Abstract

In this study, alumina ceramic plate microfiltration membranes (ACMs) were used for the treatment of oily wastewater with different concentrations. The permeate oil concentration of the system was basically less than 5 mg·L−1, and the oil rejection rate was up to 97.6%. The effects of raw oil concentration on permeation flux and oil rejection rate of oily wastewater were studied. The results showed that with the increase of raw oil concentration, the oil rejection rate increased slightly due to the existence of oil film on the surface of filtered ACMs. Moreover, the existence of oil film had little effect on the flux change of ceramic membranes. The results showed that the permeability of ACMs mainly depended on their own oleophobic properties. In this system, physical cleaning technology is used to remove oil droplets and particles blocked in membrane pores. The results showed that physical cleaning could significantly recover the permeation flux as well as improve the oil rejection rate. On this basis, a system is proposed as a potential technique for oily wastewater treatment.

1. Introduction

Oily wastewater is found in large volumes as a result of oil spill accidents and various industries such as oil and gas extraction, food industry, and metal manufacturing [1,2]. It is reported that about 250 million barrels of oily wastewater are produced every day in oil and gas fields around the world, more than 40% of which is released into the environment [3]. In China, about 5 × 108 m3 of oilfield-produced water needs to be treated every year [4]. In addition, oil spills are considered to be key factors affecting soil microbial communities [5]. The oil in wastewater is commonly present in four forms according to oil droplet size, including free oil (>100 μm), dispersed oil (10–100 μm), emulsified oil (<10 μm), and dissolved oil; among these, the rejection of emulsified oil is the most difficult [6]. The widespread existence of emulsified oil makes it difficult to treat oily wastewater by traditional methods, for instance, gravity separation, biological degradation, hydrocyclone, air flotation, and the skimmers [7,8,9,10]. In addition, the treatment of oily wastewater using routine processes renders it difficult to reach the standard of low energy consumption and high efficiency, due to the limitations of low efficiency, high energy consumption, and secondary pollution. It is very necessary for environmental safety and human health to develop environmentally friendly, economical, and efficient oil-water emulsion treatment technologies.

Membrane separation technology has gradually attracted the extensive attention of researchers, and has played an important role in the treatment of oily wastewater because of its low energy consumption and lack of secondary pollution [8,9,10,11]. In the process of separating oily wastewater by membrane technology, whether water is trapped on the membrane surface or permeated into the pores depends on the surface properties of the membrane. Furthermore, the antifouling ability and oil-water separation efficiency of membranes are also closely related to the surface properties of the membrane [12]. Ideally, the dispersed phase (oil phase) remains on the membrane surface due to the screening mechanism, while the continuous phase (water phase) enters the pore of the membrane due to the trans-membrane pressure [13]. Based on the material type, the membranes are classified into two groups: polymeric and ceramic. Ceramic membranes can be further divided into tubular, hollow fiber, and plate-type membranes according to the structure of the membrane. According to the different membrane properties and separation strategies, membrane separation technologies include microfiltration, ultrafiltration, nanofiltration, reverse osmosis, electrodialysis, and membrane bioreactor [14,15,16,17,18]. Compared with ultrafiltration, nanofiltration and reverse osmosis, microfiltration membrane needs lower transmembrane pressure difference, and can be used to separate oil substances [19]. Currently, the research and applications of polymeric membranes in the treatment of oily wastewater have relatively matured. Salahi et al. [20] studied the removal of oily wastewater using five different polymer membranes. Chen et al. [21] modified the polyethersulfone ultrafiltration membrane and used it for oil/water separation with Pluronic F127, and the flux of feed liquid of the modified membrane oil increased from 42.77 L·m−2 h−1 to 82.98 L·m−2 h−1. Although the organic membrane is easy to prepare and the pore size is controllable, Padaki et al. [1] summarized the disadvantages of polymer membranes, including the susceptibility to fouling, resulting in decreased flux and, worse, rejection. Moreover, their rapid pollution and difficult cleaning limit the development of polymeric membranes.

