Two-Step GaN Layer Growth for High-Voltage Lateral AlGaN/GaN HEMT

Abstract

1. Introduction

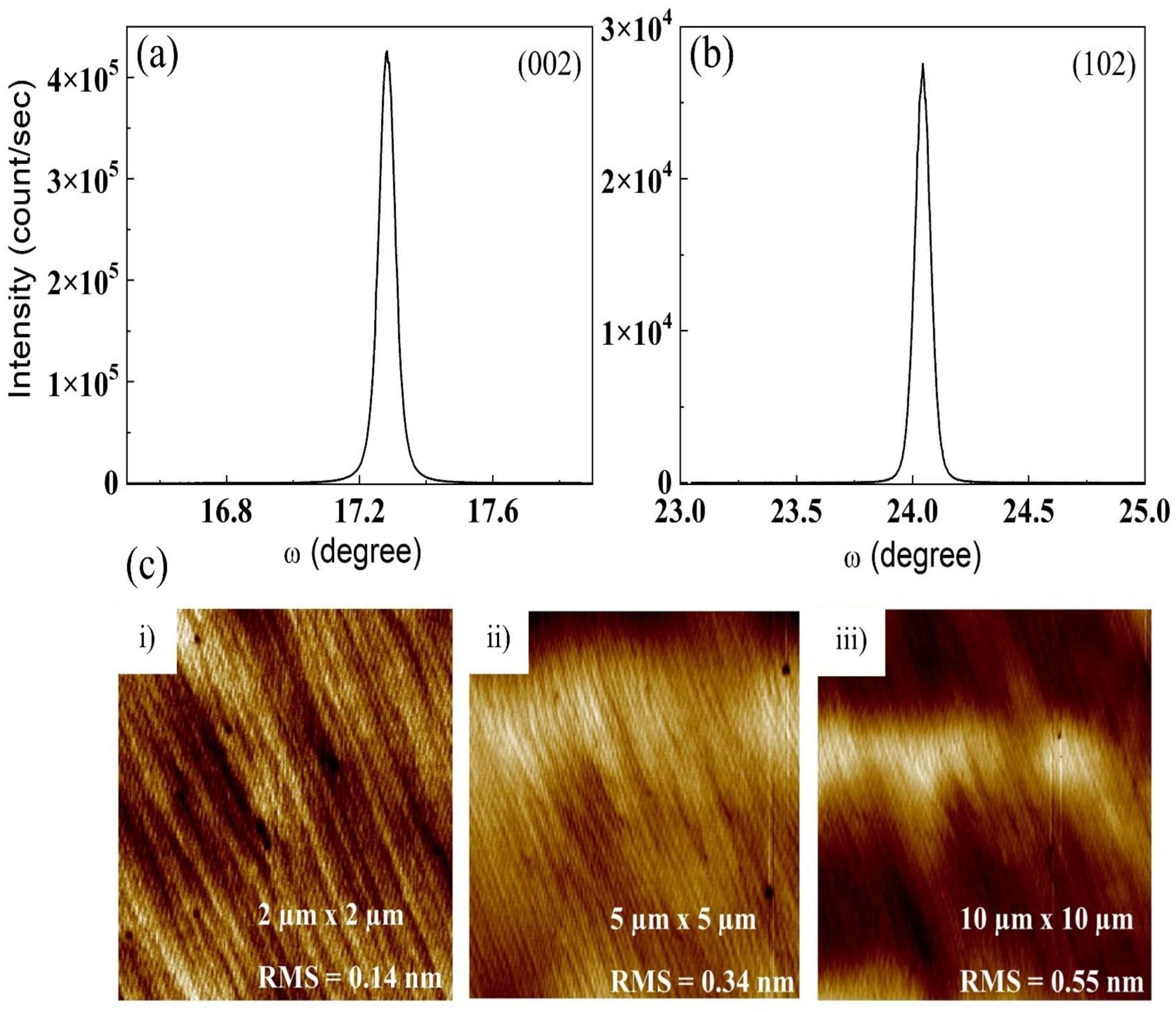

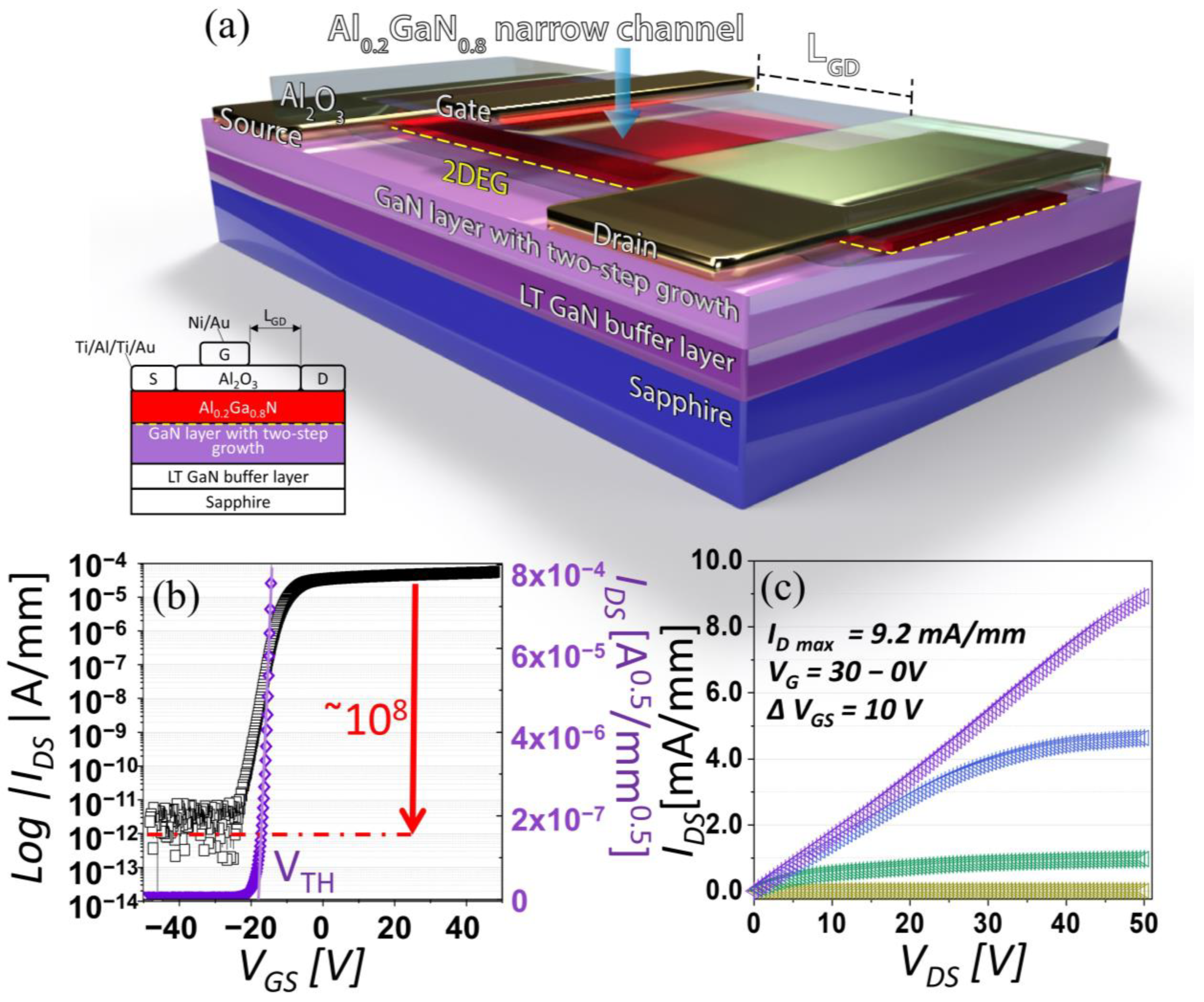

2. Materials and Methods

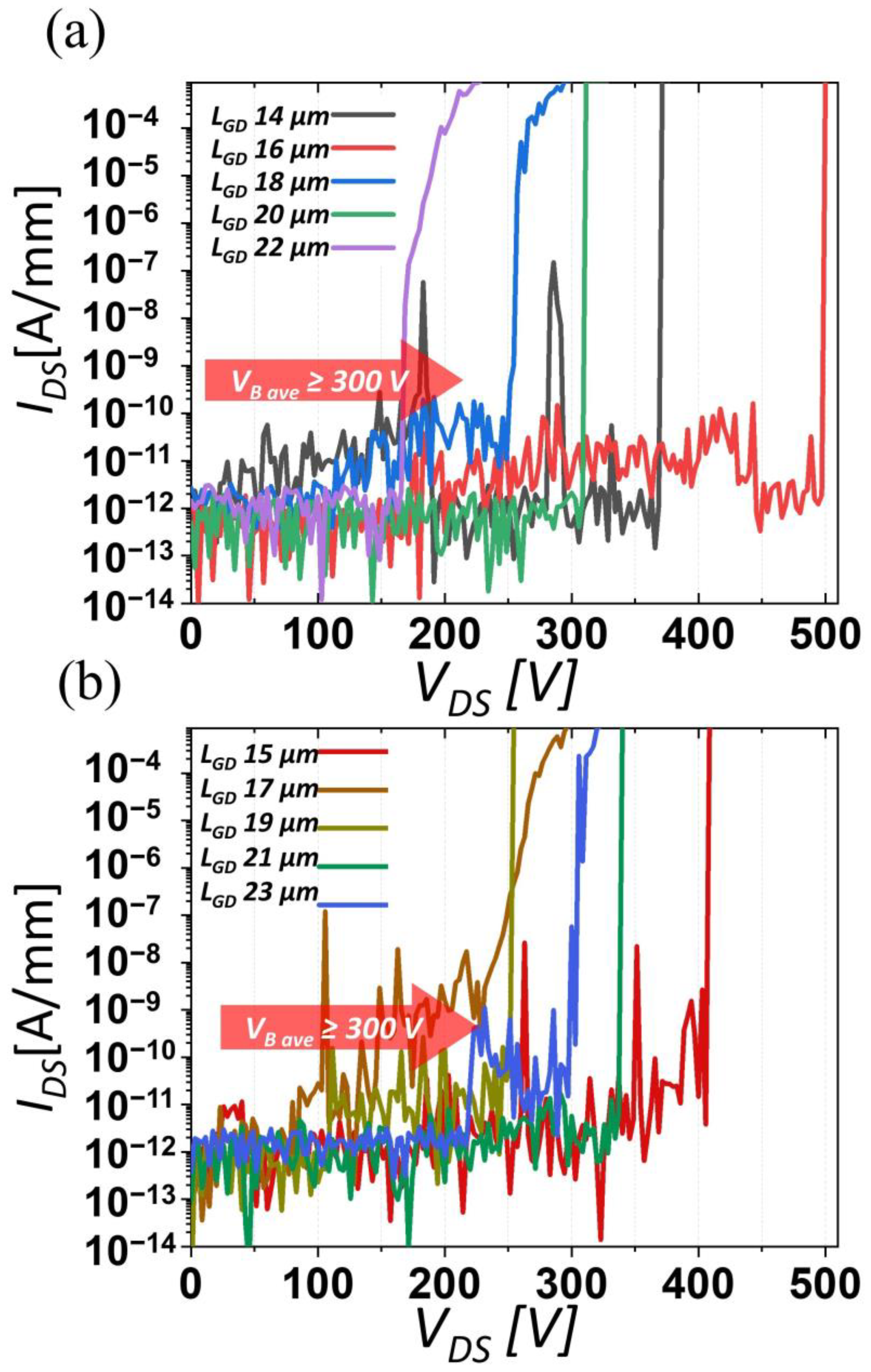

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amano, H.; Baines, Y.; Beam, E.; Borga, M.; Bouchet, T.; Chalker, P.R.; Charles, M.; Chen, K.J.; Chowdhury, N.; Chu, R.; et al. The 2018 GaN Power Electronics Roadmap. J. Phys. D Appl. Phys. 2018, 51, 163001. [Google Scholar] [CrossRef]

- Abid, I.; Kabouche, R.; Bougerol, C.; Pernot, J.; Masante, C.; Comyn, R.; Cordier, Y.; Medjdoub, F. High Lateral Breakdown Voltage in Thin Channel AlGaN/GaN High Electron Mobility Transistors on AlN/Sapphire Templates. Micromachines 2019, 10, 690. [Google Scholar] [CrossRef] [PubMed]

- Kaun, S.W.; Wong, M.H.; Mishra, U.K.; Speck, J.S. Correlation between Threading Dislocation Density and Sheet Resistance of AlGaN/AlN/GaN Heterostructures Grown by Plasma-Assisted Molecular Beam Epitaxy. Appl. Phys. Lett. 2012, 100, 262102. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, Y.; Li, Y.; Zhang, T.; Yao, Y.; Feng, Q.; Bi, Z.; Zhang, J.; Hao, Y. Mechanistic Influence on Uniformity of Sheet Resistance of AlGaN/GaN HEMT Grown on Si Substrate with the Graded AlGaN Buffer Layers. Vacuum 2022, 199, 110966. [Google Scholar] [CrossRef]

