Fischer–Tropsch: Product Selectivity–The Fingerprint of Synthetic Fuels

Abstract

1. Introduction

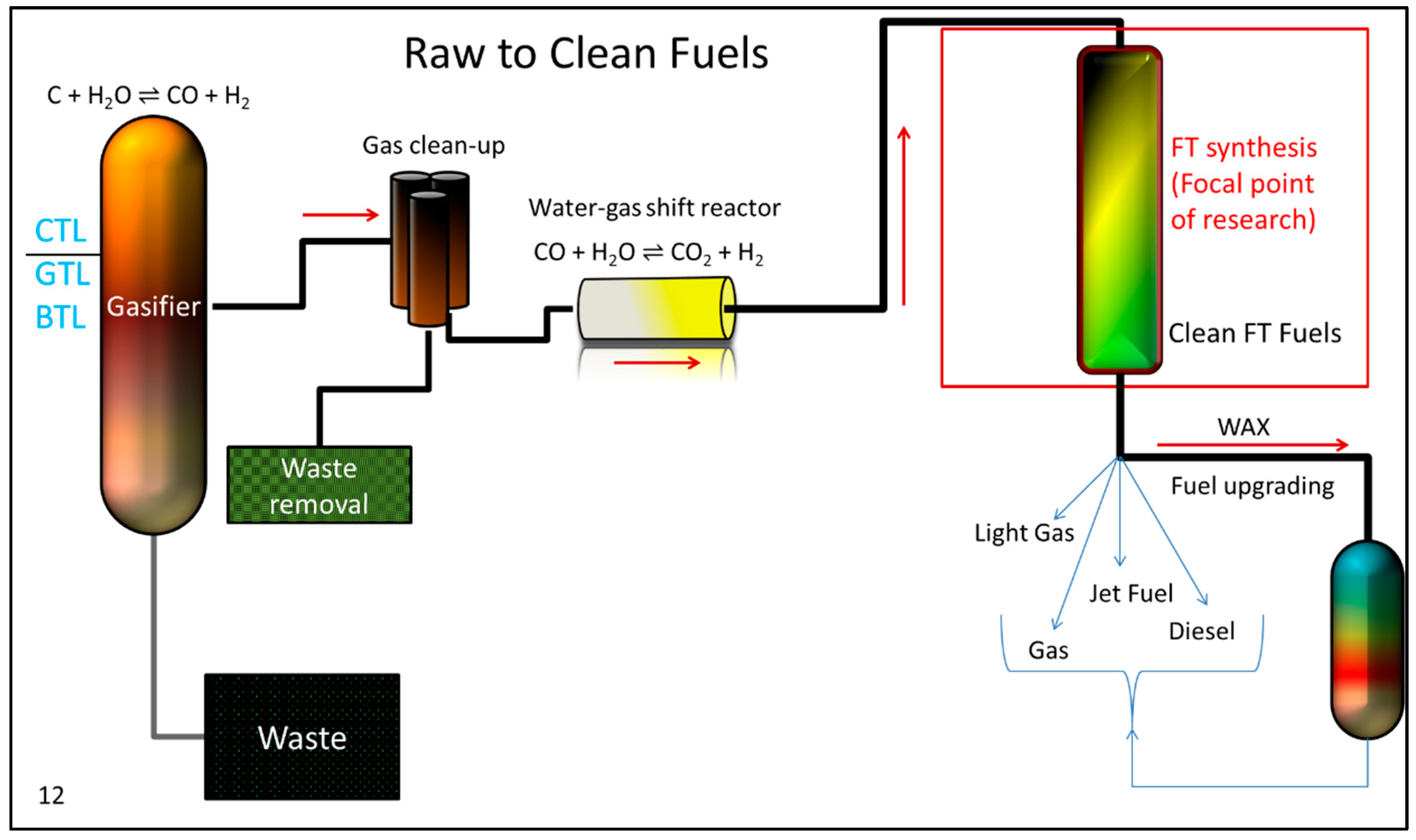

1.1. The Heart of the X-to-Liquids Process

1.2. Fischer–Tropsch Synthesis

- reactants (H2 and CO) chemisorb on active sites;

- chain growth is initiated;

- the carbon chain is then propagated;

- the chain is terminated; and,

- the final product desorbs from the catalyst surface (with the possibility of minor readsorption and reincorporation [26]).

