The Effects of Thermo-Mechanical Treatments on Microstructure and High-Temperature Mechanical Properties of a Nickel-Based Superalloy

Abstract

1. Introduction

2. Experimental Procedure

3. Results and Discussion

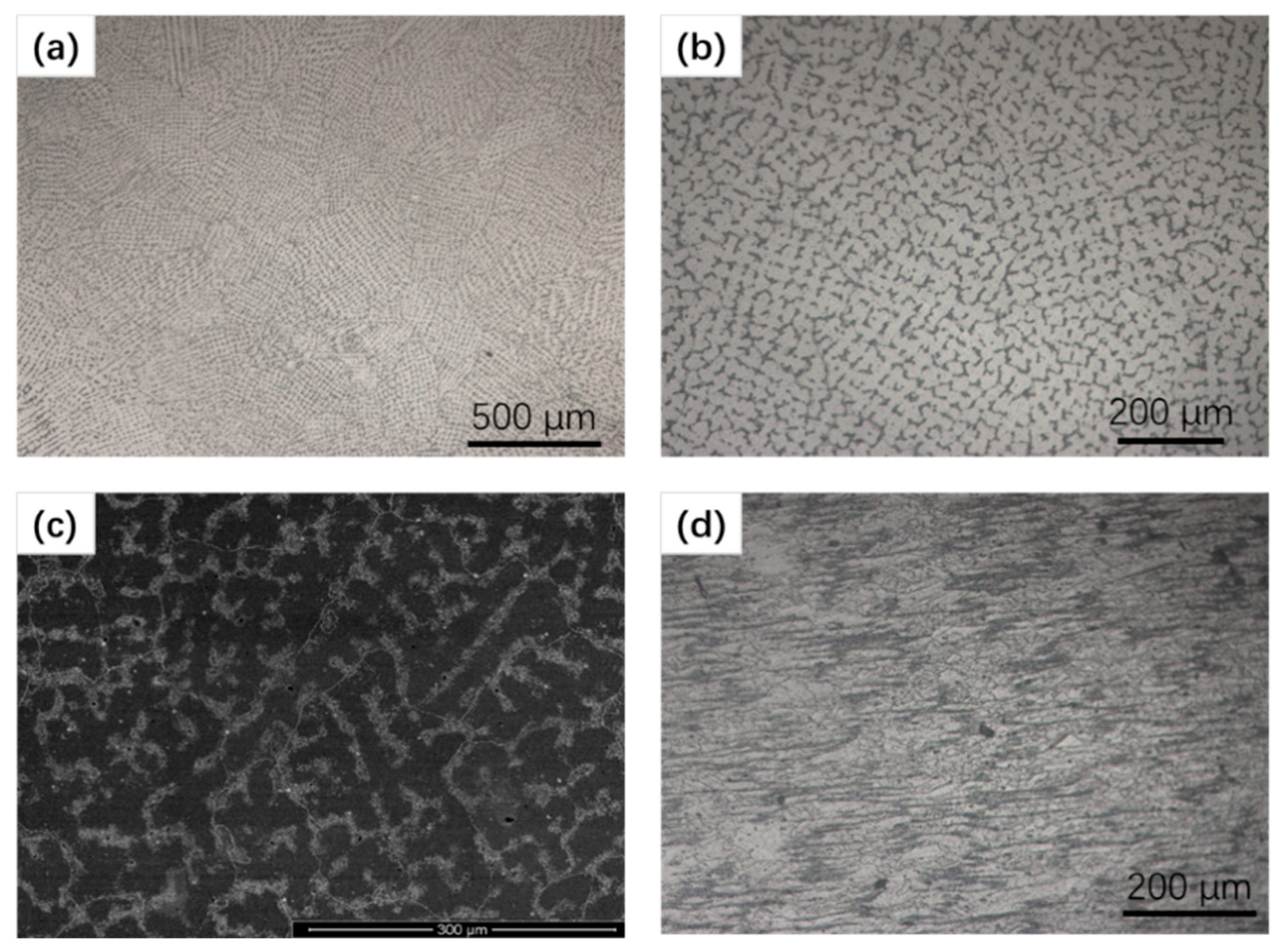

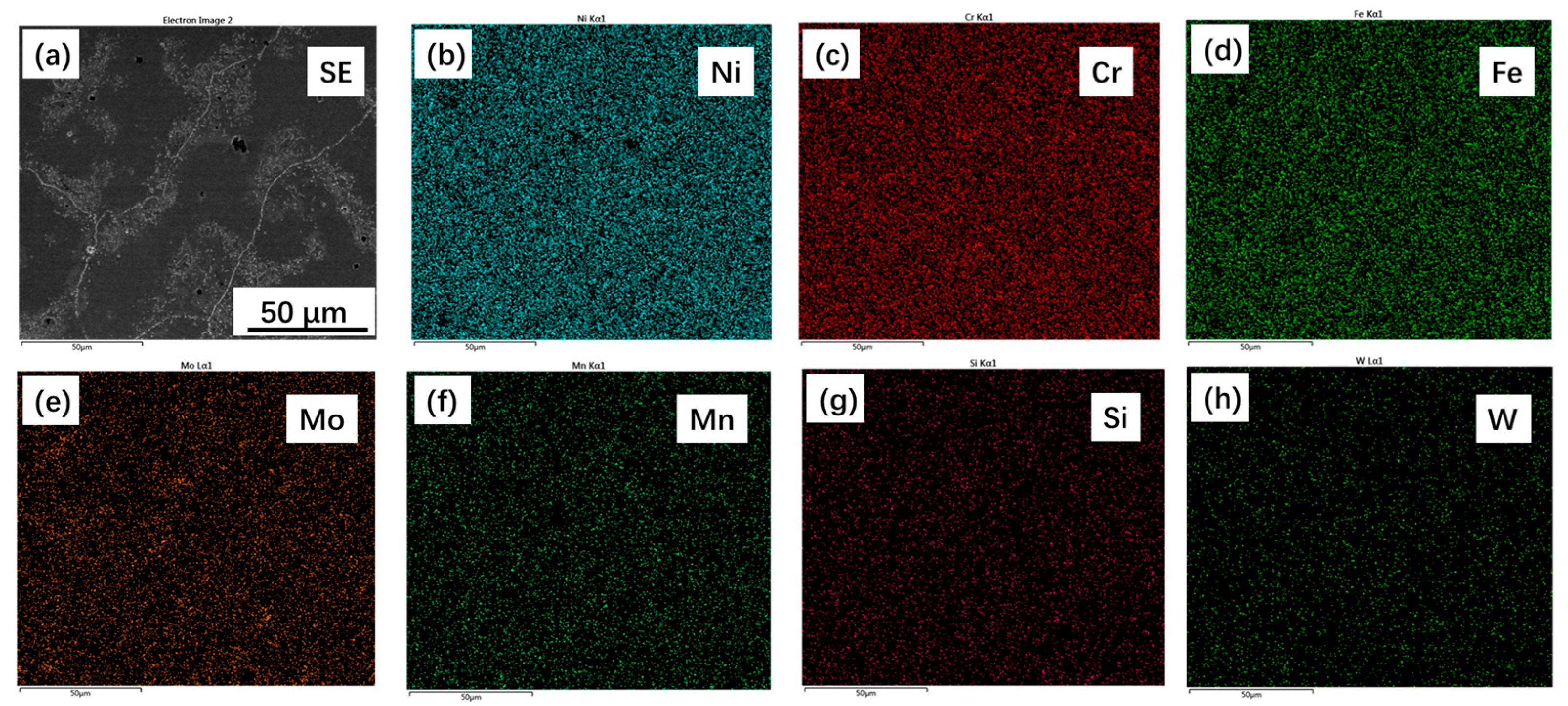

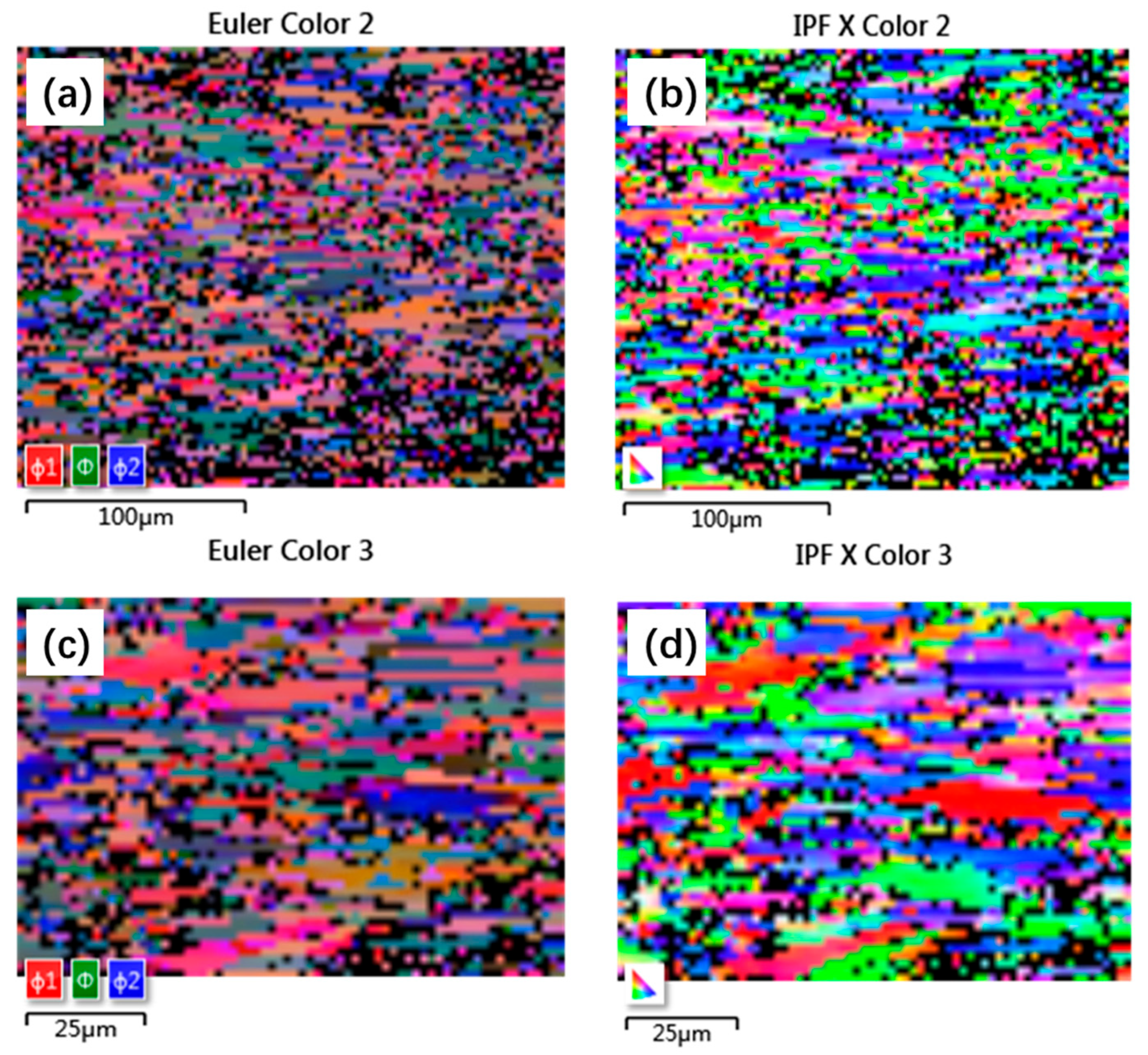

3.1. Microstructure of As-Cast Specimens

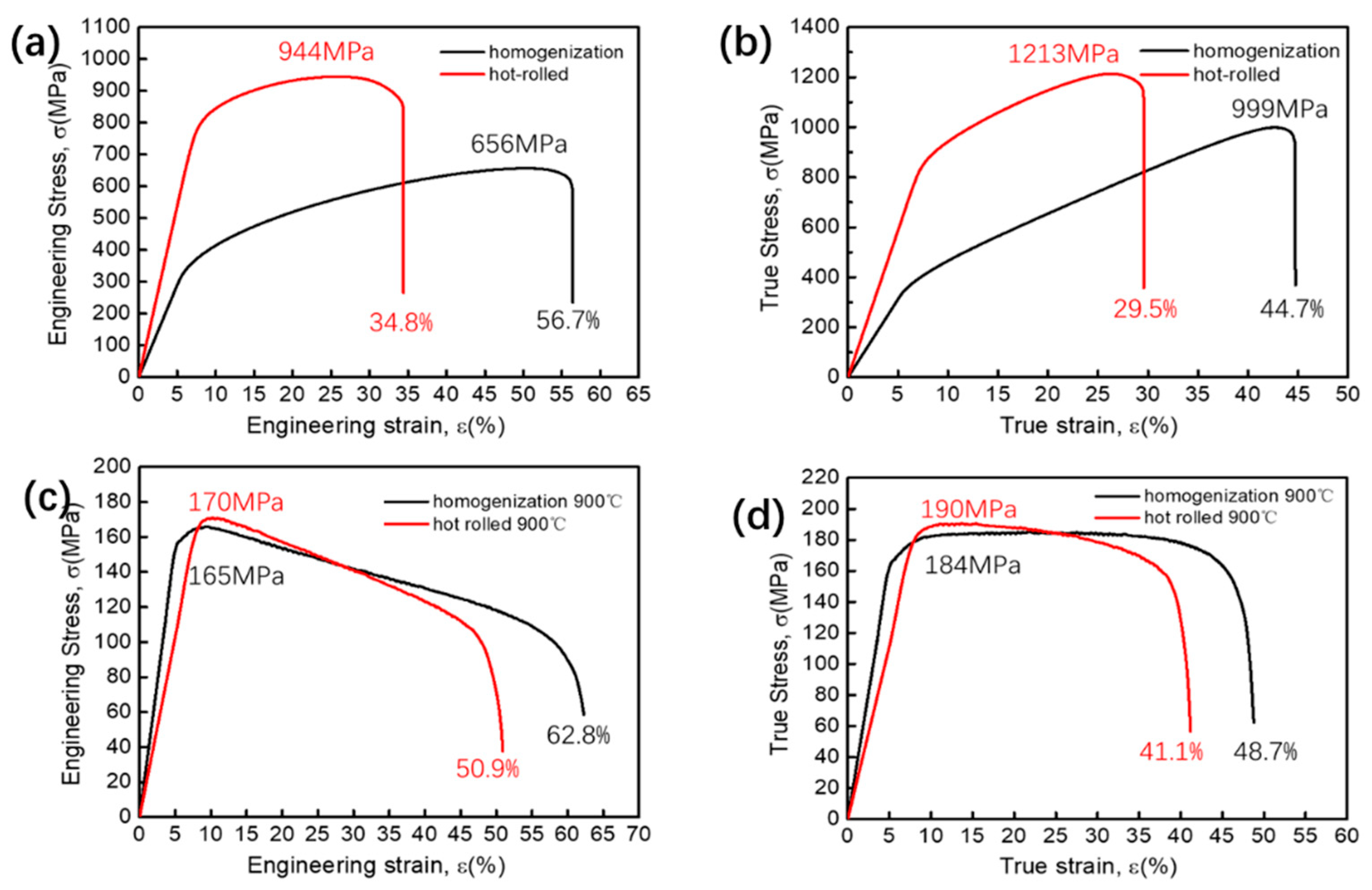

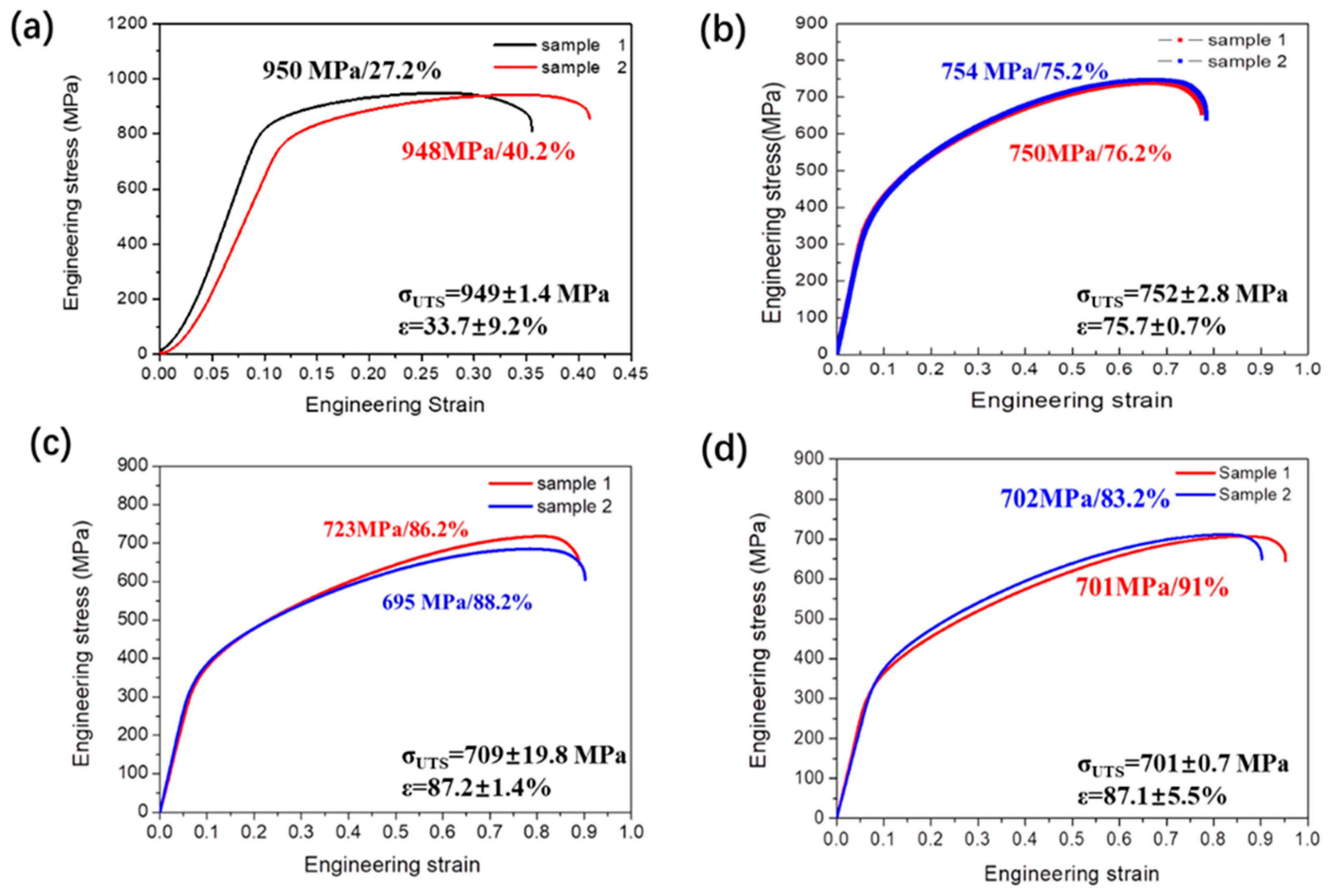

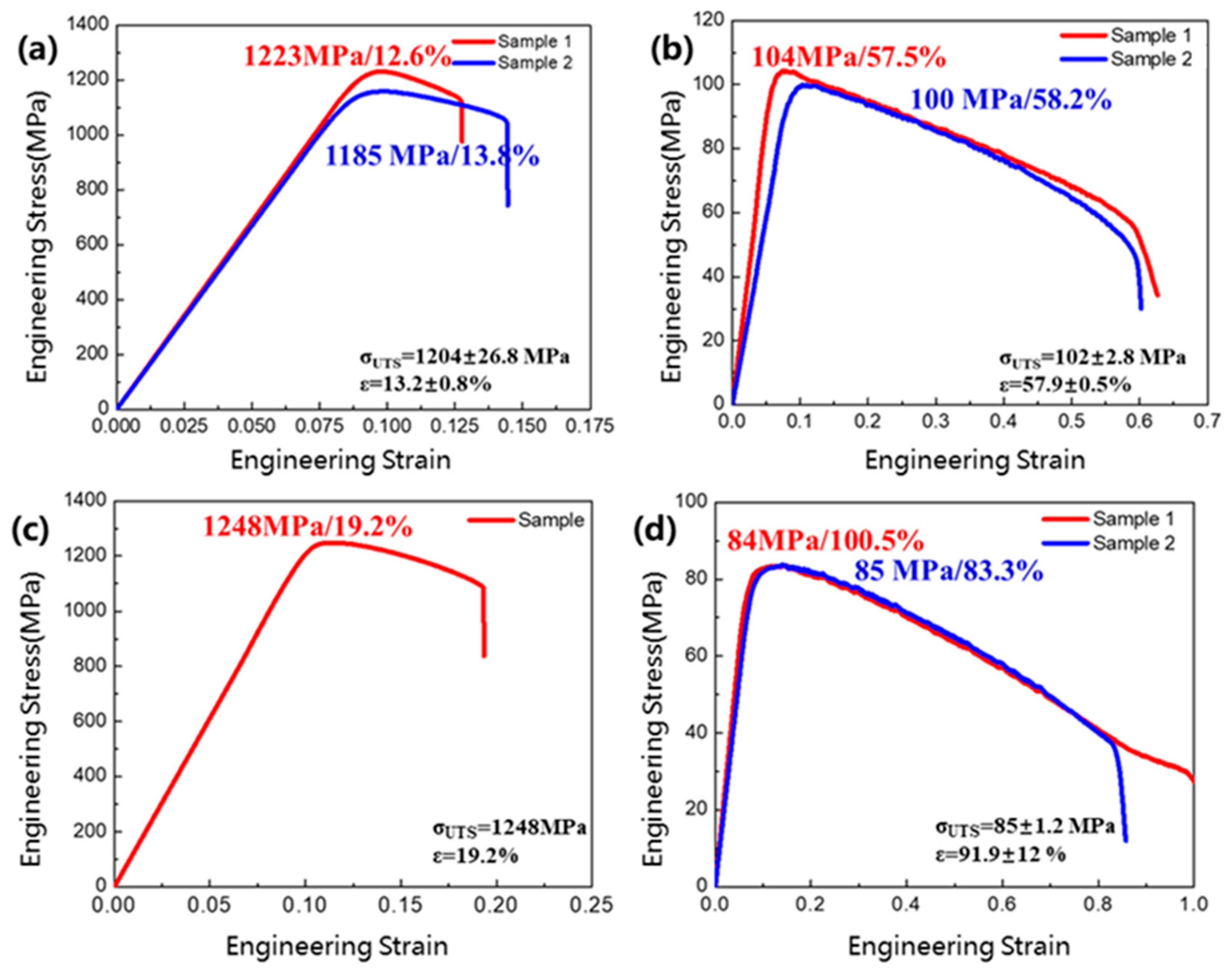

3.2. Influences of Hot Rolling on the Mechanical Properties

3.3. The Effect of Heat Treatment on the Hot-Rolled Samples’ Strength

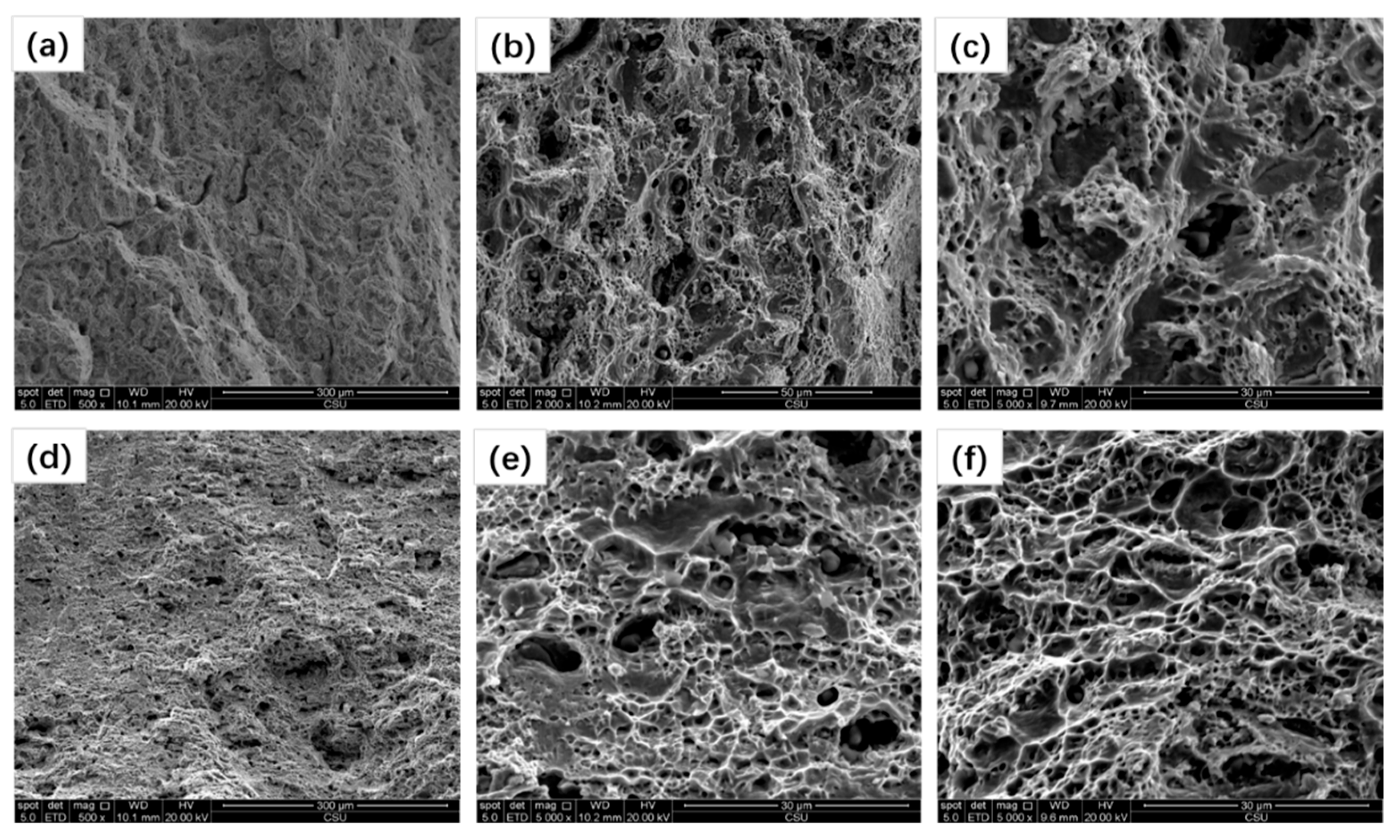

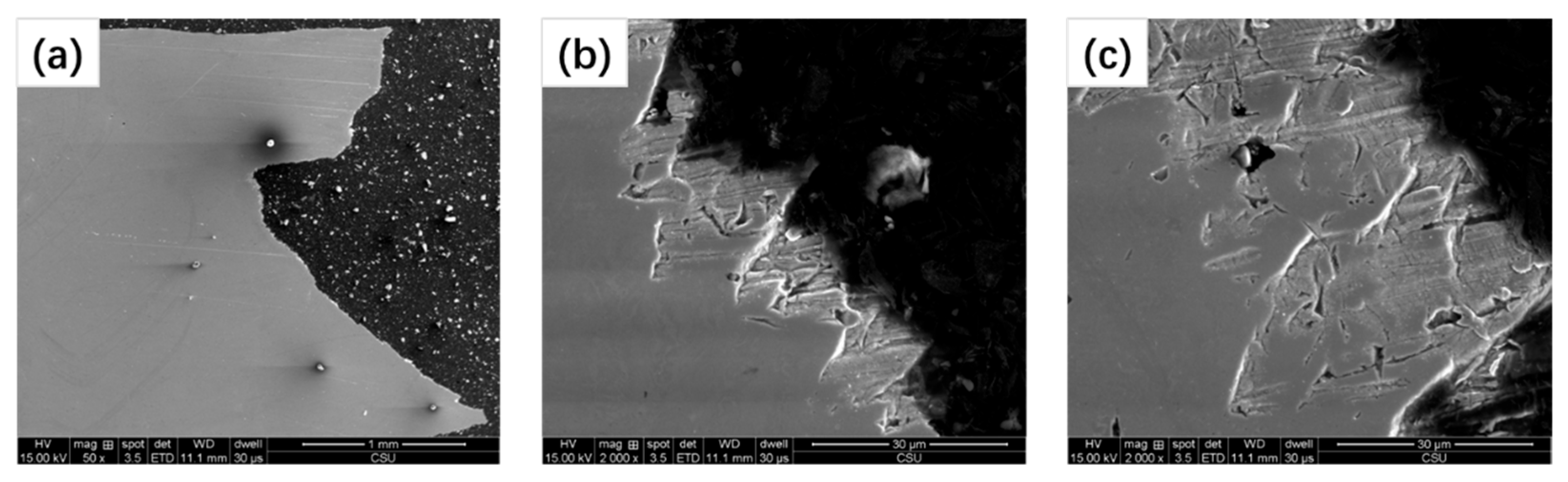

3.4. Fracture Morphology Analysis

