Experiments and Mechanical Simulation on Bubble Concrete: Studies on the Effects of Shape and Position of Hollow Bodies Mixed in Concrete

Abstract

:1. Introduction

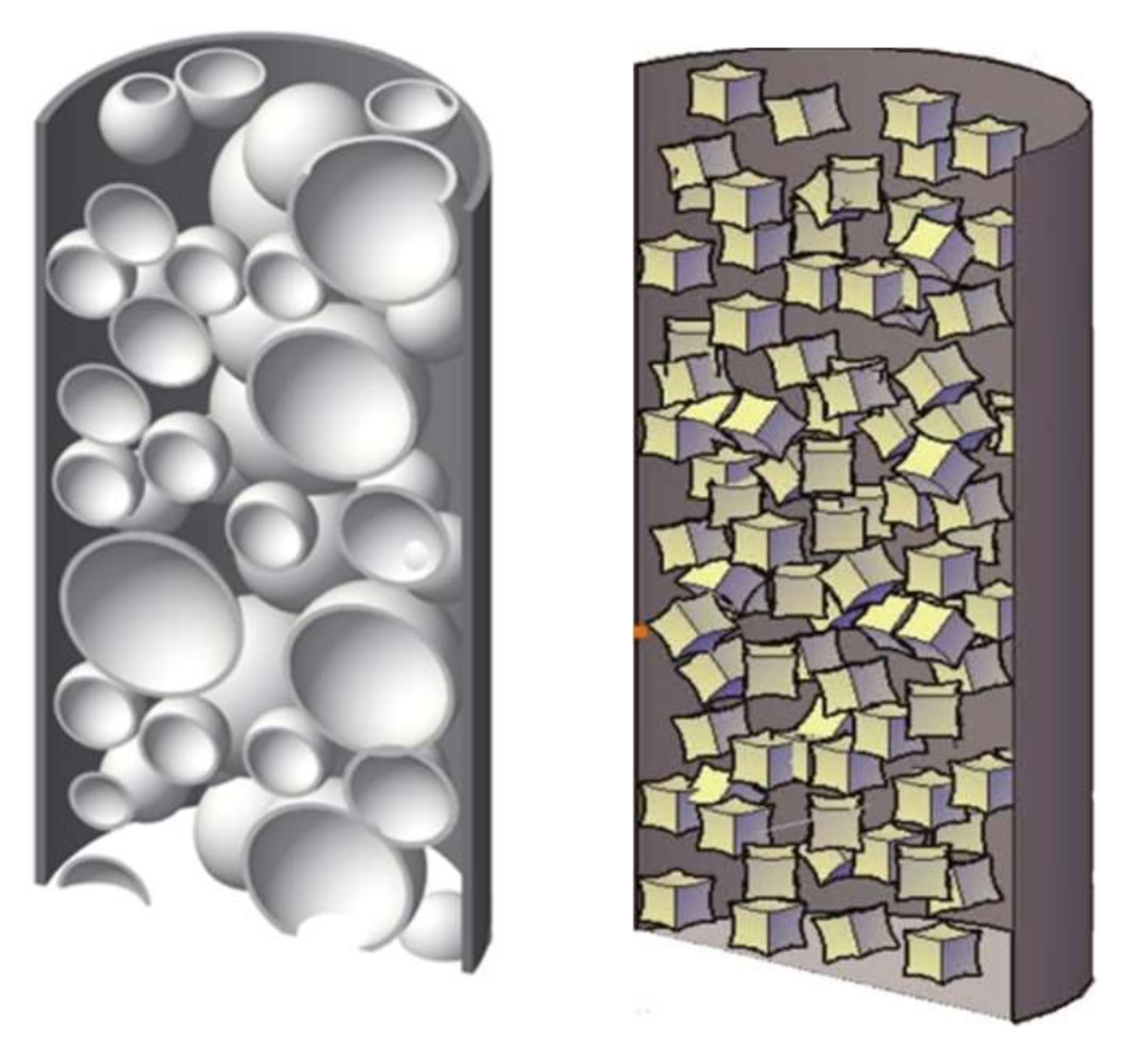

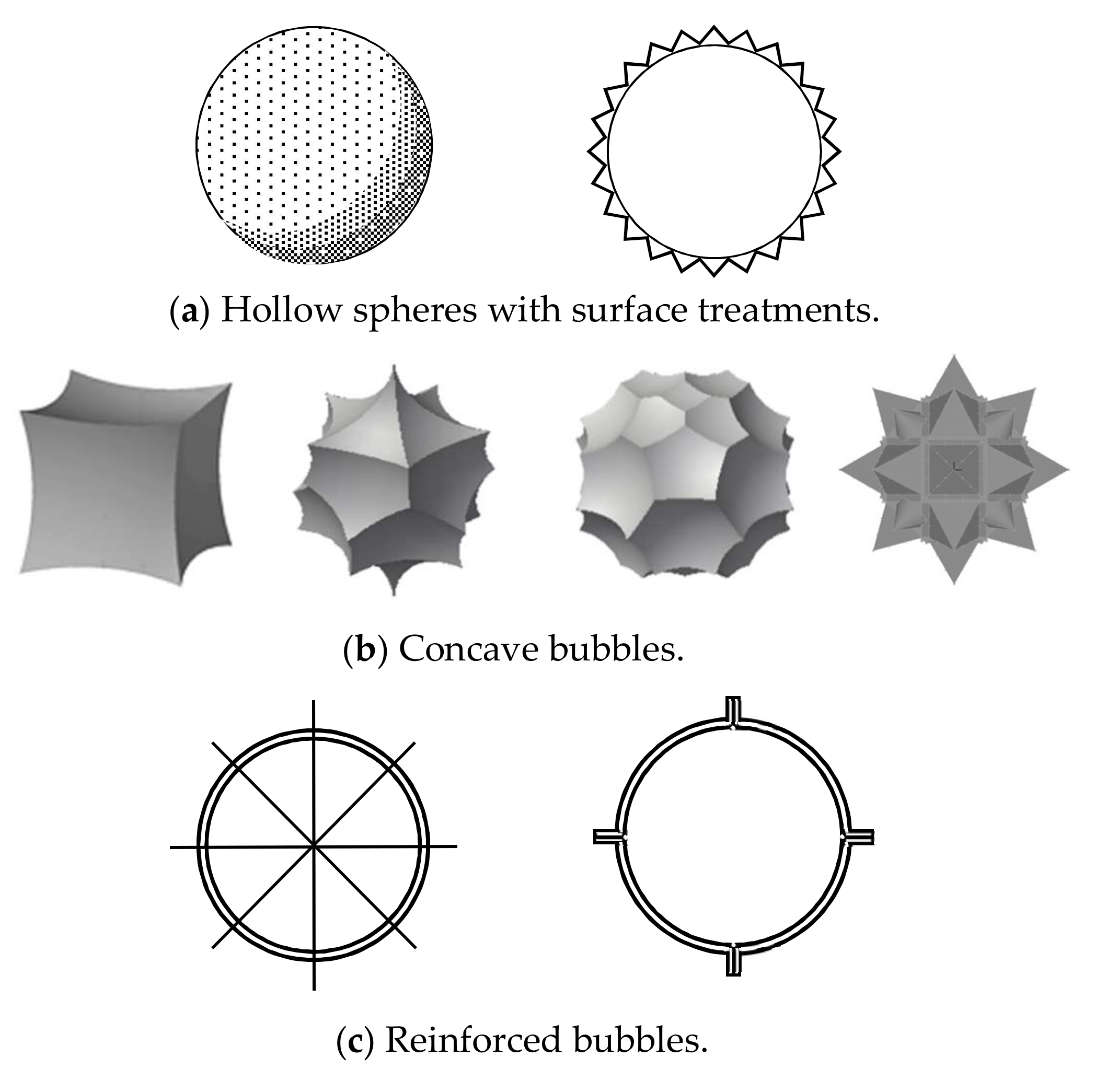

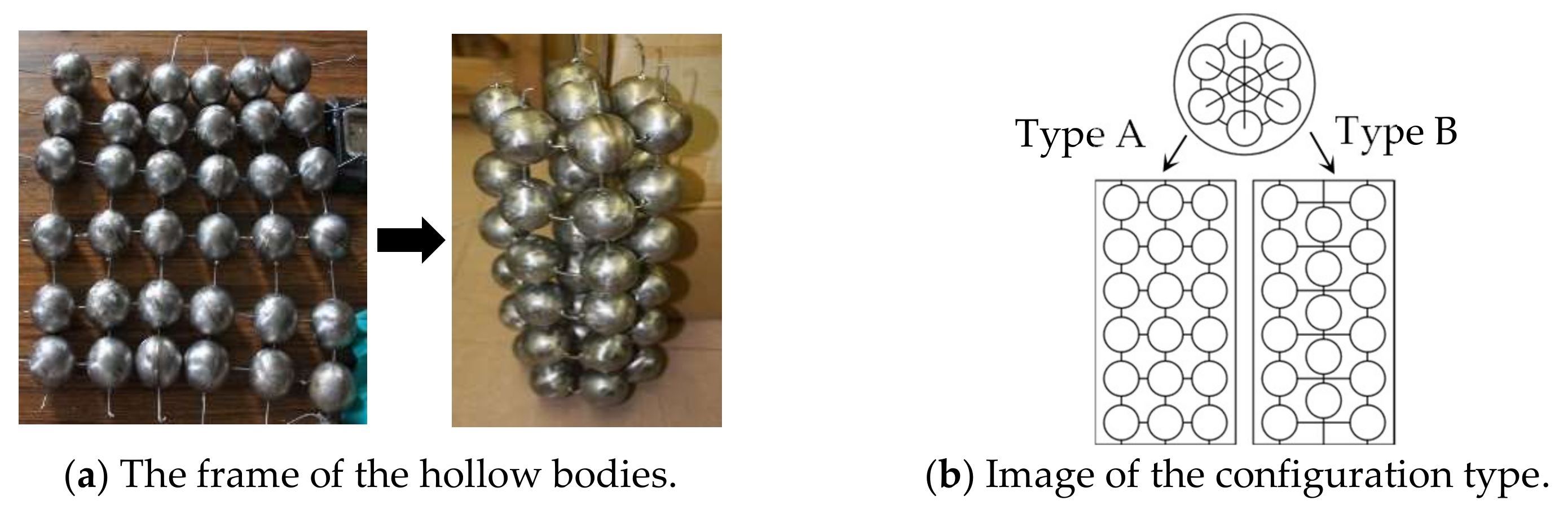

2. Fundamental Principle and Hollow Body Shapes

3. Mechanical Features of a Single Hollow Body

3.1. Mechanical Characteristics of a Single Sphere

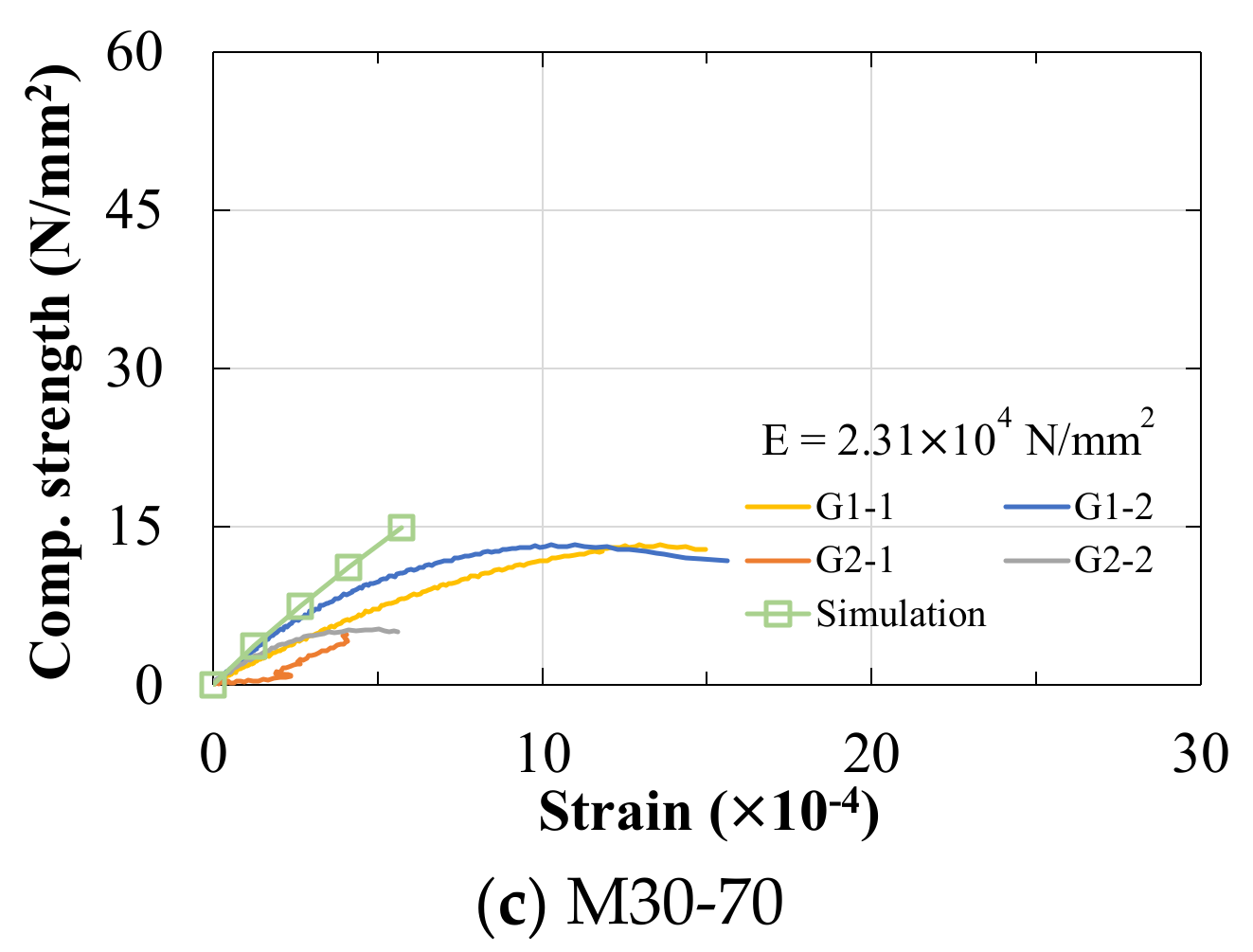

3.1.1. Concrete Compression Test of a Single Sphere

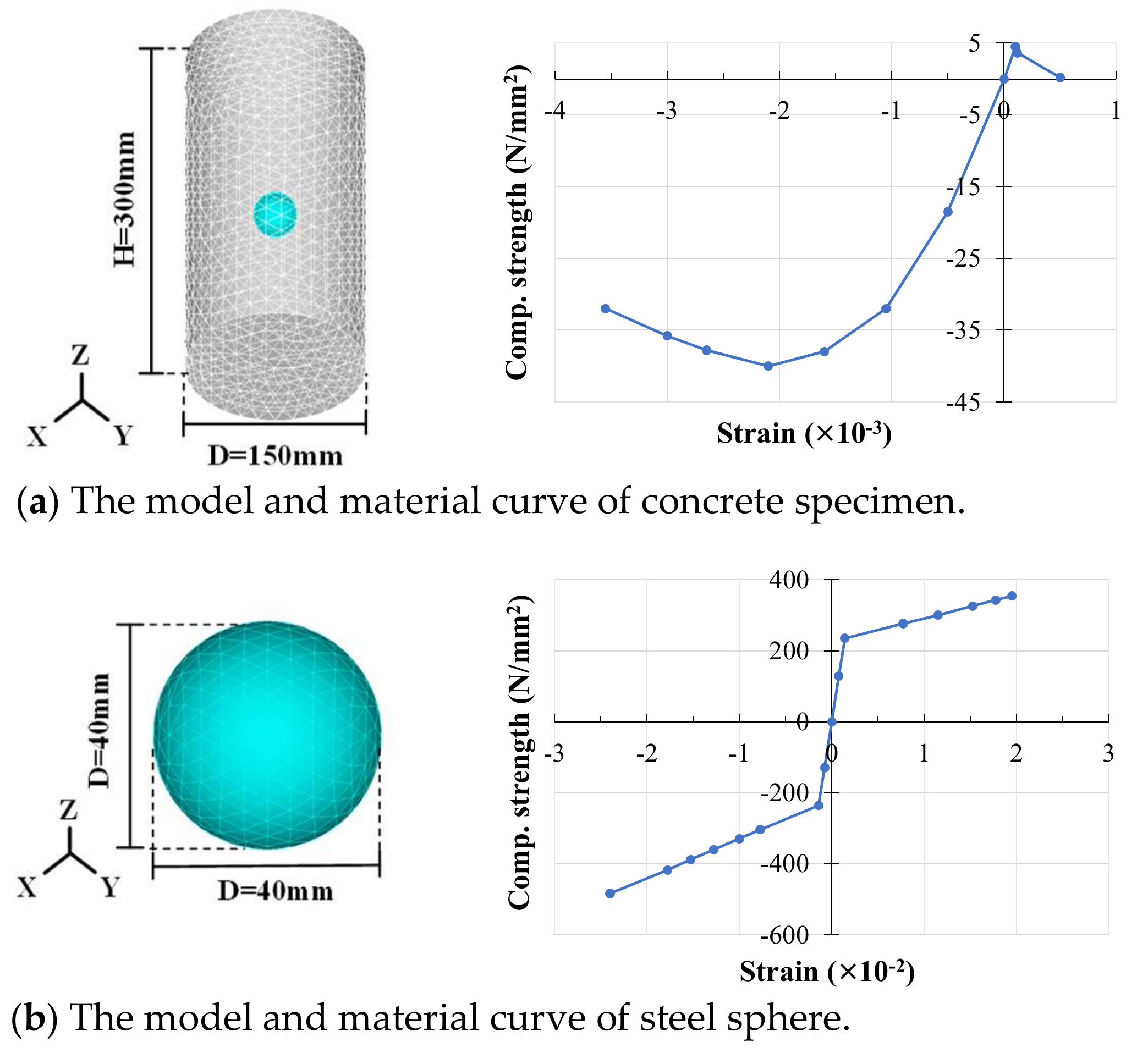

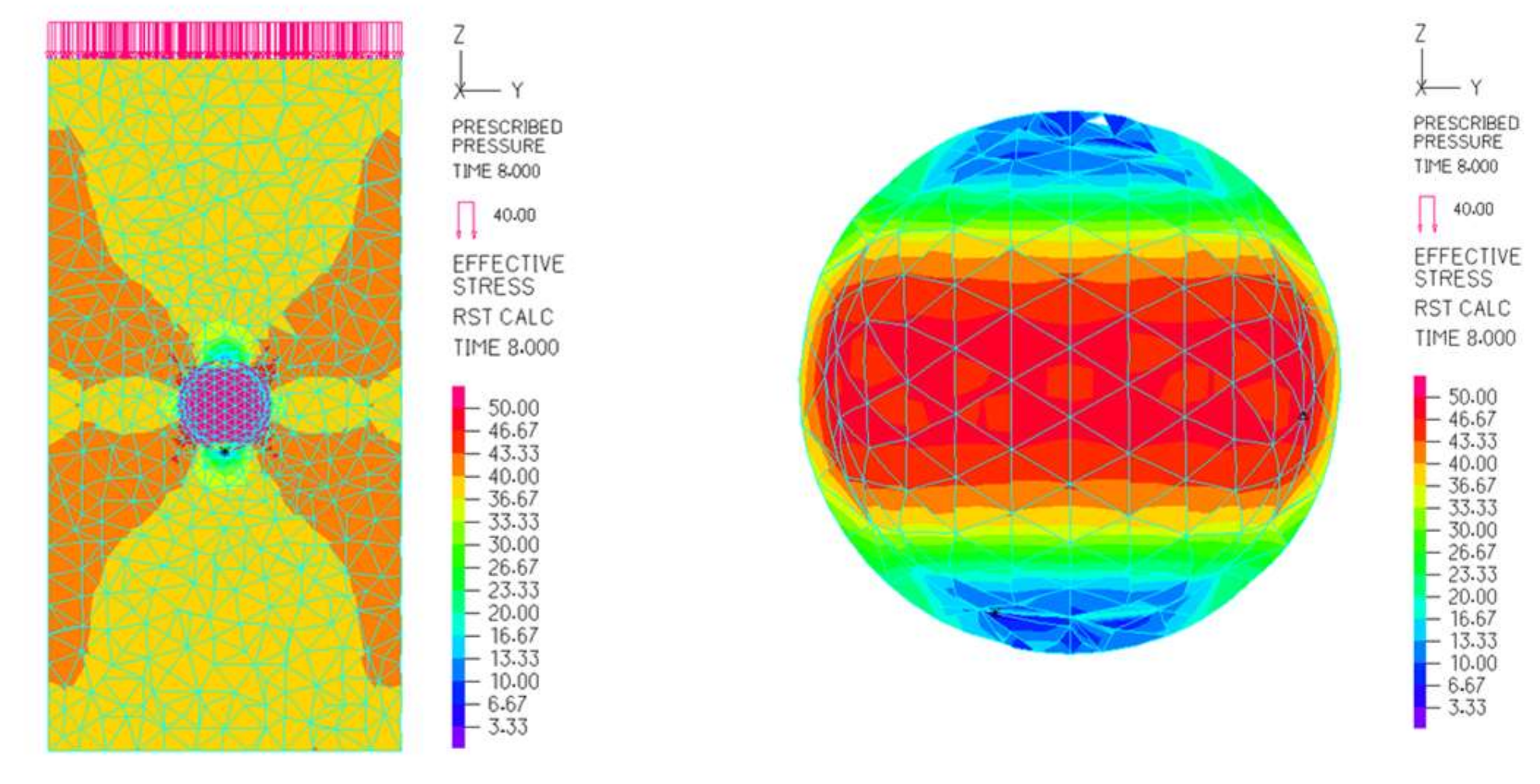

3.1.2. Nonlinear Finite Element Simulation for a Single Sphere

- The steel sphere is compressed by stress in the vertical direction. The steel sphere squeezes the surrounding concrete in the oblique direction, resulting in a stress increase; in the vertical direction, the steel sphere is stripped from the concrete, decreasing stress.

