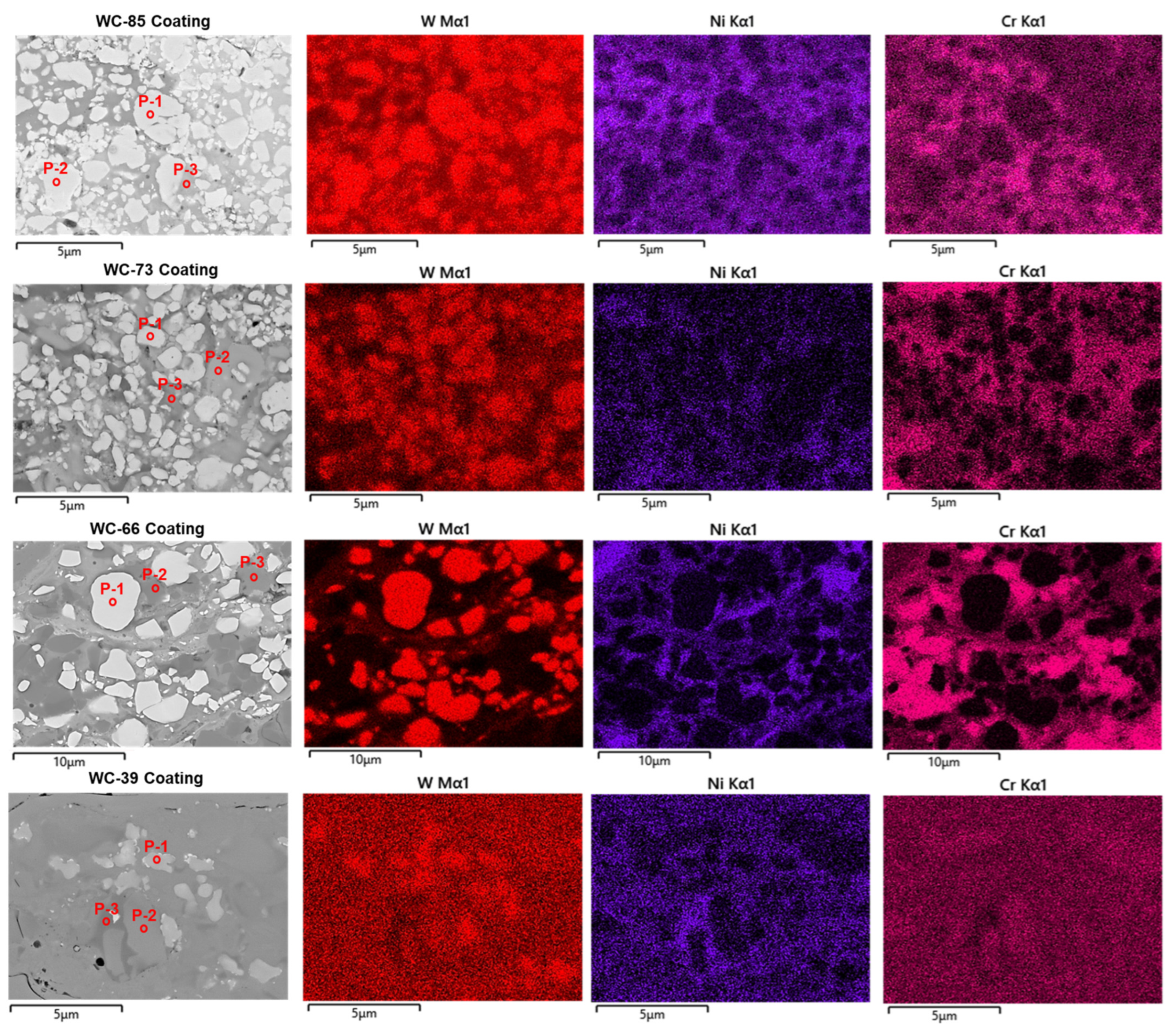

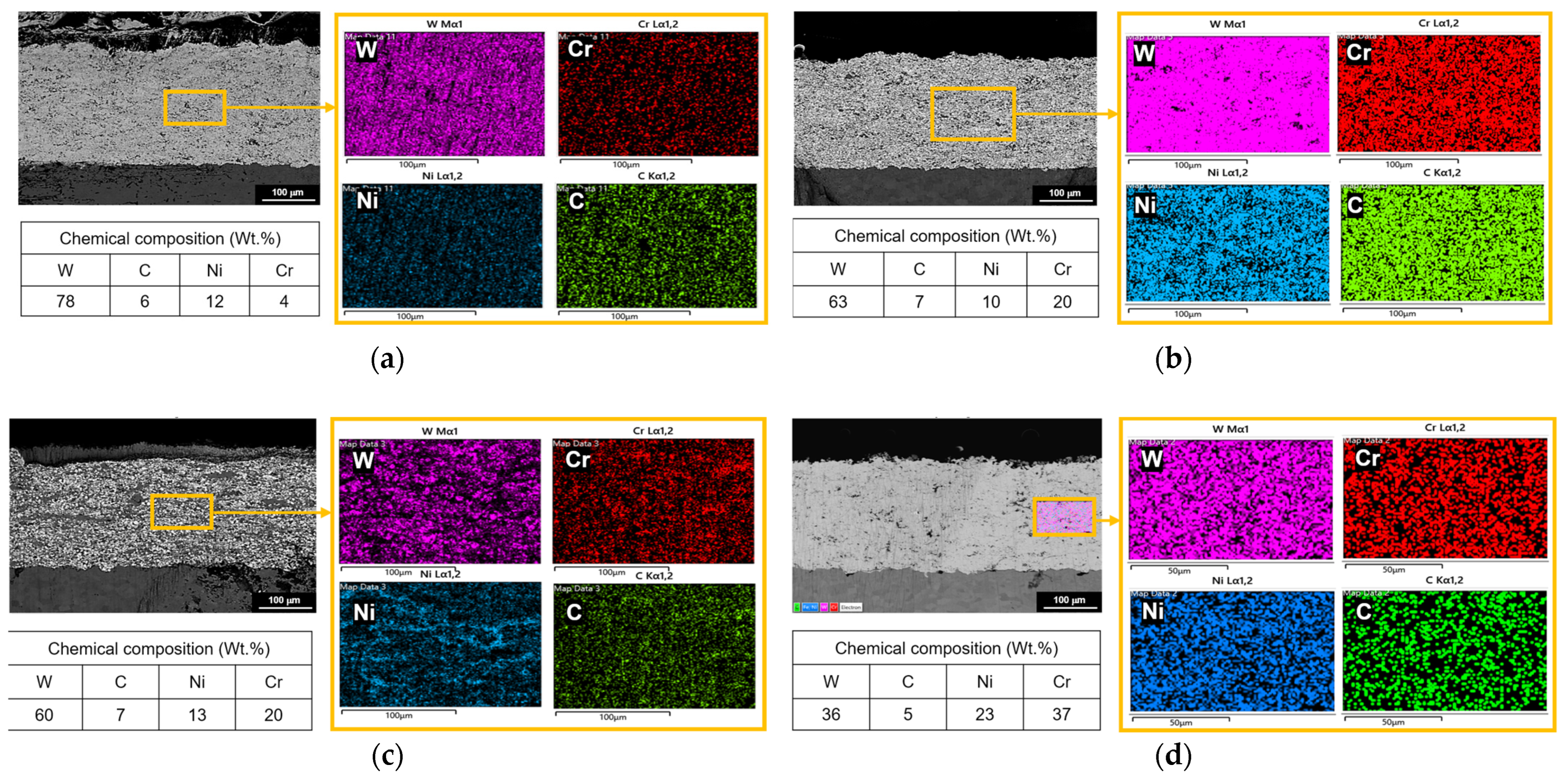

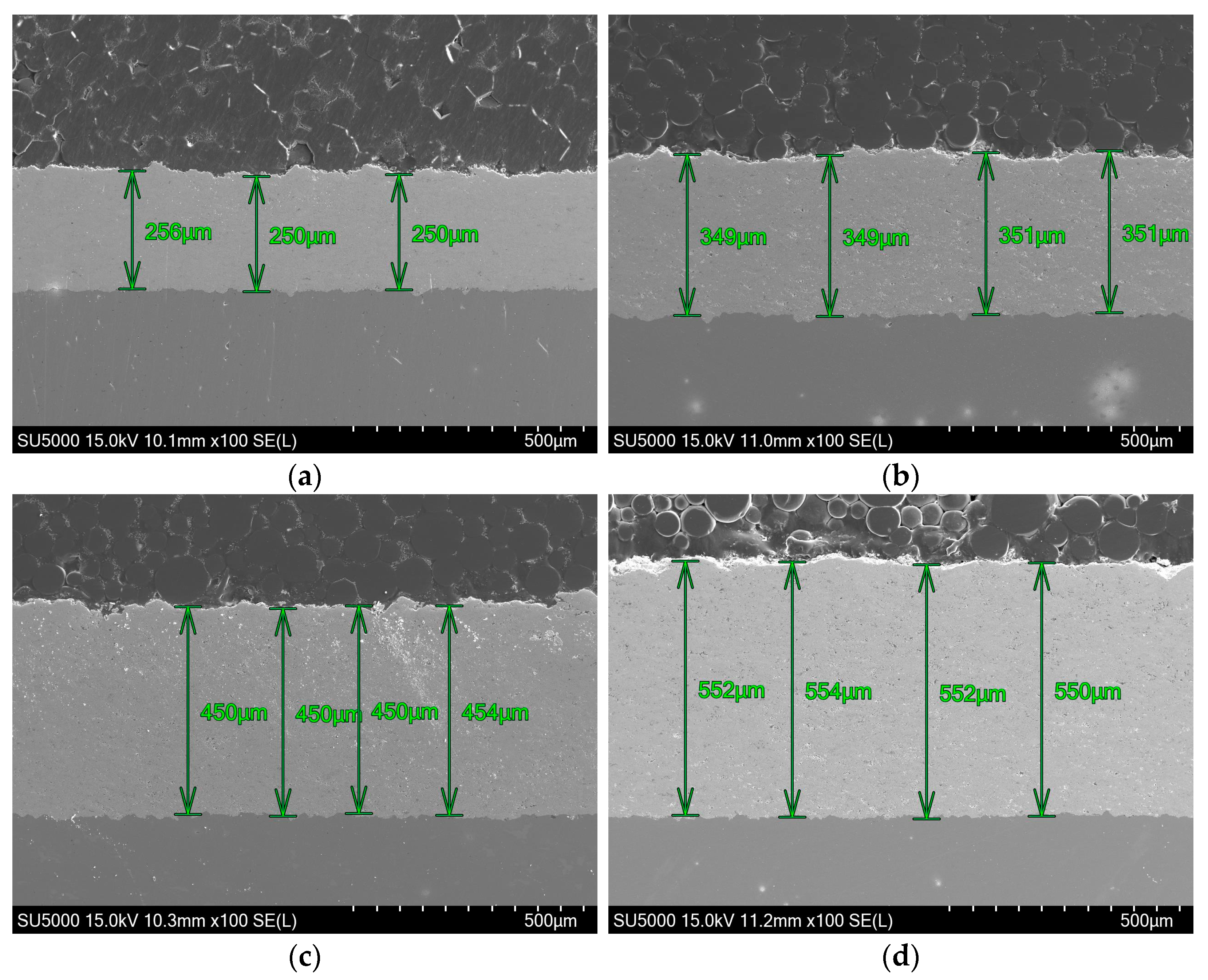

3.1. Microstructural Characteristics