Compared with polymer membranes, ceramic membranes have advantages in the treatment of oily wastewater owing to their easy cleaning, anti-pollution performance, acid and alkali resistance, and higher mechanical strength [11,20,22,23,24,25]. Chen et al. [11] studied the removal of oily wastewater by ceramic hollow fiber membrane. Li et al. [26] used the prepared calcium feldspar ceramic membrane for microfiltration of oil-in-water emulsion. Ebrahimi et al. [22] explored the effect of ceramic membrane on the treatment of oily wastewater with different oil content (32–5420 ppm) using ceramic microfiltration membrane in the pretreatment process. Son et al. [27] studied the anti-fouling effect of internal gas injection on the treatment of agricultural industrial wastewater by plate ceramic membrane. Although researchers have extensively studied the ceramic membrane filtration of oily wastewater, the treatment of oily wastewater by ACMs, regeneration performance after membrane cleaning, and related membrane fouling are rarely studied.

In this work, the oily wastewater was treated with ACMs. The morphology, microstructure and element compositions of the ACMs were characterized by scanning electron microscope (SEM) and energy dispersive spectroscopy (EDS). The changes of membrane flux and oil rejection rate over time under different oil concentrations were studied, and the recovery of membrane flux after physical cleaning was explored. Four membrane filtration models were used to fit the experimental data, and the pollution models were evaluated.

2. Materials and Methods

2.1. Materials and Chemicals

Diesel was purchased from Shandong petrochemical gas station. Hexane (C6H14, HPLC), hydrochloric acid (HCl, AR), and sodium sulfate anhydrous (Na2SO4, AR) were purchased from Tianjin Kemio Chemical Reagent Co., Ltd. (Tianjin, China); Sodium dodecyl sulfate (C12H25NaO4S, SDS, CP) was purchased from Yantai Far East Fine Chemical Co., Ltd. (Yantai, China). The above chemicals were used as received. ACMs with Al2O3 support and separation layer was supplied by Shandong Guiyuan New Material Co., Ltd., China.

2.2. O/W Emulsion Separation by Ceramic Plate Microfiltration Membranes

The oily wastewater used in the experiment was prepared manually in the laboratory. The oily wastewater consisted of 0# diesel, SDS, and distilled water. The mass ratio of 0# diesel: SDS was 10:1. After weighting, oil and SDS were added to distilled water. The emulsion was prepared using a blender (Shanghai Huxi Industrial Co., Ltd. (Shanghai, China)) by mixing for 1 h at a mediated speed (5500 rpm).

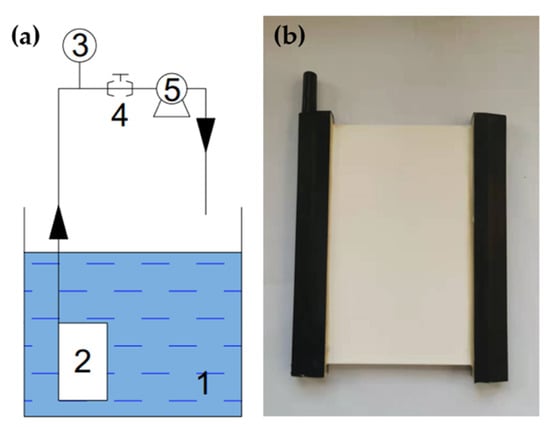

The new membranes were chosen in every filtration experiment. The ceramic membrane was put into the oil-in-water emulsion. The trans-membrane differential pressure was controlled through the pump. The oil concentration in the permeation solution was measured using an ultraviolet spectrophotometer (UV-5100B, Shanghai Yuan Analytical Instrument Co., Ltd. (Shanghai, China)). The permeation flux and the oil concentration were measured every 10 min. The reactor diagram is shown in Figure 1a. A diagram of the membrane module is shown in Figure 1b.

Figure 1.

The reactor diagram of filtration apparatus (a) 1-feed tank, 2-membrane module (b) 3-manometer, 4-regulating valve, 5-pump.

The O/W separation experiment took 120 min as a running cycle. At the end of each concentration separation run, the membranes were cleaned using physical cleaning technology. Physical cleaning technology refers to the removal of pollutants on the surface of ceramic membranes by hydraulic flushing and sponge scrubbing.

2.3. Analytical Methods

2.3.1. Permeation Flux

The permeate flux (J L m−2·h−1) was calculated by dividing the permeate volume by the membrane area and the operation time, using Equation (1) [6,8]:

where A (m2), V (L) and t (h) are the effective membrane area, volume of permeate, and sampling time, respectively.

