Prediction of Residual Stress Distribution in NM450TP Wear-Resistant Steel Welded Joints

Abstract

1. Introduction

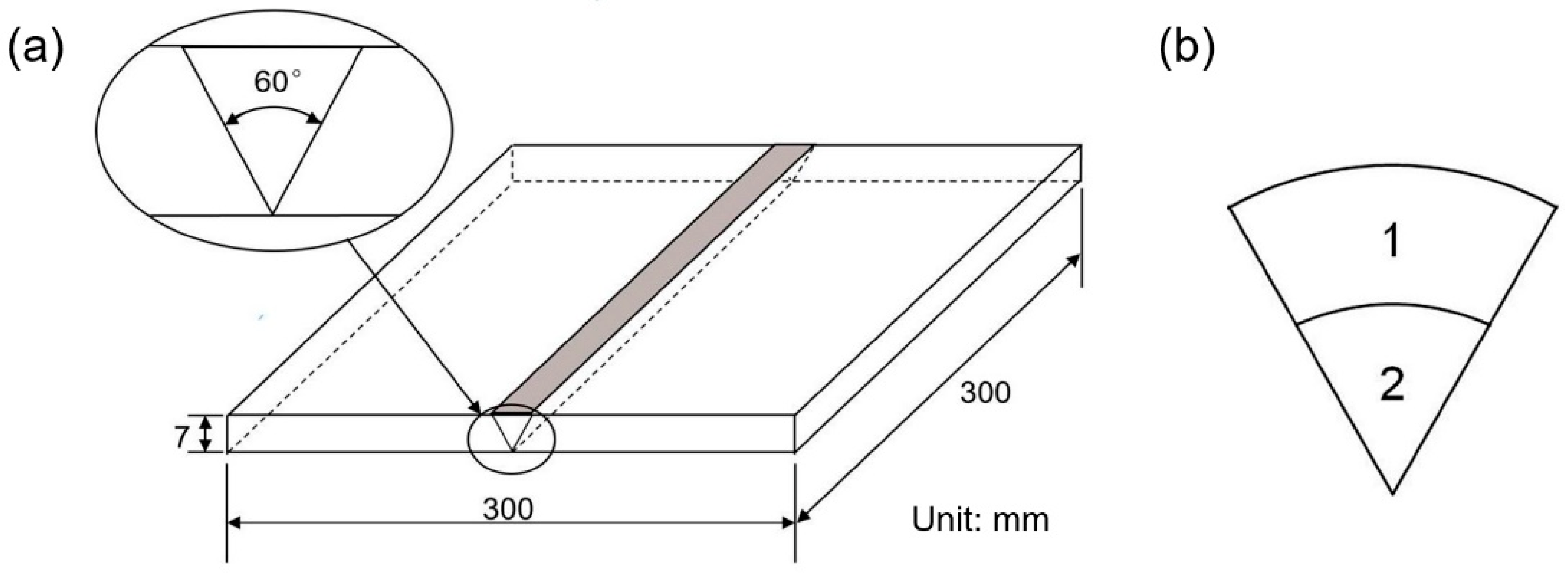

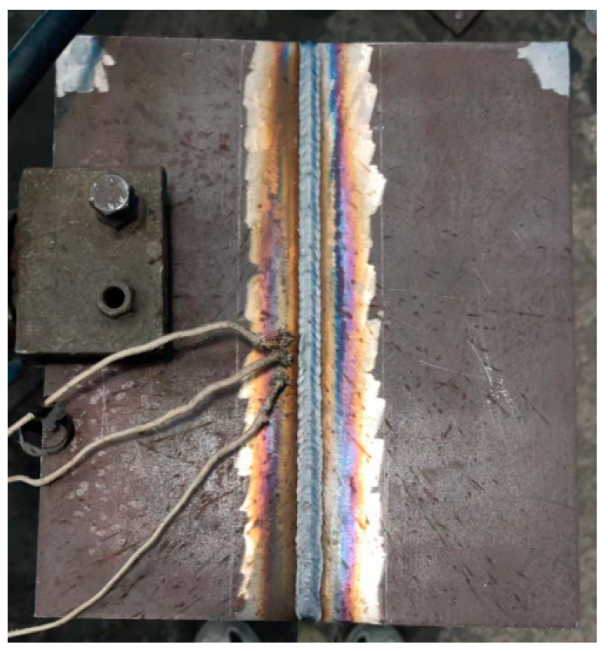

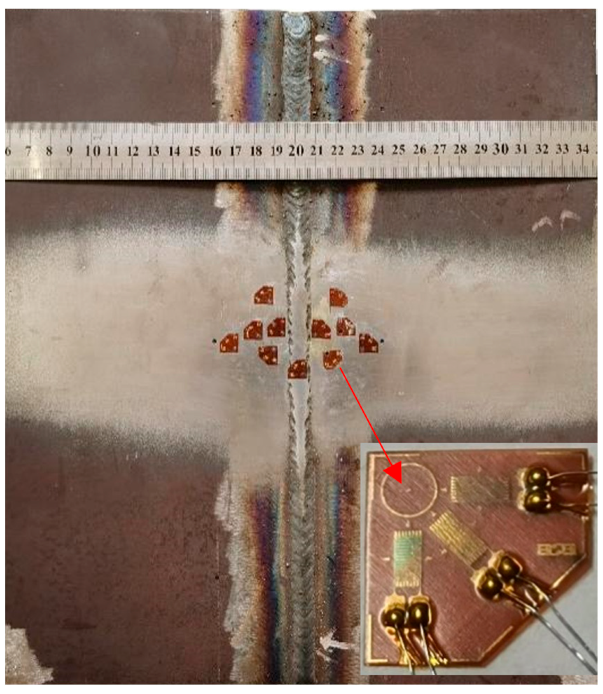

2. Materials and Methods

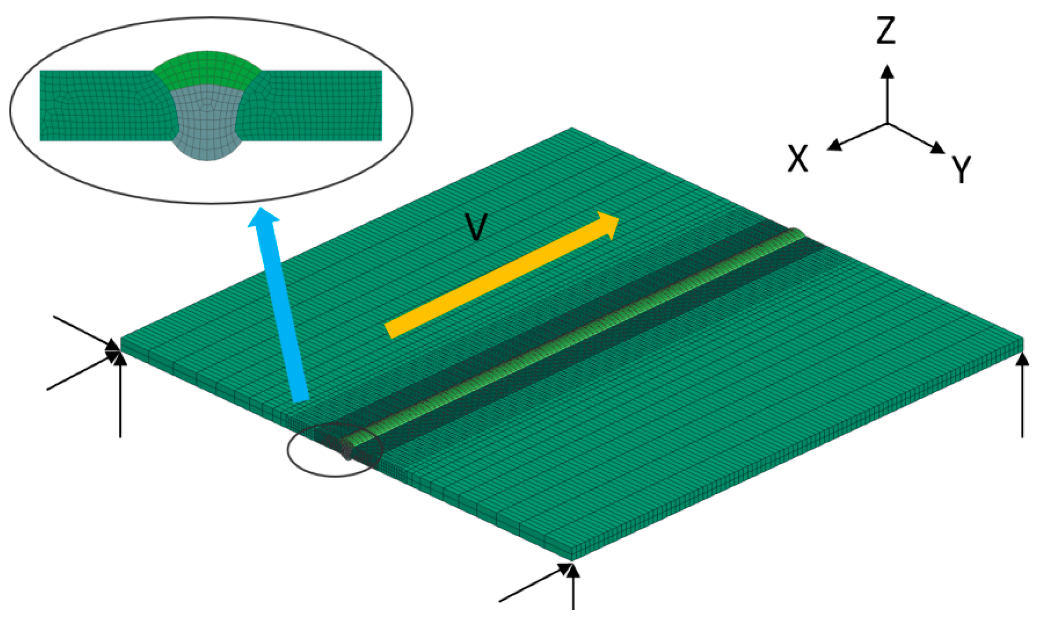

3. Finite Element Analysis

3.1. Finite Element Model

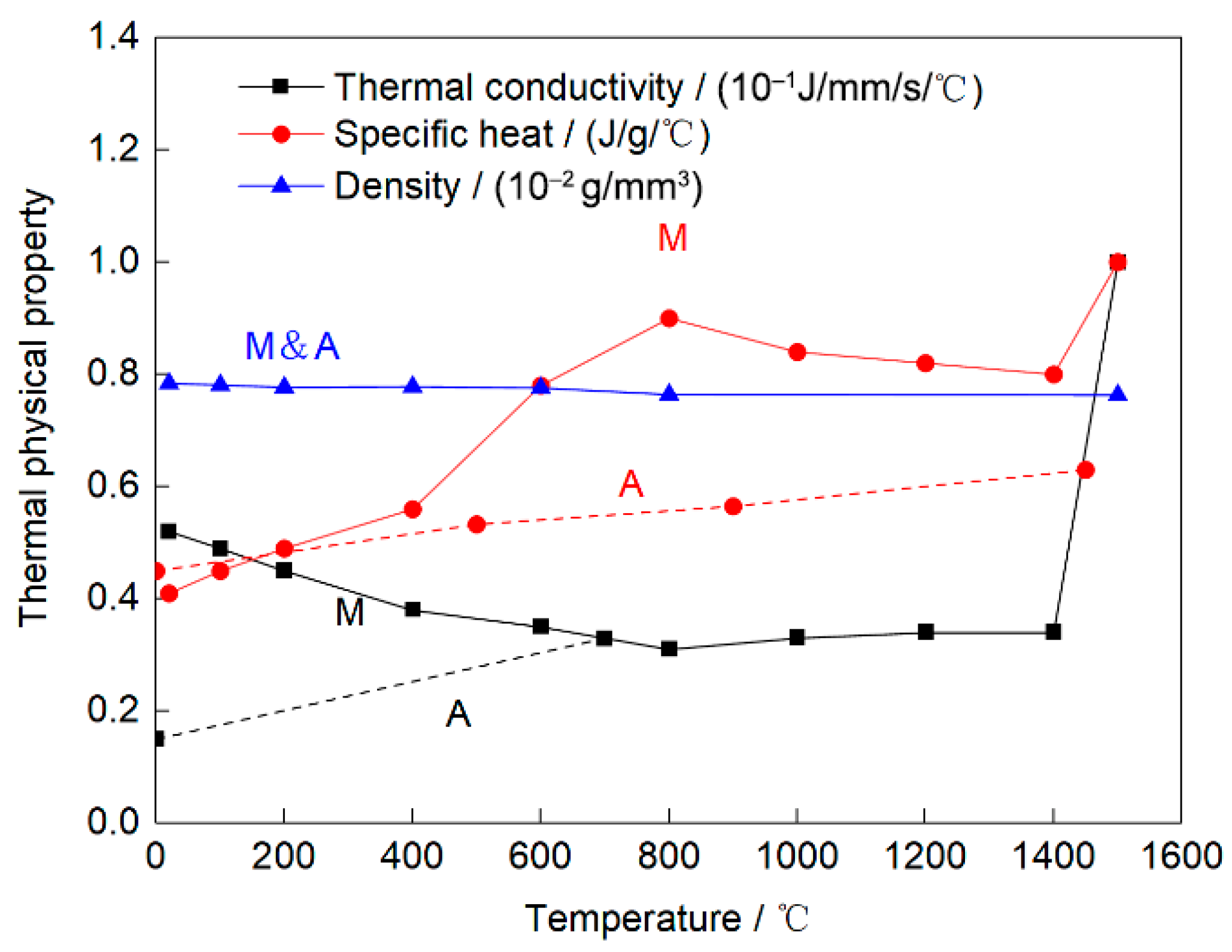

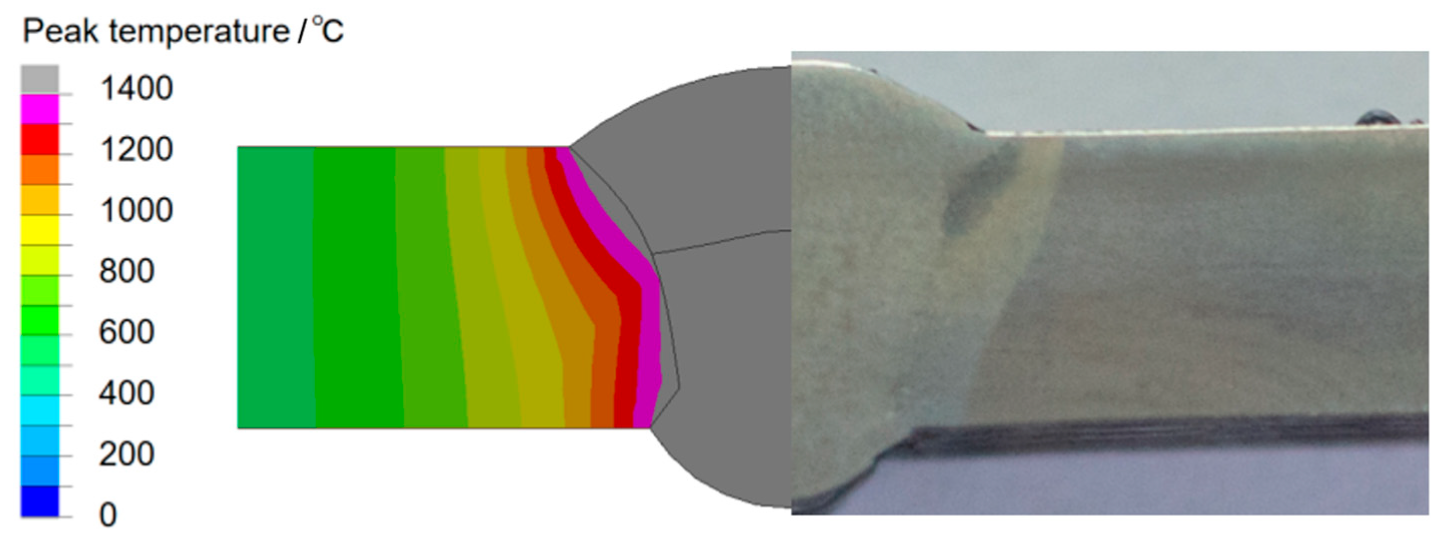

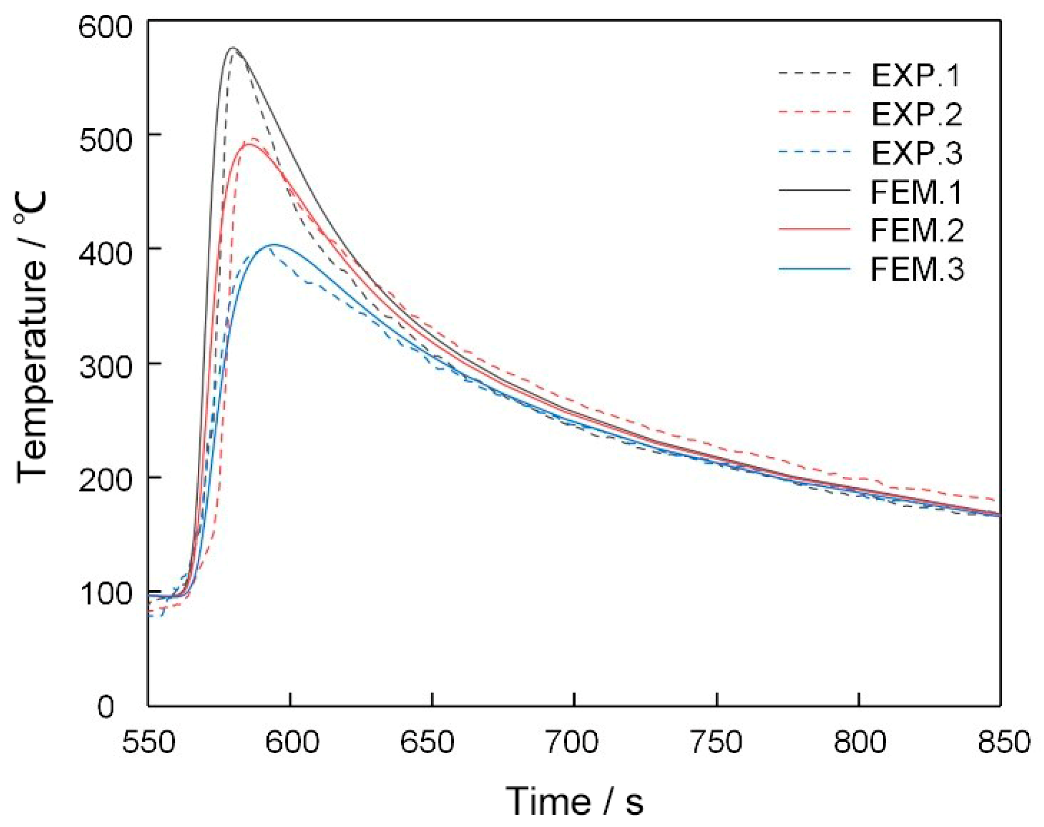

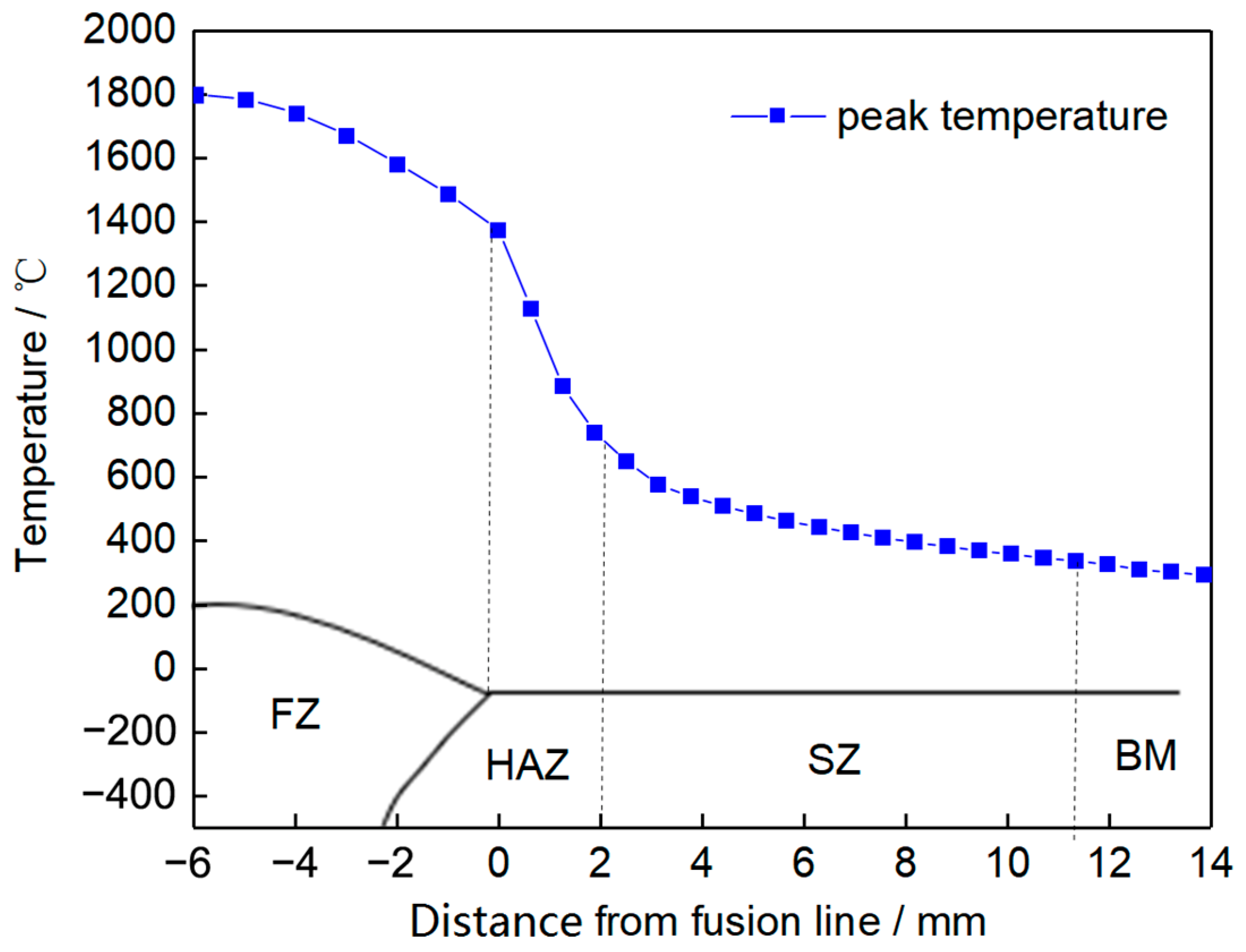

3.2. Temperature Field Calculation

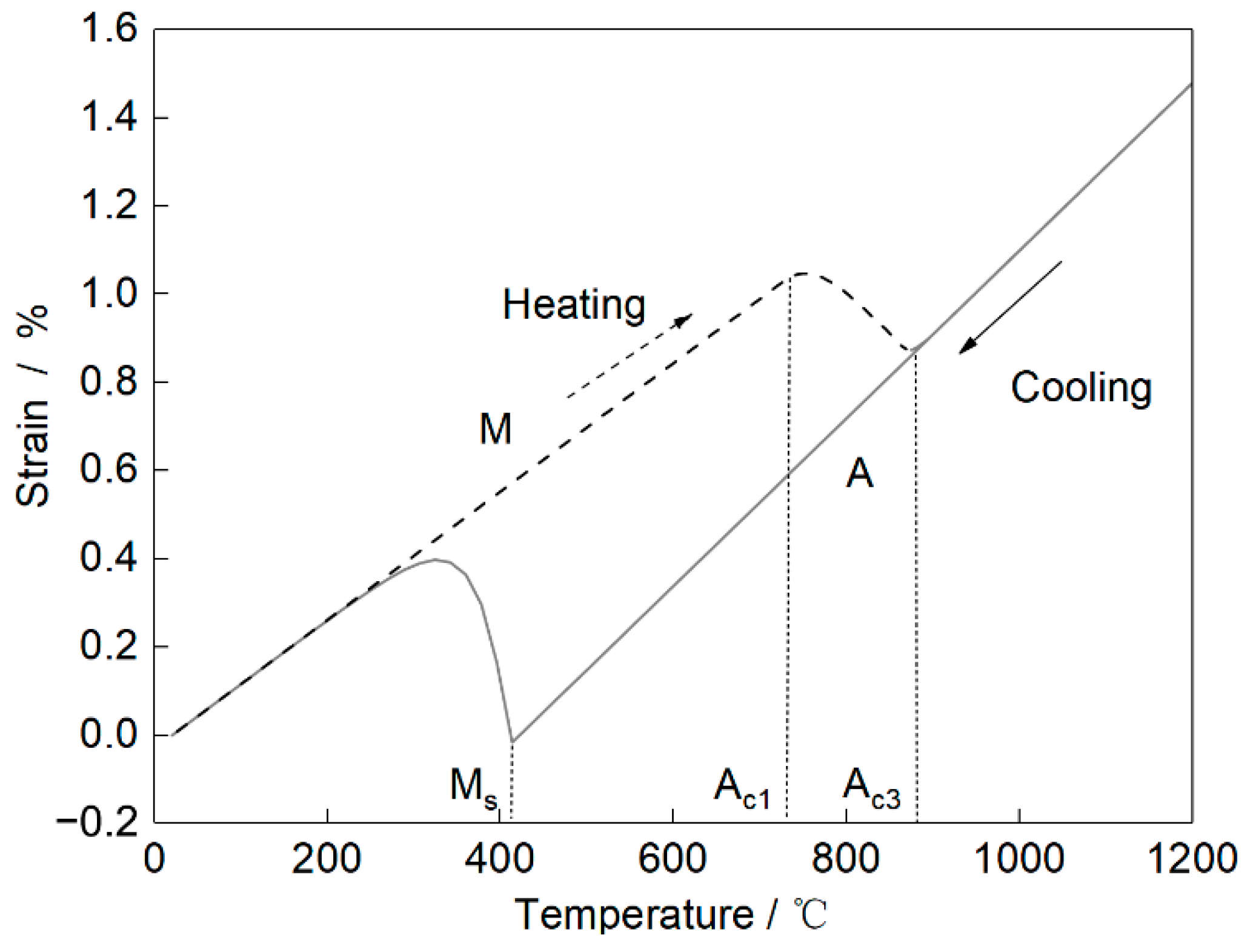

3.3. Phase Composition Calculation

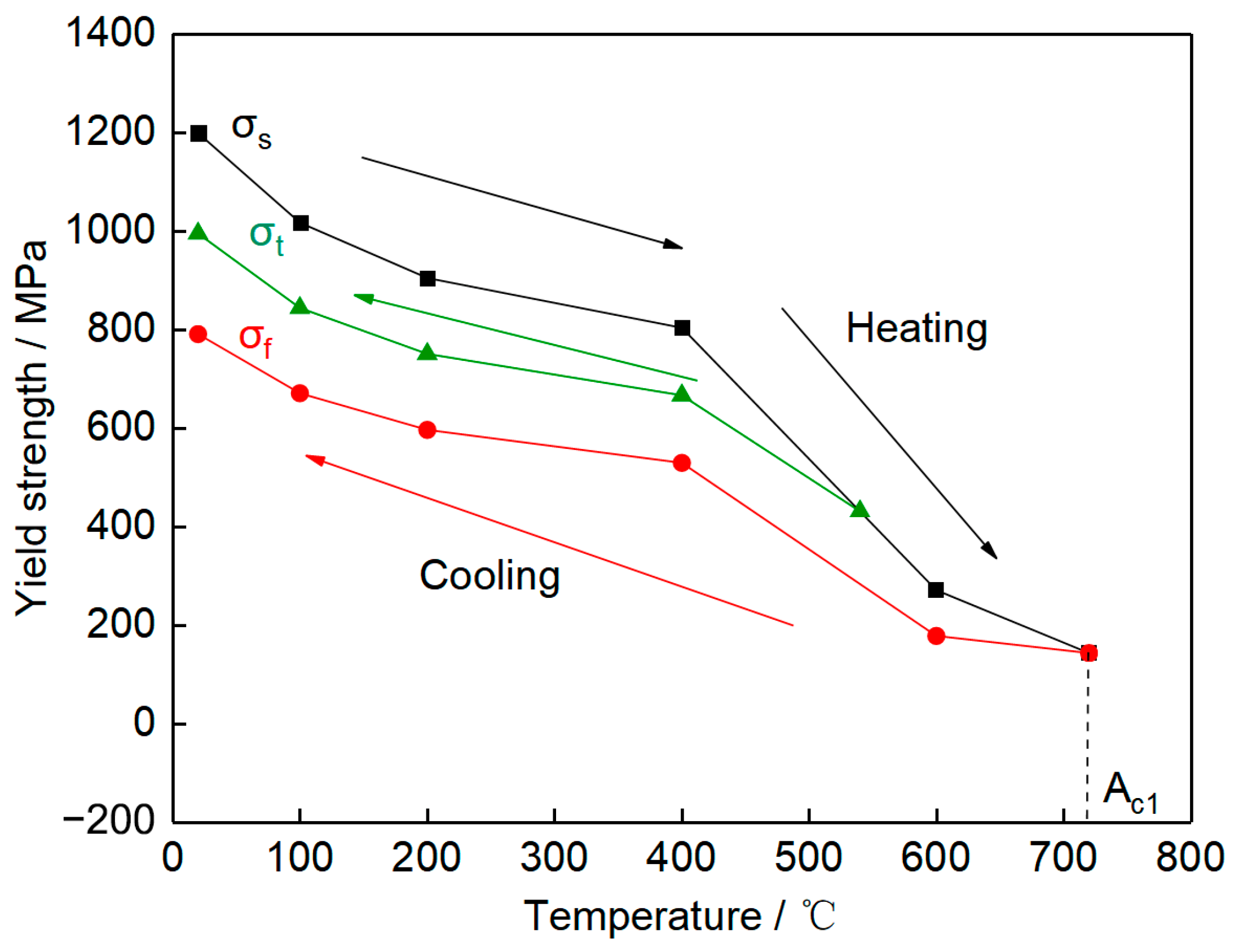

3.4. Softening Model

3.5. Stress Calculation

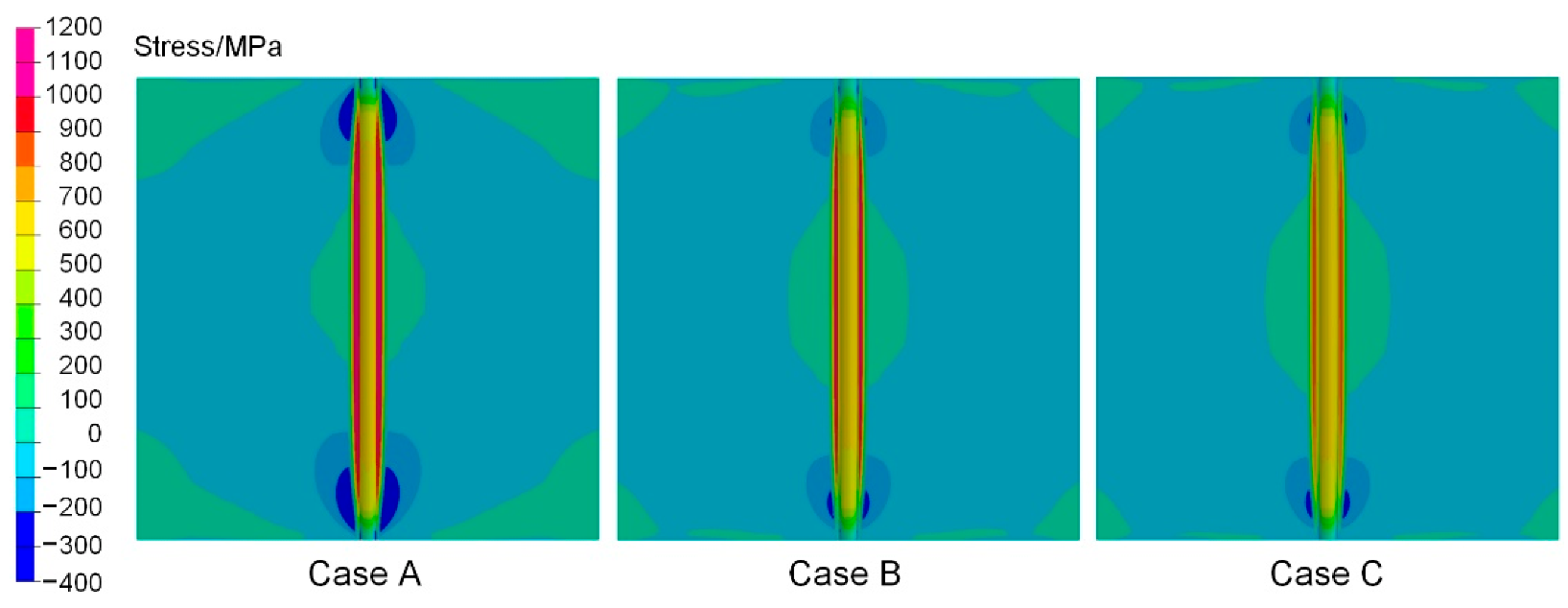

3.6. Calculation Case

4. Results and Discussion

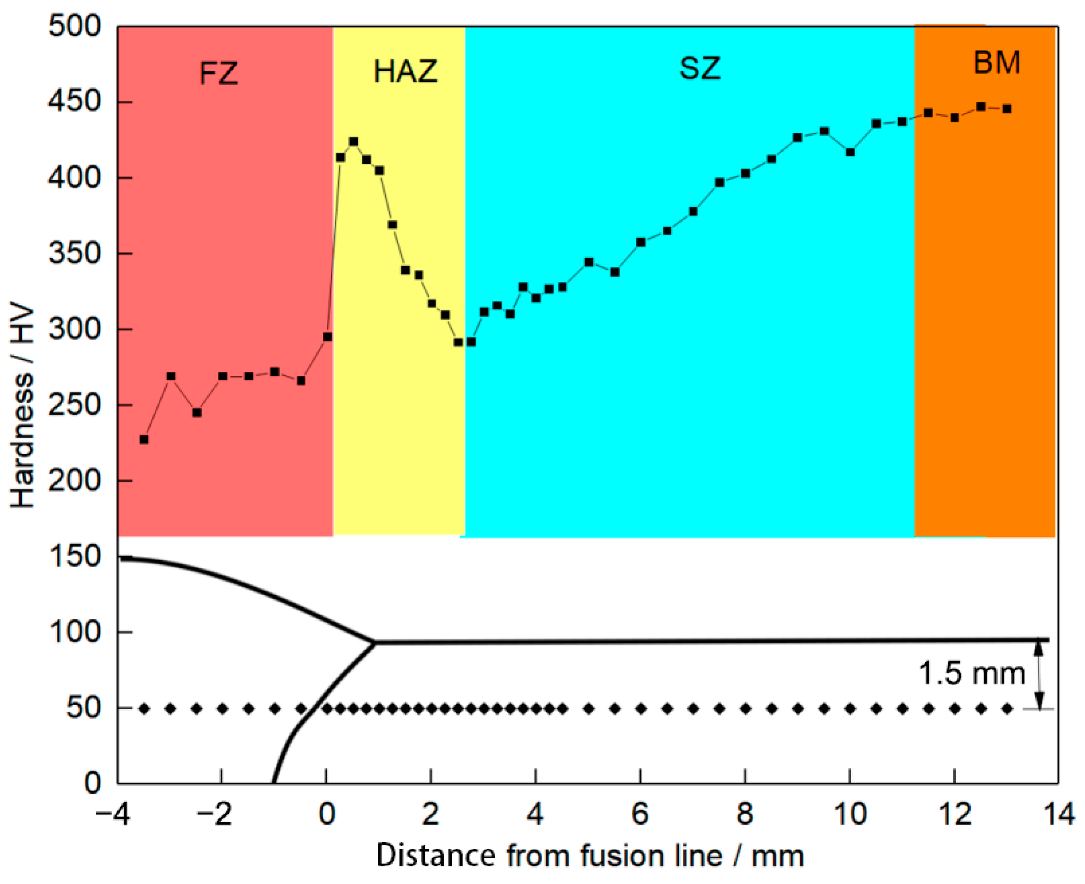

4.1. Microhardness Distribution

