Catalytic Activity of Nickel and Ruthenium–Nickel Catalysts Supported on SiO2, ZrO2, Al2O3, and MgAl2O4 in a Dry Reforming Process

Abstract

:1. Introduction

2. Results

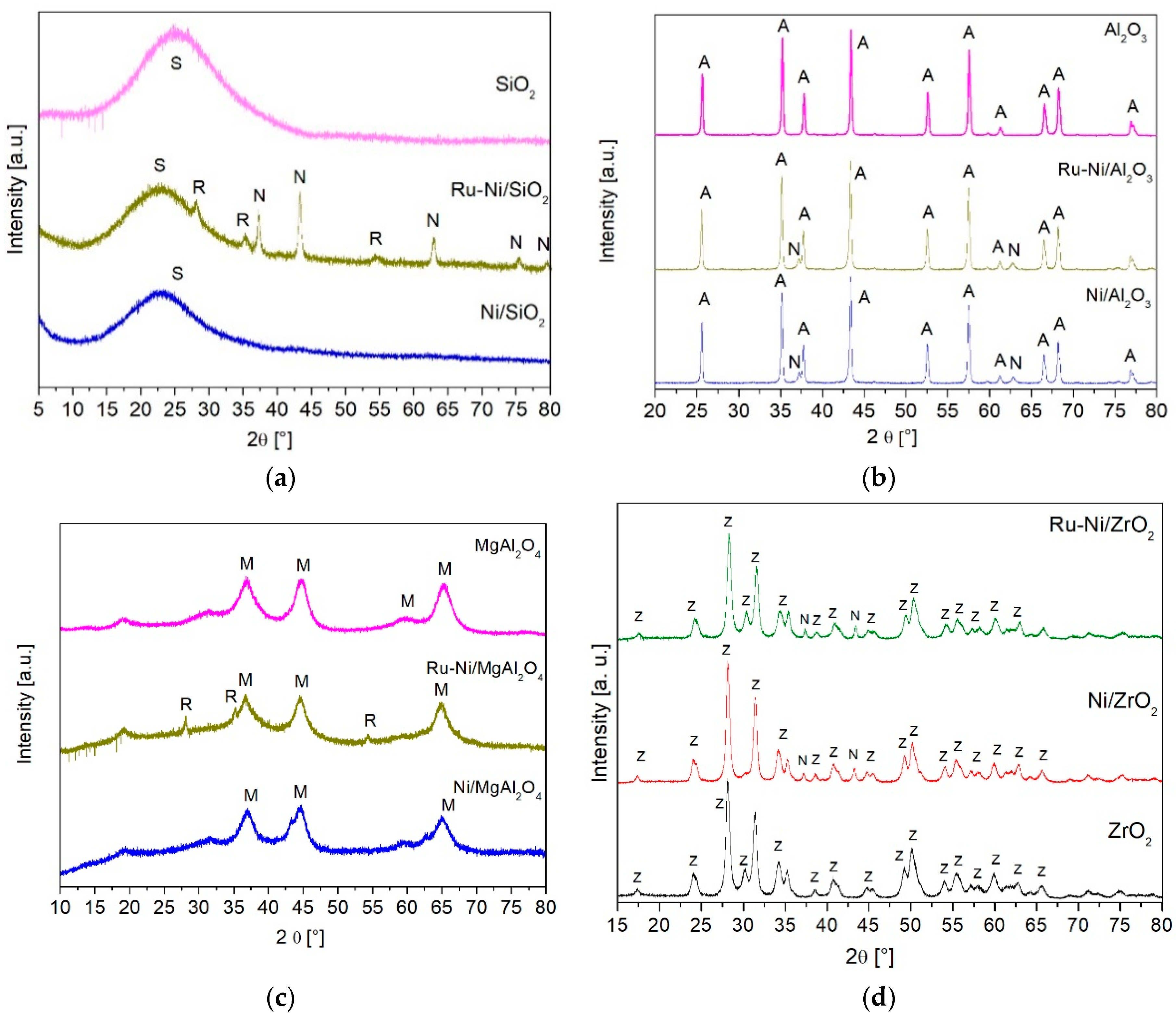

2.1. Catalyst Characterization

2.2. Catalytic Activity

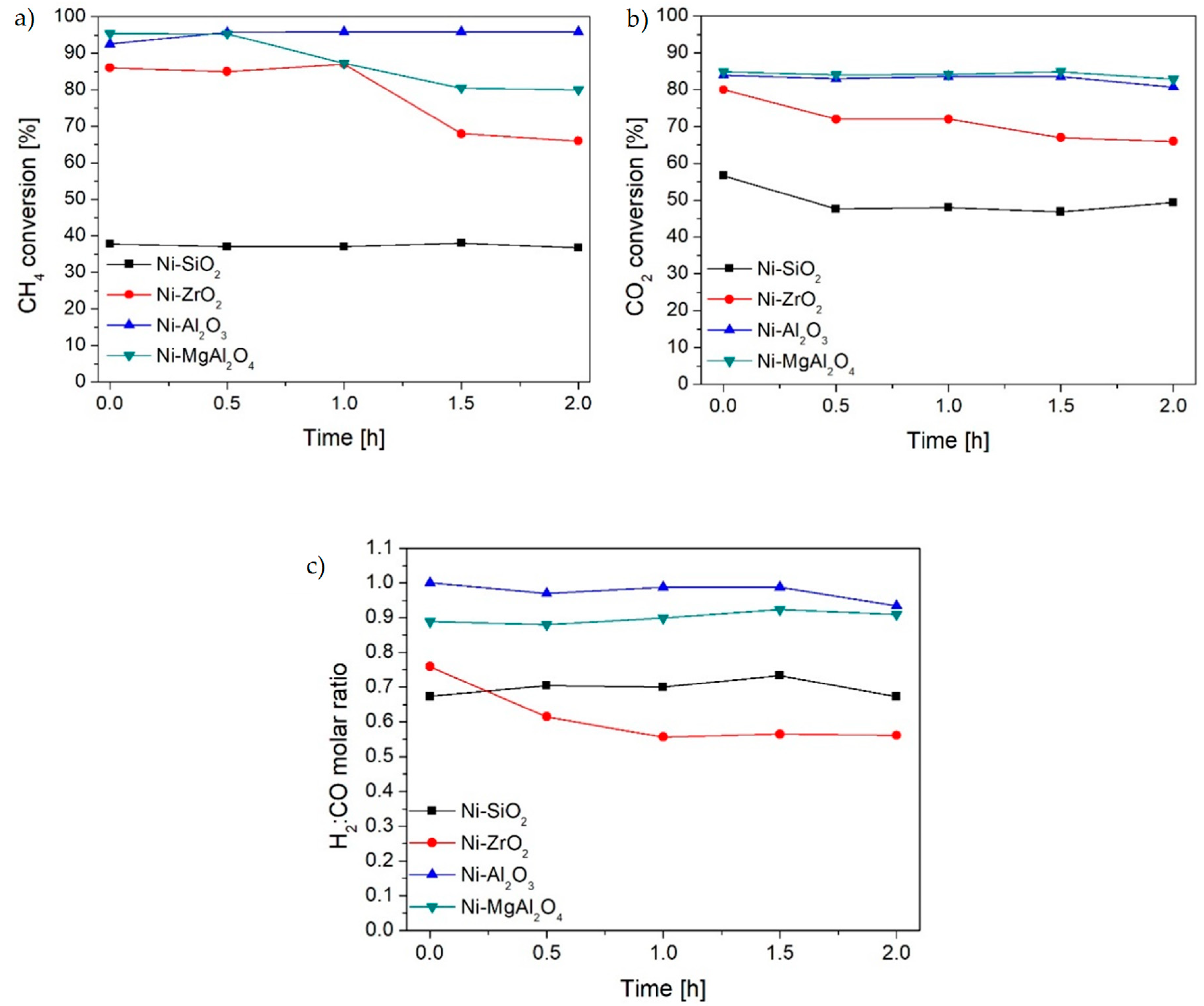

2.2.1. Nickel Catalysts

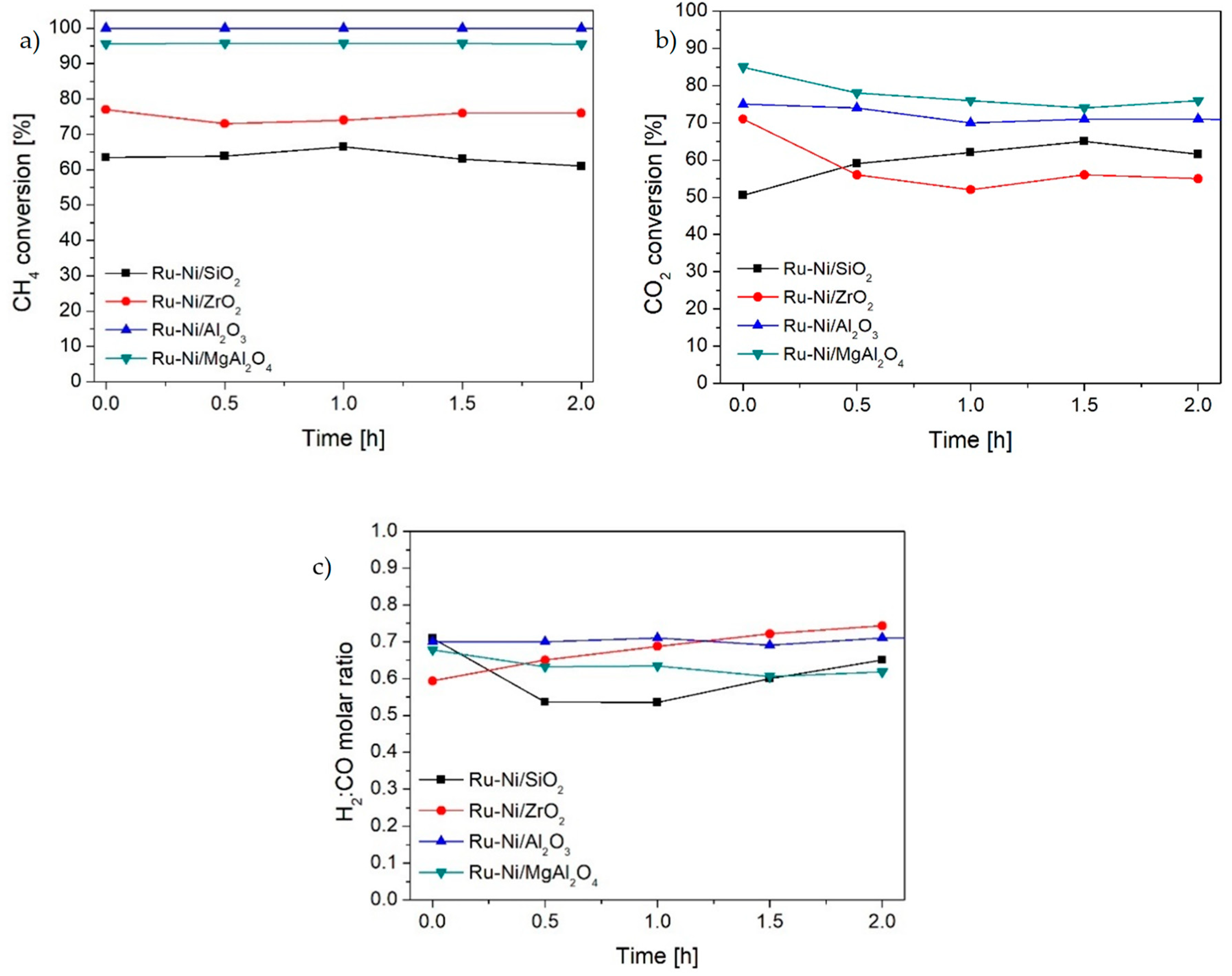

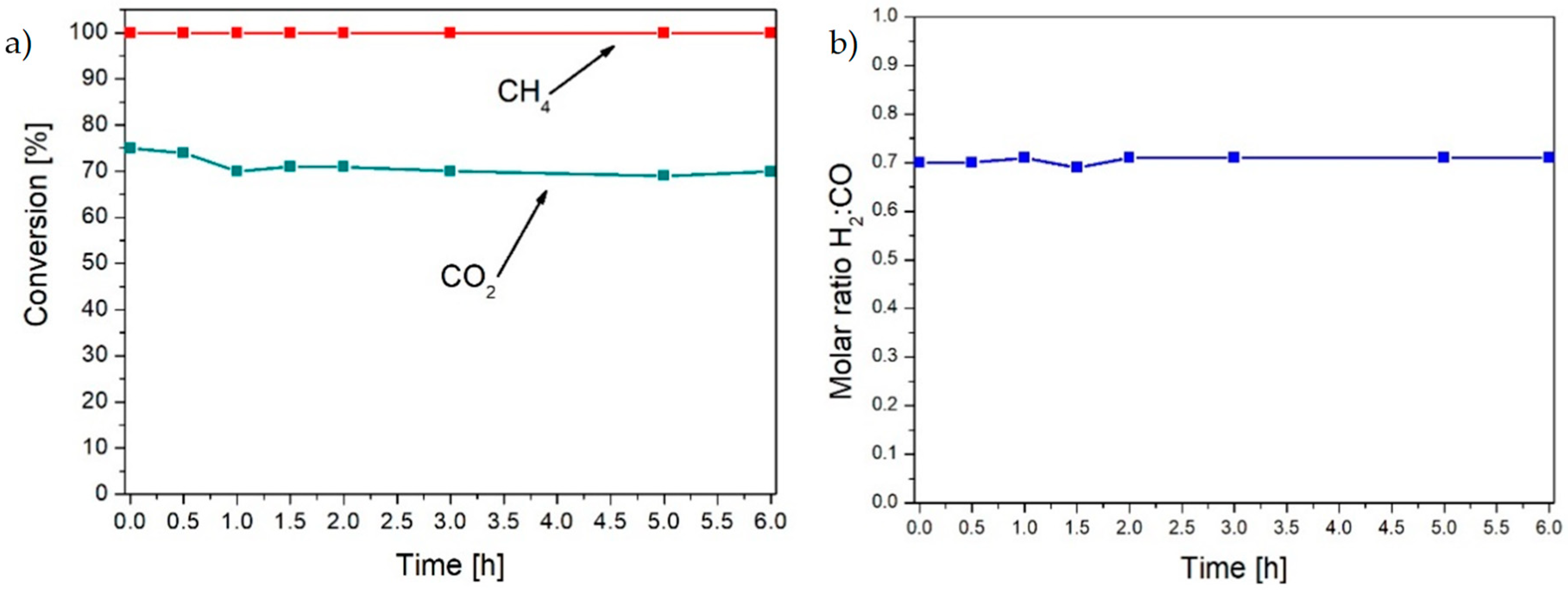

