Reliability of SnPbSb/Cu Solder Joint in the High-Temperature Application

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Evolution in Microstructure of the Solder

3.2. Evolution in Microstructure of the Joint Interface

3.3. Shear Strength of the Solder Joint

3.4. Fracture Morphologies of the Solder Joints

4. Conclusions

- (1)

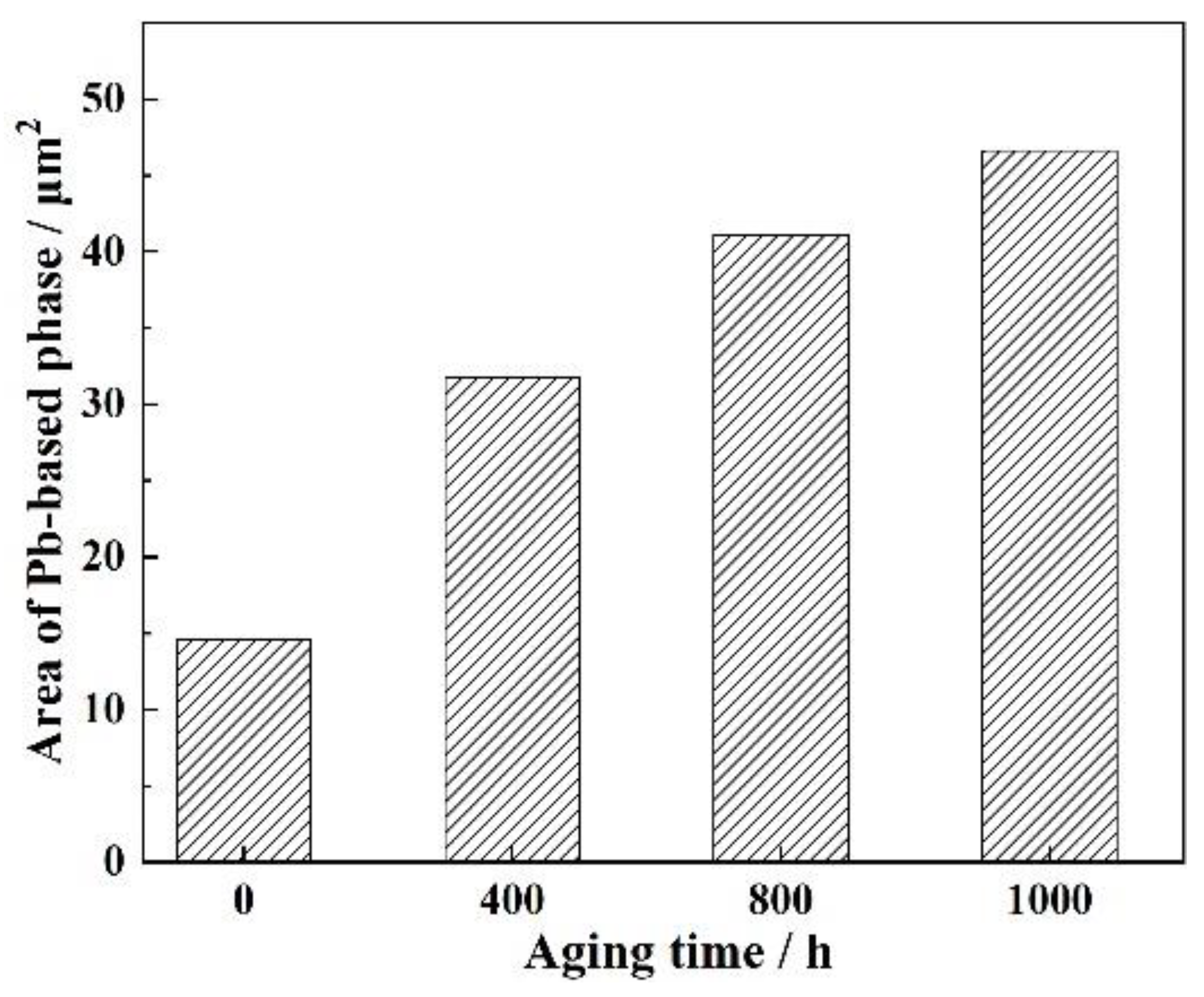

- Long-time high-temperature aging promoted the diffusion and migration of atoms, resulting in the continuous coarsening of the SnPbSb solder and the significant increase in size of the Pb-rich phase, while the eutectic structure characteristics were hardly changed.

