Elimination of Coke in an Aged Hydrotreating Catalyst via a Non-Thermal Plasma Process: Comparison with a Coked Zeolite

Abstract

:1. Introduction

2. Results and Discussion

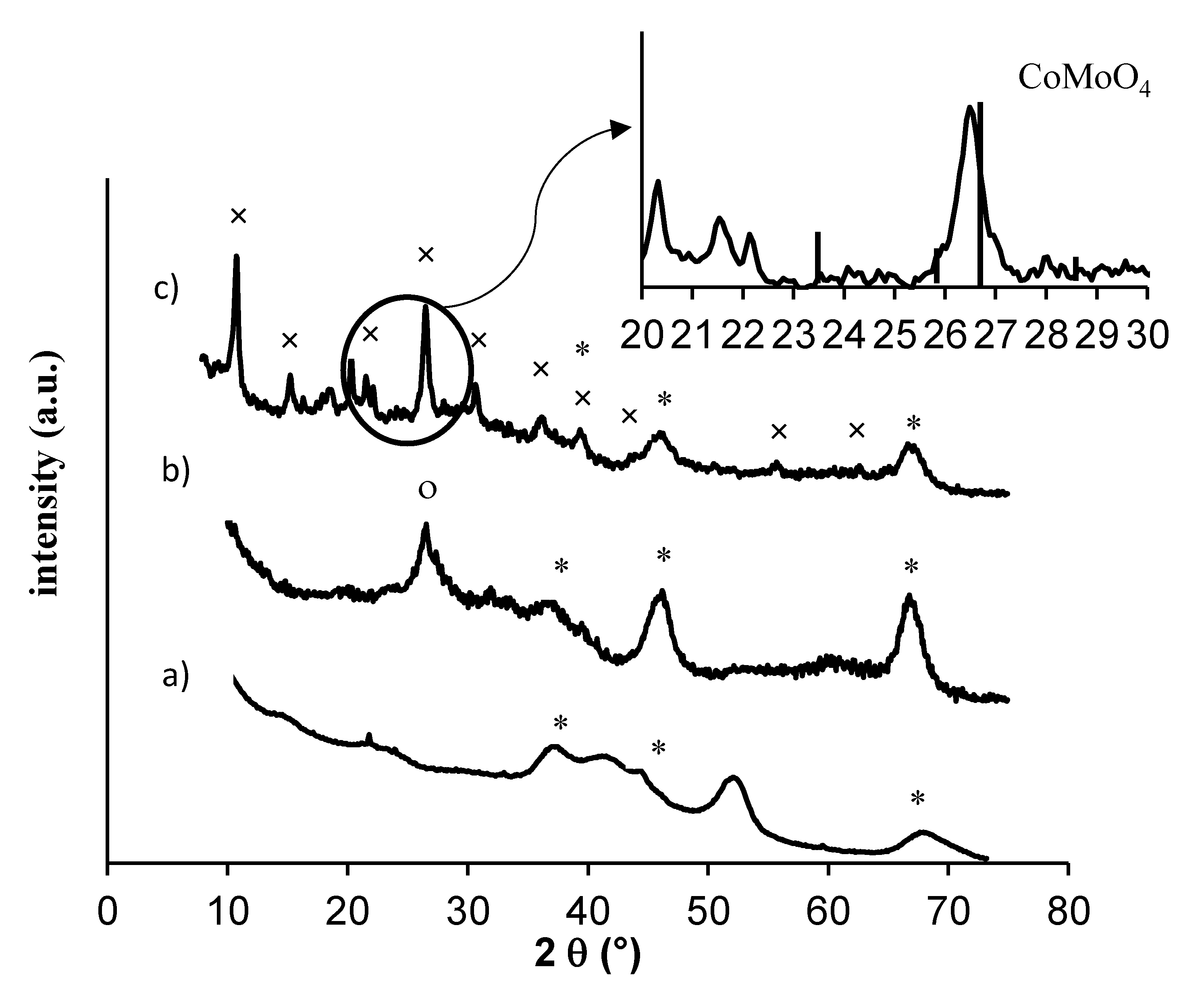

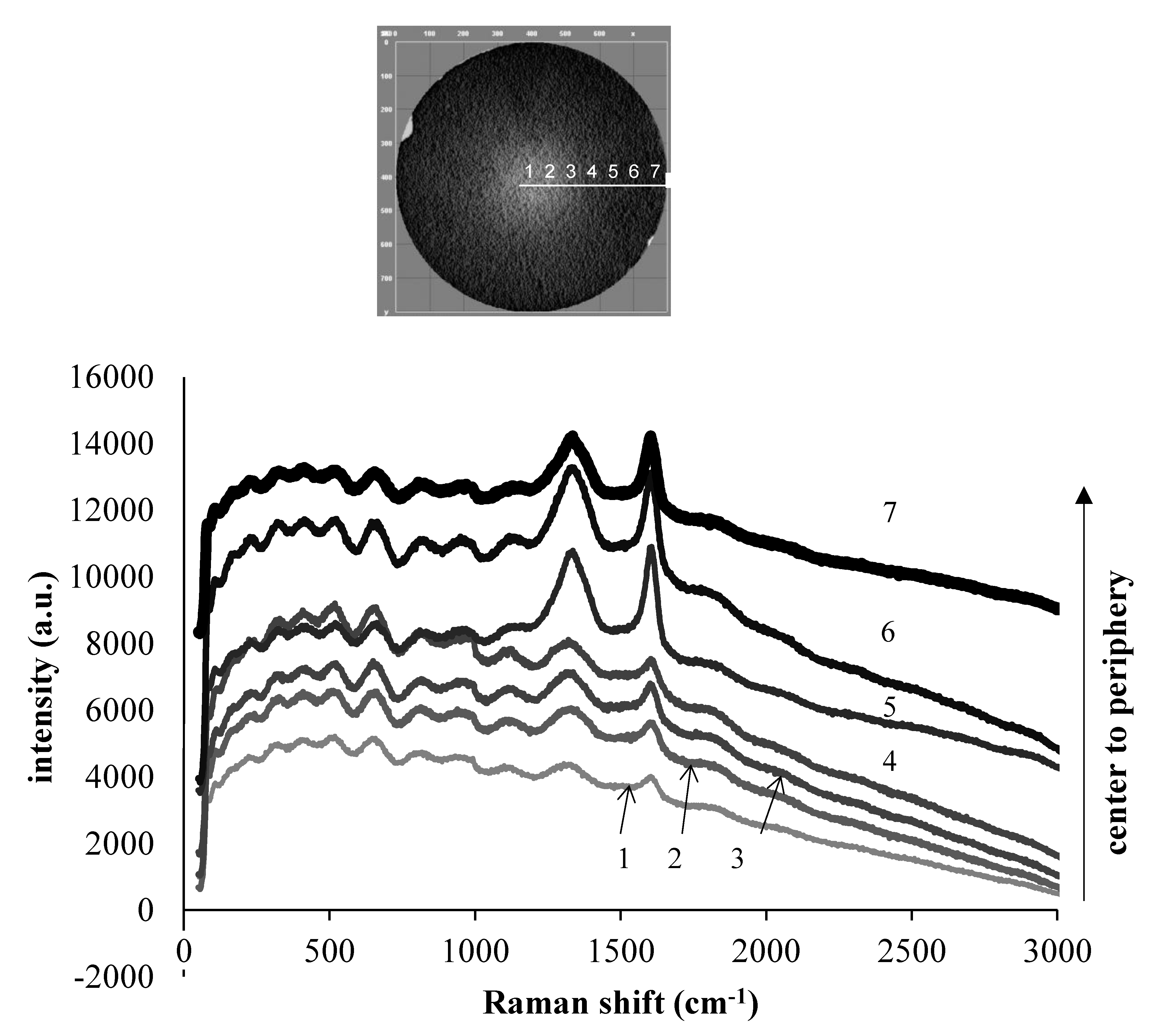

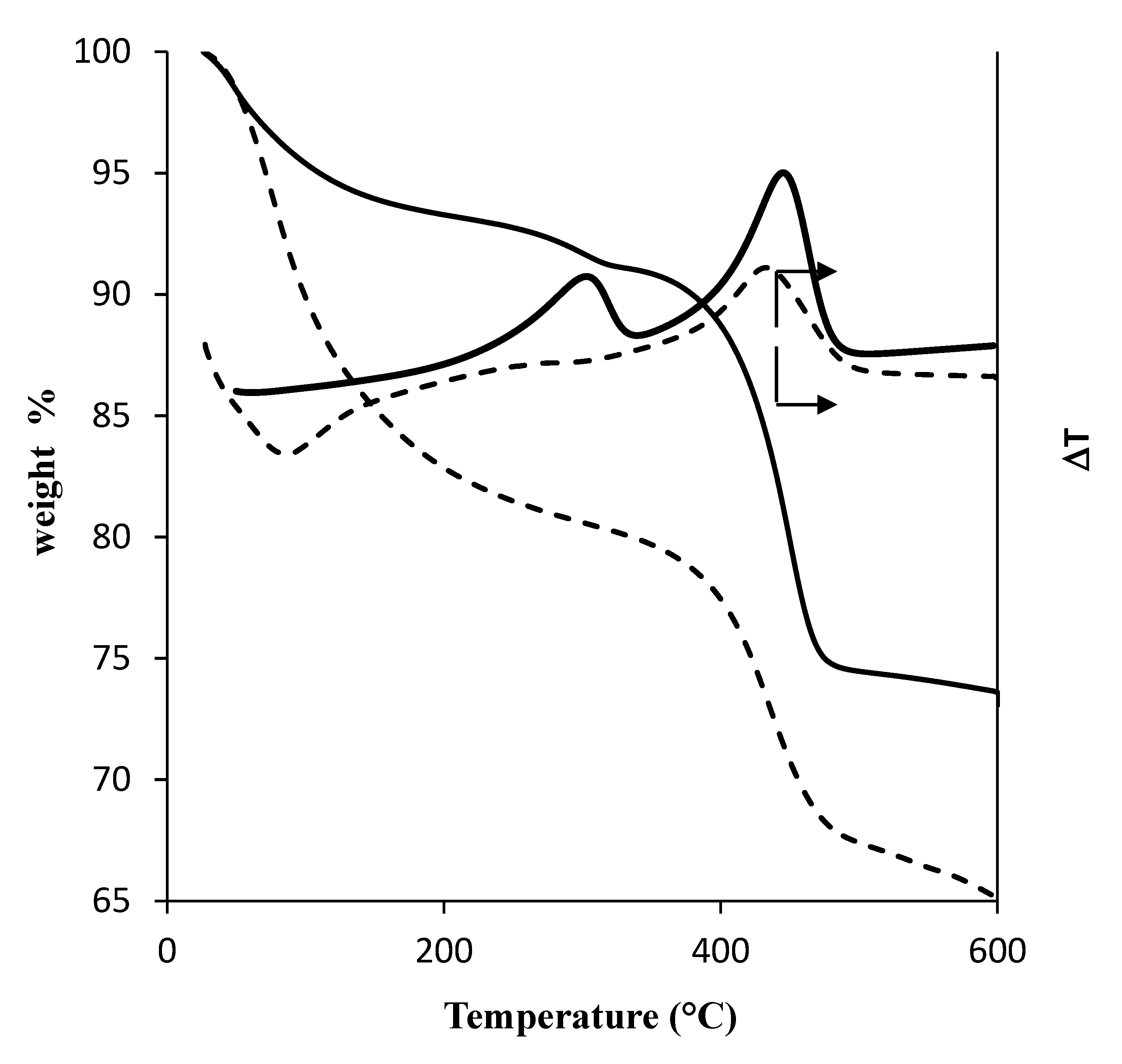

2.1. Characterization of the Catalyst before Plasma Treatment

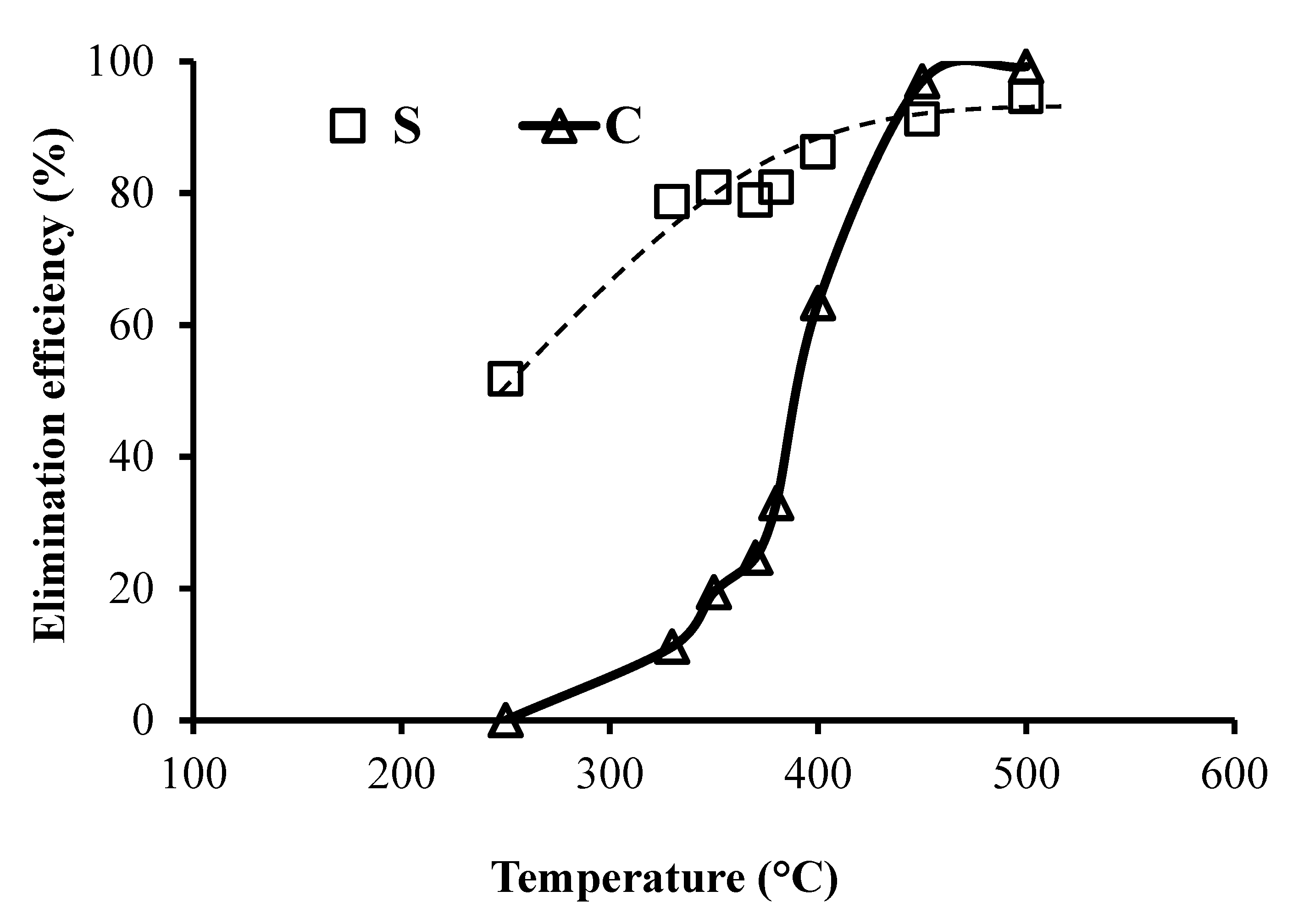

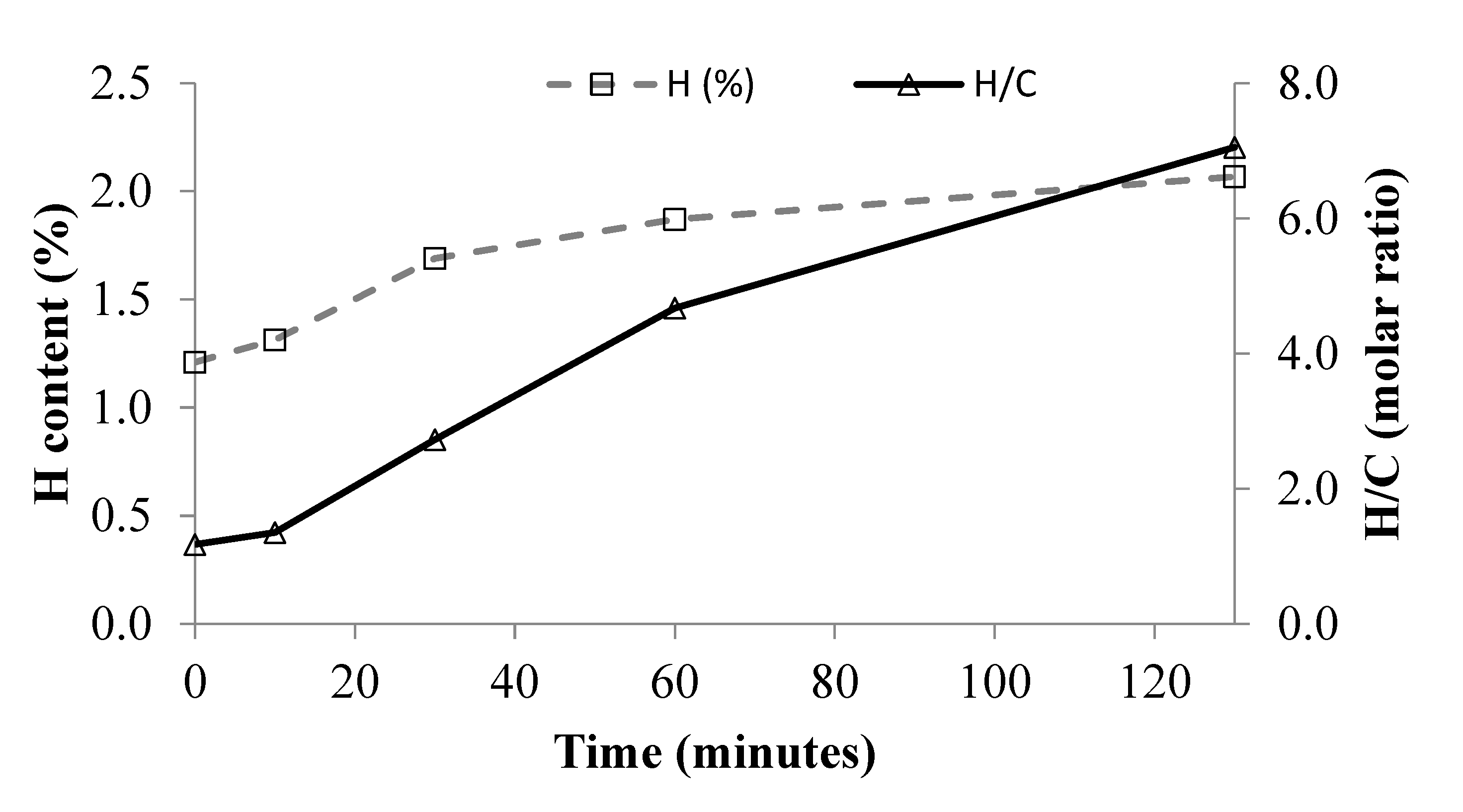

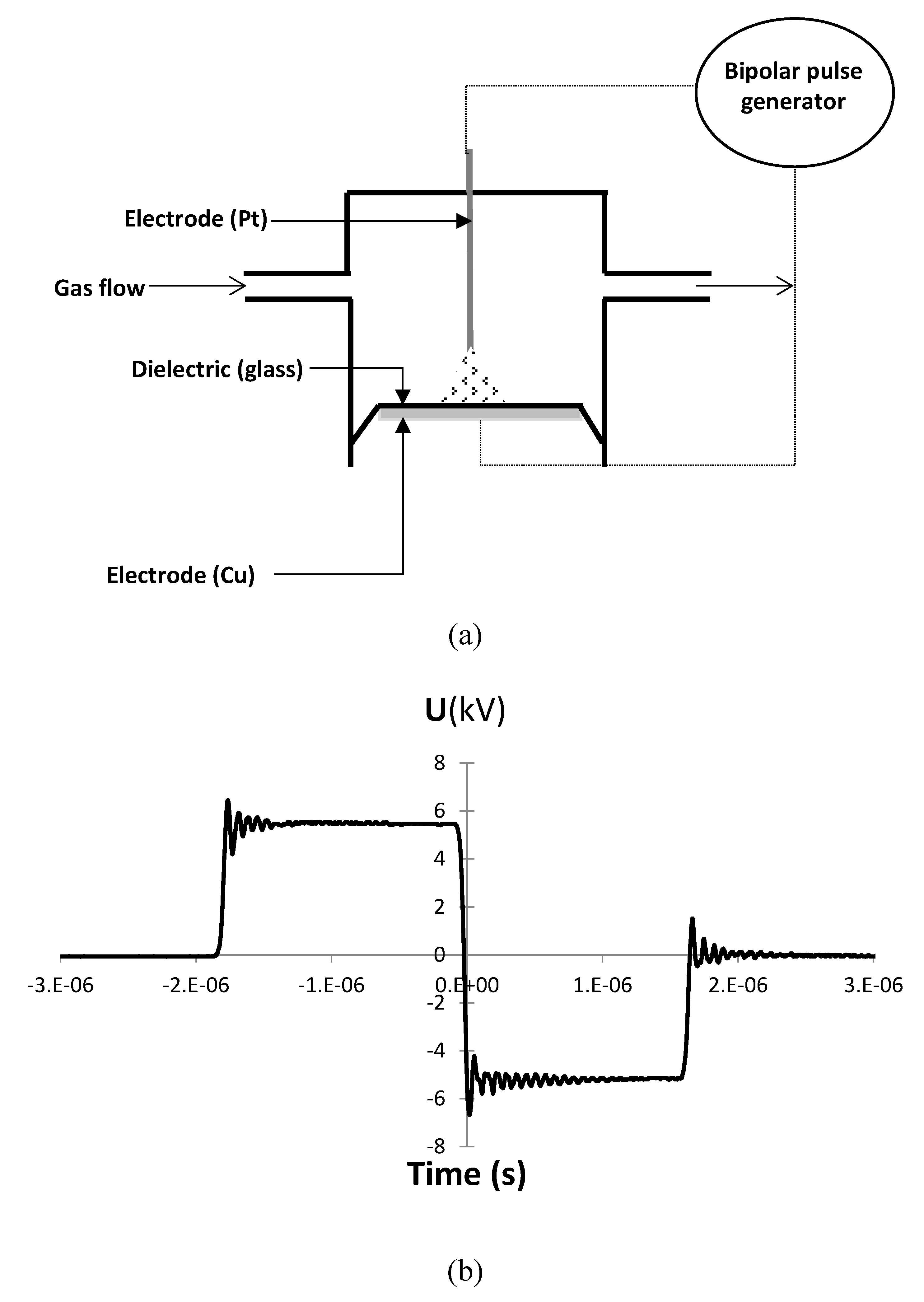

2.2. Plasma Treatment

