Investigating the Interaction between Persistent Slip Bands and Surface Hard Coatings via Crystal Plasticity Simulations

Abstract

1. Introduction

2. Computational Methods

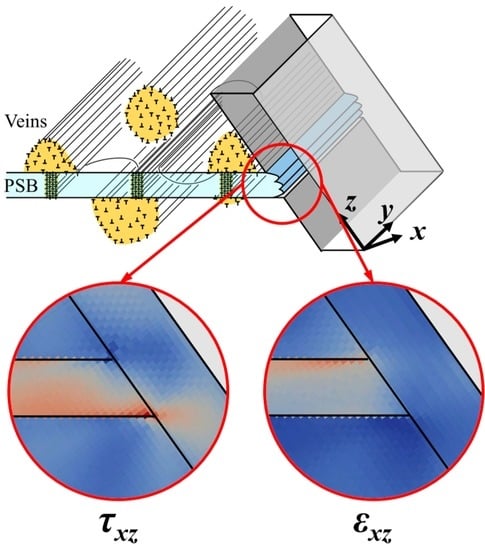

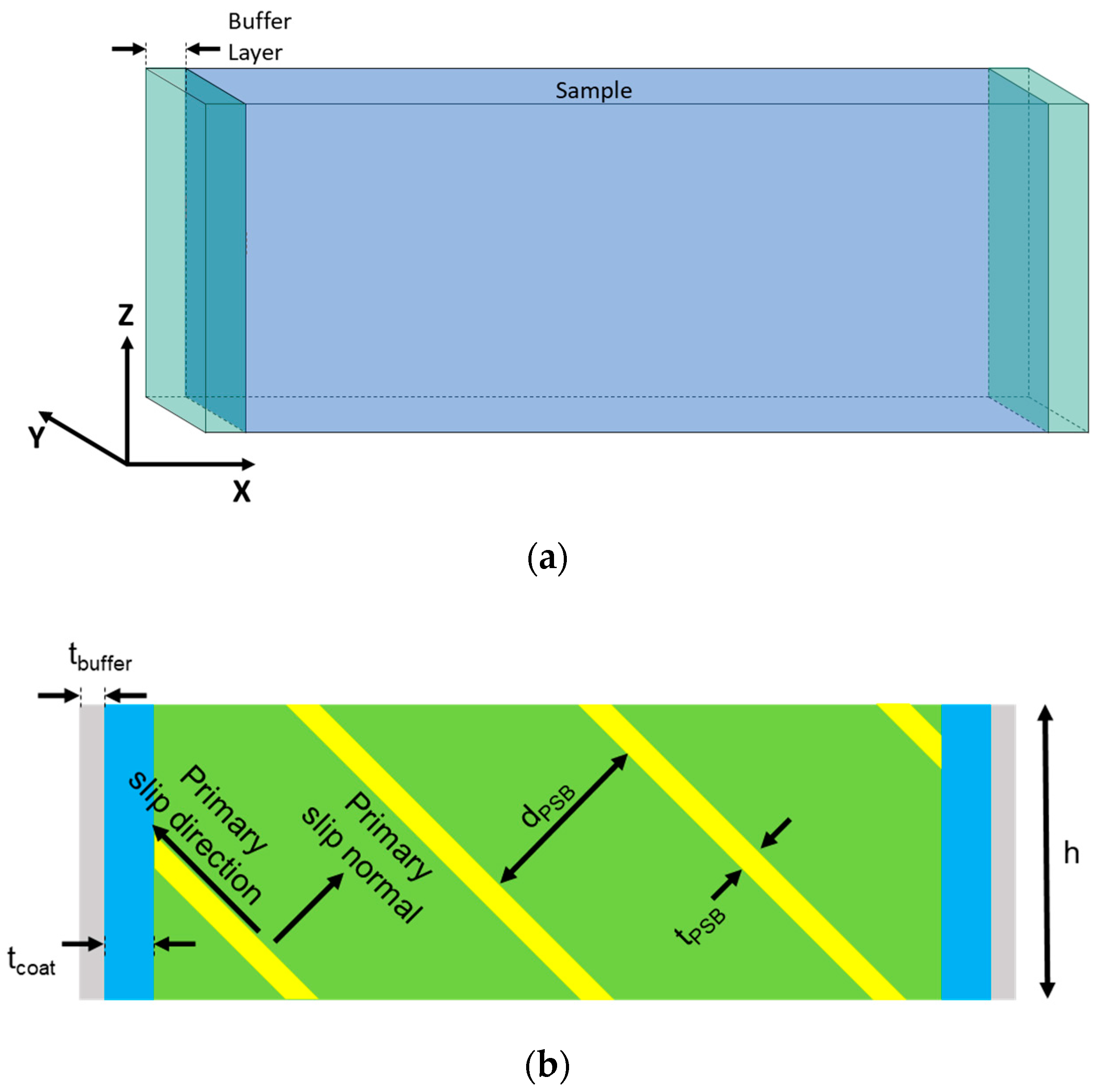

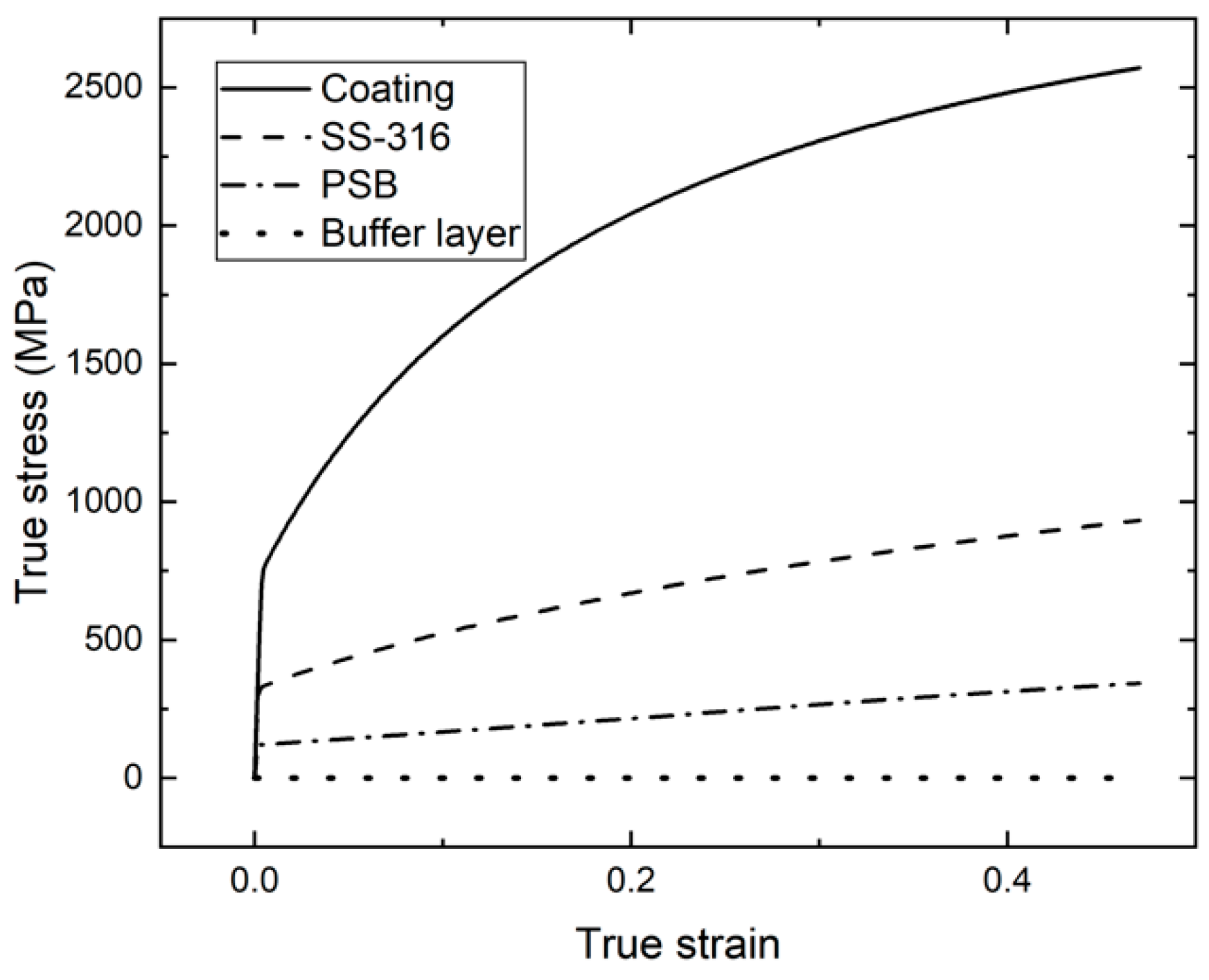

2.1. Model Setup

2.2. Post-Processing

3. Results and Discussion

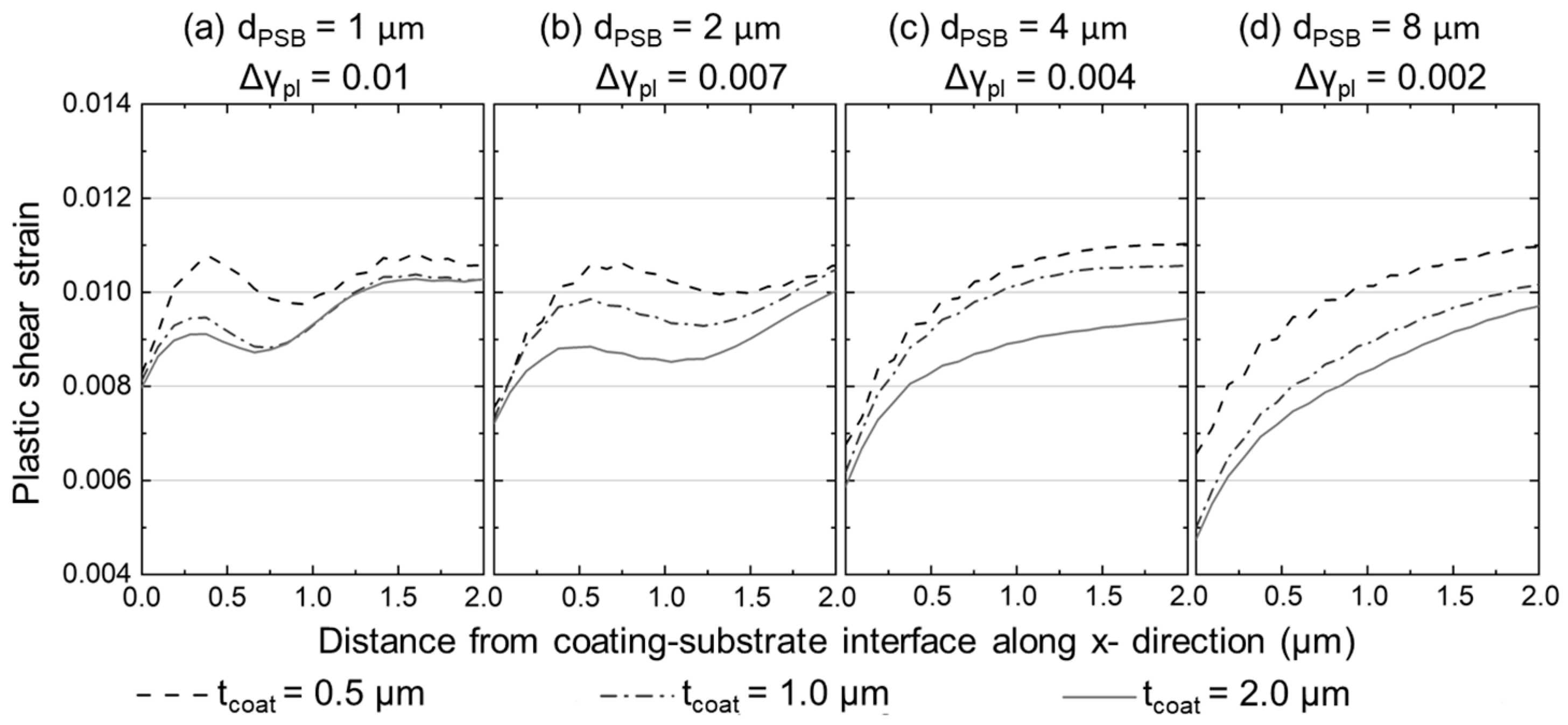