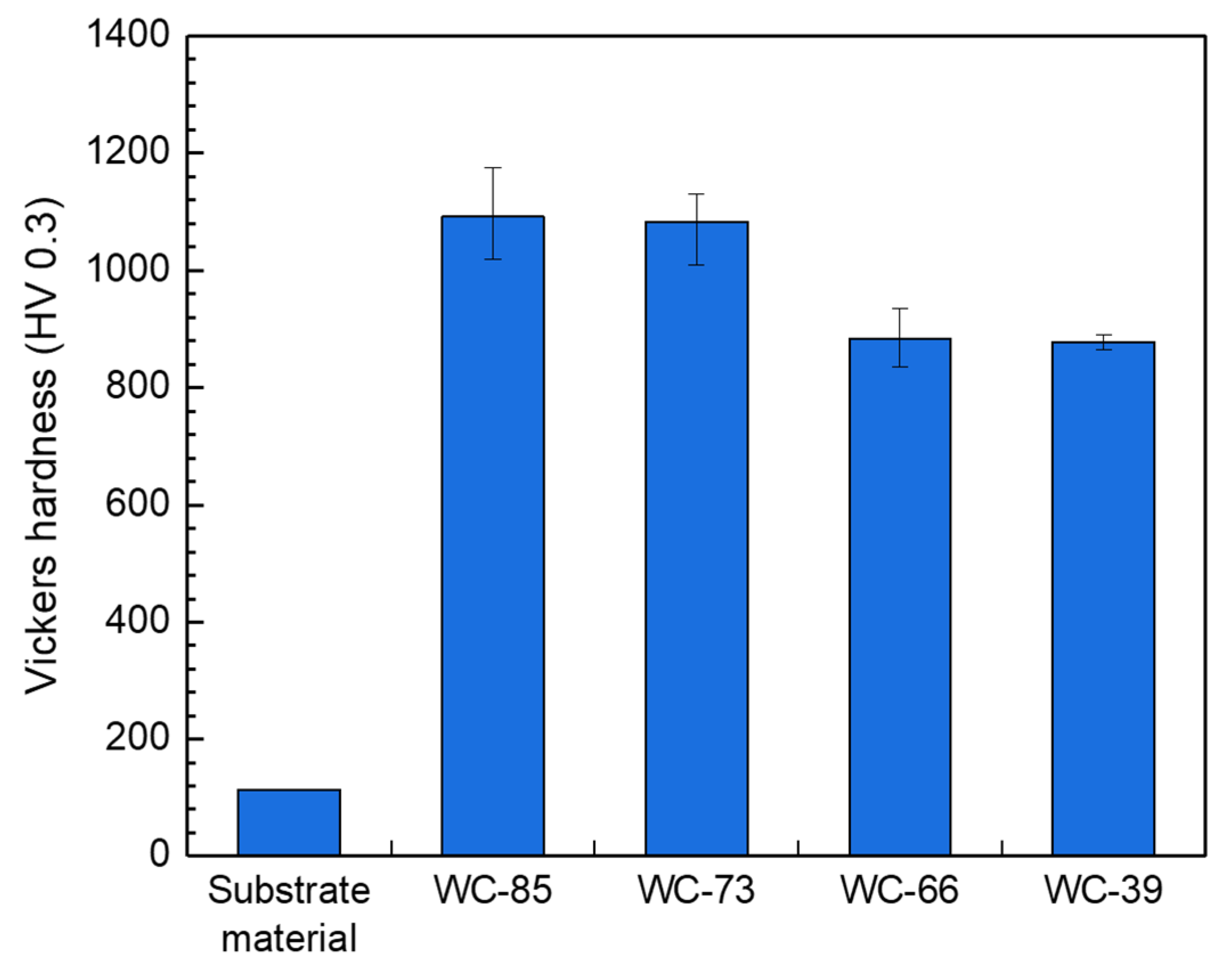

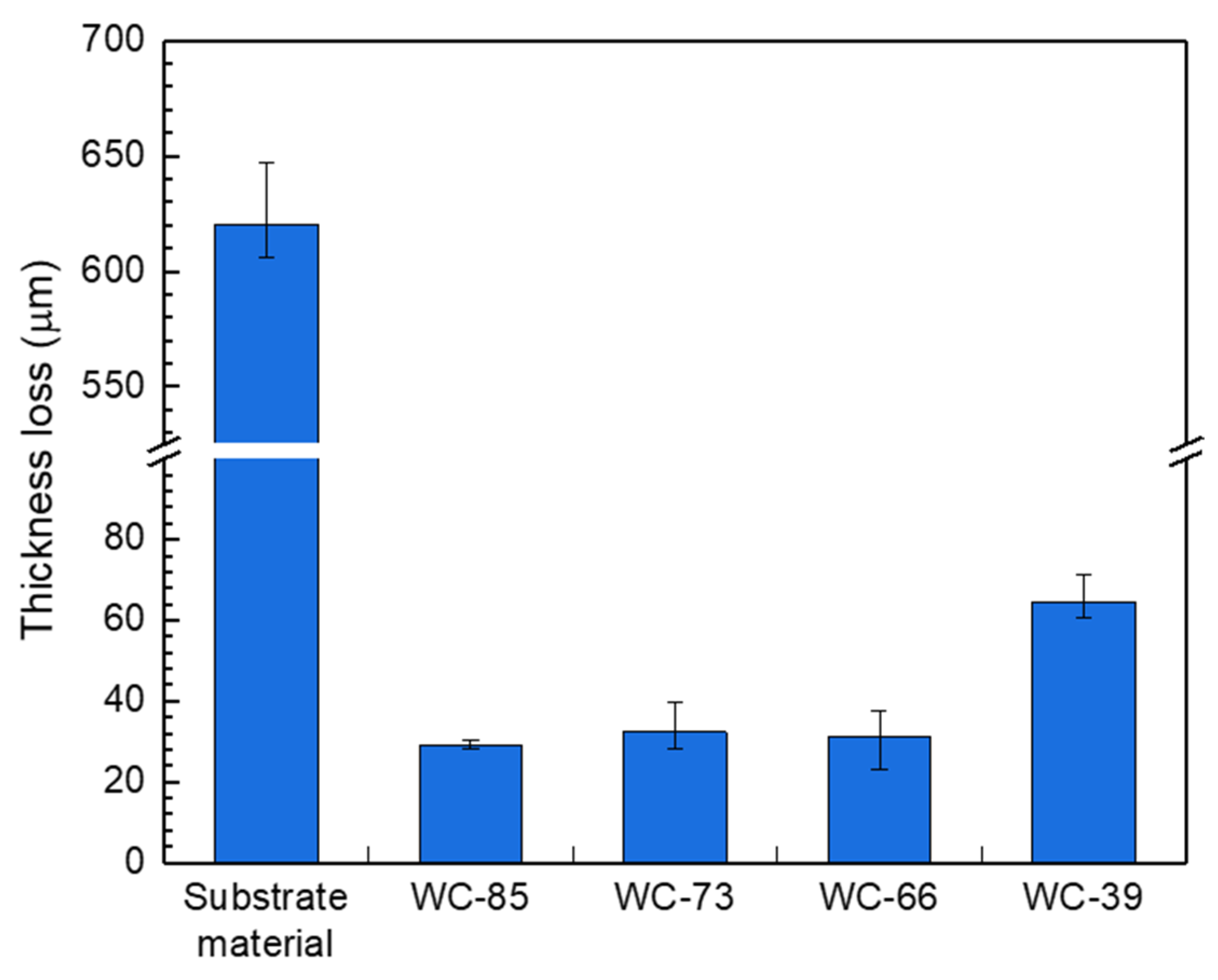

3.2. Mechanical Properties and Corrosion Resistance

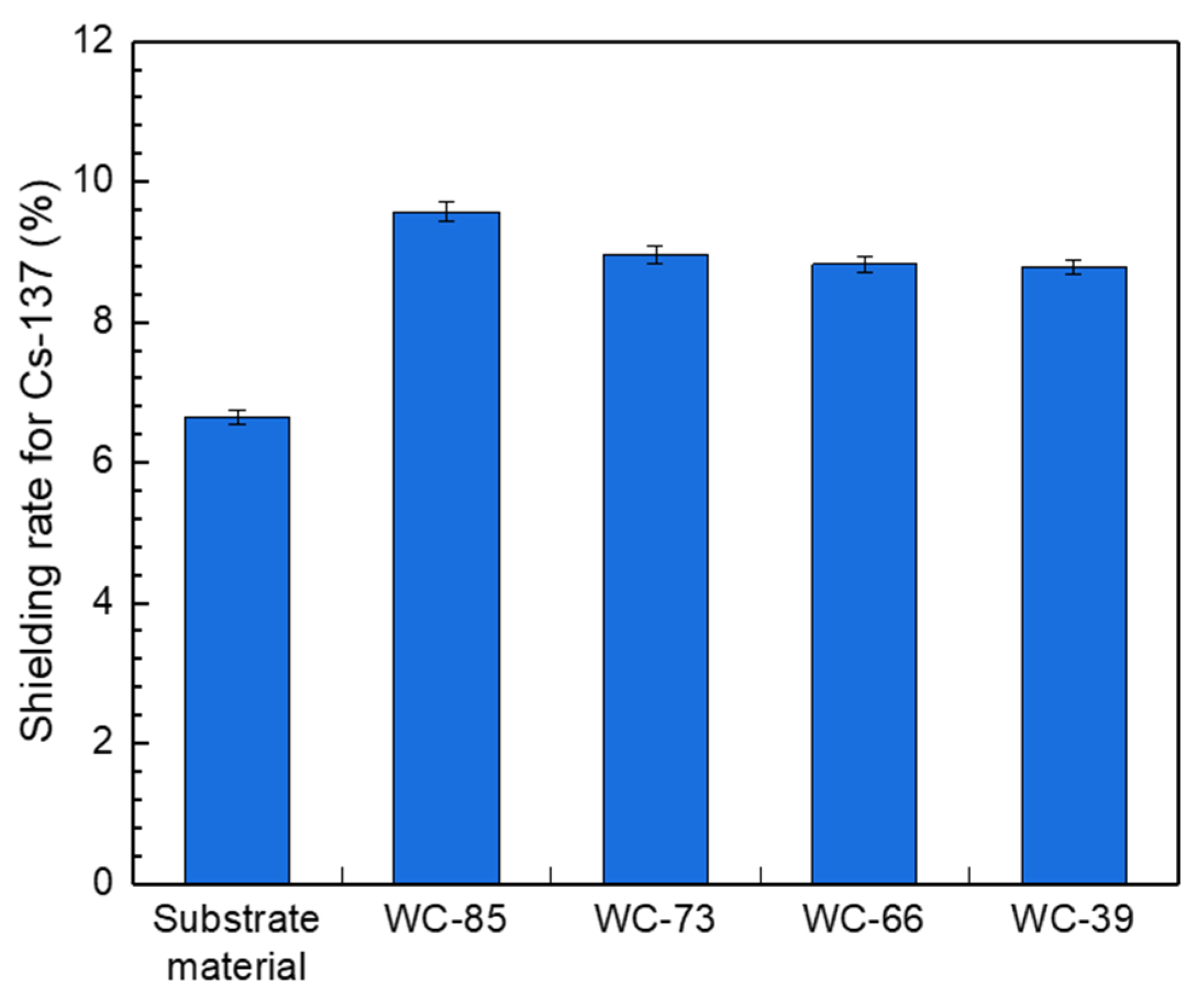

