Composition Dependence Structural and Optical Properties of Silicon Germanium (SiχGe1−χ) Thin Films

Abstract

Highlights

- The research is focused on analyzing the structural properties of SiGe alloys with different compositions, with a particular focus on the effect of annealing temperature on the quality of the crystalline structure.

- The findings suggest that the quality of the crystalline structure in SiGe alloys improves as annealing temperature increases, and that this is particularly noticeable in alloys with higher percentages of Ge. This indicates that the thermal treatment of SiGe alloys is an important factor in optimizing their properties for various applications.

- Understanding the structural properties of SiGe alloys is important for a wide range of technological applications, including electronics, optoelectronics, and thermoelectric devices.

Abstract

1. Introduction

2. Experimental Details

3. Result and Discussion

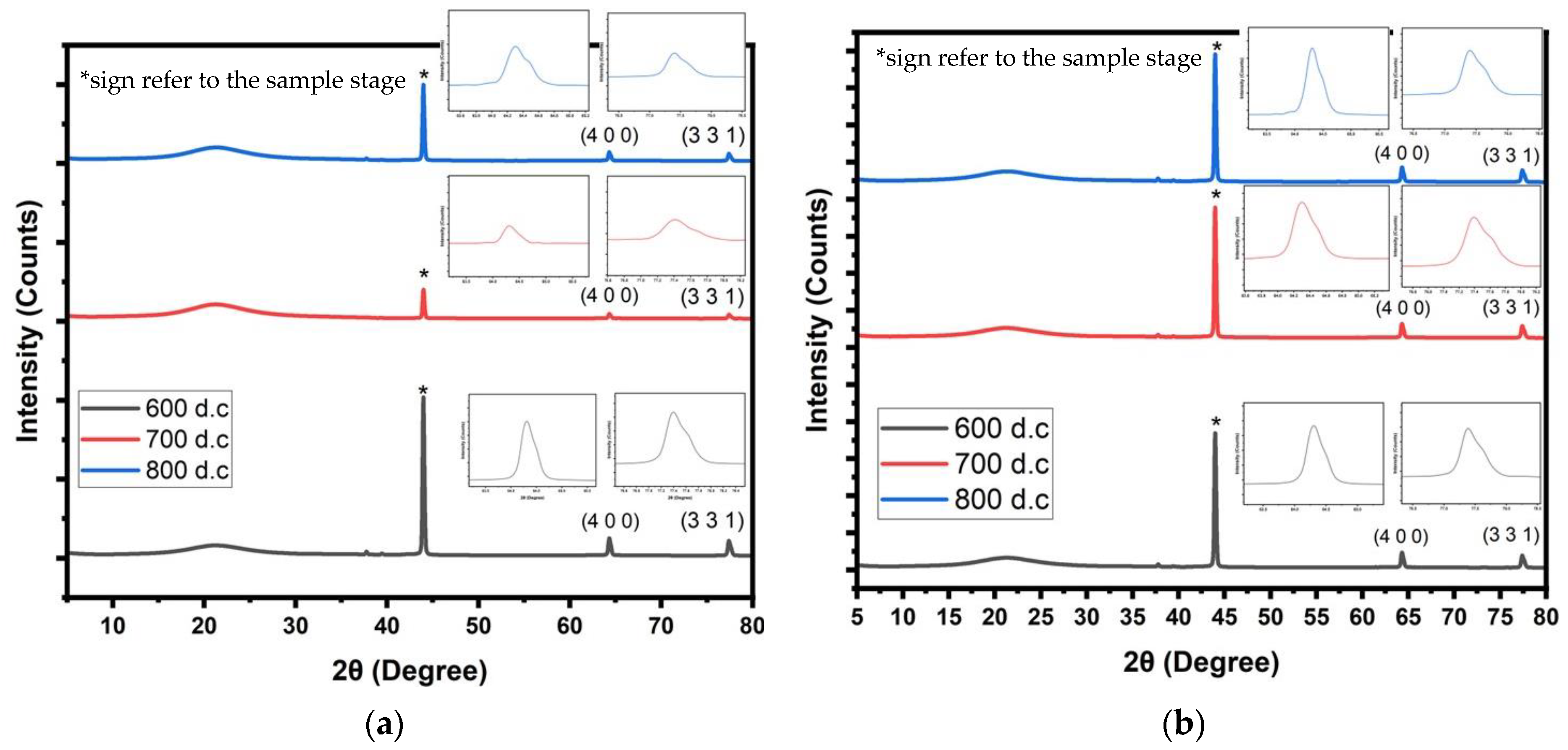

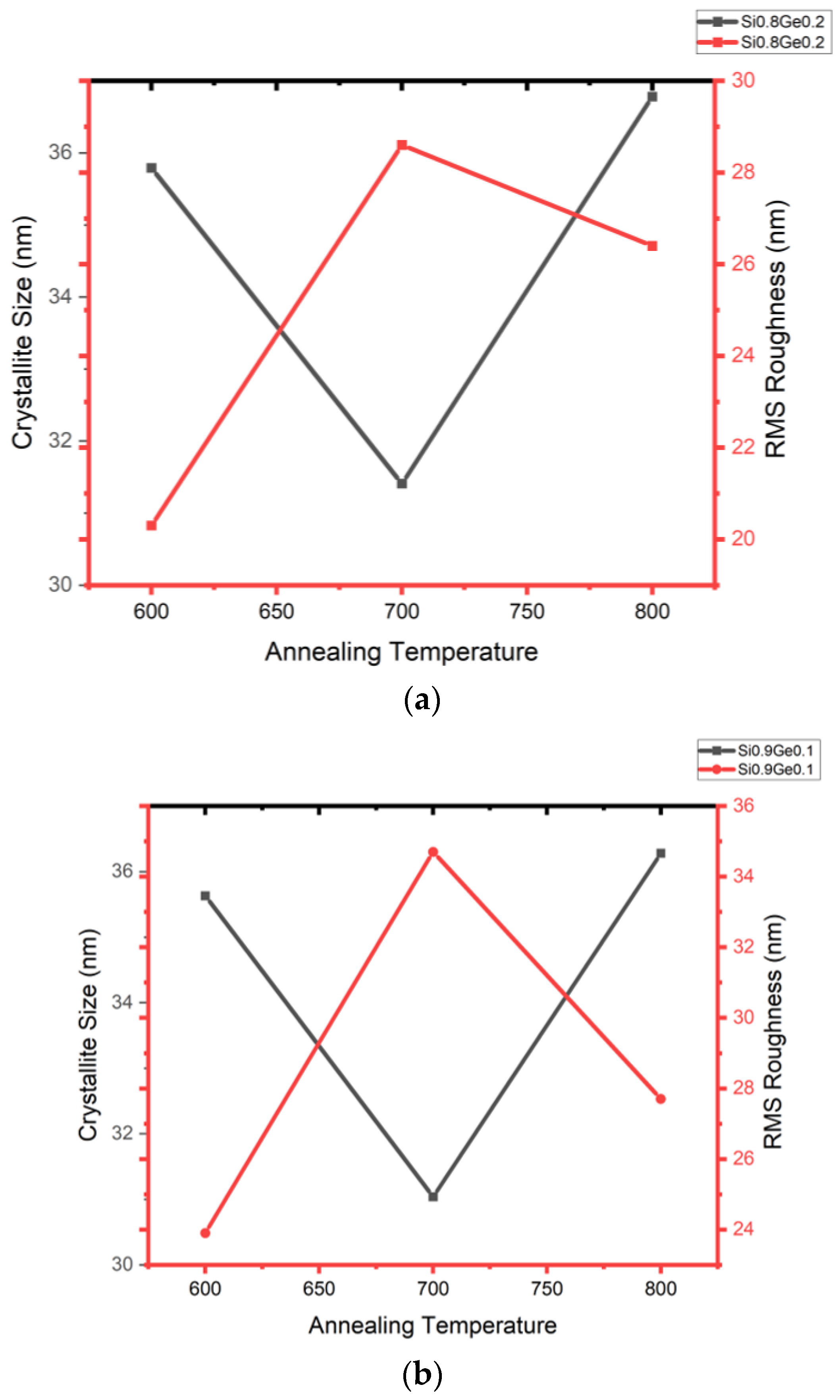

3.1. Structural Properties of Si0.8Ge0.2 and Si0.9Ge0.1 Thin Film

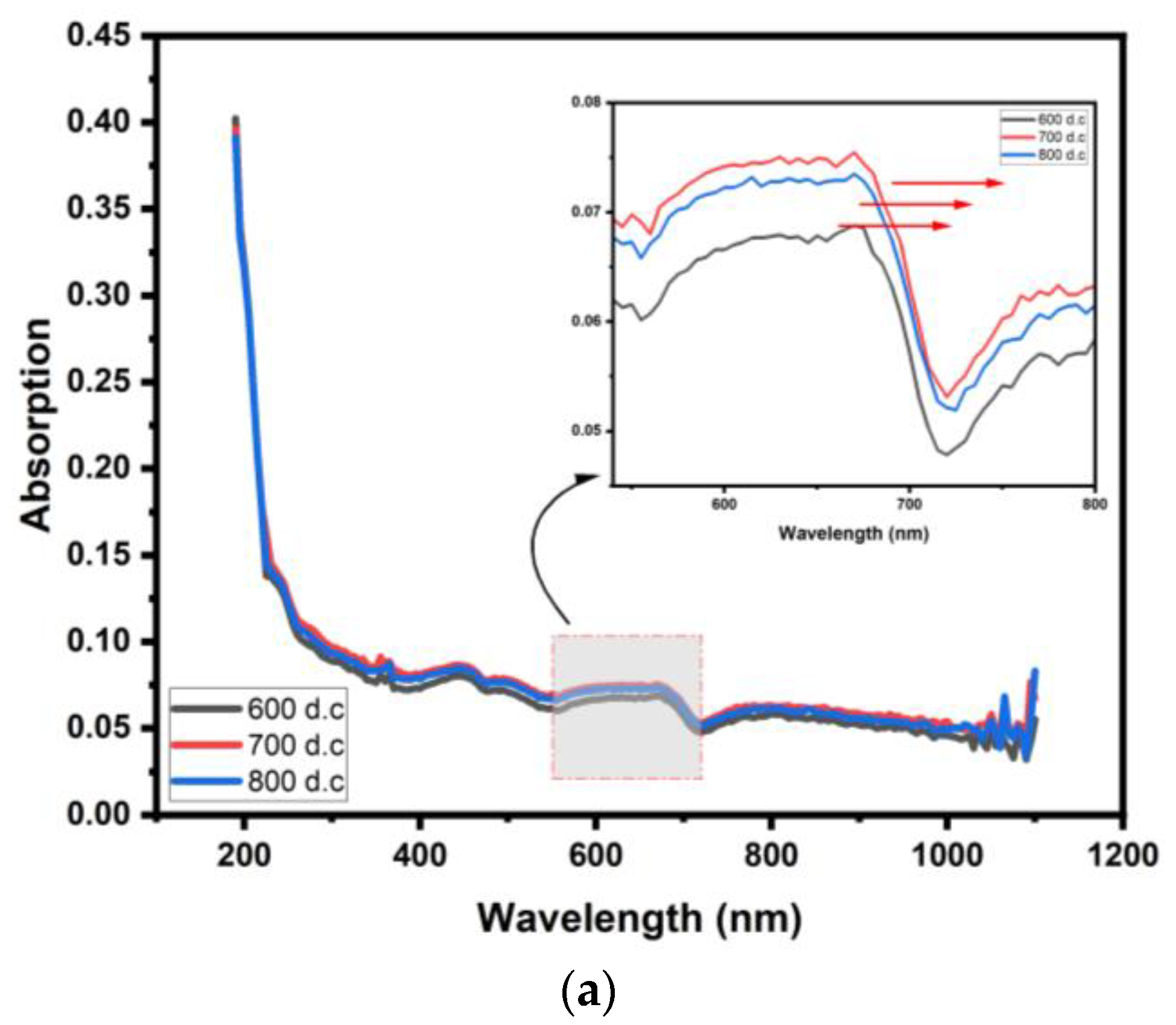

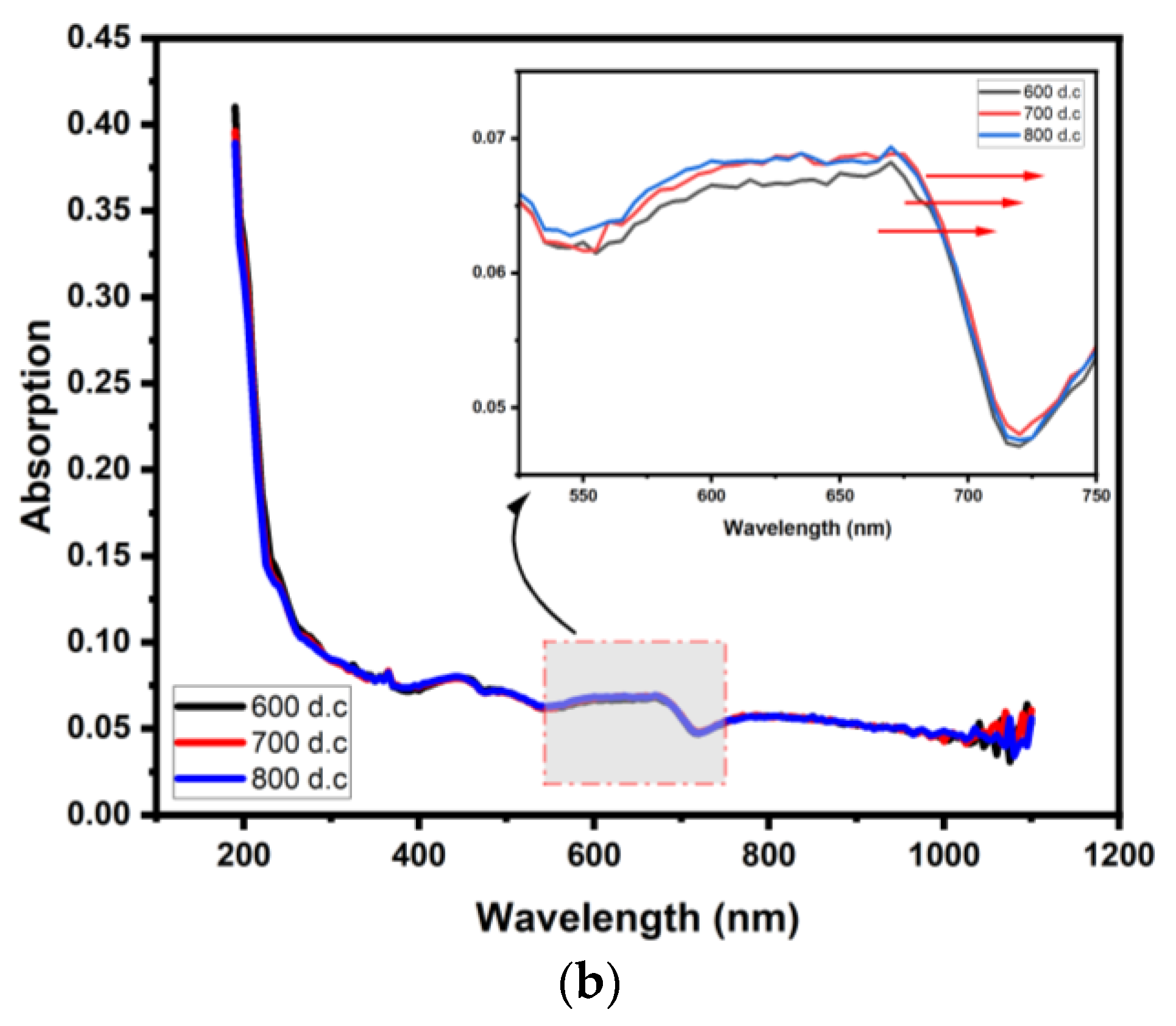

3.2. Optical Properties Analysis for Both Si0.8Ge0.2 and Si0.9Ge0.1 at Different Annealing Temperature

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Goktas, S.; Goktas, A. A comparative study on recent progress in efficient ZnO based nanocomposite and heterojunction photocatalysts: A review. J. Alloy. Compd. 2021, 863, 158734. [Google Scholar] [CrossRef]

- Feng, X.; Sun, D.; Yang, J. Eco-friendly synthesis of ferric ion-polyphenol-graphene aerogel for solar steam generation. Mater. Lett. 2022, 313, 131738. [Google Scholar] [CrossRef]