3.1. Suppressive Effects of the Coating on the Operation of PSBs (Distribution of Plastic Shear Strain in the PSBs)

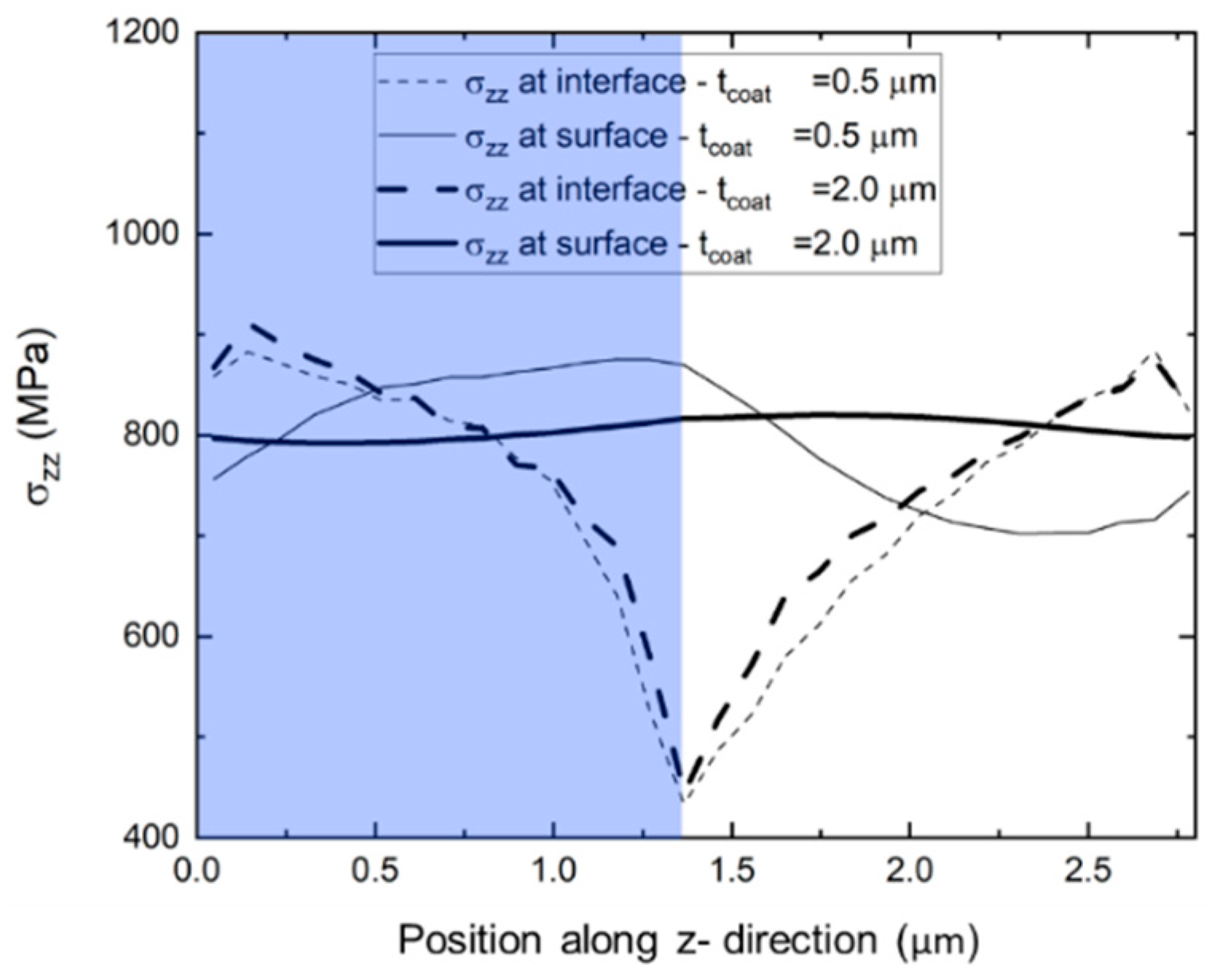

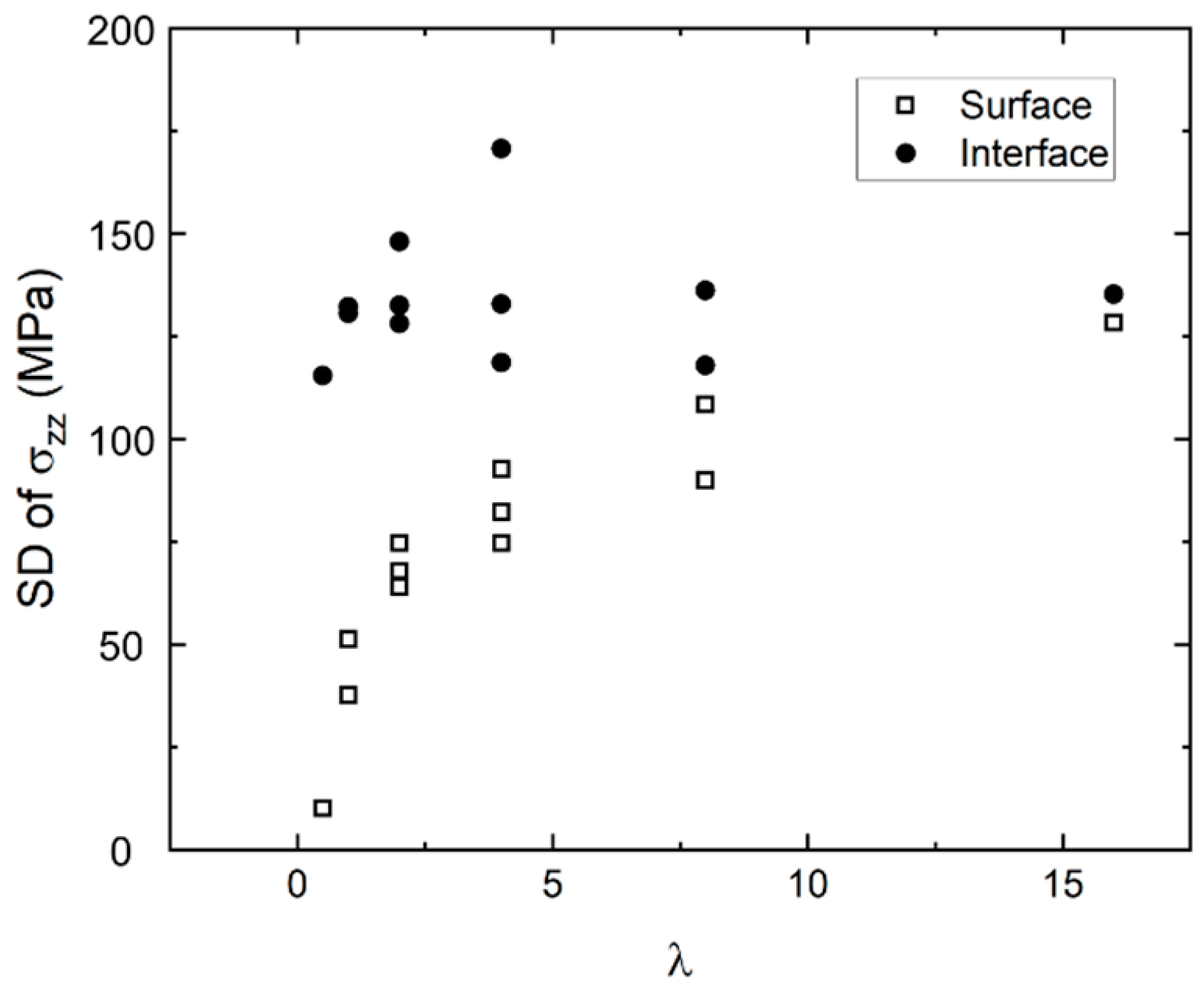

