Optimization of Parameters in Laser Powder Bed Fusion TA15 Titanium Alloy Using Taguchi Method

Abstract

1. Introduction

2. Materials and Methods

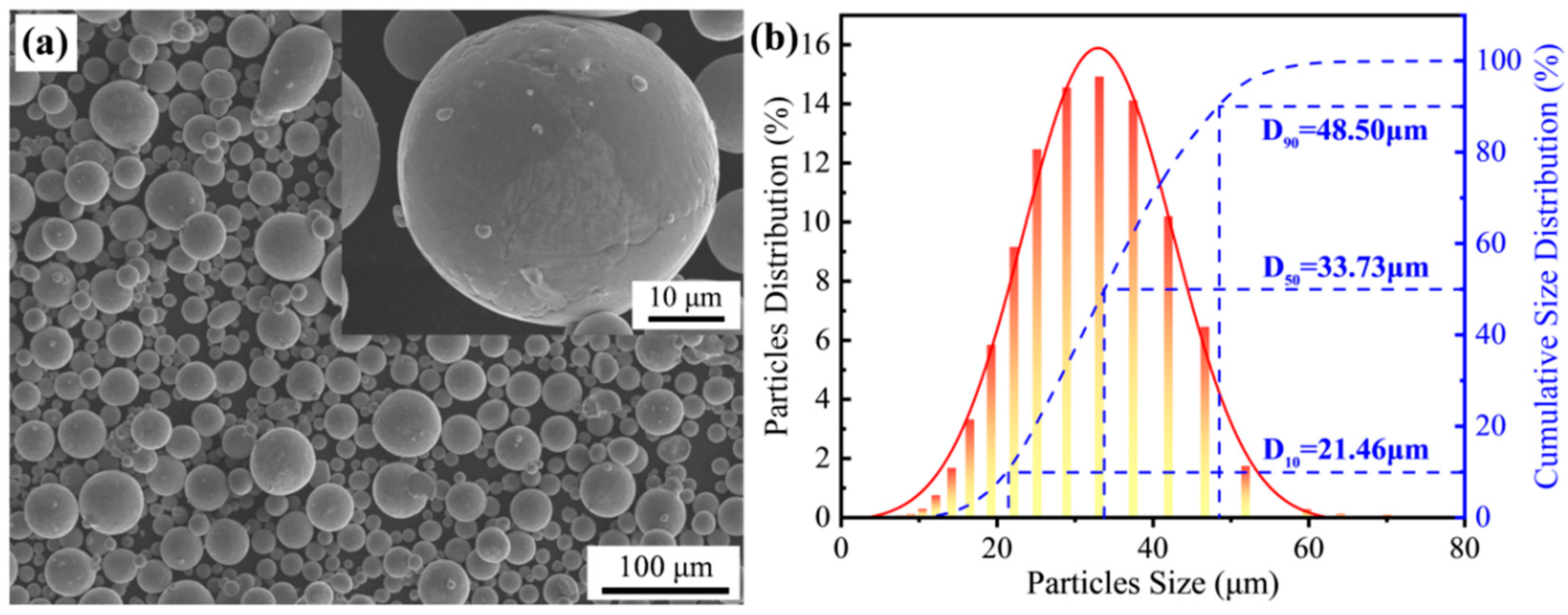

2.1. Materials

2.2. Sample Fabrications and Optimization of Parameters Using Taguchi Method

2.3. Characterizations

3. Results and Discussion