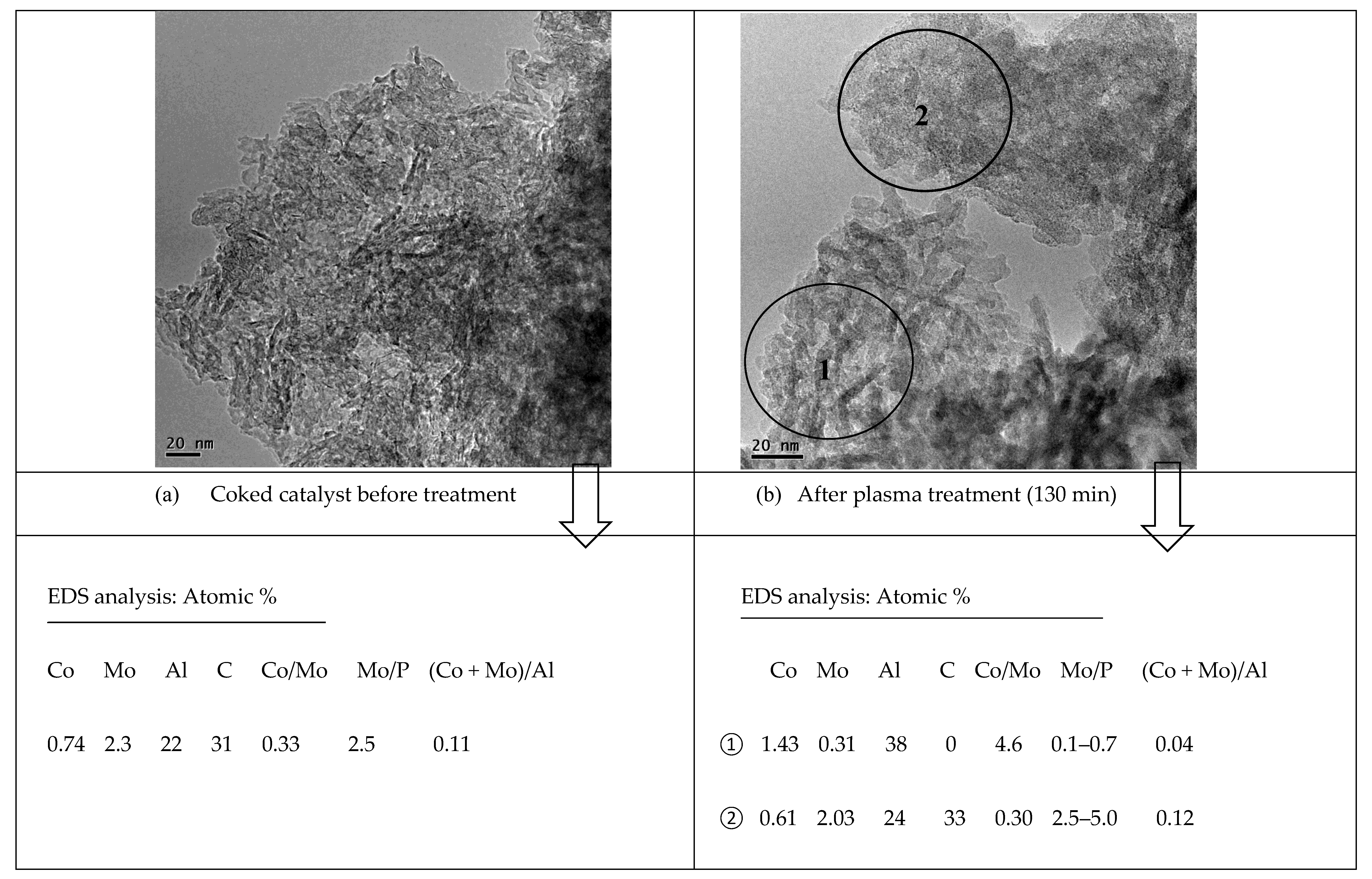

2.3. Characterizations of the Catalyst after Plasma Treatment

2.4. Comparison between Coke Removal in Zeolite and HDS Catalyst

3. Experimental

3.1. Coked Hydrotreating Catalyst, Characterization

3.2. Pin to Plate Dielectric Barrier Discharge (DBD) Reactor

3.3. Experimental Reaction Conditions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Knudsen, K.G.; Cooper, B.H.; Topsøe, H. Catalyst and process technologies for ultra low sulfur diesel. Appl. Catal. A 1999, 189, 205–215. [Google Scholar] [CrossRef]