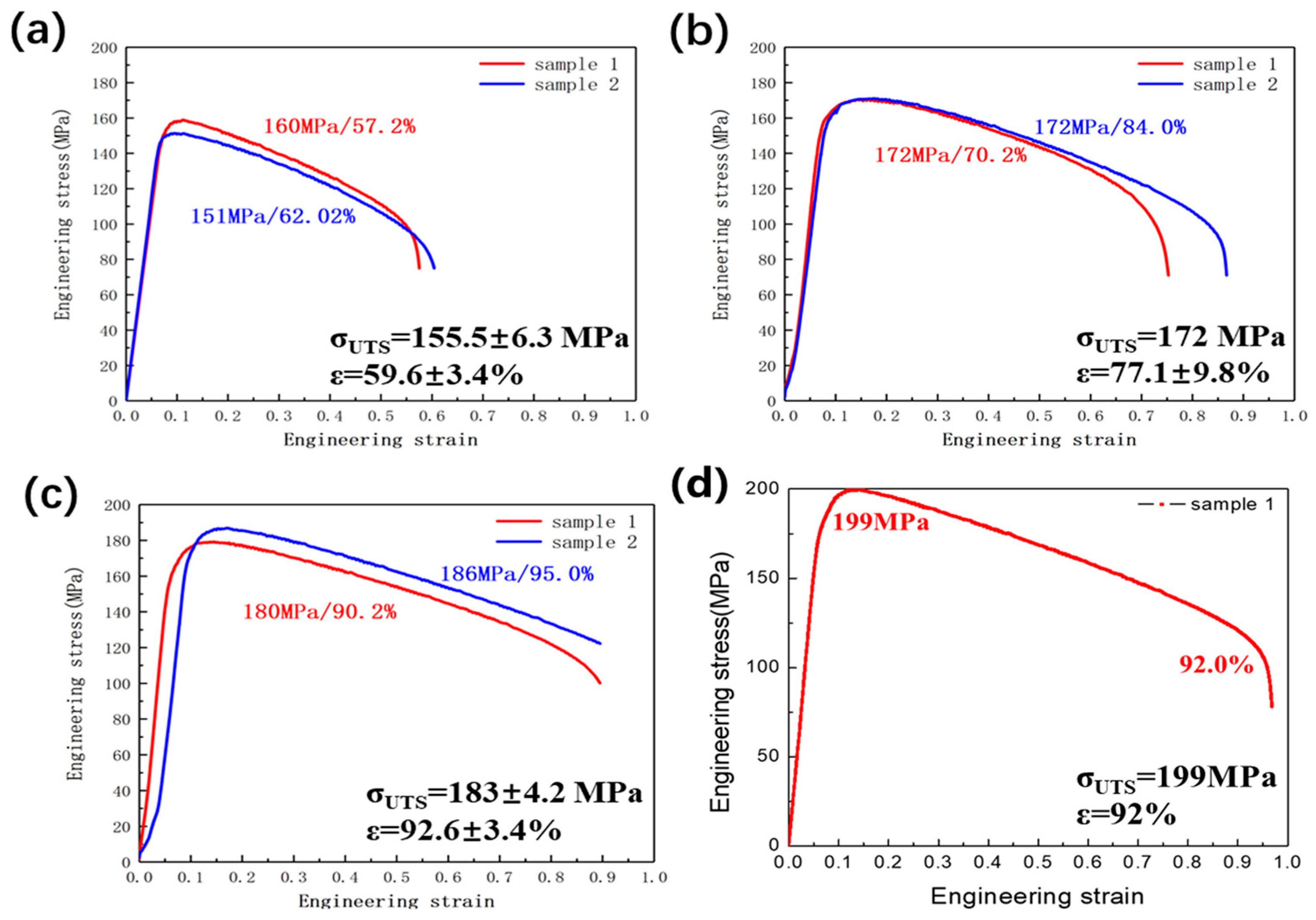

3.5. Influences of Cold Rolling on the Mechanical Properties

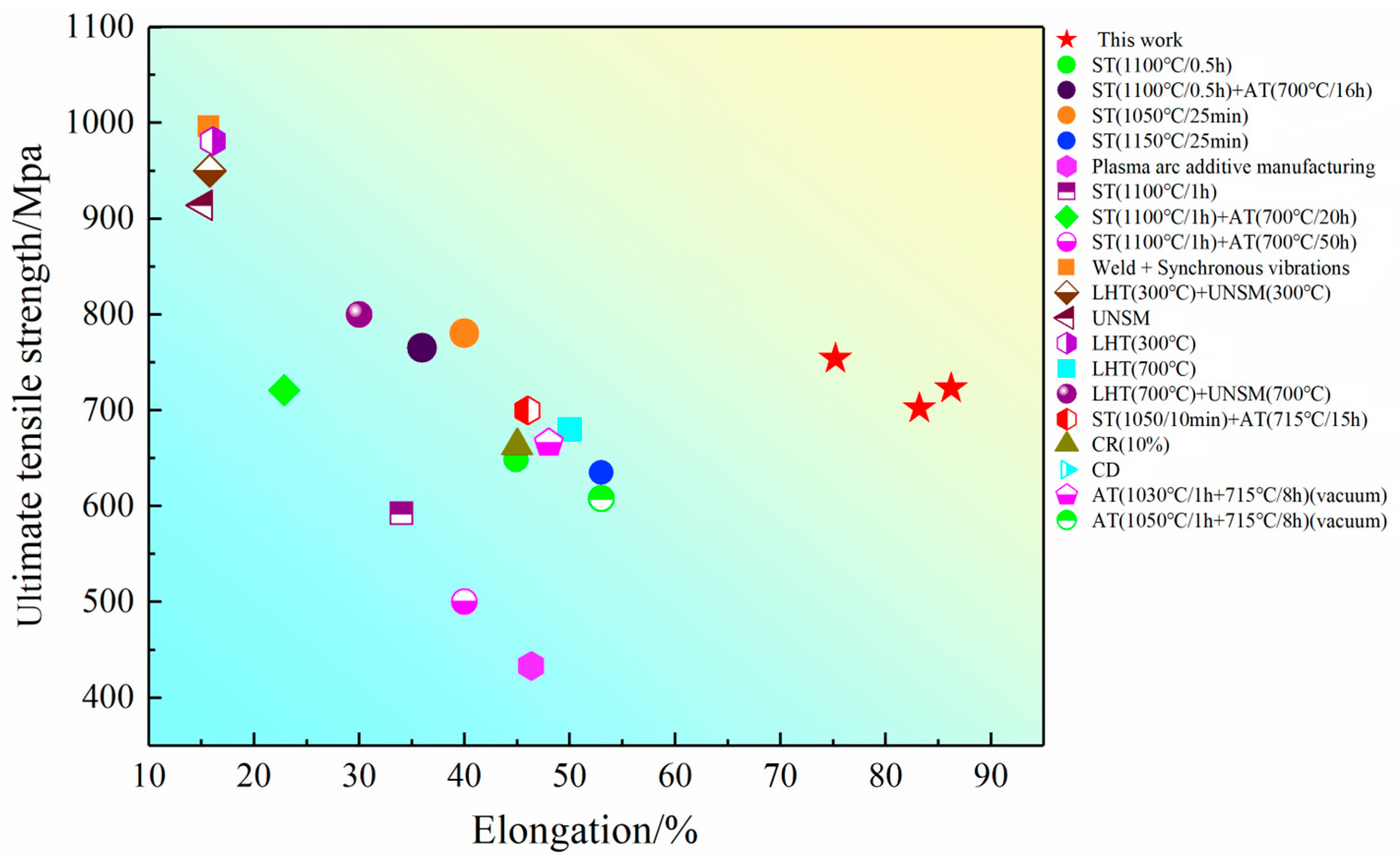

3.6. Comparison in Mechanical Properties of Alloys by Different Process

4. Conclusions

- (1)

- Thermo-mechanical treatment could improve the strength of the alloy, and the grain size of the hot-rolled sample was refined. Hot-rolled alloys achieved high tensile strength under room temperature. Its room-temperature tensile strength was 949 MPa, and the fracture elongation rate was 33.7%. Moreover, its high-temperature (900 °C) tensile strength was 156 MPa, and the fracture elongation rate was 59.6%.

- (2)

