Interfacial Microstructure and Mechanical Properties of Titanium/Sapphire Joints Brazed with AuSn20 Filler Metal

Abstract

:1. Introduction

2. Materials and Experimental Procedure

3. Results and Discussion

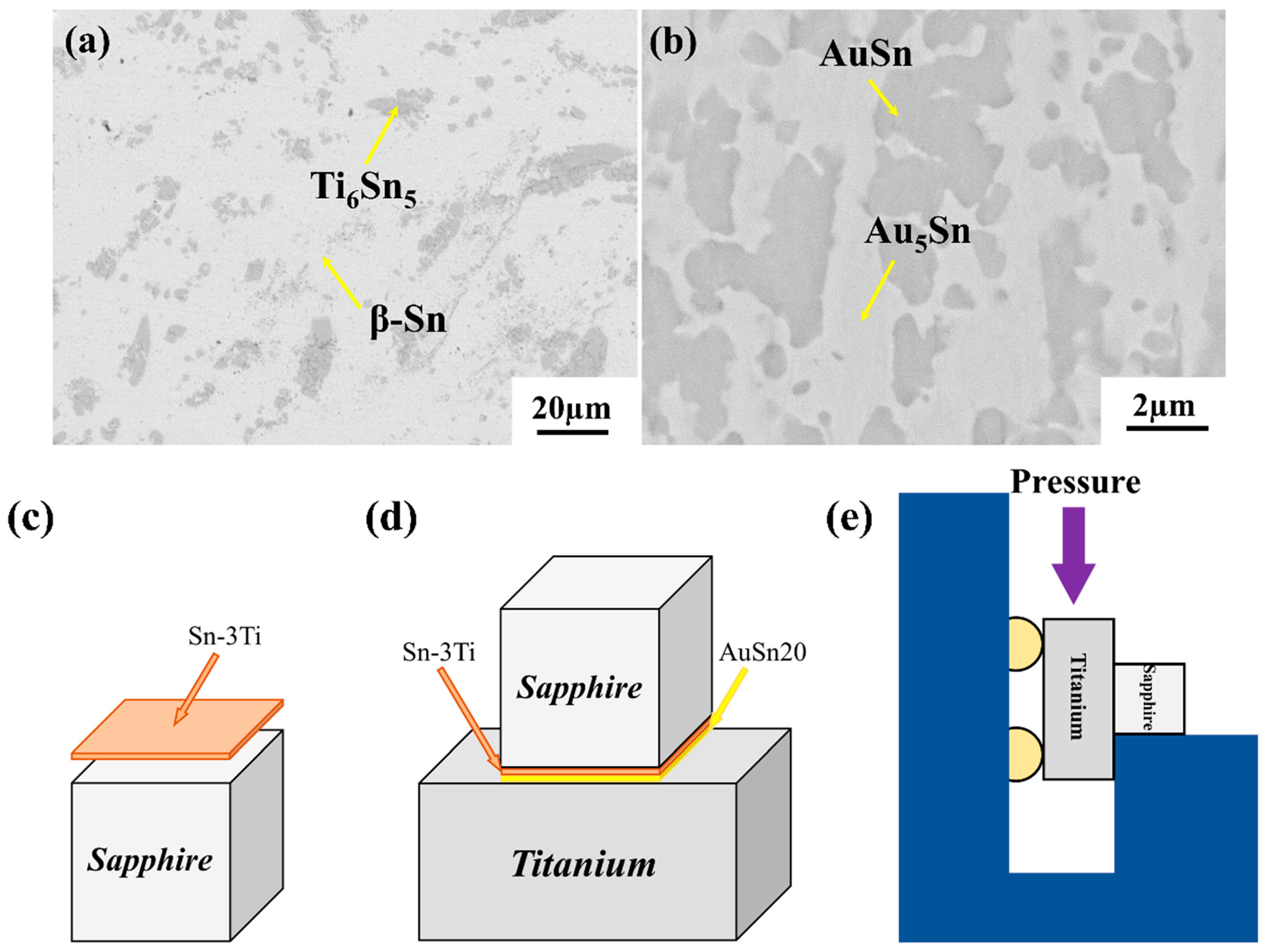

3.1. The Wetting Phenomena of Sn-3Ti/Sapphire

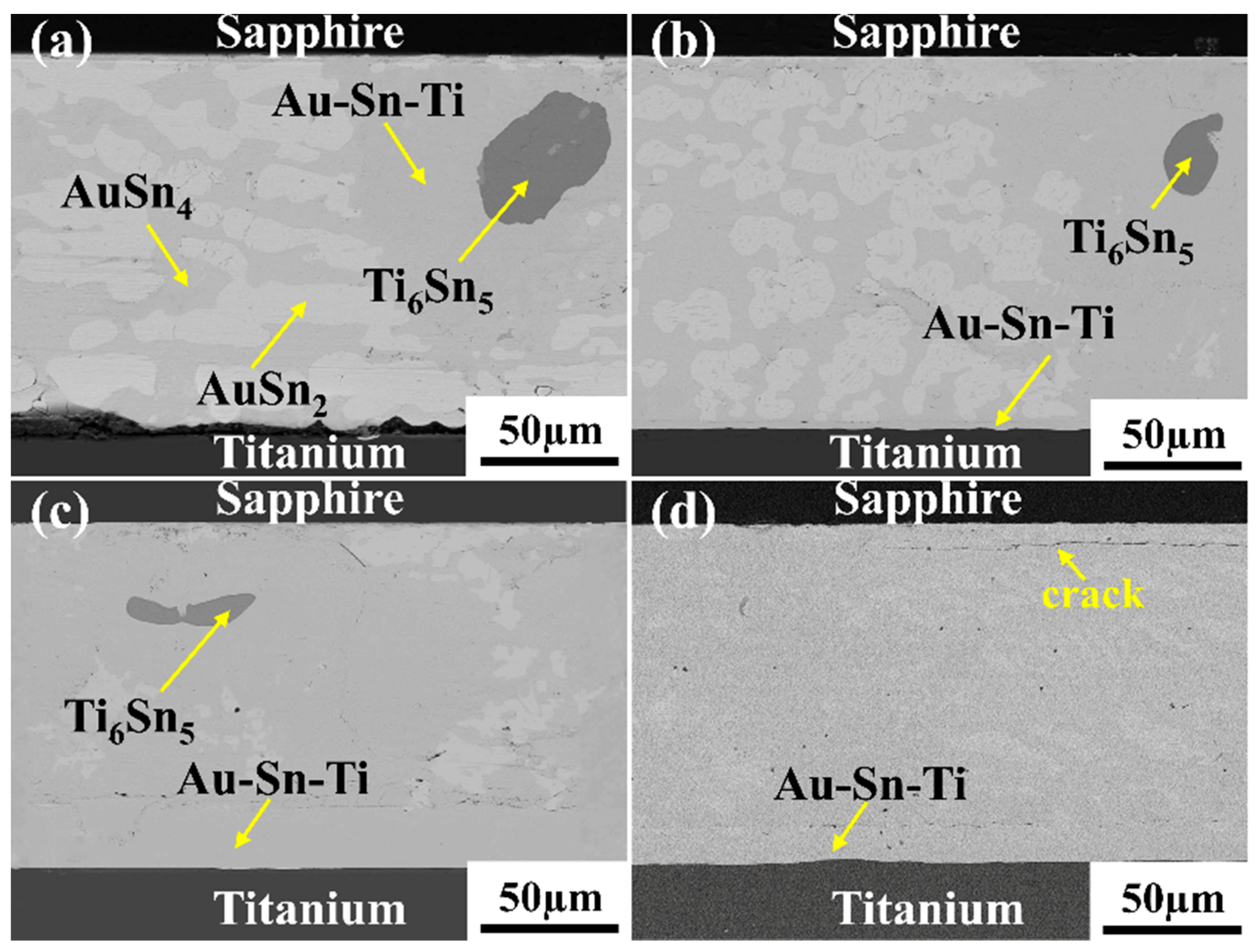

