Abstract

Hot cracking is a frequent and severe defect that occurs during laser additive manufacturing of superalloys. In this work, a pulsed-wave (PW) laser modulation process was employed to control the solidification microstructure and reduce the hot cracking susceptibility of laser additive manufactured cobalt-based superalloy. The effects of continuous-wave (CW) and PW laser processing modes on the dendrite morphology, element segregation, eutectic phase, and hot cracking of fabricated Co-based superalloys were investigated. Optical microscopy, scanning electron microscopy, and energy-dispersive X-ray spectroscopy were used to characterize the microstructural characteristics of samples. A two-color pyrometer was used to measure the molten pool temperature variation under different laser processing modes. The results show that coarse columnar dendrites, chain-like eutectic carbides, and hot cracks were observed in the CW sample. In contrast, the fine equiaxed crystals, discrete eutectic carbides, and low-level residual stresses were obtained to avoid hot cracks, owing to the high cooling rate and the periodic melting and solidification of the molten pool under the PW laser processing mode. This work provides a new method for controlling solidification structure and hot cracking of laser additive manufactured Co-based superalloy.

1. Introduction

Laser additive manufacturing (LAM) is an advanced manufacturing technology capable of fabricating complex-shaped metal parts, which usually uses high-powered lasers to melt and deposit metal powder, layer-by-layer [1,2,3,4]. Cobalt-based superalloys have high strength, good thermal fatigue resistance, thermal corrosion resistance, and wear resistance at high temperatures, and are used to fabricate the guide vanes and other high-temperature structural components of jet engines, industrial gas turbines, and marine gas turbines [5,6]. In recent years, LAM has become more and more popular in fabricating or repairing cobalt-based superalloy components [5,7]. However, due to the significant temperature gradient and high cooling rate of LAM, interdendritic element segregation, low-melting-point eutectic phase, and hot cracks are prone to occur during LAM of Co-based superalloys, which significantly reduces the mechanical and physical properties of the fabricated parts [7,8,9].

Many research works have been conducted to control the microstructure and hot cracks of LAM-fabricated Co-based or Ni-based superalloys. Zhang et al. [10] reduced the hot cracking sensitivity by optimizing process parameters to control the dendrite or grain morphology. Nie et al. [11] found that the dendrite morphology strongly depends on the temperature gradient (G) and the solidification rate (R). The high G/R ratio suppresses the columnar-to-equiaxed transition (CET) and produces columnar dendrites, whereas the low G/R ratio promotes the CET and leads to equiaxed dendrites. The formation of equiaxed dendrites is beneficial for suppressing long-chain-like eutectic phases, thereby reducing the hot cracking sensitivity [12]. Montazeri et al. [13] confirmed that the reduced energy input can reduce residual tensile stress and effectively inhibit the formation of liquefaction cracks. Idowu et al. [14] found that the residual stress and the cracking tendency were increased by reducing the energy input. The above differences indicate that, in order to establish a more universal optimization criterion of process parameters, the internal relationship among alloy composition, process parameters, and microstructure in laser additive manufacturing needs to be further studied. Qi et al. [9] found that the element segregation and the crack sensitivity of laser-cladded Co-based coating can be reduced by introducing the magnetostriction effect through applying the magnetic field. Li et al. [15] introduced ultrasonic vibration during laser cladding and found that the refined dendrites, reduced tensile stress, and suppressed the hot cracks can be obtained. Tomus et al. [16] found that microcracks can be suppressed by reducing the elemental content of manganese and silicon during laser additive manufacturing of Hastelloy X superalloy. However, the microcracks in the LAM of the Hastelloy X alloy cannot be completely eliminated by composition modification. The hot cracks were eliminated by introducing TiC nanoparticles to promote the heterogeneous nucleation during LAM of the Hastelloy X alloy [17]. Montazeri et al. found that [18] the hot isostatic pressing treatment is an effective post-treatment method to eliminate microcracks, but it leads to excessive grain coarsening. In addition, the hot isostatic pressing treatment is powerless to eliminate large-scale solid cracks and surface cracks with lengths of more than 6 μm. Therefore, it does not represent an ideal alternative to mitigate hot cracks and limit their effect on the mechanical behavior of LAM-fabricated superalloys.

Recently, a pulsed-wave (PW) laser modulation process has been proposed to refine the grain structure and inhibit the elemental segregation of various alloys [19,20,21], due to its high cooling rate. In addition, the periodic laser input of the PW laser processing mode results in the periodic melting and solidification of the molten pool, improved geometry, and solidification parameters of the molten pool [22,23]. Our previous work found that, compared with the traditional CW-LAM process, the low average heat input and high cooling rate of PW laser additive manufacturing are conducive to reducing the element segregation and the Laves eutectic phase of nickel-based superalloy [12,19]. This process provides the possibility for controlling the solidification structure and suppressing hot cracking of LAM-fabricated Co-based superalloy. However, the effect of the PW laser additive manufacturing on the dendrite morphology, element segregation, eutectic phase, and hot crack of cobalt-based superalloy is still unclear. The suppression mechanism of hot crack under this process remains to be further clarified.