- The steel sphere stiffness is different from the stiffness of the concrete. After the sphere is subjected to stress, the two different materials cannot maintain the same deformation, which causes the steel sphere to be separated from the concrete.

- The surface of the steel sphere was milled, which resulted in insufficient bonding between the sphere and concrete. Therefore, voids are easily created between them and the steel sphere cannot continue to bear and transmit the stress.

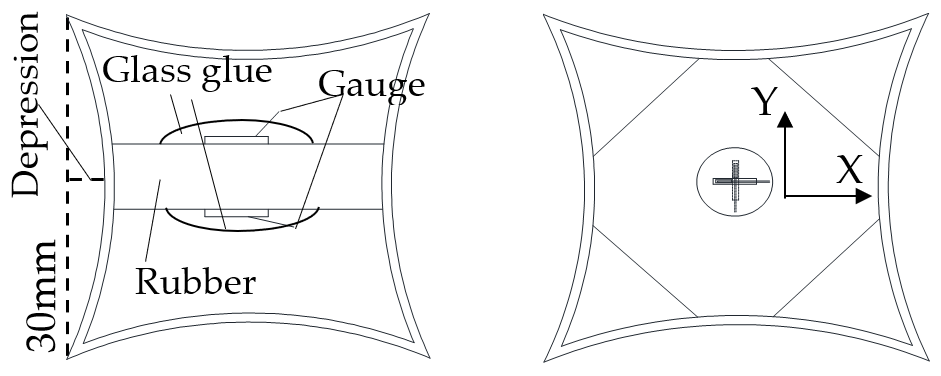

3.2. Mechanical Characteristics of a Single Cubic Concave Body

3.2.1. Compression Experiments of a Single Cubic Concave Body

3.2.2. Nonlinear Finite Element Simulation for a Single Cubic Concave Body

- The concave body is subjected to vertical compression and inward deformation after being loaded.

- The thickness of the concave body is too thin, and the poor quality of the weld causes the concave body to be damaged.

- The adhesion between the concave body and the concrete is insufficient, and when the concrete cracks, the concave body is unable to provide internal tension.