- Germain, M.; Leys, M.; Boeykens, S.; Degroote, S.; Wang, W.; Schreurs, D.; Ruythooren, W.; Choi, K.H.; van Daele, B.; van Tendeloo, G.; et al. High Electron Mobility in AlGaN/GaN HEMT Grown on Sapphire: Strain Modification by Means of AlN Interlayers. MRS Online Proc. Libr. 2004, 798, 1–6. [Google Scholar] [CrossRef]

- Ahmadi, E.; Wu, F.; Li, H.; Kaun, S.W.; Tahhan, M.; Hestroffer, K.; Keller, S.; Speck, J.S.; Mishra, U.K. N-Face GaN/AlN/GaN/InAlN and GaN/AlN/AlGaN/GaN/InAlN High-Electron-Mobility Transistor Structures Grown by Plasma-Assisted Molecular Beam Epitaxy on Vicinal Substrates. Semicond Sci. Technol. 2015, 30, 055012. [Google Scholar] [CrossRef]

- Kim, S.; Oh, J.; Kang, J.; Kim, D.; Won, J.; Kim, J.W.; Cho, H.K. Two-Step Growth of High Quality GaN Using V/III Ratio Variation in the Initial Growth Stage. J. Cryst. Growth. 2004, 262, 7–13. [Google Scholar] [CrossRef]

- Altuntas, I.; Demir, I.; Kasapoǧlu, A.E.; Mobtakeri, S.; Gür, E.; Elagoz, S. The Effects of Two-Stage HT-GaN Growth with Different V/III Ratios during 3D–2D Transition. J. Phys. D Appl. Phys. 2017, 51, 035105. [Google Scholar] [CrossRef]

- Gupta, G.; Kanamura, M.; Swenson, B.; Bisi, D.; Romanczyk, B.; Neufeld, C.; Wienecke, S.; Ogino, T.; Miyazaki, Y.; Imanishi, K.; et al. 1200V GaN Switches on Sapphire Substrate. In Proceedings of the International Symposium on Power Semiconductor Devices and ICs, Vancouver, BC, Canada, 23–25 May 2022; pp. 349–352. [Google Scholar] [CrossRef]

- Li, J.; Yin, Y.; Zeng, N.; Liao, F.; Lian, M.; Zhang, X.; Zhang, K.; Li, J. Normally-off AlGaN/AlN/GaN HEMT with a Composite Recessed Gate. Superlattices Microstruct. 2022, 161, 107064. [Google Scholar] [CrossRef]

- Zou, H.; Yang, L.A.; Ma, X.H.; Hao, Y. The Dual-Suppression of Peak Electric Field in AlGaN/GaN HEMT with Sandwich Structure. Superlattices Microstruct. 2021, 152, 106843. [Google Scholar] [CrossRef]

- Wang, H.C.; Hsieh, T.E.; Lin, Y.C.; Luc, Q.H.; Liu, S.C.; Wu, C.H.; Dee, C.F.; Majlis, B.Y.; Chang, E.Y. AlGaN/GaN MIS-HEMTs with High Quality ALD-Al2O3 Gate Dielectric Using Water and Remote Oxygen Plasma as Oxidants. IEEE J. Electron Devices Soc. 2017, 6, 110–115. [Google Scholar] [CrossRef]

- Zheng, X.H.; Chen, H.; Yan, Z.B.; Han, Y.J.; Yu, H.B.; Li, D.S.; Huang, Q.; Zhou, J.M. Determination of Twist Angle of In-Plane Mosaic Spread of GaN Films by High-Resolution X-Ray Diffraction. J. Cryst. Growth 2003, 255, 63–67. [Google Scholar] [CrossRef]

- Cai, Y.; Zhu, C.; Jiu, L.; Gong, Y.; Yu, X.; Bai, J.; Esendag, V.; Wang, T. Strain Analysis of GaN HEMTs on (111) Silicon with Two Transitional AlxGa1−xN Layers. Materials 2018, 11, 1968. [Google Scholar] [CrossRef]

- Kamiyama, S.; Iwaya, M.; Hayashi, N.; Takeuchi, T.; Amano, H.; Akasaki, I.; Watanabe, S.; Kaneko, Y.; Yamada, N. Low-Temperature-Deposited AlGaN Interlayer for Improvement of AlGaN/GaN Heterostructure. J. Cryst. Growth 2001, 223, 83–91. [Google Scholar] [CrossRef]