In this work, the PW laser modulation process is used to control the solidification structure and to suppress the hot crack through changing the molten pool solidification conditions. The effects of CW and PW laser processing modes on the dendrite morphology, element segregation, eutectic phase, and hot crack of the fabricated parts were investigated. The mechanisms of microstructure formation and hot crack suppression were analyzed. This work provides a new method to control the solidification structure and hot cracks of laser additive manufactured Co-based superalloy.

2. Materials and Methods

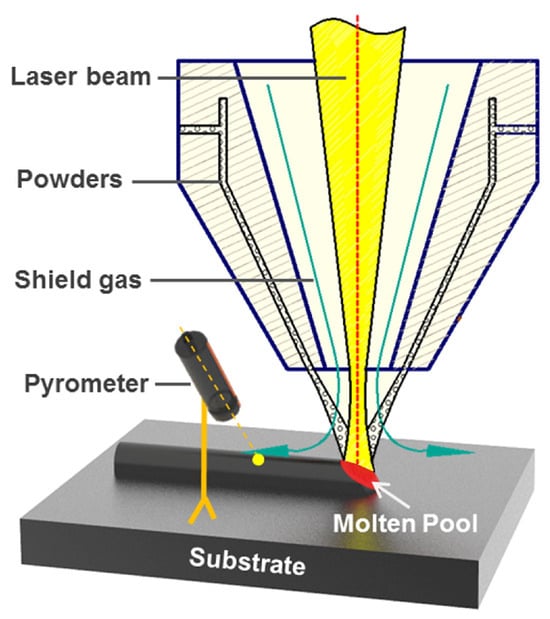

Spherical Co-based superalloy powders (Co-26Cr-11Ni-8W-0.5C) prepared by plasma rotating electrode atomization were used as deposition material. The powders have a nominal composition of 54.5 Co, 26 Cr, 11 Ni, 8 W, and 0.5 C in wt.%. The size of the powders is between 45 and120 μm. A 316L stainless steel plate with dimensions of 90 mm × 90 mm × 10 mm was used as the substrate. Bulk samples were fabricated using LAM with coaxial powder feeding (Figure 1). The rated power of the laser is 4 kW.

Figure 1.

Schematic diagram of the LAM process.

Two types of bulk samples were prepared by two different laser processing modes, CW and PW modes. For CW-LAM, a constant laser power of 600 W was used. For PW laser processing mode, laser energy is modulated to pulse output. The laser waveform is a square wave. The pulsed frequency and duty cycle are 30 Hz and 50%, respectively. The other processing parameters include a peak power of 800 W, an average power of 400 W, a pulse duration of 33.3 ms, a scan speed of 6 mm s−1, a laser spot diameter of 0.5 mm, a lap rate of 50%, and a single-layer lifting amount (layer thickness) of 1 mm. During LAM, argon is used as a protective gas stream.

During LAM, a two-color pyrometer was used to measure the molten pool temperature variation in a noncontact way. The two-color pyrometer measures the temperature by measuring the energy ratio of two spectra. Before measurement, the pyrometer was calibrated according to the ISO/IEC 17025:2017, which can be referred to in the literature [24]. The measuring range of the pyrometer was 600–3300 °C. The time resolution of the pyrometer was 1 ms. The detailed setting parameters of the pyrometer refer to the previously reported literature [12,19]. The samples were mechanically polished and then etched with a solution of 30 mL of HNO3 and 100 mL of HCl. An optical microscope and scanning electron microscope (SEM) were used for the microstructure analysis. The volume fraction of eutectic carbides was estimated using image analysis of SEM pictures after electrolytic polishing with a 10 vol% perchlorate alcohol solution at 20 V for 30 s. The phase composition of the samples was analyzed by SEM-EDS.

3. Results and Discussion

3.1. Microstructure and Hot Cracks

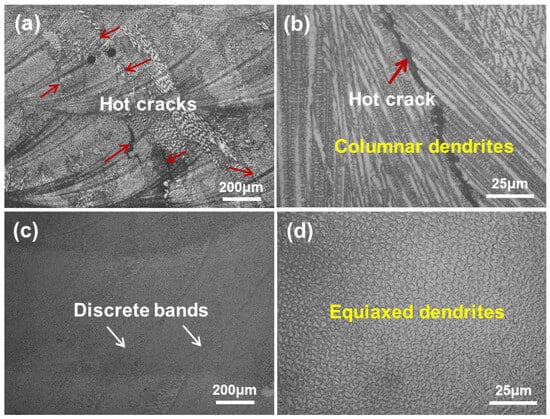

Figure 2 shows the longitudinal cross-sectional morphologies of as-fabricated CW and PW samples. The typical layer-by-layer manufacturing characteristics can be observed, and the white arrow indicates the layer band. In each layer, there are some fuzzy and curved banded structures, which are randomly distributed with uneven spacing. The formation of these banded structures is mainly attributed to the fluctuation of the molten pool caused by the powder feeding airflow or powder during LAM. The CW sample is dominated by columnar dendritic clusters with growth direction deviation. Each dendritic cluster is composed of columnar dendrites with the same growth direction. The average dendrite arm spacing is about 5.8 μm. In addition, there are a large number of microcracks in the deposited layer, especially at the interfaces of adjacent dendritic clusters with large differences in growth directions (Figure 2b). In fact, these interfaces are grain boundaries in nature. During the non-equilibrium rapid solidification of LAM, the element segregation and eutectic phase formation are inevitable. In addition, the rapid heating and cooling of the molten pool lead to high thermal stress in the forming process. High thermal stress and low-melting-point eutectic phase will increase the hot cracking sensitivity and then result in hot cracking [25,26].