- Liu, H.; Bao, S.; Cai, Z.; Xu, T.; Li, N.; Wang, L.; Chen, H.; Lu, W.; Chen, W. A novel method for ultra-deep desulfurization of liquid fuels at room temperature. Chem. Eng. J. 2017, 317, 1092–1098. [Google Scholar] [CrossRef]

- Rob Van Veen, J.A. What’s new? On the development of sulphidic HT catalysts before the molecular aspects. Catal. Today 2017, 292, 2–25. [Google Scholar] [CrossRef]

- Hamiye, R.; Lancelot, C.; Blanchard, P.; Toufaily, J.; Hamieh, T.; Lamonier, C. Diesel HDS performance of alumina supported CoMoP catalysts modified by sulfone molecules produced by ODS process. Fuels 2017, 210, 666–673. [Google Scholar] [CrossRef]

- Kasztelan, S.; Toulhoat, H.; Grimblot, J.; Bonnelle, J.P. A geometrical model of the active phase of hydrotreating catalysts. Appl. Catal. 1984, 13, 127–159. [Google Scholar] [CrossRef]

- Topsoe, H.; Clausen, B.S.; Candia, R.; Wivel, C.; Morup, S. In situ Mössbauer emission spectroscopy studies of unsupported and supported sulfided Co Mo hydrodesulfurization catalysts: Evidence for and nature of a Co Mo S. J. Catal. 1981, 68, 433–452. [Google Scholar] [CrossRef]

- Furimsky, E.; Massoth, F.E. Deactivation of hydroprocessing catalysts. Catal. Today 1999, 52, 381–495. [Google Scholar] [CrossRef]

- Dufresne, P. Hydroprocessing catalysts regeneration and recycling. Appl. Catal. A Gen. 2007, 32, 67–75. [Google Scholar] [CrossRef]

- Guichard, B. Life Cycle of an HDT Catalyst. In Catalysis by Transition Metal Sulphides from Molecular Theory to Industrial Application; Toulhoat, H., Raybaud, P., Eds.; TechnipFMC: Paris, France, 2013; chap 2.5. [Google Scholar]

- Furimsky, E.; Massoth, F.E. Regeneration of hydroprocessing catalysts. Catal. Today 1993, 17, 535–660. [Google Scholar]

- Marinkovic-Neduc, R.; Bos kovic, G.; Kis, E.; Lomic, G.; Hantsche, H.; Mic’ic’, R.; Pavlovic, P. Deactivation of industrial hydrotreating Catalyst for middle petroleum fractions processing. Appl. Catal. A 1994, 107, 133–145. [Google Scholar] [CrossRef]