- Tajima, K.; Qiu, F.; Shin, W.; Sawaguchi, N.; Izu, N.; Matsubara, I.; Murayama, N. Thermoelectric properties of RF-sputtered SiGe thin film for hydrogen gas sensor. Jpn. J. Appl. Phys. 2004, 43, 5978. [Google Scholar] [CrossRef]

- Ghosh, B.K.; Saad, I.; Teo KT, K.; Ghosh, S.K. mcSi and CdTe solar photovoltaic challenges: Pathways to progress. Optik 2020, 206, 164278. [Google Scholar] [CrossRef]

- Ferhati, H.; Djeffal, F. Role of non-uniform Ge concentration profile in enhancing the efficiency of thin-film SiGe/Si solar cells. Optik 2018, 158, 192–198. [Google Scholar] [CrossRef]

- Ali, A.; Cheow, S.L.; Azhari, A.W.; Sopian, K.; Zaidi, S.H. Enhancing crystalline silicon solar cell efficiency with SixGe1−x layers. Results Phys. 2017, 7, 225–232. [Google Scholar] [CrossRef]

- Hashemi, P.; Ando, T.; Balakrishnan, K.; Koswatta, S.; Lee, K.L.; Ott, J.A.; Mo, R.T. High performance PMOS with strained high-Ge-content SiGe fins for advanced logic applications. In Proceedings of the 2017 International Symposium on VLSI Technology, Systems and Application (VLSI-TSA), Hsinchu, Taiwan, 24–27 April 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–2. [Google Scholar]

- Zhao, C.; Dong, Z.; Shen, J. The strain model of misfit dislocations at Ge/Si hetero-interface. Vacuum 2022, 196, 110711. [Google Scholar] [CrossRef]

- Masood, K.; Jain, N.; Kumar, P.; Malik, M.; Singh, J. Nanostructured thermoelectric Materials. In Thermoelectricity and Advanced Thermoelectric Materials; Elsevier: Amsterdam, The Netherlands, 2021; pp. 261–311. [Google Scholar]