Figure 2.

Typical OM images of as-fabricated samples: (a,b) CW and (c,d) PW.

Compared with the CW sample, the PW sample shows some different microstructure characteristics. First, there are a large number of discrete bands in each layer (Figure 2c). These discrete bands represent the fusion boundary between two adjacent pulses. Secondly, the PW sample is dominated by fine equiaxed dendrites. The average diameter of equiaxed dendrites is 3.6 μm (Figure 2d). It is noted that the metallurgical bonding between the discrete interface and the solidified layer is well, and there are no defects such as pores or cracks in the deposited layer.

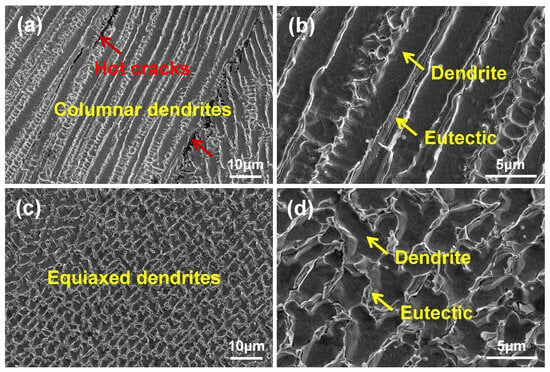

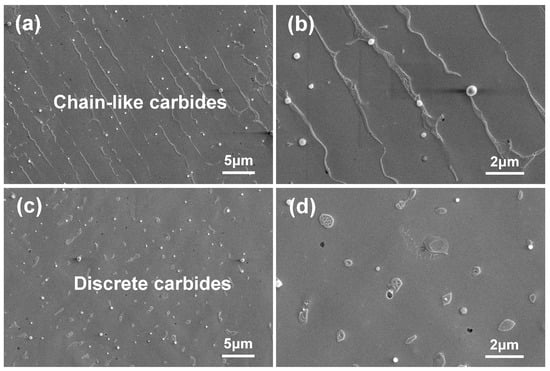

Figure 3 shows typical SEM images of the two samples. Similar to the dendrite morphology in OM images, the CW sample is dominated by columnar dendrites, and there are obvious thermal cracks in the interfaces of adjacent columnar dendrite clusters (Figure 3a). The dendrite cluster is mainly composed of dendrite matrix and interdendritic eutectic. Many chain-like phases are embedded in the eutectic structure (Figure 3b). In fact, these chain-like phases are identified as eutectic phases. For the PW sample, the microstructure is mainly composed of equiaxed dendrites and interdendritic eutectic (Figure 3c). Fine discrete particles are embedded in the eutectic structure (Figure 3d).

Figure 3.

Typical SEM images of the two fabricated samples: (a,b) CW and (c,d) PW.

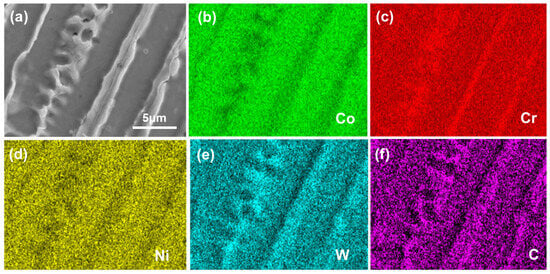

3.2. Element Segregation and Eutectic Phase Formation

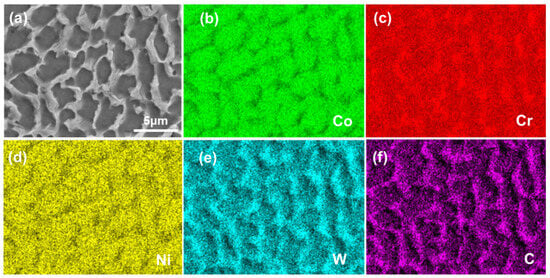

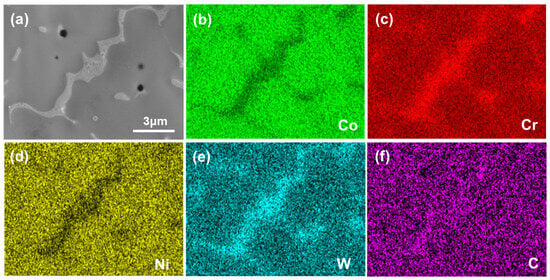

The segregation of as-deposited samples under different processing conditions was studied by SEM-EDS. Figure 4 shows the secondary electron morphology and the corresponding element distribution of the CW sample. The precipitates are rich in Cr, W, and C and have high brightness, while the dendrite core lacks these elements. According to its composition and morphological characteristics, such long chain-like precipitates are generally considered as eutectic phases [6]. It is noted that the area around the eutectic phase is also rich in Cr and W, and the brightness is slightly weak, which indicates that the interdendritic eutectic region is also rich in Cr and W compared with the matrix.