3.2. Typical Interfacial Microstructure of the Titanium/AuSn20/Sn-3Ti/Sapphire Joint

3.3. Effects of Processing Parameters on the Microstructure of the Titanium/AuSn20/Sn-3Ti/Sapphire Joint

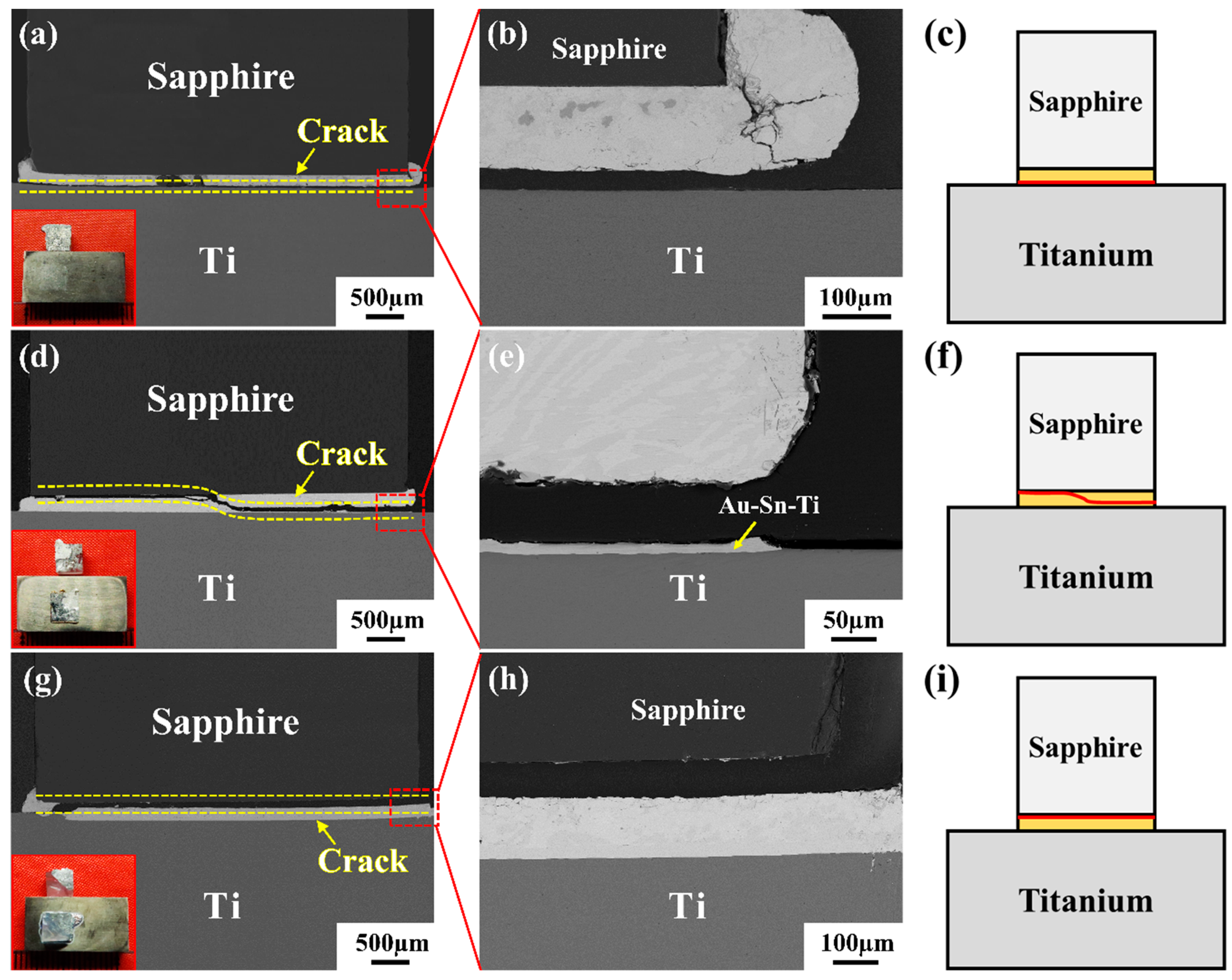

3.4. Mechanical Properties and Fracture Morphology of the Titanium/AuSn20/Sn-3Ti/Sapphire Joint

4. Conclusions

- The lowest equilibrium contact angle of Sn-3Ti on the sapphire substrate in the wetting experiment was 57°. In the Sn-3Ti/sapphire system, the Ti6Sn5 phase was formed in the solidified melt, which distributed in the Sn matrix. Meanwhile, TiO was formed at the interface between the sapphire and the droplet.