- (2)

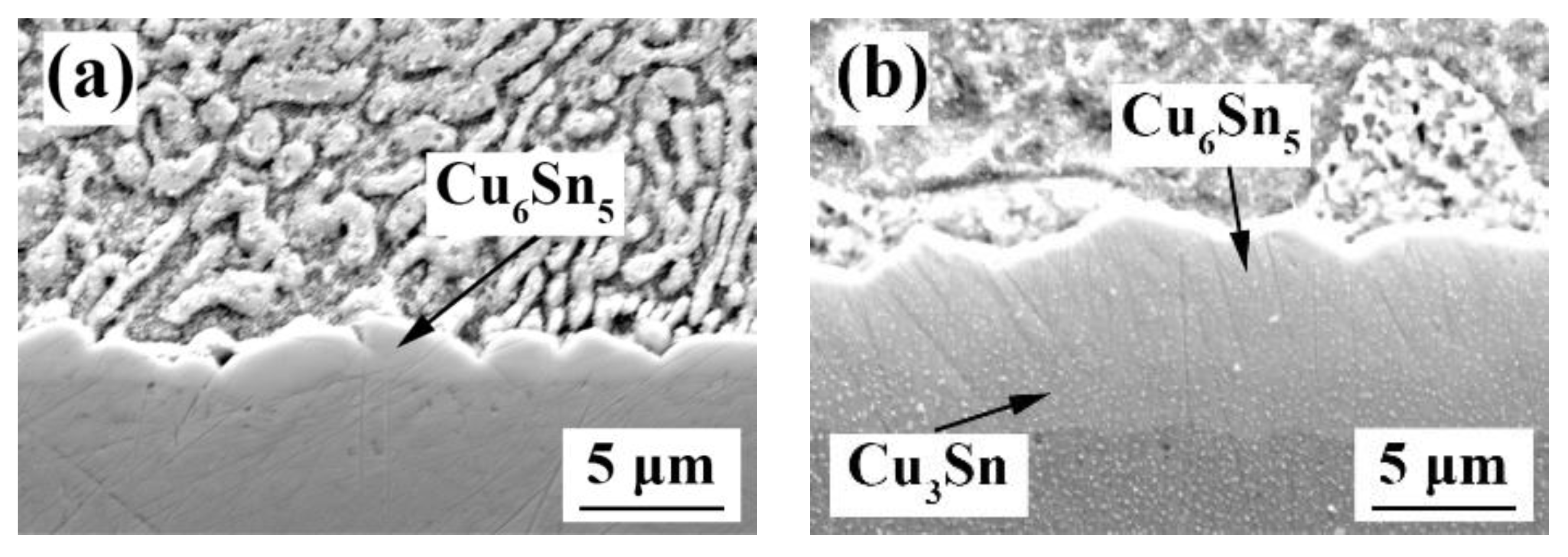

- The Cu6Sn5 layer grew gradually during the thermal aging process, and the Cu6Sn5/solder interface transformed from a scallop-like morphology into a flat morphology; a Cu3Sn layer appeared between the Cu6Sn5 and the Cu substrate. The thickness of the interfacial IMC layer increased significantly after long-time aging.

- (3)