3.1. Effect of Processing Parameters on Density and Microhardness of as-LPBFed TA15 Titanium Alloy

3.1.1. Effects of Laser Power

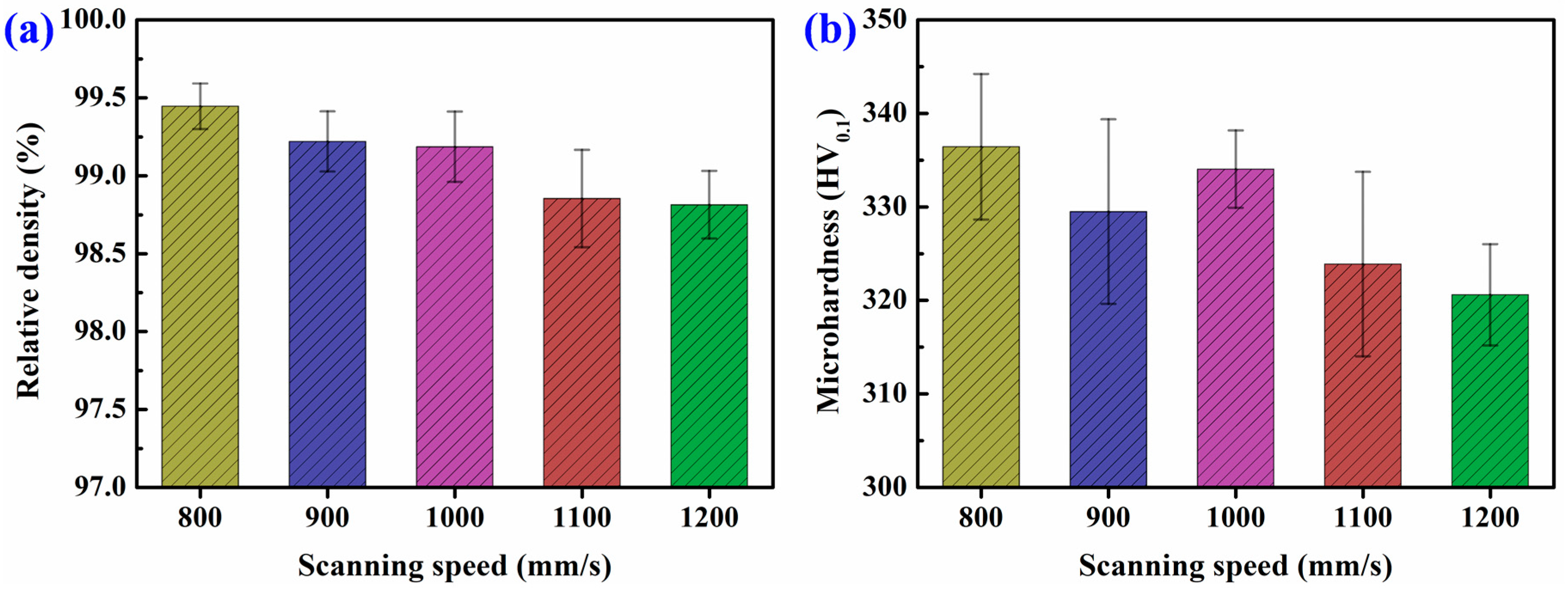

3.1.2. Effects of Scanning Speed

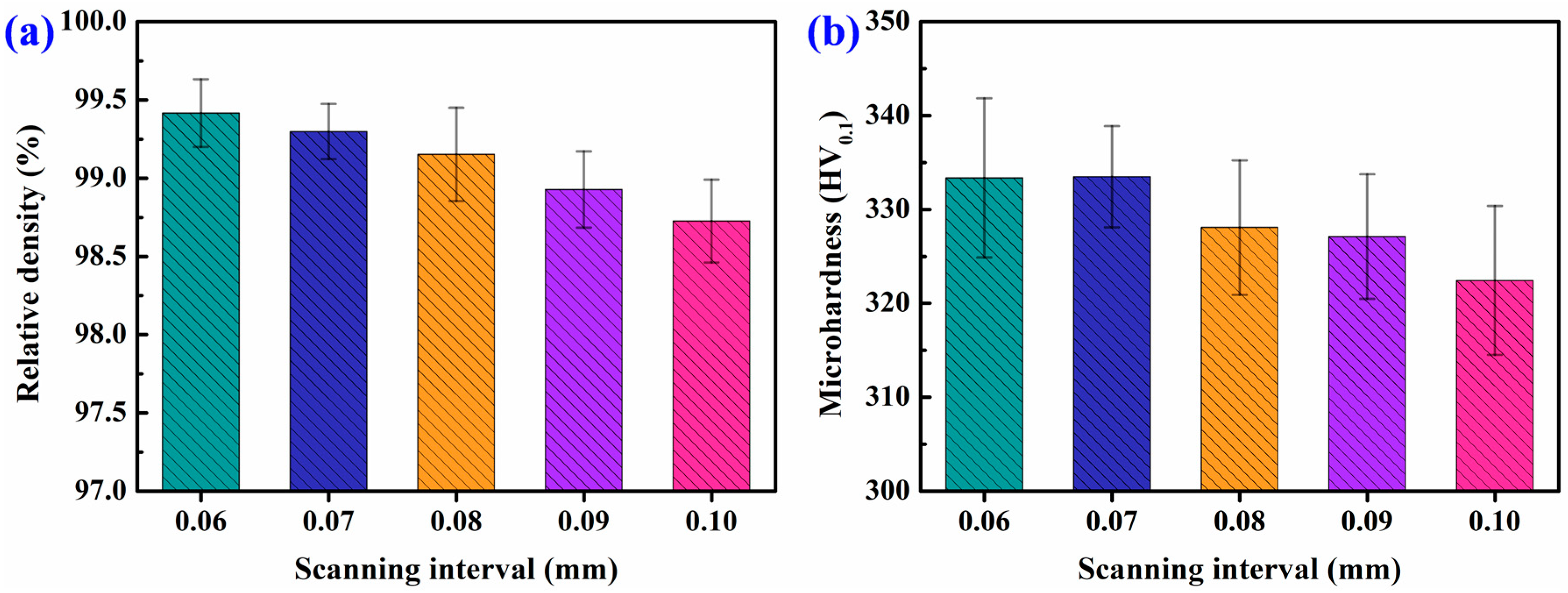

3.1.3. Effects of Scanning Interval

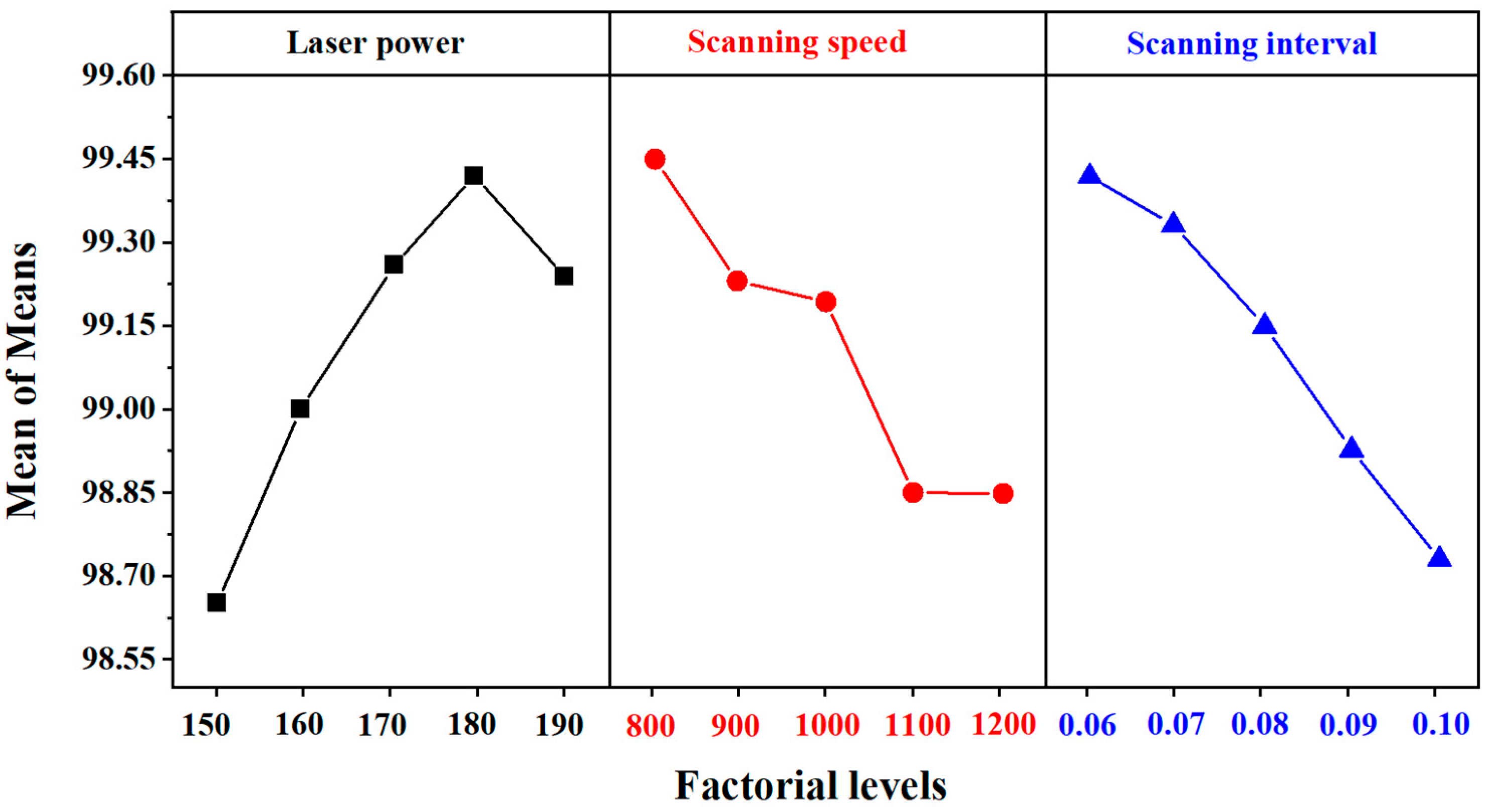

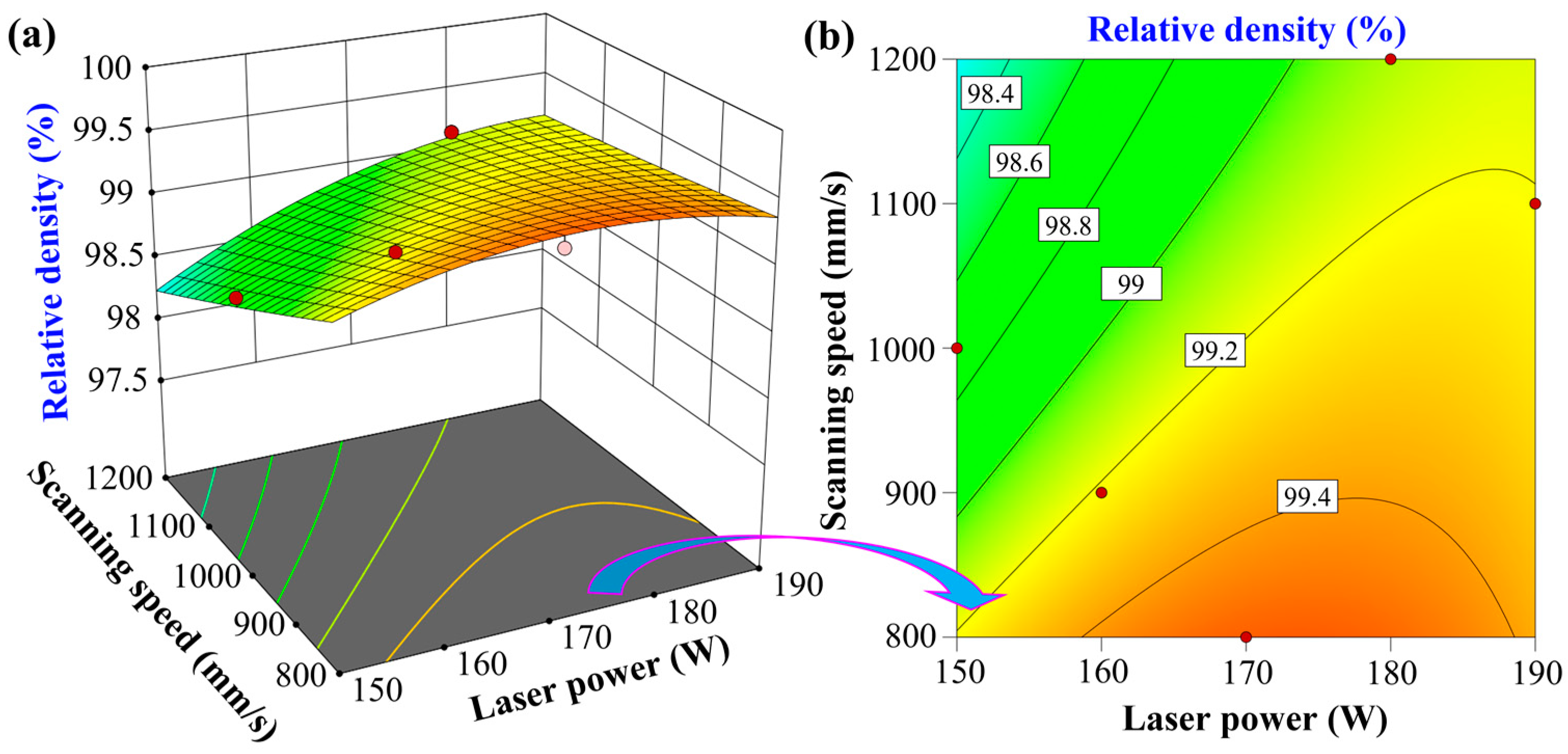

