The Analysis of Changes in the Crystal Structure of Near-Beta Titanium Alloy in the Solution-Treated and Aged Conditions after Static Tensile Testing

Abstract

1. Introduction

2. Materials and Methods

3. Research Results

4. Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Okazaki, Y.; Gotoh, E. Implant Applications of Highly Corrosion-Resistant Ti-15Zr-4Nb-4Ta Alloy. Mater. Trans. 2002, 43, 2943–2948. [Google Scholar] [CrossRef][Green Version]

- Wen, M.; Wen, C.; Hodgson, P.; Li, P. Improvement of the biomedical properties of titanium using SMAT and thermal oxidation. Colloids Surf. B Biointerfaces 2014, 116, 658–665. [Google Scholar] [CrossRef]

- Ahmed, M.; Pereloma, E.V. Observation of simultaneous operation of deformation twins in both α and β phases in metastable β titanium alloy. J. Alloy. Compd. 2022, 910, 164794. [Google Scholar] [CrossRef]

- Zhu, X.; Fan, Q.; Wang, D.; Gong, H.; Gao, Y.; Yuan, J.; Chen, K.; Qian, F. Influence of twins found in adiabatic shear bands on dynamic recrystallization of a near β Ti-5.5Mo-7.2Al-4.5Zr-2.6Sn-2.1Cr alloy. Mater. Sci. Eng. A 2022, 842, 143084. [Google Scholar] [CrossRef]

- Zhao, Q.; Bolzoni, L.; Chen, Y.; Xu, Y.; Torrens, R.; Yang, F. Processing of metastable beta titanium alloy: Comprehensive study on deformation behaviour and exceptional microstructure variation mechanisms. J. Mater. Sci. Technol. 2022, 126, 22–43. [Google Scholar] [CrossRef]

- Zhao, J.; Zhong, J.; Yan, F.; Chai, F.; Dargusch, M. Deformation behaviour and mechanisms during hot compression at supertransus temperatures in Ti-10V-2Fe-3Al. J. Alloy. Compd. 2017, 710, 616–627. [Google Scholar] [CrossRef]

- Sinyakova, E.; Panin, A.; Perevalova, O.; Shugurov, A.; Kalashnikov, M.; Teresov, D. The effect of phase transformations on the recovery of pulsed electron beam irradiated Ti-6Al-4V titanium alloy during scratching. J. Alloy. Compd. 2019, 795, 275–283. [Google Scholar] [CrossRef]

- Ellyson, B.; Fezzaa, K.; Sun, T.; Parab, N.; Saville, A.; Finfrock, C.; Rietema, C.; Smith, D.; Copley, J.; Johnson, C.; et al. Transformation and twinning induced plasticity in metastable Ti-Mo alloys under high strain rate deformation. Mater. Sci. Eng. A 2022, 857, 143716. [Google Scholar] [CrossRef]

- Wu, Z.; Kou, H.; Chen, N.; Zhang, Z.; Qiang, F.; Fan, J.; Tang, B.; Li, J. The effect of cubic-texture on fatigue cracking in a metastable β titanium alloy subjected to high-cycle fatigue. Int. J. Fatigue 2020, 141, 105872. [Google Scholar] [CrossRef]

- Chen, K.; Fan, Q.; Yang, L.; Yao, J.; Xu, S.; Lei, W.; Gao, Y. Deciphering the microstructural evolution and adiabatic shearing behavior of the titanium alloy with stress-induced ω phase transformation during dynamic compression. Mater. Des. 2022, 221, 110939. [Google Scholar] [CrossRef]

- Zhang, J.; Qian, B.; Lin, W.; Zhang, P.; Wu, Y.; Fu, Y.; Fan, Y.; Chen, Z.; Cheng, J.; Li, J.; et al. Compressive deformation-induced hierarchical microstructure in a TWIP β Ti-alloy. J. Mater. Sci. Technol. 2022, 112, 130–137. [Google Scholar] [CrossRef]

- Li, C.; Huang, L.; Zhao, M.; Guo, S.; Li, J. Hot deformation behavior and mechanism of a new metastable β titanium alloy Ti–6Cr–5Mo–5V–4Al in single phase region. Mater. Sci. Eng. A 2021, 814, 141231. [Google Scholar] [CrossRef]

- Fan, X.; Zhang, Y.; Gao, P.; Lei, Z.; Zhan, M. Deformation behavior and microstructure evolution during hot working of a coarse-grained Ti-5Al-5Mo-5V-3Cr-1Zr titanium alloy in beta phase field. Mater. Sci. Eng. A 2017, 694, 24–32. [Google Scholar] [CrossRef]

- Chuan, W.; Liang, H. Hot deformation and dynamic recrystallization of a near-beta titanium alloy in the β single phase region. Vacuum 2018, 156, 384–401. [Google Scholar] [CrossRef]

