Electron-Beam Welding Cu and Al6082T6 Aluminum Alloys with Circular Beam Oscillations

Abstract

:1. Introduction

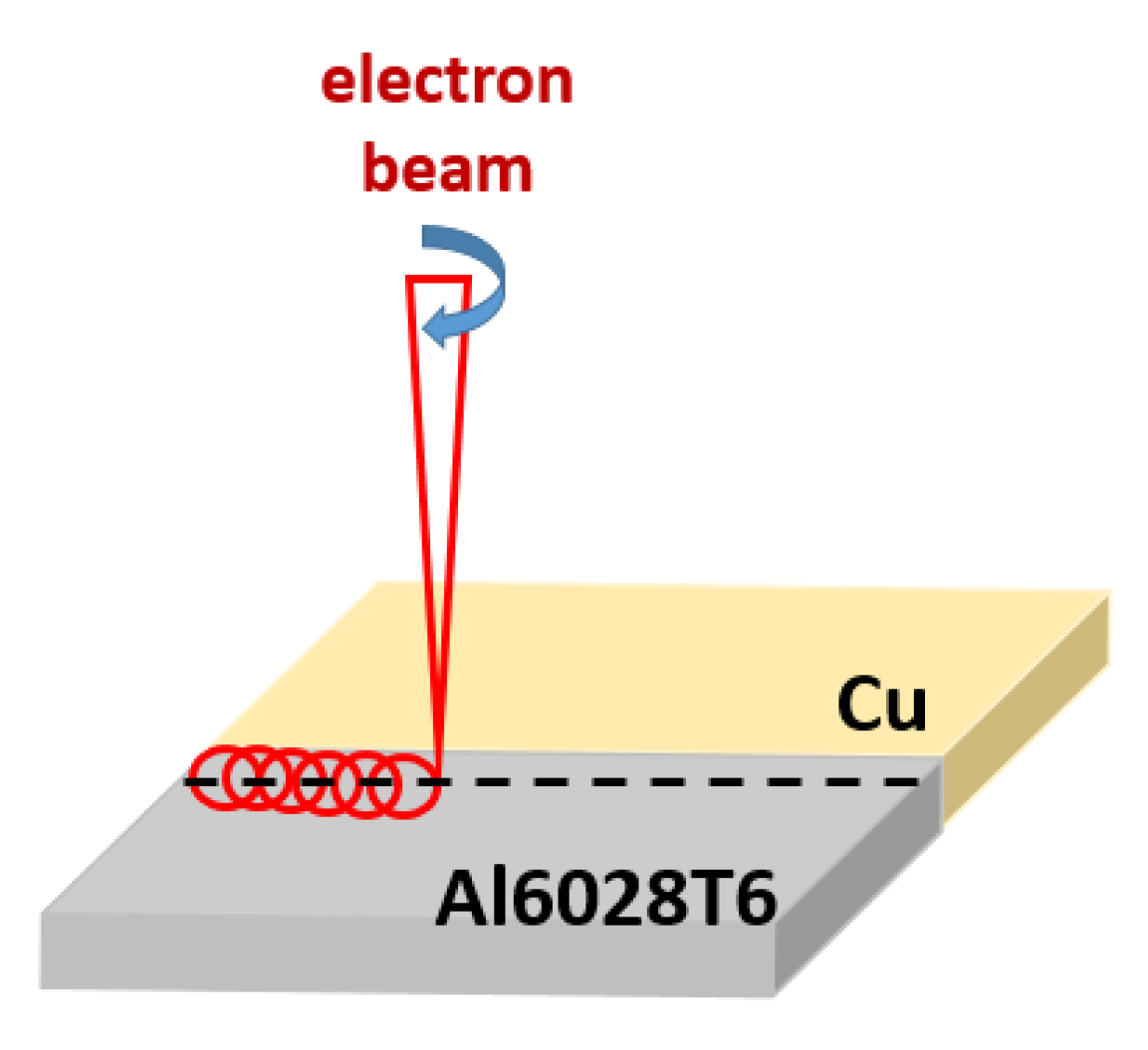

2. Materials and Methods

3. Results and Discussion

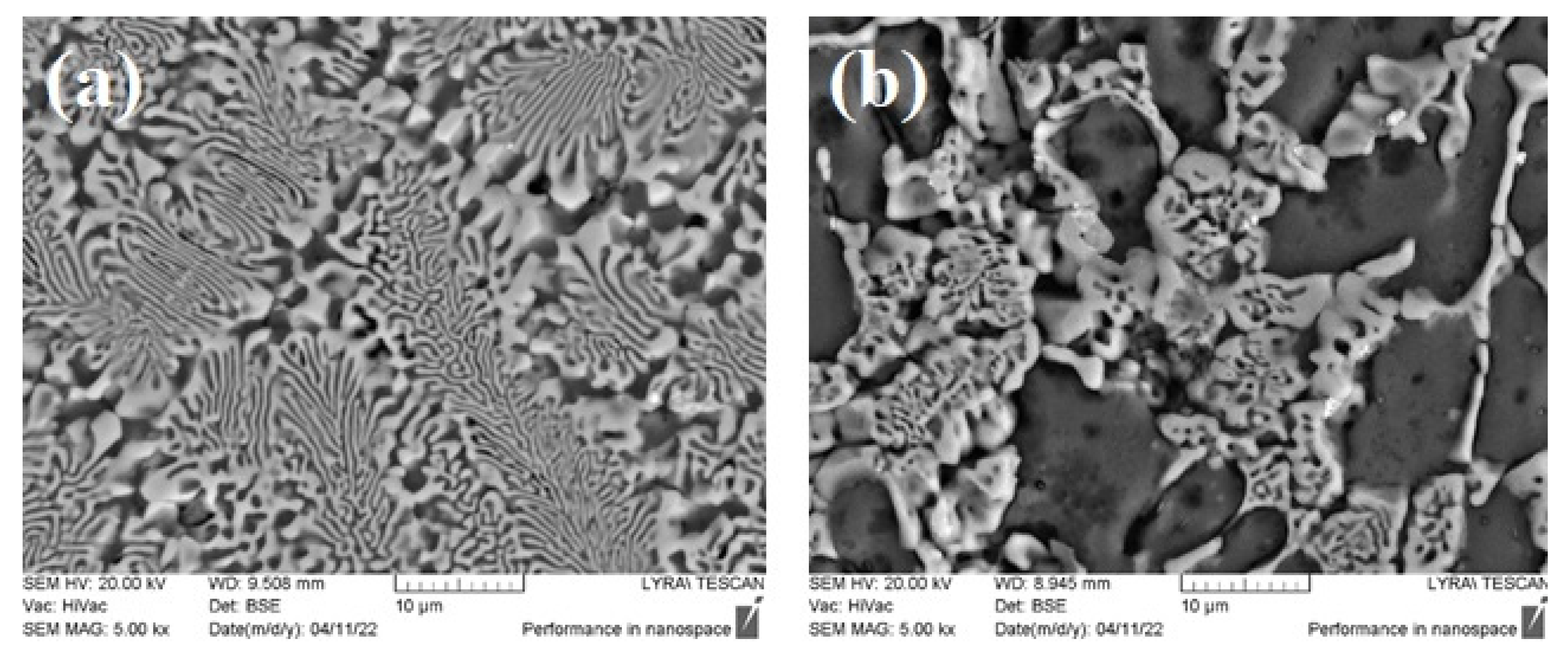

3.1. Structure and Phase Composition

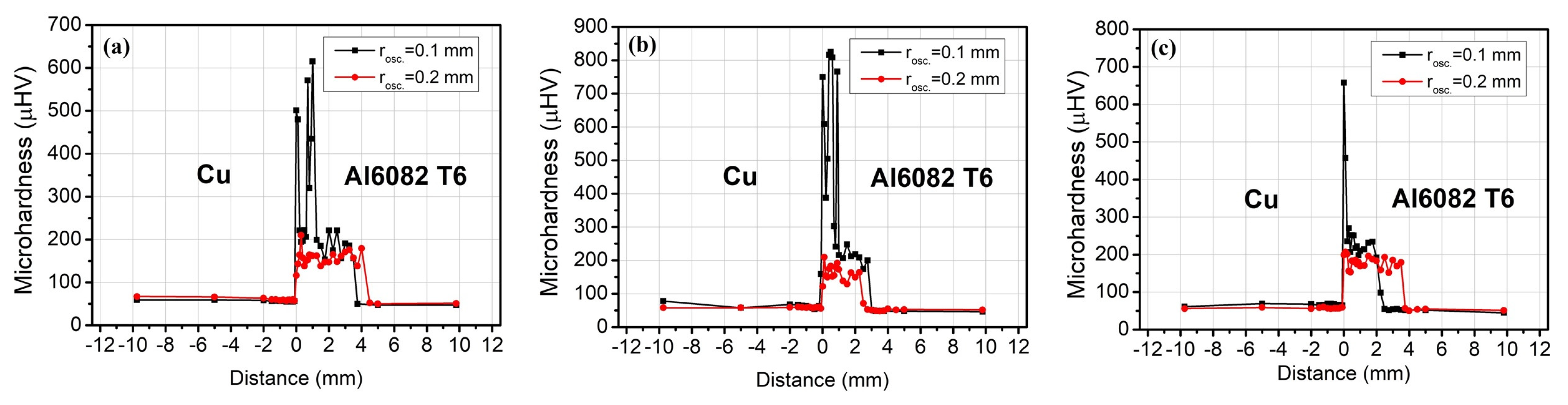

3.2. Microhardness

4. Discussion

5. Conclusions

- (1)

- A larger volume melt pool formed during the electron-beam welding procedure with an oscillating radius of 0.2 mm. This corresponds to the full penetration of the flux of accelerated electrons and the formation of a full-penetration weld seam.

- (2)

- Both specimens have a structure consisting of pure aluminum, pure copper, and a CuAl2 intermetallic compound. The aluminum and copper phases both have a face-centered cubic structure compared to the intermetallic compound, which is characterized as having a body-centered tetragonal crystal structure. A higher concentration of the CuAl2 