3.2. Optimization of Parameters for Density

3.2.1. Analysis of the Signal-to-Noise (S/N) Ratio

3.2.2. Analysis of Variance (ANOVA)

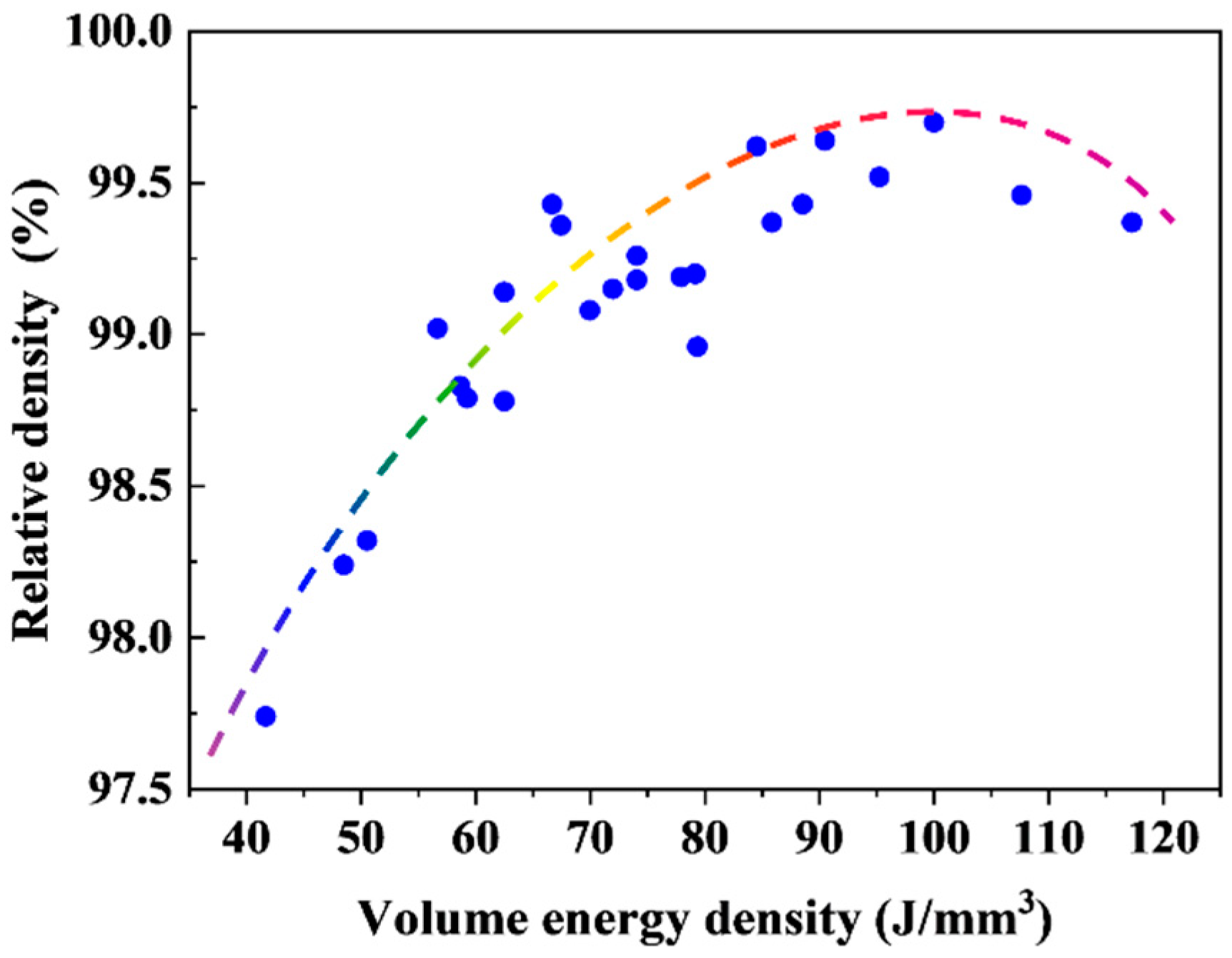

3.3. Effect of Laser Energy Density on Relative Density of as-LPBFed TA15 Titanium Alloy

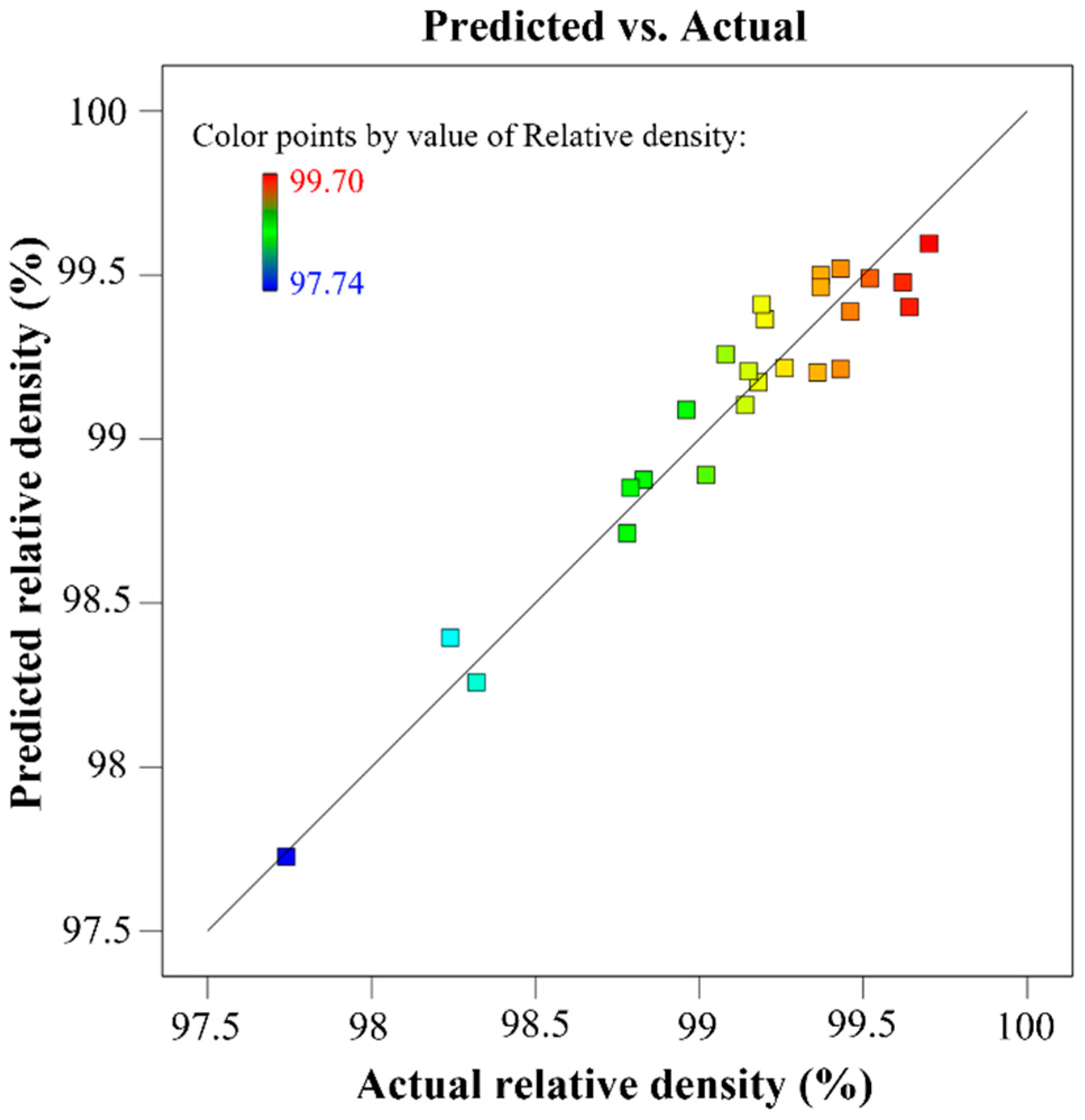

3.4. Confirmation Analysis

4. Conclusions

- (1)

- With the increase in laser power, the relative density first increased and then decreased. When the laser power was 180 W, the relative density could reach the peak value of 99.5%. However, the higher laser power of 190 W caused the decrease in relative density, which was owing to the excessive energy input to the elements by burning, resulting in the decrease in relative density.