- The typical interfacial microstructure of the titanium/AuSn20/Sn-3Ti/sapphire brazed joints was titanium substrate/Au-Sn-Ti layer/Ti6Sn5 + AuSn2 + AuSn4 + massive Au-Sn-Ti/TiO phase/sapphire.

- The shear strength of the titanium/AuSn20/Sn-3Ti/sapphire joints first increased and then declined as the temperature increased or the time was prolonged. The highest average strength of 18.7 MPa was obtained for the sample processed at 550 °C for 35 min. The crack started at the sapphire/brazing seam and propagated into the Au-Sn-Ti brittle reactive layer.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mao, W.G.; Shen, Y.G.; Lu, C. Nanoscale elastic-plastic deformation and stress distributions of the C plane of sapphire single crystal during nanoindentation. J. Eur. Ceram. Soc. 2011, 31, 1865–1871. [Google Scholar] [CrossRef] [Green Version]

- Cheng, J.; Wu, J. Experimental investigation of fracture behaviors and subsurface cracks in micro-slot-grinding of monocrystalline sapphire. J. Mater. Process. Technol. 2017, 242, 160–181. [Google Scholar] [CrossRef]

- Guo, W.; Wang, T.; Lin, T.; He, P. Bonding sapphire in air by using Bi2O3-B2O3 glass braze. Mater. Lett. 2018, 210, 117–120. [Google Scholar] [CrossRef]

- Lee, K.; Gao, Y.; Yao, Z.; Phan, J.; Wu, L.; Liang, J.; Waugh, D.S.; Zhang, Z.; Burke, T.R. Tripeptide inhibitors of Yersinia protein-tyrosine phosphatase. Bioorg. Med. Chem. Lett. 2003, 13, 2577–2581. [Google Scholar] [CrossRef] [Green Version]

- Lin, Z.; Huang, W.; Tsai, J. A study of material removal amount of sapphire wafer in application of chemical mechanical polishing with different polishing pads. J. Mech. Sci. Technol. 2012, 26, 2353–2364. [Google Scholar] [CrossRef]

- Mao, W.G.; Shen, Y.G.; Lu, C. Deformation behavior and mechanical properties of polycrystalline and single crystal alumina during nanoindentation. Scr. Mater. 2011, 65, 127–130. [Google Scholar] [CrossRef] [Green Version]

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Cui, C.; Hu, B.; Zhao, L.; Liu, S. Titanium alloy production technology, market prospects and industry development. Mater. Des. 2011, 32, 1684–1691. [Google Scholar] [CrossRef]

- Rack, H.J.; Qazi, J.I. Titanium alloys for biomedical applications. Mater. Sci. Eng. C 2006, 26, 1269–1277. [Google Scholar] [CrossRef]

- Siddiqui, M.S.; Jones, W.K. Vacuum Brazing of Alumina to Titanium for Implantable Feedthroughs Using Pure Gold as the Braze Metal. Int. J. Mater. Sci. Eng. 2014, 2, 56–62. [Google Scholar] [CrossRef]

- HU, S.; FENG, D.; XIA, L.; WANG, K.; LIU, R.; XIA, Z.; NIU, H.; SONG, X. Joints of continuous carbon fiber reinforced lithium aluminosilicate glass ceramics matrix composites to Ti60 alloy brazed using Ti-Zr-Ni-Cu active alloy. Chin. J. Aeronaut. 2019, 32, 715–722. [Google Scholar] [CrossRef]

- Dai, X.; Cao, J.; Liu, J.; Wang, D.; Feng, J. Interfacial reaction behavior and mechanical characterization of ZrO2/TC4 joint brazed by Ag-Cu filler metal. Mater. Sci. Eng. A 2015, 646, 182–189. [Google Scholar] [CrossRef]