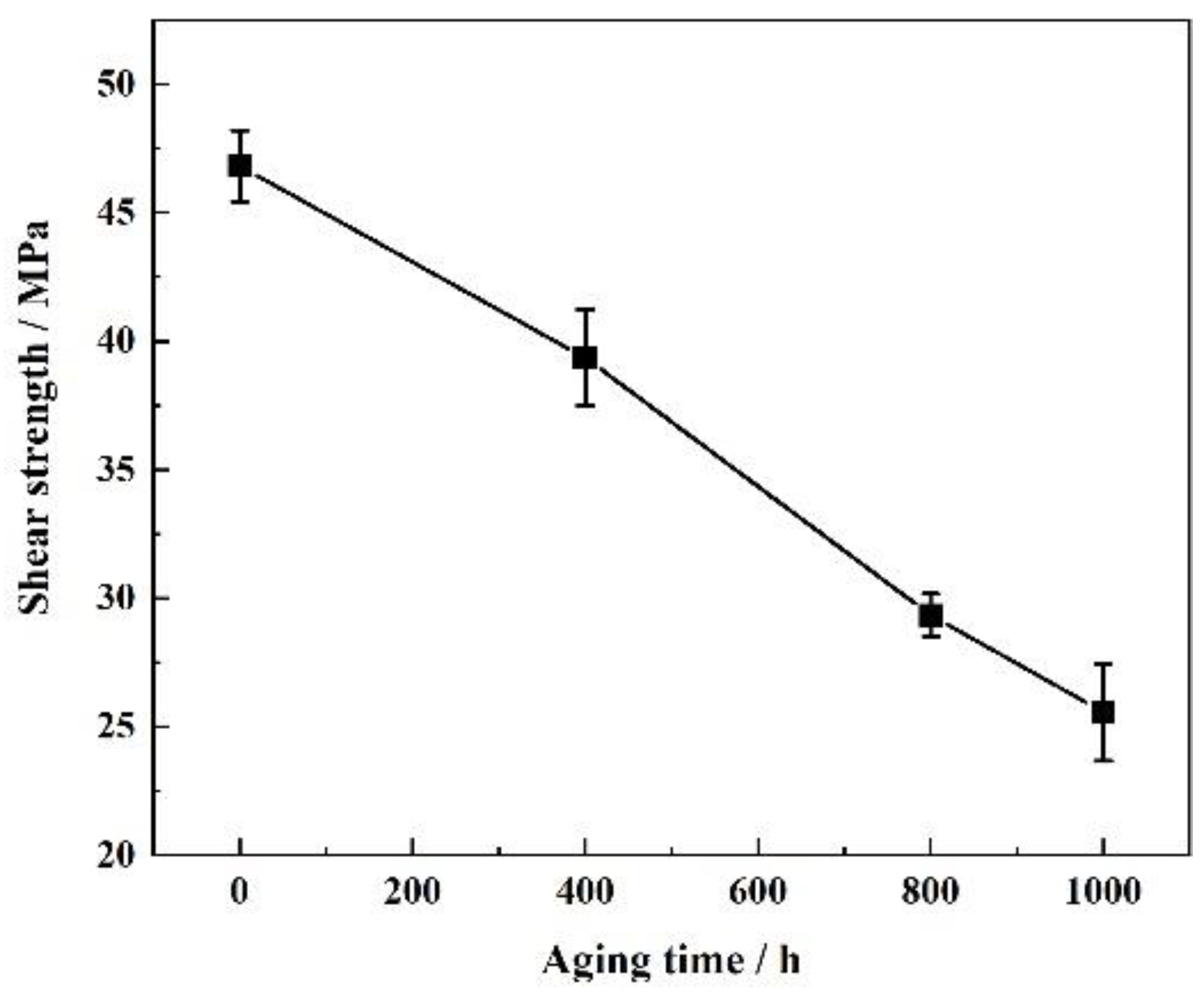

- The continuous coarsening of the solder matrix and growth of the IMC layer at the interface co-deteriorated the mechanical properties of the SnPbSb/Cu joint. The shear strength of the SnPbSb/Cu solder joint decreased from 46.83 MPa to 25.57 Mpa after aging for 1000 h.

- (4)