- Fan, J.; Kou, H.; Lai, M.; Tang, B.; Chang, H.; Li, J. Hot deformation mechanism and microstructure evolution of a new near β titanium alloy. Mater. Sci. Eng. A 2013, 584, 121–132. [Google Scholar] [CrossRef]

- Lu, T.; Dan, Z.-H.; Li, T.-J.; Dai, G.-Q.; Sun, Y.-Y.; Guo, Y.-H.; Li, K.; Yi, D.-Q.; Chang, H.; Zhou, L. Flow softening and microstructural evolution of near β titanium alloy Ti-35421 during hot compression deformation in the α+β region. J. Mater. Res. Technol. 2022, 19, 2257–2274. [Google Scholar] [CrossRef]

- Matsumoto, H.; Kitamura, M.; Li, Y.; Koizumi, Y.; Chiba, A. Hot forging characteristic of Ti–5Al–5V–5Mo–3Cr alloy with single metastable β microstructure. Mater. Sci. Eng. A 2014, 611, 337–344. [Google Scholar] [CrossRef]

- Chen, Z.-Q.; Xu, L.-J.; Cao, S.-Z.; Yang, J.-K.; Zheng, Y.-F.; Xiao, S.-L.; Tian, J.; Chen, Y.-Y. Characterization of hot deformation and microstructure evolution of a new metastable β titanium alloy. Trans. Nonferrous Met. Soc. China 2022, 32, 1513–1529. [Google Scholar] [CrossRef]

- Chen, J.; Li, J.; Tang, B.; Chen, Y.; Kou, H. Microstructure and texture evolution of a near β titanium alloy Ti-7333 during continuous cooling hot deformation. Prog. Nat. Sci. 2019, 29, 50–56. [Google Scholar] [CrossRef]

- Chen, Y.; Li, J.; Tang, B.; Kou, H.; Xue, X.; Cui, Y. Texture evolution and dynamic recrystallization in a beta titanium alloy during hot-rolling process. J. Alloy. Compd. 2015, 618, 146–152. [Google Scholar] [CrossRef]

- Wang, J.; Wang, K.; Lu, S.; Li, X.; OuYang, D.; Qiu, Q. Softening mechanism and process parameters optimization of Ti-4.2Al-0.005B titanium alloy during hot deformation. J. Mater. Res. Technol. 2022, 17, 1842–1851. [Google Scholar] [CrossRef]

- Chen, W.; Wang, H.; Lin, Y.C.; Zhang, X.; Chen, C.; Lv, Y.; Zhou, K. The dynamic responses of lamellar and equiaxed near β-Ti alloys subjected to multi-pass cross rolling. J. Mater. Sci. Technol. 2020, 43, 220–229. [Google Scholar] [CrossRef]

- Chen, W.; Yang, S.; Lin, Y.; Chen, C.; Zhang, X.; Zhou, K. Multi-scale characterization of deformation features and precipitation behavior in a near β-Ti alloy. Mater. Charact. 2020, 169, 110637. [Google Scholar] [CrossRef]

- Zhu, X.; Fan, Q.; Wang, D.; Gong, H.; Gao, Y.; Qian, F.; Jin, S.; Sha, G. A new dynamic recrystallization mechanism in adiabatic shear band of an α/β dual phase titanium alloy: Composition redistribution. Scr. Mater. 2022, 206, 114229. [Google Scholar] [CrossRef]

- Furuhara, T.; Poorganji, B.; Abe, H.; Maki, T. Dynamic recovery and recrystallization in titanium alloys by hot deformation. JOM 2007, 59, 64–67. [Google Scholar] [CrossRef]

- Ning, Y.; Luo, X.; Liang, H.; Guo, H.; Zhang, J.; Tan, K. Competition between dynamic recovery and recrystallization during hot deformation for TC18 titanium alloy. Mater. Sci. Eng. A 2015, 635, 77–85. [Google Scholar] [CrossRef]

- Wang, H.; Ge, J.; Zhang, X.; Chen, C.; Zhou, K. Investigation of the Dynamic Recovery and Recrystallization of Near-β Titanium Alloy Ti-55511 during Two-Pass Hot Compression. Metals 2021, 11, 359. [Google Scholar] [CrossRef]

- Li, J.; Dong, R.; Kou, H.; Fan, J.; Zhu, B.; Tang, B. Texture evolution and the recrystallization behavior in a near β titanium alloy Ti-7333 during the hot-rolling process. Mater. Charact. 2020, 159, 109999. [Google Scholar] [CrossRef]

- Gu, B.; Chekhonin, P.; Schaarschuch, R.; Oertel, C.-G.; Xin, S.; Ma, C.; Zhou, L.; Gan, W.; Skrotzki, W. Microstructure, texture and hardness of a metastable β-titanium alloy after bar-rolling and annealing. J. Alloy. Compd. 2020, 825, 154082. [Google Scholar] [CrossRef]