- Ballif, C.; Haug, F.J.; Boccard, M.; Verlinden, P.J.; Hahn, G. Status and perspectives of crystalline silicon photovoltaics in research and industry. Nat. Rev. Mater. 2022, 7, 597–616. [Google Scholar] [CrossRef]

- Shukla, A.K.; Sudhakar, K.; Baredar, P. Simulation and performance analysis of 110 kWp grid-connected photovoltaic system for residential building in India: A comparative analysis of various PV technology. Energy Rep. 2016, 2, 82–88. [Google Scholar] [CrossRef]

- Dos Santos, R.B.; Rivelino, R.; de Brito Mota, F.; Kakanakova-Georgieva, A.; Gueorguiev, G.K. Feasibility of novel (H 3 C) n X (SiH 3) 3−n compounds (X = B, Al, Ga, In): Structure, stability, reactivity, and Raman characterization from ab initio calculations. Dalton Trans. 2015, 44, 3356–3366. [Google Scholar] [CrossRef]

- Tsukamoto, T.; Aoyagi, Y.; Nozaki, S.; Hirose, N.; Kasamatsu, A.; Matsui, T.; Suda, Y. Increasing the critical thickness of SiGe layers on Si substrates using sputter epitaxy method. J. Cryst. Growth 2022, 600, 126900. [Google Scholar] [CrossRef]

- Shklyaev, A.A.; Vdovin, V.I.; Volodin, V.A.; Gulyaev, D.V.; Kozhukhov, A.S.; Sakuraba, M.; Murota, J. Structure and optical properties of Si and SiGe layers grown on SiO2 by chemical vapor deposition. Thin Solid Film. 2015, 579, 131–135. [Google Scholar] [CrossRef]

- Ghosh, B.K.; Nasir, S.; Chee, F.P.; Routray, S.; Saad, I.; Mohamad, K.A. Numerical study of nSi and nSiGe solar cells: Emerging microstructure nSiGe cell achieved the highest 8.55% efficiency. Opt. Mater. 2022, 129, 112539. [Google Scholar] [CrossRef]

- Lahwal, A.; Zeng, X.; Bhattacharya, S.; Zhou, M.; Hitchcock, D.; Karakaya, M.; Tritt, T.M. Enhancing Thermoelectric Properties of Si80Ge20 Alloys Utilizing the Decomposition of NaBH4 in the Spark Plasma Sintering Process. Energies 2015, 8, 10958–10970. [Google Scholar] [CrossRef]

- Wu, Y.H.; Chen, W.J.; Chin, A.; Tsai, C. The effect of native oxide on epitaxial SiGe from deposited amorphous Ge on Si. Appl. Phys. Lett. 1999, 74, 528–530. [Google Scholar] [CrossRef]

- Goktas, A.; Aslan, E.; Arslan, F.; Kilic, A. Characterization of multifunctional solution-processed Sn1-xZnxS nanostructured thin films for photosensitivity and photocatalytic applications. Opt. Mater. 2022, 133, 112984. [Google Scholar] [CrossRef]

- Li, Y.; Han, J.; Xiang, Q.; Zhang, C.; Li, J. Enhancing thermoelectric properties of p-type SiGe by SiMo addition. J. Mater. Sci. Mater. Electron. 2019, 30, 9163–9170. [Google Scholar] [CrossRef]

- Abidin, M.S.Z.; Morshed, T.; Chikita, H.; Kinoshita, Y.; Muta, S.; Anisuzzaman, M.; Park, J.H.; Matsumura, R.; Mahmood, M.R.; Sadoh, T.; et al. The Effects of Annealing Temperatures on Composition and Strain in Si x Ge1− x Obtained by Melting Growth of Electrodeposited Ge on Si (100). Materials 2014, 7, 1409–1421. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, S.; Yang, S.; Zhang, Y.; Zhang, J.; Zhang, C.; Deng, C. The Effect of Different Annealing Temperatures on Recrystallization Microstructure and Texture of Clock-Rolled Tantalum Plates with Strong Texture Gradient. Metals 2019, 9, 358. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Y.; Mishin, O.V.; Tao, N.; Pantleon, W.; Juul Jensen, D. Microstructural Analysis of Orientation-Dependent Recovery and Recrystallization in a Modified 9Cr-1Mo Steel Deformed by Compression at a High Strain Rate. Metall. Mater. Trans. A 2016, 47, 4682–4693. [Google Scholar] [CrossRef]

- Mohamed, M.; Sedky, A.; Kassem, M.A. Gradual growth of ZnO nanoparticles from globules-like to nanorods-like shapes: Effect of annealing temperature. Optik 2022, 265, 169559. [Google Scholar] [CrossRef]

- Sharma, M.; Rani, J.; Bhardwaj, S.; Agrawal, A.; Ghosh, R.K.; Kuanr, B.K. Effect of annealing temperature on structural, optical, magnetic and electrical properties of CrFeO3 multiferroic nanoparticles: A validation to first-principle calculations. J. Alloys Compd. 2022, 929, 167338. [Google Scholar] [CrossRef]

- Bruker, C. NanoScope Software 8.10 User Guide. [online] Nanoqam.ca. 2011. Available online: http://nanoqam.ca/wiki/lib/exe/fetch.php?media=nanoscope_software_8.10_user_guide-d_004-1025-000_.pdf (accessed on 7 October 2022).

