Investigation of the Effect of ITO Size and Mesa Shape on the Optoelectronic Properties of GaN-Based Micro LEDs

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

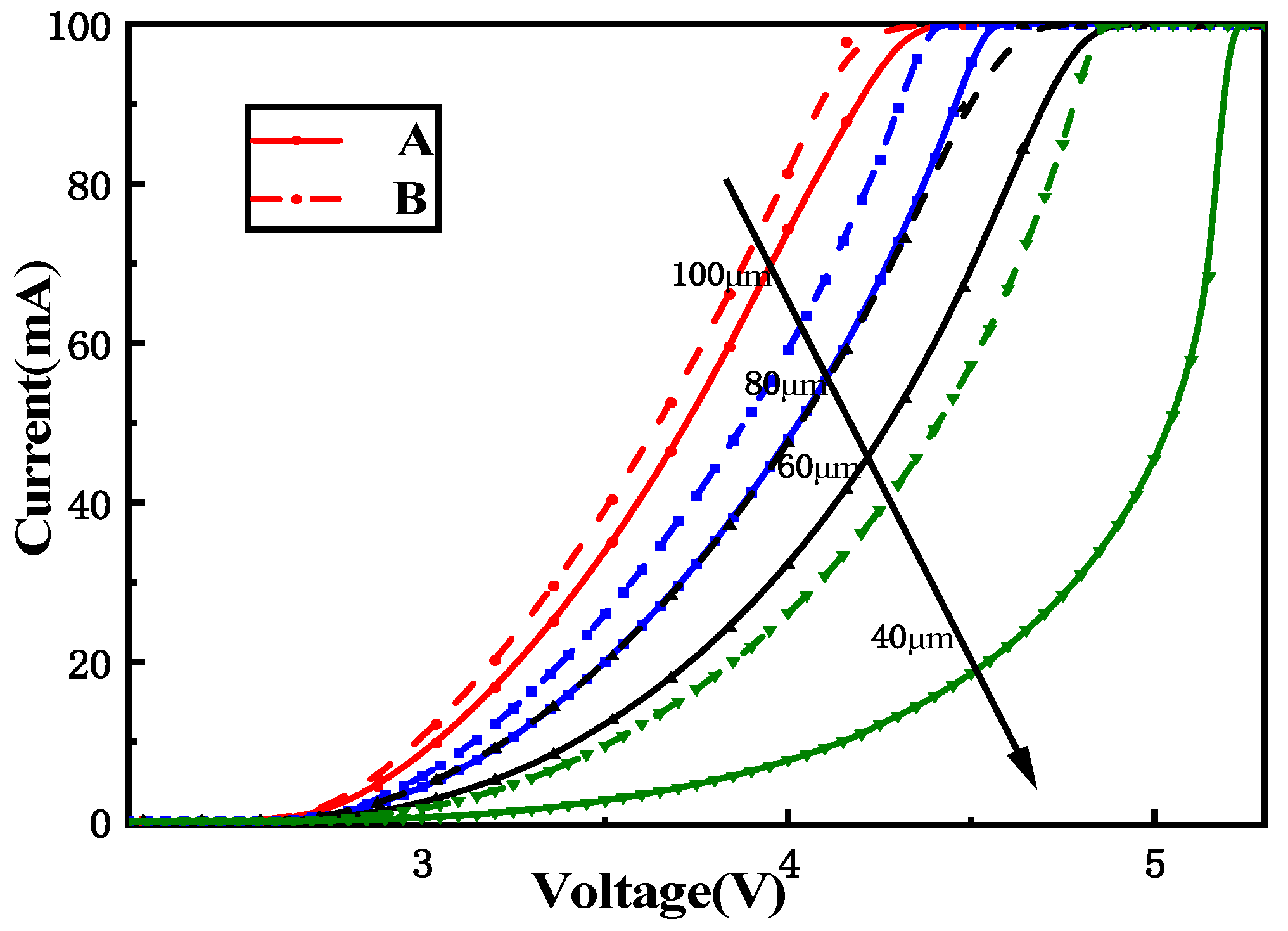

3.1. Influence of Different ITO Sizes on Optoelectronic Properties

3.2. Influence of Different Mesa Shapes on Optoelectronic Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, F.; Xu, W.; Ren, F.; Zhou, D.; Chen, D.; Zhang, R.; Zheng, Y.; Zhu, T.; Lu, H. High-Voltage Quasi-Vertical GaN Junction Barrier Schottky Diode with Fast Switching Characteristics. IEEE Electron Device Lett. 2021, 42, 974–977. [Google Scholar] [CrossRef]

- Hwangbo, S.; Hu, L.; Hoang, A.T.; Choi, J.Y.; Ahn, J.H. Wafer-scale monolithic integration of full-colour micro-LED display using MoS2 transistor. Nat. Nanotechnol. 2022, 17, 500–506. [Google Scholar] [CrossRef] [PubMed]

- Du, Z.; Li, D.; Guo, W.; Xiong, F.; Tang, P.; Zhou, X.; Zhang, Y.; Guo, T.; Yan, Q.; Sun, J. Quantum Dot Color Conversion Efficiency Enhancement in Micro-Light-Emitting Diodes by Non-radiative Energy Transfer. IEEE Electron Device Lett. 2021, 42, 1184–1187. [Google Scholar] [CrossRef]

- Huang, C.; Cheng, Y.; Tsao, Y.; Liu, X.; Kuo, H. Micro-LED backlight module by deep reinforcement learning and micro-macro-hybrid environment control agent. Photon. Res. 2022, 10, 269–279. [Google Scholar] [CrossRef]