2.2.2. Ruthenium–Nickel Catalysts

2.2.3. Carbon Deposits

3. Discussion

4. Materials and Methods

4.1. Materials

4.2. Catalyst Characterization

4.3. Catalyst Preparation

4.3.1. Support Preparation

4.3.2. Preparation of Ni and Ni-Ru Catalysts

4.4. Catalytic Activity

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Arora, S.; Prasad, R. An Overview on Dry Reforming of Methane: Strategies to Reduce Carbonaceous Deactivation of Catalysts. RSC Adv. 2016, 6, 108668–108688. [Google Scholar] [CrossRef]

- Azizi, Z.; Rezaeimanesh, M.; Tohidian, T.; Rahimpour, M.R. Dimethyl Ether: A Review of Technologies and Production Challenges. Chem. Eng. Process. Process Intensif. 2014, 82, 150–172. [Google Scholar] [CrossRef]

- Rostrup-Nielsen, J.R. Production of Synthesis Gas. Catal. Today 1993, 18, 305–324. [Google Scholar] [CrossRef]

- Mortensen, P.M.; Dybkjær, I. Industrial Scale Experience on Steam Reforming of CO2-Rich Gas. Appl. Catal. A Gen. 2015, 495, 141–151. [Google Scholar] [CrossRef]

- Abdullah, B.; Abd Ghani, N.A.; Vo, D.V.N. Recent Advances in Dry Reforming of Methane over Ni-Based Catalysts. J. Clean. Prod. 2017, 162, 170–185. [Google Scholar] [CrossRef]