intermetallic phase was observed in the case of electron-beam welding processes using an oscillation with a radius of 0.1 mm. This is attributed to the poor thermal dispersion within the welded specimens, resulting in the local melting of the samples. Due to the high local temperature density, the fusion of the copper and aluminum molten phases increases, resulting in the rapid formation of intermetallic compounds.

- (3)

- The studied microhardness of both joints indicates that the sample produced using an oscillating radius of 0.1 mm had a much higher hardness compared to the sample formed using a radius of 0.2 mm. The highest microhardness was observed in the middle of the welded seam, where most of the intermetallic compounds are formed. Furthermore, the specimens welded with an oscillating radius of 0.1 mm had much higher differences in the local maxima of the hardness due to the vastly different mechanical properties of the base materials and the intermetallic compounds. Due to the lower concentration of intermetallic compounds in the joint of the sample with an oscillating radius of 0.2 mm, increasingly homogeneous microhardness values were detected that were closer to those of the base materials. In addition, in both cases, a lower microhardness along the entire cross section of the base materials was measured in comparison to bulk copper and Al6082T6.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dilthey, U.; Stein, L. Multimaterial car body design: Challenge for welding and joining. Sci. Tech. Weld. Join. 2006, 11, 135–142. [Google Scholar] [CrossRef]

- Brand, M.; Schmidt, P.; Zaeh, M.; Jossen, A. Welding techniques for battery cells and resulting electrical contact resistances. J. Ener. Stor. 2015, 1, 7–14. [Google Scholar] [CrossRef]

- Mai, T.A.; Spowage, A.C. Characterisation of Dissimilar Joints in Laser Welding of Steel-Kovar, Copper-Steel and Copper-Aluminium. Mater. Sci. Eng. A 2004, 374, 224–233. [Google Scholar] [CrossRef]