3.2. Fracture Tendency within the Coatings (Distribution of σzz in the Coatings)

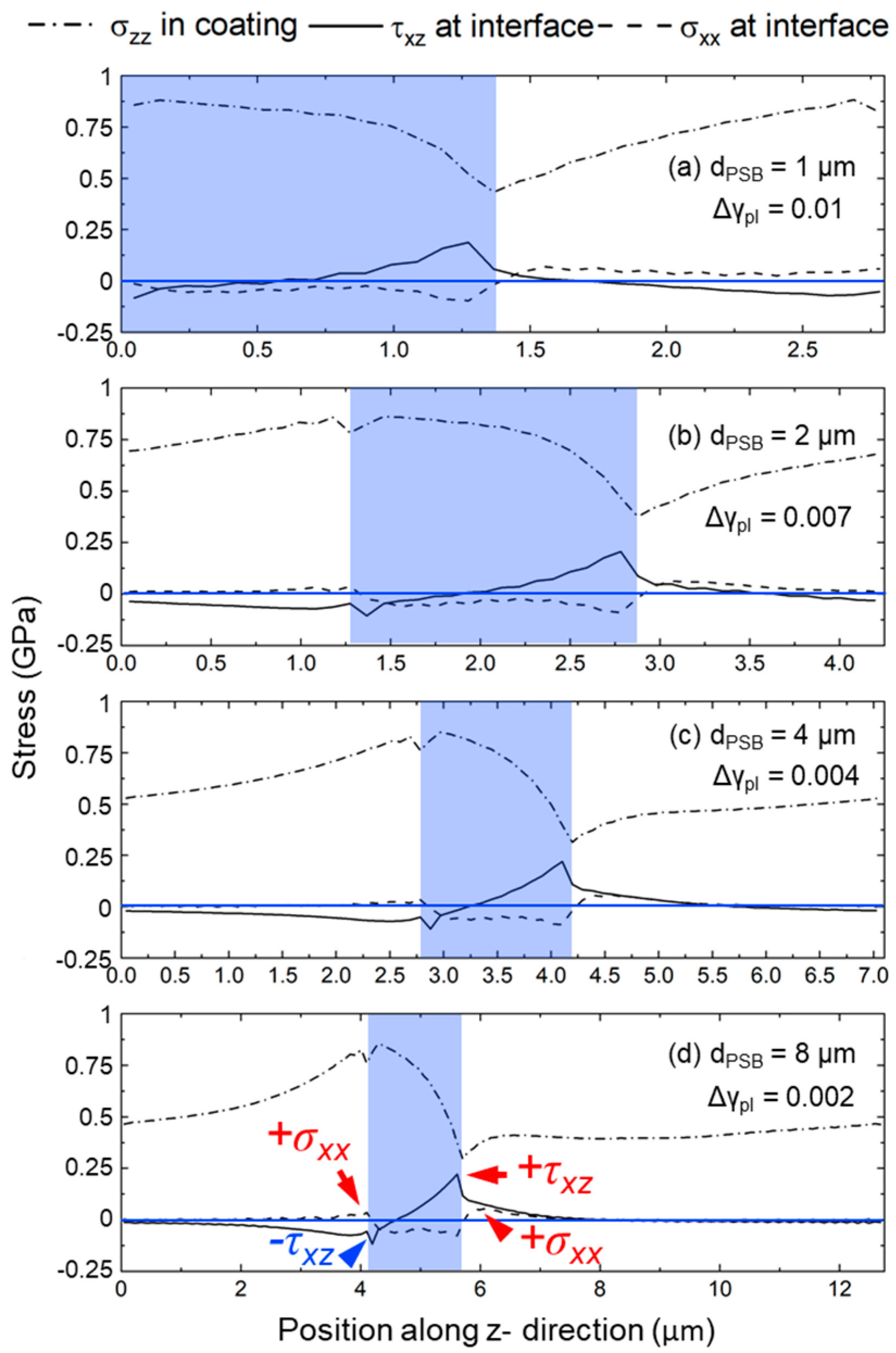

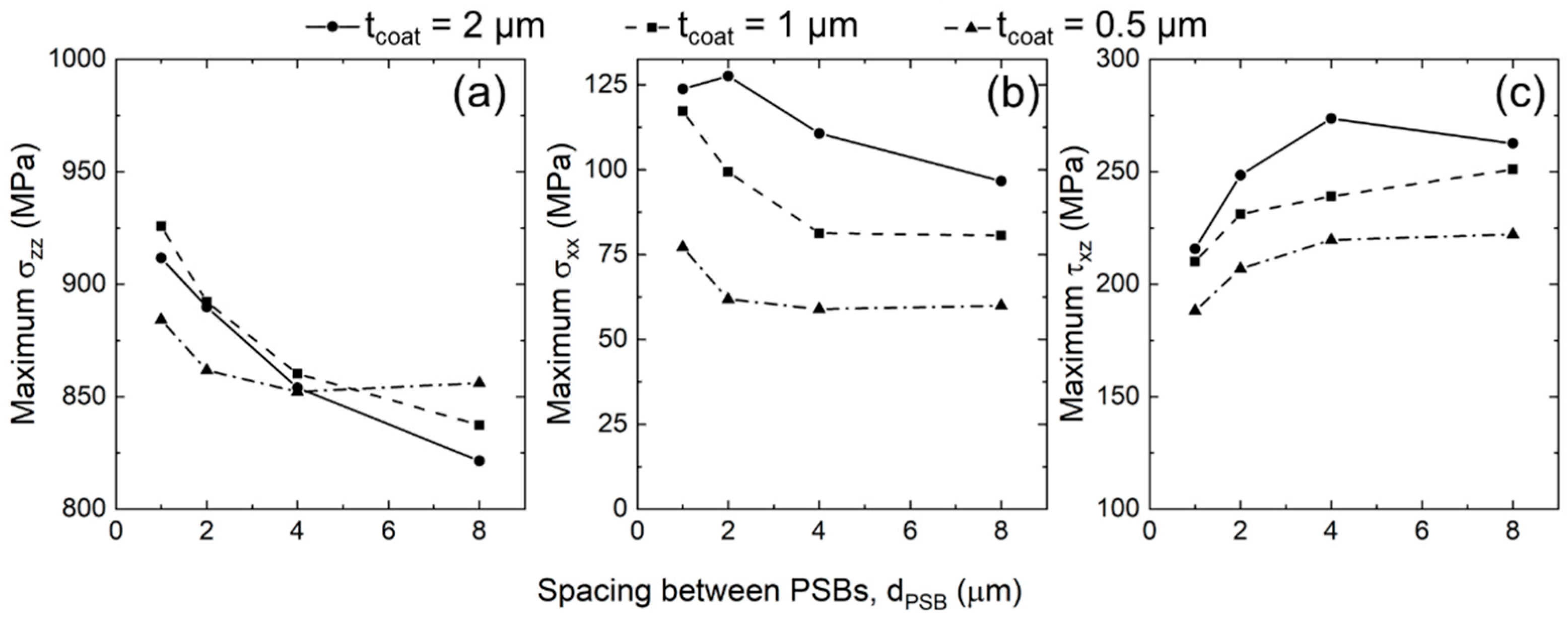

3.3. Delamination Tendency at the Coating–Substrate Interface

4. Conclusions

- (1)

- Assuming a perfect coating–substrate adhesion and the absence of coating fracture, thicker coatings offered better suppression against the plastic shear deformation of the PSBs.