- Kama, A.; Tirosh, S.; Itzhak, A.; Ejgenberg, M.; Cahen, D. New Pb-Free Stable Sn–Ge Solid Solution Halide Perovskites Fabricated by Spray Deposition. ACS Appl. Energy Mater. 2022, 5, 3638–3646. [Google Scholar] [CrossRef]

- Torimoto, T.; Kameyama, T.; Uematsu, T.; Kuwabata, S. Controlling Optical Properties and Electronic Energy Structure of I-III-VI Semiconductor Quantum Dots for Improving Their Photofunctions. J. Photochem. Photobiol. C Photochem. Rev. 2022, 54, 100569. [Google Scholar] [CrossRef]

- El-Denglawey, A.; Sharma, V.; Sharma, E.; Aly, K.A.; Dahshan, A.; Sharma, P. Optical and mechanical properties of Ag doped thermally evaporated SeTe thin films for optoelectronic applications. J. Phys. Chem. Solids 2021, 159, 110291. [Google Scholar] [CrossRef]

- Dash, P.K.; Gupta, N.C. Effect of temperature on power output from different commercially available photovoltaic modules. Int. J. Eng. Res. Appl. 2015, 5, 148–151. [Google Scholar]

- Mohammed, R.Y. Annealing Effect on the Structure and Optical Properties of CBD-ZnS Thin Films for Windscreen Coating. Materials 2021, 14, 6748. [Google Scholar] [CrossRef]

- Özen, S.; Pat, S.; Şenay, V.; Korkmaz, Ş.; Geçici, B. Some physical properties of the SiGe thin film coatings by thermionic vacuum arc (TVA). J. Nanoelectron. Optoelectron. 2015, 10, 56–60. [Google Scholar] [CrossRef]

- Markvart, T.; Castañer, L. Semiconductor materials and modeling. In McEvoy’s Handbook of Photovoltaics; Academic Press: Cambridge, MA, USA, 2018; pp. 29–57. [Google Scholar]

- Shen, L.; Zhang, X.; Wang, H.; Li, J.; Xiang, G. Structural, magnetic and Magneto-transport properties of Mn-doped SiGe thin films. J. Magn. Magn. Mater. 2022, 560, 169630. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Novikov, A.; Shaleev, M.; Yurasov, D.; Semma, M.; Gotoh, K.; Usami, N. Impact of Ge deposition temperature on parameters of c-Si solar cells with surface texture formed by etching of Si using SiGe islands as a mask. Mater. Sci. Semicond. Process. 2020, 114, 105065. [Google Scholar] [CrossRef]

- Saikumar, A.K.; Sundaresh, S.; Nehate, S.D.; Sundaram, K.B. Properties of RF magnetron-sputtered copper gallium oxide (CuGa2O4) thin films. Coatings 2021, 11, 921. [Google Scholar] [CrossRef]

- Cojocaru, O.; Lepadatu, A.M.; Nemnes, G.A.; Stoica, T.; Ciurea, M.L. Bandgap atomistic calculations on hydrogen-passivated GeSi nanocrystals. Sci. Rep. 2021, 11, 1–10. [Google Scholar] [CrossRef]

- Marsili, M.; Botti, S.; Palummo, M.; Degoli, E.; Pulci, O.; Weissker, H.C.; Del Sole, R. Ab initio electronic gaps of Ge nanodots: The role of self-energy effects. J. Phys. Chem. C 2013, 117, 14229–14234. [Google Scholar] [CrossRef]

- Bulutay, C. Interband, intraband, and excited-state direct photon absorption of silicon and germanium nanocrystals embedded in a wide bandgap lattice. Phys. Rev. B 2007, 76, 205321. [Google Scholar] [CrossRef]

- Peng, K.C.; Kao, H.C.; Liu, S.J.; Tsai, K.L.; Lin, J.C. Annealing effect on the microstructure and optical characterization of Zn2SiO4 thin film sputtered on quartz glass. Jpn. J. Appl. Phys. 2013, 52, 11NB04. [Google Scholar] [CrossRef]