- Dufresne, P.; Brahma, N.; Girardier, F. Off-site regeneration of hydroprocessing catalysts. Oil Gas Sci. Technol. 1995, 2, 283–293. [Google Scholar]

- Eijsbouts, S. Life cycle of hydroprocessing catalysts and total catalyst management. Stud. Surf. Sci. Catal. 1999, 127, 21–36. [Google Scholar]

- Yoshimura, Y.; Sato, T.; Shimada, H.; Matsubayashi, N.; Imamura, M.; Nishijima, A. Oxidative regeneration of spent molybdate and tungstate hydrotreating catalysts. Energy Fuels 1994, 8, 435–445. [Google Scholar] [CrossRef]

- Bui, N.Q.; Geantet, C.; Berhault., G. Maleic acid, an efficient additive for the activation of regenerated CoMo/Al2O3 hydrotreating catalysts. J. Catal. 2015, 330, 374–386. [Google Scholar] [CrossRef]

- Dasilva, V.; Frety, R.; Schmal, M. Activation and Regeneration of a NiMo/Al2O3 Hydrotreatment Catalyst. Ind. Eng. Chem. Res. 1994, 33, 1692–1699. [Google Scholar]

- Khan, M.A.; Al-Jalal, A.A.; Bakhtiari, I.A. Decoking of a coked zeolite catalyst in a glow discharge. Anal. Bioanal. Chem. 2003, 377, 89–96. [Google Scholar] [CrossRef]

- Khan, M.A.; Al-Jalal, A.A. Enhanced decoking of a coked zeolite catalyst using a glow discharge in Ar–O2 gas mixture. Appl. Catal. A Gen. 2004, 272, 141–149. [Google Scholar] [CrossRef]

- Jia, L.; Al Farouha, M.; Pinard, L.; Hedan, S.; Comparot, J.-D.; Dufour, A.; Ben Tayeb, K.; Vezin, H.; Batiot-Dupeyrat, C. New routes for complete regeneration of coked zeolite. Appl. Catal. B Environ. 2017, 219, 82–91. [Google Scholar] [CrossRef]

- Guichard, B.; Roy-Auberger, M.; Devers, E.; Rebours, B.; Quoineaud, A.; Digne, M. Characterization of aged hydrotreating catalysts. Part I: Coke depositions, study on the chemical nature and environment. Appl. Catal. A Gen. 2009, 367, 1–8. [Google Scholar] [CrossRef]

- Le Minh, C.; Jones, R.A.; Craven, I.E.; Brown, T.C. Temperature-Programmed Oxidation of Coke Deposited on Cracking Catalysts: Combustion Mechanism Dependence. Energy Fuels 1997, 11, 463–469. [Google Scholar] [CrossRef]

- Callejas, M.A.; Martınez, M.T.; Blasco, T.; Sastre, E. Coke characterisation in aged residue hydrotreating catalysts by solid-state 13C-NMR spectroscopy and temperature-programmed oxidation. Appl. Catal. A Gen. 2001, 218, 181–188. [Google Scholar] [CrossRef]

- Pinard, L.; Ayoub, N.; Batiot-Dupeyrat, C. Regeneration of a Coked Zeolite via Nonthermal Plasma Process: A Parametric Study. Plasma Chem. Plasma Process. 2019, 39, 929–936. [Google Scholar] [CrossRef]

- Griboval, A.; Blanchard, P.; Payen, E.; Fournier, M.; Dubois, J.L. Alumina supported HDS catalysts prepared by impregnation with new heteropolycompounds. Comparison with catalysts prepared by conventional Co–Mo–P. Catal. Today 1998, 45, 277–283. [Google Scholar] [CrossRef]

- Griboval, A.; Blanchard, P.; Payen, E.; Founier, M.; Dubois, J.L. Alumina supported HDS catalysts prepared by impregnation with new heteropolycompounds. Stud. Surf. Sci. Catal. 1997, 106, 181–193. [Google Scholar]

- Breysse, M.; Geantet, C.; Afanasiev, P.; Blanchard, J.; Vrinat, M. Recent studies on the preparation, activation and design of active phases and supports of hydrotreating catalysts. Catal. Today 2008, 130, 3–13. [Google Scholar] [CrossRef]

- Lamonier, C.; Martin, C.; Mazurelle, J.; Harle, V.; Guillaume, D.; Payen, E. Molybdocobaltate cobalt salts: New starting materials for hydrotreating catalysts. Appl. Catal. B Environ. 2007, 70, 548–556. [Google Scholar] [CrossRef]

- North, J.; Poole, O.; Alotaibi, A.; Bayahia, H.; Kozhevnikova, E.F.; Alsalme, A.; Siddiqui, M.R.H.; Kozhevnikov, I.V. Efficient hydrodesulfurization catalysts based on Keggin polyoxometalates. Appl. Catal. A Gen. 2015, 508, 16–24. [Google Scholar] [CrossRef]

- Tatibouët, J.M.; Montalescot, C.; Brückman, K.; Haber, J.; Che, M.A. Two-step transformation of the magnesium salt of phosphomolybdic acid HMgPMo12O40 supported on silica. J. Catal. 1997, 169, 22–32. [Google Scholar] [CrossRef]