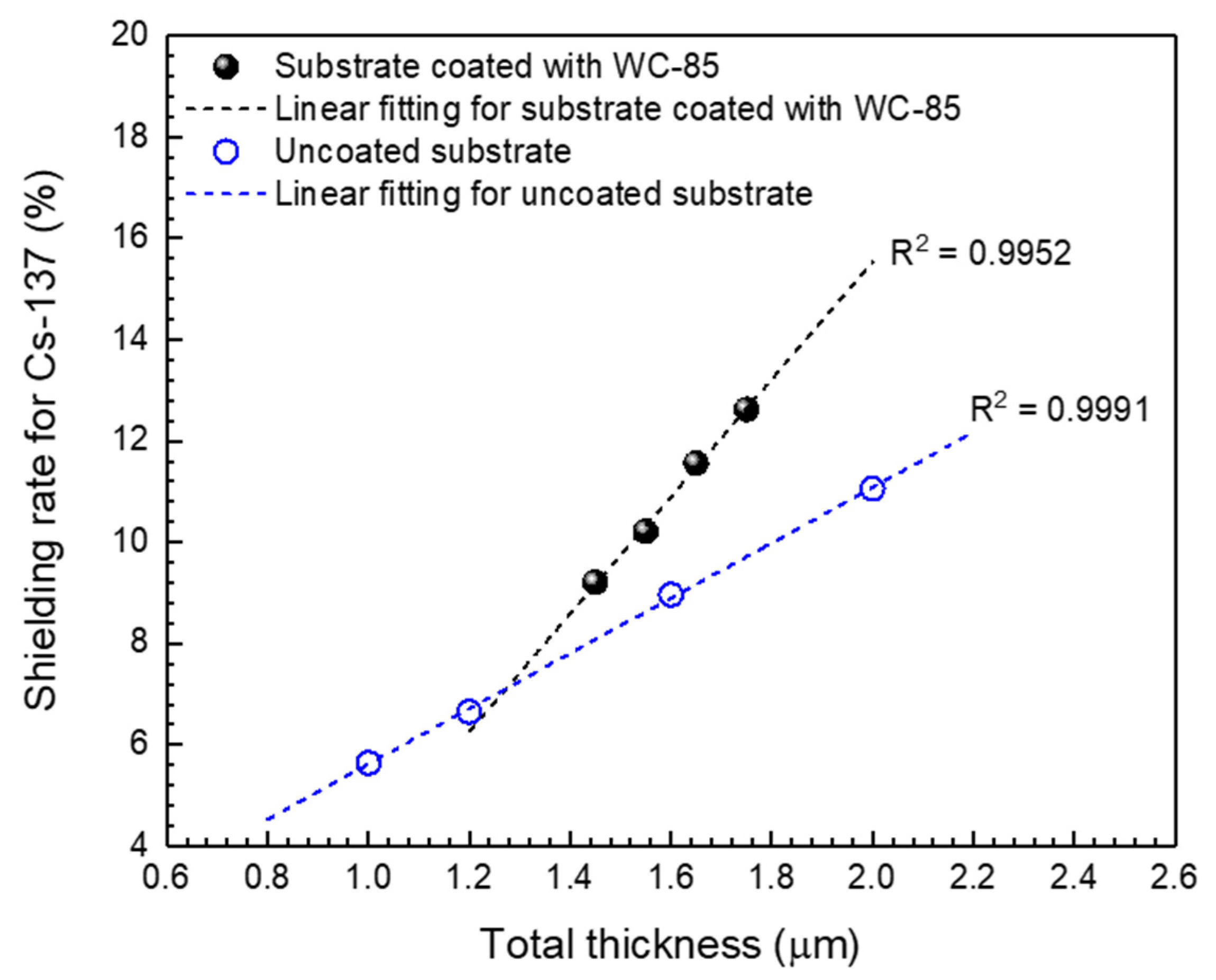

3.3. Gamma-Ray Shielding Performance

4. Conclusions

- The coatings exhibited significantly higher hardness compared to the substrate material, with hardness increasing proportionally to the WC content.

- Higher WC content in the coatings resulted in enhanced wear resistance, directly attributed to the increased hardness.