Figure 4.

The secondary electron morphology (a) and the corresponding element distribution of the CW sample (b–f).

Figure 5 shows the secondary electron morphology and the corresponding element distribution of the PW sample. The PW sample is mainly composed of equiaxed dendrites, and the eutectic region is poor in CO and Ni elements but rich in Cr, W, and C elements. Compared with the linear element distribution in the CW sample, the elements in the PW sample are distributed in a network-like pattern, which is beneficial to the homogenization of elements. The above results show that the dendrite growth mode has an important influence on the segregation mode of the as-deposited samples.

Figure 5.

The secondary electron morphology (a) and the corresponding element distribution of the PW sample (b–f).

In order to further quantitatively study the composition and quantity of the eutectic phase, the sample was electropolished to expose the eutectic phase. Figure 6 shows the typical SEM morphology of the CW and the PW samples after electropolishing. In the CW sample, most particles are linearly distributed (Figure 6a,b). In contrast, fine and discrete particles were observed in the PW sample (Figure 6c,d). In order to further understand the relationship between particles and processing technology, the volume fraction of particles in the sample was estimated by SEM image analysis. The particle volume fraction of the CW sample was about 5.88% ± 1.12%, which was significantly higher than that of the PW sample (4.12% ± 0.96%).

Figure 6.

Typical morphology of eutectic phase in (a,b) the CW and (c,d) the PW samples after electropolishing.

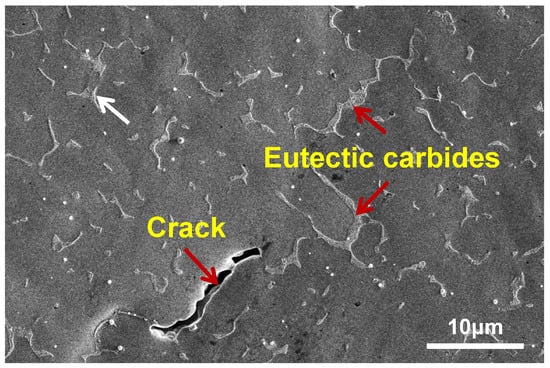

Figure 7 shows the typical SEM morphology of the CW sample after electropolishing. Two regions with different contrast can be observed. The difference in contrast is due to the different orientation of dendrites. Coarse and irregular chain-like eutectic phases can be observed at the interface (grain boundary), while irregular particles with small size can be observed at other zones, indicating the more severe segregation and coarser eutectic phase at the interface than at the interdendritic regions. In addition, cracks can be observed in the local region of the interface due to the shedding of the chain-like eutectic phase. Near the crack, there is usually severe element segregation and liquid film. Although eutectic structure exists in the grain boundary and interdendritic region of the sample, the liquefaction cracking behavior tends to occur at the grain boundary. This is because the orientation difference angle on both sides of the grain boundary is large, while there is no or very small orientation difference angle on both sides of the branch grain boundary. The larger difference in the angle of the grain orientation results in a greater difference in the solidification shrinkage degree between adjacent grains, which aggravates the cracking of the liquid film [27].

Figure 7.

The typical SEM morphology of the CW sample after electropolishing.

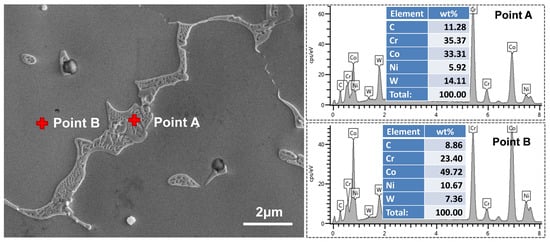

Figure 8 shows the SEM-EDS point analysis results of the coarse and long-chain-like phase. The results show that the content of Cr, W, CO, and Ni in long-chain particles is 35.37%, 14.11%, 33.31%, and 5.92%, respectively. It can be seen that the long-chain-like particles are rich in Cr and W and poor in Co and Ni. In contrast, the Cr and W in the matrix are 23.40% and 7.36%, respectively, which are significantly lower than those of long-chain-like particles. According to its composition and morphological characteristics, this long-chain particle is usually identified as M23C6 phase, which is also confirmed in reference [6].

Figure 8.

The SEM-EDS point analysis results of the coarse and long-chain-like phase.

Figure 9 shows the secondary electron morphology and the corresponding element distribution of the CW sample after electron microscope polishing. After electropolishing, coarse chain particles are exposed. The precipitates are rich in Cr, W, and C and have high brightness, while the dendrite core lacks these elements. According to its composition and morphological characteristics, such long-chain-like particles are considered a eutectic phase.

Figure 9.

The secondary electron morphology (a) and the corresponding element distribution of the CW sample (b–f) after electropolishing.