- Baer, D.R.; Thevuthasan, S. Characterization of thin films and coatings. In Handbook of Deposition Technologies for Films and Coatings; William Andrew Publishing: Norwich, NY, USA, 2010; pp. 749–864. [Google Scholar]

- Supriyanto, A.; Ramelan, A.H.; Nurosyid, F. Effect of annealing temperature on optical properties of TiO2 18 NR-T type thin film. J. Phys. Conf. Ser. 2018, 1011, 12016. [Google Scholar]

- Tang, G.; Liu, H.; Zhang, W. The variation of optical band gap for ZnO: In films prepared by sol-gel technique. Adv. Mater. Sci. Eng. 2013, 2013, 348601. [Google Scholar] [CrossRef]

- Elmorsy, M.R.; Badawy, S.A.; Abdel-Latif, E.; Assiri, M.A.; Ali, T.E. Significant improvement of dye-sensitized solar cell performance using low-band-gap chromophores based on triphenylamine and carbazole as strong donors. Dye. Pigment. 2023, 214, 111206. [Google Scholar] [CrossRef]

- Fathipour, M.; Abbaszadeh, B.; Kohani, F.; Farbiz, F. The effect of GE mole fraction on the electrical characteristics of nanoscale Si/SiGe heterostructure pMOSFET. In 2007 International Semiconductor Device Research Symposium; IEEE: Piscataway, NJ, USA, 2007; pp. 1–2. [Google Scholar]

- John, K.I.; Obu, M.; Adeleye, A.T.; Ebiekpe, V.; Adenle, A.A.; Chi, H.; Omorogie, M.O. Oxygen deficiency induction and boundary layer modulation for improved adsorption performance of titania nanoparticles. Chem. Pap. 2022, 76, 3829–3840. [Google Scholar] [CrossRef]

| Thin Film Composition |

|

|---|---|

| Material purity (Sputter target) | 99.99% |

| Target size | 3″ diameter × 0.125″ thickness |

| Substrate | Quartz Glass |

| Annealing temperature | 600 °C, 700 °C and 800 °C |

| Sputtering power | 98 W |

| Composition | Si0.8Ge0.2 | Si0.9Ge0.1 | ||||||

|---|---|---|---|---|---|---|---|---|

| Parameter | Crystallite Size (nm) | Micro-Strain, ×10−3 (Rad) | Lattice Constant | Peak Position | Crystallite Size (nm) | Micro-Strain, ×10−3 (radian) | Lattice Constant | Peak Position |