- Krawczyk, J.; Tokarski, T.; Łukaszek-Sołek, A.; Dąbrowski, R.; Śleboda, T.; Lypchanskyi, O. Dynamic Recrystallization in Titanium Alloys. Key Eng. Mater. 2016, 687, 47–54. [Google Scholar] [CrossRef]

- Lypchanskyi, O.; Śleboda, T.; Wojtaszek, M.; Muszka, K.; Łukaszek-Sołek, A.; Stanik, R.; Gude, M. The analysis of flow behavior of Ti-6Al-2Sn-4Zr-6Mo alloy based on the processing maps. Int. J. Mater. Form. 2020, 14, 523–532. [Google Scholar] [CrossRef]

- Zhang, C.; Jiang, X.; Han, J.; Zhang, S.; Peng, P.; Feng, H.; Wang, T.; Cao, P. Probing the texture transition sequence of near β titanium matrix composites by observing the uneven hot deformation microstructure. Mater. Charact. 2023, 198, 112728. [Google Scholar] [CrossRef]

- Nasirpouri, F.; Sanaeian, M.R.; Samardak, A.S.; Sukovatitsina, E.V.; Ognev, A.V.; Chebotkevich, L.A.; Hosseini, M.-G.; Abdolmaleki, M. An investigation on the effect of surface morphology and crystalline texture on corrosion behavior, structural and magnetic properties of electrodeposited nanocrystalline nickel films. Appl. Surf. Sci. 2014, 292, 795–805. [Google Scholar] [CrossRef]

- Zhao, Z.B.; Zhang, B.H.; Sun, H.; Wang, Q.J.; Liu, J.R.; Yang, R. Influence of Globularization Process on Local Texture Evolution of a Near-a Titanium Alloy with a Transformed Microstructure. Metall. Mater. Trans. A 2014, 54A, 2849–2857. [Google Scholar] [CrossRef]

- Du, Z.; Liu, J.; Jiang, S.; Xiao, S.; Kong, F.; Chen, Y. Strain rate dependence of microstructural evolution in β titanium alloy during subtransus superplastic deformation. J. Alloy. Compd. 2015, 647, 1–5. [Google Scholar] [CrossRef]