- Luyben, W.L. Design and Control of the Dry Methane Reforming Process. Ind. Eng. Chem. Res. 2014, 53, 14423–14439. [Google Scholar] [CrossRef]

- Chein, R.Y.; Chen, Y.C.; Yu, C.T.; Chung, J.N. Thermodynamic Analysis of Dry Reforming of CH4 with CO2 at High Pressures. J. Nat. Gas Sci. Eng. 2015, 26, 617–629. [Google Scholar] [CrossRef]

- Abdulrasheed, A.; Jalil, A.A.; Gambo, Y.; Ibrahim, M.; Hambali, H.U.; Shahul Hamid, M.Y. A Review on Catalyst Development for Dry Reforming of Methane to Syngas: Recent Advances. Renew. Sustain. Energy Rev. 2019, 108, 175–193. [Google Scholar] [CrossRef]

- Jang, W.J.; Shim, J.O.; Kim, H.M.; Yoo, S.Y.; Roh, H.S. A Review on Dry Reforming of Methane in Aspect of Catalytic Properties. Catal. Today 2018, 324, 15–26. [Google Scholar] [CrossRef]

- Aramouni, N.A.K.; Touma, J.G.; Tarboush, B.A.; Zeaiter, J.; Ahmad, M.N. Catalyst Design for Dry Reforming of Methane: Analysis Review. Renew. Sustain. Energy Rev. 2018, 82, 2570–2585. [Google Scholar] [CrossRef]

- Xu, Y.; Lin, Q.; Liu, B.; Jiang, F.; Xu, Y.; Liu, X. A Facile Fabrication of Supported Ni/SiO2 Catalysts for Dry Reforming of Methane with Remarkably Enhanced Catalytic Performance. Catalysts 2019, 9, 183. [Google Scholar] [CrossRef]

- Gangurde, L.S.; Sturm, G.S.J.; Valero-romero, M.J.; Mallada, R.; Santamaria, J.; Stankiewicz, A.; Stefanidis, G. Synthesis, Characterization, and Application of Ruthenium-Doped SrTiO3 Perovskite Catalysts for Microwave-Assisted Methane Dry Reforming. Chem. Eng. Process. Process. Intensif. 2018, 127, 178–190. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, T.; Sui, Z.; Zhu, Y.A.; Han, C.; Zhu, K.; Zhou, X. A Single Source Method to Generate Ru-Ni-MgO Catalysts for Methane Dry Reforming and the Kinetic Effect of Ru on Carbon Deposition and Gasification. Appl. Catal. B Environ. 2018, 233, 143–159. [Google Scholar] [CrossRef]

- Jabbour, K.; El Hassan, N.; Casale, S.; Estephane, J.; El Zakhem, H. Promotional Effect of Ru on the Activity and Stability of Co/SBA-15 Catalysts in Dry Reforming of Methane. Int. J. Hydrogen Energy 2014, 39, 7780–7787. [Google Scholar] [CrossRef]

- Li, D.; Nakagawa, Y.; Tomishige, K. Methane Reforming to Synthesis Gas over Ni Catalysts Modified with Noble Metals. Appl. Catal. A Gen. 2011, 408, 1–24. [Google Scholar] [CrossRef]

- Dou, Y.; Pang, Y.; Gu, L.; Ding, Y.; Jiang, W.; Feng, X.; Ji, W.; Au, C.T. Core-Shell Structured Ru-Ni@SiO2: Active for Partial Oxidation of Methane with Tunable H2/CO Ratio. J. Energy Chem. 2018, 27, 883–889. [Google Scholar] [CrossRef]

- Al-Fatesh, A.S.; Arafat, Y.; Atia, H.; Ibrahim, A.A.; Ha, Q.L.M.; Schneider, M.; M-Pohl, M.; Fakeeha, A.H. CO2-Reforming of Methane to Produce Syngas over Co-Ni/SBA-15 Catalyst: Effect of Support Modifiers (Mg, La and Sc) on Catalytic Stability. J. CO2 Util. 2017, 21, 395–404. [Google Scholar] [CrossRef]

