1. Introduction

Aluminium (Al) and its alloys are the most used metallic materials in industries after steel. The most significant advantage of Al alloys compared to steel is the ratio between strength and stiffness to weight [

1,

2]. Al cast alloys are applied in different areas, e.g., automotive, aerospace, and sports industries [

3]. Strength and ductility can be improved due to a combination of alloying elements and heat treatments. The strength and hardness properties of age-hardenable Al alloys are improved by applying a heat treatment that usually comprises the following three steps [

4]:

Solution heat treatment (SHT) at high temperatures to dissolve the alloying elements into the Al matrix.

Cooling with high cooling rates to suppress precipitation and to obtain a supersaturated solid solution.

Aging at room temperature (RT) (natural aging) or at higher temperature (artificial aging) to ensure a controlled formation of finely dispersed precipitates in the aluminium matrix.

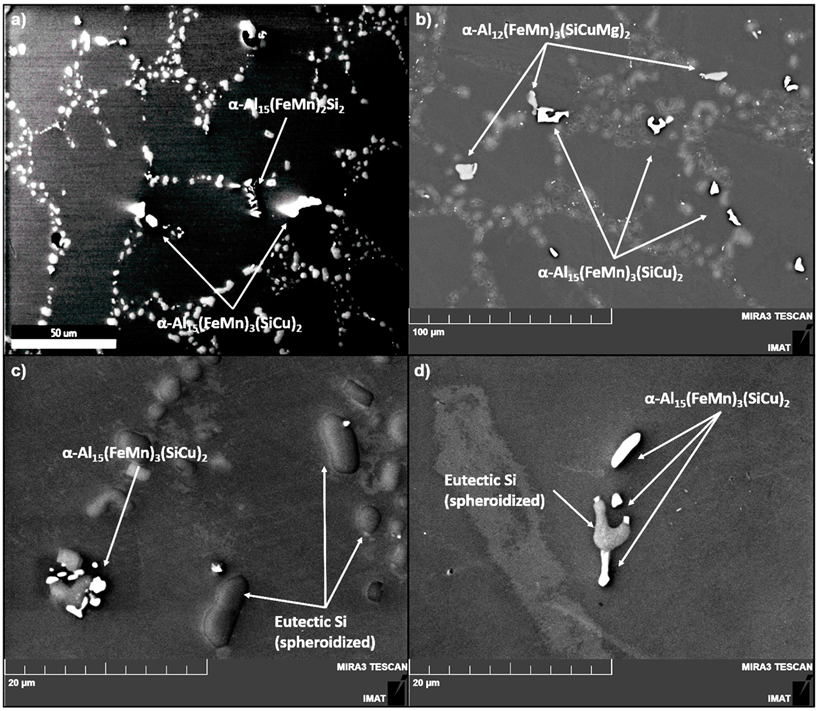

The presence of Si, Mg, and Cu in the AlSi

7Cu

0.5Mg alloy promotes the formation of metastable and stable intermetallic phases during aging: GP zones [

5,

6], β″-, β′-Mg

2Si [

7], θ″-, θ′-Al

2Cu [

4]and Q″-, Q′-Al

5Mg

8Si

6Cu

2 [

1,

8,

9,

10]. Additionally, primary phases such as eutectic Si and Fe and Mn-rich aluminides are present after the solidification and partially transformed during SHT. They are not modified by further exposure to the temperature/time of annealing treatments. The grain structure and average grain size do not change significantly at the aging temperatures, since the recrystallization temperature is much higher and the cast material is highly recrystallized [

11,

12].

After solution heat treatment, the quenching process in Al cast products provokes thermal gradients resulting from the complex geometry and inhomogeneous cooling leading to residual stresses. In the case of cylinder heads and engine blocks, unrelieved stresses can result in cracking and reduced cast component durability [

13].

Godlewski et al. [

13] investigated the relaxation of residual stresses during the aging of an E319 aluminium alloy using a sample with a geometry that provokes a significant amount of residual stresses during quenching. The samples were solution heat-treated for 4 h at 495 °C, followed by water quenching of the bottom side to 10 °C, and then artificially aged at different temperatures. After air quenching, strain gages were attached, the samples were sectioned at the bridges with a band saw, and the strain was recorded. The experimental data was then used to verify a stress relaxation model and implement it in an FEA. Phenomenological models to describe relaxation were already developed by G. R. Rao [

14] and S. Rahimi [

15]. Both models work well according to their published works, but multiple fitting parameters have to be used in both. Rahimi used three parameters in his model, and G. R. Raos used no less than eight parameters.

The prediction of the relaxation in a material during aging plays a significant role in designing the heat treatment process so that the required strength can be achieved, avoiding damage during service caused by residual stresses in the structure.

