Crystallographic Orientation Dependence of Mechanical Responses of FeCrAl Micropillars

Abstract

:1. Introduction

2. Experimental Methods

2.1. Materials

2.2. Orientation Selection of Micro-Pillars

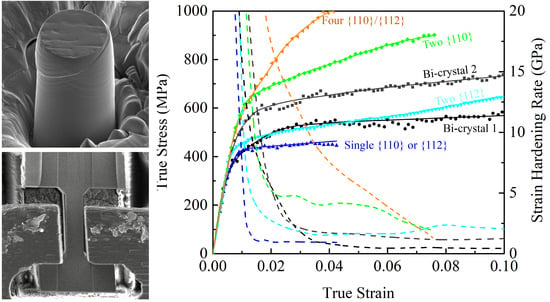

3. Results and Discussion

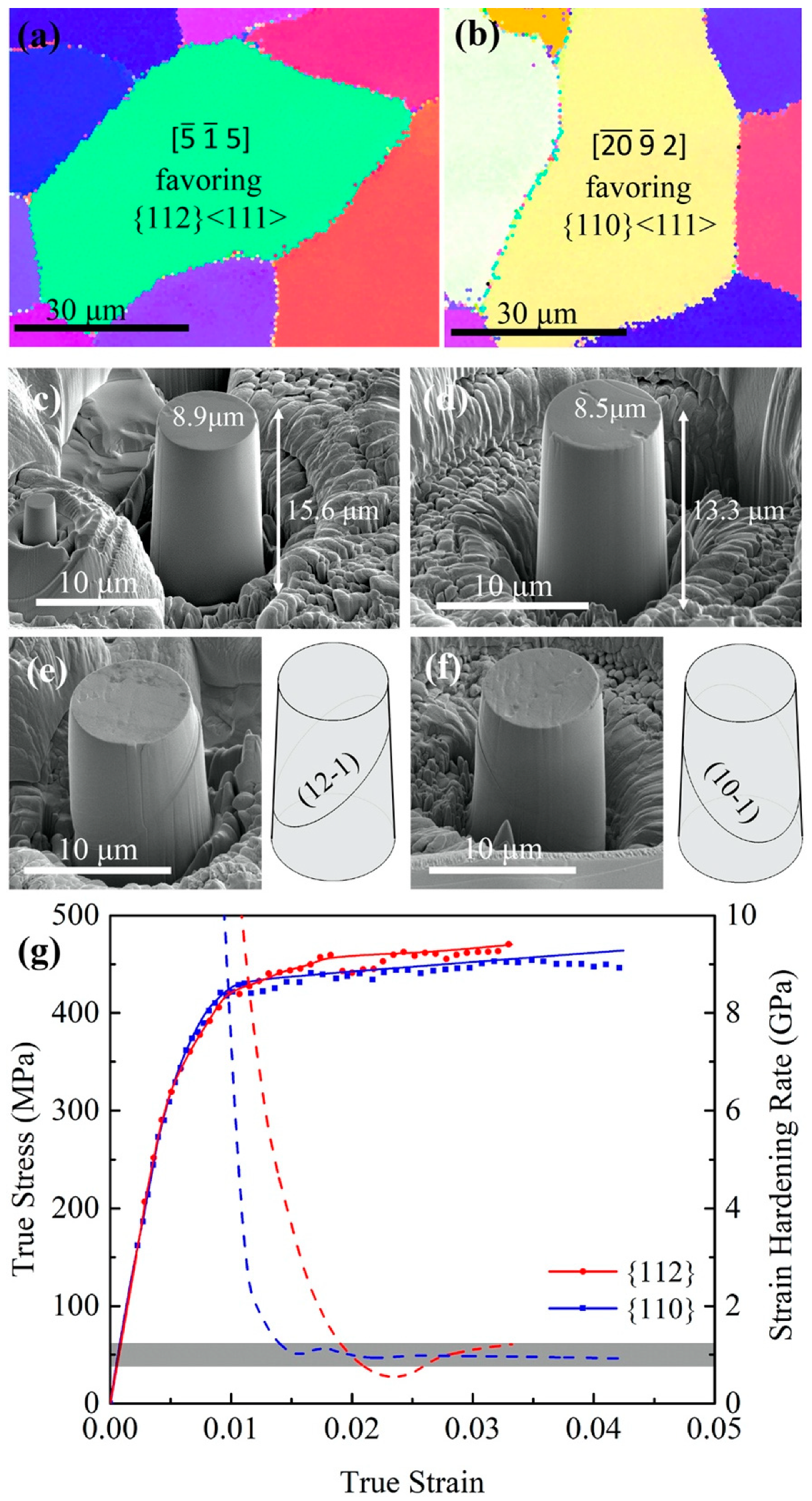

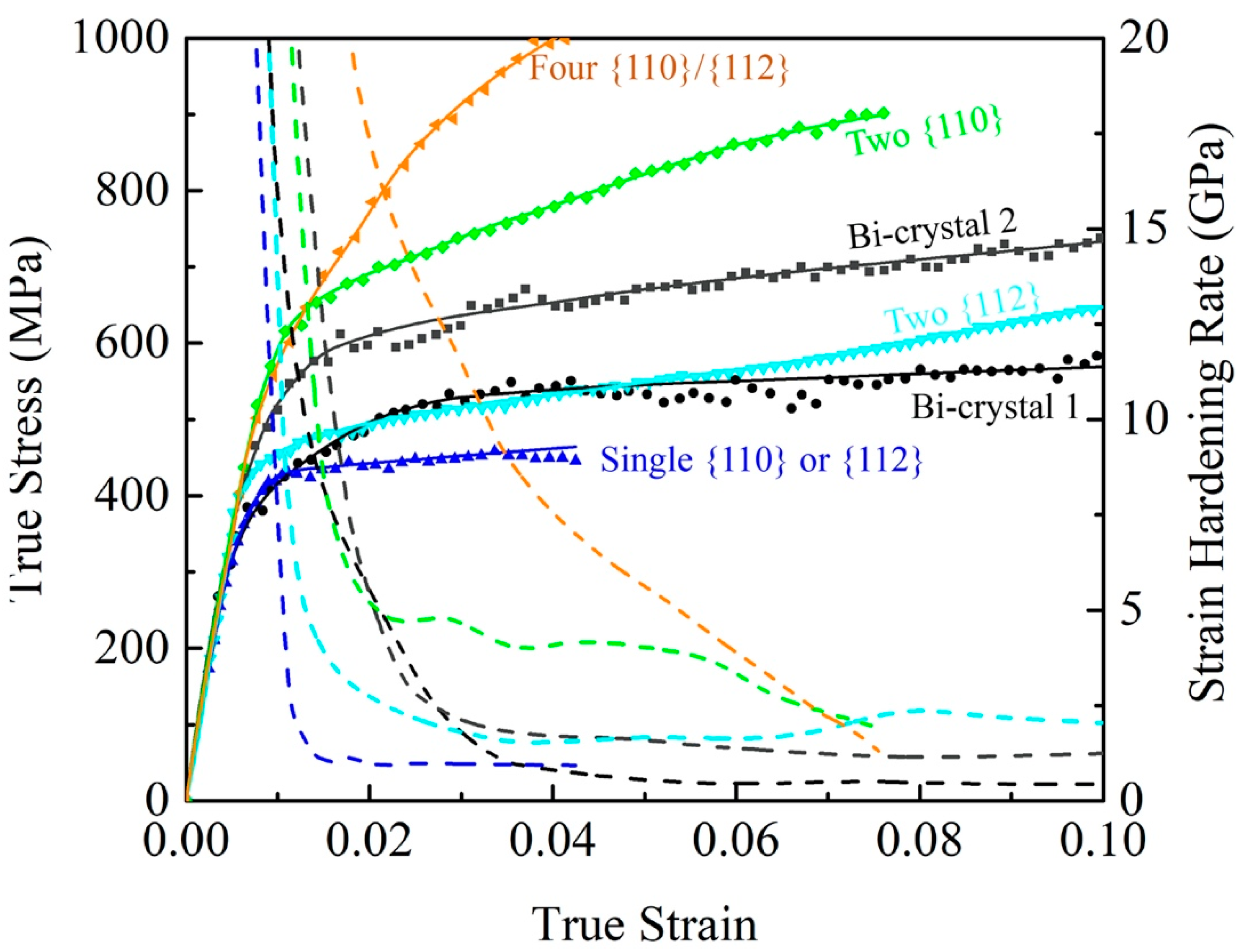