1.3. Active FTS Metals

1.4. Supports and Promoters

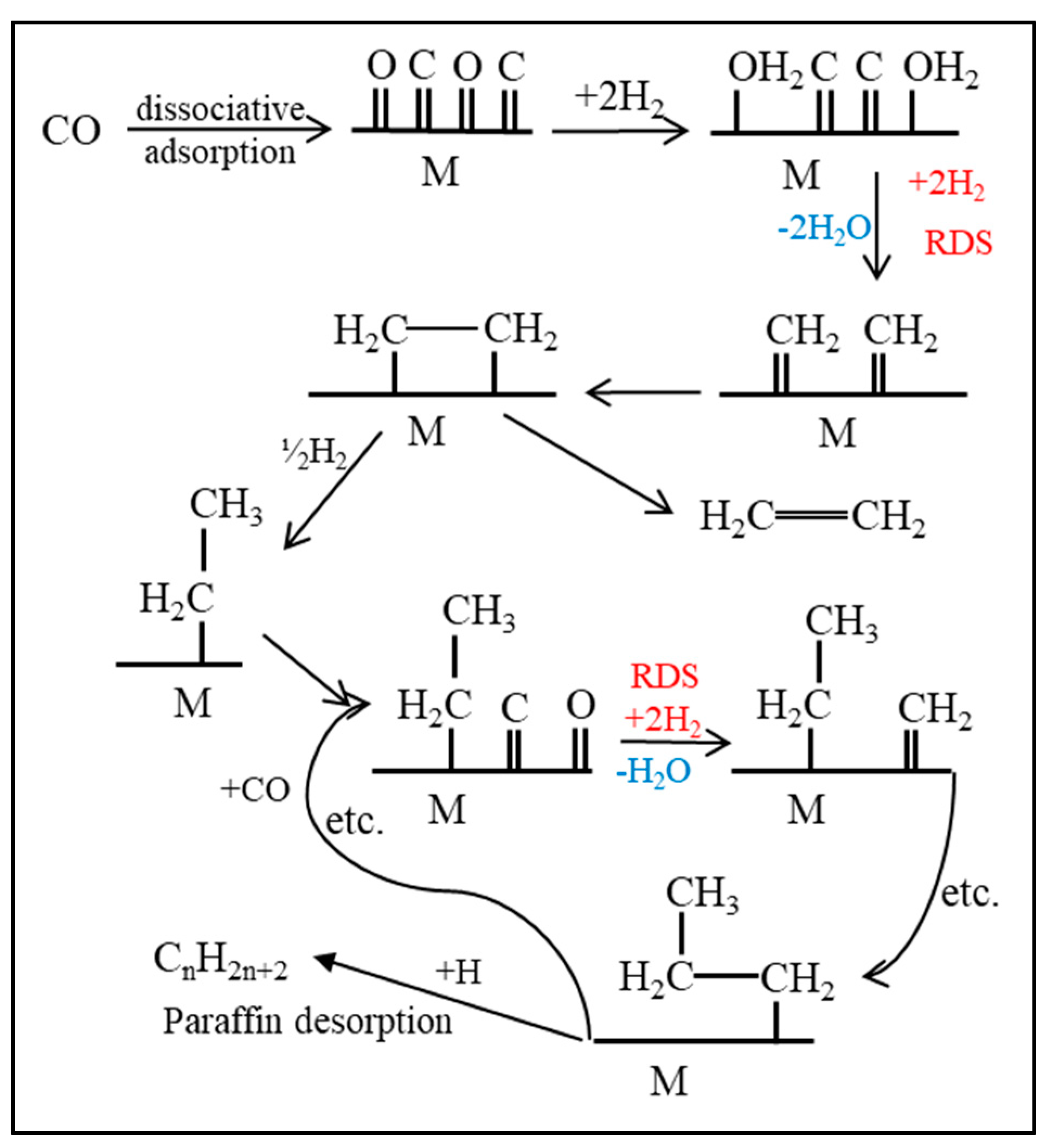

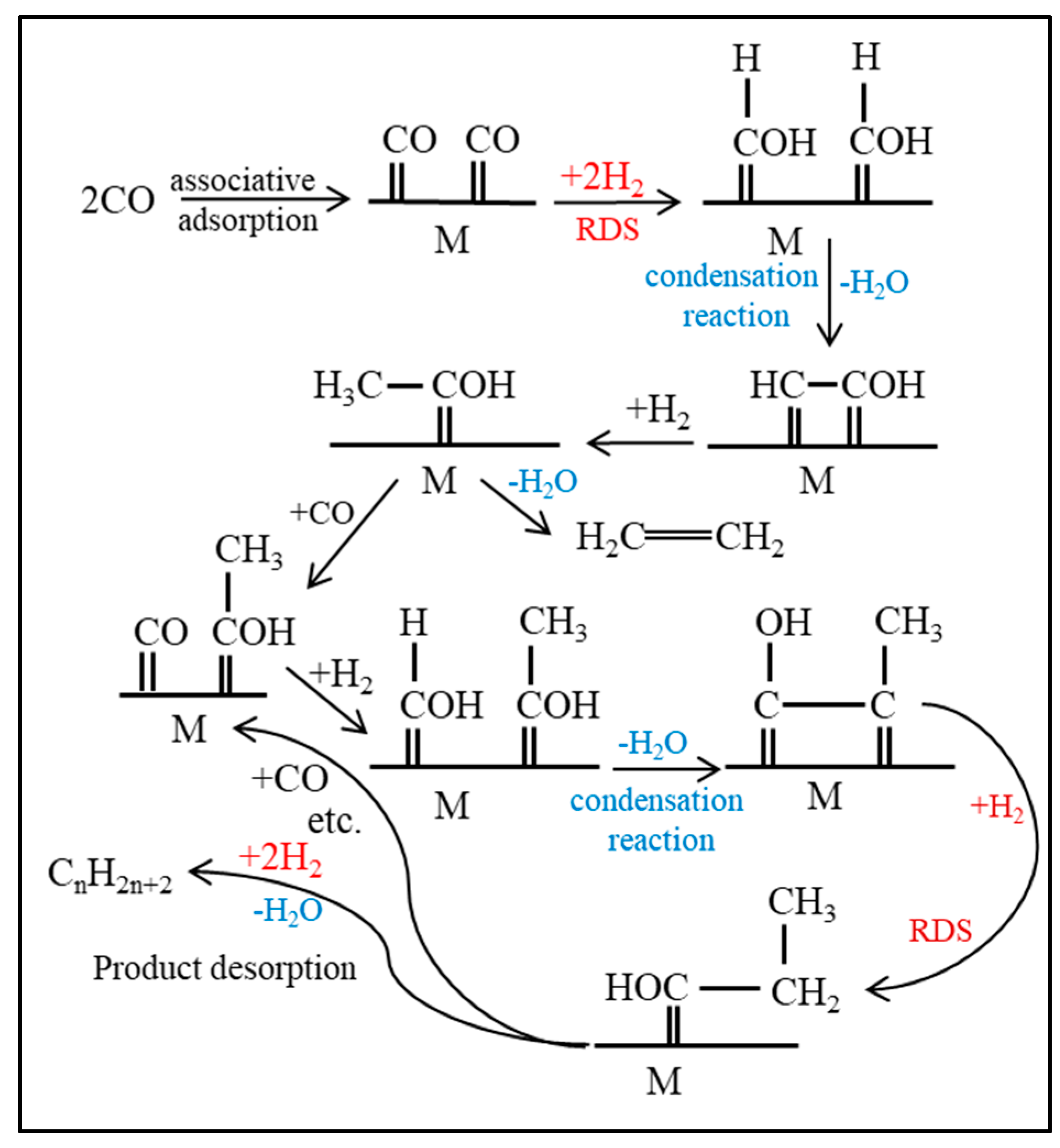

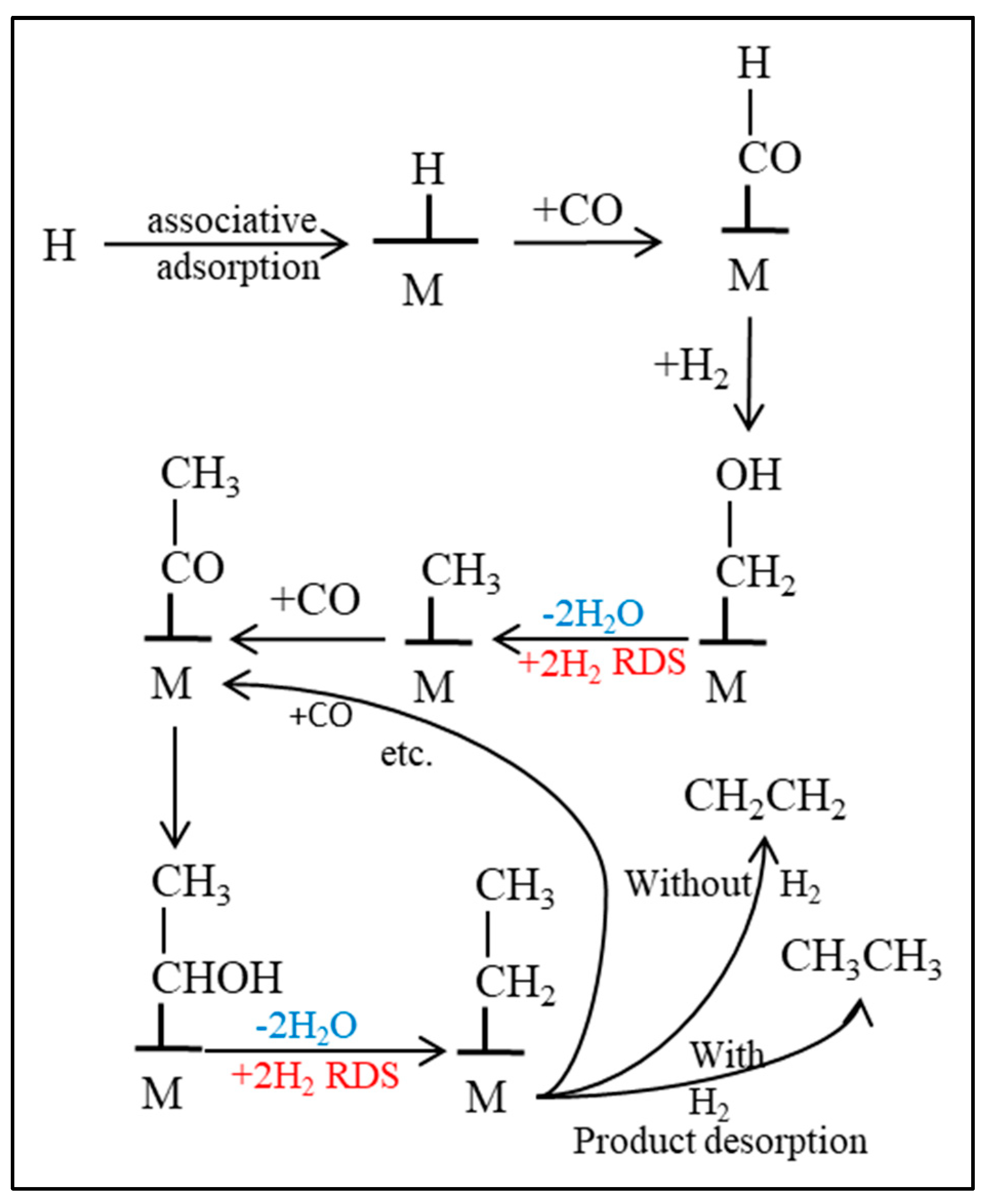

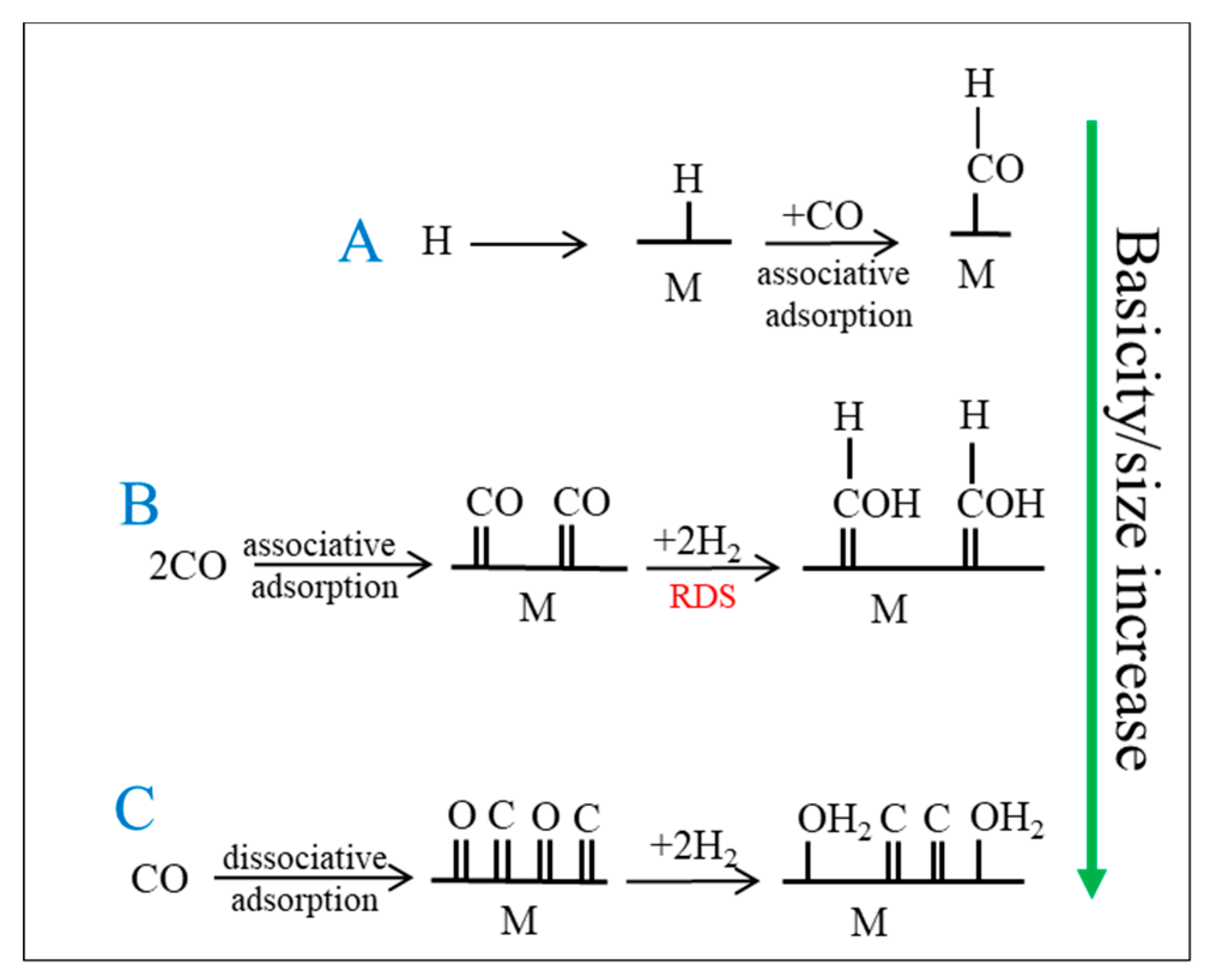

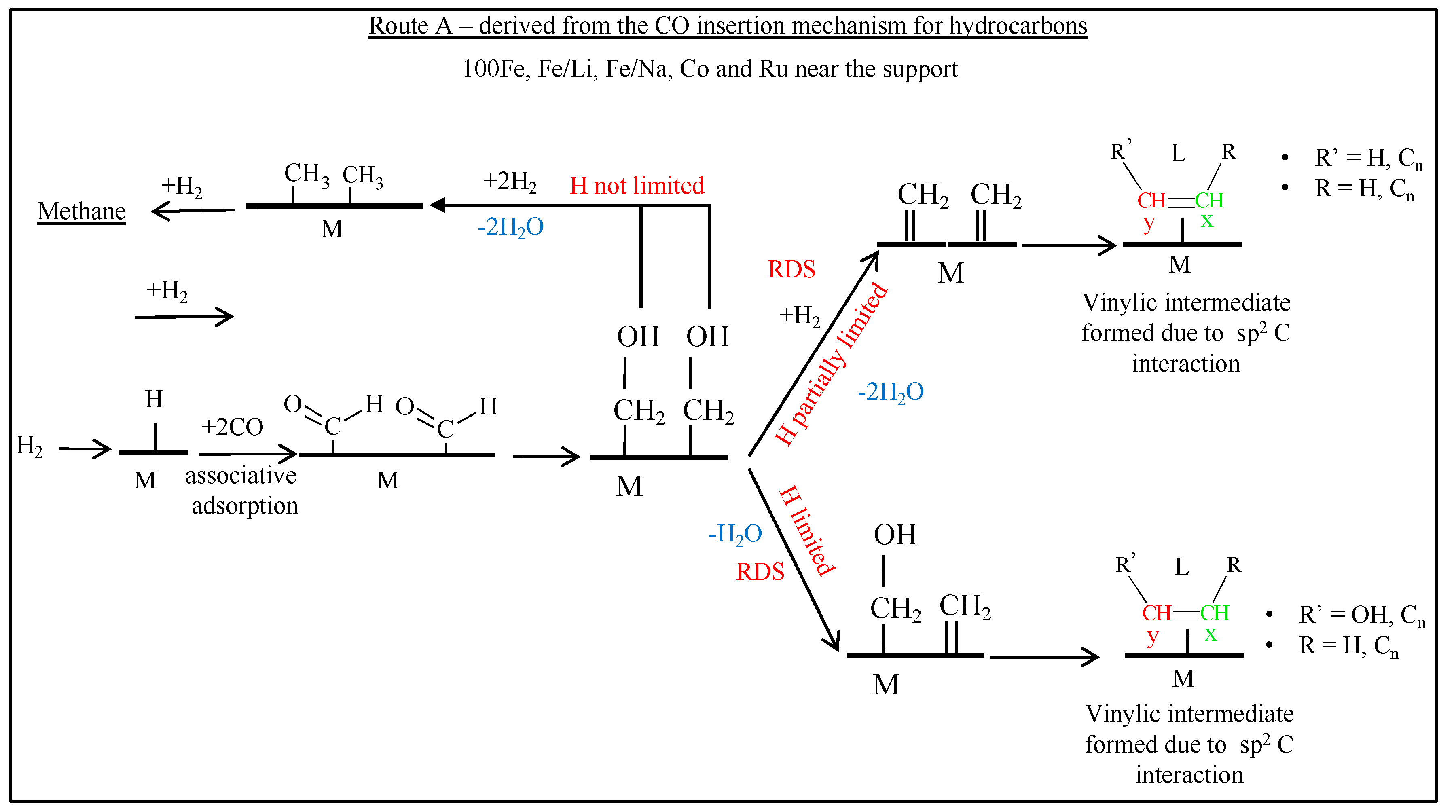

1.5. Known Mechanistic Routes

- associative/dissociative adsorption of CO (remains a point of contention);

- dissociative adsorption of hydrogen [43];

- transfer of 2 H* atoms to O* to form H2O;

- allocation of 2 H* to C* to form -CH2-;

- formation of a new C–C bond (unless methane is formed);

- desorption of H2O; and,

- desorption of aliphatic product.