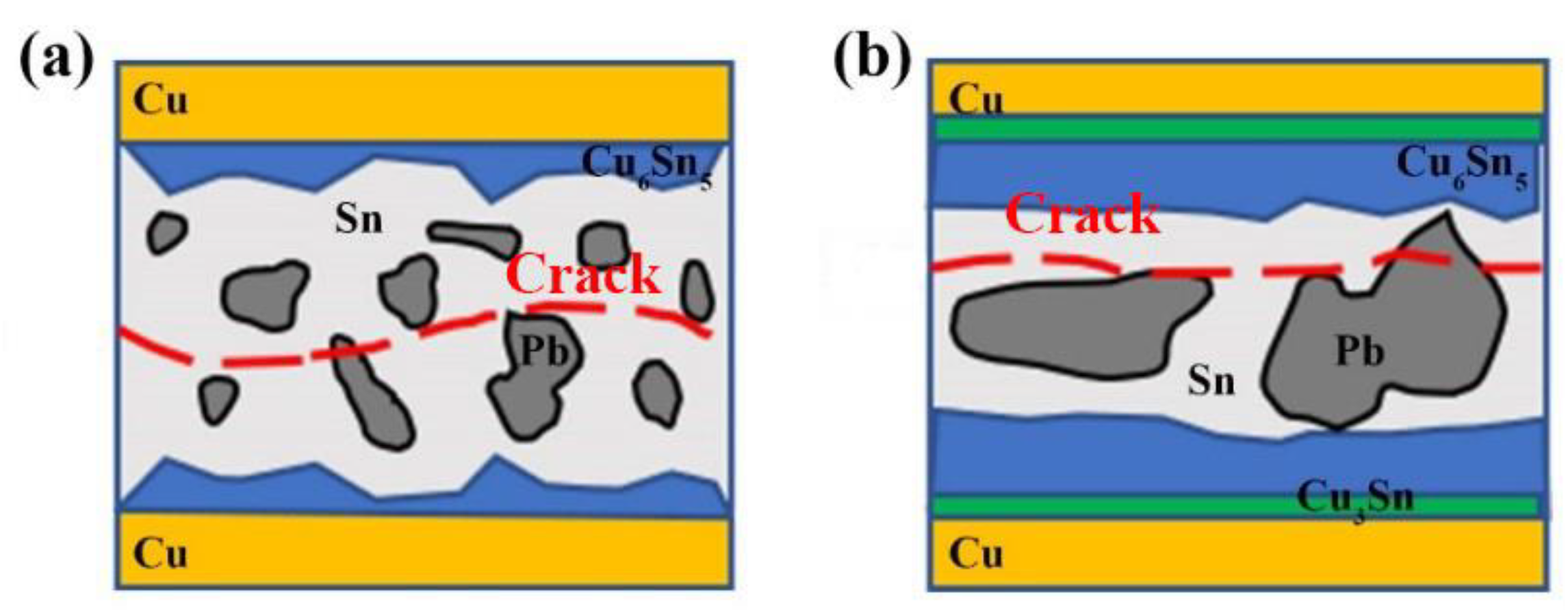

- During thermal aging, the fracture of SnPbSb/Cu solder joints was always a ductile fracture which occurred in the solder matrix. It could be concluded that the influence of the coarsening solder matrix on the mechanical properties of joints was more significant than that of the growth of the interfacial IMC layer.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ma, H.; Suhling, J.C. A review of mechanical properties of lead-free solders for electronic packaging. J. Mater. Sci. 2009, 44, 1141–1158. [Google Scholar] [CrossRef]

- Wang, J.H.; Xue, S.B.; Lv, Z.P.; Wang, L.J.; Liu, H. Present Research Status of Lead-free Solder Reinforced by Nanoparticles. Mater. Rep. 2019, 33, 2133–2145. (In Chinese) [Google Scholar]

- Tu, K.N.; Zeng, K. Tin-lead (SnPb) solder reaction in flip chip technology. Mater. Sci. Eng. R 2001, 34, 1–58. [Google Scholar] [CrossRef]

- Wang, J.H.; Xue, S.B.; Wang, J.X.; Zhang, P.; Tao, Y.; Wang, Z.Y. Comparative study on the reliability of SnPbSb solder joint under common thermal cycling and extreme thermal shocking. J. Mater. Sci. Mater. Electron. 2020, 31, 5731–5737. [Google Scholar] [CrossRef]

- Yang, L.M.; Quan, S.Y.; Liu, C.; Shi, G. Aging resistance of the Sn-Ag-Cu solder joints doped with Mo nanoparticles. Mater. Lett. 2019, 253, 191–194. [Google Scholar] [CrossRef]

- Wang, J.H.; Xue, S.B.; Zhang, P.; Zhai, P.Z.; Tao, Y. The reliability of lead-free solder joint subjected to special environment: A review. J. Mater. Sci. Mater. Electron. 2019, 30, 9065–9086. [Google Scholar] [CrossRef]

- Zhong, Y.; Liu, W.; Wang, C.; Zhao, X.J.; Caers, J.F.J.M. The influence of strengthening and recrystallization to the cracking behavior of Ni, Sb, Bi alloyed SnAgCu solder during thermal cycling. Mater. Sci. Eng. A 2016, 652, 264–270. [Google Scholar] [CrossRef]

- Wang, J.H.; Xue, S.B.; Zhang, P.; Wang, Z.Y.; Zhai, P.Z. Effect of extreme thermal shocking on the reliability of Sn50Pb49Sb1/Cu solder joint. J. Mater. Sci. Mater. Electron. 2020, 31, 1421–1429. [Google Scholar] [CrossRef]