3.3. Thermal Behavior of Molten Pool

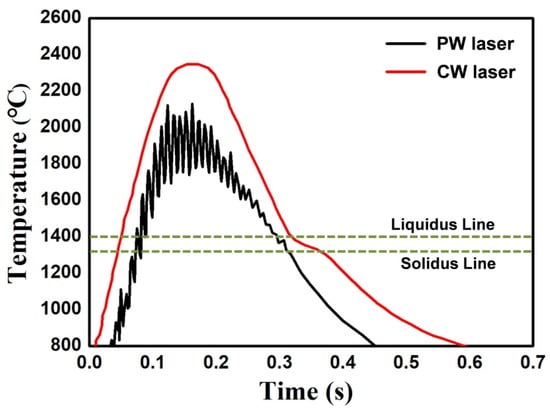

Figure 10 shows the temperature variation curves of the molten pool under two different laser processing modes. During CW-LAM, the temperature rapidly rises to the peak temperature of 2362 °C and then rapidly cools to below the melting point. The temperature curve of the molten pool is relatively smooth. Compared with the CW-LAM, the molten pool temperature under PW laser processing mode exhibits periodic oscillation due to the periodic laser energy input. It is noted that the molten pool temperature curve of PW laser processing mode is enveloped by that of CW-LAM, indicating a shorter thermal cycle and faster cooling under PW laser processing mode.

Figure 10.

The temperature variation curves of the molten pool under different laser modes.

In order to study the thermal parameter changes of the molten pool during solidification, the solidification parameters between the liquidus and solidus lines are calculated and analyzed. For CW-LAM, the cooling rate during solidification is about 3.6 × 103 °C/s, and the solidification time is about 50 ms. During the molten pool solidification process of the PW laser processing mode, the average cooling rate and the solidification time are ~18 ms and ~2.8 × 104 °C/s, respectively. It is noted that the cooling rate of the PW laser processing mode is significantly higher than that of the CW-LAM, and the solidification time is about one third of that of CW-LAM.

3.4. Molten Pool Solidification Characteristics

During CW-LAM, the moving molten pool dissipates heat through the substrate or the previous layer, resulting in a curved molten pool geometry. When the laser moves forward, the trailing edge of the molten pool solidifies along the laser scanning direction. During the solidification process, the higher temperature gradient and slower cooling rate in the molten pool lead to the growth of coarse columnar dendrites in CW-LAM. On the one hand, the high energy input of CW-LAM leads to the curved molten pool geometry and multi-directional heat flow, which are beneficial to the multidirectional development of dendritic clusters and the formation of grains with different orientations. In addition, in the CW laser processing mode, the disturbance of the molten pool boundary caused by the carrier gas/protective gas flow and powder feeding is also conducive to the formation of multi-directional dendritic clusters. Therefore, coarse columnar crystals and long-chain-like continuous grain boundaries are formed in the CW sample.

3.5. Refinement of Dendritic Microstructure

The PW laser processing mode refined the dendritic structure and promoted the formation of equiaxed grains, which is due to the significantly changed solidification conditions of the molten pool. Firstly, the cooling rate of PW laser processing mode is ~2.8 × 104 °C/s. The enhanced cooling rate leads to greater undercooling in the solidification pool, which reduces the critical nucleation radius of γ-dendrites, thereby increasing their nucleation rate and number of nuclei. In addition, in the laser-off stage of the PW laser processing mode, the temperature gradient (G) at the molten pool interface decreases rapidly, while the solidification rate (R) increases with the increase in solidification time, resulting in the rapid decrease in the G/R ratio [22]. At the low pulse frequency of PW, the longer laser-off time promotes the behavior of CET, because it can reduce the G/R value more thoroughly, and the undercooling of the molten pool is also higher. Therefore, a large number of equiaxed dendrites were formed in the PW sample.

3.6. Suppression of Element Segregation and Chain-like Eutectic Phase

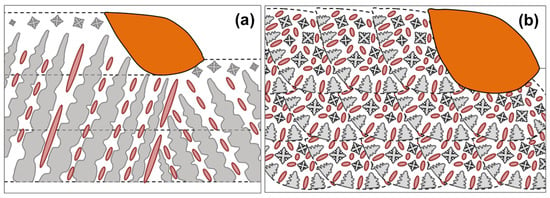

During the solidification process of cobalt-based superalloys, a large number of atoms, such as Cr and W, will migrate from the solid phase to the liquid phase through the solid–liquid interface, because the solid solubility of Cr and W in the liquid phase is significantly higher than that in the solid phase. Therefore, the content of Cr and W in the liquid phase will increase accordingly. With the advance of the solidification process, the Cr and W element concentration in the liquid phase gradually approaches the eutectic point, and the liquid phase will undergo a eutectic reaction and transform into the γ phase and the M23C6 eutectic phase. The formation of the eutectic phase is closely related to the solidification conditions. The morphology of the eutectic phase largely depends on the dendritic growth mode. In the CW laser processing mode, due to the relatively low cooling rate, the columnar dendrite growth results in a relatively large and continuous interdendritic region. Therefore, the columnar dendrite growth mode tends to form a chain-like eutectic phase (Figure 11a). In contrast, in the PW laser processing mode, the molten pool cooling rate is very high, which results in fine and equiaxed dendrite growth. Under this growth mode, it is conducive to the connection between dendrites, thus dividing the liquid phase into many small and isolated regions to form fine and discrete eutectic phases (Figure 11b).