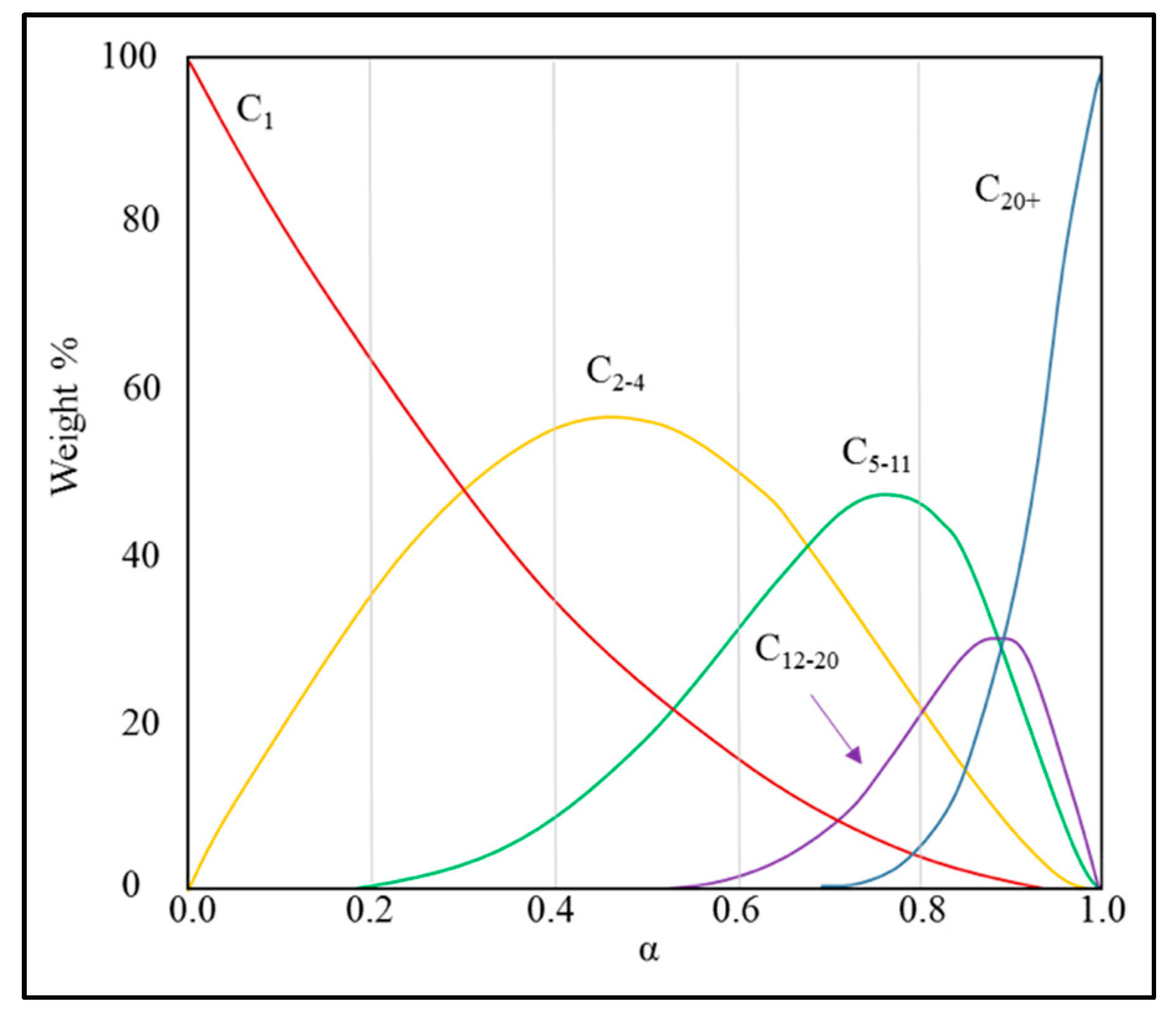

1.6. Anderson, Schulz, and Flory

1.7. Product Distribution of Fischer–Tropsch Synthesis

2. Experimental

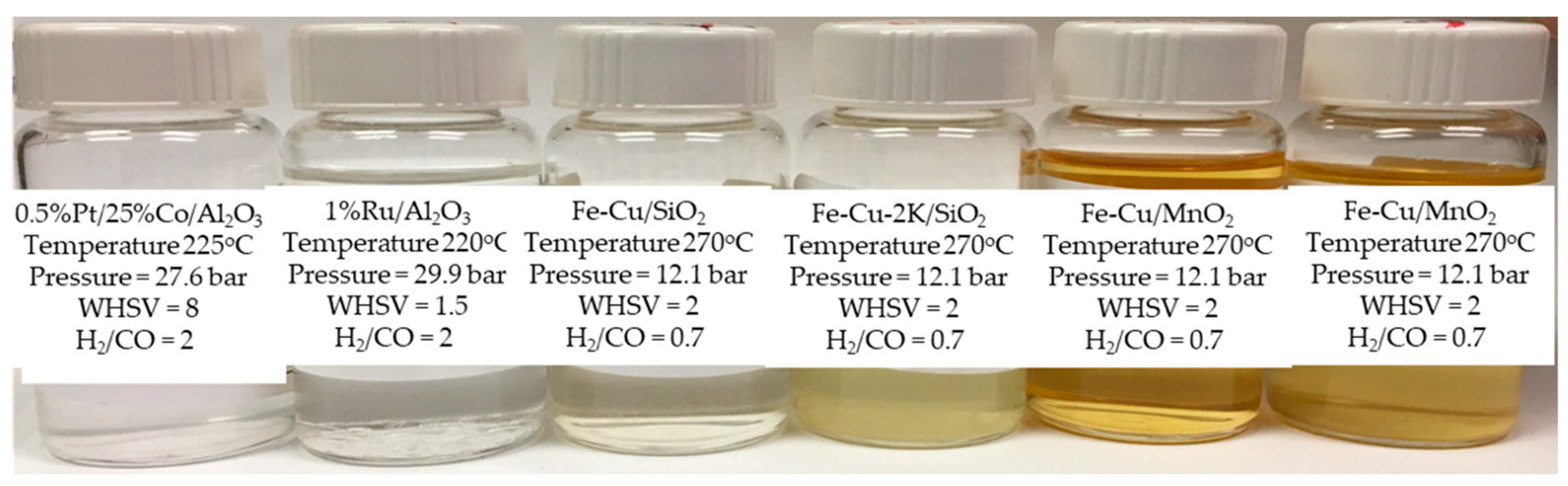