| Elements | Al | V | Cr | Zr | Mo |

|---|---|---|---|---|---|

| Nominal content | 3.0–4.0 | 7.5–8.5 | 5.5–6.5 | 3.5–4.5 | 3.5–4.5 |

| Actual content | 3.46 | 8.19 | 6.41 | 4.15 | 4.17 |

| TBe Alloy Sample | Solution Treatment | Aging |

|---|---|---|

| TBe-S | 950 °C/1 h | - |

| TBe-A450 | 950 °C/1 h | 450 °C/2 h |

| TBe-A500 | 950 °C/1 h | 500 °C/2 h |

| TBe-A550 | 950 °C/1 h | 550 °C/2 h |

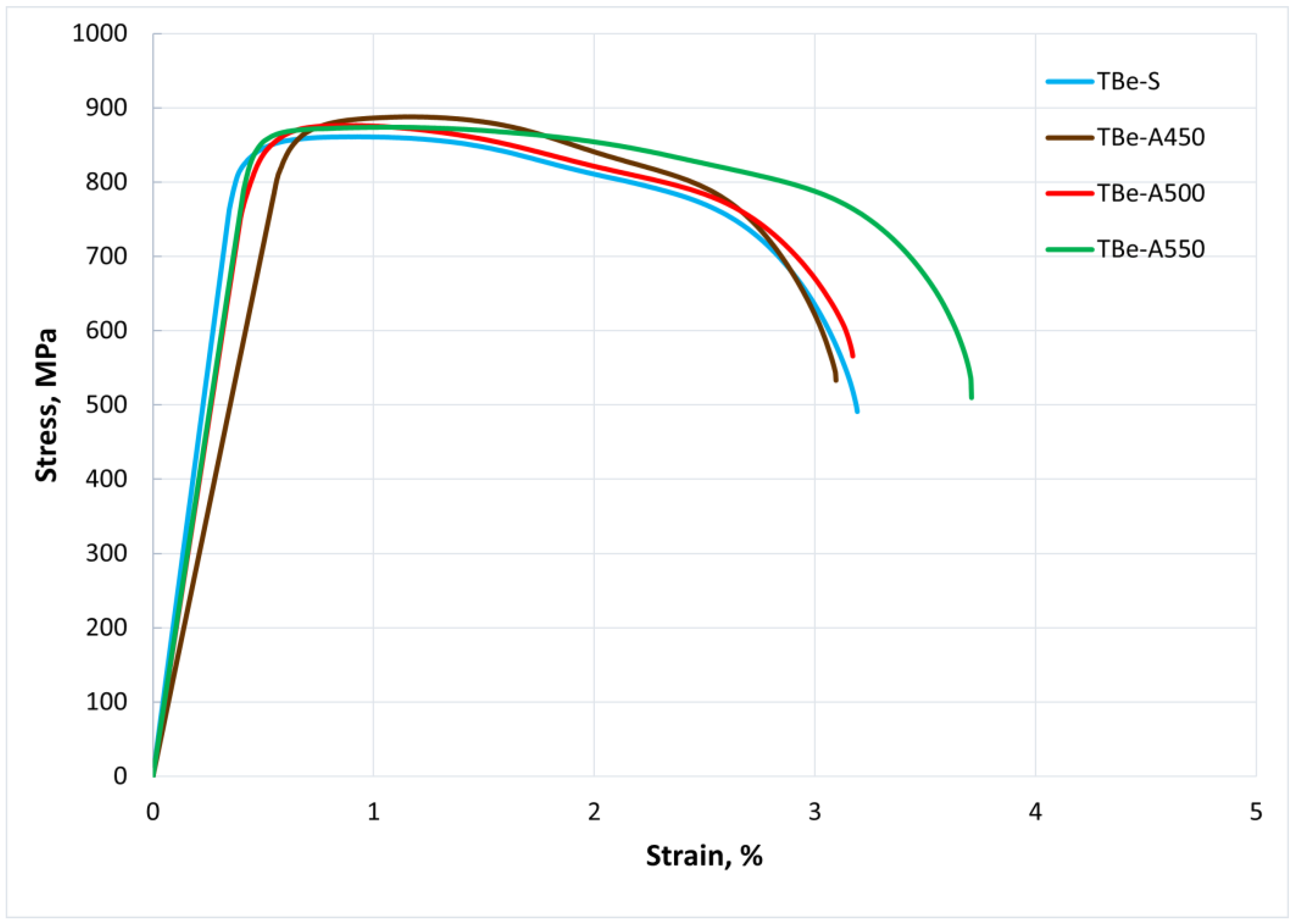

| TBe Alloy | TS (MPa) | YS (MPa) | YS/TS (%) | E (GPa) | δ (%) | EL (%) | RA (%) |

|---|---|---|---|---|---|---|---|

| TBe-S | 853 | 849 | 99.5 | 182 | 0.47 | 9.9 | 60.2 |

| TBe-A450 | 879 | 873 | 99.3 | 168 | 0.52 | 10.4 | 53.3 |

| TBe-A500 | 869 | 865 | 99.5 | 171 | 0.51 | 9.6 | 43.7 |

| TBe-A550 | 865 | 864 | 99.9 | 163 | 0.53 | 14.2 | 52.9 |

| Material Condition | Before Plastic Deformation | After Plastic Deformation | ||

|---|---|---|---|---|

| Pole Figures | Measured | Calculated | Measured | Calculated |

| Supersaturation 950 °C/1 h |  |  |  |  |

| Supersaturation 950 °C/1 h Aging 450 °C/2 h |  |  |  |  |

| Supersaturation 950 °C/1 h Aging 500 °C/2 h |  |  |  |  |

| Supersaturation 950 °C/1 h Aging 550 °C/2 h |  |  |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krawczyk, J.; Frocisz, Ł.; Goły, M.; Tomasik, S.; Śleboda, T. The Analysis of Changes in the Crystal Structure of Near-Beta Titanium Alloy in the Solution-Treated and Aged Conditions after Static Tensile Testing. Crystals 2023, 13, 1223. https://doi.org/10.3390/cryst13081223

Krawczyk J, Frocisz Ł, Goły M, Tomasik S, Śleboda T. The Analysis of Changes in the Crystal Structure of Near-Beta Titanium Alloy in the Solution-Treated and Aged Conditions after Static Tensile Testing. Crystals. 2023; 13(8):1223. https://doi.org/10.3390/cryst13081223

Chicago/Turabian StyleKrawczyk, Janusz, Łukasz Frocisz, Marcin Goły, Sylwia Tomasik, and Tomasz Śleboda. 2023. "The Analysis of Changes in the Crystal Structure of Near-Beta Titanium Alloy in the Solution-Treated and Aged Conditions after Static Tensile Testing" Crystals 13, no. 8: 1223. https://doi.org/10.3390/cryst13081223

APA StyleKrawczyk, J., Frocisz, Ł., Goły, M., Tomasik, S., & Śleboda, T. (2023). The Analysis of Changes in the Crystal Structure of Near-Beta Titanium Alloy in the Solution-Treated and Aged Conditions after Static Tensile Testing. Crystals, 13(8), 1223. https://doi.org/10.3390/cryst13081223