3.1. Weak Hardening Associated with One Activated Slip System

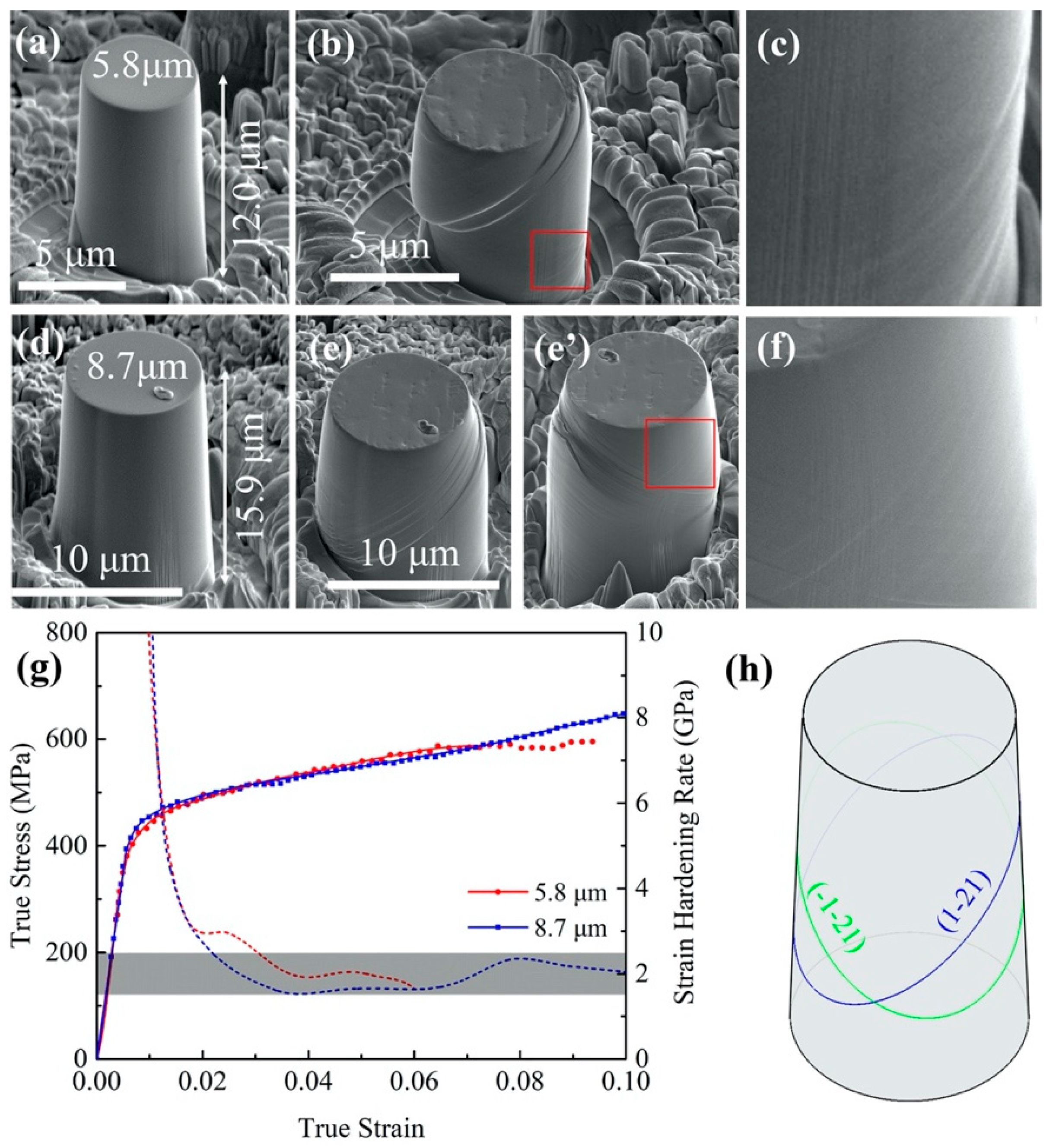

3.2. Intermediate Hardening Associated with Two Activated Slip Systems

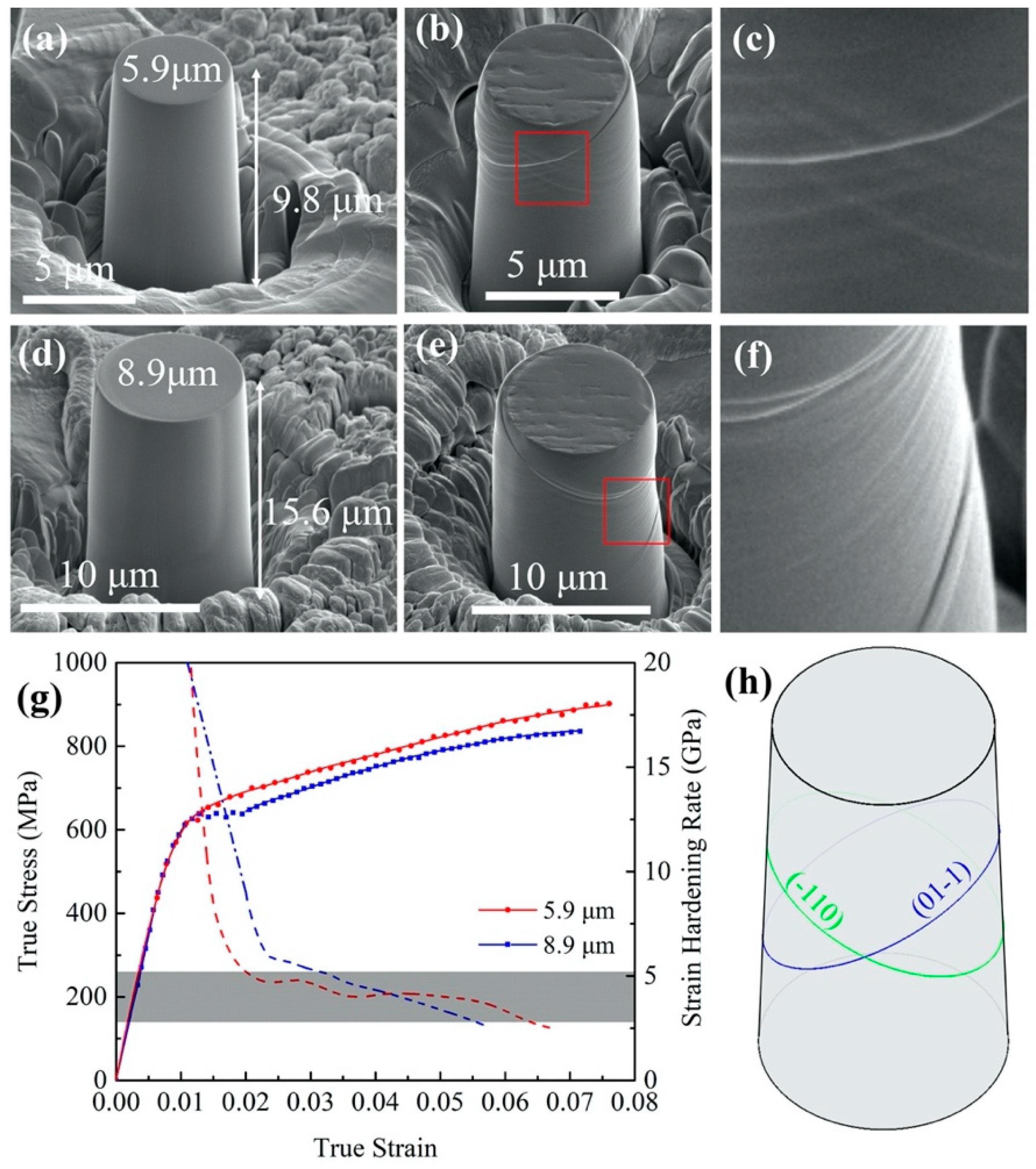

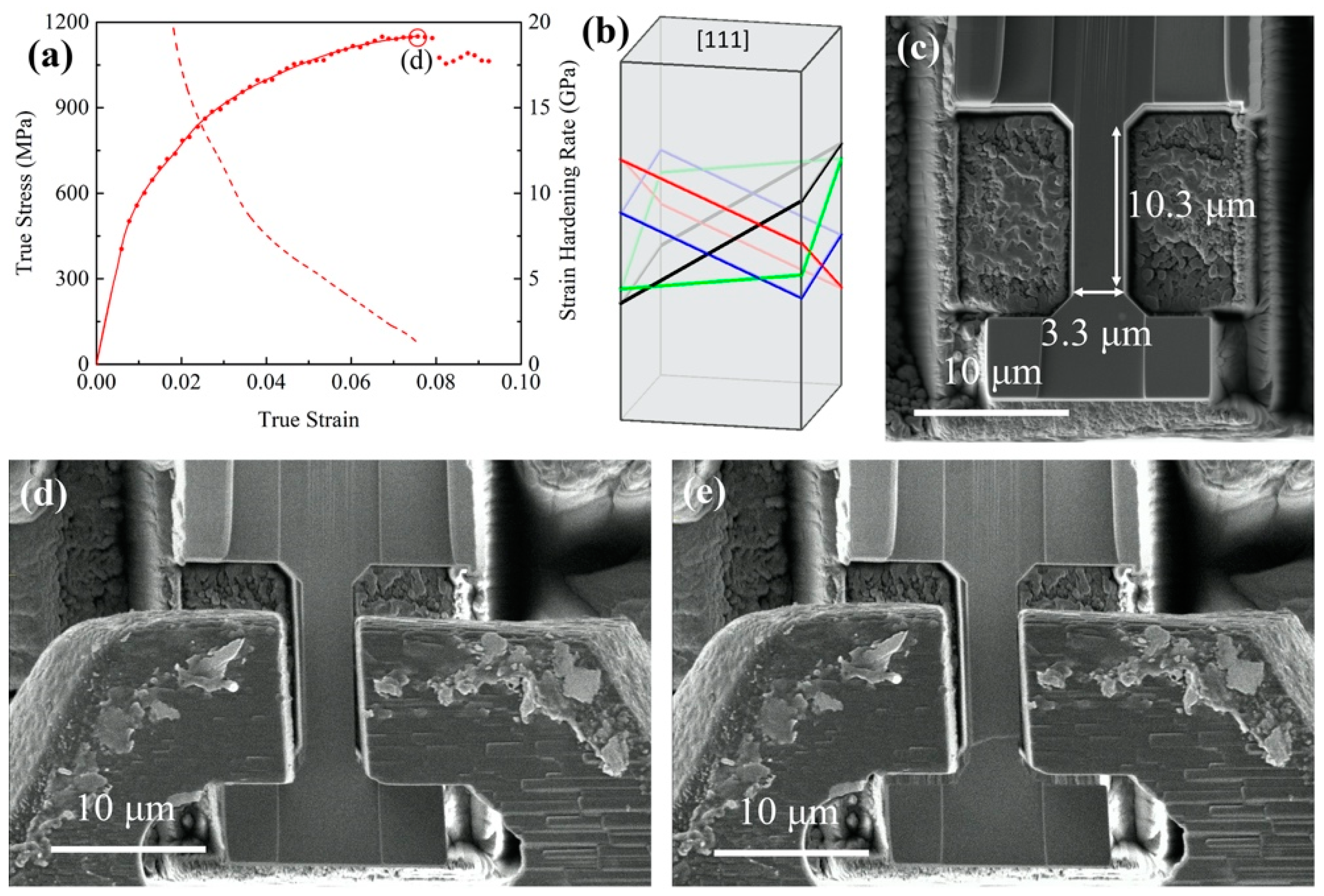

3.3. Strong Hardening Behaviors Associated with Multiple Activated Slip Systems

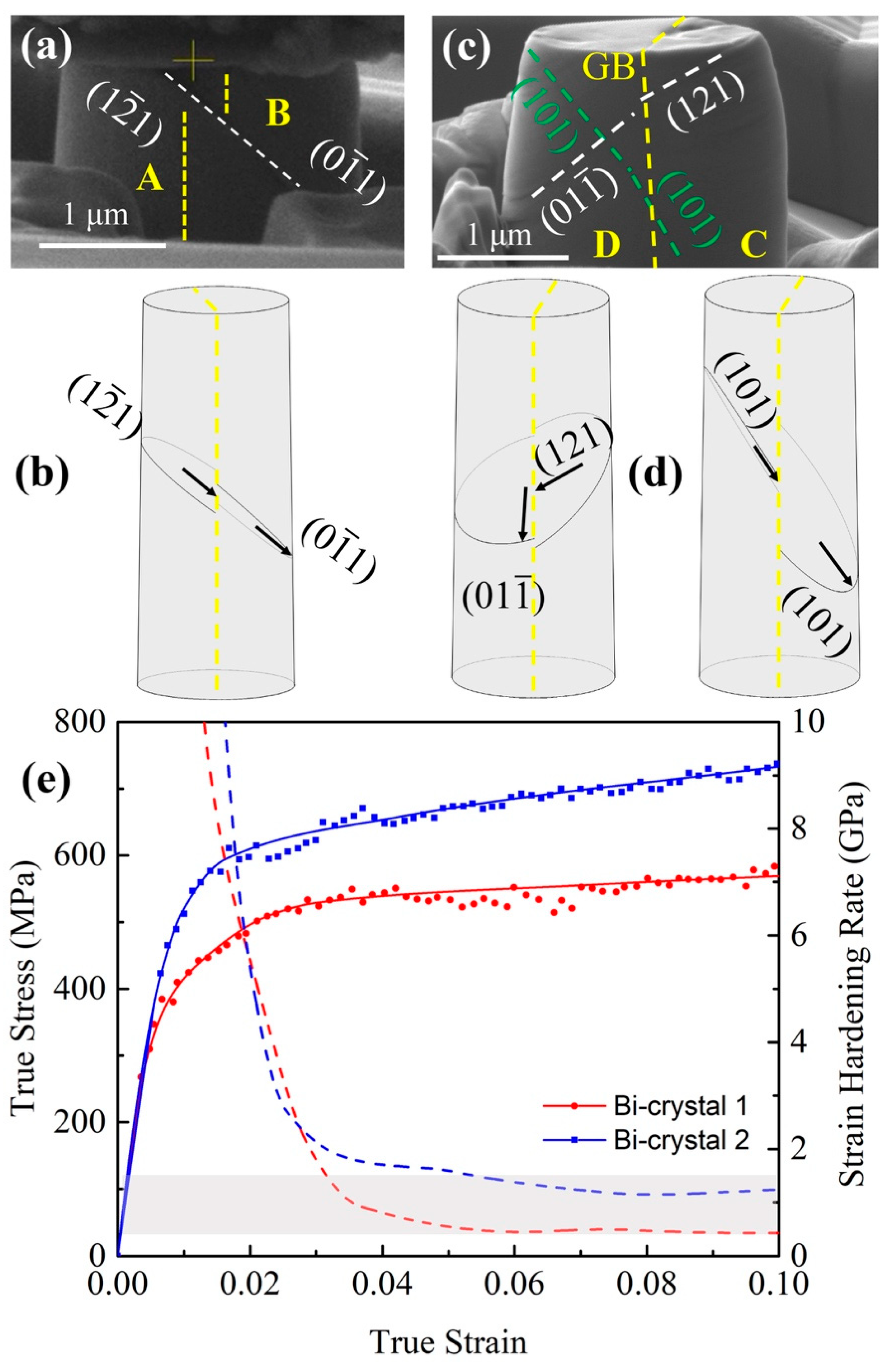