- Rouibah, K.; Barama, A.; Benrabaa, R.; Guerrero-caballero, J.; Kane, T. Dry Reforming of Methane on Nickel-Chrome, Nickel-Cobalt and Nickel-Manganese Catalysts. Int. J. Hydrogen Energy 2017, 42, 29725–29734. [Google Scholar] [CrossRef]

- Yao, L.; Galvez, M.E.; Hu, C.; Da Costa, P. Synthesis Gas Production via Dry Reforming of Methane over Manganese Promoted Nickel/Cerium-Zirconium Oxide Catalyst. Ind. Eng. Chem. Res. 2018, 57, 16645–16656. [Google Scholar] [CrossRef]

- Liu, H.; Hadjltaief, H.B.; Benzina, M.; Gálvez, M.E.; Da Costa, P. Natural Clay Based Nickel Catalysts for Dry Reforming of Methane: On the Effect of Support Promotion (La, Al, Mn). Int. J. Hydrogen Energy 2019, 4, 246–255. [Google Scholar] [CrossRef]

- Das, S.; Ashok, J.; Bian, Z.; Dewangan, N.; Wai, M.H.; Du, Y.; Borgna, A.; Hidajat, K.; Kawi, S. Silica—Ceria Sandwiched Ni Core—Shell Catalyst for Low Temperature Dry Reforming of Biogas: Coke Resistance and Mechanistic Insights. Appl. Catal. B Environ. 2018, 230, 220–236. [Google Scholar] [CrossRef]

- Kim, S.M.; Abdala, P.M.; Margossian, T.; Hosseini, D.; Foppa, L.; Armutlulu, A.; Van Beek, W.; Comas-Vives, A.; Copéret, C.; Müller, C. Cooperativity and Dynamics Increase the Performance of NiFe Dry Reforming Catalysts. J. Am. Chem. Soc. 2017, 139, 1937–1949. [Google Scholar] [CrossRef]

- Margossian, T.; Larmier, K.; Kim, S.M.; Krumeich, F.; Müller, C.; Copéret, C. Supported Bimetallic NiFe Nanoparticles through Colloid Synthesis for Improved Dry Reforming Performance. ACS Catal. 2017, 7, 6942–6948. [Google Scholar] [CrossRef]

- Świrk, K.; Gálvez, M.E.; Motak, M.; Grzybek, T.; Rønning, M.; Da Costa, P. Dry Reforming of Methane over Zr- and Y-Modified Ni/Mg/Al Double-Layered Hydroxides. Catal. Commun. 2018, 117, 26–32. [Google Scholar] [CrossRef]

- Feng, X.; Liu, J.; Zhang, P.; Zhang, Q.; Xu, L.; Zhao, L.; Song, X.; Gao, L. Highly Coke Resistant Mg–Ni/Al2O3 Catalyst Prepared via a Novel Magnesiothermic Reduction for Methane Reforming Catalysis with CO2: The Unique Role of Al–Ni Intermetallics. Nanoscale 2019, 11, 1262–1272. [Google Scholar] [CrossRef]

- Nakhaei Pour, A.; Mousavi, M. Combined Reforming of Methane by Carbon Dioxide and Water: Particle Size Effect of Ni-Mg Nanoparticles. Int. J. Hydrogen Energy 2015, 40, 12985–12992. [Google Scholar] [CrossRef]

- Nandini, A.; Pant, K.K.; Dhingra, S.C. K-, CeO2-, and Mn-Promoted Ni/Al2O3 Catalysts for Stable CO2 Reforming of Methane. Appl. Catal. A Gen. 2005, 290, 166–174. [Google Scholar] [CrossRef]

- Bailey, K.M.; Campbell, T.K.; Falconer, J.L. Potassium Promotion of Ni/Al2O3 Catalysts. Appl. Catal. 1989, 54, 159–175. [Google Scholar]

- Németh, M.; Srankó, D.; Károlyi, J.; Somodi, F.; Schay, Z.; Sáfrán, G.; Sajó, I.; Horváth, A. Na-Promoted Ni/ZrO2 Dry Reforming Catalyst with High Efficiency: Details of Na2O-ZrO2-Ni Interaction Controlling Activity and Coke Formation. Catal. Sci. Technol. 2017, 7, 5386–5401. [Google Scholar] [CrossRef]