- Shan, X.; Zhu, S.; Qiu, P.; Qian, Z.; Lin, R.; Wang, Z.; Cui, X.; Liu, R. Multifunctional Ultraviolet-C Micro-LED With Monolithically Integrated Photodetector for Optical Wireless Communication. J. Lightwave Technol. 2022, 40, 490–498. [Google Scholar] [CrossRef]

- Kim, T.; Yoon, Y.; Oh, S.; Cha, Y.; Hong, I.; Cho, M.; Hong, C.; Choi, H.; Kwak, J. Opposite Behavior of Multilayer Graphene/Indium-Tin-Oxide p-Electrode for Gallium Nitride Based-Light Emitting Diodes Depending on Thickness of Indium-Tin-Oxide Layer. J. Nanosci. Nanotechnol. 2018, 18, 6106–6111. [Google Scholar] [CrossRef] [PubMed]

- Min, J.; Kwak, H.; Kim, K.; Jeong, W.; Lee, D. Very thin ITO/metal mesh hybrid films for a high-performance transparent conductive layer in GaN-based light-emitting diodes. Nanotechnology. 2017, 28, 045201. [Google Scholar] [CrossRef] [PubMed]

- Lu, W.; Aplin, D.; Clawson, A.R.; Yu, P. Effects of the gas ambient in thermal activation of Mg-doped p-GaN on Hall effect and photoluminescence. J. Vac. Sci. Technol. A 2013, 31, 011502. [Google Scholar] [CrossRef]

- Cheng, L.; Wu, Y. InGaN-GaN Light Emitting Diode Performance Improved by Roughening Indium Tin Oxide Window Layer via Natural Lithography. Electrochem. Solid-State Lett. 2010, 13, J8–J10. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, W.; Peng, M.; Dai, J.; Chen, C. Light-extraction enhancement of GaN-based 395 nm flip-chip light-emitting diodes by an Al-doped ITO transparent conductive electrode. Opt. Lett. 2018, 43, 2684–2687. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Xu, Y.; Li, L.; Cai, X.; Li, J.; Tao, J.; Zheng, S.; Cao, B.; Xu, K. Optical and microstructural characterization of Micro-LED with sidewall treatment. J. Phys. D-Appl. Phys. 2022, 55, 43. [Google Scholar] [CrossRef]

- Chen, P.; Chang, L.C.; Tsai, C.H.; Lee, Y.C.; Lai, W.C.; Wu, M.L.; Kuo, C.H.; Sheu, J.k. GaN-Based Light-Emitting Diodes with Pillar Structures Around the Mesa Region. IEEE J. Quantum Electron. 2010, 46, 1066–1071. [Google Scholar] [CrossRef]

- Boussadi, Y.; Rochat, N.; Barnes, J.P.; Bakir, B.; Ferrands, P.; Masenelli, B.; Licitra, C. Investigation of sidewall damage induced by reactive ion etching on AlGaInP MESA for micro-LED application. J. Lumines. 2021, 234, 117937. [Google Scholar] [CrossRef]

- Wang, P.; Gan, Z.; Liu, S. Improved light extraction of GaN-based light-emitting diodes with surface-patterned ITO. Opt. Laser Technol. 2009, 41, 823–826. [Google Scholar] [CrossRef]

- Lee, Y.; Reddy, M.; Kim, B.; Park, C. Surface morphological, structural, electrical and optical properties of GaN-based light-emitting diodes using submicron-scaled Ag islands and ITO thin films. Opt. Mater. 2018, 81, 109–114. [Google Scholar] [CrossRef]

- Park, J.; Kim, J.; Kim, J.; Kim, D.; Na, J.; Kim, S. Formation of an indium tin oxide nanodot/Ag nanowire electrode as a current spreader for near ultraviolet AlGaN-based light-emitting diodes. Nanotechnology 2017, 28, 045205. [Google Scholar] [CrossRef] [PubMed]

| Group | Length of C (L) | Area of C | Diameter of D (R) | Area of D |

|---|---|---|---|---|

| I | 30 μm | 900 μm2 | 34 μm | 908 μm2 |

| II | 40 μm | 1600 μm2 | 45 μm | 1590 μm2 |

| III | 80 μm | 6400 μm2 | 90 μm | 6362 μm2 |

| IV | 100 μm | 10,000 μm2 | 113 μm | 10,028 μm2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, A.; Xu, H.; Guo, W.; Liu, J.; Chen, J.; Li, M. Investigation of the Effect of ITO Size and Mesa Shape on the Optoelectronic Properties of GaN-Based Micro LEDs. Crystals 2022, 12, 1593. https://doi.org/10.3390/cryst12111593

Fang A, Xu H, Guo W, Liu J, Chen J, Li M. Investigation of the Effect of ITO Size and Mesa Shape on the Optoelectronic Properties of GaN-Based Micro LEDs. Crystals. 2022; 12(11):1593. https://doi.org/10.3390/cryst12111593

Chicago/Turabian StyleFang, Aoqi, Hao Xu, Weiling Guo, Jixin Liu, Jiaxin Chen, and Mengmei Li. 2022. "Investigation of the Effect of ITO Size and Mesa Shape on the Optoelectronic Properties of GaN-Based Micro LEDs" Crystals 12, no. 11: 1593. https://doi.org/10.3390/cryst12111593

APA StyleFang, A., Xu, H., Guo, W., Liu, J., Chen, J., & Li, M. (2022). Investigation of the Effect of ITO Size and Mesa Shape on the Optoelectronic Properties of GaN-Based Micro LEDs. Crystals, 12(11), 1593. https://doi.org/10.3390/cryst12111593