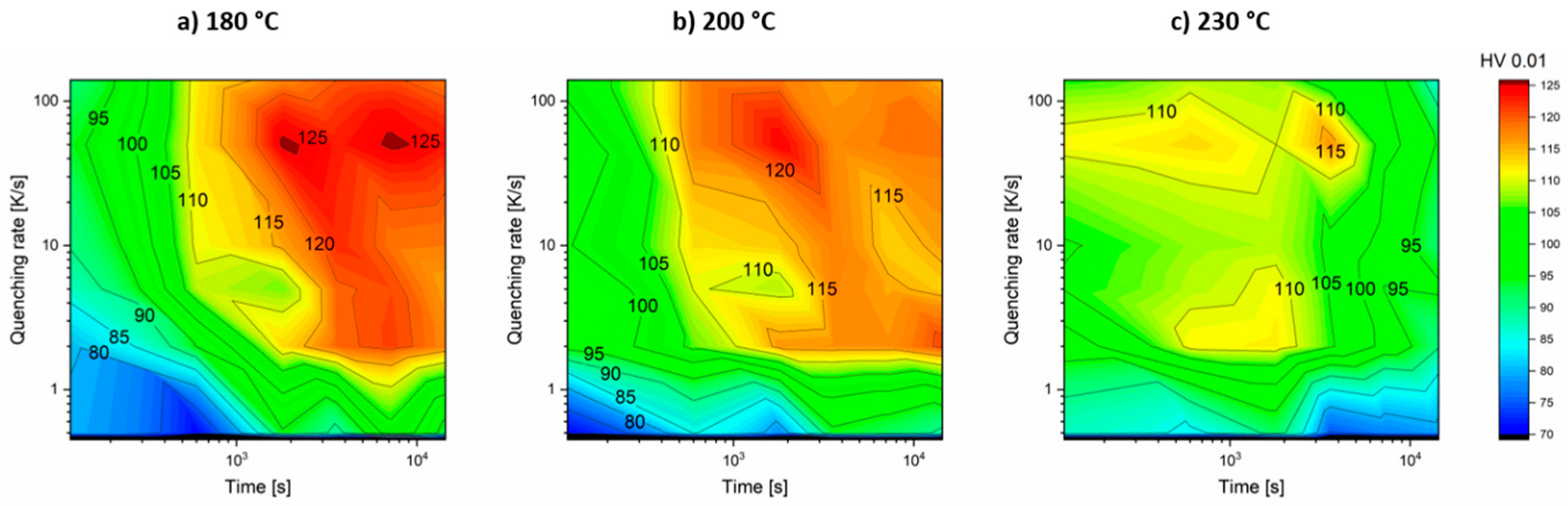

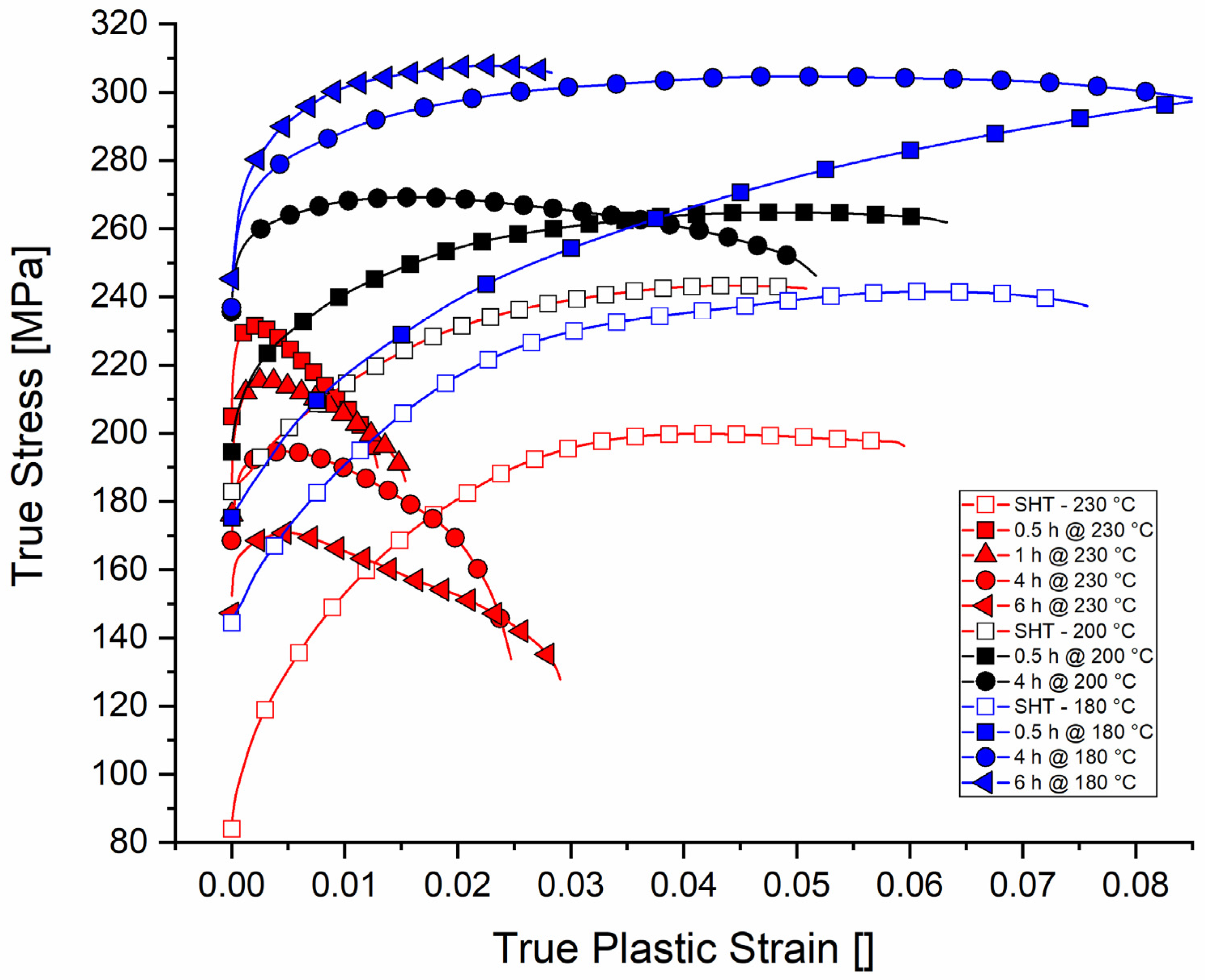

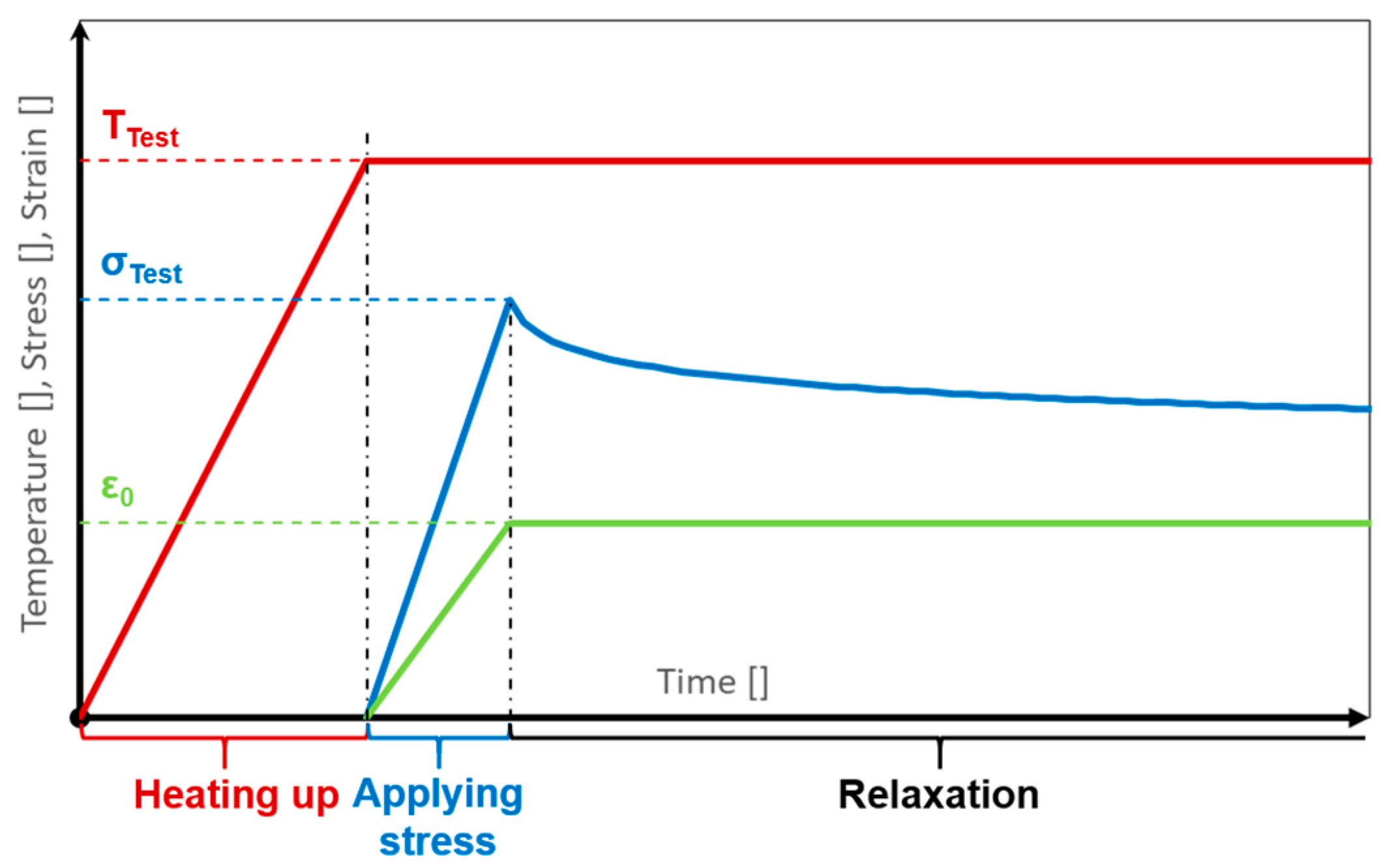

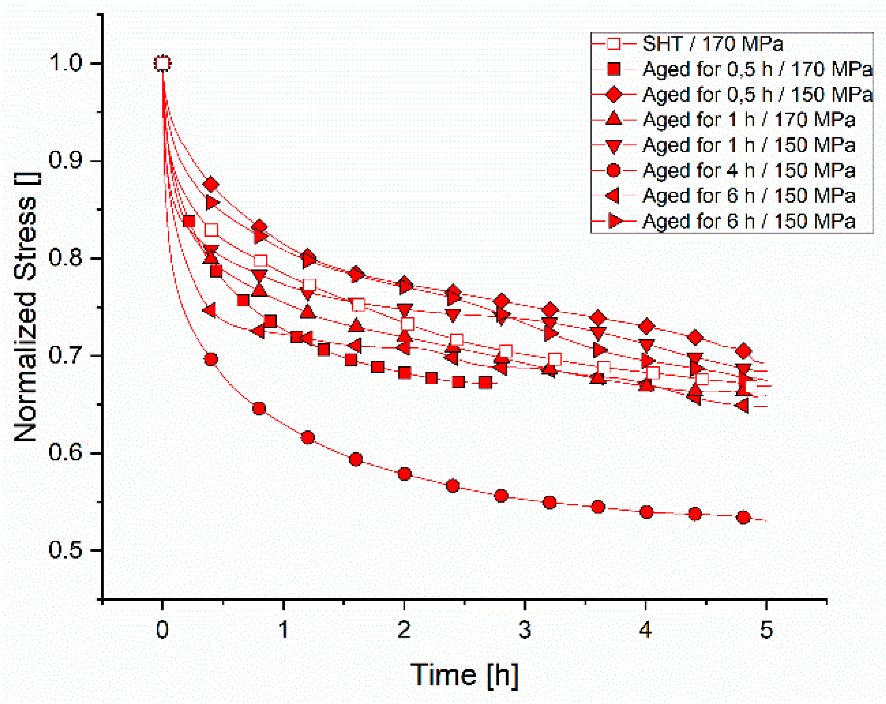

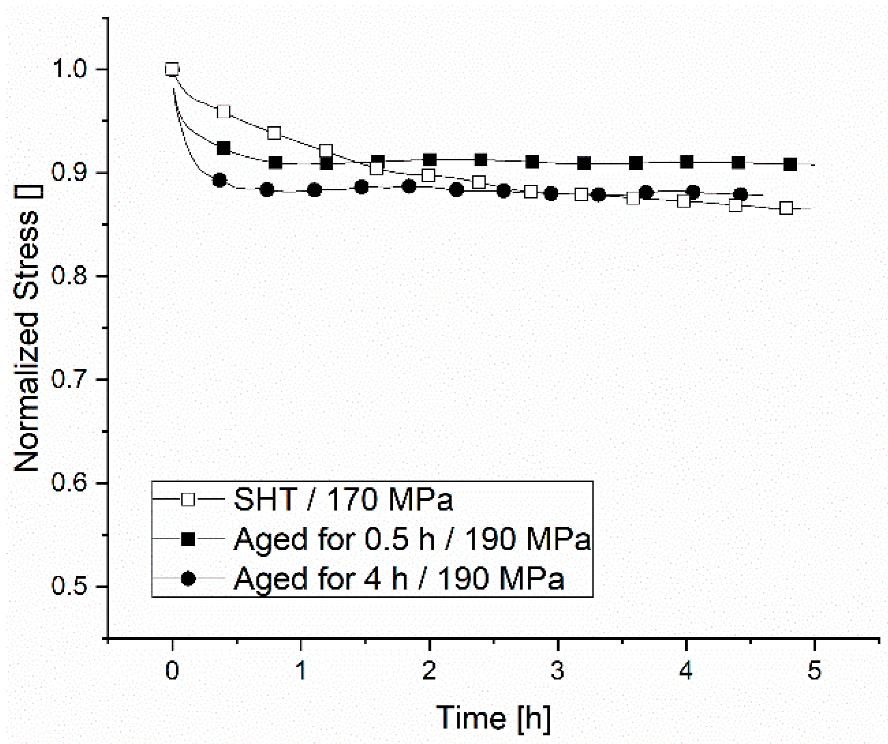

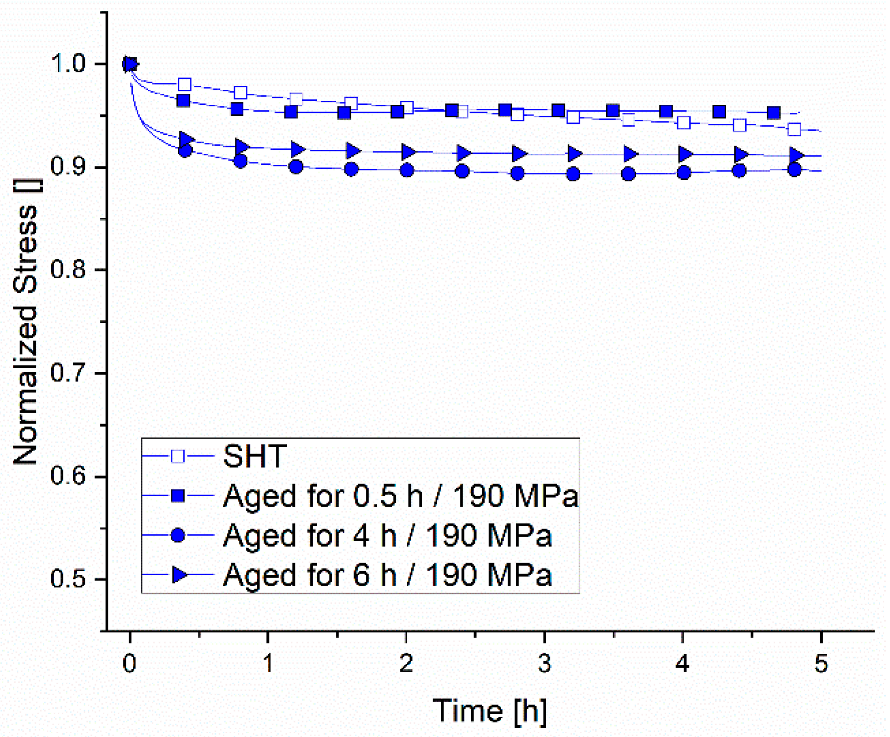

This work presents the results of several tensile stress relaxation tests conducted at different temperatures and stress levels. The material was tested in different microstructural conditions, including SHT-, under-, peak- and overaged states. The results were then used to develop a phenomenological model to predict this stress relaxation process. The model is based on the work of S. Rahimi et al. [

15], which deals with the relaxation of an IN718 nickel-based superalloy. The same procedure is now applied to the AlSi

7Cu

0.5Mg alloy, but the parameters in this work were correlated to the test temperature, stress level, and precipitation state. Furthermore, the plastic strain rates (PSRs) were analyzed and the model was evaluated.

4. Discussion

The relaxation proceeds by the plastic deformation of the material.

where

,

, and

are the total, the elastic, and the plastic strains, respectively. During the stress relaxation, the total strain given by Equation 4 is equal to 0. The plastic strain rate (PSR) is also zero during stress relaxation tests

are the corresponding strain rates. Using Hook’s law for the elastic part, we obtain Equation (6)

where

is the stress and

E is the Young’s modulus. If the plastic strain rate can be correlated to the stresses using a power law, then:

and taking logarithms

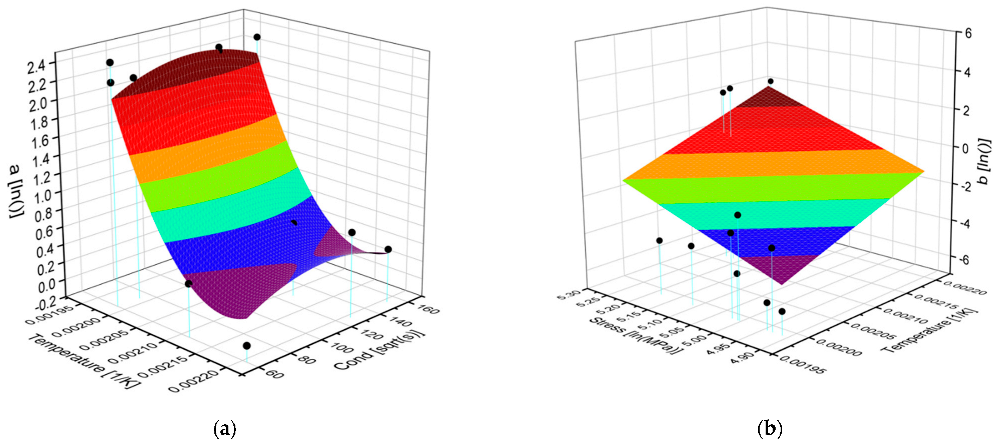

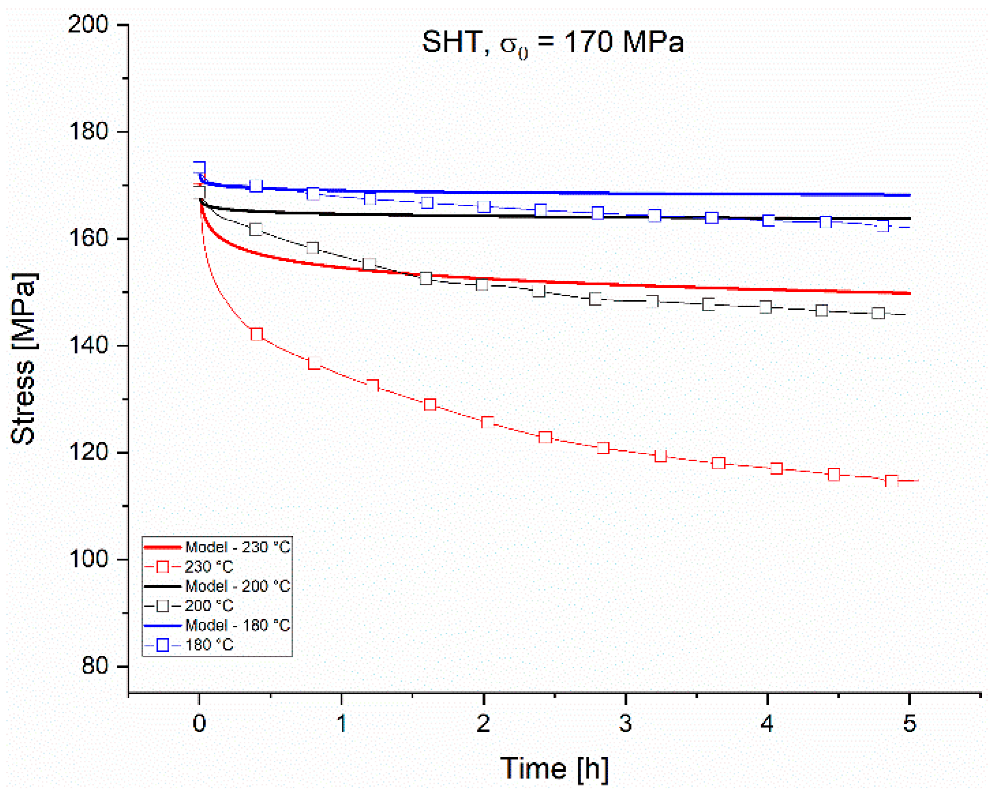

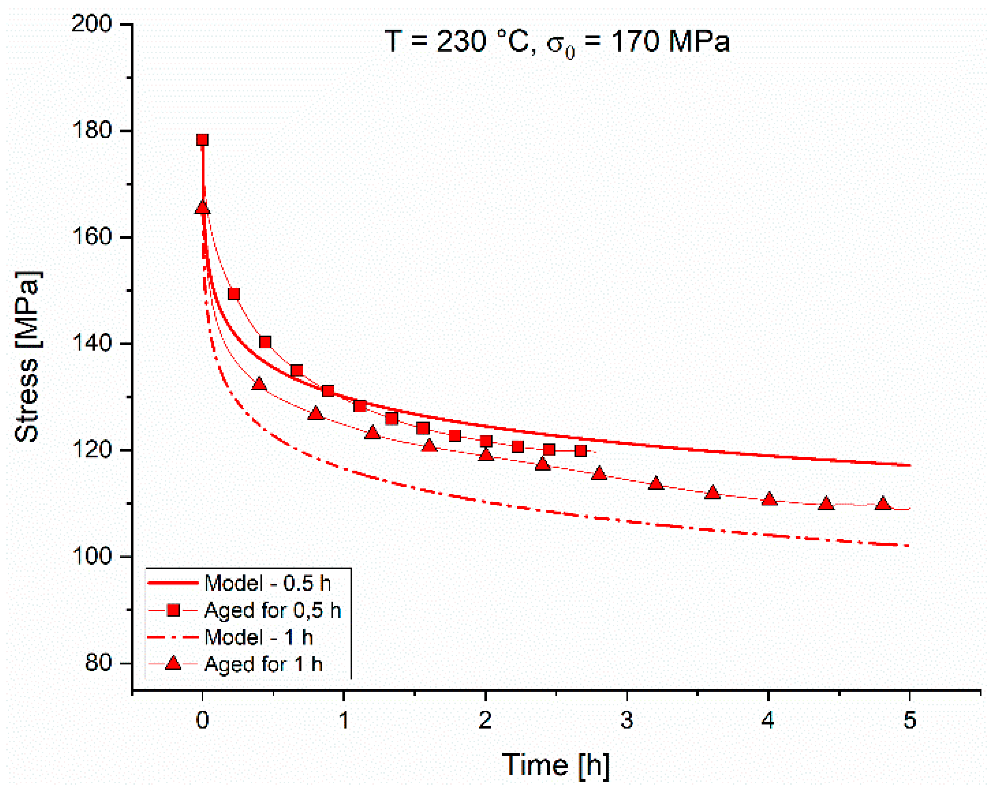

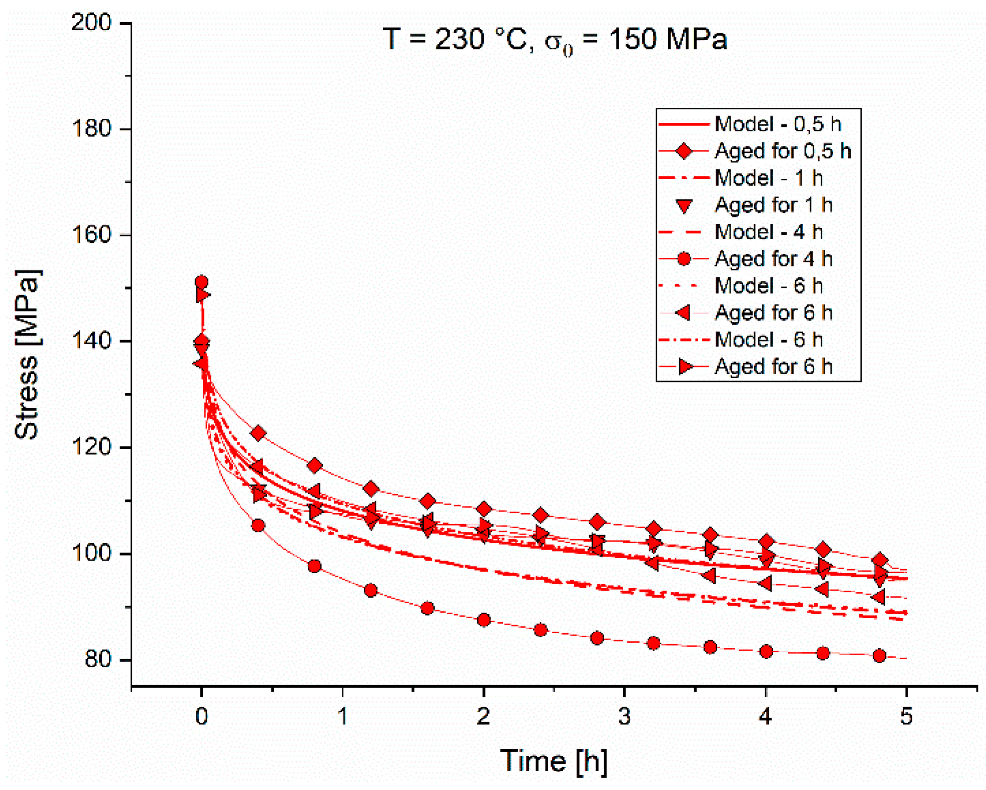

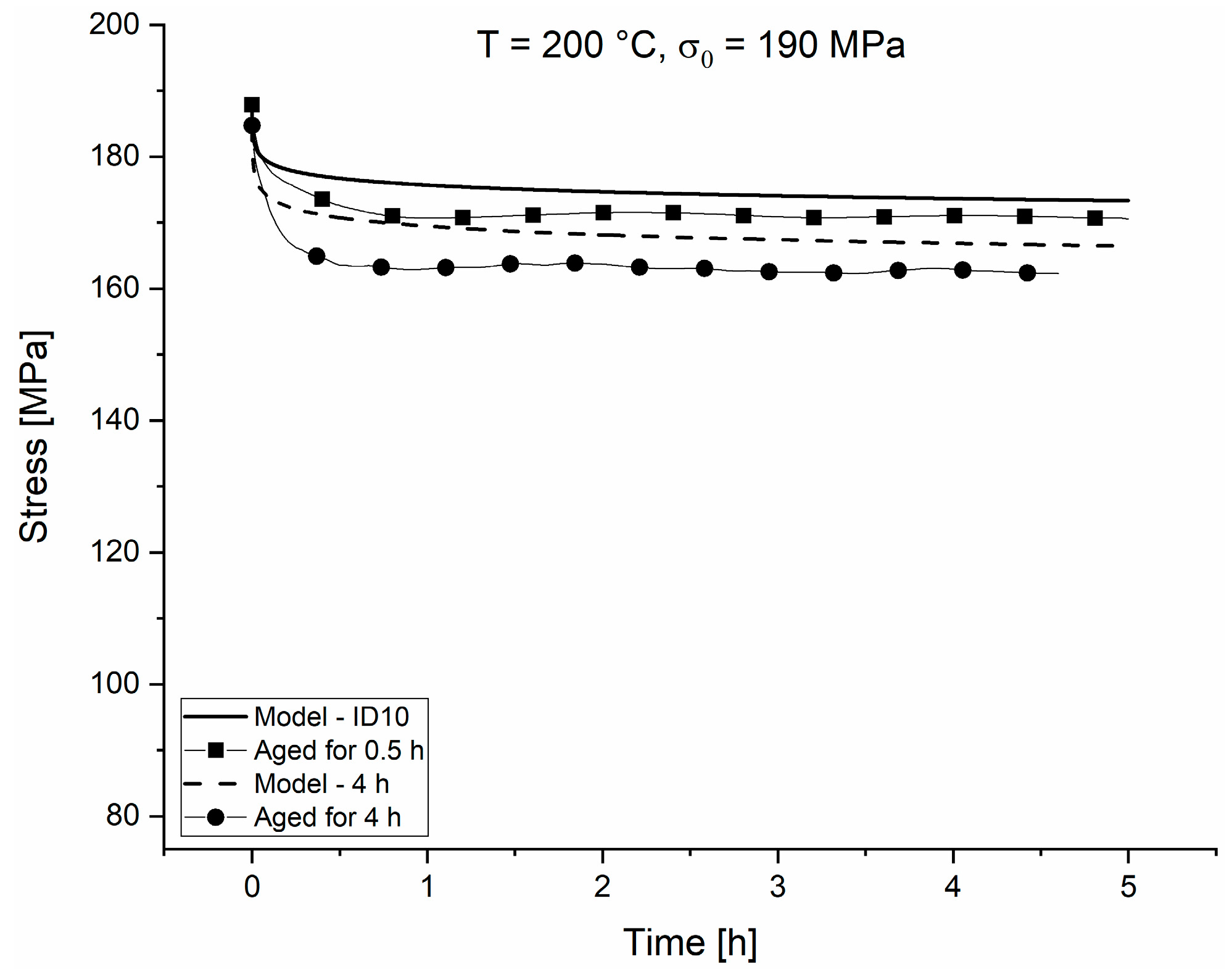

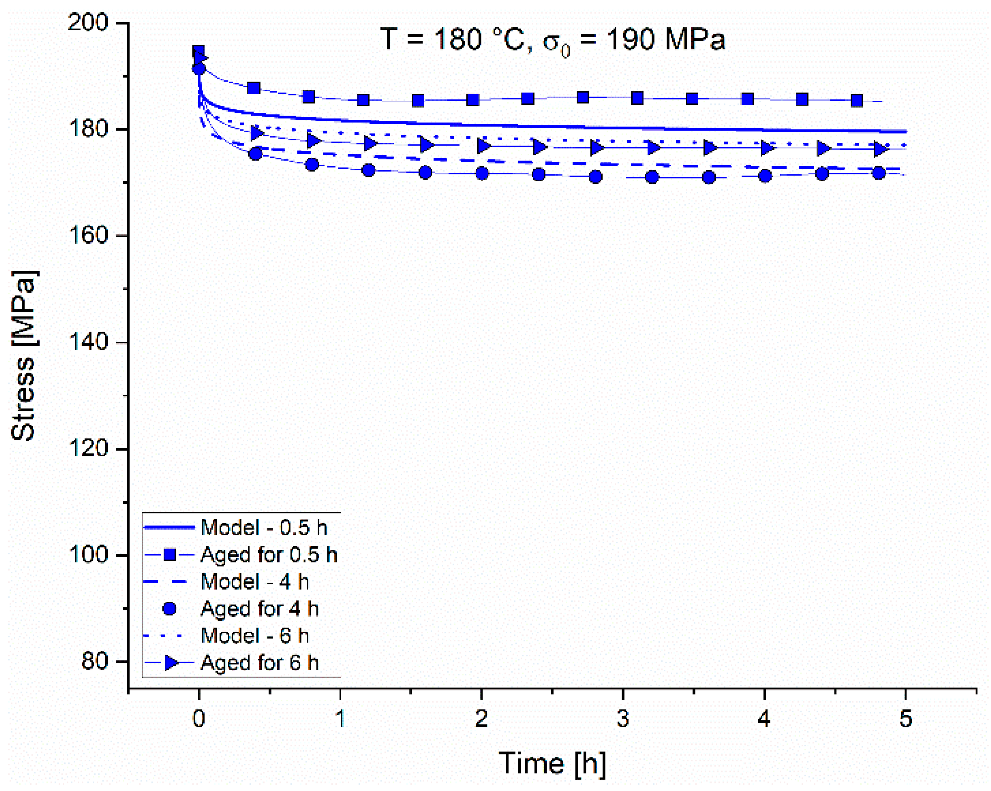

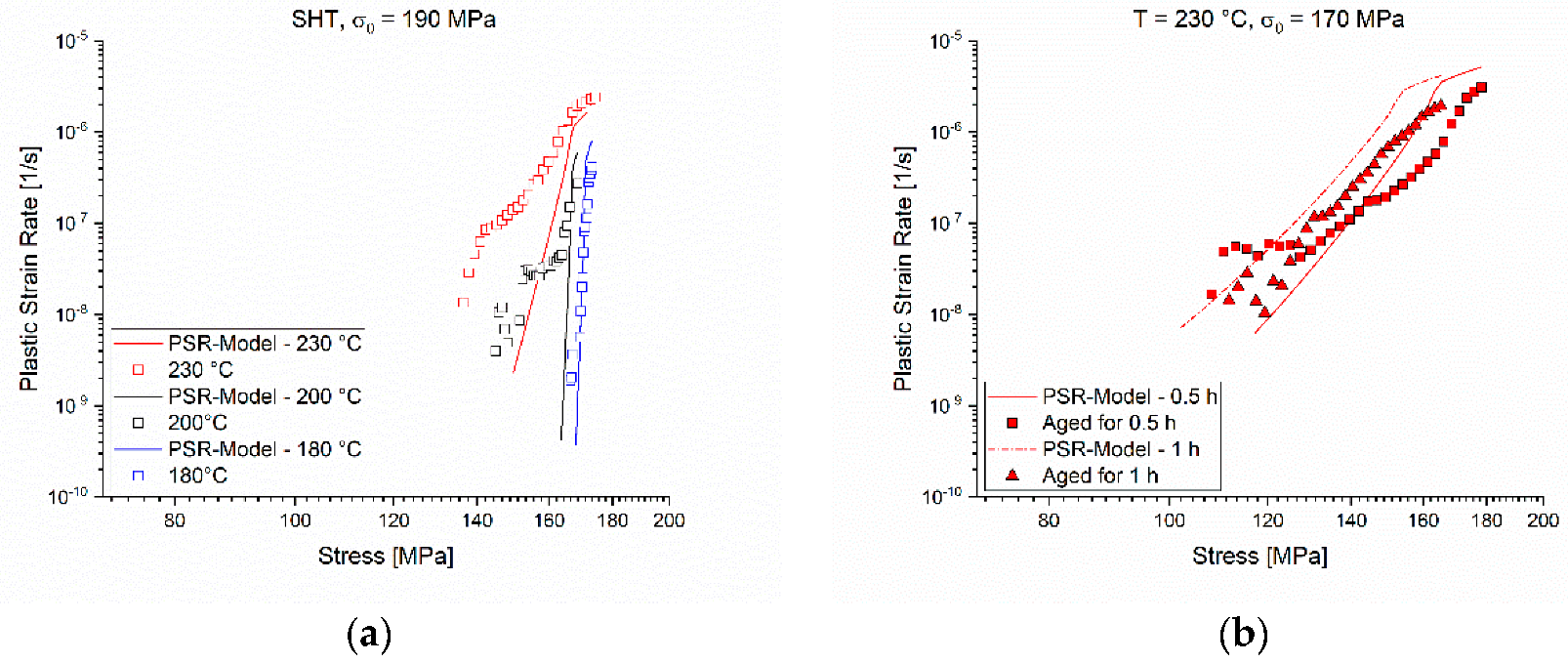

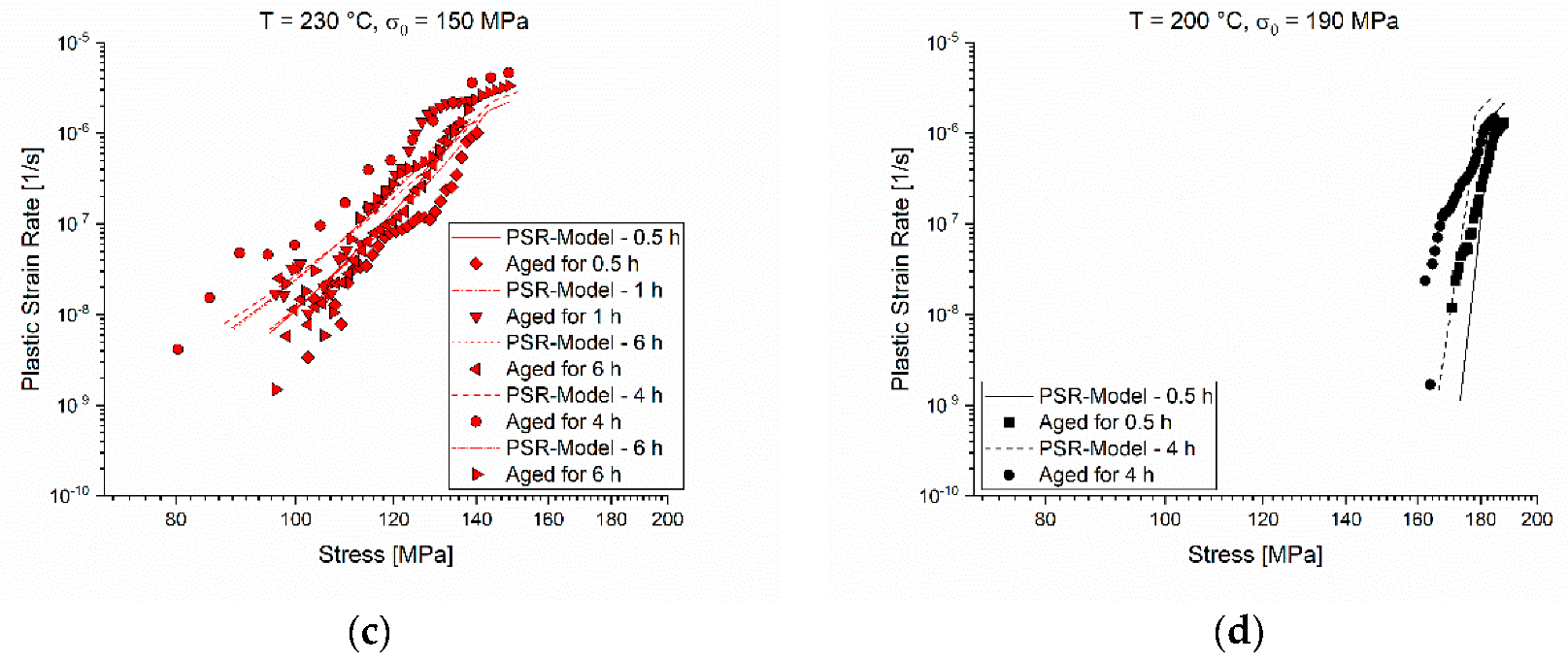

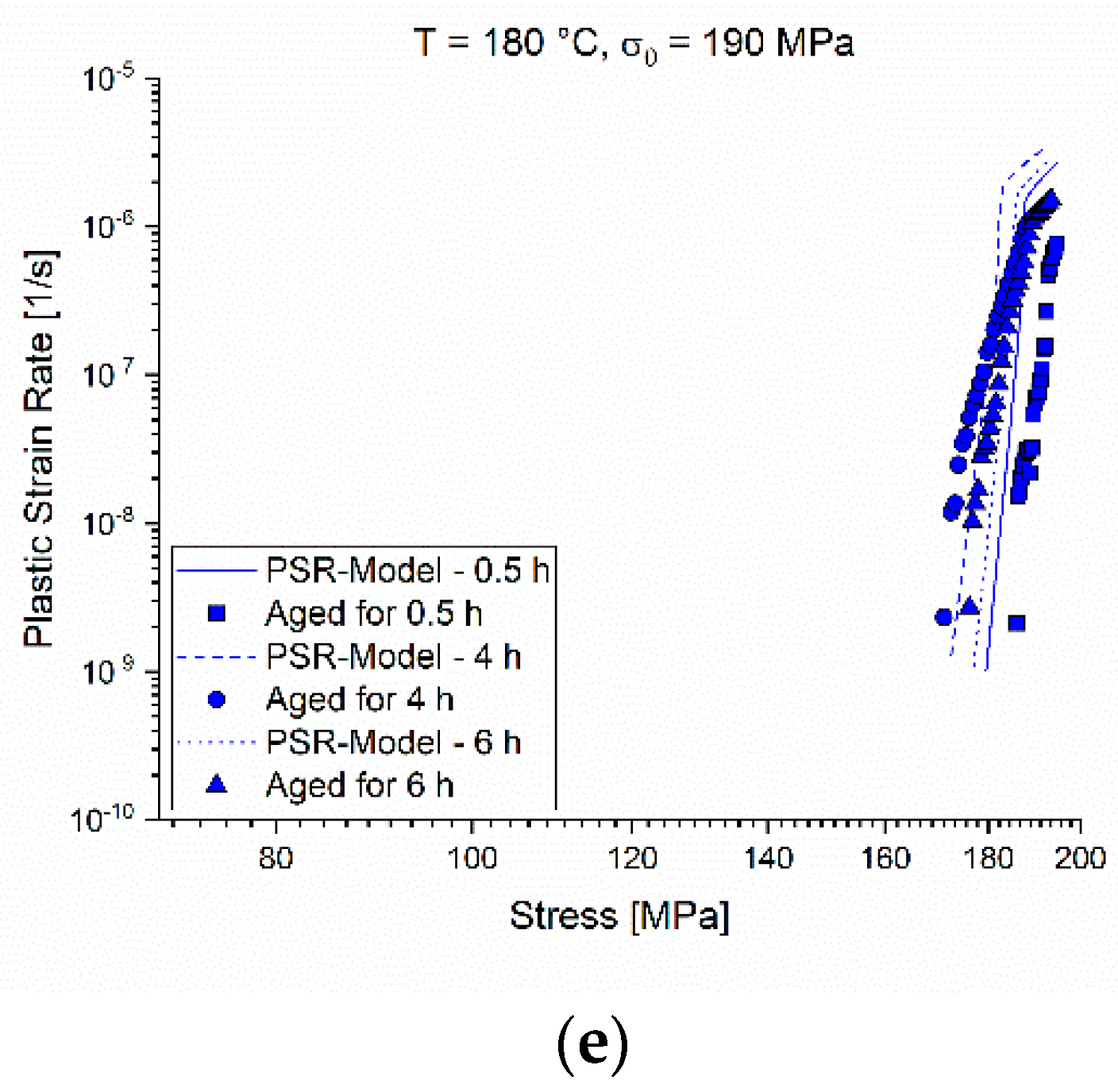

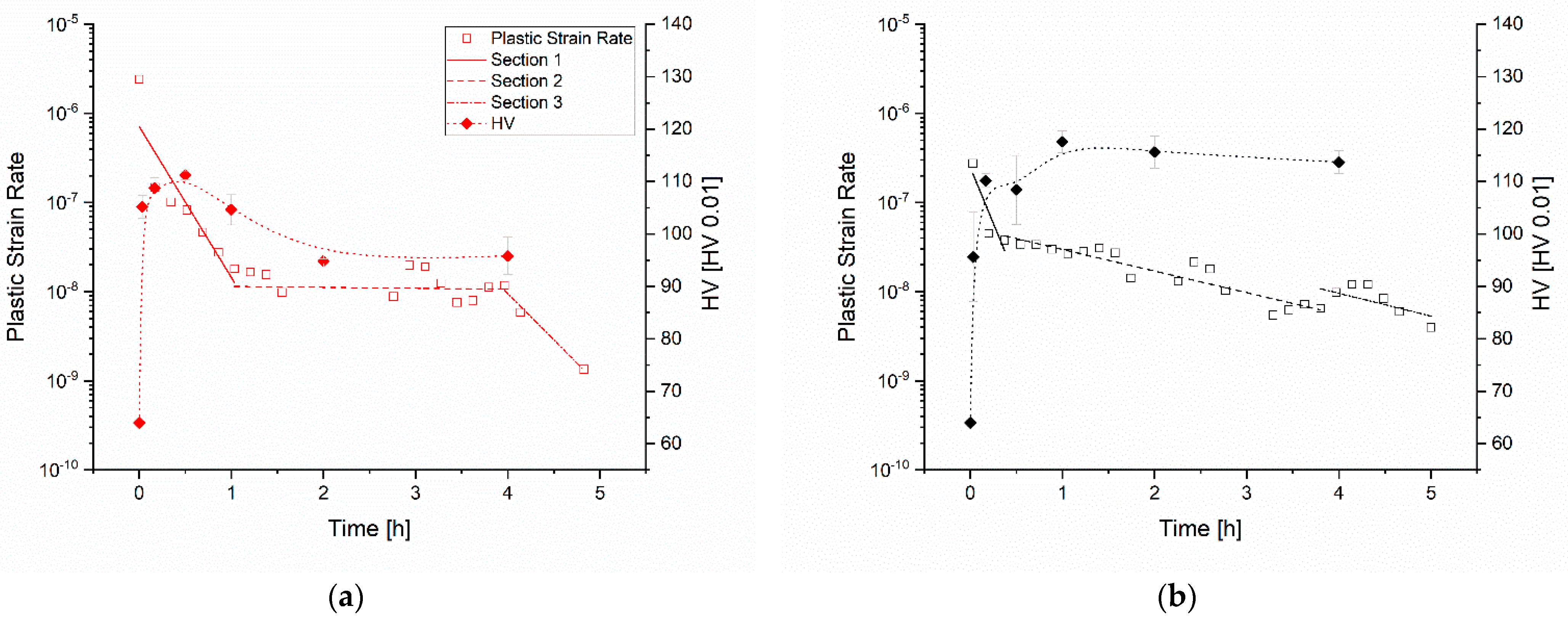

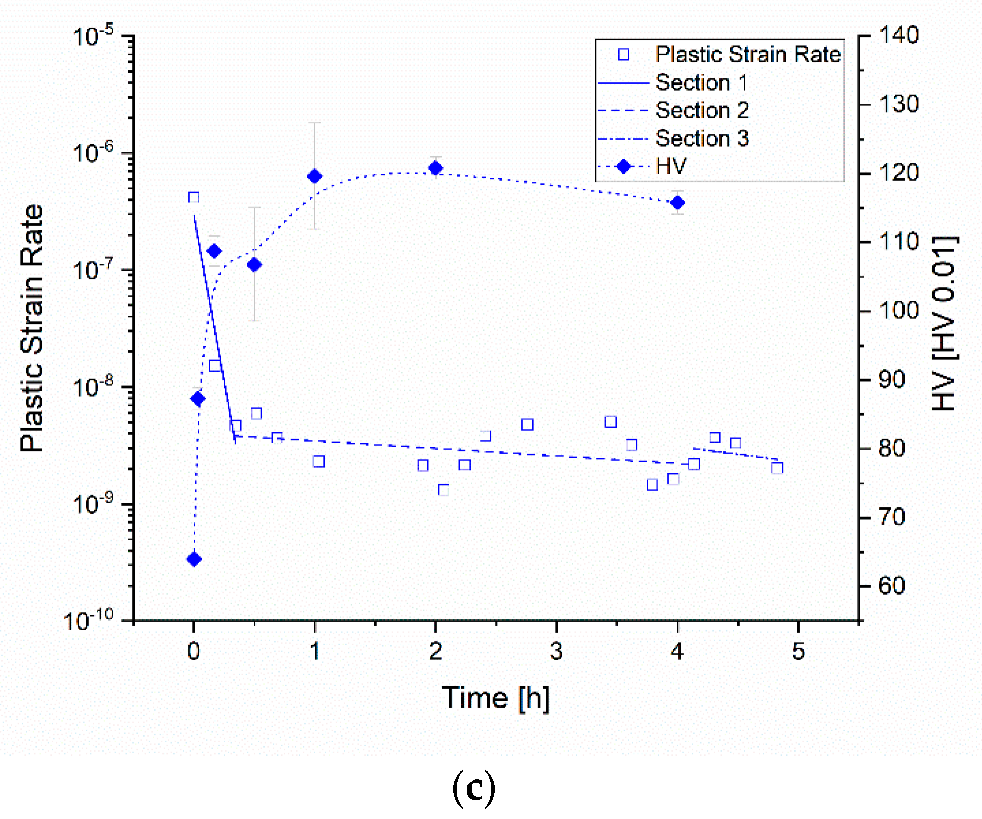

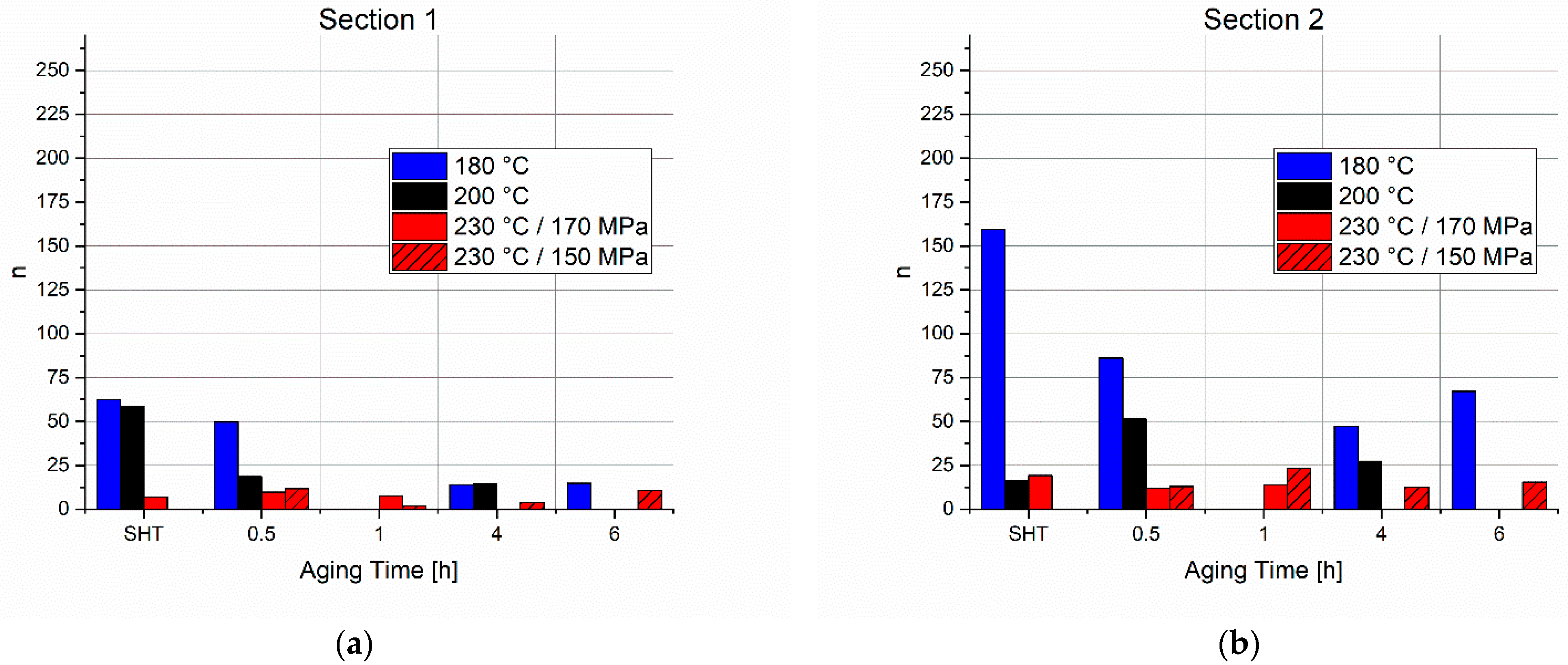

The comparisons of the experimental and modelled PSRs over time are plotted in double logarithmic graphs in

Figure 14a–e. For better visualization, the tests are separated as in the chapter above. The deviations seen in the direct comparison of the experimental and modelled relaxation curves in