- (2)

- As the scanning interval increased from 0.06 mm to 0.10 mm with an interval of 0.01 mm, the density of the as-LPBFed TA15 titanium alloy decreased correspondingly from 99.41% to 98.72% with a smooth trend. The descent trend of density with increasing scanning interval was owing to the lower energy density per unit volume, causing the decreased energy absorbed by the TA15 powders.

- (3)

- The correlation between relative density, laser power, scanning speed, and scanning interval was analyzed by the regression expression (A: laser power, B: scanning speed, and C: scanning interval) as follows:

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, C.S.; Li, C.L.; Chen, R.; Qin, H.Z.; Ma, L.; Mei, Q.S.; Zhang, G.D. Multistep Low-to-High-Temperature Heating as a Suitable Alternative to Hot Isostatic Pressing for Improving Laser Powder-Bed Fusion-Fabricated Ti-6Al-2Zr-1Mo-1V Microstructural and Mechanical Properties. Mater. Sci. Eng. A 2022, 841, 143022. [Google Scholar] [CrossRef]

- Huang, S.; Sun, B.; Guo, S. Microstructure and Property Evaluation of TA15 Titanium Alloy Fabricated by Selective Laser Melting after Heat Treatment. Opt. Laser Technol. 2021, 144, 107422. [Google Scholar] [CrossRef]

- Li, S.; Lan, X.; Wang, Z.; Mei, S. Microstructure and Mechanical Properties of Ti-6.5Al-2Zr-Mo-V Alloy Processed by Laser Powder Bed Fusion and Subsequent Heat Treatments. Addit. Manuf. 2021, 48, 102382. [Google Scholar] [CrossRef]

- Takase, A.; Ishimoto, T.; Morita, N.; Ikeo, N.; Nakano, T. Comparison of Phase Characteristics and Residual Stresses in Ti-6al-4v Alloy Manufactured by Laser Powder Bed Fusion (L-Pbf) and Electron Beam Powder Bed Fusion (Eb-Pbf) Techniques. Crystals 2021, 11, 796. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, S.; Zou, Z.; Shi, Y. Achieving an Ideal Combination of Strength and Plasticity in Additive Manufactured Ti–6.5Al–2Zr–1Mo–1V Alloy through the Development of Tri-Modal Microstructure. Mater. Sci. Eng. A 2022, 840, 142944. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, Y.; Zou, Z.; Shi, Y.; Zang, Y. The Microstructure and Tensile Properties of Additively Manufactured Ti–6Al–2Zr–1Mo–1V with a Trimodal Microstructure Obtained by Multiple Annealing Heat Treatment. Mater. Sci. Eng. A 2022, 831, 142241. [Google Scholar] [CrossRef]

- Hu, M.; Wang, L.; Li, G.; Huang, Q.; Liu, Y.; He, J.; Wu, H.; Song, M. Investigations on Microstructure and Properties of Ti-Nb-Zr Medium-Entropy Alloys for Metallic Biomaterials. Intermetallics 2022, 145, 107568. [Google Scholar] [CrossRef]

- Tao, P.; Shao, H.; Ji, Z.; Nan, H.; Xu, Q. Numerical Simulation for the Investment Casting Process of a Large-Size Titanium Alloy Thin-Wall Casing. Prog. Nat. Sci. Mater. Int. 2018, 28, 520–528. [Google Scholar] [CrossRef]

- Uwanyuze, R.S.; Kanyo, J.E.; Myrick, S.F.; Schafföner, S. A Review on Alpha Case Formation and Modeling of Mass Transfer during Investment Casting of Titanium Alloys. J. Alloys Compd. 2021, 865, 158558. [Google Scholar] [CrossRef]

- Sun, Z.C.; Zhang, J.; Yang, H.; Wu, H.L. Effect of Workpiece Size on Microstructure Evolution of Different Regions for TA15 Ti-Alloy Isothermal near-β Forging by Local Loading. J. Mater. Process. Technol. 2015, 222, 234–243. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, D.J.; Yuan, S.J. Effect of Multi-Directional Forging on the Microstructure and Mechanical Properties of TiBw/TA15 Composite with Network Architecture. Mater. Des. 2017, 134, 250–258. [Google Scholar] [CrossRef]

- Liu, W.; Sheng, Q.; Ma, Y.; Cai, Q.; Wang, J.; Liu, Y. Interfacial Microstructures, Residual Stress and Mechanical Analysis of Hot Isostatic Pressing Diffusion Bonded Joint of 93W–4.9Ni–2.1Fe Alloy and 30CrMnSiNi2A Steel. Fusion Eng. Des. 2020, 156, 111602. [Google Scholar] [CrossRef]

- Li, J.; Shen, J.; Hu, S.; Zhang, H.; Bu, X. Microstructure and Mechanical Properties of Ti-22Al-25Nb/TA15 Dissimilar Joint Fabricated by Dual-Beam Laser Welding. Opt. Laser Technol. 2019, 109, 123–130. [Google Scholar] [CrossRef]

- Wang, C.; Guo, Q.; Shao, M.; Zhang, H.; Wang, F.; Song, B.; Ji, Y.; Li, H. Microstructure and Corrosion Behavior of Linear Friction Welded TA15 and TC17 Dissimilar Joint. Mater. Charact. 2022, 187, 111871. [Google Scholar] [CrossRef]

- Samal, S.K.; Vishwanatha, H.M.; Saxena, K.K.; Behera, A.; Nguyen, T.A.; Behera, A.; Prakash, C.; Dixit, S.; Mohammed, K.A. 3D-Printed Satellite Brackets: Materials, Manufacturing and Applications. Crystals 2022, 12, 1148. [Google Scholar] [CrossRef]