2.1. Catalyst Synthesis

2.1.1. Iron Catalysts

2.1.2. Cobalt Catalysts

2.1.3. Ruthenium Catalysts

2.2. Catalyst Testing

2.2.1. Iron Catalysts

2.2.2. Cobalt Catalysts

2.2.3. Ruthenium Catalysts

2.3. FTS Product Analysis

Instrumentation Methods

3. Results and Discussion

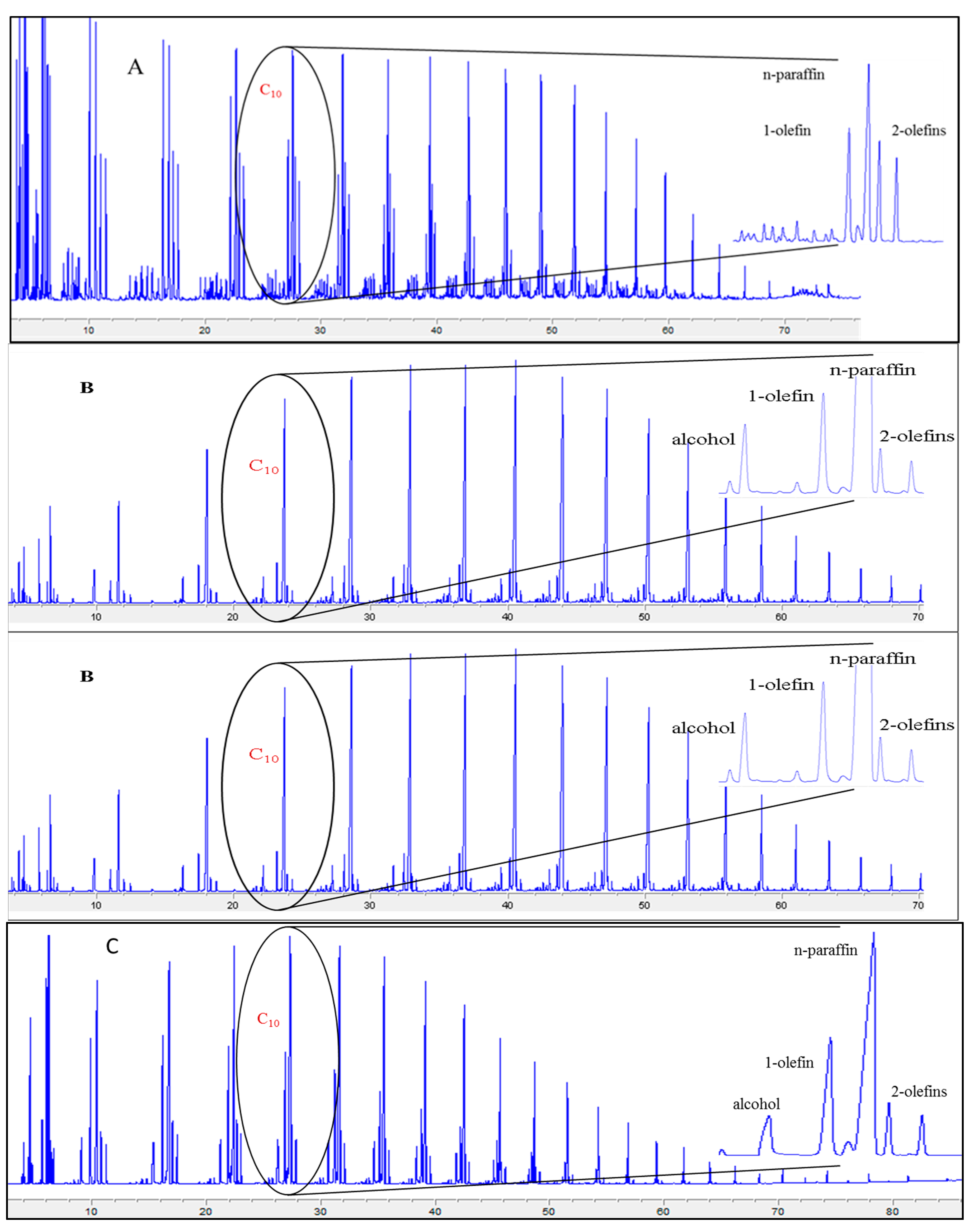

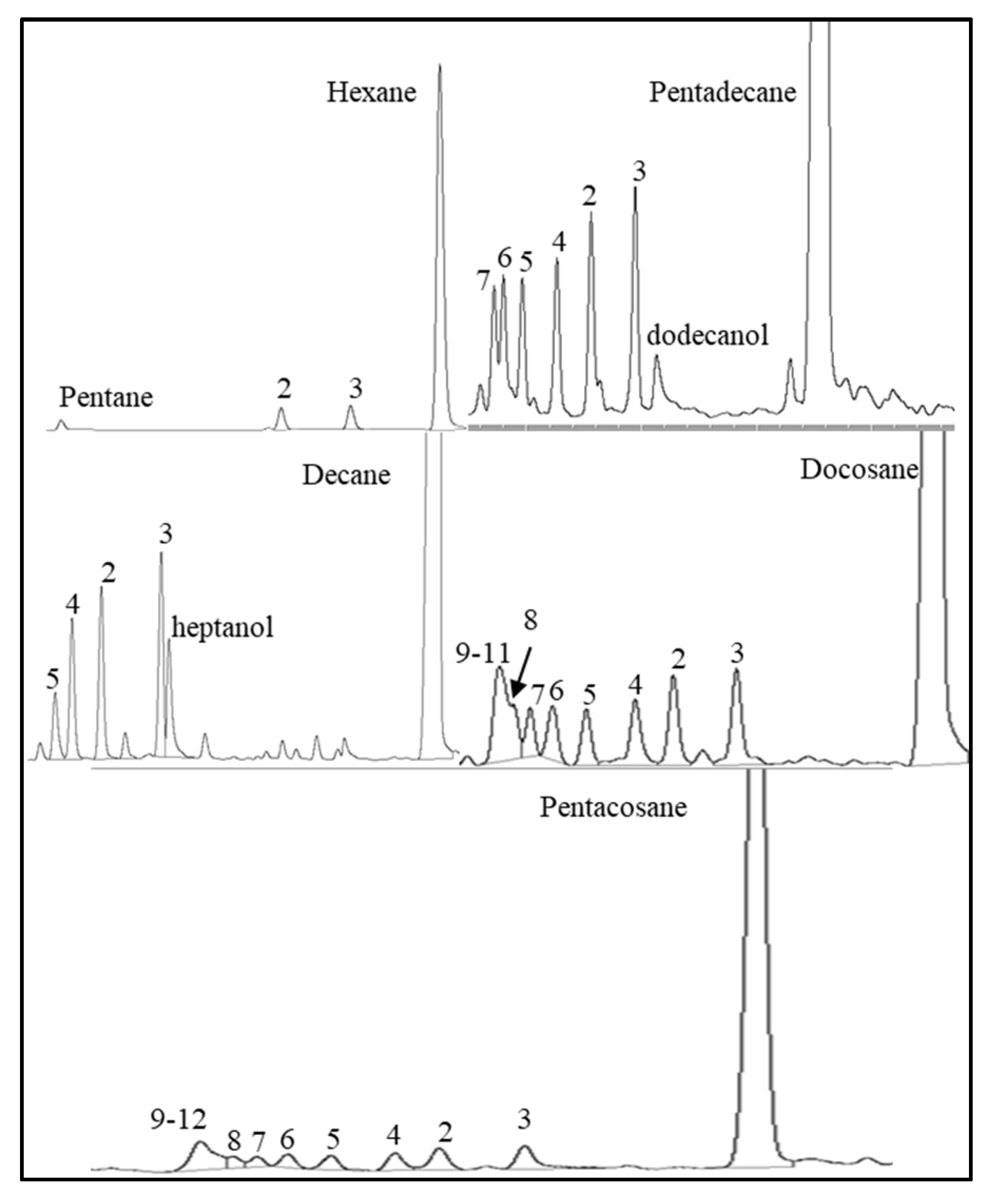

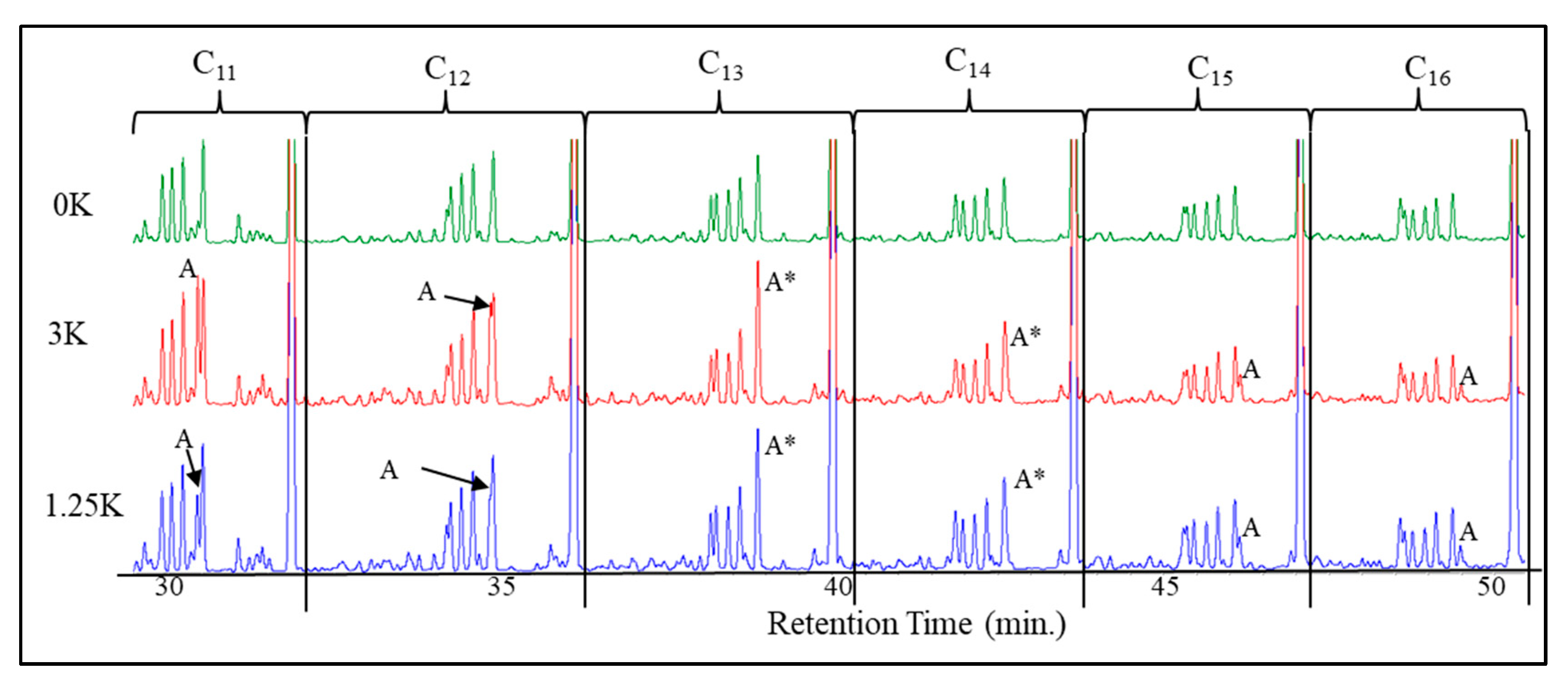