Figure 11.

Schematic diagram of the microstructure evolution under two laser processing modes: (a) CW laser processing mode and (b) PW laser processing mode.

The size and number of eutectic phases are mainly affected by solidification conditions. In the PW laser processing mode, the molten pool cooling rate is significantly increased, and the solidification time is significantly shortened, which has a significant impact on the characteristics of the eutectic phase. Firstly, PW laser processing mode significantly improves the cooling rate of the molten pool, which leads to a significant reduction in the redistribution time of Cr and W elements, thus effectively reducing the segregation of Cr and W elements. Secondly, the significant increase in solidification rate enhances the ability to capture Cr and W atoms, effectively inhibits the continuous accumulation of Cr and W in the liquid phase, and thus reduces the number of M23C6 eutectic phases. Therefore, in the PW laser processing mode, the size and number of eutectic phases show a significant reduction trend.

3.7. Prevention of Hot Cracking

The molten pool solidification process in LAM is characterized by a high temperature gradient, a high cooling rate, and a cyclic heating–cooling effect, which usually leads to serious element segregation, a chain eutectic phase, and a high level of thermal stress [7,26]. In this work, the generation of hot cracks is mainly attributed to the large thermal stress caused by high temperature gradients and high cooling rates, and the low-melting-point eutectic phase caused by interdendritic element segregation. When the temperature reaches the solid–liquid two-phase region, the continuous liquid phase film formed at the grain boundary and chain-like eutectic phase cracks under thermal stress. Although the low-melting-point eutectic phases exist at the grain boundary and also at the interdendritic region, the liquefaction cracking behavior is concentrated at the grain boundary. This is because the orientation angle difference on both sides of the grain boundary is large, while there are no or very small differences in orientation angles on either side of the interdendrites. The larger the grain boundary orientation difference angle is, the greater the difference of solidification shrinkage degree between adjacent grains is, and it is easier to aggravate the cracking of the liquid film.

In this work, the cooling rate of the PW sample is significantly higher than that of the CW sample, which may improve the hot crack sensitivity. However, the fine equiaxed dendritic structure and discrete eutectic phase reduce the hot crack sensitivity because the hot crack initiation and propagation are inhibited under this microstructure feature [11,28]. In addition, Zou et al. [29] found that the PW laser processing mode reduces the thermal stress level of the sample due to its periodic melting and solidification of the molten pool. Therefore, the discrete eutectic phase and the low thermal stress level of the PW sample reduce its hot crack sensitivity. In the CW sample, the coarse columnar dendrite structure, the continuously distributed low-melting-point eutectic phase, and the high thermal stress level are more likely to initiate and expand hot cracks [11,30]. Based on the above results, we propose that, if the laser modulation parameters are selected to achieve the high cooling rate and induce the periodic melting and solidification of the molten pool, the fine equiaxed dendrites, the discrete eutectic phase, and the low thermal stress level can be obtained to reduce the hot cracking sensitivity of the LAM-fabricated part.

4. Conclusions

Hot cracking has been a long-term challenge for laser additive manufacturing of superalloys. In this work, a PW laser modulation process was employed to control the solidification microstructure and reduce the hot cracking susceptibility of laser additive manufactured cobalt-based superalloy. The effects of CW and PW laser processing modes on the dendrite morphology, element segregation, eutectic phase, and hot cracking of fabricated Co-based superalloys were investigated. The main conclusions are as follows:

- The CW sample is composed of coarse columnar dendrite and interdendritic chain-like carbide eutectic. In addition, there are a lot of hot cracks along the grain boundary. The relatively low cooling rate of the molten pool in the CW laser processing mode lead to columnar dendrite growth, severe element segregation, and eutectic carbide formation, which increase the hot cracking sensitivity.

- Compared with the CW laser processing mode, the PW laser processing mode significantly changed the solidification conditions of the molten pool, induced periodic melting and solidification of the molten pool, improved the cooling rate and shortened the solidification time.

- The refined dendritic structure, inhibited element segregation, and fine and discrete eutectic phase were obtained to successfully avoid the hot crack under the PW laser processing mode, which is due to the significant changes in solidification conditions.

- The molten pool solidification mode can be modified, and the molten pool cooling rate can be improved by the reasonable PW laser modulation. Under this situation, the fine equiaxed dendrites, the discrete eutectic phase, and the reduced thermal stress level can be simultaneously achieved to reduce the hot cracking sensitivity of the LAM- fabricated part.