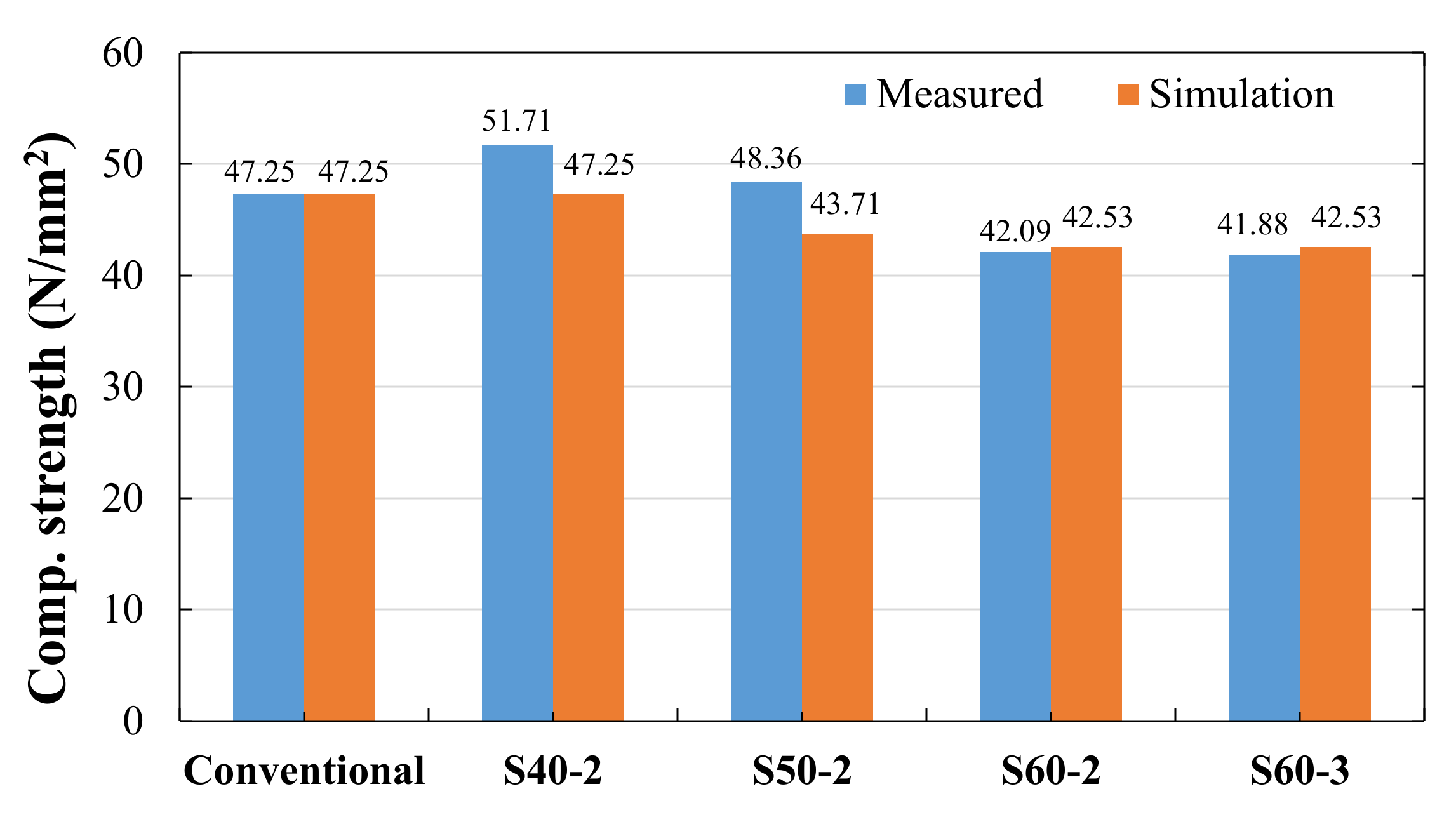

4. Mechanical Features of Multiple Steel Hollow Bodies

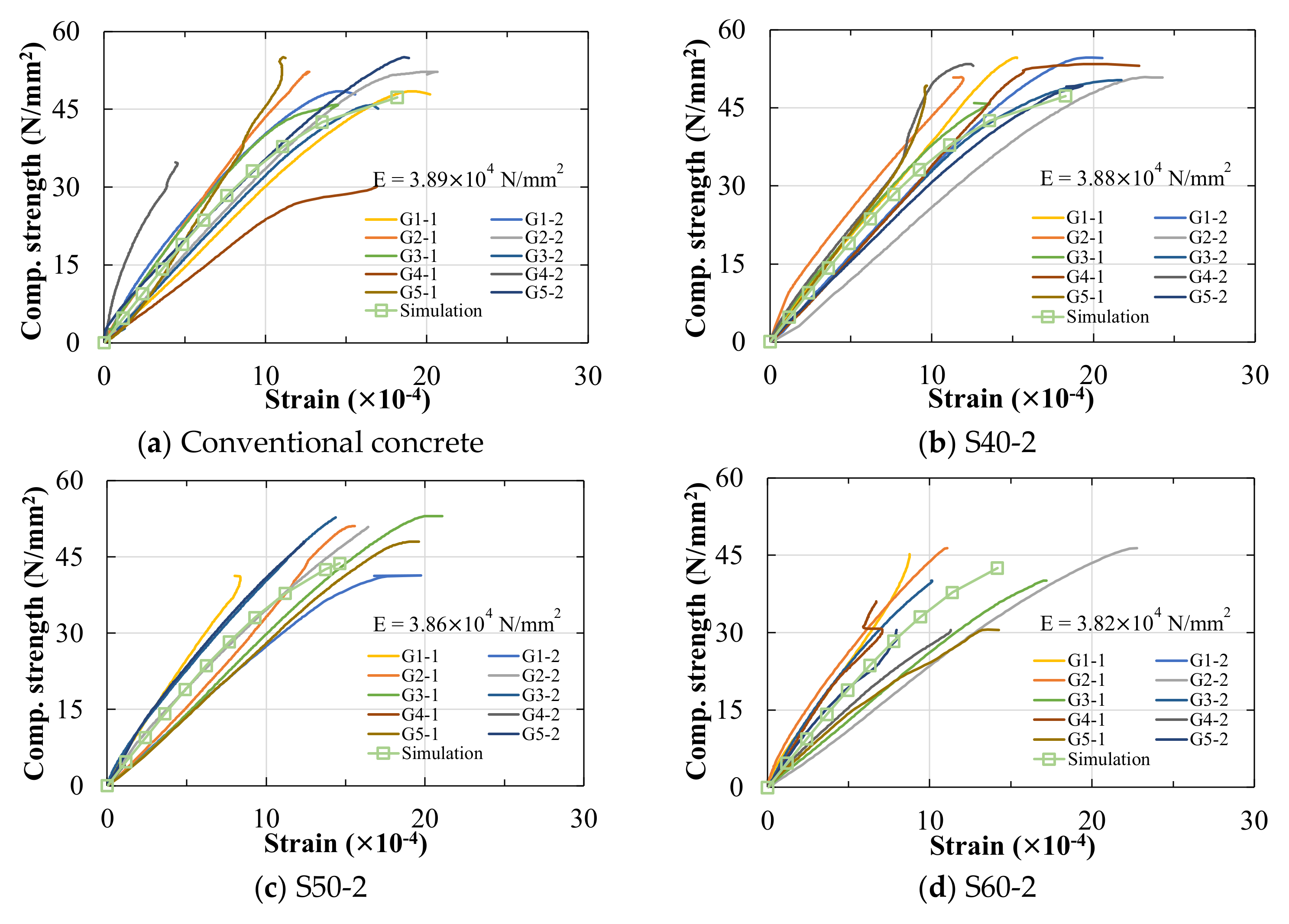

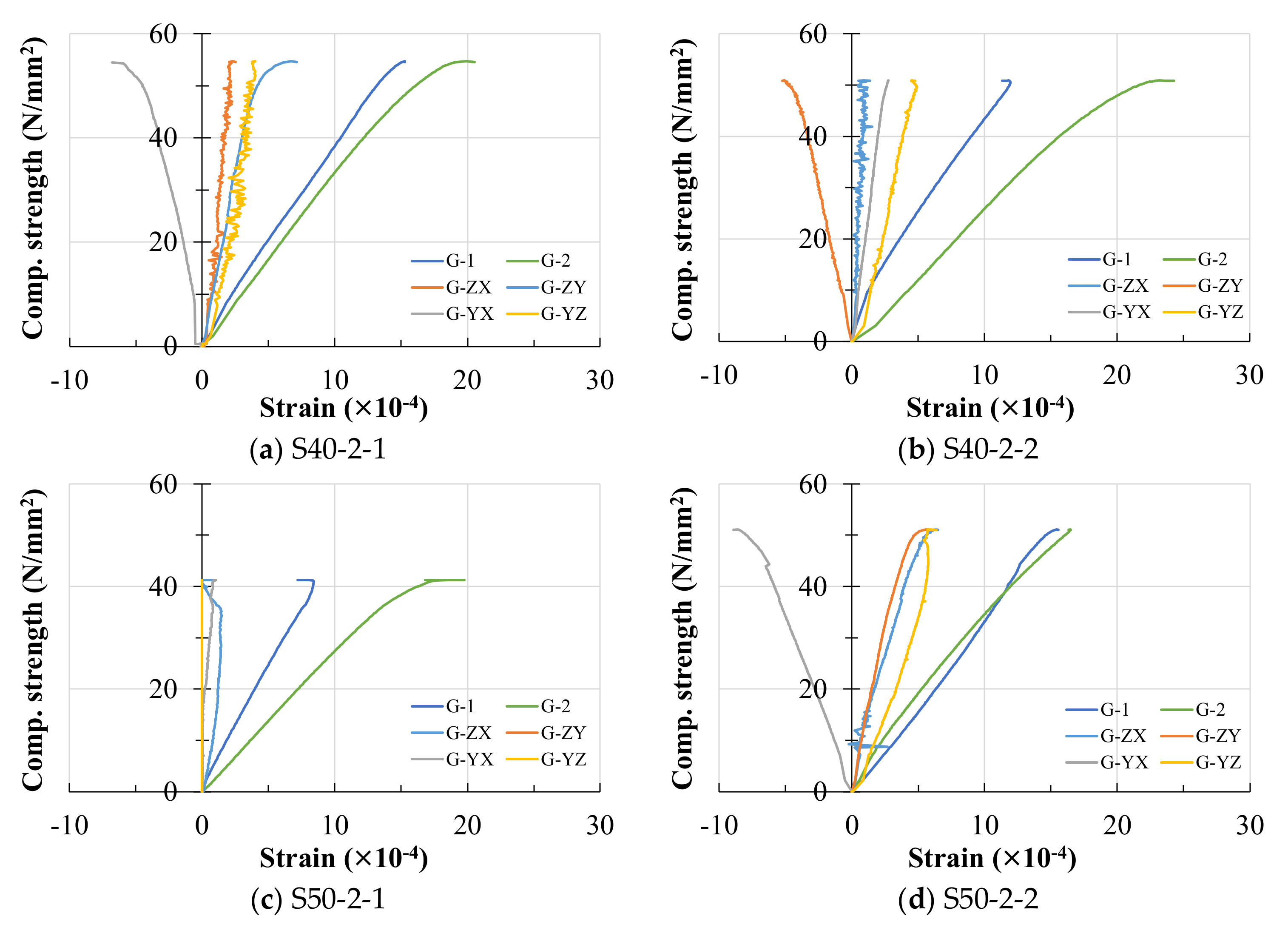

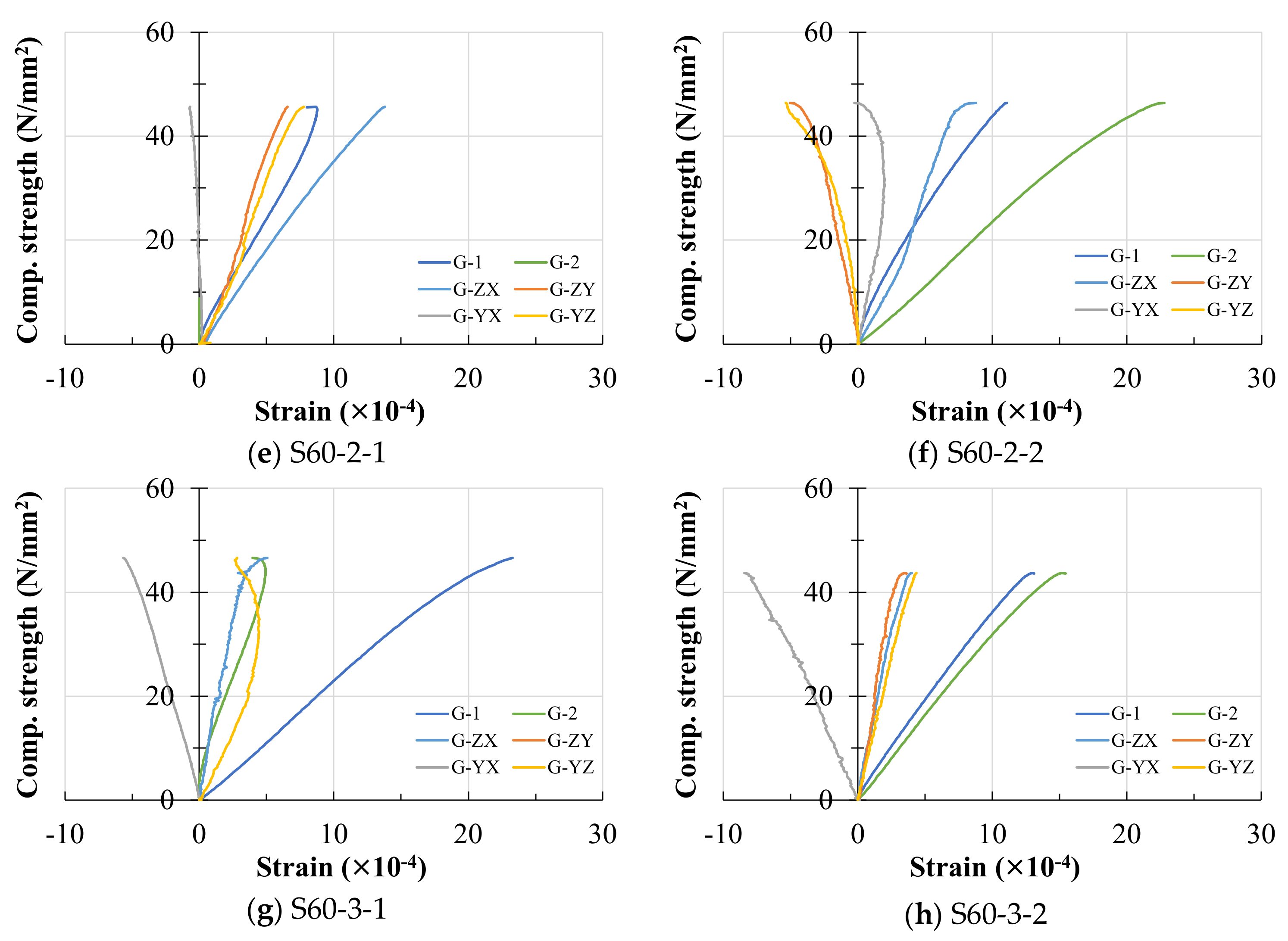

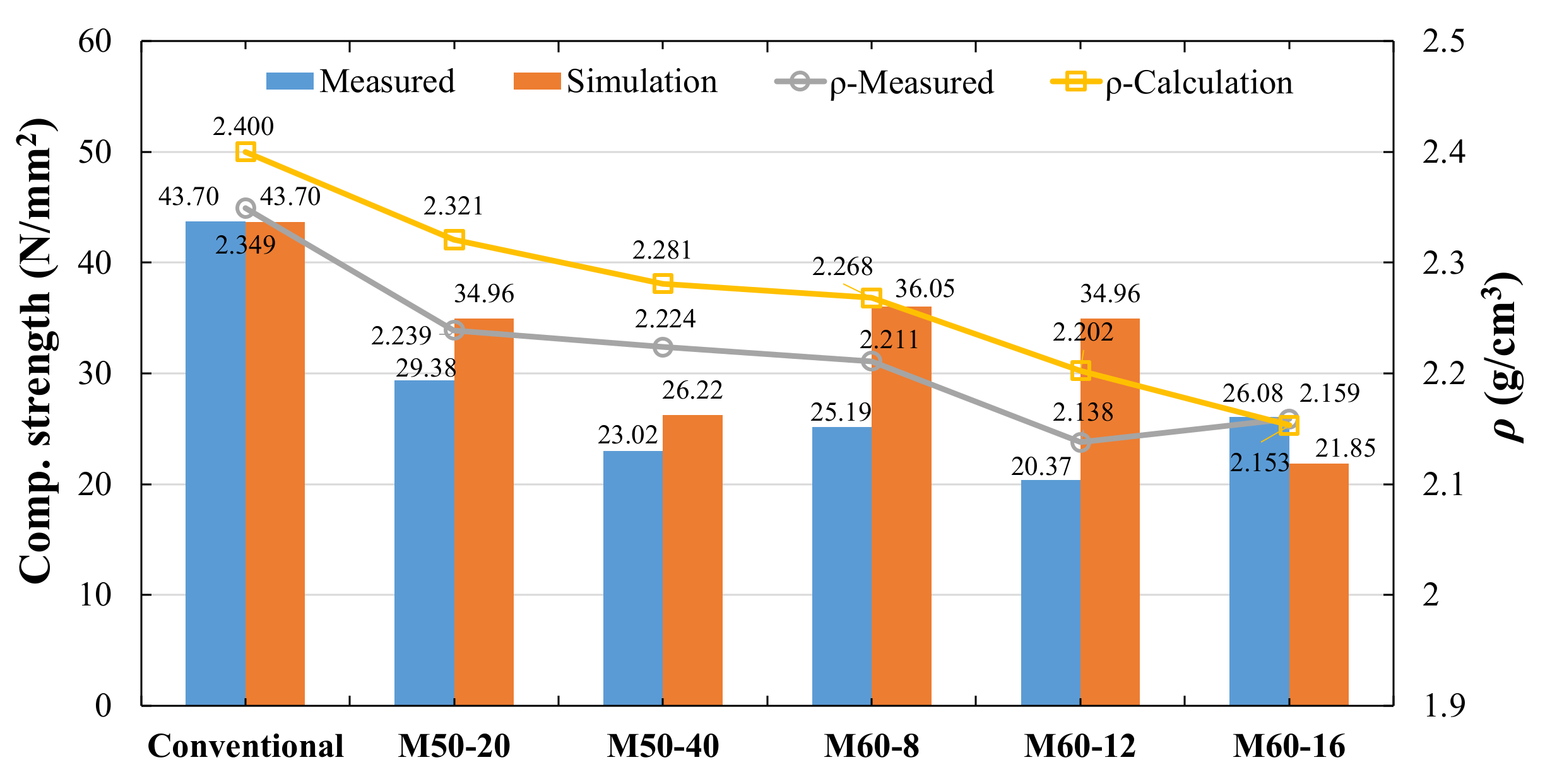

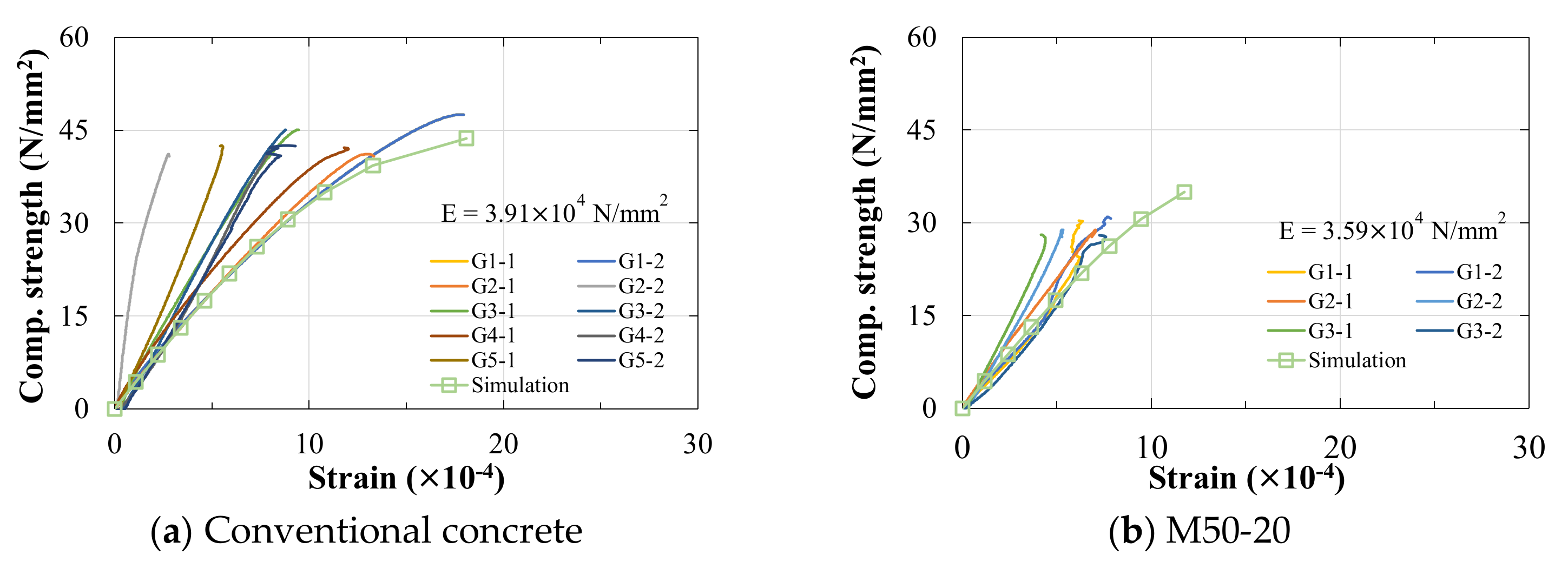

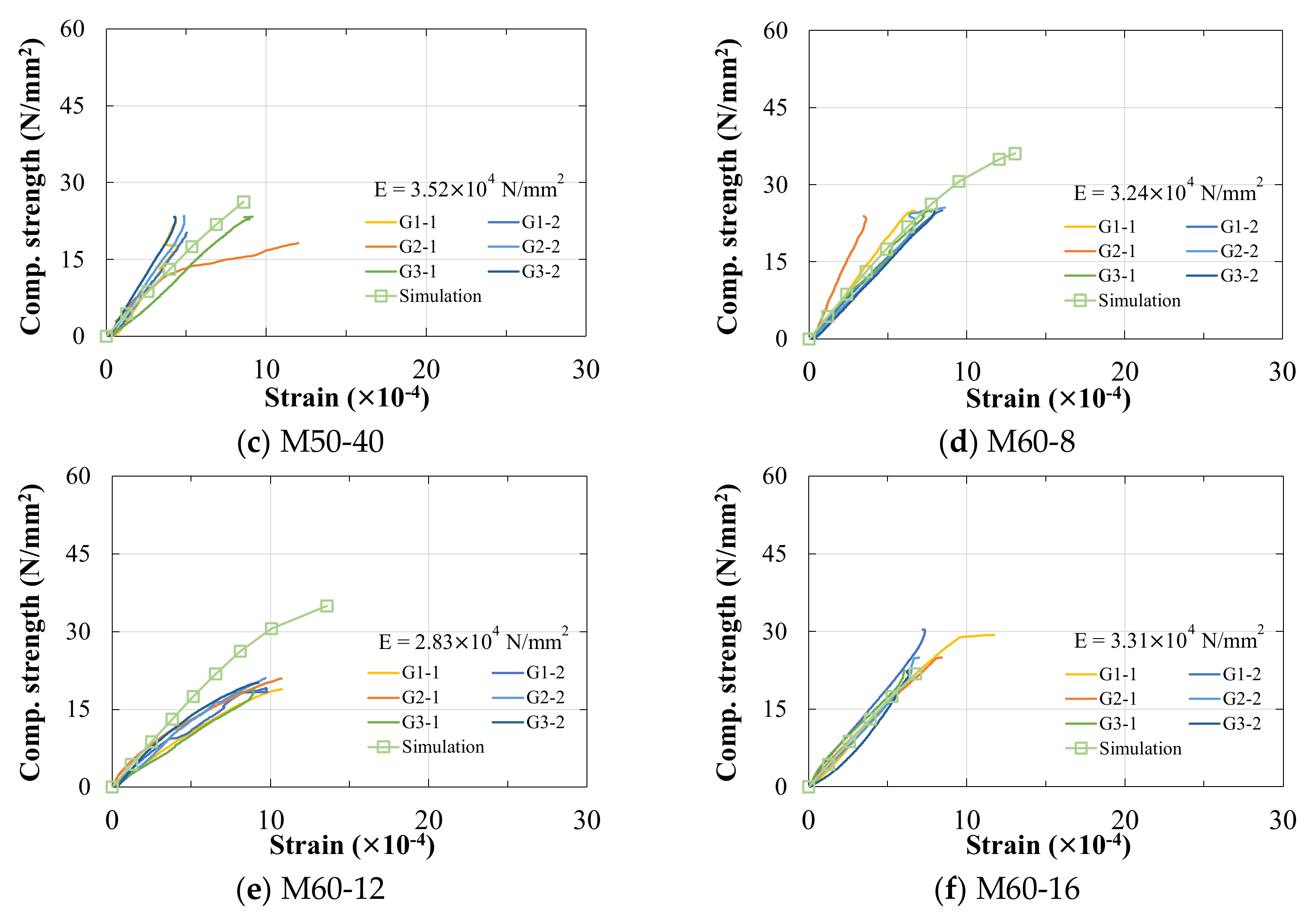

4.1. Mechanical Characteristics of Multiple Spheres

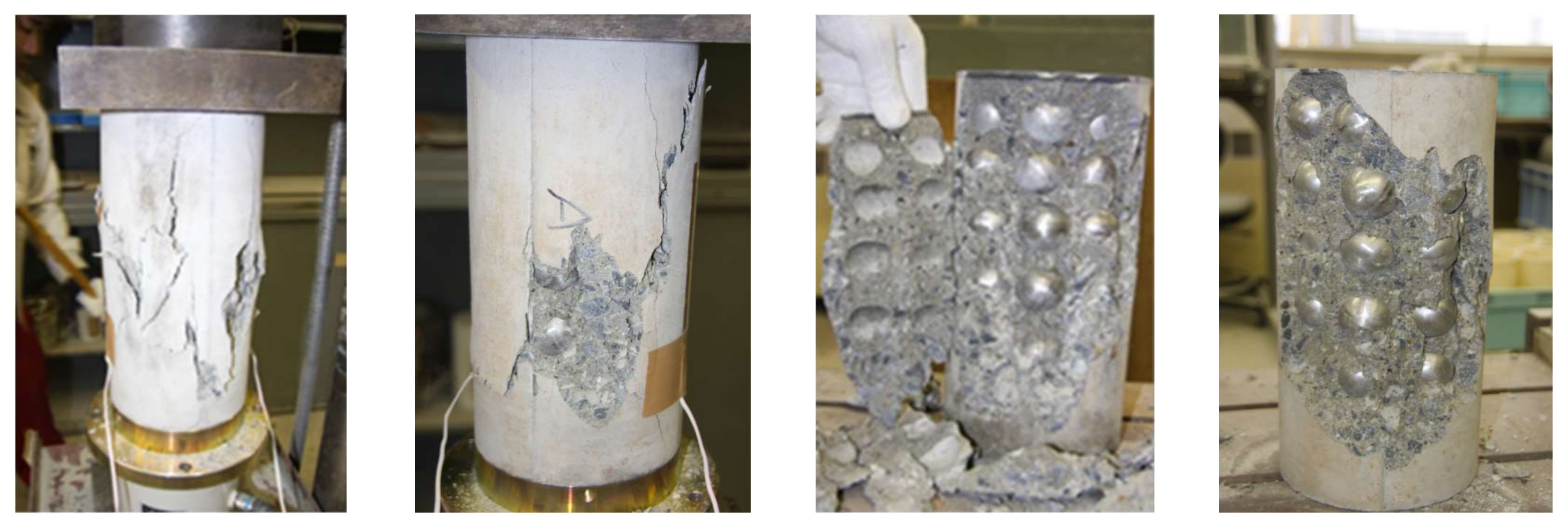

4.1.1. Concrete Compression Experiments of Multiple Spheres