- According to results of the tensile tests, with the elevation of annealing temperature, the room-temperature tensile strength of the alloy decreased, whereas the strength increased at 900 °C. When the annealing temperature was 1100 °C, the UTS was 752 MPa at room temperature. The UTS of alloys under 900 °C was 199 MPa when the annealing temperature was 1200 °C.

- (3)

- The rupture morphology of the room-temperature and 900 °C tensile test samples were captured, and the precipitated particles formed during high-temperature annealing were detected. There were some local oxidation phenomena on the fracture surface of the high-temperature test samples.

- (4)

- The ultimate engineering stress and engineering strain of the studied superalloys with solid solution treated at 1175 °C for 4 h were 709 ± 19.8 MPa and 87.2 ± 1.4%, which achieved the highest strength times elongation (PSE) value, up to 61.8 GPa·%.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, K.; Du, D.; Zhang, L.; Andresen, P.L. Corrosion fatigue crack growth behavior of alloy 690 in high temperature pressurized water. Corrosion 2017, 73, 724–733. [Google Scholar]

- Dutta, R.S.; Arya, A.; Yusufali, C.; Vishwanadh, B.; Tewari, R.; Dey, G.K. Formation of aluminides on Ni-based superalloy 690 substrate, their characterization and first-principle Ni(111)/NiAl(110) interface simulations. Surf. Coat. Technol. 2013, 235, 741–747. [Google Scholar]

- Dutta, R.S.; Yusufali, C.; Tewari, R.; Arya, A.K.; Dey, G.K. Characterization of nickel aluminide formed on Ni-based superalloy 690 substrate, First-Principle