- Terasaki, N.; Sakaguchi, M.; Chiba, H.; Ohashi, T.; Nagatomo, Y.; Kuromitsu, Y.; Sekino, T.; Knowles, K.M. Growth mechanism of TiN reaction layers produced on AlN via active metal bonding. J. Mater. Sci. 2022, 57, 13300–13313. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Z.W.; Zhang, L.X.; Wang, D.P.; Feng, J.C. Low-temperature diffusion brazing of actively metallized Al2O3 ceramic tube and 5A05 aluminum alloy. Mater. Des. 2015, 86, 328–337. [Google Scholar] [CrossRef]

- Ghosh, S.; Sengupta, A.; Pal, K.S.; Dandapat, N.; Chakraborty, R.; Datta, S.; Basu, D. Characterization of Metallized Alumina Ceramics. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2011, 43, 912–920. [Google Scholar] [CrossRef]

- Hudycz, M. Titanium metallization coating deposited on AlN ceramics substrate by means friction surfacing process. Weld. Technol. Rev. 2020, 92, 35–44. [Google Scholar] [CrossRef]

- Li, J.; Pan, W.; Yuan, Z.; Chen, Y. Titanium metallization of alumina ceramics by molten salt reaction. Appl. Surf. Sci. 2008, 254, 4584–4590. [Google Scholar] [CrossRef]

- Teng, P.; Li, X.; Hua, P.; Liu, H.; Wang, G. Effect of metallization temperature on brazing joints of SiC ceramics and 2219 aluminum alloy. Int. J. Appl. Ceram. Tec. 2022, 19, 498–507. [Google Scholar] [CrossRef]

- Xin, C.; Li, N.; Yan, J. Microstructural evolution in the braze joint of sapphire to Kovar alloy by Ti-Cu metallization layer. J. Mater. Process. Technol. 2017, 248, 115–122. [Google Scholar] [CrossRef]

- Song, X.; Chen, Z.; Hu, S.; Duan, X.; Lei, Y.; Niu, C.; Feng, J. Wetting behavior and brazing of titanium-coated SiC ceramics using Sn0.3Ag0.7Cu filler. J. Am. Ceram. Soc. 2020, 103, 912–920. [Google Scholar] [CrossRef]

- Kang, J.R.; Song, X.G.; Hu, S.P.; Liu, D.; Guo, W.J.; Fu, W.; Cao, J. Wetting and Brazing of Alumina by Sn0.3Ag0.7Cu-Ti Alloy. Metall. Mater. Trans. A 2017, 48, 5870–5878. [Google Scholar] [CrossRef]

- Fu, W.; Passerone, A.; Bian, H.; Hu, S.; Zhao, Y.; Song, X.; Wang, M.; Valenza, F. Wetting and interfacial behavior of Sn-Ti alloys on zirconia. J. Mater. Sci. 2019, 54, 812–822. [Google Scholar] [CrossRef]

- Blugan, G.; Kuebler, J.; Bissig, V.; Janczak-Rusch, J. Brazing of silicon nitride ceramic composite to steel using SiC-particle-reinforced active brazing alloy. Ceram. Int. 2007, 33, 1033–1039. [Google Scholar] [CrossRef]

- Park, J.; Mendez, P.F.; Eagar, T.W. Strain energy release in ceramic-to-metal joints by ductile metal interlayers. Scr. Mater. 2005, 53, 857–861. [Google Scholar] [CrossRef]

- Park, J.; Mendez, P.F.; Eagar, T.W. Strain energy distribution in ceramic-to-metal joints. Acta Mater. 2002, 50, 883–899. [Google Scholar] [CrossRef]

- Zhao, Y.X.; Wang, M.R.; Cao, J.; Song, X.G.; Tang, D.Y.; Feng, J.C. Brazing TC4 alloy to Si3N4 ceramic using nano-Si3N4 reinforced AgCu composite filler. Mater. Des. 2015, 76, 40–46. [Google Scholar] [CrossRef]