3.4. Grain Boundary Effects on Mechanical Behavior

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- He, Y.; Liu, J.; Han, Z.; Deng, Z.; Su, X.; Ji, Y. Phase transformation and precipitation during solidification of FeCrAl alloy for automobile exhaust gas purifying systems. J. Alloy. Comp. 2017, 714, 251–257. [Google Scholar] [CrossRef]

- Field, K.G.; Briggs, S.A.; Edmondson, P.D.; Haley, J.C.; Howard, R.H.; Hu, X.; Littrell, K.C.; Parish, C.M.; Yamamoto, Y. Database on Performance of Neutron Irradiated FeCrAl Alloys; Oak Ridge National Laboratory (ORNL): Oak Ridge, TN, USA, 2016.

- Du, C.; Maresca, F.; Geers, M.G.; Hoefnagels, J.P. Ferrite slip system activation investigated by uniaxial micro-tensile tests and simulations. Acta Mater. 2018, 146, 314–327. [Google Scholar] [CrossRef]

- Sun, Z.; Yamamoto, Y.; Chen, X. Impact toughness of commercial and model FeCrAl alloys. Mater. Sci. Eng. A 2018, 734, 93–101. [Google Scholar] [CrossRef]

- Peirce, D.; Asaro, R.J.; Needleman, A. An analysis of nonuniform and localized deformation in ductile single crystals. Acta Metal. 1982, 30, 1087–1119. [Google Scholar] [CrossRef]