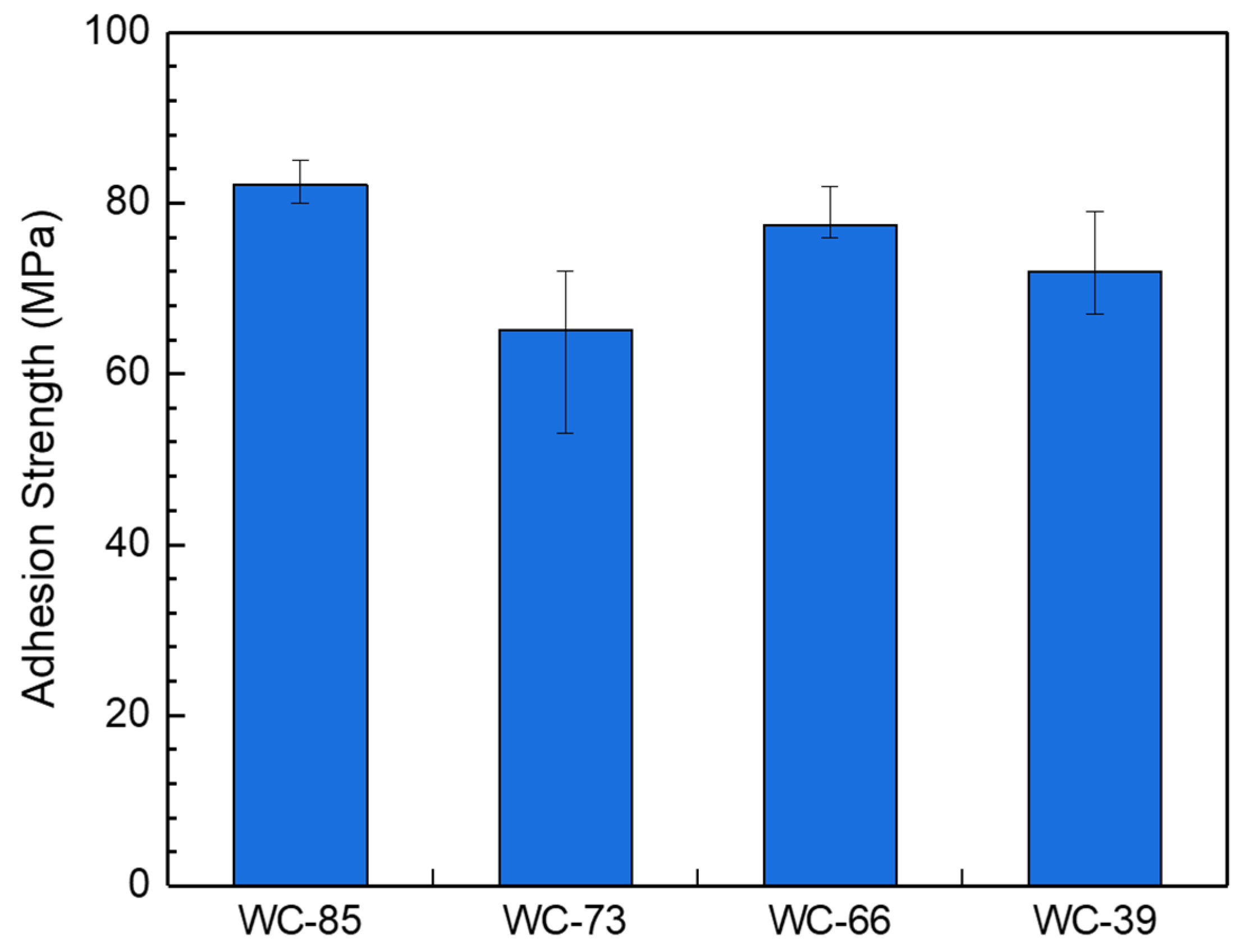

- Adhesion strength was consistent across all WC contents, with most coatings demonstrating excellent adhesive properties, exceeding approximately 70 MPa, except for WC-73.