Ni(Cr)/NiAl interface simulations and stability of aluminide in aggressive environment in Pre-oxidized state. Trans. Indian Inst. Met. 2016, 69, 1889–1897. [Google Scholar]

- Fan, H.; Zhao, Y.; Wang, S.; Guo, H. Effect of jet electrodeposition conditions on microstructure and mechanical properties of Cu-Al2O3 composite coatings. Int. J. Adv. Manuf. Technol. 2019, 105, 4509–4516. [Google Scholar]

- Han, F.; Song, Z.G.; Zheng, W.J.; Chen, B.; Ji, X.M. Effect of solution treatment on microstructure and mechanical property of inconel 690. J. Iron Steel Res. 2009, 21, 46–50. [Google Scholar]

- Ganeev, A.A.; Valitov, V.A.; Utyashev, F.Z.; Imaev, V.M. Effect of thermomechanical treatment on the formation of gradient structure and mechanical properties in a disk made of Powder-Metallurgy Nickel-based superalloy. Phys. Met. Metallogr. 2019, 120, 410–416. [Google Scholar]

- Park, N.K.; Kim, J.J.; Chai, Y.S.; Lee, H.S. Microstructural evolution of Inconel 690 alloy for steam generator tubes. In Proceedings of the Asian Pacific Conference for Fracture and Strength (APCFS’06), Sanya, China, 22–25 November 2007; pp. 353–358. [Google Scholar]

- Park, S.Y.; Lee, D.B. Oxidation of inconel 690 alloys at 800–1000 degrees C in Air. In Proceedings of the 3rd International Conference on Machine Design and Manufacturing Engineering (ICMDME), Jeju Island, Republic of Korea, 24–25 May 2014; pp. 7–11. [Google Scholar]

- Rao, M.S.; Venkaiah, N. A modified cuckoo search algorithm to optimize Wire-EDM process while machining Inconel-690. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 1647–1661. [Google Scholar]

- Zheng, L.; Zhang, M.; Dong, J. Thermodynamic simulation of precipitating behaivour of equilibrium phases in alloy 690. Rare Met. Mater. Eng. 2012, 41, 983–988. [Google Scholar]

- Yaohui, L.; Wang, K.; Xuan, Z.; Xu, B. Effects of different parameters on microstructures of Ni-based superalloy fabricated by plasma arc additive manufacturing. Weld. Join. 2018, 66, 21–24. [Google Scholar]

- Li, X.; Wang, J.; Han, E.-H.; Guo, Y.; Zheng, H.; Yang, S. Electrochemistry and in situ scratch behavior of 690 alloy in simulated nuclear power high temperature high pressure water. Acta Metall. Sin. 2020, 56, 1474–1484. [Google Scholar]