- Wang, Y.; Yao, L.; Wang, Y.; Wang, S.; Zhao, Q.; Mao, D.; Hu, C. Low-Temperature Catalytic CO2 Dry Reforming of Methane on Ni-Si/ZrO2 Catalyst. ACS Catal. 2018, 8, 6495–6506. [Google Scholar] [CrossRef]

- Galhenage, R.P.; Yan, H.; Tenney, S.A.; Park, N.; Henkelman, G.; Albrecht, P.; Mullins, D.R.; Chen, D.A. Understanding the Nucleation and Growth of Metals on TiO2: Co Compared to Au, Ni, and Pt. J. Phys. Chem. C 2013, 117, 7191–7201. [Google Scholar] [CrossRef]

- Zhang, R.; Xia, G.; Li, M.; Wu, Y.; Nie, H.; Li, D. Effect of Supports on the Performance of Ni-Based Catalysts in Methane Dry Reforming. J. Fuel Chem. Technol. 2015, 43, 1359–1365. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Q.; Tsubaki, N.; Tan, Y.; Han, Y. Carbon Dioxide Reforming of Methane over Ni Nanoparticles Incorporated into Mesoporous Amorphous ZrO2 Matrix. Fuel 2015, 147, 243–252. [Google Scholar] [CrossRef]

- Wang, F.; Xu, L.; Shi, W. Syngas Production from CO2 Reforming with Methane over Core-Shell Ni@SiO2 Catalysts. J. CO2 Util. 2016, 16, 318–327. [Google Scholar] [CrossRef]

- Ferreira-Aparicio, P.; Rodriguez-Ramos, I.; Anderson, J.A.; Guerrero-Ruiz, A. Mechanistic Aspects of the Dry Reforming of Methane over Ruthenium Catalysts. Appl. Catal. A Gen. 2000, 202, 183–196. [Google Scholar] [CrossRef]

- Frontera, P.; Macario, A.; Aloise, A.; Antonucci, P.L.; Giordano, G.; Nagy, J.B. Effect of Support Surface on Methane Dry-Reforming Catalyst Preparation. Catal. Today 2013, 218–219, 18–29. [Google Scholar] [CrossRef]

- Wang, F.; Han, B.; Zhang, L.; Xu, L.; Yu, H.; Shi, W. CO2 Reforming with Methane over Small-Sized Ni@SiO2 Catalysts with Unique Features of Sintering-Free and Low Carbon. Appl. Catal. B Environ. 2018, 235, 26–35. [Google Scholar] [CrossRef]

- Habibi, N.; Wang, Y.; Arandiyan, H.; Rezaei, M. Effect of Substitution by Ni in MgAl2O4 Spinel for Biogas Dry Reforming. Int. J. Hydrogen Energy 2017, 42, 24159–24168. [Google Scholar] [CrossRef]

- Zarei, M.; Meshkani, F.; Rezaei, M. Preparation of Mesoporous Nanocrystalline Ni-MgAl2O4 Catalysts by Sol-Gel Combustion Method and Its Applications in Dry Reforming Reaction. Adv. Powder Technol. 2016, 27, 1963–1970. [Google Scholar] [CrossRef]

- Nazemi, M.K.; Sheibani, S.; Rashchi, F.; Gonzalez-Delacruz, V.M.; Caballero, A. Preparation of Nanostructured Nickel Aluminate Spinel Powder from Spent NiO/Al2O3 Catalyst by Mechano-Chemical Synthesis. Adv. Powder Technol. 2012, 23, 833–838. [Google Scholar] [CrossRef]

- Park, J.; Yeo, S.; Chang, T. Effect of Supports on the Performance of Co-Based Catalysts in Methane Dry Reforming. J. CO2 Util. 2018, 26, 465–475. [Google Scholar] [CrossRef]

- Han, J.W.; Park, J.S.; Choi, M.S.; Lee, H. Uncoupling the Size and Support Effects of Ni Catalysts for Dry Reforming of Methane. Appl. Catal. B Environ. 2017, 203, 625–632. [Google Scholar] [CrossRef]

- Lemonidou, A.A.; Vasalos, I.A. Carbon Dioxide Reforming of Methane Over. Appl. Catal. A Gen. 2002, 228, 227–235. [Google Scholar]