Author Contributions

Conceptualization, X.L. and H.X.; methodology, X.L.; validation, X.L. and W.X.; formal analysis, X.L. and J.Z.; investigation, W.X., J.Z. and H.X.; resources, H.X.; data curation, J.Z. and K.H.; writing—original draft preparation, X.L. and X.X.; writing—review and editing, X.X., H.X., and K.H.; supervision, K.H.; project administration, H.X.; funding acquisition, X.X. and H.X. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (grant Nos. 5217070447 and 52001065), the National Key R&D Program of China (grant No. 2023YFB2504703), the Guangdong Basic and Applied Basic Research Foundation [Nos. 2024A1515030147, 2023A1515140190, and 2022A1515140068], the Scientific Research Project of Education Department of Guangdong Province [2023ZDZX3031], and the Hunan Provincial Natural Science Foundation of China [Nos. 2021JJ30146 and 2023JJ30157].

Data Availability Statement

Data are contained within the article.

Acknowledgments

We acknowledge Man Chen for his help in data analysis.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gu, D.; Shi, X.; Poprawe, R.; Bourell, D.L.; Setchi, R.; Zhu, J. Material-structure-performance integrated laser-metal additive manufacturing. Science 2021, 372, eabg1487. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, M.; Rathee, S.; Patel, V.; Kumar, A.; Koppad, P.G. A review of various materials for additive manufacturing: Recent trends and processing issues. J. Mater. Res. Technol. 2022, 21, 2612–2641. [Google Scholar] [CrossRef]

- Wei, Q.; Xie, Y.; Teng, Q.; Shen, M.; Sun, S.; Cai, C. Crack Types, Mechanisms, and Suppression Methods during High-energy Beam Additive Manufacturing of Nickel-based Superalloys: A Review. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100055. [Google Scholar] [CrossRef]

- Huang, D.; Dong, Y.; Chen, H.; Zhou, Y.; Zhang, M.X.; Yan, M. Effects of processing parameters on a β-solidifying TiAl alloy fabricated by laser-based additive manufacturing. Microstructures 2022, 2, 2022019. [Google Scholar] [CrossRef]

- Yao, Z.; Bao, L.; Yang, M.; Chen, Y.; He, M.; Yi, J.; Yang, X.; Yang, T.; Zhao, Y.; Wang, C.; et al. Thermally stable strong texture in additively manufactured cobalt-based superalloys. Scr. Mater. 2024, 242, 115942. [Google Scholar] [CrossRef]

- Sun, G.; Liu, C.; Song, L.; Mazumder, J. Microstructure and Wear Behavior of Laser-Aided Direct Metal Deposited Co-285 and Co-285 + WC Coatings. Met. Mater. Trans. A 2010, 41, 1592–1603. [Google Scholar] [CrossRef][Green Version]

- Wu, Y.; Sun, B.; Chen, B.; Chen, P.; Yan, T.; Zhang, X.; Huang, C.; Liu, W. Cracking mechanism of GH5188 alloy during laser powder bed fusion additive manufacturing. Mater. Charact. 2024, 207, 113548. [Google Scholar] [CrossRef]

- Cui, H.; Tan, Y.; Ning, L.; Bai, R.; You, X.; Cui, C.; Li, P. Microstructure control and hot cracking behavior of the new Ni-Co based superalloy prepared by electron beam smelting layered solidification technology. J. Mater. Sci. Technol. 2024, 175, 55–71. [Google Scholar] [CrossRef]

- Qi, K.; Yang, Y.; Sun, R.; Hu, G.; Lu, X.; Li, J.; Liang, W.; Jin, K.; Xiong, L. Effect of magnetic field on crack control of Co-based alloy laser cladding. Opt. Laser Technol. 2021, 141, 107129. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, H.; Xu, L.; Xu, J.; Ren, X.; Chen, X. Cracking mechanism and susceptibility of laser melting deposited Inconel 738 superalloy. Mater. Des. 2019, 183, 108105. [Google Scholar] [CrossRef]

- Nie, P.; Ojo, O.; Li, Z. Numerical modeling of microstructure evolution during laser additive manufacturing of a nickel-based superalloy. Acta Mater. 2014, 77, 85–95. [Google Scholar] [CrossRef]

- Xiao, H.; Li, S.; Han, X.; Mazumder, J.; Song, L. Laves phase control of Inconel 718 alloy using quasi-continuous-wave laser additive manufacturing. Mater. Des. 2017, 122, 330–339. [Google Scholar] [CrossRef]

- Montazeri, M.; Ghaini, F. The liquation cracking behavior of IN738LC superalloy during low power Nd:YAG pulsed laser welding. Mater. Charact. 2012, 67, 65–73. [Google Scholar] [CrossRef]

- Idowu, O.; Ojo, O.; Chaturvedi, M. Effect of heat input on heat affected zone cracking in laser welded ATI Allvac 718Plus superalloy. Mater. Sci. Eng. A 2006, 454–455, 389–397. [Google Scholar] [CrossRef]

- Li, M.; Zhang, Q.; Han, B.; Song, L.; Cui, G.; Yang, J.; Li, J. Microstructure and property of Ni/WC/La2O3 coatings by ultrasonic vibration-assisted laser cladding treatment. Opt. Lasers Eng. 2020, 125, 105848. [Google Scholar] [CrossRef]

- Tomus, D.; Jarvis, T.; Wu, X.; Mei, J.; Rometsch, P.; Herny, E.; Rideau, J.-F.; Vaillant, S. Controlling the Microstructure of Hastelloy-X Components Manufactured by Selective Laser Melting. Phys. Procedia 2013, 41, 816–820. [Google Scholar] [CrossRef]