J = V/At,

2.3.2. Rejection Percentage (%)

The separation performance of the ceramic membrane was observed by the rejection percentage of oil concentration in microfiltration processes and calculated using Equation (2) [6,8]:

where Cp (mg·L−1) and Cf (mg·L−1) represents the concentration of oil in permeate and feed, respectively.

R (%) = (1 − Cp / Cf) × 100%,

2.4. Membrane Characterization

Microstructures of the membrane surface were visually observed using a FEI Sirion 200 Scanning Electron Microscope (SEM). The composition of membrane support layer and separation layer were analyzed by a FEI Sirion 200 Energy Dispersive Spectrometer (EDS). The water contact angle on the membrane surface was characterized using the theta optical contact angle measuring system.

2.5. Membrane Fouling Models

In order to analyze the microfiltration flux decline profile of O/W emulsion, four blot models were used, namely cake filtration model, intermediate pore blocking model, standard pore blocking model, and complete pore blocking model, respectively [16,28,29,30,31,32,33]. A cake filtration model is suitable for the deposition of larger than average pore size particles on the membrane surface to form a cake filtration layer that provides an additional porous barrier for the permeable fluid. When using the intermediate pore clogging model, the membrane pore is considered to be not necessarily blocked by solute particles, since solute particles are comparable in size to the membrane pore. When the solute particle size is smaller than the membrane pore, standard pore obstruction occurs in the membrane pore. When using this model, membrane pore blocking is considered to be caused by pore heterogeneity. Complete pore obstruction usually occurs on the membrane surface rather than in the membrane pores. This model is thought to be due to the fact that the size of sol particles is larger than the membrane pores. The four pollution models are represented by the following linear equation of membrane flux (J) and time (t), as shown in Table 1 [33,34]:

Table 1.

The four pollution models [33,34].

Where J (L·m−2·h−1), J0 (L·m−2·h−1) and t (h) represents the permeate flux of O/W emulsion, pure water flux and sampling time, respectively.

The experimental data were fitted through the above linear form, and R2 was analyzed, respectively.

3. Results and Discussion

3.1. Characterization and Basic Properties Test of Membranes

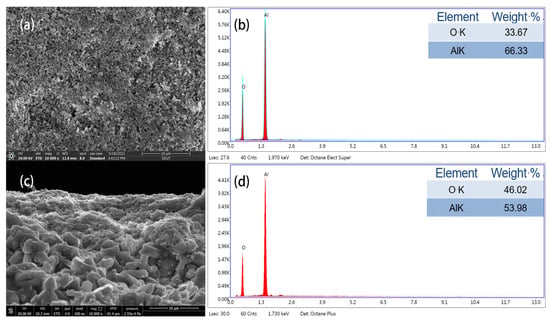

The membrane surface was characterized by SEM and EDS in Figure 2a,b. From the above results, the ACMs presented the advantages of uniformity and relatively smooth surfaces without cracks. In Figure 2b, the EDS result showed that the membrane surface was composed of alumina. In addition to surface morphology, SEM images were also used to observe the cross-sectional morphologies of ACMs, as shown in Figure 2c. Compared with the intermediate support layer, the surface of each ACMs was relatively denser. Al2O3 particles are closely arranged on the surface of the ACMs, while in the support, the arrangement of Al2O3 particles was looser and the pore diameter was larger. From the above results, the ACMs were composed of an alumina support layer and a denser alumina coating. In addition, in Figure 2d, the EDS result showed that alumina is the main element composition of the support layer. In general, combined with the result of SEM and EDS, ACMs are composed of alumina support and dense alumina coating.

Figure 2.

SEM and EDS images of the top section (a,b) and cross-section (c,d) of the ACMs.

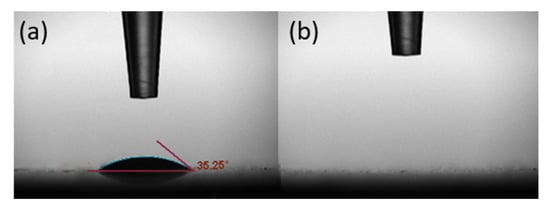

In order to investigate the surface wettability of ACMs, static water contact angle under air was measured. In Figure 3a,b, the water droplets diffused rapidly after 2 s through the surface of ACMs, perhaps due to the high-porosity surface and hydrophilicity of the packed Al2O3 particles. In fact, in most cases, super hydrophilic surfaces also have underwater super oleophobic properties [22]. Water molecules are trapped in rough hydrophilic micro/nano structures with strong surface energy underwater, and oil droplets are excluded.