- Li, Q.; Ma, N.; Lei, Y.; Lin, J.; Fu, H.; Gu, J. Characterization of Low-Melting-Point Sn-Bi-In Lead-Free Solders. J. Electron. Mater. 2016, 45, 5800–5810. [Google Scholar] [CrossRef]

- Wang, F.; Wang, H.; Wang, J.; Lu, J.; Luo, P.; Chang, Y.; Ma, X.; Dong, S. Effects of low melting point metals (Ga, In, Sn) on hydrolysis properties of aluminum alloys. T. Nonferr. Metal. Soc. 2016, 26, 152–159. [Google Scholar] [CrossRef]

- Goodman, P. Current and future uses of gold in electronics. Gold Bull. 2002, 35, 21–26. [Google Scholar] [CrossRef] [Green Version]

- Tollefsen, T.A.; Larsson, A.; Løvvik, O.M.; Aasmundtveit, K. Au-Sn SLID Bonding—Properties and Possibilities. Metall. Mater. Trans. B Process. Metall. Mater. Process. Sci. 2011, 43, 397–405. [Google Scholar] [CrossRef]

- Wei, X.; Wang, R.; Peng, C.; Feng, Y.; Zhu, X. Microstructural evolutions of Cu(Ni)/AuSn/Ni joints during reflow. Prog. Nat. Sci. 2011, 21, 347–354. [Google Scholar] [CrossRef] [Green Version]

- Yoon, J.; Chun, H.; Lee, H.; Jung, S. Microstructural evolution and interfacial reactions of fluxless-bonded Au-20Sn/Cu solder joint during reflow and aging. J. Mater. Res. 2007, 22, 2817–2824. [Google Scholar] [CrossRef]

- Yu, D.Q.; Oppermann, H.; Kleff, J.; Hutter, M. Stability of AuSn eutectic solder cap on Au socket during reflow. J. Mater. Sci. Mater. Electron. 2009, 20, 55–59. [Google Scholar] [CrossRef]

- Bobzin, K.; Lugscheider, E.; Ernst, F.; Rösing, J.; Ferrara, S. Challenging gold based filler metals for uses in medicine. Mater. Sci. Technol. 2009, 25, 1422–1431. [Google Scholar] [CrossRef]

- Lei, Y.Z.; Bian, H.; Jang, N.; Song, X.G.; Li, J.C.; Zhao, H.Y.; Long, W.M. Low temperature brazing of biomedical titanium and zirconia metallized with Sn-Ti metal foil. Mater. Charact. 2022, 193, 112333. [Google Scholar] [CrossRef]

- Fu, W.; Song, X.; Passerone, A.; Hu, S.; Bian, H.; Zhao, Y.; Wang, M.; Valenza, F. Interactions, joining and microstructure of Sn-Ti/ZrO2 system. J. Eur. Ceram. Soc. 2019, 39, 1525–1531. [Google Scholar] [CrossRef]

- Song, X.; Passerone, A.; Fu, W.; Hu, S.; Niu, C.; Zhao, Y.; Wang, M.; Valenza, F. Wetting and spreading behavior of Sn-Ti alloys on SiC. Materialia 2018, 3, 57–63. [Google Scholar] [CrossRef]

- Ali, M.; Knowles, K.M.; Mallinson, P.M.; Fernie, J.A. Interfacial reactions between sapphire and Ag-Cu-Ti-based active braze alloys. Acta Mater. 2016, 103, 859–869. [Google Scholar] [CrossRef] [Green Version]

- Ali, M.; Knowles, K.M.; Mallinson, P.M.; Fernie, J.A. Microstructural evolution and characterisation of interfacial phases in Al2O3/Ag-Cu-Ti/Al2O3 braze joints. Acta Mater. 2015, 96, 143–158. [Google Scholar] [CrossRef]

- Bian, H.; Liu, Y.; Song, X.; Long, W.; Fu, W.; Chen, Y.; Niu, H. Diffusion bonding of implantable Al2O3/Ti-13Nb-13Zr joints: Interfacial microstructure and mechanical properties. Mater. Charact. 2022, 184, 111665. [Google Scholar] [CrossRef]