- Follansbee, P.S.; Kocks, U.F. A constitutive description of the deformation of copper based on the use of the mechanical threshold stress as an internal state variable. Acta Metal. 1988, 36, 81–93. [Google Scholar] [CrossRef] [Green Version]

- Zerilli, F.J.; Armstrong, R.W. Dislocation-mechanics-based constitutive relations for material dynamics calculations. J. Appl. Phys. 1987, 61, 1816–1825. [Google Scholar] [CrossRef] [Green Version]

- Lee, M.G.; Lim, H.; Adams, B.L.; Hirth, J.P.; Wagoner, R.H. A dislocation density-based single crystal constitutive equation. Int. J. Plast. 2010, 26, 925–938. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; Tomé, C.N. A dislocation-based constitutive law for pure Zr including temperature effects. Int. J. Plast. 2008, 24, 867–895. [Google Scholar] [CrossRef]

- Bertin, N.; Capolungo, L.; Beyerlein, I.J. Hybrid dislocation dynamics based strain hardening constitutive model. Int. J. Plast. 2013, 49, 119–144. [Google Scholar] [CrossRef]

- Lin, Y.C.; Wen, D.-X.; Huang, Y.-C.; Chen, X.-M.; Chen, X.-W. A unified physically based constitutive model for describing strain hardening effect and dynamic recovery behavior of a Ni-based superalloy. J. Mater. Res. 2015, 30, 3784–3794. [Google Scholar] [CrossRef]

- Ma, A.; Roters, F.; Raabe, D. On the consideration of interactions between dislocations and grain boundaries in crystal plasticity finite element modeling—Theory, experiments, and simulations. Acta Mater. 2006, 54, 2181–2194. [Google Scholar] [CrossRef]

- Zaefferer, S. A study of active deformation systems in titanium alloys: Dependence on alloy composition and correlation with deformation texture. Mater. Sci. Eng. A 2003, 344, 20–30. [Google Scholar] [CrossRef]

- Li, H.; Mason, D.E.; Bieler, T.R.; Boehlert, C.J.; Crimp, M.A. Methodology for estimating the critical resolved shear stress ratios of α-phase Ti using EBSD-based trace analysis. Acta Mater. 2013, 61, 7555–7567. [Google Scholar] [CrossRef]

- Barkia, B.; Doquet, V.; Couzinié, J.P.; Guillot, I.; Héripré, E. In Situ monitoring of the deformation mechanisms in titanium with different oxygen contents. Mater. Sci. Eng. A 2015, 636, 91–102. [Google Scholar] [CrossRef]

- Wu, X.; Kalidindi, S.R.; Necker, C.; Salem, A.A. Prediction of crystallographic texture evolution and anisotropic stress-strain curves during large plastic strains in high purity α-titanium using a Taylor-type crystal plasticity model. Acta Mater. 2007, 55, 423–432. [Google Scholar] [CrossRef]

- Knezevic, M.; Lebensohn, R.A.; Cazacu, O.; Revil-Baudard, B.; Proust, G.; Vogel, S.C.; Nixon, M.E. Modeling bending of α-titanium with embedded polycrystal plasticity in implicit finite elements. Mater. Sci. Eng. A 2013, 564, 116–126. [Google Scholar] [CrossRef]

- Chakraborty, A.; Eisenlohr, P. Evaluation of an inverse methodology for estimating constitutive parameters in face-centered cubic materials from single crystal indentations. Eur. J. Mech. A/Solids 2017, 66, 114–124. [Google Scholar] [CrossRef]

- Sánchez-Martín, R.; Pérez-Prado, M.T.; Segurado, J.; Bohlen, J.; Gutiérrez-Urrutia, I.; Llorca, J.; Molina-Aldareguia, J.M. Measuring the critical resolved shear stresses in Mg alloys by instrumented nanoindentation. Acta Mater. 2014, 71, 283–292. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Zheng, Z.; Phukan, H.; Kenesei, P.; Park, J.S.; Lind, J.; Suter, R.M.; Bieler, T.R. Direct measurement of critical resolved shear stress of prismatic and basal slip in polycrystalline Ti using high energy X-ray diffraction microscopy. Acta Mater. 2017, 132, 598–610. [Google Scholar] [CrossRef]

- Pagan, D.C.; Shade, P.A.; Barton, N.R.; Park, J.-S.; Kenesei, P.; Menasche, D.B.; Bernier, J.V. Modeling slip system strength evolution in Ti-7Al informed by in-situ grain stress measurements. Acta Mater. 2017, 128, 406–417. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Li, N.; Arul Kumar, M.; Pathak, S.; Wang, J.; McCabe, R.J.; Mara, N.A.; Tomé, C.N. Experimentally quantifying critical stresses associated with basal slip and twinning in magnesium using micropillars. Acta Mater. 2017, 135, 411–421. [Google Scholar] [CrossRef]

- Gong, J.; Wilkinson, A.J. Anisotropy in the plastic flow properties of single-crystal α titanium determined from micro-cantilever beams. Acta Mater. 2009, 57, 5693–5705. [Google Scholar] [CrossRef]

- Kim, J.-Y.; Greer, J.R. Tensile and compressive behavior of gold and molybdenum single crystals at the nano-scale. Acta Mater. 2009, 57, 5245–5253. [Google Scholar] [CrossRef]