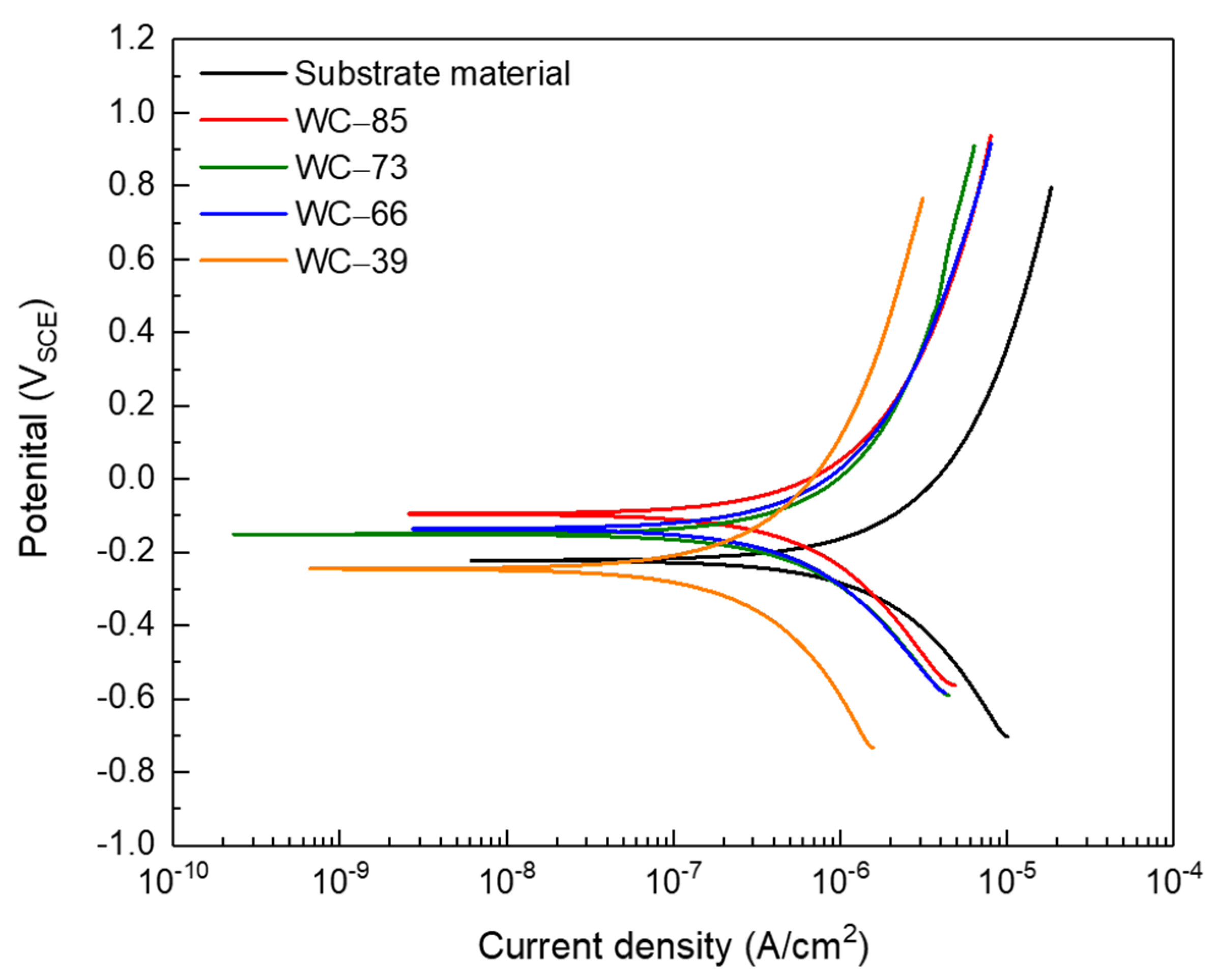

- Corrosion resistance improved with higher Cr content in the coatings. WC-39, with the highest NiCr content, exhibited superior performance in this regard.

- Gamma-ray shielding performance was significantly enhanced with increased W content due to its high atomic number. The WC-85 coating, which contained the highest W content, demonstrated over a 40% improvement in shielding efficiency compared to the uncoated substrate of the same thickness.

- Depending on the storage container’s operational environment and durability requirements, the composition of NiCr and WC in coatings can be tailored to optimize specific properties such as corrosion resistance, mechanical strength, or gamma-ray shielding efficiency.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- IAEA. Long Term Behaviour of Low and Intermediate Level Waste Packages Under Repository Conditions; IAEA-TECHDOC-1397; IAEA: Vienna, Austria, 2004. [Google Scholar]

- Byeon, H.; Jeong, G.Y.; Park, J. Structural stability analysis of waste packages containing low- and intermediate-level radioactive waste in a silo-type repository. Nucl. Eng. Technol. 2021, 53, 1524–1533. [Google Scholar] [CrossRef]

- Ahn, J.; Kim, W.S.; Park, J.B.; Francis, A.J.; Um, W. Temporal changes of geochemistry and microbial community in low and intermediate level waste (LILW) repository, South Korea. Ann. Nucl. Energy 2019, 128, 309–317. [Google Scholar] [CrossRef]

- IAEA. Containers for Packaging of Solid and Intermediate Level Radioactive Wastes; Technical Reports Series NO. 355; IAEA: Vienna, Austria, 1993. [Google Scholar]

- Vehovar, L.; Tandler, M. Stainless steel containers for the storage of low and medium level radioactive waste. Nucl. Eng. Des. 2001, 206, 21–33. [Google Scholar] [CrossRef]

- Bonin, H.W.; Walker, M.W.; Bui, V.T. Application of Polymers for the Long-Term Storage and Disposal of Low- and Intermediate-Level Radioactive Waste. Nucl. Technol. 2004, 145, 82–101. [Google Scholar] [CrossRef]

- Uhm, Y.R.; Kim, J.; Jung, J.; Rhee, C.K. Fabrications of pva coated nano-b4c reinforced hdpe composites. Mod. Phys. Lett. B 2009, 23, 3931–3936. [Google Scholar] [CrossRef]

- Jung, J.; Kim, J.; Uhm, Y.R.; Jeon, J.K.; Lee, S.; Lee, H.M.; Rhee, C.K. Preparations and thermal properties of micro- and nano-BN dispersed HDPE composites. Thermochim. Acta 2010, 449, 8–14. [Google Scholar] [CrossRef]

- Ghattas, N.K.; Eskander, S.B.; Bayoumi, T.A.; Saleh, H.M. Cement-Polymer Composite Containers for Radioactive Wastes Disposal. J. Radiat. Res. Appl. Sci. 2009, 2, 103–118. [Google Scholar]

- Nie, H.; Li, Z.; Zhou, H.; Wu, J.; Wen, G.; Li, Y. Study on the wear resistance and mechanism of HVOF-sprayed WC10Co4Cr coatings. Surf. Coat. Technol. 2024, 494, 131368. [Google Scholar] [CrossRef]

- Kumar, V.; Verma, R. Effect of GNP and laser-surface texturing on HVOF sprayed WC10Co4Cr coatings for high-wear resistance. Tribol. Int. 2023, 178, 108057. [Google Scholar] [CrossRef]

- Kumar, R.; Sharma, S.; Singh, J.P.; Gulati, P.; Singh, G.; Dwivedi, S.P.; Li, C.; Kumar, A.; Tag-Eldin, E.M.; Abbas, M. Enhancement in wear-resistance of 30MNCRB5 boron steel-substrate using HVOF thermal sprayed WC–10% Co–4% Cr coatings: A comprehensive research on microstructural, tribological, and morphological analysis. J. Mater. Res. Technol. 2023, 27, 1072–1096. [Google Scholar] [CrossRef]

- Mishra, B.B.; Nautiyal, H. Frictional and wear behavior of Cr3C2-NiCr coating on AISI-304 stainless steel. Adv. Mater. Process. Technol. 2022, 8, 4007–4017. [Google Scholar] [CrossRef]

- Wen, Y.; Zhang, Y.; Zhang, X.; Zhao, Z.; Yan, Q. The tribological behavior of Cu-based brake materials against Cr3C2-NiCr coated steel disks with varying roughness. Tribol. Trans. 2024; accepted. [Google Scholar]

- Kumar, N.; Choubey, V.K. Experimental investigation on hot corrosion, oxidation and microstructure of WC based cermet HVOF coating. High Temp. Corros. Mater. 2024, 101, 413–432. [Google Scholar] [CrossRef]

- Pereira, P.; Rocha, A.F.; Sacramento, J.; Oliveira, F.J.; Senos, A.M.R.; Malheiros, L.F.; Bastos, A.C. Corrosion resistance of WC hardmetals with different Co and Ni-based binders. Int. J. Refract. Met. Hard Mater. 2022, 104, 105799. [Google Scholar] [CrossRef]

- Wang, K.; Hong, S.; Wei, Z.; Hu, N.; Cheng, J.; Wu, Y. Long-term corrosion behavior of HVOF sprayed Cr3C2–NiCr coatings in sulfide-containing 3.5 wt.% NaCl solution. J. Mater. Res. Technol. 2021, 15, 3122–3132. [Google Scholar] [CrossRef]

- Chen, X.; Wang, H.T.; Ji, G.C.; Bai, X.B.; Fu, W. Microstructure and properties of TiB2–Ni coatings with different binder phase 452 contents deposited by HVOF spray process. Rare Met. 2022, 41, 1385–1393. [Google Scholar] [CrossRef]