- Liu, C.; Liu, Y.; Wang, T.; Liu, W.; Ma, Y. Effects of Heat Treatment on the Microstructure and Properties of Graded-Density Powder Aluminum Alloys. Met. Sci. Heat Treat. 2022, 63, 590–598. [Google Scholar] [CrossRef]

- Song, X.; Zhang, K.; Song, Y.; Duan, Z.; Liu, Q.; Liu, Y. Morphology, Microstructure and Mechanical Properties of Electrospun Alumina Nanofibers Prepared Using Different Polymer Templates: A Comparative Study. J. Alloys Compd. 2020, 829, 154502. [Google Scholar] [CrossRef]

- Wen, Z.; Song, X.; Chen, D.; Fan, T.; Liu, Y.; Cai, Q. Electrospinning Preparation and Microstructure Characterization of Homogeneous Diphasic Mullite Ceramic Nanofibers. Ceram. Int. 2020, 46, 12172–12179. [Google Scholar] [CrossRef]

- Song, Y.; Ding, X.; Xiao, L.; Liu, W.; Chen, Y.; Zhao, X. The Effect of Ni Plating on the Residual Stress and Micro-Yield Strength in an Al-Cu-Mg Alloy Under Different Diffusion Treatments. JOM 2019, 71, 4370–4377. [Google Scholar] [CrossRef]

- Xiao, L.R.; Tu, X.X.; Zhao, X.J.; Cai, Z.Y.; Song, Y.F. Microstructural Evolution and Dimensional Stability of TiC-Reinforced Steel Matrix Composite during Tempering. Mater. Lett. 2020, 259, 8–12. [Google Scholar] [CrossRef]

- Song, Y.F.; Ding, X.F.; Zhao, X.J.; Xiao, L.R.; Yu, C.X. The Effect of SiC Addition on the Dimensional Stability of Al-Cu-Mg Alloy. J. Alloys Compd. 2018, 750, 111–116. [Google Scholar] [CrossRef]

- Tang, X.; Din, C.; Yu, S.; Liu, Y.; Luo, H.; Zhang, D.; Chen, S. Synthesis of Dielectric Polystyrene via One-Step Nitration Reaction for Large-Scale Energy Storage. Chem. Eng. J. 2022, 446, 137281. [Google Scholar] [CrossRef]

- Yu, S.; Ding, C.; Liu, Y.; Liu, Y.; Zhang, Y.; Luo, H.; Zhang, D.; Chen, S. Enhanced Breakdown Strength and Energy Density over a Broad Temperature Range in Polyimide Dielectrics Using Oxidized MXenes Filler. J. Power Sources 2022, 535, 231415. [Google Scholar] [CrossRef]

- Cai, C.; Wu, X.; Liu, W.; Zhu, W.; Chen, H.; Qiu, J.C.D.; Sun, C.N.; Liu, J.; Wei, Q.; Shi, Y. Selective Laser Melting of Near-α Titanium Alloy Ti-6Al-2Zr-1Mo-1V: Parameter Optimization, Heat Treatment and Mechanical Performance. J. Mater. Sci. Technol. 2020, 57, 51–64. [Google Scholar] [CrossRef]

- Xu, J.; Wu, Z.; Niu, J.; Song, Y.; Liang, C.; Yang, K.; Chen, Y.; Liu, Y. Effect of Laser Energy Density on the Microstructure and Microhardness of Inconel 718 Alloy Fabricated by Selective Laser Melting. Crystals 2022, 12, 1243. [Google Scholar] [CrossRef]

- Yang, H.; Liu, B.; Niu, P.; Fan, Z.; Yuan, T.; Wang, Y.; Liu, Y.; Li, R. Effect of Laser Scanning Angle on Shear Slip Behavior along Melt Track of Selective Laser Melted 316l Stainless Steel during Tensile Failure. Mater. Charact. 2022, 193, 112297. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, W.; Ma, Y.; Liang, C.; Liu, C.; Zhang, C.; Cai, Q. Microstructure and Wear Resistance of Compositionally Graded Ti–Al Intermetallic Coating on Ti6Al4V Alloy Fabricated by Laser Powder Deposition. Surf. Coat. Technol. 2018, 353, 32–40. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, C.; Liu, W.; Ma, Y.; Zhang, C.; Cai, Q.; Liu, B. Microstructure and Properties of Ti/Al Lightweight Graded Material by Direct Laser Deposition. Mater. Sci. Technol. 2018, 34, 945–951. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, Z.; Liu, W.; Ma, Y. Microstructure Evolution and Reaction Mechanism of Continuously Compositionally Ti/Al Intermetallic Graded Material Fabricated by Laser Powder Deposition. J. Mater. Res. Technol. 2022, 20, 4173–4185. [Google Scholar] [CrossRef]

- Li, R.; Wang, H.; He, B.; Li, Z.; Zhu, Y.; Zheng, D.; Tian, X.; Zhang, S. Effect of α Texture on the Anisotropy of Yield Strength in Ti–6Al–2Zr–1Mo–1V Alloy Fabricated by Laser Directed Energy Deposition Technique. Mater. Sci. Eng. A 2021, 824, 141771. [Google Scholar] [CrossRef]

- Li, R.; Wang, H.; Zheng, D.; Gao, X.; Zhang, S. Texture Evolution during Sub-Critical Annealing and Its Effect on Yield Strength Anisotropy of Laser Directed Energy Deposited Ti-6Al-2Zr-1Mo-1V Alloy. Mater. Sci. Eng. A 2022, 850, 143556. [Google Scholar] [CrossRef]

- Abd-elaziem, W.; Elkatatny, S.; Abd-elaziem, A.; Khedr, M.; El-baky, M.A.A.; Ali Hassan, M.; Abu-Okail, M.; Mohammed, M. On the Current Research Progress of Metallic Materials Fabricated by Laser Powder Bed Fusion Process: A Review. J. Mater. Res. Technol. 2022, 20, 681–707. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, D.; Guo, Y.; Zhang, T.; Liu, Z. Microstructure and Mechanical Evolution Behavior of LPBF (Laser Powder Bed Fusion)-Fabricated TA15 Alloy. J. Alloys Compd. 2021, 873, 159639. [Google Scholar] [CrossRef]