- Pakhare, D.; Spivey, J. A Review of Dry (CO2) Reforming of Methane over Noble Metal Catalysts. Chem. Soc. Rev. 2014, 43, 7813–7837. [Google Scholar] [CrossRef]

| Catalyst | Metal Content (wt.%) | Surface Area SBET (m2 g−1) | Phase Composition | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Support | Catalytically Active Phase | ||||||||

| Nickel(II) Oxide | Ruthenium(IV) Oxide | ||||||||

| Ni | Ru | d (nm) | S–Q (wt.%) | d (nm) | S–Q (wt.%) | d (nm) | S–Q (wt.%) | ||

| SiO2 | - | - | 300 | 1 | 100 | - | - | - | - |

| Ni/SiO2 | 6.02 ± 0.30 | - | 391 | 1 | 100 | n.d. | - | - | - |

| Ru-Ni/SiO2 | 6.93 ± 0.35 | 0.75 ± 0.04 | 151 | 1 | 76 ± 8 | 19 | 19 ± 5 | 8 | 5 ± 5 |

| Al2O3 | - | - | 7 | 41 | 100 | - | - | - | - |

| Ni/Al2O3 | 8.00 ± 0.40 | - | 6 | 41 | 95 ± 3 | 22 | 5 ± 1 | - | - |

| Ru-Ni/Al2O3 | 8.18 ± 0.41 | 0.66 ± 0.02 | 6 | 41 | 95 ± 4 | 21 | 5 ± 1 | n.d. | - |

| MgAl2O4 | - | - | 145 | 3 | 100 | - | - | - | - |

| Ni/MgAl2O4 | 6.74 ± 0.24 | - | 98 | 3 | 100 | n.d. | - | - | - |

| Ru-Ni/MgAl2O4 | 6.78 ± 0.23 | 0.56 ± 0.01 | 169 | 3 | 99 ± 9 | n.d. | - | 32 | 1 ± 2 |

| ZrO2 | - | - | 30 | 15 | 100 | - | - | - | - |

| Ni/ZrO2 | 8.40 ± 0.47 | - | 23 | 17 | 94 ± 5 | 22 | 6 ± 5 | - | - |

| Ru-Ni/ZrO2 | 7.40 ± 0.47 | 0.81 ± 0.07 | 23 | 15 | 95 ± 7 | 19 | 5 ± 3 | n.d. | n.d. |

| Catalyst | Carbon Content (wt.%) |

|---|---|

| Ni/MgAl2O4 | <0.1 |

| Ru-Ni/MgAl2O4 | <0.1 |

| Ni/SiO2 | 0.38 |

| Ru-Ni/SiO2 | 0.42 |

| Ni/Al2O3 | <0.1 |

| Ru-Ni/Al2O3 | <0.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wysocka, I.; Hupka, J.; Rogala, A. Catalytic Activity of Nickel and Ruthenium–Nickel Catalysts Supported on SiO2, ZrO2, Al2O3, and MgAl2O4 in a Dry Reforming Process. Catalysts 2019, 9, 540. https://doi.org/10.3390/catal9060540

Wysocka I, Hupka J, Rogala A. Catalytic Activity of Nickel and Ruthenium–Nickel Catalysts Supported on SiO2, ZrO2, Al2O3, and MgAl2O4 in a Dry Reforming Process. Catalysts. 2019; 9(6):540. https://doi.org/10.3390/catal9060540

Chicago/Turabian StyleWysocka, Izabela, Jan Hupka, and Andrzej Rogala. 2019. "Catalytic Activity of Nickel and Ruthenium–Nickel Catalysts Supported on SiO2, ZrO2, Al2O3, and MgAl2O4 in a Dry Reforming Process" Catalysts 9, no. 6: 540. https://doi.org/10.3390/catal9060540

APA StyleWysocka, I., Hupka, J., & Rogala, A. (2019). Catalytic Activity of Nickel and Ruthenium–Nickel Catalysts Supported on SiO2, ZrO2, Al2O3, and MgAl2O4 in a Dry Reforming Process. Catalysts, 9(6), 540. https://doi.org/10.3390/catal9060540