- Han, Q.; Gu, Y.; Setchi, R.; Lacan, F.; Johnston, R.; Evans, S.L.; Yang, S. Additive manufacturing of high-strength crack-free Ni-based Hastelloy X superalloy. Addit. Manuf. 2019, 30, 100919. [Google Scholar] [CrossRef]

- Han, Q.; Mertens, R.; Montero-Sistiaga, M.L.; Yang, S.; Setchi, R.; Vanmeensel, K.; Van Hooreweder, B.; Evans, S.L.; Fan, H. Laser powder bed fusion of Hastelloy X: Effects of hot isostatic pressing and the hot cracking mechanism. Mater. Sci. Eng. A 2018, 732, 228–239. [Google Scholar] [CrossRef]

- Xiao, H.; Xie, P.; Cheng, M.; Song, L. Enhancing mechanical properties of quasi-continuous-wave laser additive manufactured Inconel 718 through controlling the niobium-rich precipitates. Addit. Manuf. 2020, 34, 101278. [Google Scholar] [CrossRef]

- Yang, K.; Wang, Z.D.; Chen, M.Z.; Lan, H.F.; Sun, G.F.; Ni, Z.H. Effect of pulse frequency on the morphology, microstructure, and corrosion resistance of high-nitrogen steel prepared by laser directed energy deposition. Surf. Coat. Technol. 2021, 421, 127450. [Google Scholar] [CrossRef]

- Chen, M.; Yang, K.; Wang, Z.; Wang, S.; Lu, Y.; Ni, Z.; Sun, G. Quasi-continuous-wave laser directed energy deposition on inclined NV E690 steel plates: Melt pool and temperature evolution. Surf. Coat. Technol. 2022, 437, 128344. [Google Scholar] [CrossRef]

- Xiao, H.; Li, Y.; Xiao, W.; Liu, C.; Xie, P.; Song, L. Grain structure and texture control of additive manufactured nickel-based superalloy using quasi-continuous-wave laser directed energy deposition. Addit. Manuf. 2023, 69, 103520. [Google Scholar] [CrossRef]

- Han, B.; Li, R.; Pi, Q.; Shi, Y.; Qi, H.; Sun, G.; Bi, K. Deposit characteristics, morphology and microstructure regulation of single-track nickel-based alloy using quasi-continuous-wave laser direct energy deposition. Surf. Coat. Technol. 2024, 478, 130481. [Google Scholar] [CrossRef]

- Carcel, B.; Sampedro, J.; Perez, I.; Fernandez, E.; Ramos, J.A. Improved laser metal deposition (LMD) of nickel base superalloys by pyrometry process control. In Proceedings of the XVIII International Symposium on Gas Flow, Chemical Lasers, and High-Power Lasers, Sofia, Bulgaria, 30 August–3 September 2010; Dreischuh, T., Atanasov, P.A., Sabotinov, N.V., Eds.; SPIE: Bellingham, WA, USA, 2010; p. 775123. [Google Scholar]

- Mostafaei, A.; Ghiaasiaan, R.; Ho, I.-T.; Strayer, S.; Chang, K.-C.; Shamsaei, N.; Shao, S.; Paul, S.; Yeh, A.-C.; Tin, S.; et al. Additive manufacturing of nickel-based superalloys: A state-of-the-art review on process-structure-defect-property relationship. Prog. Mater. Sci. 2023, 136, 101108. [Google Scholar] [CrossRef]

- Guo, C.; Li, G.; Li, S.; Hu, X.; Lu, H.; Li, X.; Xu, Z.; Chen, Y.; Li, Q.; Lu, J.; et al. Additive manufacturing of Ni-based superalloys: Residual stress, mechanisms of crack formation and strategies for crack inhibition. Nano Mater. Sci. 2023, 5, 53–77. [Google Scholar] [CrossRef]

- Zhou, Z.; Huang, L.; Shang, Y.; Li, Y.; Jiang, L.; Lei, Q. Causes analysis on cracks in nickel-based single crystal superalloy fabricated by laser powder deposition additive manufacturing. Mater. Des. 2018, 160, 1238–1249. [Google Scholar] [CrossRef]

- Chen, Y.; Lu, F.; Zhang, K.; Nie, P.; Hosseini, S.R.E.; Feng, K.; Li, Z. Dendritic microstructure and hot cracking of laser additive manufactured Inconel 718 under improved base cooling. J. Alloys Compd. 2016, 670, 312–321. [Google Scholar] [CrossRef]

- Zou, X.; Chang, T.; Yan, Z.; Zhao, Z.S.; Pan, Y.; Liu, W.; Song, L. Control of thermal strain and residual stress in pulsed-wave direct laser deposition. Opt. Laser Technol. 2023, 163, 109386. [Google Scholar] [CrossRef]

- Song, W.; Yang, J.; Liang, J.; Lu, N.; Zhou, Y.; Sun, X.; Li, J. A new approach to design advanced superalloys for additive manufacturing. Addit. Manuf. 2024, 84, 104098. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).