- Biellanski, A.; Malecka, A.; Pozniczek, J. DTA and TG analysis of heteropolyacids of the series H(3+x)PMo(12−x)VxO40·nH2O. J. Therm. Anal. 1989, 35, 1699–1707. [Google Scholar] [CrossRef]

- Guichard, B.; Roy-Auberger, M.; Devers, E.; Pichon, C.; Legens, C. Characterization of aged hydrotreating catalysts. Part II: The evolution of the mixed phase. Effects of deactivation, activation and/or regeneration. Appl. Catal. A Gen. 2009, 367, 9–22. [Google Scholar] [CrossRef]

- Magnoux, P.; Guisnet, M. Coking, ageing and regeneration of zeolites: VI. Comparison of the Rates of Coke Oxidation of HY, H-Mordenite and HZSM-5. Appl. Catal. 1988, 38, 341–352. [Google Scholar] [CrossRef]

- Guisnet, M.; Ribeiro, F.R. Deactivation and Regeneration of Zeolite Catalysts, 1st ed.; Imperial College Press: London, UK, 2011. [Google Scholar]

- Astafan, A.; Batiot-Dupeyrat, C. Mechanism and Kinetic of Coke Oxidation by Nonthermal Plasma in Fixed-Bed Dielectric Barrier Reactor. J. Phys. Chem. C 2019, 123, 9168–9175. [Google Scholar] [CrossRef]

- Eliasson, B.; Kogelschatz, U. Modeling and applications of silent discharge plasmas. IEEE Trans. Plasma Sci. 1991, 19, 309–323. [Google Scholar] [CrossRef]

- Stefanovic, I.; Bibinov, N.K.; Deryugin, A.A.; Vinogradov, I.P.; Napartovich, A.P.; Wiesemann, K. Kinetics of ozone and nitric oxides in dielectric barrier discharges in O2/NOx and N2/O2/NOx mixtures. Plasma Sour. Sci. Technol. 2001, 10, 406–416. [Google Scholar] [CrossRef]

- Tu, X.; Gallon, H.J.; Twigg, M.V.; Gorry, P.A.; Whitehead, J.C. Dry reforming of methane over a Ni/Al2O3 catalyst in a coaxial dielectric barrier discharge reactor. J. Phys. D Appl. Phys. 2011, 44, 274007–274017. [Google Scholar] [CrossRef]

- Jo, S.; Kim, T.; Lee, D.H.; Kang, W.S.; Song, Y.H. Effect of the electric conductivity of a catalyst on methane activation in a dielectric barrier discharge reactor. Plasma Chem. Plasma Process. 2014, 34, 175–186. [Google Scholar] [CrossRef]

| Catalyst | S BET (m2/g) | %C ** | %S |

|---|---|---|---|

| Coked | 145 | 13 | 8 |

| Regenerated * | 173 | 0 | 0 |

| Catalyst | Coke | Weight Loss T (°C) | Plasma Treatment * | ||

|---|---|---|---|---|---|

| Amount | Nature | Initial Rate of CO2 Formation (mol CO2/mol C/min) | Ozone Concentration (ppm) | ||

| Zeolite H-MFI | 10% | Alkylbenzene, alkylnaphtalene, alkylpyrene | 512 | 4.54 | 1400–1600 |

| HDS catalyst | 13% | 2 types: Soft and strong | 397 | 0.92 | 200–350 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Srour, H.; Alnaboulsi, A.; Astafan, A.; Devers, E.; Toufaily, J.; Hamieh, T.; Pinard, L.; Batiot-Dupeyrat, C. Elimination of Coke in an Aged Hydrotreating Catalyst via a Non-Thermal Plasma Process: Comparison with a Coked Zeolite. Catalysts 2019, 9, 783. https://doi.org/10.3390/catal9090783

Srour H, Alnaboulsi A, Astafan A, Devers E, Toufaily J, Hamieh T, Pinard L, Batiot-Dupeyrat C. Elimination of Coke in an Aged Hydrotreating Catalyst via a Non-Thermal Plasma Process: Comparison with a Coked Zeolite. Catalysts. 2019; 9(9):783. https://doi.org/10.3390/catal9090783

Chicago/Turabian StyleSrour, Hawraa, Ammar Alnaboulsi, Amir Astafan, Elodie Devers, Joumana Toufaily, Tayssir Hamieh, Ludovic Pinard, and Catherine Batiot-Dupeyrat. 2019. "Elimination of Coke in an Aged Hydrotreating Catalyst via a Non-Thermal Plasma Process: Comparison with a Coked Zeolite" Catalysts 9, no. 9: 783. https://doi.org/10.3390/catal9090783

APA StyleSrour, H., Alnaboulsi, A., Astafan, A., Devers, E., Toufaily, J., Hamieh, T., Pinard, L., & Batiot-Dupeyrat, C. (2019). Elimination of Coke in an Aged Hydrotreating Catalyst via a Non-Thermal Plasma Process: Comparison with a Coked Zeolite. Catalysts, 9(9), 783. https://doi.org/10.3390/catal9090783