- Li, C.J.; Ji, G.C.; Wang, Y.Y.; Sonoya, K. Dominant effect of carbide rebounding on the carbon loss during high velocity oxy-fuel 454 spraying of Cr3C2–NiCr. Thin Solid Film. 2002, 419, 137–143. [Google Scholar] [CrossRef]

- Jose, S.A.; John, M.; Menezes, P.L. Cermet systems: Synthesis, properties, and applications. Ceramics 2022, 5, 210–236. [Google Scholar] [CrossRef]

- Zhang, F.; Tabecki, A.; Bennett, M.; Begg, H.; Lionetti, S.; Paul, S. Feasibility Study of High-Velocity Oxy-fuel (HVOF) Sprayed Cermet and Alloy Coatings for Geothermal Applications. J. Therm. Spray Technol. 2023, 32, 339–351. [Google Scholar] [CrossRef]

- Wielage, B.; Wank, A.; Pokhmurska, H.; Grund, T.; Rupprecht, C.; Reisel, G.; Friesen, E. Development and trends in HVOF spraying technology. Surf. Coat. Technol. 2006, 201, 2032–2037. [Google Scholar] [CrossRef]

- Staia, M.H.; Mejias, A.; Kossman, S.; Puchi-Cabrera, E.S. Tribocorrosion Performance of WC-12Co HVOF-Sprayed Coatings Reinforced with Carbon Nanotubes. Crystals 2023, 13, 457. [Google Scholar] [CrossRef]

- Berger, L.M.; Saaro, S.; Naumann, T.; Wiener, M.; Weihnacht, V.; Thiele, S.; Suchánek, J. Microstructure and properties of HVOF-sprayed chromium alloyed WC–Co and WC–Ni coatings. Surf. Coat. Technol. 2008, 202, 4417–4421. [Google Scholar] [CrossRef]

- Song, B.; Murray, J.W.; Wellman, R.G.; Pala, Z.; Hussain, T. Dry sliding wear behaviour of HVOF thermal sprayed WC-Co-Cr and WC-CrxCy-Ni coatings. Wear 2020, 442, 203114. [Google Scholar] [CrossRef]

- Wu, Y.; Hong, S.; Zhang, J.; He, Z.; Guo, W.; Wang, Q. Microstructure and cavitation erosion behavior of WC–Co–Cr coating on 1Cr18Ni9Ti stainless steel by HVOF thermal spraying. Int. J. Refract. Met. Hard Mater. 2012, 32, 21–26. [Google Scholar] [CrossRef]

- El Rayes, M.M.; Sherif, E.S.M.; Abdo, H.S. Comparative study into microstructural and mechanical characterization of HVOF-WC-based coatings. Crystals 2022, 12, 969. [Google Scholar] [CrossRef]

- McAlister, D.R. Gamma Ray Attenuation Properties of Common Shielding Materials; University Lane Lisle: Lisle, IL, USA, 2012. [Google Scholar]

- Thermal Spray Powder. Available online: https://www.alloymstech.com/Coating-Powder.php (accessed on 10 December 2024).

- ASTM E384; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2005.

- Song, G.D.; Hwang, J.H.; Kim, D.W.; Park, B.C.; Hahn, J.; Hong, S.G. Coexistence of two distinct fatigue failure mechanisms in Super304H welded joint at elevated temperatures. Mater. Sci. Eng. A 2021, 819, 141462. [Google Scholar] [CrossRef]

- ASTM F1978; Standard Test Method for Measuring Abrasion Resistance of Metallic Thermal Spray Coatings by Using the Taber Abraser. ASTM International: West Conshohocken, PA, USA, 2001.

- Wank, A.; Wielage, B.; Reisel, G.; Grund, T.; Friesen, E. Performance of thermal spray coatings under dry abrasive wear conditions. In Proceedings of the Coatings, Erlangen, Germany, 5–7 April 2004. [Google Scholar]

- ASTM C633; Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings. ASTM International: West Conshohocken, PA, USA, 2021.

- Kim, J.H. Atmospheric acidic deposition: State of acid rain in Korea and the world. Korean J. Ecol. 2005, 28, 169–180. [Google Scholar] [CrossRef]

- Song, G.D.; Jeon, S.H.; Son, Y.H.; Kim, J.G.; Hur, D.H. Galvanic effect of magnetite on the corrosion behavior of carbon steel in deaerated alkaline solutions under flowing conditions. Corros. Sci. 2018, 131, 71–80. [Google Scholar] [CrossRef]

- Qadr, H.M. Calculation for gamma ray buildup factor for aluminium, graphite and lead. Int. J. Nucl. Energy Sci. Technol. 2019, 13, 61–69. [Google Scholar] [CrossRef]

- Lamana, M.S.; Pukasiewicz, A.G.; Sampath, S. Influence of cobalt content and HVOF deposition process on the cavitation erosion resistance of WC-Co coatings. Wear 2018, 398, 209–219. [Google Scholar] [CrossRef]

- Nahvi, S.M.; Jafari, M. Microstructural and mechanical properties of advanced HVOF-sprayed WC-based cermet coatings. Surf. Coat. Technol. 2016, 286, 95–102. [Google Scholar] [CrossRef]

- Agüero, A.; Camón, F.; García de Blas, J.; Del Hoyo, J.C.; Muelas, R.; Santaballa, A.; Ulargui, S.; Vallés, P. HVOF-deposited WCCoCr as replacement for hard Cr in landing gear actuators. J. Therm. Spray Technol. 2011, 20, 1292–1309. [Google Scholar] [CrossRef]

- Klaasen, H.; Kübarsepp, J. Abrasive wear performance of carbide composites. Wear 2006, 261, 520–526. [Google Scholar] [CrossRef]

- Jeong, D.H.; Erb, U.; Aust, K.T.; Palumbo, G. The relationship between hardness and abrasive wear resistance of electrodeposited nanocrystalline Ni–P coatings. Scr. Mater. 2003, 48, 1067–1072. [Google Scholar] [CrossRef]

- Hokkirigawa, K.; Kato, K.; Li, Z.Z. The effect of hardness on the transition of the abrasive wear mechanism of steels. Wear 1988, 123, 241–251. [Google Scholar] [CrossRef]

- Khruschov, M.M. Principles of abrasive wear. Wear 1974, 28, 69–88. [Google Scholar] [CrossRef]

- Houdková, Š.; Zahálka, F.; Kašparová, M.; Berger, L.M. Comparative study of thermally sprayed coatings under different types of wear conditions for hard chromium replacement. Tribol. Lett. 2011, 43, 139–154. [Google Scholar] [CrossRef]

- Shinde, S.; Sampath, S. A critical analysis of the tensile adhesion test for thermally sprayed coatings. J. Therm. Spray Technol. 2022, 31, 2247–2279. [Google Scholar] [CrossRef]

- Jones, D.A. Principles and Prevention, 2nd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 1996. [Google Scholar]

- A Designers’ Handbook Series, Design Guidelines for the Selection and Use of Stainless Steels; Nickel Institute: Toronto, ON, Canada, 2020.