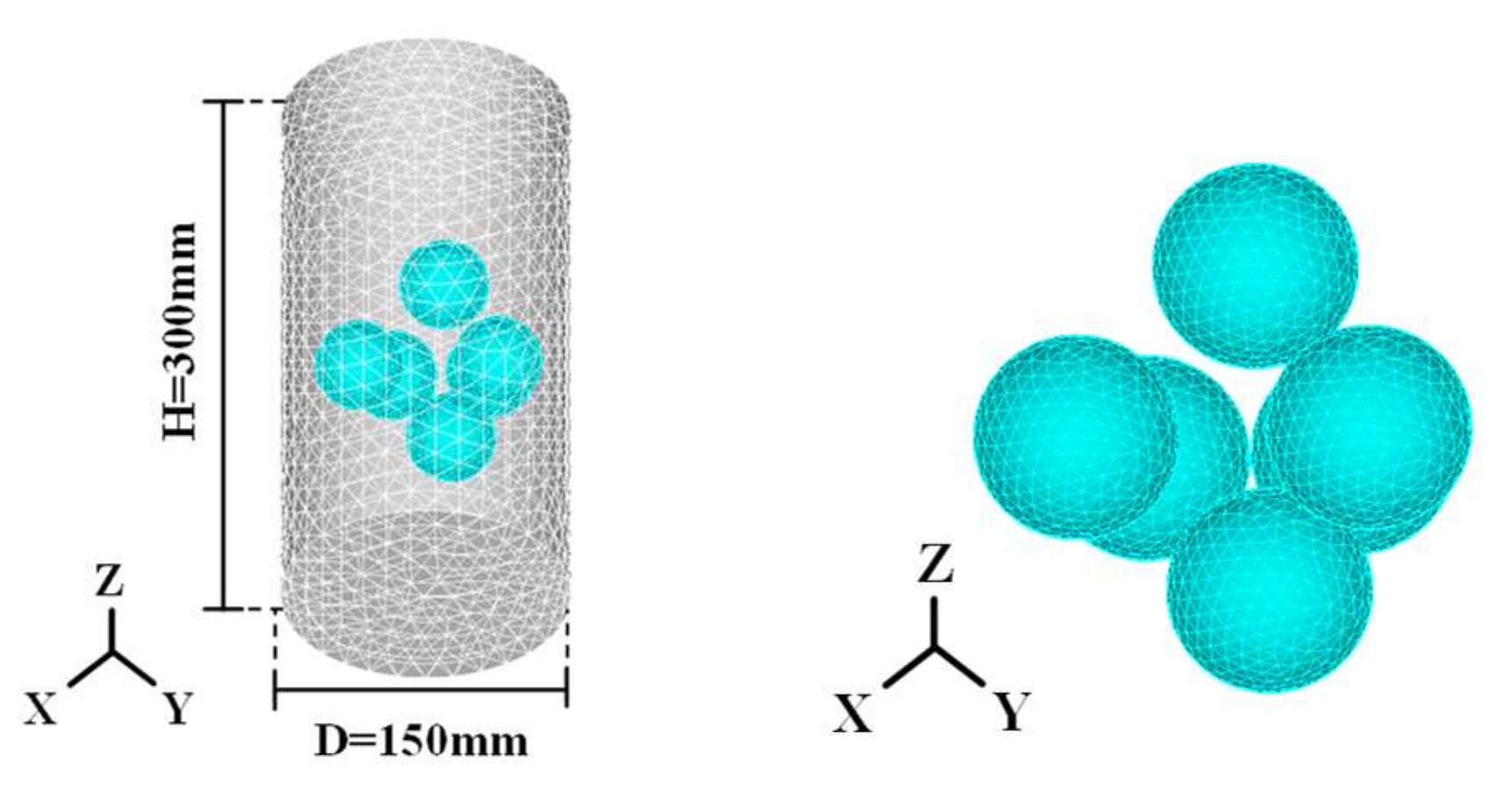

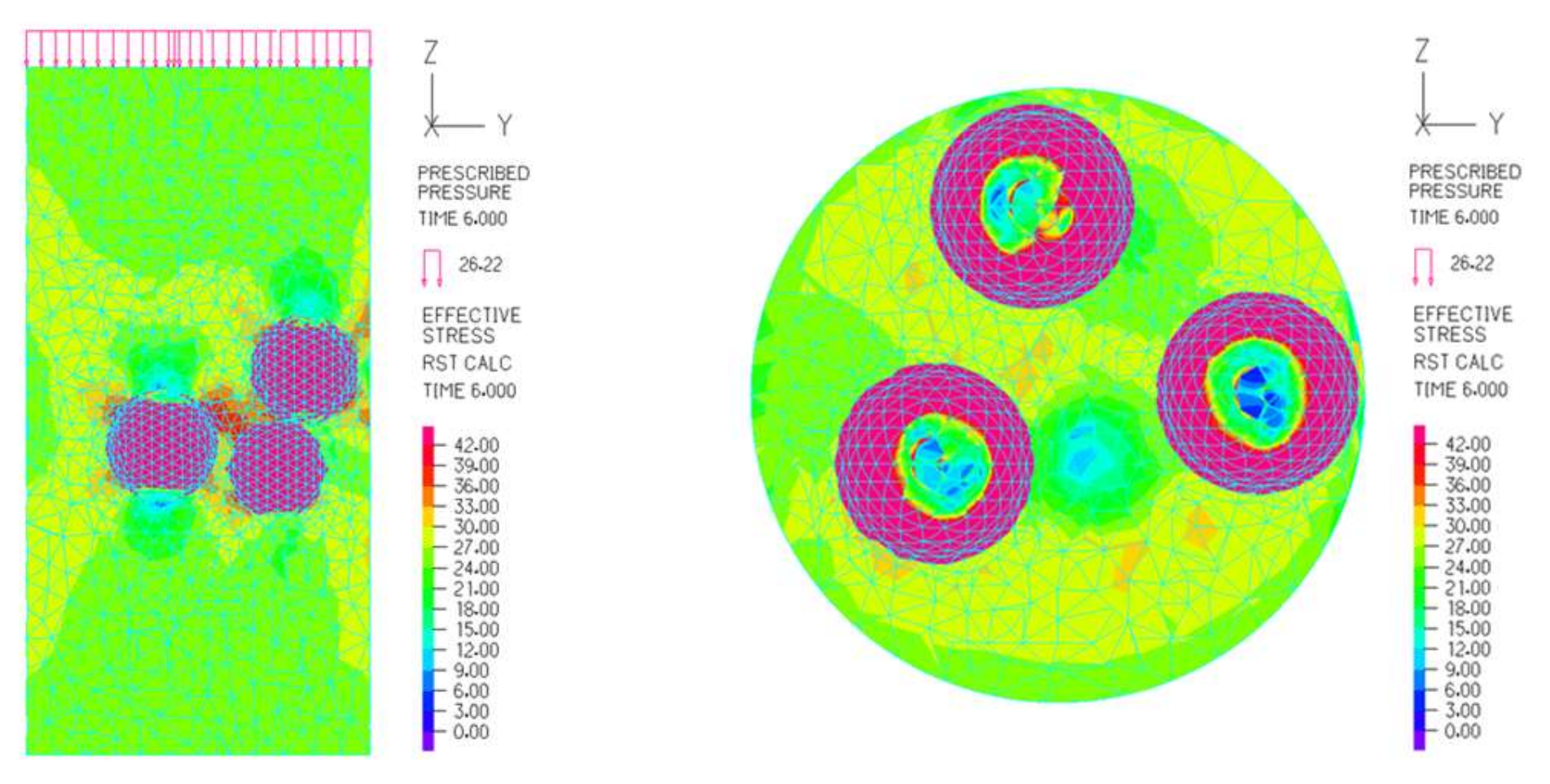

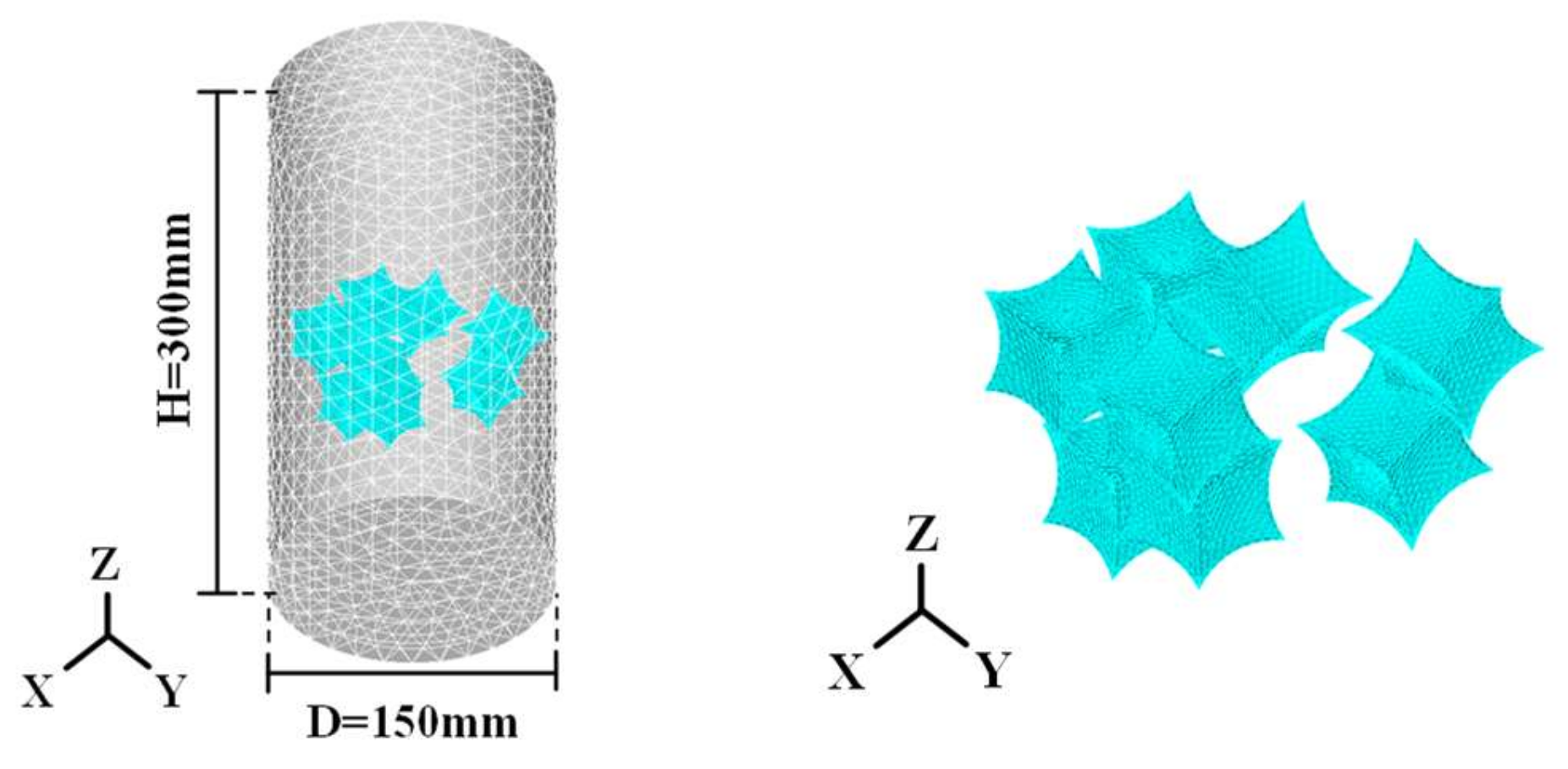

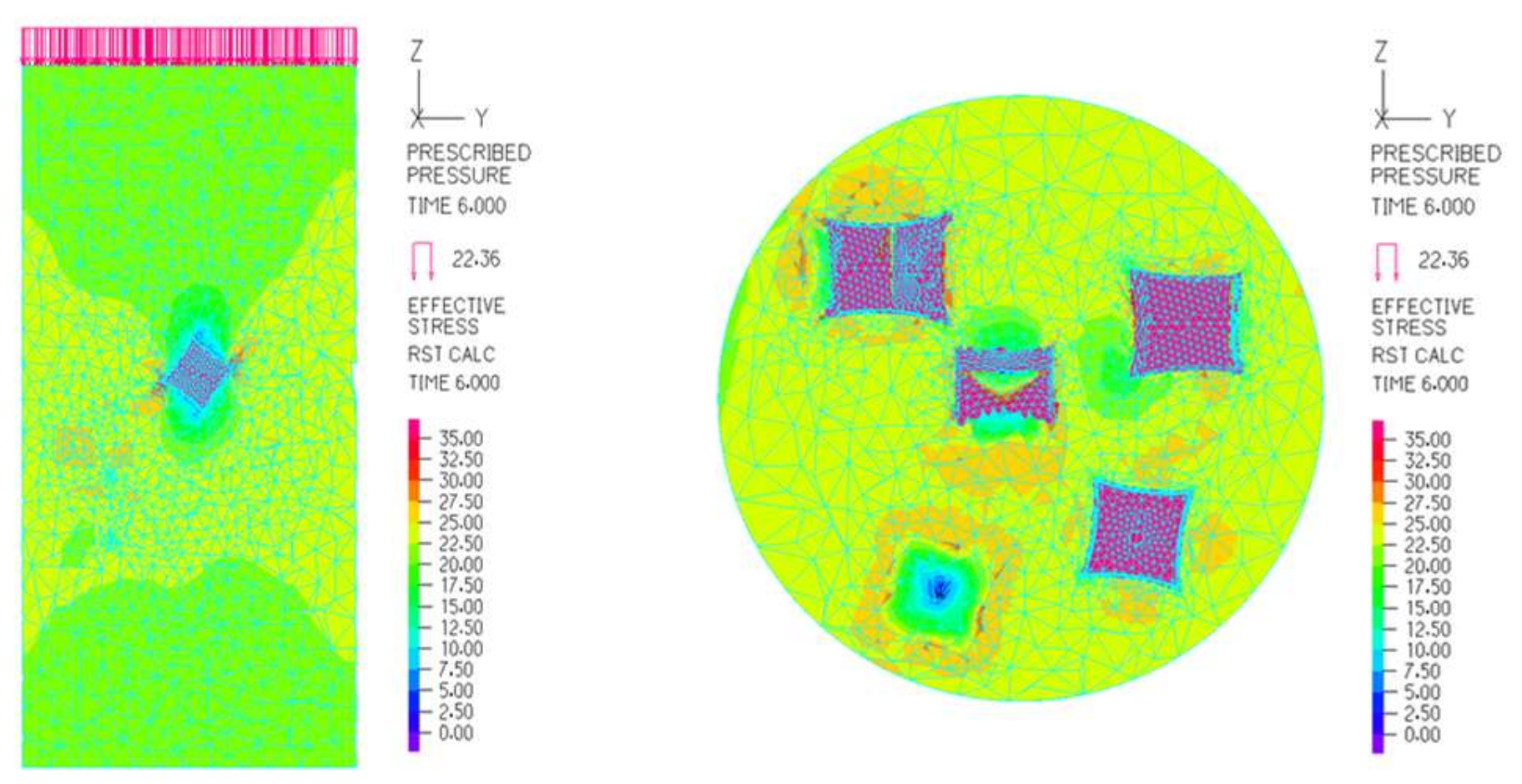

4.1.2. Nonlinear Finite Element Simulation of Multiple Spheres

- (1)

- Compression occurs in the vertical direction. In contrast, the oblique direction produces expansion, increasing stress. If the steel sphere is close to the edge of the concrete, it may cause the outer concrete to peel off quickly.

- (2)

- The steel sphere has poor adhesion to the concrete, so the steel sphere is stripped from the concrete. Moreover, the concrete on the outside is susceptible to outward crumbling when it is extruded laterally.

- (3)

- The steel spheres, as additional aggregates, lead to a reduction in cement paste content, which causes the adhesion within the concrete to decrease. Moreover, since the density of steel spheres is lower than that of cement, the steel spheres tend to float on the concrete paste and aggregate when fabricating concrete specimens.