4.2. Temperature Field

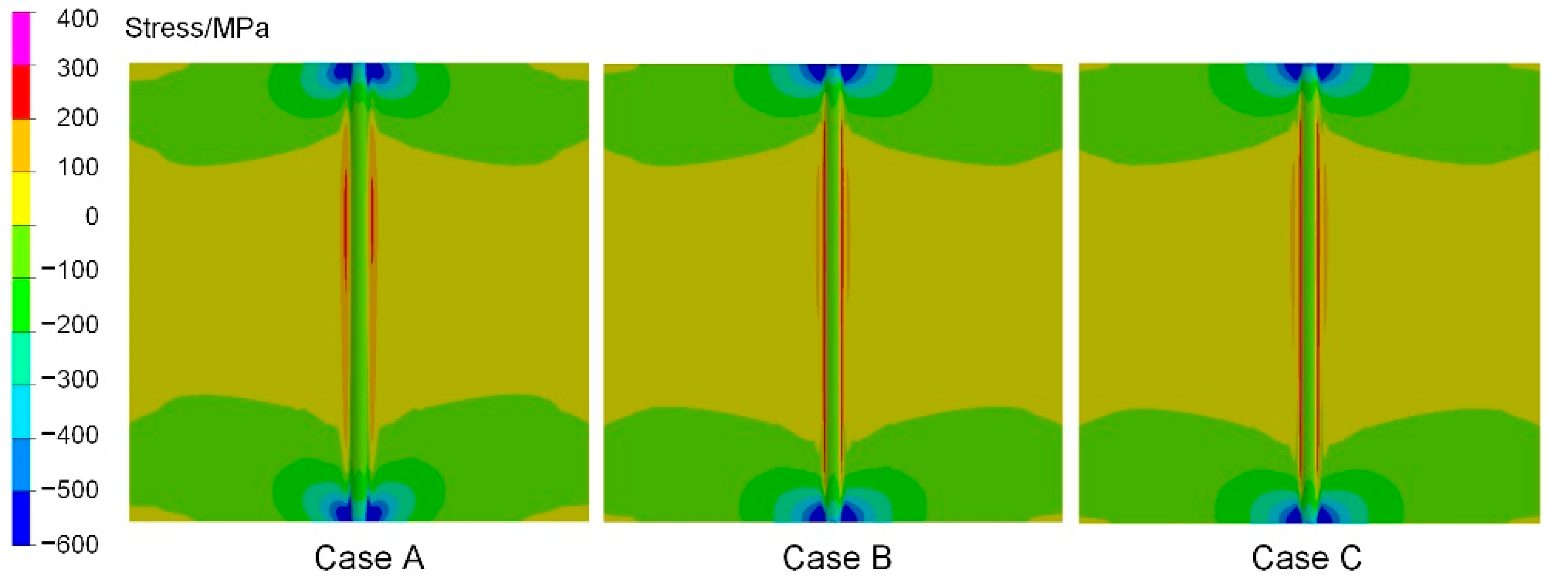

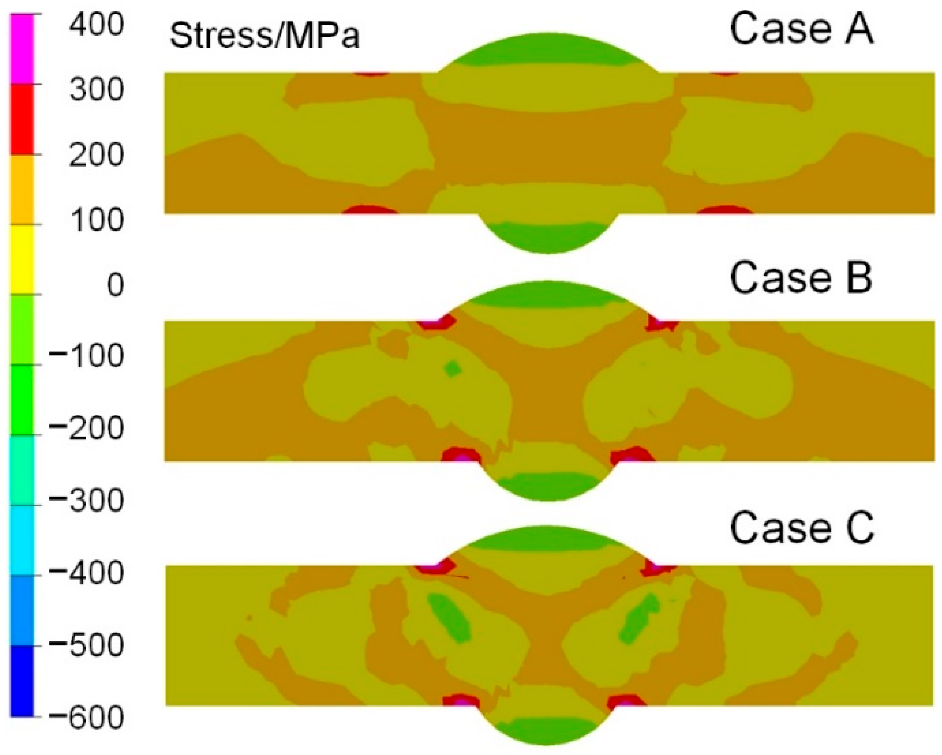

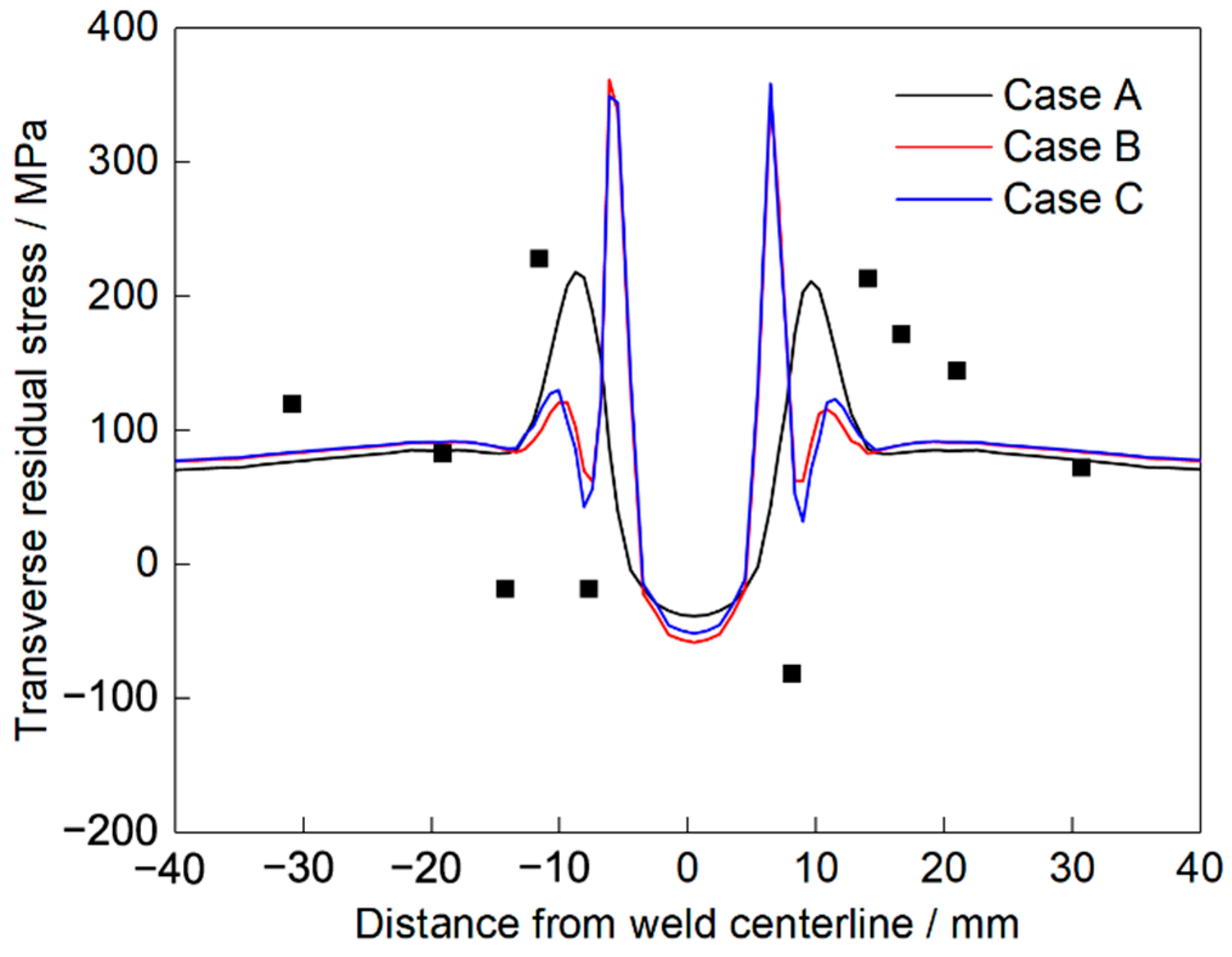

4.3. Residual Stress

5. Conclusions

- (1)

- The average microhardness of the base metal of NM450TP wear-resistant steel was about 450 HV. The maximum microhardness of the heat-affected zone in the joint was 426 HV. The minimum microhardness of the softening zone was about 290 HV, and the width of the softening zone was about 9 mm. The welding thermal cycle had a more significant influence on the hardness of the softening zone than that of the heat-affected zone.

- (2)

- The solid-state phase transformation had a significant effect on the calculation results of longitudinal residual stress. When considering the solid-state phase transformation, the longitudinal residual stress in the heat-affected zone decreased significantly, and the longitudinal