Figure 3.

Static water contact angles of ACMs at 0 s (a) and 2 s (b) under air.

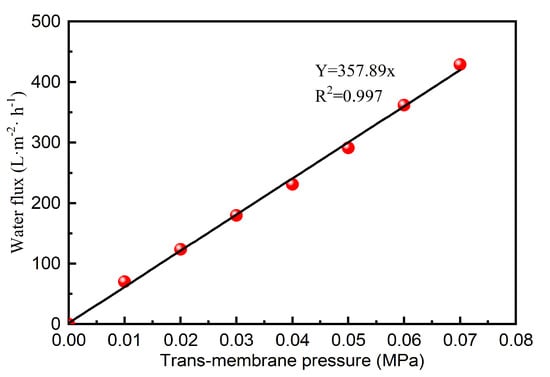

Pure water flux of selected ACMs was measured under different trans-membrane pressures. The results are shown in Figure 4. Good linear relationships were found between the pure water flux and the trans-membrane pressure, and attractive pure water permeability values of 6129 L·m−2·h−1·bar−1 were obtained from the slopes in Figure 4. The above results showed that the ceramic membranes had a good pure water permeability.

Figure 4.

Effect of trans-membrane differential pressure on pure water flux.

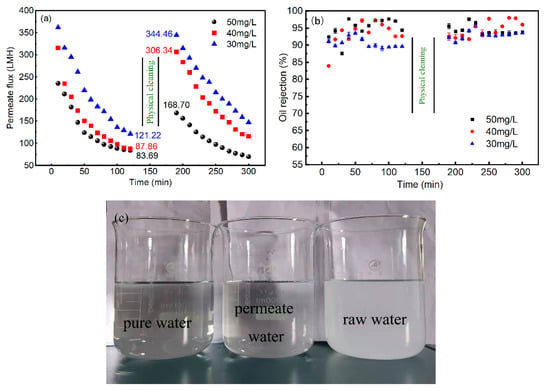

3.2. Separation Performance

High water permeability is an excellent property of membranes for wastewater treatment, which is expected to be a necessary property for the treatment of a large number of industrial waste water. In order to evaluate the separation performance of ACMs for oily wastewater, as a simulated mixture (SDS), a surfactant-stabilized oil in water emulsion was prepared with oil concentrations of 30, 40, and 50 mg·L−1. The change of permeation flux over time during the membrane filtration process of oily wastewater is shown in Figure 5a. Within 120 min of the first filtration cycle, the initial permeation flux of the oil in water emulsion can reach ~5399 L·m−2·h−1·bar−1. A rapid decrease in emulsion permeability was observed in the first 30 min before the emulsion permeability reached a relatively stable level, which was similar to the work of Yu et al. [9] After the flux became stable, the ACMs simultaneously exhibited relatively high steady-state permeability of 1071–1707 L·m−2·h−1·bar−1 and high separation efficiency of >90%. According to the research of Hu et al. [29] and Bortot Coelho et al. [30], the flux of oily wastewater treated by ceramic membrane is about 300–700 L·m−2·h−1·bar−1. In addition, the permeation flux in this study was higher, and the oil removal rate was also at a higher level than other studies in Table 2. In addition, the stable permeability of ACM with a lower feed concentration (30 mg·L−1) was slightly higher than that ACMs with higher feed concentrations (40 and 50 mg·L−1), which may be due to reducing the feed oil concentration and reducing the effect of pore blockage. After physical cleaning and regeneration, it was found that the flux of ACMs under three oil concentrations recovers well, which demonstrated that the anti-fouling property of membranes is satisfactory. The change of oil rejection rate over time during membrane filtration of oily wastewater is shown in Figure 5b. It may be seen that the rejection rate remained basically at more than 90% at all concentration levels. Among them, the rejection rate under raw water concentration of 40 and 50 mg·L−1 was slightly higher than that of 30 mg·L−1, which may be because of the higher concentration making the membrane plug faster, resulting in better oil barrier performance. Similarly, after physical cleaning and regeneration, it was found that its rejection rate not only recovered, but was also higher than that of the first time. It was still considered that the filtration performance of the blocked membrane pore was better due to the particles blocked by the membrane pore. Interestingly, the rejection rate of 40 mg L−1 after cleaning is better than any other concentration, which may be due to the greater thickness of the membrane separation layer and deeper pollution than other membranes, as shown in Figure 6. At the same time, after regeneration, the good quality separation of oil in water emulsions could be directly observed through the transparency of the emulsions before and after filtration, as shown in Figure 5c. No oil droplets were observed after filtration. The above result showed that the ceramic membrane had higher permeate flux and pollutant interception properties, as well as good anti-pollution performance. In this work, the ceramic membrane is only recycled once. With the increase of the number of cycles, the pollution may be more serious, resulting in the decline of membrane performance after certain cleaning.