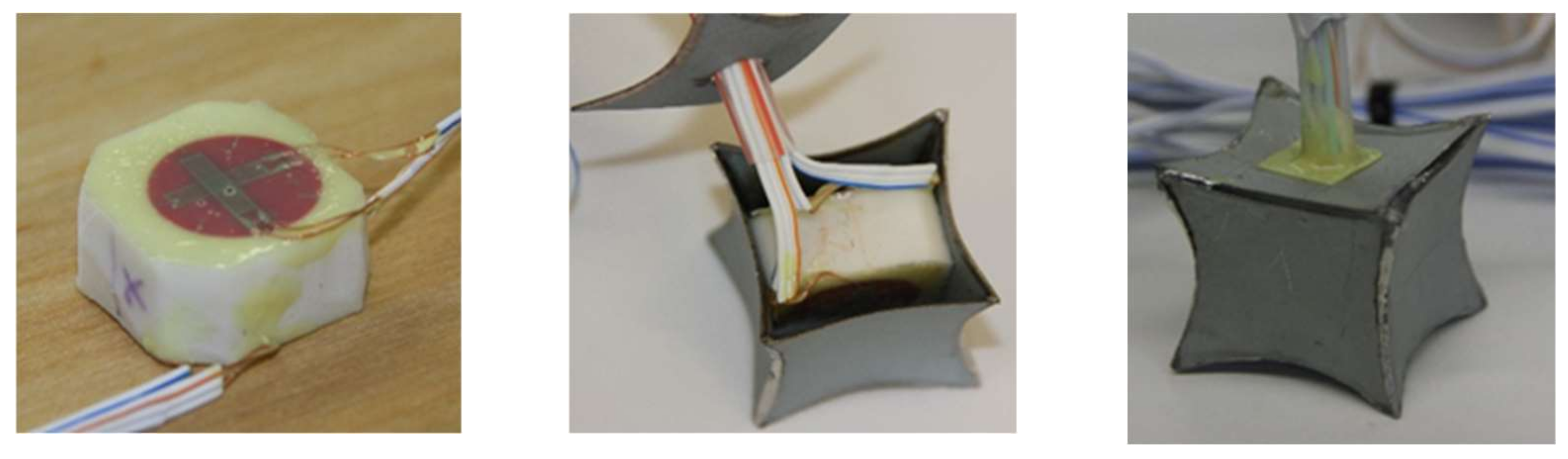

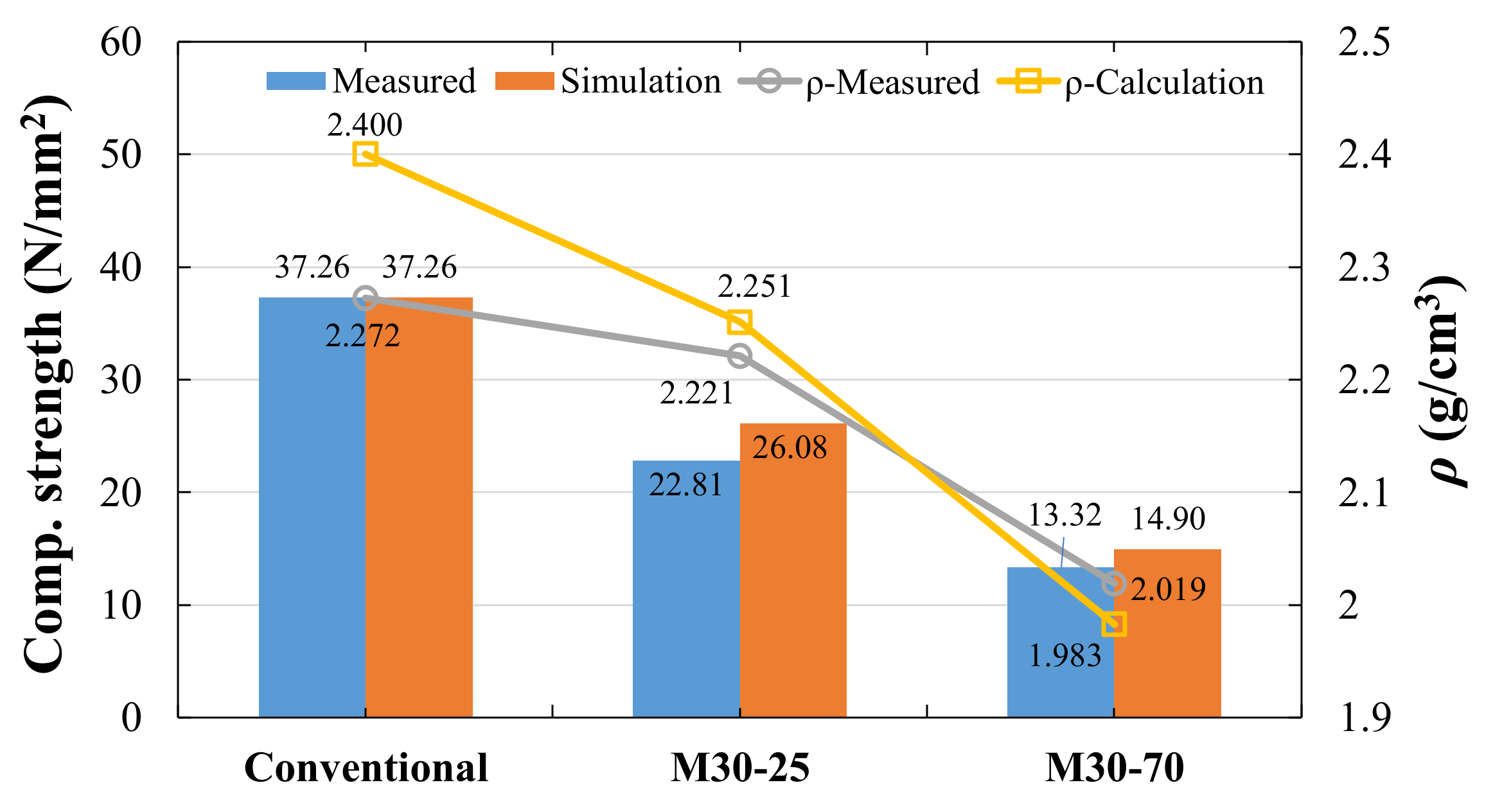

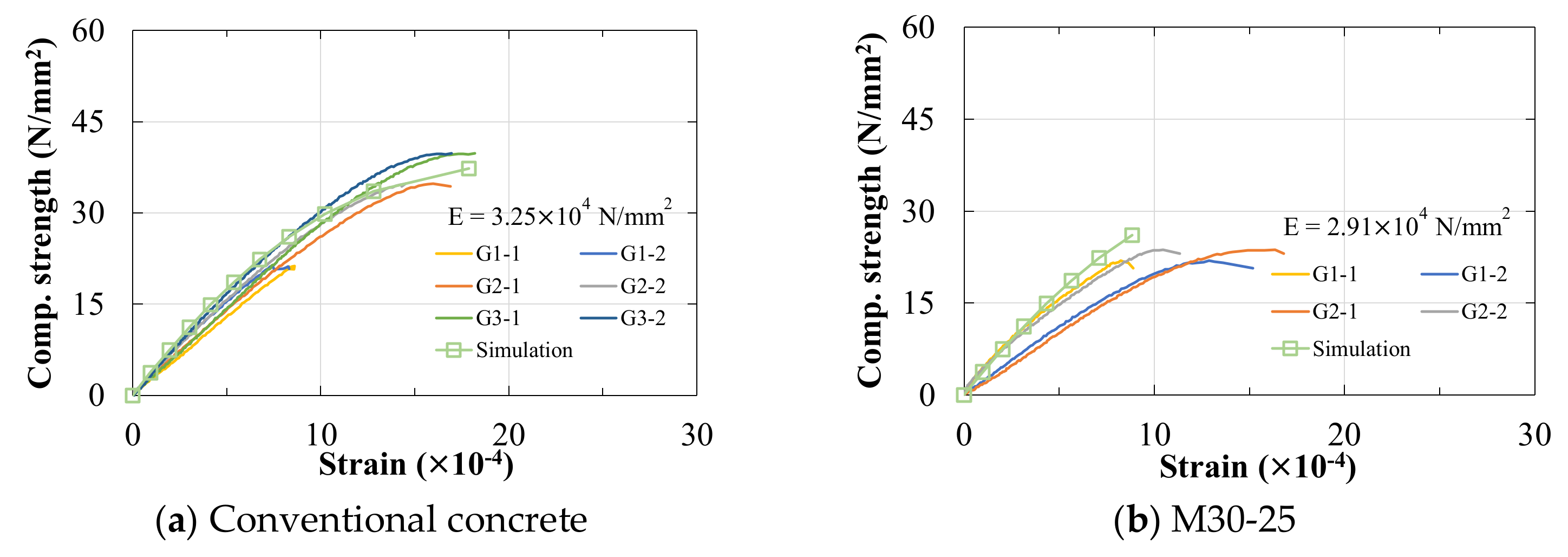

4.2. Mechanical Characteristics of Multiple Cubic Concave Bodies

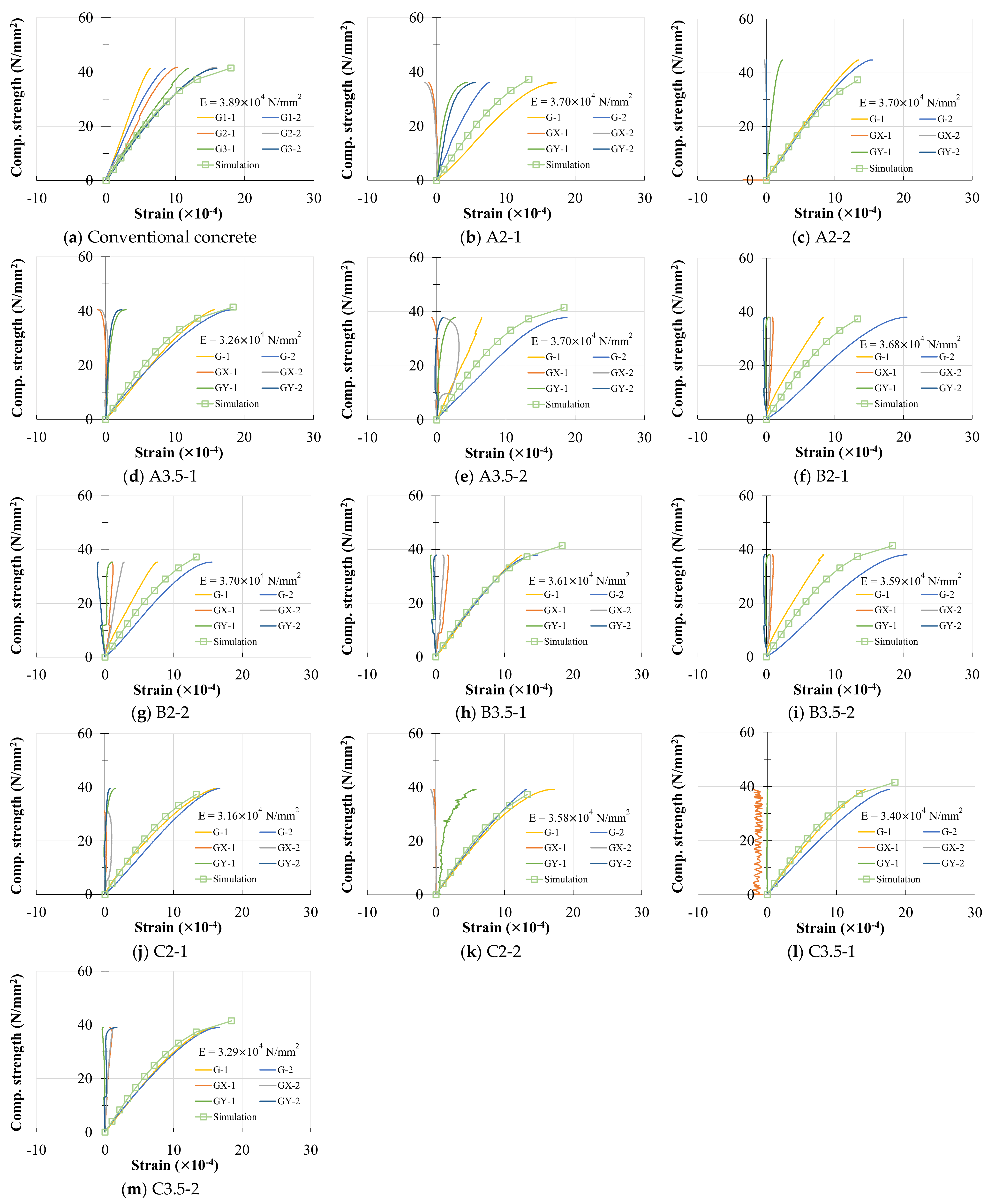

4.2.1. Concrete Compression Experiments of Multiple Cubic Concave Bodies

4.2.2. Nonlinear Finite Element Simulation of Multiple Cubic Concave Bodies

- Compared to spheres, concave bodies are prone to deformation because the thickness of the cubic concave model used in this study was only 0.8 mm. Moreover, it quickly peels off from the concrete after deformation.

- The surface of the concave body is a milled face and the adhesion between the concave bodies and the concrete is poor. When the concrete bears the load, it easily produces many cracks between the concave bodies and the concrete.