- Franciosi, P.; Berveiller, M.; Zaoui, A. Latent hardening in copper and aluminium single crystals. Acta Metal. 1980, 28, 273–283. [Google Scholar] [CrossRef]

- Devincre, B.; Kubin, L.; Hoc, T. Physical analyses of crystal plasticity by DD simulations. Scr. Mater. 2006, 54, 741–746. [Google Scholar] [CrossRef]

- Po, G.; Mohamed, M.S.; Crosby, T.; Erel, C.; El-Azab, A.; Ghoniem, N. Recent progress in discrete dislocation dynamics and its applications to micro plasticity. JOM 2014, 66, 2108–2120. [Google Scholar] [CrossRef]

- Queyreau, S.; Monnet, G.; Devincre, B. Slip systems interactions in α-iron determined by dislocation dynamics simulations. Int. J. Plast. 2009, 25, 361–377. [Google Scholar] [CrossRef]

- Nomoto, A.; Soneda, N.; Takahashi, A.; Ishino, S. Interaction analysis between edge dislocation and self interstitial type dislocation loop in BCC iron using molecular dynamics. Mater. Trans. 2005, 46, 463–468. [Google Scholar] [CrossRef] [Green Version]

- Buehler, M.J.; Hartmaier, A.; Gao, H.; Duchaineau, M.A.; Abraham, F.F. The dynamical complexity of work-hardening: A large-scale molecular dynamics simulation. Acta Mech. Sin. 2005, 21, 103–111. [Google Scholar] [CrossRef]

- Choudhary, B.K.; Samuel, E.I.; Bhanu Sankara Rao, K.; Mannan, S.L. Tensile stress–strain and work hardening behaviour of 316LN austenitic stainless steel. Mater. Sci. Technol. 2001, 17, 223–231. [Google Scholar] [CrossRef]

- Sainath, G.; Choudhary, B.K.; Christopher, J.; Isaac Samuel, E.; Mathew, M.D. Applicability of Voce equation for tensile flow and work hardening behaviour of P92 ferritic steel. Int. J. Press. Vessel. Pip. 2015, 132, 1–9. [Google Scholar] [CrossRef]

- Kocks, U.F. Laws for work-hardening and low-temperature creep. J. Eng. Mater. Technol. 1976, 98, 76–85. [Google Scholar] [CrossRef]

- Sengupta, A.; Putatunda, S.K.; Bartosiewicz, L.; Hangas, J.; Nailos, P.J.; Peputapeck, M.; Alberts, F.E. Tensile behavior of a new single-crystal nickel-based superalloy (CMSX-4) at room and elevated temperatures. J. Mater. Eng. Perfor. 1994, 3, 73–81. [Google Scholar] [CrossRef]

- Ludwik, P. Fließvorgänge bei einfachen Beanspruchungen. In Elemente der Technologischen Mechanik; Springer: Berlin/Heidelberg, Germany, 1909; pp. 11–35. [Google Scholar]

- Hollomon, J.H. Tensile deformation. Aime Trans. 1945, 12, 1–22. [Google Scholar]

- Swift, H.W. Plastic instability under plane stress. J. Mech. Phys. Solid. 1952, 1, 1–18. [Google Scholar] [CrossRef]

- Voce, E. The relationship between stress and strain for homogeneous deformation. J. Inst. Met. 1948, 74, 537–562. [Google Scholar]

- Wu, T.-Y.; Bassani, J.L.; Laird, C. Latent hardening in single crystals—I. Theory and experiments. Proc. Roy. Soc. London. A Math. Phys. Sci. 1991, 435, 1–19. [Google Scholar]

- Wang, M.; Shi, L.; Li, C.; Wang, Z.G.; Xiao, J.M. A study of latent hardening behavior in aluminium single crystals. Scr. Mater. 1996, 35, 1183–1188. [Google Scholar]

- Frick, C.P.; Clark, B.G.; Orso, S.; Schneider, A.S.; Arzt, E. Size effect on strength and strain hardening of small-scale [111] nickel compression pillars. Mater. Sci. Eng. A 2008, 489, 319–329. [Google Scholar] [CrossRef]

- Kiener, D.; Guruprasad, P.J.; Keralavarma, S.M.; Dehm, G.; Benzerga, A.A. Work hardening in micropillar compression: In Situ experiments and modeling. Acta Mater. 2011, 59, 3825–3840. [Google Scholar] [CrossRef]

- Greer, J.R.; De Hosson, J.T.M. Plasticity in small-sized metallic systems: Intrinsic versus extrinsic size effect. Prog. Mater. Sci. 2011, 56, 654–724. [Google Scholar] [CrossRef]

- Uchic, M.D.; Dimiduk, D.M.; Florando, J.N.; Nix, W.D. Sample dimensions influence strength and crystal plasticity. Science 2004, 305, 986–989. [Google Scholar] [CrossRef]

- Uchic, M.D.; Shade, P.A.; Dimiduk, D.M. Plasticity of micrometer-scale single crystals in compression. Ann. Rev. Mater. Res. 2009, 39, 361–386. [Google Scholar] [CrossRef] [Green Version]