Figure 5.

The separation performance of ACMs for oil in water emulsions, (a) permeability flux with time before and after physical cleaning; (b) the oil rejection rate of ACMs at different feed oil concentrations of 30–50 mg·L−1; (c) photograph comparison of raw water, permeate water and pure water.

Table 2.

Comparison of water flux and oil rejection between ACMs membrane and state-of-the-art ceramic membranes reported in literature.

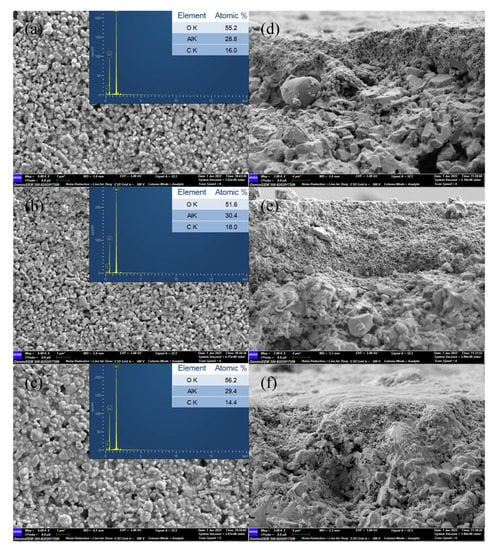

Figure 6.

SEM and EDS images of the surface of ACMs after cleaning: (a) 30 mg·L−1; (b) 40 mg·L−1; (c) 50 mg·L−1; SEM images of the surface of ACMs after cleaning: (e) 30 mg·L−1; (d) 40 mg·L−1; (f) 50 mg L−1.

Characterizations of the membrane surface after cleaning may be observed in Figure 6a–c. A thin oil film was observed on the surface of ACMs after cleaning. The SEM image of the cross-section of ACMs after cleaning is shown in Figure 6d–f. Compared with Figure 2a,b, the results showed that there was still a certain oil film on the surface of ACMs after cleaning. However, combined with the previous research results, it was found that the existence of the oil film had no significant effect on the flux. On the contrary, the existence of the oil film improves the oil rejection rate; the existence of the oil film makes the membrane pore smaller, which improves the interception performance of the membrane. In general, it appears that the ACMs have good reusability.

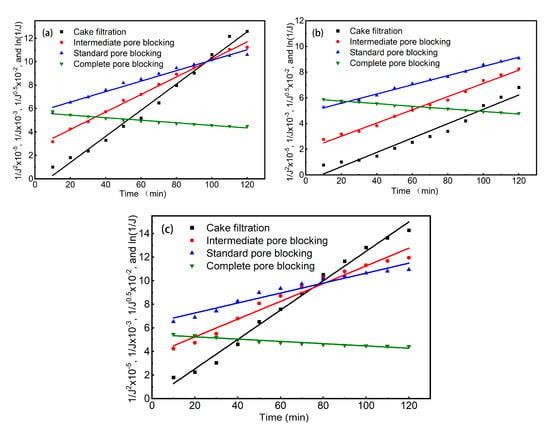

3.3. Membrane Fouling Model Analysis

Figure 7 shows the correlation of different pore blocking models for alumina ceramic flat films at different feed concentrations (30, 40, 50 mg·L−1). The parameters of the four filtering models are summarized in Table 3. The complete plug model, the intermediate pore plug model, and the cake filter model showed the best fitting effect on ACMs at three feed concentrations (30, 40, 50 mg·L−1), respectively. Vasanth et al. [25] obtained similar results in the study of oily wastewater treatment. Combined with previous characterization results, the filter cake layer was indeed formed on the ceramic surface. This was considered to be because the oil droplets were relatively small and the membrane pore size was relatively large, so several models played a certain role in the process of membrane fouling. In addition, according to the analysis of membrane separation performance, the existence of oil film did not have a great impact on the flux. Combined with the contact angle analysis, it was considered that the rejection rate of the membrane depended on the oleophobic character of the membrane itself.