- Too many concave bodies were used, and the concave surface bodies cannot be fully contacted. When the concave surface body is deformed, it cannot provide enough cohesion stress.

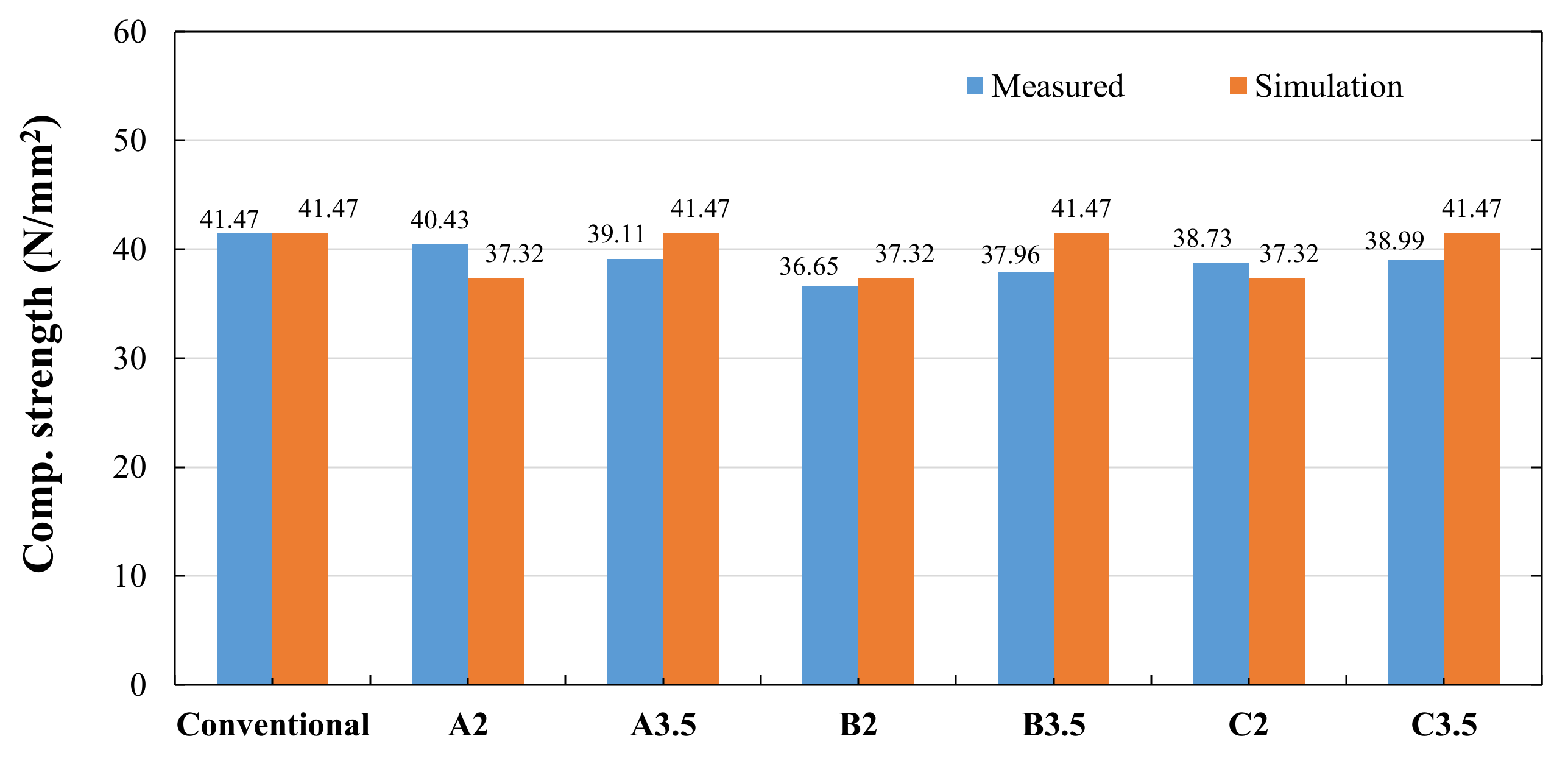

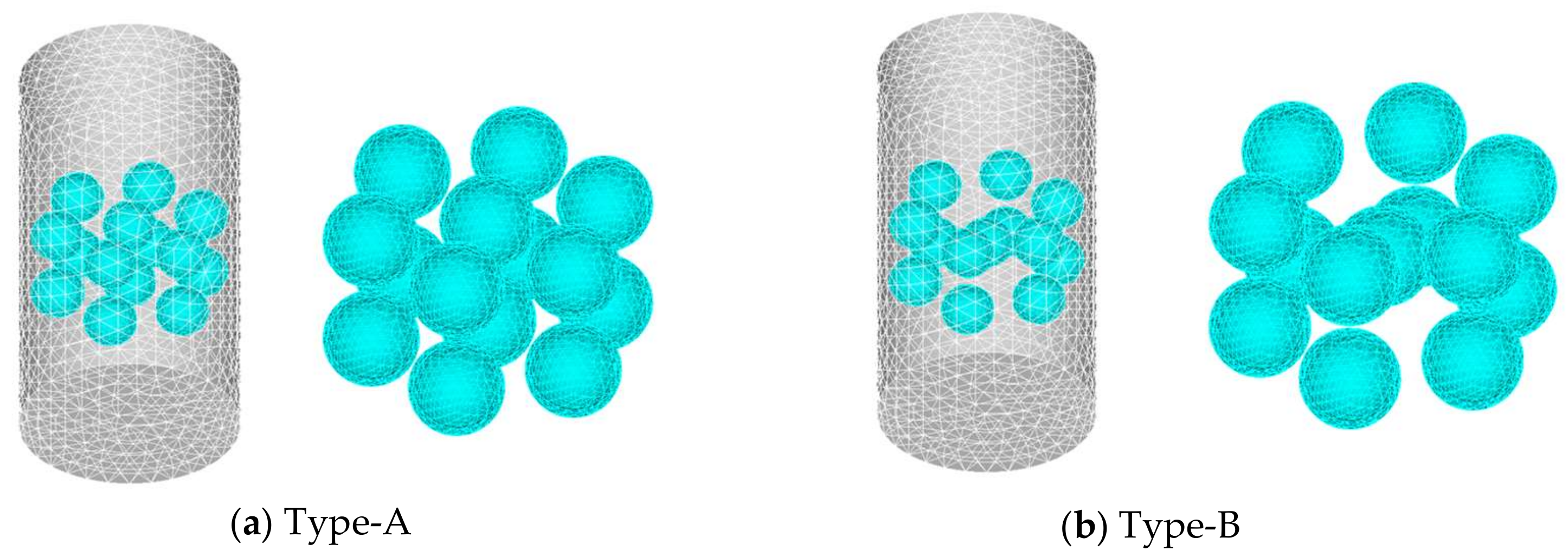

5. Mechanical Features of Hollow Bodies with Fixed Sphere Positions

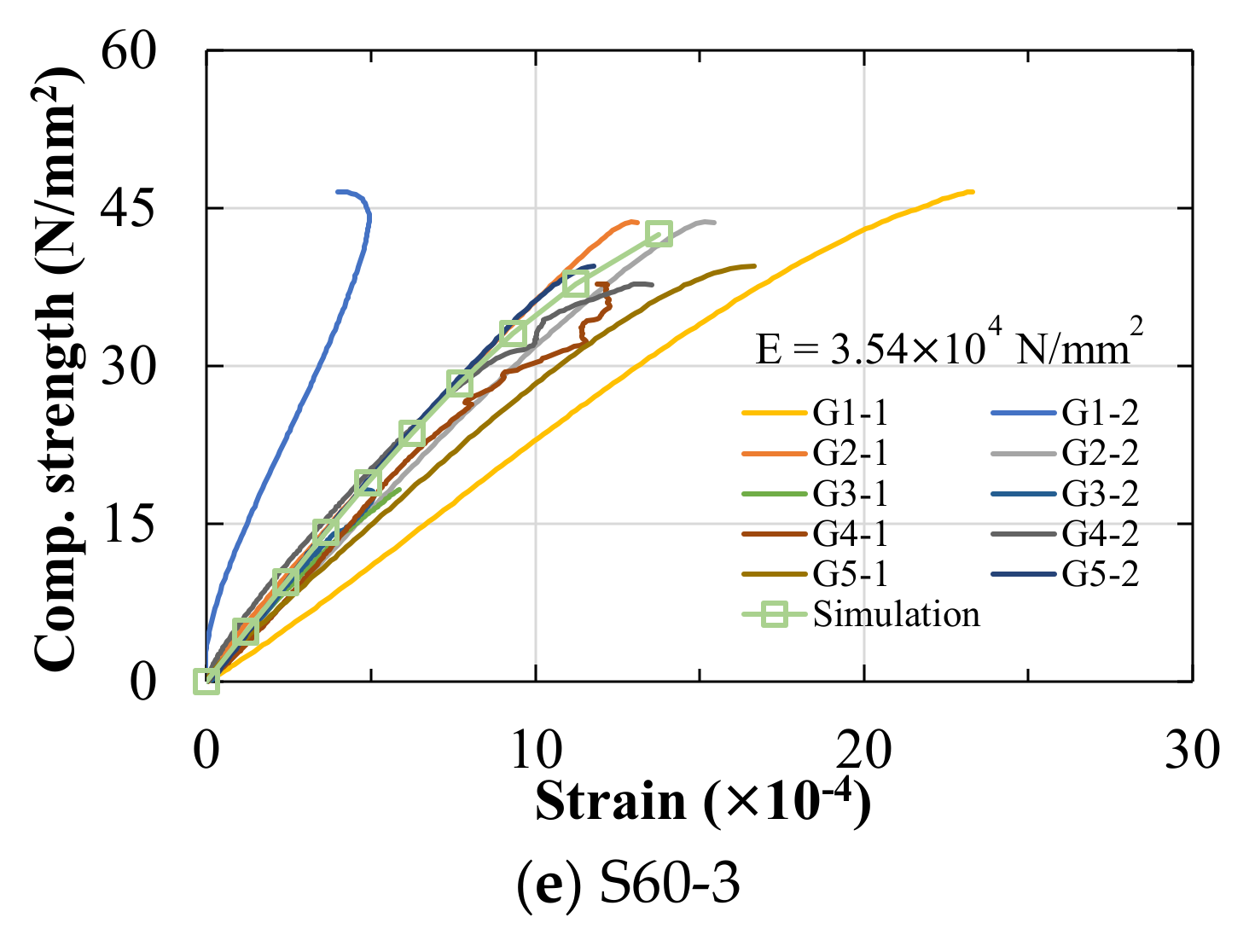

5.1. Concrete Compression Experiments of Fixed Sphere Positions

5.2. Nonlinear Finite Element Simulation of Hollow Bodies with Fixed Positions

6. Conclusions

- Searching for suitable material for the hollow bodies to increase the adhesion between the hollow bodies and concrete.