| 600 °C | 35.79 | 1.92 | 5.58002 | 64.4°, 77.5° | 35.63 | 1.91 | 5.57932 | 64.4°, 77.5° |

| 700 °C | 31.41 | 143.76 | 5.58086 | 64.4°, 77.5° | 22.98 | 1.92 | 5.58102 | 64.4°, 77.5° |

| 800 °C | 36.78 | 165.49 | 5.58057 | 64.4°, 77.5° | 36.28 | 0.97 | 5.58063 | 64.4°, 77.5° |

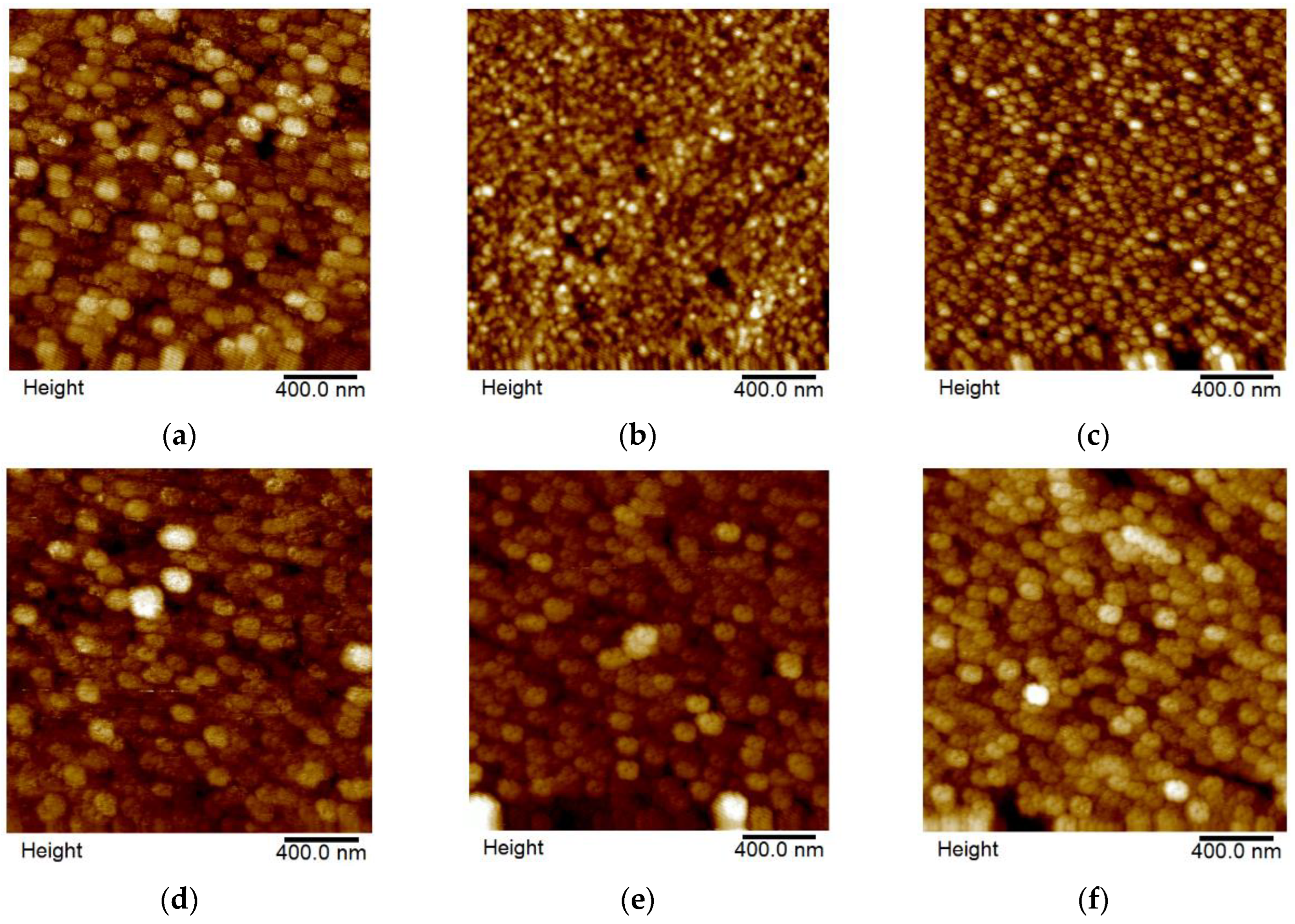

| Composition | Si0.8Ge0.2 | Si0.9Ge0.1 | ||||

|---|---|---|---|---|---|---|

| Parameter | Grain Size (nm) | RMS Roughness (nm) | Particle Density (µm−2) | Grain Size (nm) | RMS Roughness (nm) | Particle Density (µm−2) |

| 600 °C | 61.078 | 20.3 | 19.961 | 69.359 | 23.9 | 24.897 |

| 700 °C | 70.895 | 28.6 | 51.401 | 87.978 | 34.7 | 17.889 |

| 800 °C | 74.868 | 26.4 | 52.486 | 97.689 | 27.7 | 19.868 |

| Composition | Si0.8Ge0.2 | Si0.9Ge0.1 | ||

|---|---|---|---|---|

| Optical Parameter | Transmittance (%) | Bandgap (eV) | Transmittance (%) | Bandgap (eV) |

| 600 °C | 87.87 | 5.505 | 87.9 | 5.528 |

| 700 °C | 86.86 | 5.380 | 87.9 | 5.558 |

| 800 °C | 87.28 | 5.595 | 87.9 | 5.429 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nasir, S.; Chee, F.P.; Ghosh, B.K.; Rumaling, M.I.; Rasmidi, R.; Duinong, M.; Juhim, F. Composition Dependence Structural and Optical Properties of Silicon Germanium (SiχGe1−χ) Thin Films. Crystals 2023, 13, 791. https://doi.org/10.3390/cryst13050791

Nasir S, Chee FP, Ghosh BK, Rumaling MI, Rasmidi R, Duinong M, Juhim F. Composition Dependence Structural and Optical Properties of Silicon Germanium (SiχGe1−χ) Thin Films. Crystals. 2023; 13(5):791. https://doi.org/10.3390/cryst13050791

Chicago/Turabian StyleNasir, Syafiqa, Fuei Pien Chee, Bablu Kumar Ghosh, Muhammad Izzuddin Rumaling, Rosfayanti Rasmidi, Mivolil Duinong, and Floressy Juhim. 2023. "Composition Dependence Structural and Optical Properties of Silicon Germanium (SiχGe1−χ) Thin Films" Crystals 13, no. 5: 791. https://doi.org/10.3390/cryst13050791

APA StyleNasir, S., Chee, F. P., Ghosh, B. K., Rumaling, M. I., Rasmidi, R., Duinong, M., & Juhim, F. (2023). Composition Dependence Structural and Optical Properties of Silicon Germanium (SiχGe1−χ) Thin Films. Crystals, 13(5), 791. https://doi.org/10.3390/cryst13050791