Figure 7.

The flux function and time diagrams of four different pore blocking models under different concentrations: (a) 30 mg·L−1, (b) 40 mg·L−1 and (c) 50 mg·L−1.

Table 3.

Related parameters of different pore blocking models with different oil concentrations.

4. Conclusions

In this paper, ACMs were successfully applied to the treatment of oily wastewater. The results showed that the ceramic membrane had good permeation flux and good oil rejection rate on low concentration oily wastewater. In the experimental test based on ACMs, it was observed that the oil rejection rate was up to 97.6%. Among these results, due to the influence of oil film at higher concentrations, the oil rejection rate of ceramic membranes was slightly improved. In addition, the existence of oil film had little effect on the flux of ceramic membranes. The results showed that the permeability of ACMs mainly depends on their own oil repellency. The physical cleaning process was used to remove reversible dirt. After physical cleaning, the membrane flux and the oil rejection rate ware effectively recovered. In a word, the system is proposed as a potential technique for oily wastewater treatment and may also have potential application prospects for the treatment of heavy metal wastewater, printing and dyeing wastewater, and other pollutants.

Author Contributions

Conceptualization, J.C. and X.X.; methodology, Q.L. and Q.M.; formal analysis, X.L. (Xiao Li); investigation, Y.L. and X.Z.; writing—original draft preparation, J.C. and X.L. (Xinpeng Liu); project administration: P.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Science Foundation of Shandong Provincial (ZR2020ME251), Zibo School-City Integration Development Project (2019ZBXC245), and Open Research Fund Program of Shandong Province Key Laboratory of Oilfield Produced Water Treatment and Environmental Pollution Control (SPE2019003).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. Shandong Provincial Key Laboratory of Oilfield Produced Water Treatment and Environment Pollution Control, North China Oil&Gas Company of SINOPEO, Sinopec Petroleum Engineering Corporation and Shandong University of Technology have only scientific cooperation and no commercial corporation.

References

- Padaki, M.; Murali, R.S.; Abdullah, M.S.; Misdan, N.; Moslehyani, A.; Kassim, M.A.; Hilal, N.; Ismail, A.F. Membrane technology enhancement in oil–water separation. A review. Desalination 2015, 357, 197–207. [Google Scholar] [CrossRef]

- Tomczak, W.; Gryta, M. Application of ultrafiltration ceramic membrane for separation of oily wastewater generated by maritime transportation. Sep. Purif. Technol. 2021, 261, 118259. [Google Scholar] [CrossRef]

- Igunnu, E.T.; Chen, G.Z. Produced water treatment technologies. Int. J. Low-Carbon Technol. 2012, 9, 157–177. [Google Scholar] [CrossRef] [Green Version]

- Cheng, H.B.W.J.F. New progress in oilfield produced water treatment technology. Mod. Chem. Ind. 2018, 38, 52–57. [Google Scholar]

- Li, A.; Li, G.; Yang, J.; Yang, Y.; Liang, Y.; Zhang, D. Geo-distribution pattern of microbial carbon cycling genes responsive to petroleum contamination in continental horizontal oilfields. Sci. Total Environ. 2020, 731, 139188. [Google Scholar] [CrossRef]

- Lu, D.; Zhang, T.; Gutierrez, L.; Ma, J.; Croué, J.-P. Influence of Surface Properties of Filtration-Layer Metal Oxide on Ceramic Membrane Fouling during Ultrafiltration of Oil/Water Emulsion. Environ. Sci. Technol. 2016, 50, 4668–4674. [Google Scholar] [CrossRef] [Green Version]

- Liu, M.; Chen, J.; Cai, X.; Han, Y.; Xiong, S. Oil–water pre-separation with a novel axial hydrocyclone. Chin. J. Chem. Eng. 2018, 26, 60–66. [Google Scholar] [CrossRef]

- Suresh, K.; Pugazhenthi, G. Cross flow microfiltration of oil-water emulsions using clay based ceramic membrane support and TiO2 composite membrane. Egypt. J. Pet. 2017, 26, 679–694. [Google Scholar] [CrossRef] [Green Version]