residual stress peak was transferred from the heat-affected zone to the base metal adjacent to the heat-affected zone. The solid-state phase transformation had a certain influence on the calculation results of the transverse residual stress. When considering the solid-state phase transition, the calculated peak value of the transverse residual stress increased.

- (3)

- The softening effect had little effect on the distribution of longitudinal residual stress but influenced the peak longitudinal residual stress in the softening zone. The peak stress on the base metal adjacent to the heat-affected zone was 870 MPa, which decreased by 300 MPa compared to the calculated result without considering the softening effect. The softening effect had little effect on the distribution shape and peak value of the transverse residual stress. The peak value of the transverse residual stress was 370 MPa, which was much smaller than the room-temperature yield strength of the base metal.

- (4)

- The comparison between the numerical simulation results and the experimental results indicated that the calculation results of the welding residual stress in the joint were in the best agreement with the experimental values when the solid-state phase transformation and softening effects were considered at the same time. When calculating the welding residual stress of similar materials, it was recommended to consider both solid-state phase transformation and softening effects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Feng, G.; Wang, H.; Wang, Y.; Deng, D.; Zhang, J. Numerical Simulation of Residual Stress and Deformation in Wire Arc Additive Manufacturing. Crystals 2022, 12, 803. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, G.; Pu, X.; Deng, D. Influence of welding sequence on residual stress distribution and deformation in Q345 steel H-section butt-welded joint. J. Mater. Res. Technol. 