- Budiman, A.S.; Narayanan, K.R.; Li, N.; Wang, J.; Tamura, N.; Kunz, M.; Misra, A. Plasticity evolution in nanoscale Cu/Nb single-crystal multilayers as revealed by synchrotron X-ray microdiffraction. Mater. Sci. Eng. A 2015, 635, 6–12. [Google Scholar] [CrossRef] [Green Version]

- Fei, H.; Abraham, A.; Chawla, N.; Jiang, H. Evaluation of micro-pillar compression tests for accurate determination of elastic-plastic constitutive relations. J. Appl. Mech. 2012, 79, 061011. [Google Scholar] [CrossRef] [Green Version]

- Ming, K.; Gu, C.; Su, Q.; Wang, Y.; Zare, A.; Lucca, D.A.; Nastasi, M.; Wang, J. Strength and plasticity of amorphous silicon oxycarbide. J. Nucl. Mater. 2019, 516, 289–296. [Google Scholar] [CrossRef] [Green Version]

- Tsien, L.; Chow, Y. The glide of single crystals of molybdenum. Proc. Roy. Soc. London. A Math. Phys. Sci. 1937, 163, 19–28. [Google Scholar]

- Barrett, C.S.; Ansel, G.; Mehl, R. Slip, twinning and cleavage in iron and silicon ferrite. Trans. ASM 1937, 25, 702. [Google Scholar]

- Sun, Z.; Yamamoto, Y. Processability evaluation of a Mo-containing FeCrAl alloy for seamless thin-wall tube fabrication. Mater. Sci. Eng. A 2017, 700, 554–561. [Google Scholar] [CrossRef]

- Xu, S.; Xie, D.; Liu, G.; Ming, K.; Wang, J. Quantifying the resistance to dislocation Gglide in single phase FeCrAl alloy. Int. J. Plast. 2020, 132, 102770. [Google Scholar] [CrossRef]

- Greer, J.R.; Nix, W.D. Nanoscale gold pillars strengthened through dislocation starvation. Phys. Rev. B 2006, 73, 245410. [Google Scholar] [CrossRef] [Green Version]

- Luster, J.; Morris, M. Compatibility of deformation in two-phase Ti-Al alloys: Dependence on microstructure and orientation relationships. Metal. Mater. Trans. A 1995, 26, 1745–1756. [Google Scholar] [CrossRef]

- Kacher, J.; Sabisch, J.E.; Minor, A.M. Statistical analysis of twin/grain boundary interactions in pure rhenium. Acta Mater. 2019, 173, 44–51. [Google Scholar] [CrossRef]

- Wang, L.; Eisenlohr, P.; Yang, Y.; Bieler, T.; Crimp, M. Nucleation of paired twins at grain boundaries in titanium. Scr. Mater. 2010, 63, 827–830. [Google Scholar] [CrossRef]

- Xin, R.; Liu, Z.; Sun, Y.; Wang, H.; Guo, C.; Ren, W.; Liu, Q. Understanding common grain boundary twins in Mg alloys by a composite Schmid factor. Int. J. Plast. 2019, 123, 208–223. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; Wang, J.; Kang, K.; Zheng, S.; Mara, N. Twinnability of bimetal interfaces in nanostructured composites. Mater. Res. Lett. 2013, 1, 89–95. [Google Scholar] [CrossRef] [Green Version]

- Wang, J. Atomistic simulations of dislocation pileup: Grain boundaries interaction. JOM 2015, 67, 1515–1525. [Google Scholar] [CrossRef]

- Molodov, K.D.; Molodov, D.A. Grain boundary mediated plasticity: On the evaluation of grain boundary migration—Shear coupling. Acta Mater. 2018, 153, 336–353. [Google Scholar] [CrossRef]

- Liu, G.; Xie, D.; Wang, S.; Misra, A.; Wang, J. Mesoscale crystal plasticity modeling of nanoscale Al–Al2Cu eutectic alloy. Int. J. Plast. 2019, 121, 134–152. [Google Scholar] [CrossRef]

- Wang, H.; Wu, P.; Wang, J.; Tomé, C.N. A crystal plasticity model for hexagonal close packed (HCP) crystals including twinning and de-twinning mechanisms. Int. J. Plast. 2013, 49, 36–52. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, D.; Wei, B.; Wu, W.; Wang, J. Crystallographic Orientation Dependence of Mechanical Responses of FeCrAl Micropillars. Crystals 2020, 10, 943. https://doi.org/10.3390/cryst10100943

Xie D, Wei B, Wu W, Wang J. Crystallographic Orientation Dependence of Mechanical Responses of FeCrAl Micropillars. Crystals. 2020; 10(10):943. https://doi.org/10.3390/cryst10100943

Chicago/Turabian StyleXie, Dongyue, Binqiang Wei, Wenqian Wu, and Jian Wang. 2020. "Crystallographic Orientation Dependence of Mechanical Responses of FeCrAl Micropillars" Crystals 10, no. 10: 943. https://doi.org/10.3390/cryst10100943

APA StyleXie, D., Wei, B., Wu, W., & Wang, J. (2020). Crystallographic Orientation Dependence of Mechanical Responses of FeCrAl Micropillars. Crystals, 10(10), 943. https://doi.org/10.3390/cryst10100943