- Weigl, M.; Grimm, A.; Schmidt, M. Laser-welded connections for high-power electronics in mobile systems. Electr. Drives Prod. Conf. 2011, 88–92. [Google Scholar] [CrossRef]

- Freudenberger, J.; Warlimont, H. Copper and copper alloys. In Springer Handbook of Materials Data, 2nd ed.; Warlimont, H., Martienssen, W., Eds.; Springer: Cham, Switzerland, 2018; pp. 297–305. [Google Scholar]

- Kammer, C. Aluminum and aluminum alloys. In Springer Handbook of Materials Data, 2nd ed.; Warlimont, H., Martienssen, W., Eds.; Springer: Cham, Switzerland, 2018; pp. 161–197. [Google Scholar]

- Kah, P.; Vimalraj, C.; Martikainen, J.; Suoranta, R. Factors influencing Al-Cu weld properties by intermetallic compound formation. Intern. J. Mech. Mat. Eng. 2015, 10, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Berlanga-Labari, C.; Albístur-Goñi, A.; Balerdi-Azpilicueta, P.; Gutiérrez-Peinado, M.; Ferńandez Carrasquilla, J. Study and selection of the most appropriate filler materials for an Al/Cu brazing joint in cooling circuits. Mat. Manuf. Proces. 2011, 26, 236–241. [Google Scholar] [CrossRef]

- Kim, I.; Hong, S. Effect of heat treatment on the bending behavior of tri-layered Cu/Al/Cu composite plates. Mat. Des. 2013, 47, 590–598. [Google Scholar] [CrossRef]

- Lee, S.J.; Nakumura, H.; Kawahito, Y.; Katayama, S. Effect of welding speed on microstructural and mechanical properties of laser lap weld joints in dissimilar Al and Cu sheets. Sci. Tech. Weld. Join. 2014, 19, 111–118. [Google Scholar] [CrossRef]

- Tan, C.; Jiang, Z.G.; Li, L.; Chen, Y.; Chen, X. Microstructural evolution and mechanical properties of dissimilar Al-Cu joints produced by friction stir welding. Mater. Des. 2013, 51, 466–473. [Google Scholar] [CrossRef]

- Firouzdor, V.; Kou, S. Al-to-Cu friction stir lap welding. Metall. Mater. Trans. A 2012, 43, 303–315. [Google Scholar] [CrossRef]

- Sharma, N.; Khan, Z.; Siddiquee, A. Friction stir welding of aluminum to copper–An overview. Trans. Nonfer. Met. Soc. China 2017, 27, 2113–2136. [Google Scholar] [CrossRef]

- Xue, P.; Xiao, B.; Ma, Z. Effect of interfacial microstructure evolution on mechanical properties and fracture behavior of friction stir-welded Al-Cu joints. Metall. Mater. Trans. A 2015, 46, 3091–3103. [Google Scholar] [CrossRef]

- Acarer, M. Electrical, Corrosion, and Mechanical Properties of Aluminum-Copper Joints Produced by Explosive. Weld. J. Mat. Eng. Perform. 2012, 21, 2375–2379. [Google Scholar] [CrossRef]

- Schmalen, P.; Plapper, P. Evaluation of laser braze-welded dissimilar Al-Cu joints. Phys. Proc. 2016, 83, 506–514. [Google Scholar] [CrossRef] [Green Version]

- Kermanidis, A.T.; Christodoulou, P.I.; Hontzopoulos, E.; Haidemenopoulos, G.N.; Kamoutsi, H.; Zervaki, A.D. Mechanical performance of laser spot-welded joints in Al-Al/Cu solar thermal absorbers. Mater. Des. 2018, 155, 148–160. [Google Scholar] [CrossRef]

- Boucherit, A.; Abdi, S.; Aissani, M.; Mehdi, B.; Abib, K.; Badji, R. Weldability, microstructure, and residual stress in Al/Cu and Cu/Al friction stir spot weld joints with Zn interlayer. Int. J. Adv. Manuf. Techn. 2020, 111, 1553–1569. [Google Scholar] [CrossRef]