Figure 9,

Figure 10,

Figure 11,

Figure 12 and

Figure 13 appear here more clearly. The model is not capable of tracking every single fluctuation of the experimental PSRs exactly, but it can predict the major changes of the PSRs.

The deviations from the model accounted for the development of the microstructure during the aging/relaxation of the specimen. Since the model takes only the starting condition of the sample in form of aging time and aging temperature into account, no meaningful microstructure

modifications, e.g., size and density, are incorporated in the model. On the

other hand, notwithstanding the precautions taken for performing tests at a

constant temperature, an isothermal temperature distribution in the specimen is

not completely granted and a thermal expansion could lead to a faster relaxation.

Three sections were identified with different slopes (stress exponents

n), as described in Equation (7). The three sections correspond to the stress state and the three phases in the precipitation kinetics: (1) nucleation, (2) growth, and (3) coarsening. In

Figure 15, the PSRs of the tests in the SHT state and their linear fits are compared to the hardness evolution of the material for each temperature.

High plastic strain rates appear at the beginning of the test (Section 1) when the nucleation of precipitates starts, stresses and dislocation densities are high, and the dislocation movement is fast. The test at 230 °C starts with the highest PSR and the lowest deceleration. The tests at the other two temperatures start at PSRs a magnitude lower and decelerate much faster.

After reaching peak hardness (start of Section 2), the dislocation movement and relaxation process slowed down drastically in all the tests, indicating the presence of highly dispersed small particles interacting with a lower amount of dislocations that annihilate over time. The much faster precipitation process at 230 °C approaches the coarsening stage earlier and therefore the relaxation rate decreases not as much as for lower temperatures. The lower temperatures show no such coarsening stage within 5 h. The hardness profiles show a stable hardness of the material already after 1 h at a higher level than at 230 °C. Section 3 shows either further hardening for 180 °C and 200 °C or further coarsening accompanied by softening after the relatively stable Section 2 for 230 °C.