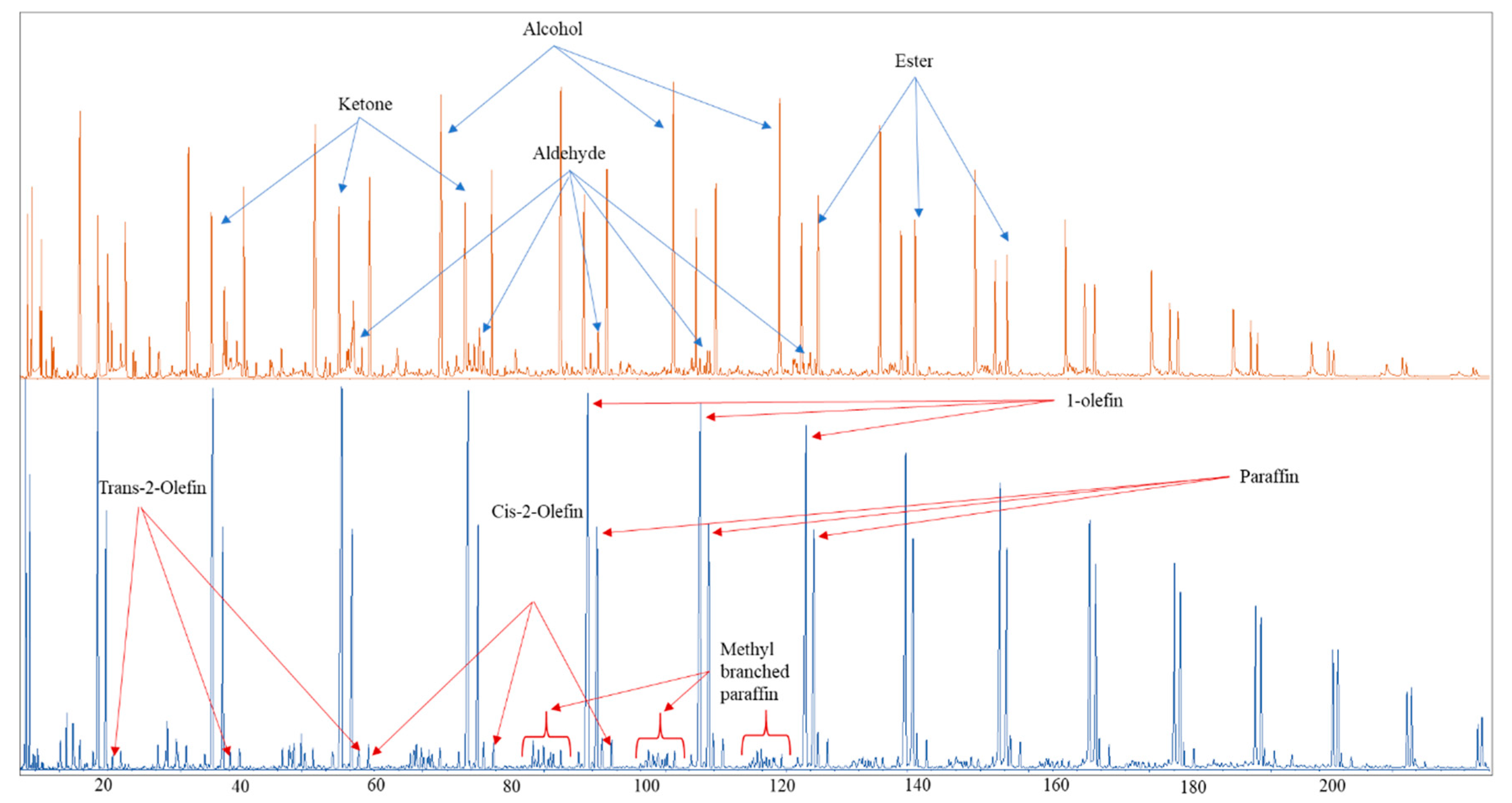

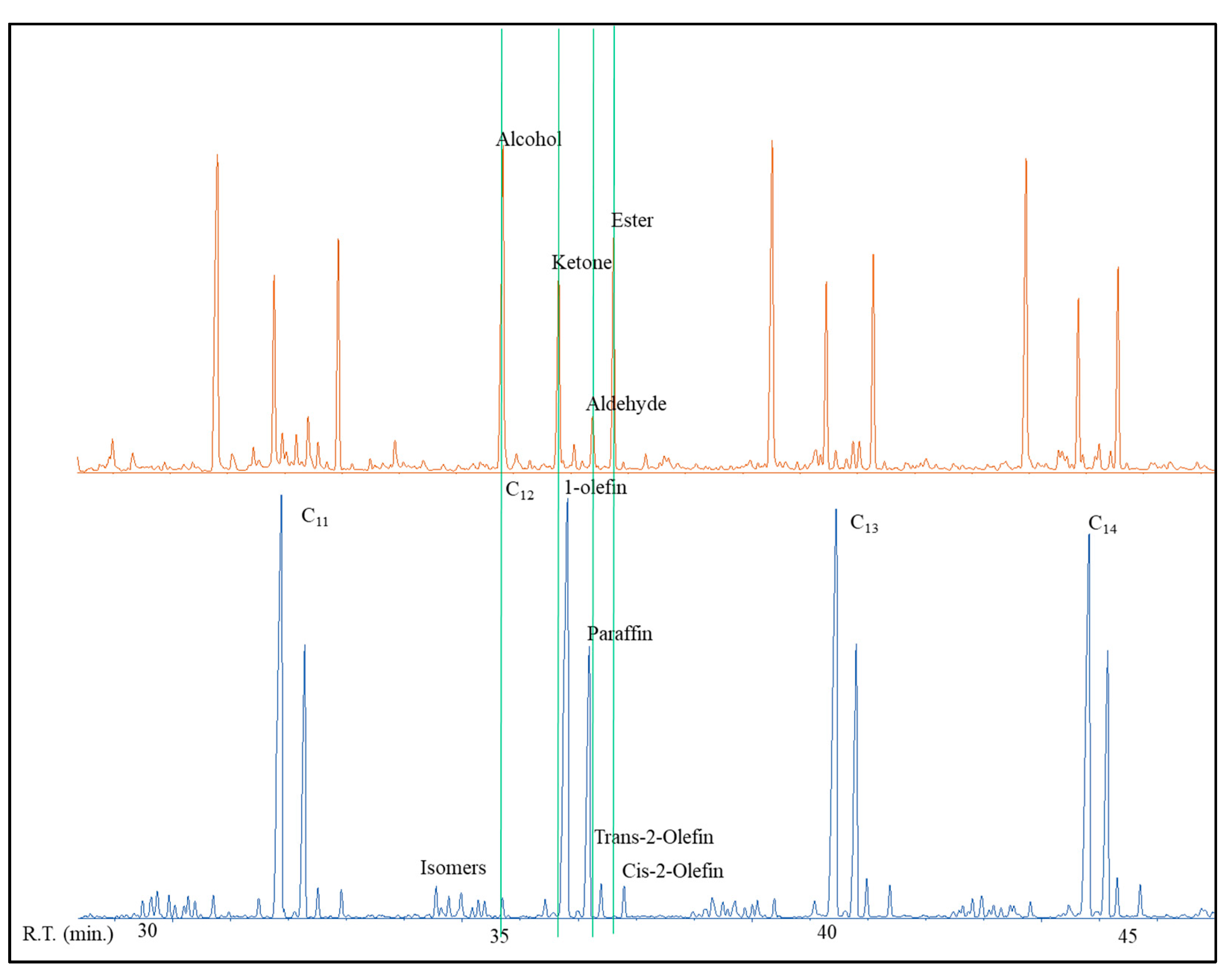

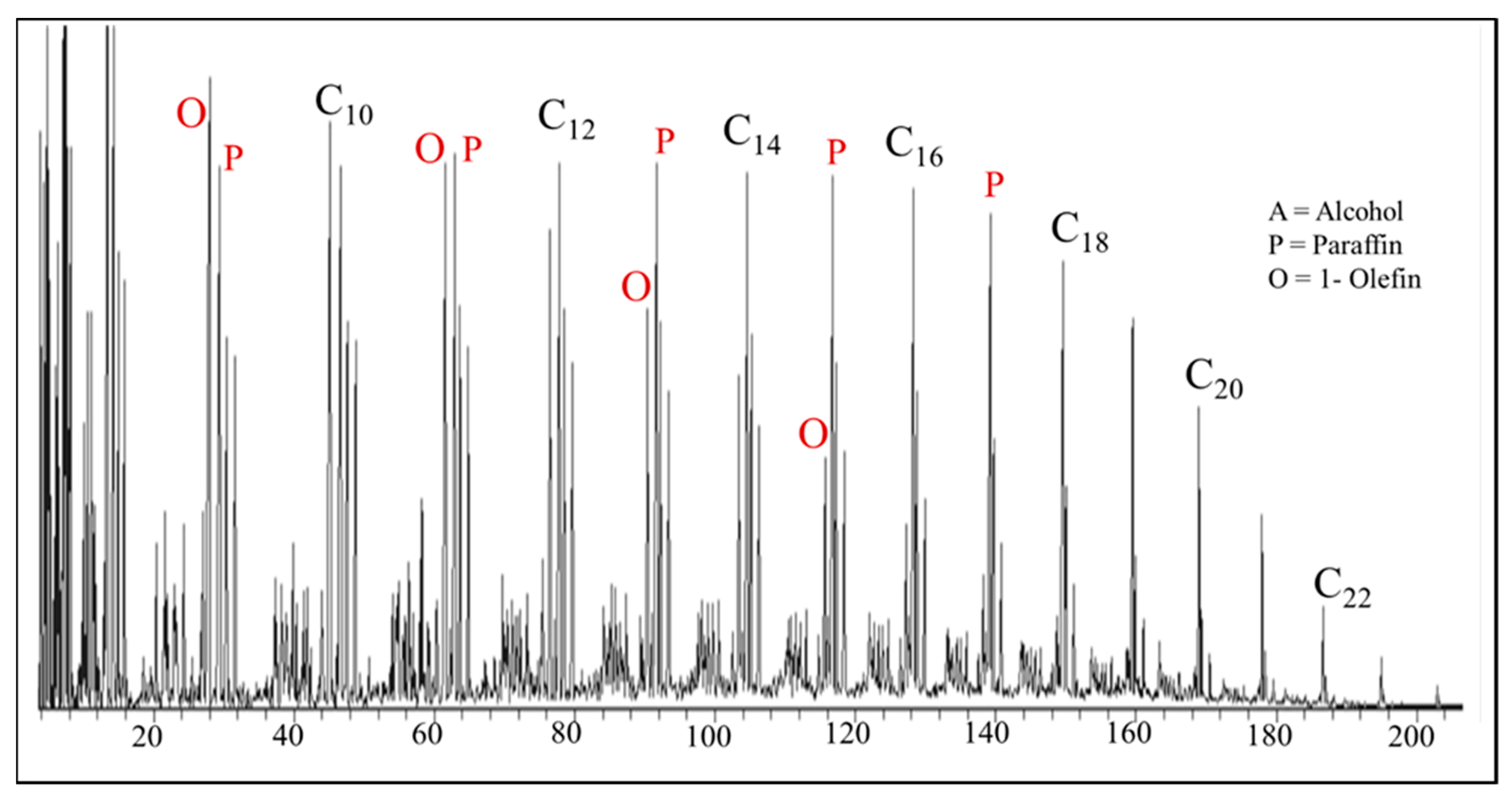

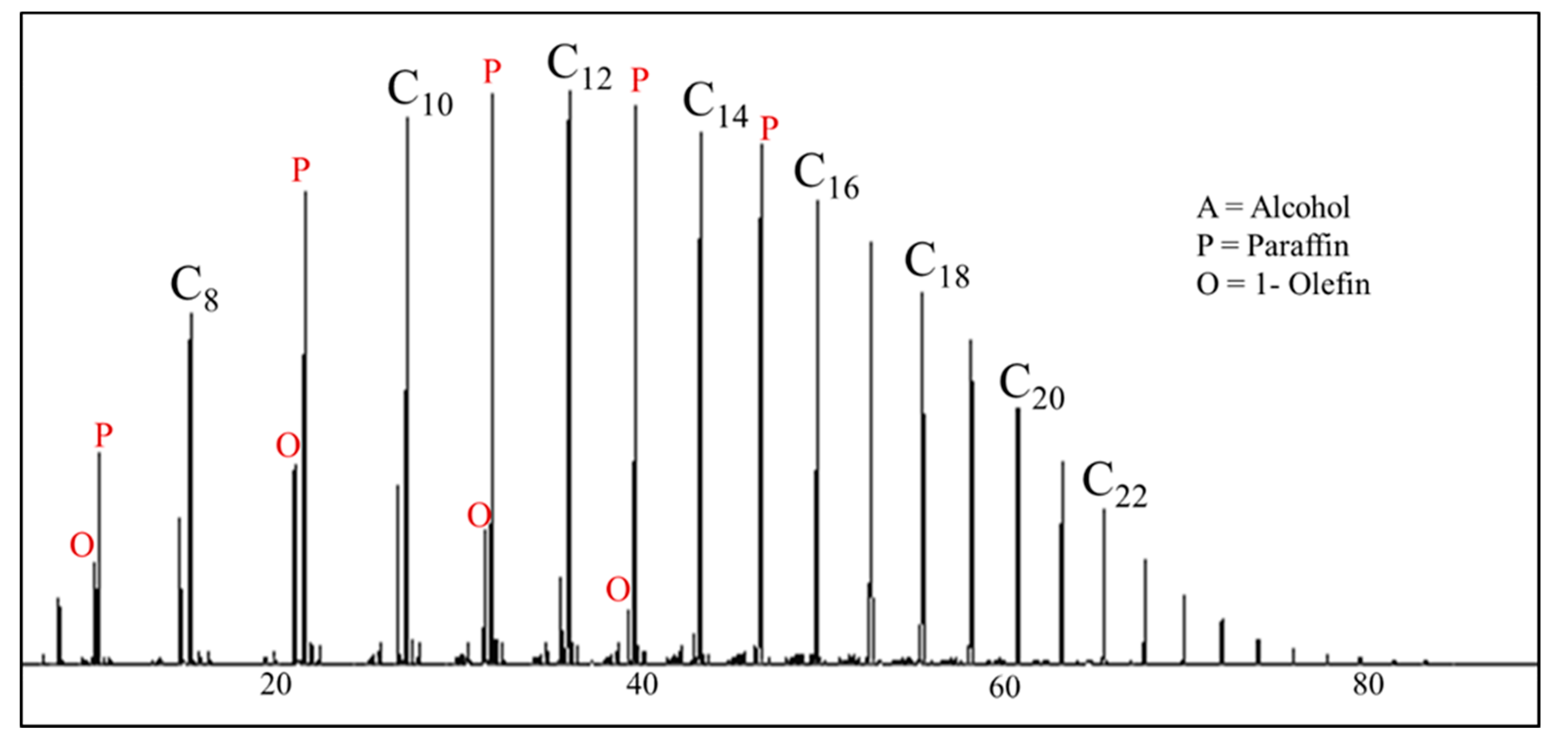

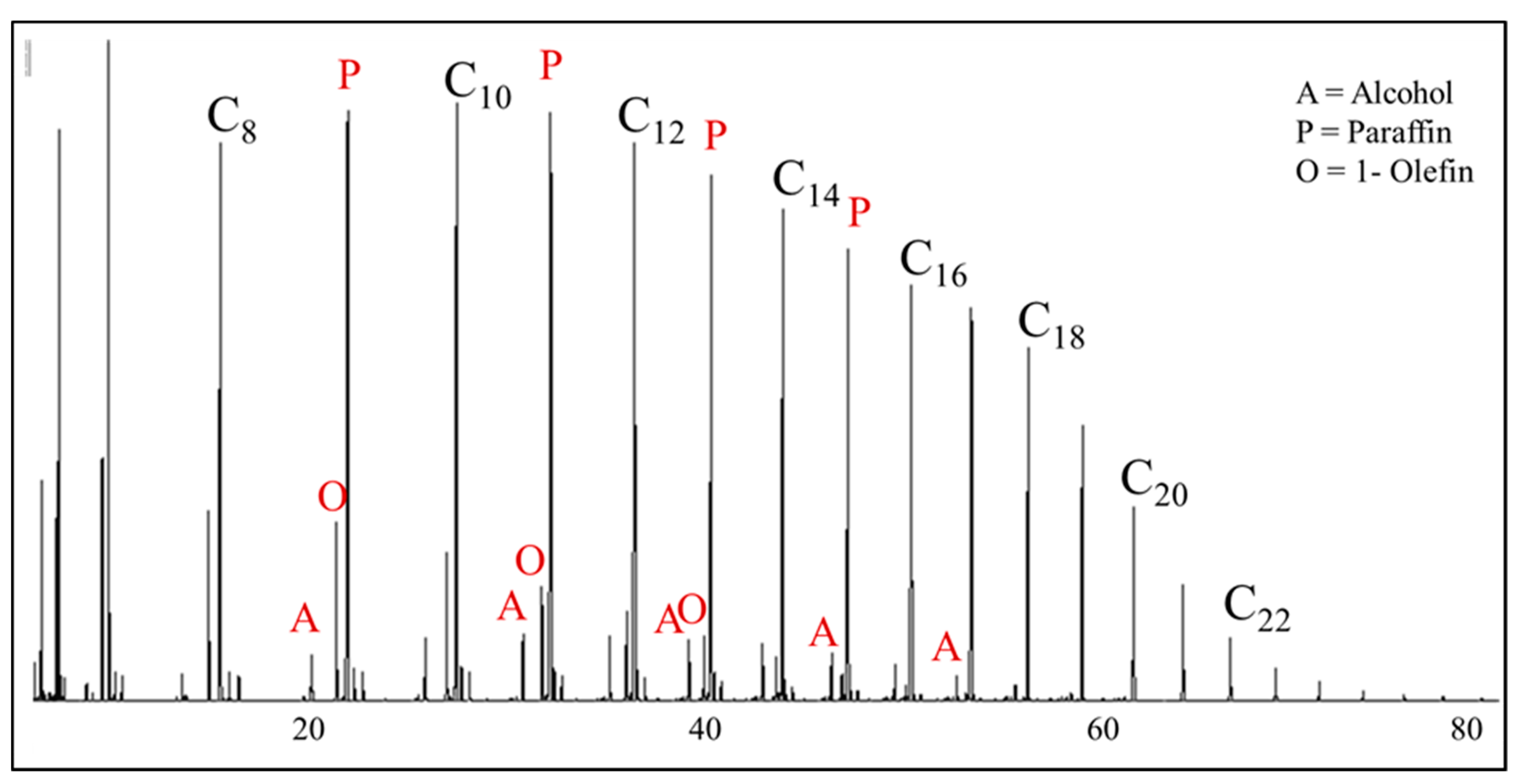