- Adjusting the mix ratio of concrete and finding the appropriate number of hollow bodies to be mixed into the concrete.

- Researching the suitable arrangement position and size of the hollow bodies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Haque, M.N.; Al-Khaiat, H.; Kayali, O. Strength and durability of lightweight concrete. Cem. Concr. Compos. 2004, 26, 307–314. [Google Scholar] [CrossRef]

- Min, H.Z.; Odd, E.G. Mechanical Properties of High-Strength Lightweight Concrete. Mater. J. 1991, 88, 240–247. [Google Scholar]

- Kan, A.; Demirboğa, R. A novel material for lightweight concrete production. Cem. Concr. Compos. 2009, 31, 489–495. [Google Scholar] [CrossRef]

- Lo, T.Y.; Tang, W.C.; Cui, H.Z. The effects of aggregate properties on lightweight concrete. Build. Environ. 2007, 42, 3025–3029. [Google Scholar] [CrossRef]

- Palle, N.-C.; Tommy, P.H.N. Modal determination of the effect of bond between coarse aggregate and mortar on the compressive strength of concrete. J. Proc. 1969, 66, 66–67. [Google Scholar]

- Abdullah, M.M.A.B.; Hussin, K.; Bnhussain, M.; Ismail, K.N.; Yahya, Z.; Abdul Razak, R. Fly Ash-based Geopolymer Lightweight Concrete Using Foaming Agent. Int. J. Mol. Sci. 2012, 13, 7186–7198. [Google Scholar] [CrossRef] [PubMed]

- Fahrizal, Z.; Mahyuddin, R. Performance and characteristic foamed concrete mix design with silica fume for housing development. Int. J. Acad. Res. 2011, 3, 1198–1206. [Google Scholar]

- Ducman, V.; Mirtič, B. The applicability of different waste materials for the production of lightweight aggregates. Waste Manag. 2009, 29, 2361–2368. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.-S. A study report on light weight concrete mixed with high strength hollow bubbles. In Proceeding of AIJ Tohoku Chapter Architectural Research Meeting (Kouzoukei); Architectural Institute of Japan: Tokyo, Japan, 2008; No.71; pp. 57–62. [Google Scholar]

- Chen, P.-S. Bubble Concrete. Japan Patent Office JP2008308395, 25 December 2008. Available online: https://patentfield.com/patents/JP2007181500A (accessed on 25 December 2008).

- Galilei, G. Dialogues Concerning Two New Sciences; Crew, H., de Salvio, A., Eds.; Macmillan Company: London, UK, 1638. [Google Scholar]

- Evans, H.E.; Heiser, J.B. What’s inside: Anatomy and physiology. In The Cornell Lab of Ornithology’s Handbook of Bird Biology; Podulka, S., Rohrbaugh, R.W., Bonney, R., Eds.; Wiley-Blackwell: Hoboken, NJ, USA, 2004. [Google Scholar]

- Andersen, O.; Waag, U.; Schneider, L.; Stephani, G.; Kieback, B. Novel Metallic Hollow Sphere Structures. Adv. Eng. Mater. 2000, 4, 192–195. [Google Scholar] [CrossRef]

- Lim, T.-J.; Smith, B.; McDowell, D.L. Behavior of a random hollow sphere metal foam. Acta Mater. 2002, 50, 2867–2879. [Google Scholar] [CrossRef]

- Sanders, W.S.; Gibson, L.J. Mechanics of hollow sphere foams. Mater. Sci. Eng. A 2003, 347, 70–85. [Google Scholar] [CrossRef]

- Schnellenbach-Held, M.; Pfeffer, K. Punching Behavior of Biaxial Hollow Slabs. Cem. Concr. Compos. 2002, 24, 551–556. [Google Scholar] [CrossRef]

- Schnellenbach-Held, M.; Pfeffer, K. Punching shear capacity of biaxial hollow slabs. In Proceedings of the International Workshop on Punching Shear Capacity of RC Slabs; Royal Institute of Technology: Stockholm, Sweden, 2000; Volume 9, pp. 423–430. [Google Scholar]

- Chen, P.-S.; Tsukinaga, Y. Basic Research on the Development of Light Weight Concrete Mixed With Hollow Spheres. J. Soc. Mater. Sci. Jpn. 2015, 64, 711–717. [Google Scholar] [CrossRef] [Green Version]

- Yoshiji, N.; Wataru, K.; Koji, N. Failure Processes of Concrete under Triaxial Compressive Stress. Proc. Jpn. Soc. Civ. Eng. 1971, 185, 31–41. Available online: https://www.jstage.jst.go.jp/article/jscej1969/1971/185/1971_185_31/_pdf (accessed on 28 June 2021).

- Yoshio, K.; Yasuo, T.; Fukuo, O. Compressive Strength of Concrete with Cubic Aggregate of Cement Mortar. In Summaries of Technical Papers of Annual Meeting Architectural Institute of Japan; Architectural Institute of Japan: Tokyo, Japan, 1971; pp. 41–46. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, H.; Gao, H.; He, Y.; Jiang, M. Effect of bubble feature parameters on rheological properties of fresh concrete. Constr. Build. Mater. 2019, 196, 245–255. [Google Scholar] [CrossRef]

- Dils, J.; Boel, V.; De Schutter, G. Influence of cement type and mixing pressure on air content, rheology and mechanical properties of U.H.P.C. Constr. Build. Mater. 2013, 41, 455–463. [Google Scholar] [CrossRef]

- Kwan, A.K.H.; Li, L.G. Combined effects of water film, paste film and mortar film thicknesses on fresh properties of concrete. Constr. Build. Mater. 2014, 50, 598–608. [Google Scholar] [CrossRef]

- Japanese Industrial Standard (JIS). 2018; JIS A 1108. Available online: https://webdesk.jsa.or.jp/preview/pre_jis_a_01108_000_000_2018_j_ed10_ch.pdf (accessed on 28 June 2021).

| Type | Type-A | Type-B | Type-C | Type-D (Conventional Concrete) | |

|---|---|---|---|---|---|

| Depression | 2mm | A2-1 | B2-1 | C2-1 | D-1 D-2 D-3 |

| A2-2 | B2-2 | C2-2 | |||

| 3mm | A3.5-1 | B3.5-1 | C3.5-1 | ||

| A3.5-2 | B3.5-2 | C3.5-2 | |||

| Number of specimens | 4 | 4 | 4 | 3 | |

| Type | Diameter (mm) | Thickness (mm) | Sphere Number | Specimen Number |

|---|---|---|---|---|

| M50-20 | 48.6 | 2.3 | 18 | 3 |

| M50-40 | 48.6 | 2.3 | 27 | 3 |

| M60-8 | 60.5 | 2.3 | 8 | 3 |

| M60-12 | 60.5 | 2.3 | 12 | 3 |

| M60-16 | 60.5 | 2.3 | 15 | 3 |

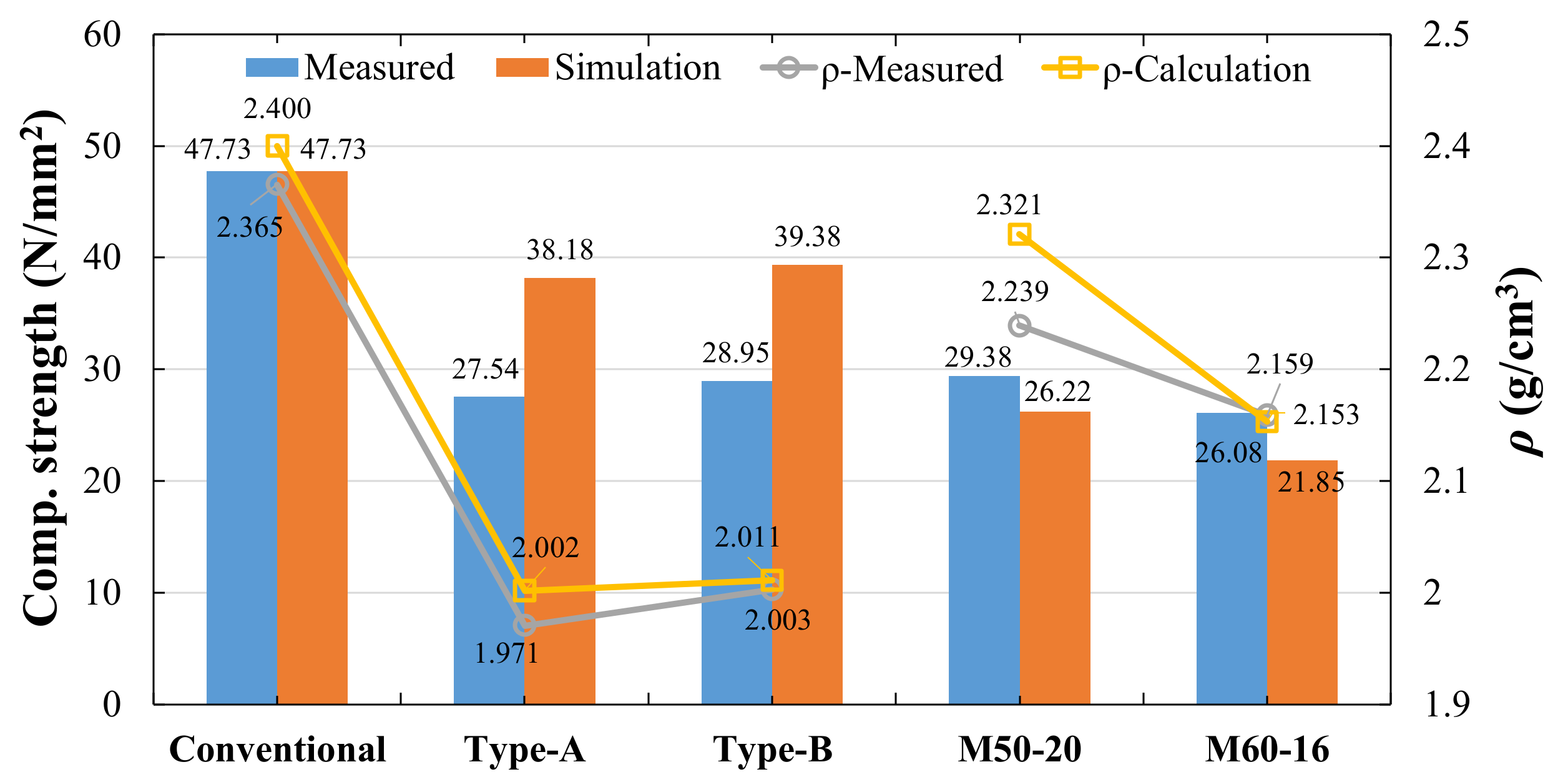

| Type | Density (g/cm3) | Average Strength (N/mm2) | Simulation Strength (N/mm2) |

|---|---|---|---|

| Steel sphere | 2.138–2.239 (91.0–95.3%) | 20.372–29.382 (46.6–67.2%) | 21.850–36.053 (50.0–82.5%) |

| Cubic concave body | 2.019–2.221 (88.9–97.7%) | 13.317–22.805 (35.7–61.2%) | 14.904–26.082 (40.0–70.0%) |

| Fixed position | 1.971–2.003 (83.3–84.7%) | 27.536–28.954 (57.7–60.7%) | 38.184–39.377 (80.0–82.5%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, X.; Chen, P.-S.; Al-Fakih, A.; Liu, B.; Mohammed, B.S.; Jin, J. Experiments and Mechanical Simulation on Bubble Concrete: Studies on the Effects of Shape and Position of Hollow Bodies Mixed in Concrete. Crystals 2021, 11, 858. https://doi.org/10.3390/cryst11080858

Yan X, Chen P-S, Al-Fakih A, Liu B, Mohammed BS, Jin J. Experiments and Mechanical Simulation on Bubble Concrete: Studies on the Effects of Shape and Position of Hollow Bodies Mixed in Concrete. Crystals. 2021; 11(8):858. https://doi.org/10.3390/cryst11080858

Chicago/Turabian StyleYan, Xiangdong, Pei-Shan Chen, Amin Al-Fakih, Baoxin Liu, Bashar S. Mohammed, and Jialiang Jin. 2021. "Experiments and Mechanical Simulation on Bubble Concrete: Studies on the Effects of Shape and Position of Hollow Bodies Mixed in Concrete" Crystals 11, no. 8: 858. https://doi.org/10.3390/cryst11080858

APA StyleYan, X., Chen, P.-S., Al-Fakih, A., Liu, B., Mohammed, B. S., & Jin, J. (2021). Experiments and Mechanical Simulation on Bubble Concrete: Studies on the Effects of Shape and Position of Hollow Bodies Mixed in Concrete. Crystals, 11(8), 858. https://doi.org/10.3390/cryst11080858