- Yu, L.; Kanezashi, M.; Nagasawa, H.; Tsuru, T. Phase inversion/sintering-induced porous ceramic microsheet membranes for high-quality separation of oily wastewater. J. Membr. Sci. 2020, 595, 595. [Google Scholar] [CrossRef]

- Zhu, L.; Chen, M.; Dong, Y.; Tang, C.Y.; Huang, A.; Li, L. A low-cost mullite-titania composite ceramic hollow fiber micro-filtration membrane for highly efficient separation of oil-in-water emulsion. Water Res. 2016, 90, 277–285. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Zhu, L.; Chen, J.; Yang, F.; Tang, C.Y.; Guiver, M.; Dong, Y. Spinel-based ceramic membranes coupling solid sludge recycling with oily wastewater treatment. Water Res. 2020, 169, 115180. [Google Scholar] [CrossRef]

- Fan, Z.; Zhou, S.; Mao, H.; Li, M.; Xue, A.; Zhao, Y.; Xing, W. A novel ceramic microfiltration membrane fabricated by an-thurium andraeanum-like attapulgite nanofibers for high-efficiency oil-in-water emulsions separation. J. Membr. Sci. 2021, 630, 119291. [Google Scholar] [CrossRef]

- Hlavacek, M. Break-up of oil-in-water emulsions induced by permeation through a microfiltration membrane. J. Membr. Sci. 1995, 102, 1–7. [Google Scholar] [CrossRef]

- Abdel-Fatah, M.A. Nanofiltration systems and applications in wastewater treatment: Review article. Ain Shams Eng. J. 2018, 9, 3077–3092. [Google Scholar] [CrossRef]

- Nasir, A.; Masood, F.; Yasin, T.; Hameed, A. Progress in polymeric nanocomposite membranes for wastewater treatment: Preparation, properties and applications. J. Ind. Eng. Chem. 2019, 79, 29–40. [Google Scholar] [CrossRef]

- Ng, L.Y.; Mohammad, A.W.; Leo, C.P.; Hilal, N. Polymeric membranes incorporated with metal/metal oxide nanoparticles: A comprehensive review. Desalination 2013, 308, 15–33. [Google Scholar] [CrossRef]

- Su, Y.-N.; Lin, W.-S.; Hou, C.-H.; Den, W. Performance of integrated membrane filtration and electrodialysis processes for copper recovery from wafer polishing wastewater. J. Water Process Eng. 2014, 4, 149–158. [Google Scholar] [CrossRef]

- Sandu, T.; Chiriac, A.L.; Tsyntsarski, B.; Stoycheva, I.; Căprărescu, S.; Damian, C.M.; Iordache, T.V.; Pătroi, D.; Marinescu, V.; Sârbu, A. Advanced hybrid membranes for efficient nickel retention from simulated wastewater. Polym. Int. 2021, 70, 866–876. [Google Scholar] [CrossRef]

- Ezugbe, E.O.; Rathilal, S. Membrane Technologies in Wastewater Treatment: A Review. Membranes 2020, 10, 89. [Google Scholar] [CrossRef]

- Salahi, A.; Gheshlaghi, A.; Mohammadi, T.; Madaeni, S.S. Experimental performance evaluation of polymeric membranes for treatment of an industrial oily wastewater. Desalination 2010, 262, 235–242. [Google Scholar] [CrossRef]

- Chen, W.; Peng, J.; Su, Y.; Zheng, L.; Wang, L.; Jiang, Z. Separation of oil/water emulsion using Pluronic F127 modified polyethersulfone ultrafiltration membranes. Sep. Purif. Technol. 2009, 66, 591–597. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Willershausen, D.; Ashaghi, K.S.; Engel, L.; Placido, L.; Mund, P.; Bolduan, P.; Czermak, P. Investigations on the use of different ceramic membranes for efficient oil-field produced water treatment. Desalination 2010, 250, 991–996. [Google Scholar] [CrossRef] [Green Version]

- Lu, D.; Zhang, T.; Ma, J. Ceramic membrane fouling during ultrafiltration of oil/water emulsions: Roles played by stabili-zation surfactants of oil droplets. Environ. Sci. Technol. 2015, 49, 4235–4244. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, H.; Li, J.; He, B.; Wang, T.; Liao, S. Novel functionalized nano-TiO2 loading electrocatalytic membrane for oily wastewater treatment. Environ. Sci. Technol. 2012, 46, 6815–6821. [Google Scholar] [CrossRef] [PubMed]