- (2)

- The suppression effects of the coatings were attenuated at higher applied plastic shear strains (higher PSB densities).

- (3)

- The distribution of the normal stress parallel to the loading direction in thinner coatings was highly heterogeneous and was strongly affected by the PSBs. However, the distribution of this stress was much more uniform for thicker coatings.

- (4)

- The interfacial shear stress parallel to the loading direction and the interfacial normal stress perpendicular to the interface increased significantly with increasing coating thickness, which can potentially result in delamination.

- (5)

- The peak values of the stresses mentioned in Conclusions (3) and (4) varied differently with increasing applied strains due to the superposition of the stress fields caused by the neighboring PSB–coating interactions.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ewing, J.A.; Humfrey, J.C.W. The Fracture of Metals under Repeated Alternations of Stress. Philos. Trans. R. Soc. A 1903, 200, 241–250. [Google Scholar] [CrossRef]

- Stephens, R.I.; Fatemi, A.; Stephens, R.R.; Fuchs, H.O. Metal Fatigue in Engineering, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2000; ISBN 978-0-471-51059-8. [Google Scholar]

- Thompson, N.; Wadsworth, N.; Louat, N. Xi. The origin of fatigue fracture in copper. Philos. Mag. 1956, 1, 113–126. [Google Scholar] [CrossRef]

- Dodaran, M.; Khonsari, M.M.; Shao, S. Critical operating stress of persistent slip bands in Cu. Comput. Mater. Sci. 2019, 165, 114–120. [Google Scholar] [CrossRef]

- Kuhlmann-Wilsdorf, D.; Laird, C. Dislocation behavior in fatigue. Mater. Sci. Eng. 1977, 27, 137–156. [Google Scholar] [CrossRef]

- Kuhlmann-Wilsdorf, D. Theory of plastic deformation—Properties of low energy dislocation structures. Mater. Sci. Eng. A 1989, 113, 1–41. [Google Scholar] [CrossRef]

- Neumann, P. Low energy dislocation configurations: A possible key to the understanding of fatigue. Mater. Sci. Eng. 1986, 81, 465–475. [Google Scholar] [CrossRef]

- Mughrabi, H. The cyclic hardening and saturation behaviour of copper single crystals. Mater. Sci. Eng. 1978, 33, 207–223. [Google Scholar] [CrossRef]

- Hancock, J.; Grosskreutz, J. Mechanisms of fatigue hardening in copper single crystals. Acta Metall. 1969, 17, 77–97. [Google Scholar] [CrossRef]

- Castelluccio, G.M.; Musinski, W.D.; McDowell, D.L. Computational micromechanics of fatigue of microstructures in the HCF–VHCF regimes. Int. J. Fatigue 2016, 93, 387–396. [Google Scholar] [CrossRef]

- Mughrabi, H.; Wang, R.; Differt, K.; Essmann, U. Fatigue Crack Initiation by Cyclic Slip Irreversibilities in High-Cycle Fatigue. In Fatigue Mechanisms: Advances in Quantitative Measurement of Physical Damage; ASTM International: West Conshohocken, PA, USA, 1983; Volume 5, pp. 35–41. [Google Scholar]

- Mughrabi, H. Cyclic Slip Irreversibilities and the Evolution of Fatigue Damage. Metall. Mater. Trans. A 2009, 40, 1257–1279. [Google Scholar] [CrossRef]

- Man, J.; Obrtlík, K.; Polák, J. Extrusions and intrusions in fatigued metals. Part 1. State of the art and history†. Philos. Mag. 2009, 89, 1295–1336. [Google Scholar] [CrossRef]

- Man, J.; Klapetek, P.; Man, O.; Weidner†, A.; Obrtlík, K.; Polák, J. Extrusions and intrusions in fatigued metals. Part 2. AFM and EBSD study of the early growth of extrusions and intrusions in 316L steel fatigued at room temperature. Philos. Mag. 2009, 89, 1337–1372. [Google Scholar] [CrossRef]

- Basinski, Z.S.; Pascual, R.; Basinski, S.J. Low amplitude fatigue of copper single crystals—I. The role of the surface in fatigue failure. Acta Metall. 1983, 31, 591–602. [Google Scholar] [CrossRef]

- Soyama, H.; Chighizola, C.R.; Hill, M.R. Effect of compressive residual stress introduced by cavitation peening and shot peening on the improvement of fatigue strength of stainless steel. J. Mater. Process. Technol. 2021, 288, 116877. [Google Scholar] [CrossRef]

- Lee, C.M.; Chu, J.P.; Chang, W.Z.; Lee, J.W.; Jang, J.S.C.; Liaw, P.K. Fatigue property improvements of Ti–6Al–4V by thin film coatings of metallic glass and TiN: A comparison study. Thin Solid Films 2014, 561, 33–37. [Google Scholar] [CrossRef]