- Yao, Z.; Yang, T.; Yang, M.; Jia, X.; Wang, C.; Yu, J.; Li, Z.; Han, H.; Liu, W.; Xie, G.; et al. Martensite Colony Engineering: A Novel Solution to Realize the High Ductility in Full Martensitic 3D-Printed Ti Alloys. Mater. Des. 2022, 215, 110445. [Google Scholar] [CrossRef]

- Liu, Y.; Liang, C.; Liu, W.; Ma, Y.; Liu, C.; Zhang, C. Dilution of Al and V through Laser Powder Deposition Enables a Continuously Compositionally Ti/Ti6Al4V Graded Structure. J. Alloys Compd. 2018, 763, 376–383. [Google Scholar] [CrossRef]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of Keyhole-Mode Laser Melting in Laser Powder-Bed Fusion Additive Manufacturing. J. Mater. Process. Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

- Wang, W.; Liang, S.Y. Physics-Based Predictive Model of Lack-of-Fusion Porosity in Laser Powder Bed Fusion Considering Cap Area. Crystals 2021, 11, 1568. [Google Scholar] [CrossRef]

- Chowdhury, S.; Yadaiah, N.; Prakash, C. Laser Powder Bed Fusion: A State-of-the-Art Review of the Technology, Materials, Properties & Defects and Numerical Modelling. J. Mater. Res. Technol. 2022, 20, 2109–2172. [Google Scholar] [CrossRef]

- Li, S.; Yang, J.; Wang, Z. Multi-Laser Powder Bed Fusion of Ti-6.5Al-2Zr-Mo-V Alloy Powder: Defect Formation Mechanism and Microstructural Evolution. Powder Technol. 2021, 384, 100–111. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Humbeeck, J.V.; Kruth, J.P. A Study of the Microstructural Evolution during Selective Laser Melting of Ti-6Al-4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, C.; Liu, W.; Ma, Y.; Tang, S.; Liang, C.; Cai, Q.; Zhang, C. Optimization of Parameters in Laser Powder Deposition AlSi10Mg Alloy Using Taguchi Method. Opt. Laser Technol. 2019, 111, 470–480. [Google Scholar] [CrossRef]

- Jiang, H.Z.; Li, Z.Y.; Feng, T.; Wu, P.Y.; Chen, Q.S.; Feng, Y.L.; Li, S.W.; Gao, H.; Xu, H.J. Factor Analysis of Selective Laser Melting Process Parameters with Normalised Quantities and Taguchi Method. Opt. Laser Technol. 2019, 119, 105592. [Google Scholar] [CrossRef]

- Canel, T.; Zeren, M.; Sınmazçelik, T. Laser Parameters Optimization of Surface Treating of Al 6082-T6 with Taguchi Method. Opt. Laser Technol. 2019, 120, 105714. [Google Scholar] [CrossRef]

- Kumar, R.; Katyal, P.; Mandhania, S. Grey Relational Analysis Based Multiresponse Optimization for WEDM of ZE41A Magnesium Alloy. Int. J. Light. Mater. Manuf. 2022, 5, 543–554. [Google Scholar] [CrossRef]

- Pandel, D.; Kumar Singh, A.; Kumar Banerjee, M.; Gupta, R. Optimization of Mg2(Si-Sn) Based Thermoelectric Generators Using the Taguchi Method. Mater. Today Proc. 2020, 44, 4124–4130. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, C.; Liu, W.; Ma, Y.; Zhang, C.; Liang, C.; Cai, Q. Laser Powder Deposition Parametric Optimization and Property Development for Ti-6Al-4V Alloy. J. Mater. Eng. Perform. 2018, 27, 5613–5621. [Google Scholar] [CrossRef]

- Wei, M.; Chen, S.; Liang, J.; Liu, C. Effect of Atomization Pressure on the Breakup of TA15 Titanium Alloy Powder Prepared by EIGA Method for Laser 3D Printing. Vacuum 2017, 143, 185–194. [Google Scholar] [CrossRef]

- Li, Y.; Hu, Y.; Cong, W.; Zhi, L.; Guo, Z. Additive Manufacturing of Alumina Using Laser Engineered Net Shaping: Effects of Deposition Variables. Ceram. Int. 2017, 43, 7768–7775. [Google Scholar] [CrossRef]

- Jiang, J.; Chen, J.; Ren, Z.; Mao, Z.; Ma, X.; Zhang, D.Z. The Influence of Process Parameters and Scanning Strategy on Lower Surface Quality of TA15 Parts Fabricated by Selective Laser Melting. Metals 2020, 10, 1228. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective Laser Melting of AlSi10Mg Alloy: Process Optimisation and Mechanical Properties Development. Mater. Des. 2015, 65, 417–424. [Google Scholar] [CrossRef]

| Elements | Al | V | Zr | Mo | Si | Fe | Ti |

|---|---|---|---|---|---|---|---|

| TA15 | 6.42 | 1.94 | 1.93 | 1.43 | 0.02 | 0.03 | Balance |

| Parameters | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

|---|---|---|---|---|---|

| A: Laser power (W) | 150 | 160 | 170 | 180 | 190 |

| B: Scanning speed (mm/s) | 800 | 900 | 1000 | 1100 | 1200 |

| C: Scanning interval (mm) | 0.06 | 0.07 | 0.08 | 0.09 | 0.10 |

| Runs | Laser Power (W) | Scanning Speed (mm/s) | Scanning Interval (mm) | Laser Energy Density (J/mm3) | Microhardness (HV0.1) | Relative Density (%) | ||