- Zhaoyu Bai, R.Z. Songxue Wang Membrane fouling behaviors of ceramic hollow fiber microfiltration (MF) membranes by typical organic matters. Sep. Purif. Technol. 2021, 274, 1–9. [Google Scholar]

- Li, L.; Cao, G.; Zhao, R.; Wu, S.; Wang, L.; Li, X.; Zeng, S. Recycling of construction and demolition waste to fabricate cost-effective anorthite ceramic membranes for enhanced separation of an oil-in-water emulsion. Constr. Build. Mater. 2020, 265, 120512. [Google Scholar] [CrossRef]

- Son, D.-J.; Kim, D.-G.; Kim, W.-Y.; Hong, K.-H. Anti-fouling effect by internal air injection in plate-type ceramic membrane fabricated for the treatment of agro-industrial wastewater. J. Water Process. Eng. 2021, 41, 102021. [Google Scholar] [CrossRef]

- Chen, M.; Zhu, L.; Dong, Y.; Li, L.; Liu, J. Waste-to-Resource Strategy To Fabricate Highly Porous Whisker-Structured Mul-lite Ceramic Membrane for Simulated Oil-in-Water Emulsion Wastewater Treatment. ACS Sustain. Chem. Eng. 2016, 4, 2098–2106. [Google Scholar] [CrossRef]

- Hu, X.; Yu, Y.; Zhou, J.; Wang, Y.; Liang, J.; Zhang, X.; Chang, Q.; Song, L. The improved oil/water separation performance of graphene oxide modified Al2O3 microfiltration membrane. J. Membr. Sci. 2015, 476, 200–204. [Google Scholar] [CrossRef]

- Bortot Coelho, F.E.; Kaiser, N.N.; Magnacca, G.; Candelario, V.M. Corrosion resistant ZrO2/SiC ultrafiltration membranes for wastewater treatment and operation in harsh environments. J. Eur. Ceram. Soc. 2021, 41, 7792–7806. [Google Scholar] [CrossRef]

- Nandi, B.K.; Moparthi, A.; Uppaluri, R.; Purkait, M.K. Treatment of oily wastewater using low cost ceramic membrane: Comparative assessment of pore blocking and artificial neural network models. Chem. Eng. Res. Des. 2010, 88, 881–892. [Google Scholar] [CrossRef]

- Kumar, R.V.; Ghoshal, A.K.; Pugazhenthi, G. Elaboration of novel tubular ceramic membrane from inexpensive raw materials by extrusion method and its performance in microfiltration of synthetic oily wastewater treatment. J. Membr. Sci. 2015, 490, 92–102. [Google Scholar] [CrossRef]

- Vasanth, D.; Pugazhenthi, G.; Uppaluri, R. Cross-flow microfiltration of oil-in-water emulsions using low cost ceramic membranes. Desalination 2013, 320, 86–95. [Google Scholar] [CrossRef]

- Hermia, J. Constant pressure blocking filtration laws-application to power-law non-Newtonian fluids. Chem. Eng. Res. 1982, 60, 183–187. [Google Scholar]

- Zhu, L.; Dong, X.; Xu, M.; Yang, F.; Guiver, M.; Dong, Y. Fabrication of mullite ceramic-supported carbon nanotube composite membranes with enhanced performance in direct separation of high-temperature emulsified oil droplets. J. Membr. Sci. 2019, 582, 140–150. [Google Scholar] [CrossRef]

- Abadikhah, H.; Zou, C.-N.; Hao, Y.; Wang, J.-W.; Lin, L.; Khan, S.A.; Xu, X.; Chen, C.-S.; Agathopoulos, S. Application of asymmetric Si3N4 hollow fiber membrane for cross-flow microfiltration of oily waste water. J. Eur. Ceram. Soc. 2018, 38, 4384–4394. [Google Scholar] [CrossRef]

- Liu, M.; Zhu, Z.; Zhang, Z.; Chu, Y.; Yuan, B.; Wei, Z. Development of highly porous mullite whisker ceramic membranes for oil-in-water separation and resource utilization of coal gangue. Sep. Purif. Technol. 2020, 237, 116483. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).