- Li, M.; Zhang, C.; Wang, D.; Zhou, L.; Wellmann, D.; Tian, Y. Friction stir spot welding of aluminum and copper: A review. Materials 2019, 13, 156. [Google Scholar] [CrossRef] [Green Version]

- Sansan, A.; Li, C.; Zhang, W.; Wu, M.; Chen, Y.; Luo, Z. Microstructure evolution and mechanical properties of Al/Cu ultrasonic spot welded joints during thermal processing. J. Manuf. Proces. 2019, 41, 307–314. [Google Scholar]

- Bergmann, J.; Regensburg, A.; Schürer, R.; Petzoldt, F.; Herb, A. Effect of the interface characteristics on the joint properties and diffusion mechanisms during ultrasonic metal welding of Al/Cu. Weld. World 2017, 61, 499–506. [Google Scholar] [CrossRef]

- Mohan Raj, N.; Kumaraswamidhas, L.; Nalajam, P.; Vendan, S. Studies on electro mechanical aspects in ultrasonically welded Al/Cu joints. Trans. Indian Inst. Met. 2018, 71, 107–116. [Google Scholar] [CrossRef]

- Sun, Z.; Karppi, R. The application of electron beam welding for the joining of dissimilar metals: An overview. J. Mater. Proces. Tech. 1996, 59, 257–267. [Google Scholar] [CrossRef]

- Ochi, H.; Ogawa, K.; Yamamoto, Y.; Kawai, G.; Sawai, T. The formation of intermetallic compounds in aluminium alloy to copper friction-welded joints and their effect on joint efficiency. Weld. Intern. 2004, 18, 516–523. [Google Scholar] [CrossRef]

- Kar, J.; Roy, S.K.; Roy, G.G. Effect of beam oscillation on electron beam welding of copper with AISI-304 stainless steel. J. Mater. Process. Tech. 2016, 233, 174–185. [Google Scholar] [CrossRef]

- Valkov, S.; Ormanova, M.; Petrov, P. Electron-Beam Surface Treatment of Metals and Alloys: Techniques and Trends. Metals 2020, 10, 1219. [Google Scholar] [CrossRef]

- Valkov, S.; Ormanova, M.; Petrov, P. Surface manufacturing of materials by high energy fluxes. In Advanced Surface Engineering Research; Chowdhury, M.A., Ed.; IntechOpen: London, UK, 2018; pp. 69–87. [Google Scholar]

- Yeganeh, V.E.; Li, P. Effect of beam offset on microstructure and mechanical properties of dissimilar electron beam welded high temperature titanium alloys. Mater. Des. 2017, 124, 78–86. [Google Scholar] [CrossRef]

- Otten, C.; Reisgen, U.; Schmachtenberg, M. Electron beam welding of aluminum to copper: Mechanical properties and their relation to microstructure. Weld. World 2016, 60, 21–31. [Google Scholar] [CrossRef]

- Kaisheva, D.; Anchev, A.; Valkov, S.; Dunchev, V.; Kotlarski, G.; Stoyanov, B.; Ormanova, M.; Atanasova, M.; Petrov, P. Influence of Beam Power on Structures and Mechanical Characteristics of Electron-Beam-Welded Joints of Copper and Stainless Steel. Metals 2022, 12, 737. [Google Scholar] [CrossRef]

- Solchenbach, T.; Plapper, P. Mechanical characteristics of laser braze-welded aluminium–copper connections. Opt. Laser Tech. 2013, 54, 249–256. [Google Scholar] [CrossRef]

- Murray, J.L. The aluminium-copper system. Inter. Met. Rev. 1985, 30, 211–234. [Google Scholar] [CrossRef]

- Zobac, O.; Kroupa, A.; Zemanova, A.; Richter, K.W. Experimental description of the Al-Cu binary phase diagram. Metall. Mater. Trans. A 2019, 50, 3805–3815. [Google Scholar] [CrossRef] [Green Version]