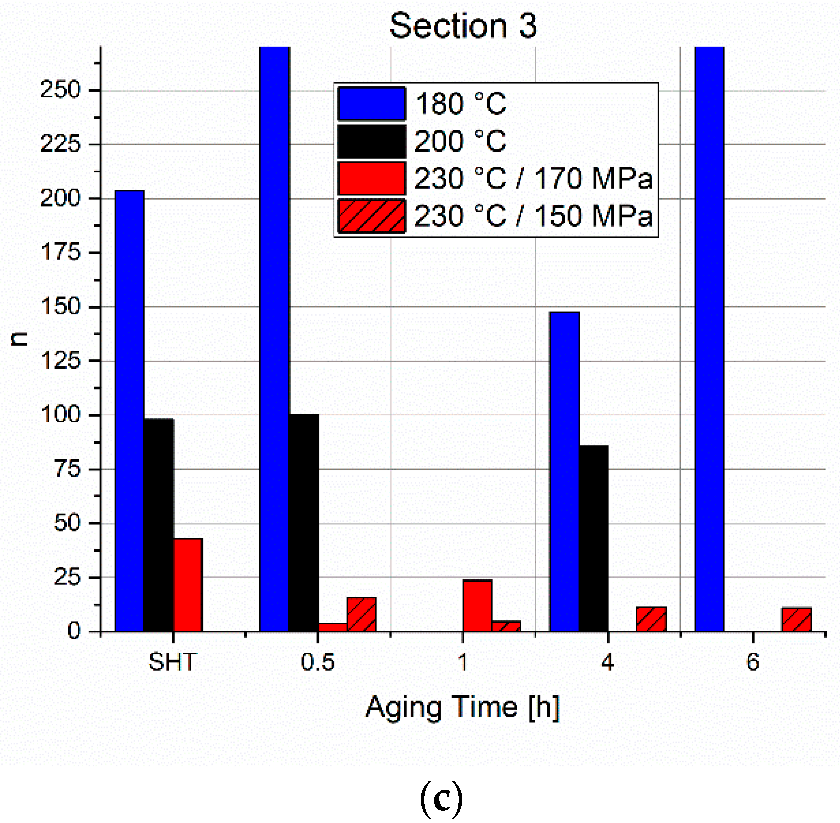

The stress exponents are plotted in

Figure 16a–c, grouped by the different sections. In general, values of n showed that

. This tendency represents the annihilation rate of dislocations starting with a large number density of dislocations at the beginning and decreasing over time. Overall, the tests at 180 °C have the highest values for

n in all sections, followed by the values for 200 °C and 230 °C. This temperature dependence indicates much lower mobility of dislocations in the microstructure at lower temperatures. Whereas the values for

n2 and

n3 at 180/200 °C are high, much lower values were obtained at 230 °C. The lowest stress exponents are found in the first section, see

Figure 16a, compared to the other two sections. That concludes that in the early stage of the relaxation, the dislocation density in the microstructure is high and the dislocation movement and annihilation are fast. Additionally, the low precipitate number density, especially for the tests in the SHT state accelerates the relaxation.

In Section 2 (

Figure 16b), further nucleation and growth of precipitates hinder the movement of the dislocations. Furthermore, the dislocation density increases, and the stress relaxation slows down. The increase in

n2 at 230 °C is much less than the increase in the tests at 200 °C and lower. According to the microhardness maps, the precipitates at higher temperatures are already in coarsening stage and the strength is lower than for 200 °C and 180 °C.

In the last section, the relaxation process comes to an end, indicated by the large values for

n3 in

Figure 16c for the tests at the two lower temperatures. The movement of dislocations is blocked due to Zener drag, and the low dislocation density does not suffer relevant annihilation. The still small values for

n3 of the 230 °C means that the relaxation process is not finished after 5 h and that the precipitates coarsen, incrementing the stress relaxation rate.

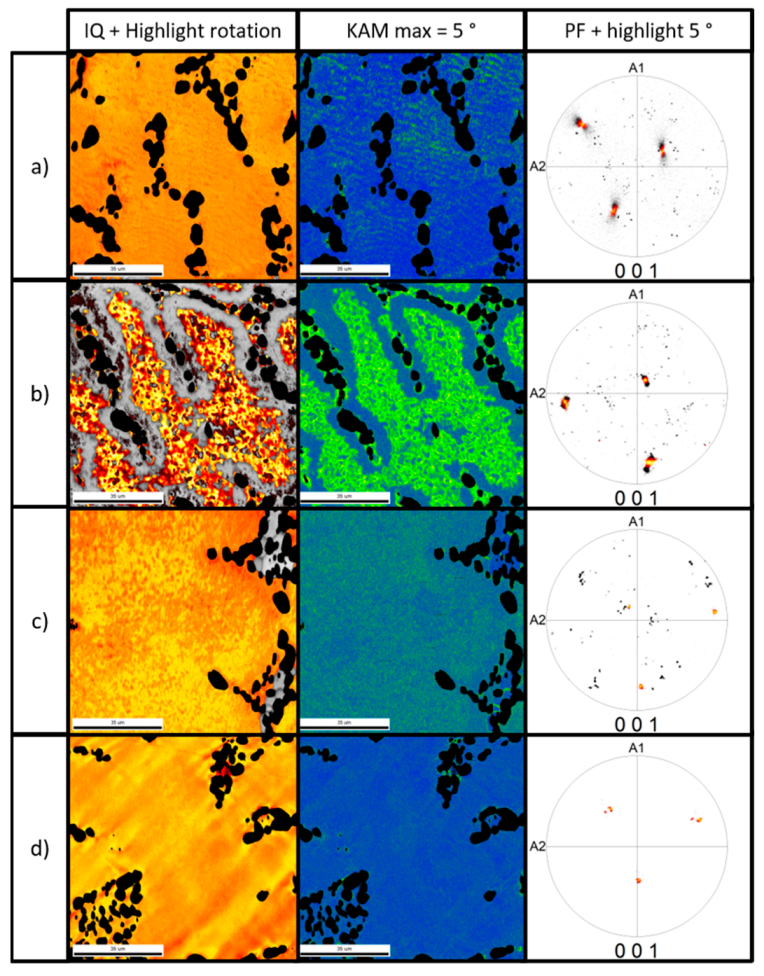

Figure 17 showing the kernel average misorientation of the material after SHT and water quenching, and after heat treated samples. The misorientation seen in the sample in the SHT state is due to the quenching-induced dislocations. The relaxation process reduces the spread of misorientation mainly dependent on the relaxation temperature. Whereas the dislocation movement needed for relaxation is hindered at 180 °C, the misorientation spread is still observed. The misorientation spread is significantly lower after relaxation at 200 °C and at 230 °C due to dislocation annihilation.

5. Summary and Conclusions

In this study, experiments on the stress relaxation of an AlSiMg alloy with Cu addition were performed. A phenomenological model based on the work of Rahimi et al. [

15] was developed for the prediction of residual stress at any time and starting condition. The results of the tests and the simulation were then compared and the model was validated. Furthermore, the results of the test were linked to corresponding microhardness profiles and EBSD data to get an understanding of the processes during the competing mechanisms of precipitation and relaxation.

Relaxation is strongly dependent on the thermal history of the samples and the relaxation temperature. A microstructure that is already overaged showed a higher ability to relax, whereas samples in the SHT and shortly-aged states showed higher stress levels after 5 h. The higher mobility of dislocations in a microstructure with coarse precipitates was found in overaged conditions at 230 °C. Higher relaxation temperatures lead to lower stress levels after a certain time, which can also be explained by the increased mobility of dislocations at a higher temperature. The dislocations of the material in the SHT state lose the ability to move at 180 °C and 200 °C by increasing Zener drag and a later coarsening stage. Plastic strain rates are calculated for all tests and three sections with different stress exponents are identified, which correspond to the stages found in the precipitation kinetics.

The phenomenological model is dependent on the materials’ starting condition and the relaxation condition. A good agreement with the tests with an average deviation of 3.4% was found. The highest precision of the model was found to be for 180 °C and 200 °C. Since for each state only one experiment could be conducted, a variation of the results can be expected (e.g., 230 °C, 150 MPa, 6 h aged) and an improvement of the model’s accuracy might be necessary. The deviations in the experimental results could be related to the testing machine and inhomogeneous temperature distribution on the specimen during the test or sample heterogeneities. Nevertheless, the phenomenological model can be used for a fast assessment of the relaxation process without a large number of input parameters, but with low computational capability. Further works on a more physical model to predict the relaxation process due to microstructural changes obtained at different aging conditions, dislocation movement, and annihilation are needed.