2021, 13, 144–153. [Google Scholar] [CrossRef]

- Peng, Y.; Song, L.; Zhao, L.; Ma, C.; Zhao, H.; Tian, Z. Research progress on weldability of advanced steel materials. Acta Metall. Sin. 2020, 56, 601–618. [Google Scholar]

- Berg, J.; Stranghoener, N.; Kern, A.; Hoevel, M. Variable amplitude fatigue tests at high frequency hammer peened welded ultra high strength steel S1100. Procedia Struct. Int. 2016, 2, 3554–3561. [Google Scholar] [CrossRef][Green Version]

- Tomkow, J.; Landoski, M.; Fydrych, D.; Rogalski, G. Underwater wet welding of S1300 ultra-high strength steel. Mar. Struct. 2022, 81, 103120. [Google Scholar] [CrossRef]

- Derazkola, H.A.; García Gil, E.; Murillo-Marrodán, A.; Méresse, D. Review on Dynamic Recrystallization of Martensitic Stainless Steels during Hot Deformation: Part I—Experimental Study. Metals 2021, 11, 572. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Garcia, E.; Murillo-Marrodán, A.; Fernandez, A.C. Review on modeling and simulation of dynamic recrystallization of martensitic stainless steels during bulk hot deformation. J. Mater. Res. Technol. 2022, 18, 2993–3025. [Google Scholar] [CrossRef]

- Hu, X.; Feng, G.; Wang, Y.; Zhang, C.; Deng, D. Influence of lumping passes on calculation accuracy and efficiency of welding residual stress of thick-plate butt joint in boiling water reactor. Eng. Struct. 2020, 222, 111136. [Google Scholar] [CrossRef]

- Lu, S.; Wang, H.; Dai, P.; Deng, D. Effect of creep on prediction accuracy and calculating efficiency of residual stress in post weld heat treatment. Acta Metall. Sin. 2019, 55, 1581–1592. [Google Scholar]

- Deng, D.; Zhang, C.; Pu, X.; Liang, W. Influence of material model on prediction accuracy of welding residual stress in an austenitic stainless steel multi-pass butt-welded joint. J. Mater. Eng. Perform. 2017, 26, 1494–1505. [Google Scholar] [CrossRef]

- Qu, Z.; Xia, L. Study on welding deformation numerical simulation for ultra-high strength steel BS960E. Procedia Manuf. 2019, 37, 97–104. [Google Scholar] [CrossRef]

- Sun, Y.; Shi, Q.; Qi, Y.; Zhang, S.; Cui, Q. Numerical simulation of multiphysics coupling in welding process of high strength and low alloy steel. J. Mech. Eng. 2019, 55, 168–177. [Google Scholar]

- Deng, D.; Murakawa, H. FEM prediction of buckling distortion induced by welding in thin plate panel structures. Comput. Mater. Sci. 2008, 43, 591–607. [Google Scholar] [CrossRef]

- Deng, D.; Zhang, Y.; Li, S.; Tong, Y. Influence of solid-state phase transformation on residual stress in P92 steel welded joint. Acta Metall. Sin. 2016, 52, 394–402. [Google Scholar]