- Tian, R.; Hang, C.; Tian, Y.; Wu, B.; Liu, Y.; Zhao, J. Interfacial intermetallic compound growth in Sn-3Ag-0.5Cu/Cu solder joints induced by stress gradient at cryogenic temperatures. J. Alloy. Compd. 2019, 800, 180–190. [Google Scholar] [CrossRef]

- Wang, J.H.; Xue, S.B.; Lv, Z.P.; Wen, L.; Liu, S. Microstructure and performance evolution of SnPbSb solder joint under γ-ray irradiation and thermal cycling. J. Mater. Sci. Mater. Electron. 2019, 30, 4990–4999. [Google Scholar] [CrossRef]

- Bao, N.; Hu, X.; Li, Y.; Jiang, X. Effects of thermal aging on growth behavior of interfacial intermetallic compound of dip soldered Sn/Cu joints. J. Mater. Sci. Mater. Electron. 2018, 29, 8863–8875. [Google Scholar] [CrossRef]

- Wang, J.H.; Xue, S.B.; Lv, Z.P.; Wang, L.J.; Liu, H.; Wen, L. Effect of gamma-ray irradiation on microstructure and mechanical property of Sn63Pb37 solder joints. J. Mater. Sci. Mater. Electron. 2018, 29, 20726–20733. [Google Scholar] [CrossRef]

- Wang, J.H.; Xue, S.B.; Liu, L.; Zhang, P.; Nishikawa, H. Three-dimensional interface and property of SnPb solder joint under extreme thermal shocking. Sci. Technol. Weld. Join. 2022, 27, 186–196. [Google Scholar] [CrossRef]

- Yang., L.; Zhou, W.; Ma, Y.; Li, X.; Liang, Y.; Cui, W.; Wu, P. Effects of Ni addition on mechanical properties of Sn58Bi solder alloy during solid-state aging. Mater. Sci. Eng. A 2016, 667, 368–375. [Google Scholar] [CrossRef]

- Wang, J.H.; Liu, X.D.; Huo, F.P.; Kariya, K.; Masago, N.; Nishikawa, H. Novel transient liquid phase bonding method using In-coated Cu sheet for high-temperature die attach. Mater. Res. Bull. 2022, 149, 111713. [Google Scholar] [CrossRef]

- Hall, E.O. The deformation and ageing of mild steel: III discussion of results. Proc. Phys. Soc. Sect. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

| Area | Chemical Composition/wt.% | ||

|---|---|---|---|

| Sn | Pb | Sb | |

| A | Bal. | 49.25 | 0.93 |

| B | Bal. | 49.95 | 0.89 |

| C | Bal. | 48.03 | 1.07 |

| D | Bal. | 48.71 | 1.05 |

| E | Bal. | 49.82 | 0.68 |

| Aging Time/h | Thickness/μm | ||

|---|---|---|---|

| Cu6Sn5 Layer | Cu3Sn Layer | Total IMC Layer | |

| 0 | 1.31 | 0 | 1.31 |

| 400 | 3.73 | 1.95 | 5.68 |

| 800 | 5.26 | 2.69 | 7.95 |

| 1000 | 6.67 | 3.31 | 9.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Fu, Y.; Zhou, X.; Zhang, J.; Xue, S. Reliability of SnPbSb/Cu Solder Joint in the High-Temperature Application. Crystals 2022, 12, 1724. https://doi.org/10.3390/cryst12121724

Xu J, Fu Y, Zhou X, Zhang J, Xue S. Reliability of SnPbSb/Cu Solder Joint in the High-Temperature Application. Crystals. 2022; 12(12):1724. https://doi.org/10.3390/cryst12121724

Chicago/Turabian StyleXu, Jiachen, Yucan Fu, Xiaoxiao Zhou, Junqian Zhang, and Songbai Xue. 2022. "Reliability of SnPbSb/Cu Solder Joint in the High-Temperature Application" Crystals 12, no. 12: 1724. https://doi.org/10.3390/cryst12121724

APA StyleXu, J., Fu, Y., Zhou, X., Zhang, J., & Xue, S. (2022). Reliability of SnPbSb/Cu Solder Joint in the High-Temperature Application. Crystals, 12(12), 1724. https://doi.org/10.3390/cryst12121724