|---|---|---|---|---|---|---|---|---|

| Experimental Value | Predicted Value | Error (%) | ||||||

| 1 | 150 | 800 | 0.06 | 107.64 | 365.56 | 99.46 | 99.26 | −0.2007 |

| 2 | 150 | 900 | 0.07 | 79.36 | 336.00 | 98.96 | 99.10 | 0.1437 |

| 3 | 150 | 1000 | 0.08 | 62.5 | 350.66 | 98.78 | 98.77 | −0.0138 |

| 4 | 150 | 1100 | 0.09 | 50.51 | 321.18 | 98.32 | 98.25 | −0.0681 |

| 5 | 150 | 1200 | 0.10 | 41.67 | 319.53 | 97.74 | 97.56 | −0.1821 |

| 6 | 160 | 800 | 0.07 | 95.24 | 347.96 | 99.52 | 99.30 | −0.2206 |

| 7 | 160 | 900 | 0.08 | 74.07 | 327.26 | 99.26 | 99.12 | −0.1384 |

| 8 | 160 | 1000 | 0.09 | 59.26 | 353.04 | 98.79 | 98.75 | −0.0376 |

| 9 | 160 | 1100 | 0.10 | 48.48 | 324.46 | 98.24 | 98.19 | −0.0497 |

| 10 | 160 | 1200 | 0.06 | 74.07 | 328.90 | 99.18 | 99.01 | −0.1746 |

| 11 | 170 | 800 | 0.08 | 88.54 | 327.84 | 99.43 | 99.32 | −0.1068 |

| 12 | 170 | 900 | 0.09 | 69.96 | 331.06 | 99.08 | 99.11 | 0.0323 |

| 13 | 170 | 1000 | 0.10 | 56.67 | 327.00 | 99.02 | 98.69 | −0.3292 |

| 14 | 170 | 1100 | 0.06 | 85.86 | 326.94 | 99.37 | 99.3 | −0.0620 |

| 15 | 170 | 1200 | 0.07 | 67.46 | 328.96 | 99.36 | 98.99 | −0.3688 |

| 16 | 180 | 800 | 0.09 | 84.51 | 322.14 | 99.62 | 99.33 | −0.2907 |

| 17 | 180 | 900 | 0.10 | 66.67 | 322.50 | 99.43 | 99.07 | −0.3617 |

| 18 | 180 | 1000 | 0.06 | 100 | 317.46 | 99.7 | 99.43 | −0.2746 |

| 19 | 180 | 1100 | 0.07 | 77.92 | 329.76 | 99.19 | 99.28 | 0.0872 |

| 20 | 180 | 1200 | 0.08 | 62.5 | 317.50 | 99.14 | 98.91 | −0.2359 |

| 21 | 190 | 800 | 0.10 | 79.17 | 318.70 | 99.2 | 99.32 | 0.1214 |

| 22 | 190 | 900 | 0.06 | 117.28 | 330.66 | 99.37 | 99.36 | −0.0099 |

| 23 | 190 | 1000 | 0.07 | 90.48 | 324.74 | 99.64 | 99.39 | −0.2509 |

| 24 | 190 | 1100 | 0.08 | 71.97 | 317.10 | 99.15 | 99.18 | 0.0351 |

| 25 | 190 | 1200 | 0.09 | 58.64 | 308.12 | 98.83 | 98.74 | −0.0864 |

| Level | Laser Power | Scanning Speed | Scanning Interval |

|---|---|---|---|

| 1 | 98.65 | 99.45 | 99.42 |

| 2 | 99.00 | 99.22 | 99.33 |

| 3 | 99.25 | 99.19 | 99.15 |

| 4 | 99.42 | 98.85 | 98.93 |

| 5 | 99.24 | 98.85 | 98.73 |

| Delta | 0.76 | 0.60 | 0.69 |

| Rank | 1 | 3 | 2 |

| Level | Laser Power | Scanning Speed | Scanning Interval |

|---|---|---|---|

| 1 | 39.88 | 39.95 | 39.95 |

| 2 | 39.91 | 39.93 | 39.94 |

| 3 | 39.93 | 39.93 | 39.93 |

| 4 | 39.95 | 39.90 | 39.91 |

| 5 | 39.93 | 39.90 | 39.89 |

| Delta | 0.07 | 0.05 | 0.06 |

| Rank | 1 | 3 | 2 |

| Source | DF | Seq. SS | Adj. SS | Adj. MS | F | P | Percentage of Contribution (%) |

|---|---|---|---|---|---|---|---|

| Laser power | 4 | 1.7624 | 1.7624 | 0.44061 | 10.72 | 0.001 | 33.86 |

| Scanning speed | 4 | 1.3195 | 1.3195 | 0.32988 | 8.03 | 0.002 | 25.35 |

| Scanning interval | 4 | 1.6307 | 1.6307 | 0.40769 | 9.92 | 0.001 | 31.33 |

| Error | 12 | 0.4930 | 0.4930 | 0.04108 | — | — | 9.47 |

| Total | 24 | 5.2057 | — | — | — | — | 100 |

| Coefficient | The Corresponding Value |

|---|---|

| a0 | 111.61 |

| a1 | −1.06 × 10−1 |

| a2 | −1.64 × 10−2 |

| a3 | 5.23 |

| a4 | 1.35 × 10−4 |

| a5 | 4.91 × 10−1 |

| a6 | 1.89 × 10−2 |

| a7 | −7.18 × 10−4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Wu, Z.; Wang, Q.; Zhao, L.; Zhang, X.; Gao, W.; Xu, J.; Song, Y.; Song, X.; Zhang, X. Optimization of Parameters in Laser Powder Bed Fusion TA15 Titanium Alloy Using Taguchi Method. Crystals 2022, 12, 1385. https://doi.org/10.3390/cryst12101385

Liu Y, Wu Z, Wang Q, Zhao L, Zhang X, Gao W, Xu J, Song Y, Song X, Zhang X. Optimization of Parameters in Laser Powder Bed Fusion TA15 Titanium Alloy Using Taguchi Method. Crystals. 2022; 12(10):1385. https://doi.org/10.3390/cryst12101385

Chicago/Turabian StyleLiu, Yang, Zichun Wu, Qing Wang, Lizhong Zhao, Xichen Zhang, Wei Gao, Jing Xu, Yufeng Song, Xiaolei Song, and Xuefeng Zhang. 2022. "Optimization of Parameters in Laser Powder Bed Fusion TA15 Titanium Alloy Using Taguchi Method" Crystals 12, no. 10: 1385. https://doi.org/10.3390/cryst12101385

APA StyleLiu, Y., Wu, Z., Wang, Q., Zhao, L., Zhang, X., Gao, W., Xu, J., Song, Y., Song, X., & Zhang, X. (2022). Optimization of Parameters in Laser Powder Bed Fusion TA15 Titanium Alloy Using Taguchi Method. Crystals, 12(10), 1385. https://doi.org/10.3390/cryst12101385