- Petrov, P.; Tongov, M. Numerical modelling of heat source during electron beam welding. Vacuum 2020, 171, 108991. [Google Scholar] [CrossRef]

- Petrov, P.; Georgiev, C.; Petrov, G. Experimental investigation of weld pool formation in electron beam welding. Vacuum 1998, 51, 339–343. [Google Scholar] [CrossRef]

- Stoltze, P.; Norskov, J.; Landman, U. Disordering and Melting of Aluminum Surfaces. Phys. Rev. Lett. 1988, 61, 440. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, L.; Li, G.; Zhang, R.; Zhou, W.; He, W.; Huang, Y.; Song, X. Microstructure evolution and mechanical properties of friction stir spot welded dissimilar aluminum-copper joint. J. Alloy. Comp. 2019, 775, 372–382. [Google Scholar] [CrossRef]

- Woelke, P.; Hiriyur, B.; Nahshon, K.; Hutchinson, J. A practical approach to modeling aluminum weld fracture for structural applications. Eng. Frac. Mech 2017, 175, 72–85. [Google Scholar] [CrossRef]

- Hust, J.; Lankford, A. Thermal Conductivity of Aluminum, Copper, Iron, and Tungsten for Temperatures from 1 K to the Melting Point; U.S. Department of Commerce: Boulder, CO, USA, 1984. [Google Scholar]

- Yousefian, P.; Tiryakioglu, M. Pore Formation During Solidification of Aluminum: Reconciliation of Experimental Observations, Modeling Assumptions, and Classical Nucleation Theory. Metall. Mater. Trans. A 2018, 49, 563–575. [Google Scholar] [CrossRef]

- Teng, T.; Chang, P. Effect of residual stresses on fatigue crack initiation life for butt-welded joints. J. Mater. Process. Tech. 2004, 145, 325–335. [Google Scholar] [CrossRef]

| Sample | U, kV | Ib, mA | Q, W | v, mm/s | rosc, mm |

|---|---|---|---|---|---|

| 1 | 60 | 45 | 2700 | 15 | 0.1 |

| 2 | 60 | 45 | 2700 | 15 | 0.2 |

| Element, wt. % | Point 1 | Point 2 |

|---|---|---|

| Cu | 44.08 ± 1.3% | 3.39 ± 0.2% |

| Al | 55.92 ± 2.7% | 96.61 ± 5.3% |

| Element, wt. % | Point 3 | Point 4 |

|---|---|---|

| Cu | 51.35 ± 1.8% | 4.52 ± 0.4% |

| Al | 48.65 ± 2.6% | 95.48 ± 5.3% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaisheva, D.; Anchev, A.; Dunchev, V.; Kotlarski, G.; Stoyanov, B.; Ormanova, M.; Valkov, S. Electron-Beam Welding Cu and Al6082T6 Aluminum Alloys with Circular Beam Oscillations. Crystals 2022, 12, 1757. https://doi.org/10.3390/cryst12121757

Kaisheva D, Anchev A, Dunchev V, Kotlarski G, Stoyanov B, Ormanova M, Valkov S. Electron-Beam Welding Cu and Al6082T6 Aluminum Alloys with Circular Beam Oscillations. Crystals. 2022; 12(12):1757. https://doi.org/10.3390/cryst12121757

Chicago/Turabian StyleKaisheva, Darina, Angel Anchev, Vladimir Dunchev, Georgi Kotlarski, Borislav Stoyanov, Maria Ormanova, and Stefan Valkov. 2022. "Electron-Beam Welding Cu and Al6082T6 Aluminum Alloys with Circular Beam Oscillations" Crystals 12, no. 12: 1757. https://doi.org/10.3390/cryst12121757

APA StyleKaisheva, D., Anchev, A., Dunchev, V., Kotlarski, G., Stoyanov, B., Ormanova, M., & Valkov, S. (2022). Electron-Beam Welding Cu and Al6082T6 Aluminum Alloys with Circular Beam Oscillations. Crystals, 12(12), 1757. https://doi.org/10.3390/cryst12121757