- Xiang, Y.; Wang, Z.; Yang, X.; Li, Z.; Ni, W. The upper limit of moisture content for supercritical CO2 pipeline transport. J. Supercrit. Fluids 2012, 67, 14–21. [Google Scholar] [CrossRef]

- Folić, R.; Zenunović, D. Durability design of concrete structures, Part 2: Modelling and structural assessment. Facta Univ. -Ser. Archit. Civ. Eng. 2010, 8, 45–66. [Google Scholar] [CrossRef]

- Bossio, A.; Bitondo, C.; Monetta, T.; Bellucci, F.; Mollo, L. Corrosion of steel arches in support of tuff masonry. A case study. In Proceedings of the EUROSTEEL 2014, Naples, Italy, 10–12 September 2014. [Google Scholar]

| Sample | Chemical Composition (wt.%) | Particle Size (µm) | ||||

|---|---|---|---|---|---|---|

| W | C | Ni | Cr | Co | ||

| WC-85 | 79.2 | 5.4 | 10.2 | 5.2 | - | 15–45 |

| WC-73 | 66.7 | 5.9 | 7.4 | 19.9 | 0.1 | 16–46 |

| WC-66 | 59.5 | 6.4 | 16.3 | 17.7 | - | 10–53 |

| WC-39 | 35.3 | 3.6 | 18.1 | 43.0 | - | 16–45 |

| Operation Process | Parameter | Value |

|---|---|---|

| Spray Equipment Supplements | Gun Type | JK 3000 |

| Nozzle (Anode) (cm) | 22.86 | |

| Electrode (Cathode) | N/A | |

| Type of Gas (Primary) | Oxygen | |

| Type of Gas (Secondary) | Hydrogen | |

| Powder Feeder | Powder Gas Type | Argon |

| Carrier Gas (kPa) | 1034 ± 34 | |

| Carrier Gas (FMR) | 9 ± 1 | |

| Feed Rate (g/min) | 25 ± 5 | |

| Feeder Hose to Gun, Inner Dia. (cm). | 0.47 | |

| Feeder Hose to Gun, Length (m) | 3~5 | |

| Coating Data | Pre-heat method | 1 cycle of flame |

| Gun-to-Work Distance (cm) | 22.86 ± 1.27 | |

| Applicable Angle | 90 ± 5° | |

| Gun Traverse Speed (mm/s) | 5 | |

| Surface Speed (ft/min) (ref.) | 188 ± 18 | |

| Cooling Substrate | Auxiliary Cooling Gas Pressure (kPa) | 275 (Min.) |

| Auxiliary Cooling Gas Distance (cm) | 7.6~17.8 | |

| Auxiliary Cooling Gas Angle | 45° (Min.) |

| Sample | Porosity (%) | Average Thickness (µm) |

|---|---|---|

| WC-85 | <1 | 253 |

| WC-73 | <1 | 245 |

| WC-66 | <1 | 256 |

| WC-39 | <1 | 244 |

| Sample | EDS Point | Chemical Composition (wt.%) | |||

|---|---|---|---|---|---|

| W | C | Ni | Cr | ||

| WC-85 | P-1 | 90.6 | 8.1 | 1.3 | - |

| P-2 | 89.3 | 8.3 | 2.0 | 0.4 | |

| P-3 | 34.5 | 1.8 | 49.9 | 13.8 | |

| WC-73 | P-1 | 89.0 | 9.4 | 0.9 | 0.7 |

| P-2 | 58.1 | 9.5 | 31.6 | 0.8 | |

| P-3 | 38.8 | 9.3 | 21.5 | 30.4 | |

| WC-66 | P-1 | 91.1 | 8.9 | - | - |

| P-2 | 11.9 | 9.7 | 1.2 | 77.2 | |

| P-3 | 3.4 | 4.8 | 72.3 | 19.5 | |

| WC-39 | P-1 | 41.1 | 6.8 | 17.6 | 34.5 |

| P-2 | 35.7 | 7.6 | 9.4 | 47.3 | |

| P-3 | 35.2 | 8.1 | 11.1 | 45.6 | |

| Sample | Composition Change (wt. %) | |||

|---|---|---|---|---|

| W | C | Ni | Cr | |

| WC-85 | −1.2 | +0.6 | +1.8 | −1.2 |

| WC-73 | −3.7 | +1.1 | +0.2 | +0.1 |

| WC-66 | +0.5 | +0.6 | −3.3 | −2.3 |

| WC-39 | +0.7 | +1.4 | +4.9 | −6.0 |

| Sample | Ecorr (VSCE) | icorr (μA/cm2) |

|---|---|---|

| Substrate material | −0.219 | 2.224 |

| WC-85 | −0.095 | 0.620 |

| WC-73 | −0.147 | 0.433 |

| WC-66 | −0.136 | 0.392 |

| WC-39 | −0.255 | 0.232 |

| Element | Density (g/cm3) | HVL * for Co-60 (cm) |

|---|---|---|

| W | 19.30 | 0.8 |

| Pb | 11.34 | 1.2 |

| Bi | 9.80 | 1.4 |

| Cu | 8.96 | 1.9 |

| Fe | 7.86 | 2.2 |

| Al | 2.70 | 6.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Son, Y.-H.; Baek, S.H.; Kim, B.K.; Hwang, J.H.; Lee, J.H.; Song, G.D. Comparison of Durability and Gamma-Ray Shielding Performance of High-Velocity Oxygen Fuel Tungsten Carbide-Based Coatings on Cold-Rolled Steel Surface. Crystals 2025, 15, 21. https://doi.org/10.3390/cryst15010021

Son Y-H, Baek SH, Kim BK, Hwang JH, Lee JH, Song GD. Comparison of Durability and Gamma-Ray Shielding Performance of High-Velocity Oxygen Fuel Tungsten Carbide-Based Coatings on Cold-Rolled Steel Surface. Crystals. 2025; 15(1):21. https://doi.org/10.3390/cryst15010021

Chicago/Turabian StyleSon, Yeong-Ho, Seung Heon Baek, Beom Kyu Kim, Jeong Ho Hwang, Jae Hun Lee, and Geun Dong Song. 2025. "Comparison of Durability and Gamma-Ray Shielding Performance of High-Velocity Oxygen Fuel Tungsten Carbide-Based Coatings on Cold-Rolled Steel Surface" Crystals 15, no. 1: 21. https://doi.org/10.3390/cryst15010021

APA StyleSon, Y.-H., Baek, S. H., Kim, B. K., Hwang, J. H., Lee, J. H., & Song, G. D. (2025). Comparison of Durability and Gamma-Ray Shielding Performance of High-Velocity Oxygen Fuel Tungsten Carbide-Based Coatings on Cold-Rolled Steel Surface. Crystals, 15(1), 21. https://doi.org/10.3390/cryst15010021