- Bagherifard, S.; Fernández Pariente, I.; Ghelichi, R.; Guagliano, M. Fatigue properties of nanocrystallized surfaces obtained by high energy shot peening. Procedia Eng. 2010, 2, 1683–1690. [Google Scholar] [CrossRef][Green Version]

- Zhang, B.; Haghshenas, A.; Zhang, X.; Zhao, J.; Shao, S.; Khonsari, M.M.; Guo, S.; Meng, W.J. On the failure mechanisms of Cr-coated 316 stainless steel in bending fatigue tests. Int. J. Fatigue 2020, 139, 105733. [Google Scholar] [CrossRef]

- Yu, C.-C.; Chu, J.P.; Jia, H.; Shen, Y.-L.; Gao, Y.; Liaw, P.K.; Yokoyama, Y. Influence of thin-film metallic glass coating on fatigue behavior of bulk metallic glass: Experiments and finite element modeling. Mater. Sci. Eng. A 2017, 692, 146–155. [Google Scholar] [CrossRef]

- Tsai, P.H.; Li, T.H.; Hsu, K.T.; Ke, J.H.; Jang, J.S.C.; Chu, J.P. Coating thickness effect of metallic glass thin film on the fatigue-properties improvement of 7075 aluminum alloy. Thin Solid Films 2019, 677, 68–72. [Google Scholar] [CrossRef]

- Su, Y.L.; Yao, S.H.; Wei, C.S.; Kao, W.H.; Wu, C.T. Influence of single- and multilayer TiN films on the axial tension and fatigue performance of AISI 1045 steel. Thin Solid Films 1999, 338, 177–184. [Google Scholar] [CrossRef]

- Zhou, Y.; Rao, G.B.; Wang, J.Q.; Zhang, B.; Yu, Z.M.; Ke, W.; Han, E.H. Influence of Ti/TiN bilayered and multilayered films on the axial fatigue performance of Ti46Al8Nb alloy. Thin Solid Films 2011, 519, 2207–2212. [Google Scholar] [CrossRef]

- Wang, Y.M.; Zhang, P.F.; Guo, L.X.; Ouyang, J.H.; Zhou, Y.; Jia, D.C. Effect of microarc oxidation coating on fatigue performance of Ti–Al–Zr alloy. Appl. Surf. Sci. 2009, 255, 8616–8623. [Google Scholar] [CrossRef]

- Du, D.; Liu, D.; Ye, Z.; Zhang, X.; Li, F.; Zhou, Z.; Yu, L. Fretting wear and fretting fatigue behaviors of diamond-like carbon and graphite-like carbon films deposited on Ti-6Al-4V alloy. Appl. Surf. Sci. 2014, 313, 462–469. [Google Scholar] [CrossRef]

- Stoudt, M.; Ricker, R.; Cammarata, R. The influence of a multilayered metallic coating on fatigue crack nucleation. Int. J. Fatigue 2001, 23, 215–223. [Google Scholar] [CrossRef]

- Akebono, H.; Komotori, J.; Suzuki, H. The Effect of coating thickness on fatigue properties of steel thermally sprayed with ni -based self-fluxing alloy. Int. J. Mod. Phys. B 2006, 20, 3599–3604. [Google Scholar] [CrossRef]

- Sangid, M.D.; Maier, H.J.; Sehitoglu, H. A physically based fatigue model for prediction of crack initiation from persistent slip bands in polycrystals. Acta Mater. 2011, 59, 328–341. [Google Scholar] [CrossRef]

- Sangid, M.D. The physics of fatigue crack initiation. Int. J. Fatigue 2013, 57, 58–72. [Google Scholar] [CrossRef]

- Roters, F.; Diehl, M.; Shanthraj, P.; Eisenlohr, P.; Reuber, C.; Wong, S.L.; Maiti, T.; Ebrahimi, A.; Hochrainer, T.; Fabritius, H.-O.; et al. DAMASK—The Düsseldorf Advanced Material Simulation Kit for modeling multi-physics crystal plasticity, thermal, and damage phenomena from the single crystal up to the component scale. Comput. Mater. Sci. 2019, 158, 420–478. [Google Scholar] [CrossRef]

- Eisenlohr, P.; Diehl, M.; Lebensohn, R.A.; Roters, F. A spectral method solution to crystal elasto-viscoplasticity at finite strains. Int. J. Plast. 2013, 46, 37–53. [Google Scholar] [CrossRef]

- Shanthraj, P.; Eisenlohr, P.; Diehl, M.; Roters, F. Numerically robust spectral methods for crystal plasticity simulations of heterogeneous materials. Int. J. Plast. 2015, 66, 31–45. [Google Scholar] [CrossRef]

- Pokharel, R.; Lind, J.; Kanjarla, A.K.; Lebensohn, R.A.; Li, S.F.; Kenesei, P.; Suter, R.M.; Rollett, A.D. Polycrystal Plasticity: Comparison Between Grain—Scale Observations of Deformation and Simulations. Annu. Rev. Condens. Matter Phys. 2014, 5, 317–346. [Google Scholar] [CrossRef]

- Dodaran, M.; Wang, J.; Chen, Y.; Meng, W.J.; Shao, S. Energetic, structural and mechanical properties of terraced interfaces. Acta Mater. 2019, 171. [Google Scholar] [CrossRef]

- Lavenstein, S.; Gu, Y.; Madisetti, D.; El-Awady, J.A. The heterogeneity of persistent slip band nucleation and evolution in metals at the micrometer scale. Science 2020, 370, eabb2690. [Google Scholar] [CrossRef]