- Cao, Y.; Yan, J.; Li, N.; Zheng, Y.; Xin, C. Effects of brazing temperature on microstructure and mechanical performance of Al2O3/AgCuTi/Fe-Ni-Co brazed joints. J. Alloy. Compd. 2015, 650, 30–36. [Google Scholar] [CrossRef]

- Kar, A.; Mandal, S.; Ghosh, R.N.; Ghosh, T.K.; Ray, A.K. Role of Ti diffusion on the formation of phases in the Al2O3-Al2O3 brazed interface. J. Mater. Sci. 2007, 42, 5556–5561. [Google Scholar] [CrossRef]

- Laik, A.; Mishra, P.; Bhanumurthy, K.; Kale, G.B.; Kashyap, B.P. Microstructural evolution during reactive brazing of alumina to Inconel 600 using Ag-based alloy. Acta Mater. 2013, 61, 126–138. [Google Scholar] [CrossRef]

- Voytovych, R.; Robaut, F.; Eustathopoulos, N. The relation between wetting and interfacial chemistry in the CuAgTi/alumina system. Acta Mater. 2006, 54, 2205–2214. [Google Scholar] [CrossRef]

- Zhu, W.; Chen, J.; Jiang, C.; Hao, C.; Zhang, J. Effects of Ti thickness on microstructure and mechanical properties of alumina-Kovar joints brazed with Ag-Pd/Ti filler. Ceram. Int. 2014, 40, 5699–5705. [Google Scholar] [CrossRef]

| Process | Temperature | Time | Vacuum |

|---|---|---|---|

| Wetting | 1050 °C | - | 3.0 × 10−3 Pa |

| Metallization | 1000 °C | 10 min | |

| Brazing | 450 °C to 650 °C | 20 min to 35 min |

| Spot | Sn | Ti | Possible Phases |

|---|---|---|---|

| A | 100.00 | 0 | β-Sn |

| B | 41.22 | 58.78 | Ti6Sn5 |

| Spot | Au | Sn | Ti | Al | O | Possible Phases |

|---|---|---|---|---|---|---|

| A | 2.00 | 1.40 | 40.30 | 1.60 | 54.70 | TiO |

| B | 25.11 | 40.41 | 29.11 | 0 | 0 | Au-Sn-Ti |

| C | 0 | 40.58 | 56.81 | 0 | 0 | Ti6Sn5 |

| D | 27.33 | 42.04 | 30.63 | 0 | 0 | Au-Sn-Ti |

| E | 33.53 | 58.29 | 0.30 | 0.30 | 7.58 | AuSn2 |

| F | 23.10 | 76.90 | 0 | 0 | 0 | AuSn4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Bian, H.; Song, X.; Lei, Y.; Sun, M.; Long, W.; Zhong, S.; Jia, L. Interfacial Microstructure and Mechanical Properties of Titanium/Sapphire Joints Brazed with AuSn20 Filler Metal. Crystals 2022, 12, 1687. https://doi.org/10.3390/cryst12121687

Zhou Y, Bian H, Song X, Lei Y, Sun M, Long W, Zhong S, Jia L. Interfacial Microstructure and Mechanical Properties of Titanium/Sapphire Joints Brazed with AuSn20 Filler Metal. Crystals. 2022; 12(12):1687. https://doi.org/10.3390/cryst12121687

Chicago/Turabian StyleZhou, Yi, Hong Bian, Xiaoguo Song, Yuzhen Lei, Mingjun Sun, Weimin Long, Sujuan Zhong, and Lianhui Jia. 2022. "Interfacial Microstructure and Mechanical Properties of Titanium/Sapphire Joints Brazed with AuSn20 Filler Metal" Crystals 12, no. 12: 1687. https://doi.org/10.3390/cryst12121687

APA StyleZhou, Y., Bian, H., Song, X., Lei, Y., Sun, M., Long, W., Zhong, S., & Jia, L. (2022). Interfacial Microstructure and Mechanical Properties of Titanium/Sapphire Joints Brazed with AuSn20 Filler Metal. Crystals, 12(12), 1687. https://doi.org/10.3390/cryst12121687