- Uesugi, K.; Shojiki, K.; Tezen, Y.; Hayashi, Y.; Miyake, H. Suppression of Dislocation-Induced Spiral Hillocks in MOVPE-Grown AlGaN on Face-to-Face Annealed Sputter-Deposited AlN Template. Appl. Phys. Lett. 2020, 116, 062101. [Google Scholar] [CrossRef]

- Meneghesso, G.; Meneghini, M.; Zanoni, E. Breakdown Mechanisms in AlGaN/GaN HEMTs: An Overview. Jpn J. Appl. Phys. 2014, 53, 100211. [Google Scholar] [CrossRef]

- Saito, W.; Suwa, T.; Uchihara, T.; Naka, T.; Kobayashi, T. Breakdown Behaviour of High-Voltage GaN-HEMTs. Microelectron. Reliab. 2015, 55, 1682–1686. [Google Scholar] [CrossRef]

- Syamsul, M.; Oi, N.; Okubo, S.; Kageura, T.; Kawarada, H. Heteroepitaxial Diamond Field-Effect Transistor for High Voltage Applications. IEEE Electron Device Lett. 2018, 39, 51–54. [Google Scholar] [CrossRef]

- Bie, Y.N.; Du, C.L.; Cai, X.L.; Ye, R.; Liu, H.J.; Zhang, Y.; Duan, X.Y.; Zhu, J.J. Effect of Source Field Plate Cracks on the Electrical Performance of AlGaN/GaN HEMT Devices. Crystals 2022, 12, 1195. [Google Scholar] [CrossRef]

- Moore, W.J.; Freitas, J.A.; Braga, G.C.B.; Molnar, R.J.; Lee, S.K.; Lee, K.Y.; Song, I.J. Identification of Si and O Donors in Hydride-Vapor-Phase Epitaxial GaN. Appl. Phys. Lett. 2001, 79, 2570. [Google Scholar] [CrossRef]

- Gao, S.; Zhou, Q.; Li, X.; Xie, Z.; Wang, H. A Method for Obtaining the Real Off-State Breakdown Voltage of AlGaN/GaN MIS-HEMTs in On-Wafer Tests by Optimizing Protective Layer. IEEE J. Electron Devices Soc. 2019, 7, 902–907. [Google Scholar] [CrossRef]

- Choi, Y.C.; Pophristic, M.; Spencer, M.G.; Eastman, L.F. High Breakdown Voltage and Low Specific On-Resistance C-Doped GaN-on-Sapphire HFETs for Low-Loss and High-Power Switching Applications. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition—APEC, Anaheim, CA, USA, 25 February–1 March 2007; pp. 1264–1267. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yusuf, Y.; Samsudin, M.E.A.; Taib, M.I.M.; Ahmad, M.A.; Mohamed, M.F.P.; Kawarada, H.; Falina, S.; Zainal, N.; Syamsul, M. Two-Step GaN Layer Growth for High-Voltage Lateral AlGaN/GaN HEMT. Crystals 2023, 13, 90. https://doi.org/10.3390/cryst13010090

Yusuf Y, Samsudin MEA, Taib MIM, Ahmad MA, Mohamed MFP, Kawarada H, Falina S, Zainal N, Syamsul M. Two-Step GaN Layer Growth for High-Voltage Lateral AlGaN/GaN HEMT. Crystals. 2023; 13(1):90. https://doi.org/10.3390/cryst13010090

Chicago/Turabian StyleYusuf, Yusnizam, Muhammad Esmed Alif Samsudin, Muhamad Ikram Md Taib, Mohd Anas Ahmad, Mohamed Fauzi Packeer Mohamed, Hiroshi Kawarada, Shaili Falina, Norzaini Zainal, and Mohd Syamsul. 2023. "Two-Step GaN Layer Growth for High-Voltage Lateral AlGaN/GaN HEMT" Crystals 13, no. 1: 90. https://doi.org/10.3390/cryst13010090

APA StyleYusuf, Y., Samsudin, M. E. A., Taib, M. I. M., Ahmad, M. A., Mohamed, M. F. P., Kawarada, H., Falina, S., Zainal, N., & Syamsul, M. (2023). Two-Step GaN Layer Growth for High-Voltage Lateral AlGaN/GaN HEMT. Crystals, 13(1), 90. https://doi.org/10.3390/cryst13010090