- Fang, J.; Dong, S.; Xu, B.; Wang, Y.; He, P.; Xia, D.; Zhang, Z. Finite element analysis of stress field in laser cladding forming considering solid state phase transformation. Chin. J. Lasers 2015, 42, 0503009. [Google Scholar]

- Nishimura, R.; Ma, N.; Liu, Y.; Li, W.; Yasuki, T. Measurement and analysis of welding deformation and residual stress in CMT welded lap joints of 1180MPa steel sheets. J. Manuf. Process. 2021, 72, 515–528. [Google Scholar] [CrossRef]

- Li, H.; Huang, Z.; Zhang, C.; Wei, W. Study on softening phenomenon of welded joints of low-alloy high-strength wear-resistant steel. Hot Work. Technol. 2020, 49, 19–23. [Google Scholar]

- Li, S.; Ren, S.; Zhang, Y.; Deng, D.; Murakawa, H. Numerical investigation of formation mechanism of welding residual stress in P92 steel multi-pass joints. J. Mater. Process. Technol. 2017, 244, 240–252. [Google Scholar] [CrossRef]

- Khalaf, H.I.; Al-Sabur, R.; Abdullah, M.E.; Kubit, A.; Derazkola, H.A. Effects of Underwater Friction Stir Welding Heat Generation on Residual Stress of AA6068-T6 Aluminum Alloy. Materials 2022, 15, 2223. [Google Scholar] [CrossRef]

- Deng, D.; Murakawa, H. Numerical simulation of temperature field and residual stress in multi-pass welds in stainless steel pipe and comparison with experimental measurements. Comput. Mater. Sci. 2006, 37, 269–277. [Google Scholar] [CrossRef]

- Deng, D. Influence of deposition sequence on welding residual stress and deformation in an austenitic stainless steel J-groove welded joint. Mater. Des. 2013, 49, 1022–1033. [Google Scholar] [CrossRef]

- Deng, D.; Kiyoshima, S. Influence of annealing temperature on calculation accuracy of welding residual stress in a SUS304 stainless steel joint. Acta Metall. Sin. 2014, 50, 626–632. [Google Scholar]

- Goldak, J.; Chakravarti, A.; Bibby, M. A new finite element model for welding heat sources. Metall. Mater. Trans. 1984, 15, 299–305. [Google Scholar] [CrossRef]

- Kumar-Krishnasamy, R.; Siegele, D. 3D modelling of a multi pass dissimilar tube welding and post weld heat treatment of nickel based alloy and chromium steel. Int. J. Press. Vessel. Pip. 2010, 87, 643–649. [Google Scholar] [CrossRef]

- Hu, L.; Wang, Y.; Li, S.; Zhang, C.; Deng, D. Research on microstructure and hardness prediction method of Q345 steel welded joints based on SH-CCT Diagram. Acta Metall. Sin. 2021, 57, 1073–1086. [Google Scholar]

- Kumar, S.; Awasthi, R.; Viswanadham, C.S.; Bhanumurthy, K.; Dey, G. Thermo-metallurgical and thermo-mechanical computations for laser welded joint in 9Cr–1Mo(V, Nb) ferritic/martensitic steel. Mater. Des. 2014, 59, 211–220. [Google Scholar] [CrossRef]

- Yaghi, A.H.; Hyde, T.H.; Becker, A.A.; Williams, J.A.; Sun, W. Residual stress simulation in welded sections of P91 pipes. J. Mater. Process. Technol. 2005, 167, 480–487. [Google Scholar] [CrossRef]

- Ruitenberg, G.; Woldt, E.; Petford-Long, A.K. Comparing the Johnson–Mehl–Avrami–Kolmogorov equations for isothermal and linear heating conditions. Thermochim. Acta 2001, 378, 97–105. [Google Scholar] [CrossRef]

- Tatsuo, I. Unified transformation-thermoplasticity and the application. J. Jpn. Soc. Mater. Sci. 2007, 56, 352–356. [Google Scholar]

- Leblond, J.B.; Devaux, J.C. Mathematical modelling of transformation plasticity in steels I: Case of ideal-plastic phases. Int. J. Plast. 1989, 5, 551–572. [Google Scholar] [CrossRef]

- Perić, M.; Nižetić, S.; Garašić, I.; Gubeljak, N.; Vuherer, T.; Tonković, Z. Numerical calculation and experimental measurement of temperatures and welding residual stresses in a thick-walled T-joint structure. J. Therm. Anal. Calorim. 2020, 141, 313–322. [Google Scholar] [CrossRef]

- Gannon, L.; Liu, Y.; Pegg, N.; Smith, M. Effect of welding sequence on residual stress and distortion in flat-bar stiffened plates. Mar. Struct. 2010, 23, 385–404. [Google Scholar] [CrossRef]

- Wei, L.; Murakawa, H.; Deng, D. Investigation of welding residual stress distribution in a thick-plate joint with an emphasis on the features near weld end-start. Mater. Des. 2015, 67, 303–312. [Google Scholar]

| Materials | C | Si | Mn | P | S | Al | Nb | Ti | B |

|---|---|---|---|---|---|---|---|---|---|

| NM450TP | ≤0.28 | ≤1.80 | ≤2.00 | ≤0.025 | ≤0.010 | ≤0.015 | ≤0.22 | ≤0.22 | ≤0.0060 |

| Materials | C | Si | Mn | Cr | Ni | Mo |

|---|---|---|---|---|---|---|

| ER100S-G | <0.1 | 0.5 | 1.6 | 0.3 | 1.4 | 0.2 |

| Welding Pass | Current (A) | Voltage (V) | Welding Speed (mm/s) |

|---|---|---|---|

| 1 | 164 | 17 | 2.0 |

| 2 | 168 | 17 | 2.4 |

| Case | Solid-State Phase Transformation | Softening Effect |

|---|---|---|

| A | No | No |

| B | Yes | No |

| C | Yes | Yes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Feng, G.; Wang, C.; Hu, L.; Li, T.; Deng, D. Prediction of Residual Stress Distribution in NM450TP Wear-Resistant Steel Welded Joints. Crystals 2022, 12, 1093. https://doi.org/10.3390/cryst12081093

Li G, Feng G, Wang C, Hu L, Li T, Deng D. Prediction of Residual Stress Distribution in NM450TP Wear-Resistant Steel Welded Joints. Crystals. 2022; 12(8):1093. https://doi.org/10.3390/cryst12081093

Chicago/Turabian StyleLi, Guannan, Guangjie Feng, Chongyang Wang, Long Hu, Tao Li, and Dean Deng. 2022. "Prediction of Residual Stress Distribution in NM450TP Wear-Resistant Steel Welded Joints" Crystals 12, no. 8: 1093. https://doi.org/10.3390/cryst12081093

APA StyleLi, G., Feng, G., Wang, C., Hu, L., Li, T., & Deng, D. (2022). Prediction of Residual Stress Distribution in NM450TP Wear-Resistant Steel Welded Joints. Crystals, 12(8), 1093. https://doi.org/10.3390/cryst12081093