- Li, Z.; Nai, Q.; Wang, B.; Su, C.; Dong, J. Effect of high strain rate on hot deformation behavior and extrusion feasibility of 690 alloy. Rare Met. Mater. Eng. 2018, 47, 3372–3380. [Google Scholar]

- Liu, Y.; Hu, S.; Chen, L. Experimental study on the influence of single-pass deformation on recrystallization behavior and microstructure. In Proceedings of the 2nd International Conference on Advanced Engineering Materials and Technology (AEMT), Zhuhai, China, 6–8 July 2012; pp. 1175–1178. [Google Scholar]

- Lee, T.-H.; Lee, Y.-J.; Park, D.-J.; Noh, J.-S.; Park, C.-H.; Lee, J.-H. Effects of fabrication process on microstructure and texture of Inconel 690 tubes for steam generator. J. Nucl. Sci. Technol. 2015, 52, 1490–1495. [Google Scholar]

- Amanov, A.; Umarov, R. The effects of ultrasonic nanocrystal surface modification temperature on the mechanical properties and fretting wear resistance of Inconel 690 alloy. Appl. Surf. Sci. 2018, 441, 515–529. [Google Scholar]

- Sheng, J.; Huang, S.; Zhou, J.Z.; Wang, Z.W. Effects of warm laser peening on the elevated temperature tensile properties and fracture behavior of IN718 nickel-based superalloy. Eng. Fract. Mech. 2017, 169, 99–108. [Google Scholar]

- Tang, Z.; Meng, F.; Zhang, P.; Xu, X.; Hu, S. Evaluation of caustic stress corrosion resistance of steam generator tubing alloy 690 for nuclear power plant. Rare Met. Mater. Eng. 2019, 48, 3541–3547. [Google Scholar]

- Wang, J.; Zhai, S.-C. Dynamic recrystallization kinetics of 690 alloy during hot compression of Double-Cone samples. J. Mater. Eng. Perform. 2017, 26, 1433–1443. [Google Scholar]

- Zijun, W.; Wenjie, Z.; Zhigang, S.; Jinzhong, X.; Han, F. Effect of solution treatment on structure and mechanical properties of nickel base alloy 690. Spec. Steel 2011, 32, 67–70. [Google Scholar]

- Xia, D.; Song, S.; Wang, J.; Luo, J. Research progress on Sulfur-Induced corrosion of alloys 690 and 800 in high temperature and high pressure water. Acta Metall. Sin. 2017, 53, 1541–1554. [Google Scholar]

- Xia, S.; Zhou, B.; Chen, W. Effect of deformation and heat-treatments on the grain boundary character distribution for 690 alloy. Rare Met. Mater. Eng. 2008, 37, 999–1003. [Google Scholar]

- Yang, L.; Dong, J.; Zhang, M. Effect of grain Size on hot deformation characteristics of 690 alloy. Rare Met. Mater. Eng. 2012, 41, 1477–1482. [Google Scholar]

- Yang, L.; Dong, J.; Zhang, M. Deformation behavior and dynamic recrystallization model for 690 alloy at elevated temperature. Rare Met. Mater. Eng. 2012, 41, 727–732. [Google Scholar]

- Lee, T.-H.; Suh, H.-Y.; Han, S.-K.; Noh, J.-S.; Lee, J.-H. Effect of a heat treatment on the precipitation behavior and tensile properties of alloy 690 steam generator tubes. J. Nucl. Mater. 2016, 479, 85–92. [Google Scholar]

- Luo, L.; Wei, X.; Chen, J. Grain boundary carbides evolution and their effects on mechanical properties of Ni 690 strip weld metal at elevated temperature. In Transactions on Intelligent Welding Manufacturing; Springer: Singapore, 2019. [Google Scholar]

- Wu, W.T.; Lin, D.Y.; Chen, S.H. Mechanical properties of weldment affected by various vibration frequencies. J. Mater. Sci. Lett. 1999, 18, 1829–1831. [Google Scholar]

- Liu, K.; Hao, X.; Gao, M.; Li, S.; Li, Y.; Wang, B. Effect of N content on mechanical properties and microstructure of alloy 690. In Proceedings of the 17th International Conference on Nuclear Engineering, Brussels, Belgium, 12–16 July 2009; pp. 327–336. [Google Scholar]

- Zhang, S.C.; Zheng, W.J.; Song, Z.G.; Feng, H.; Sun, Y. Effect of cold deformation on structure and mechanical behavior of Inconel 690 alloy. J. Iron Steel Res. 2009, 21, 49–54. [Google Scholar]

- Jun-Ye, L.I.; Hui, W.U.; Song, Z.G.; Feng, H. Heat Treatment Process for 690 Alloy Used for Shear Cap for Squib Valve. Steel Res. Inst. 2016, 3, 22–25. [Google Scholar]

| Fe | Mo | Mn | Cr | W | Ni |

|---|---|---|---|---|---|

| 12.3 | 7 | 1.7 | 20 | 3 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, Z.; Ma, Y.; Lei, Q. The Effects of Thermo-Mechanical Treatments on Microstructure and High-Temperature Mechanical Properties of a Nickel-Based Superalloy. Crystals 2025, 15, 630. https://doi.org/10.3390/cryst15070630

Kang Z, Ma Y, Lei Q. The Effects of Thermo-Mechanical Treatments on Microstructure and High-Temperature Mechanical Properties of a Nickel-Based Superalloy. Crystals. 2025; 15(7):630. https://doi.org/10.3390/cryst15070630

Chicago/Turabian StyleKang, Zihan, Yaxing Ma, and Qian Lei. 2025. "The Effects of Thermo-Mechanical Treatments on Microstructure and High-Temperature Mechanical Properties of a Nickel-Based Superalloy" Crystals 15, no. 7: 630. https://doi.org/10.3390/cryst15070630

APA StyleKang, Z., Ma, Y., & Lei, Q. (2025). The Effects of Thermo-Mechanical Treatments on Microstructure and High-Temperature Mechanical Properties of a Nickel-Based Superalloy. Crystals, 15(7), 630. https://doi.org/10.3390/cryst15070630