- Palmer, S.B.; Lee, E.W. The elastic constants of chromium. Philos. Mag. A J. Theor. Exp. Appl. Phys. 1971, 24, 311–318. [Google Scholar] [CrossRef]

- Dodaran, M.; Ettefagh, A.H.; Guo, S.M.; Khonsari, M.M.; Meng, W.J.; Shamsaei, N.; Shao, S. Effect of alloying elements on the γ’ antiphase boundary energy in Ni-base superalloys. Intermetallics 2020, 117. [Google Scholar] [CrossRef]

- Bolef, D.I.; de Klerk, J. Anomalies in the Elastic Constants and Thermal Expansion of Chromium Single Crystals. Phys. Rev. 1963, 129, 1063–1067. [Google Scholar] [CrossRef]

- Kweon, H.D.; Kim, J.W.; Song, O.; Oh, D. Determination of true stress-strain curve of type 304 and 316 stainless steels using a typical tensile test and finite element analysis. Nucl. Eng. Technol. 2020. [Google Scholar] [CrossRef]

- Zhang, X.; Mu, Y.; Dodaran, M.; Shao, S.; Moldovan, D.; Meng, W.J. Mechanical failure of CrN/Cu/CrN interfacial regions under tensile loading. Acta Mater. 2018, 160, 1–13. [Google Scholar] [CrossRef]

- Zhang, B.; Dodaran, M.; Ahmed, S.; Shao, S.; Meng, W.J.; Juul, K.J.; Nielsen, K.L. Grain-size affected mechanical response and deformation behavior in microscale reverse extrusion. Materialia 2019, 6. [Google Scholar] [CrossRef]

- Marin, E.B. On the Formulation of a Crystal Plasticity Model; Sandia National Laboratories: Albuquerque, NM, USA; Livermore, CA, USA, 2006. [Google Scholar]

- Lienert, U.; Han, T.-S.; Almer, J.; Dawson, P.R.; Leffers, T.; Margulies, L.; Nielsen, S.F.; Poulsen, H.F.; Schmidt, S. Investigating the effect of grain interaction during plastic deformation of copper. Acta Mater. 2004, 52, 4461–4467. [Google Scholar] [CrossRef]

- Tu, S.-T.; Zhang, X.-C. Fatigue Crack Initiation Mechanisms. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Diehl, M. A Spectral Method Using Fast Fourier Transform To Solve Elastoviscoplastic Mechanical Boundary Value Problems; TU München: München, Germany, 2010. [Google Scholar]

- Ahrens, J.; Geveci, B.; Law, C. ParaView: An End-User Tool for Large-Data Visualization. In Visualization Handbook; Elsevier: Amsterdam, The Netherlands, 2005; pp. 717–731. [Google Scholar]

- Fatemi, A.; Socie, D.F. A critical plane approach to multiaxial fatigue damage including out-of-phase loading. Fatigue Fract. Eng. Mater. Struct. 1988, 11, 149–165. [Google Scholar] [CrossRef]

| tPSB (μm) | dPSB (μm) | |||

|---|---|---|---|---|

| 0.5 | 1 | 2 | 4 | 8 |

| 1 | 1 | 2 | 4 | 8 |

| 2 | 1 | 2 | 4 | 8 |

| Material | C11 (GPa) | C12 (GPa) | C44 (GPa) | 0 (1/sec) | n | ξ0 (MPa) | ξ∞ (MPa) | a | h0 (MPa) |

|---|---|---|---|---|---|---|---|---|---|

| SS 316 matrix | 207.0 | 133.0 | 117.0 | 0.001 | 20.0 | 115.0 | 430.0 | 2.25 | 50.0 |

| PSB primary | 207.0 | 133.0 | 117.0 | 0.001 | 50.0 | 40.0 1 | 400.0 1 | 2.25 | 50.0 |

| Material | C11 (GPa) | C12 (GPa) | 0 (1/sec) | M | n | ξ0 (MPa) | ξ∞ (MPa) | a | h0 (MPa) |

|---|---|---|---|---|---|---|---|---|---|

| Buffer | 20.0 | 10.0 | 0.1 | 3 | 5 | 3.0 | 6.3 | 2.5 | 7.5 |

| Coating | 279.0 | 115.0 | 0.001 | 30 | 20 | 20.0 1 | 100.0 1 | 2.5 | 18.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dodaran, M.S.; Wang, J.; Shamsaei, N.; Shao, S. Investigating the Interaction between Persistent Slip Bands and Surface Hard Coatings via Crystal Plasticity Simulations. Crystals 2020, 10, 1012. https://doi.org/10.3390/cryst10111012

Dodaran MS, Wang J, Shamsaei N, Shao S. Investigating the Interaction between Persistent Slip Bands and Surface Hard Coatings via Crystal Plasticity Simulations. Crystals. 2020; 10(11):1012. https://doi.org/10.3390/cryst10111012

Chicago/Turabian StyleDodaran, Mohammad S., Jian Wang, Nima Shamsaei, and Shuai Shao. 2020. "Investigating the Interaction between Persistent Slip Bands and Surface Hard Coatings via Crystal Plasticity Simulations" Crystals 10, no. 11: 1012. https://doi.org/10.3390/cryst10111012

APA StyleDodaran, M. S., Wang, J., Shamsaei, N., & Shao, S. (2020). Investigating the Interaction between Persistent Slip Bands and Surface Hard Coatings via Crystal Plasticity Simulations. Crystals, 10(11), 1012. https://doi.org/10.3390/cryst10111012