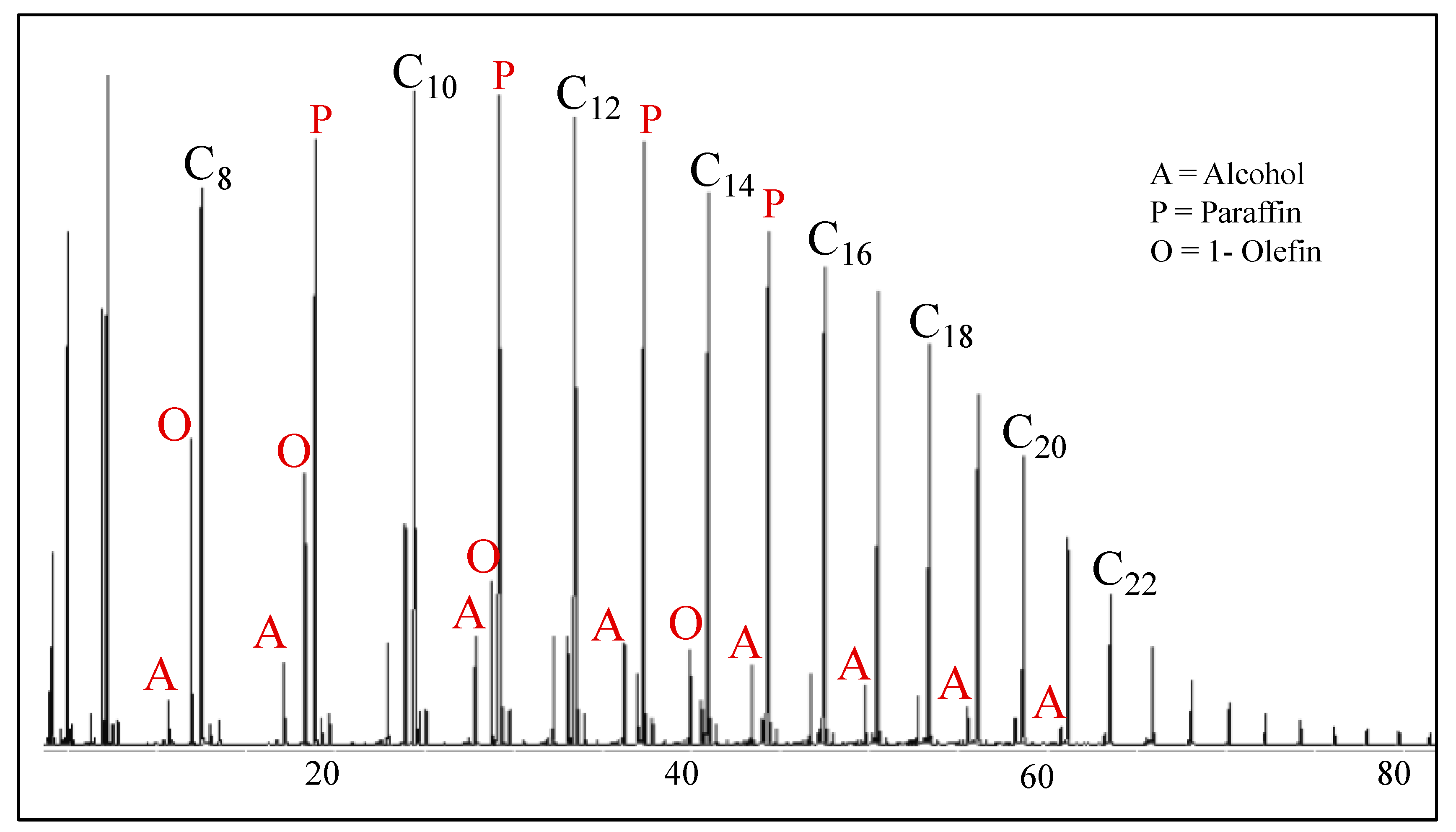

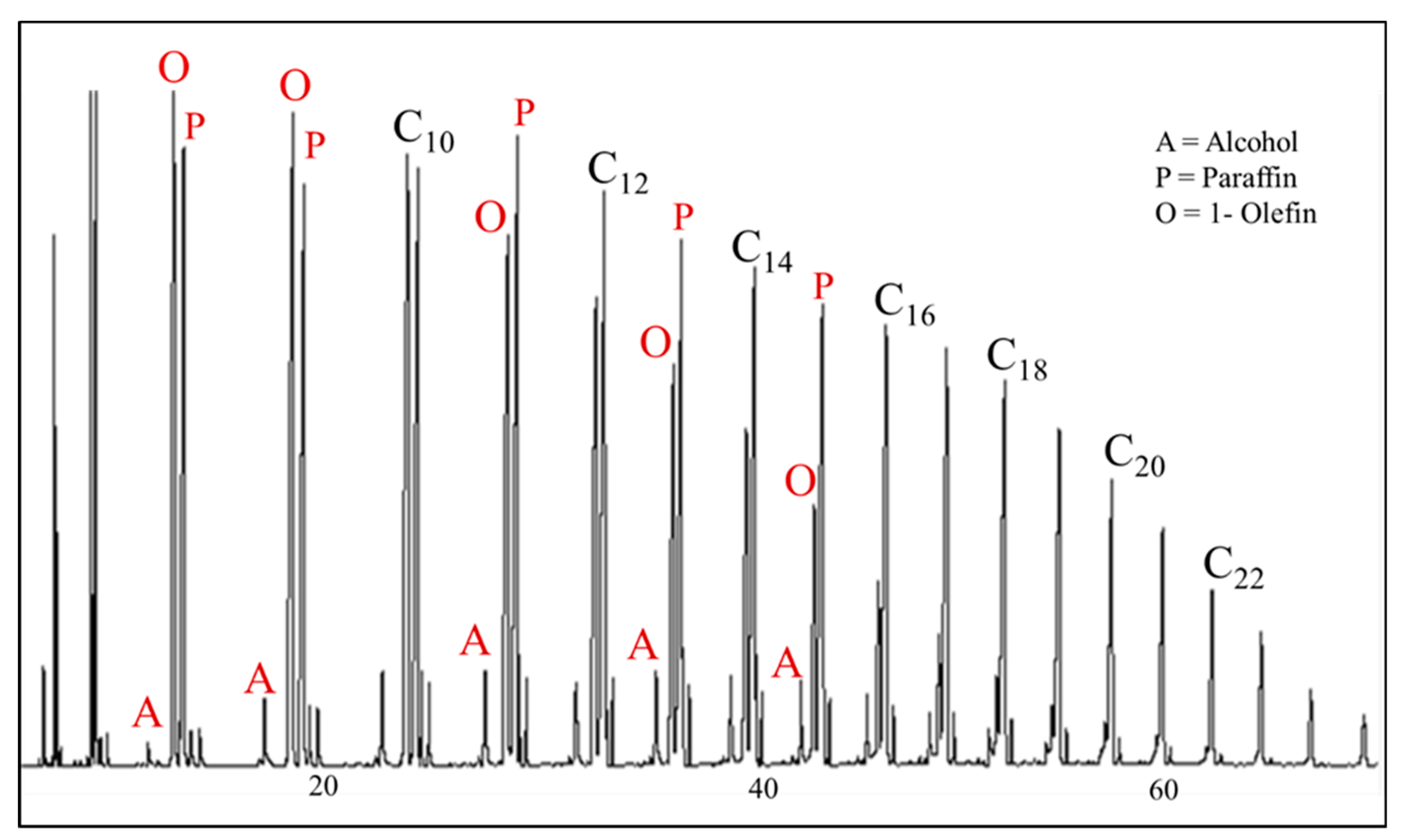

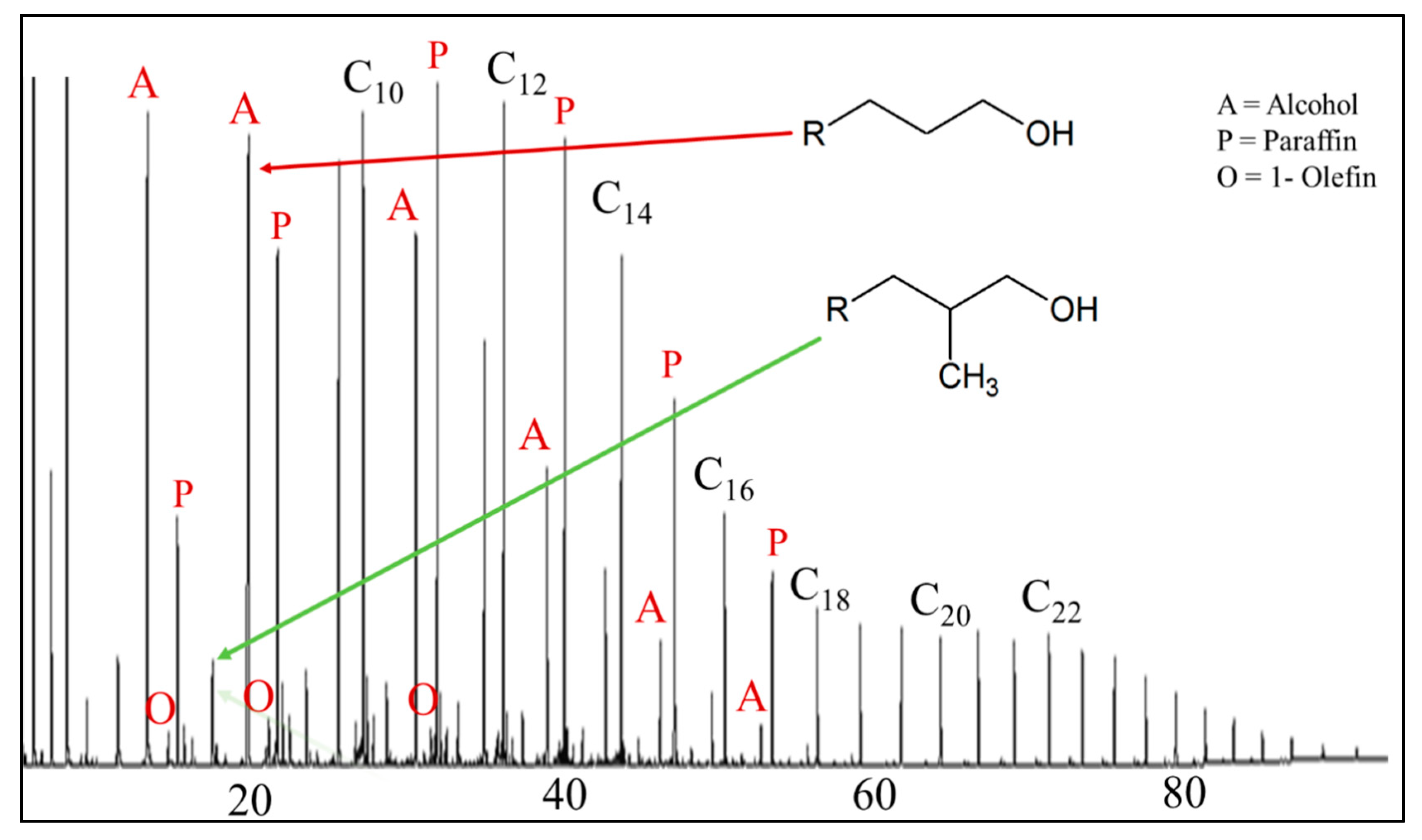

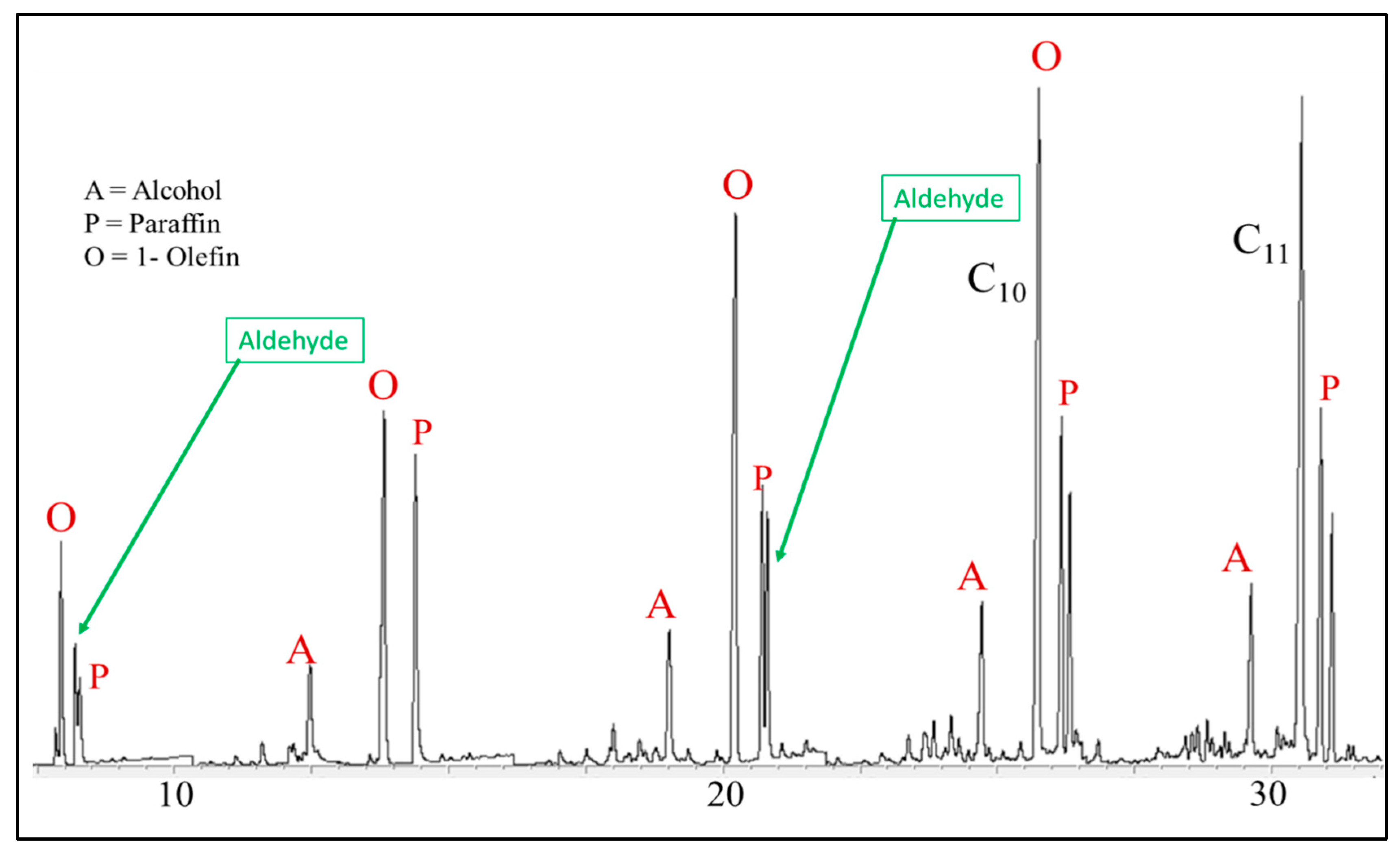

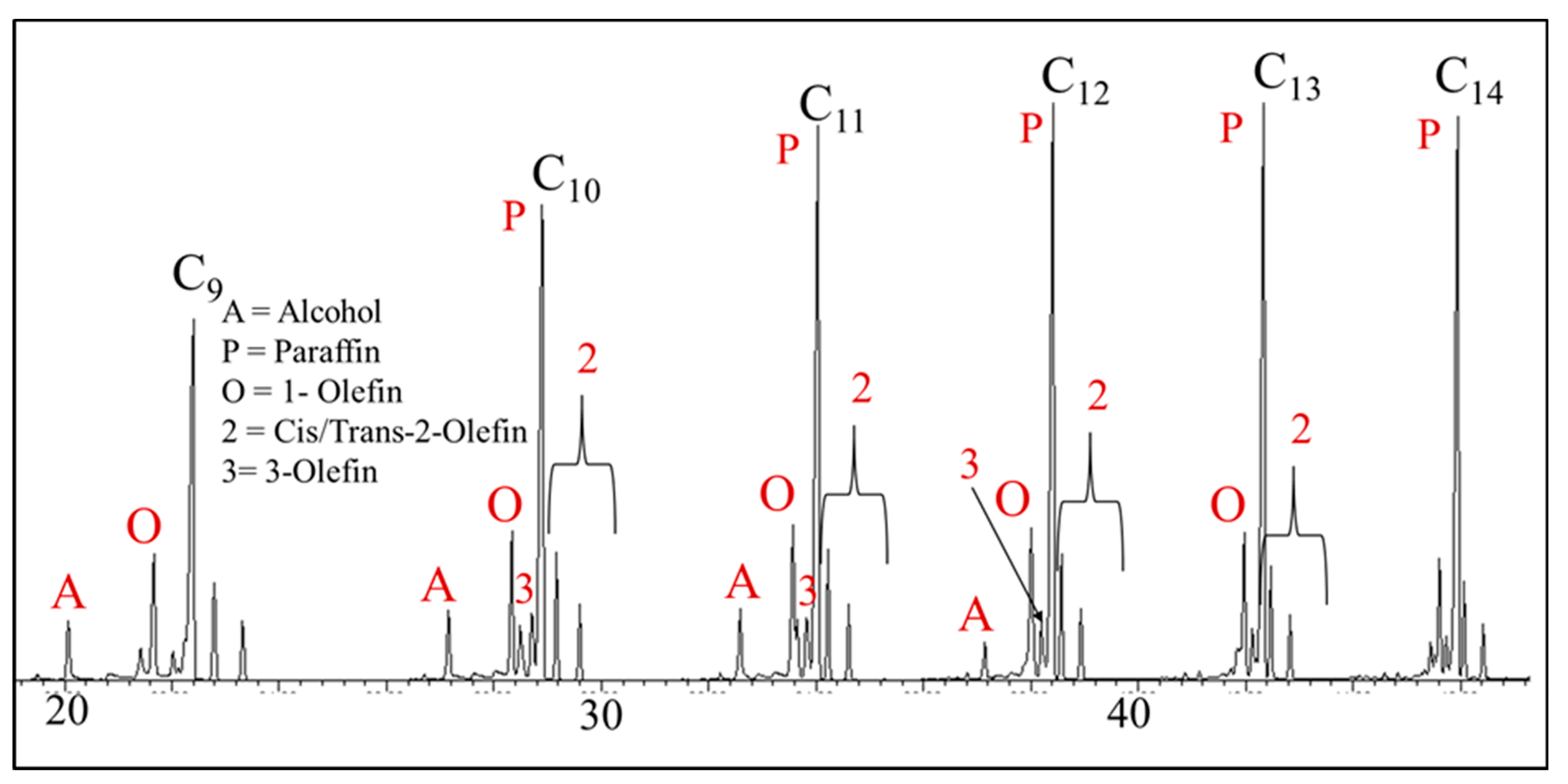

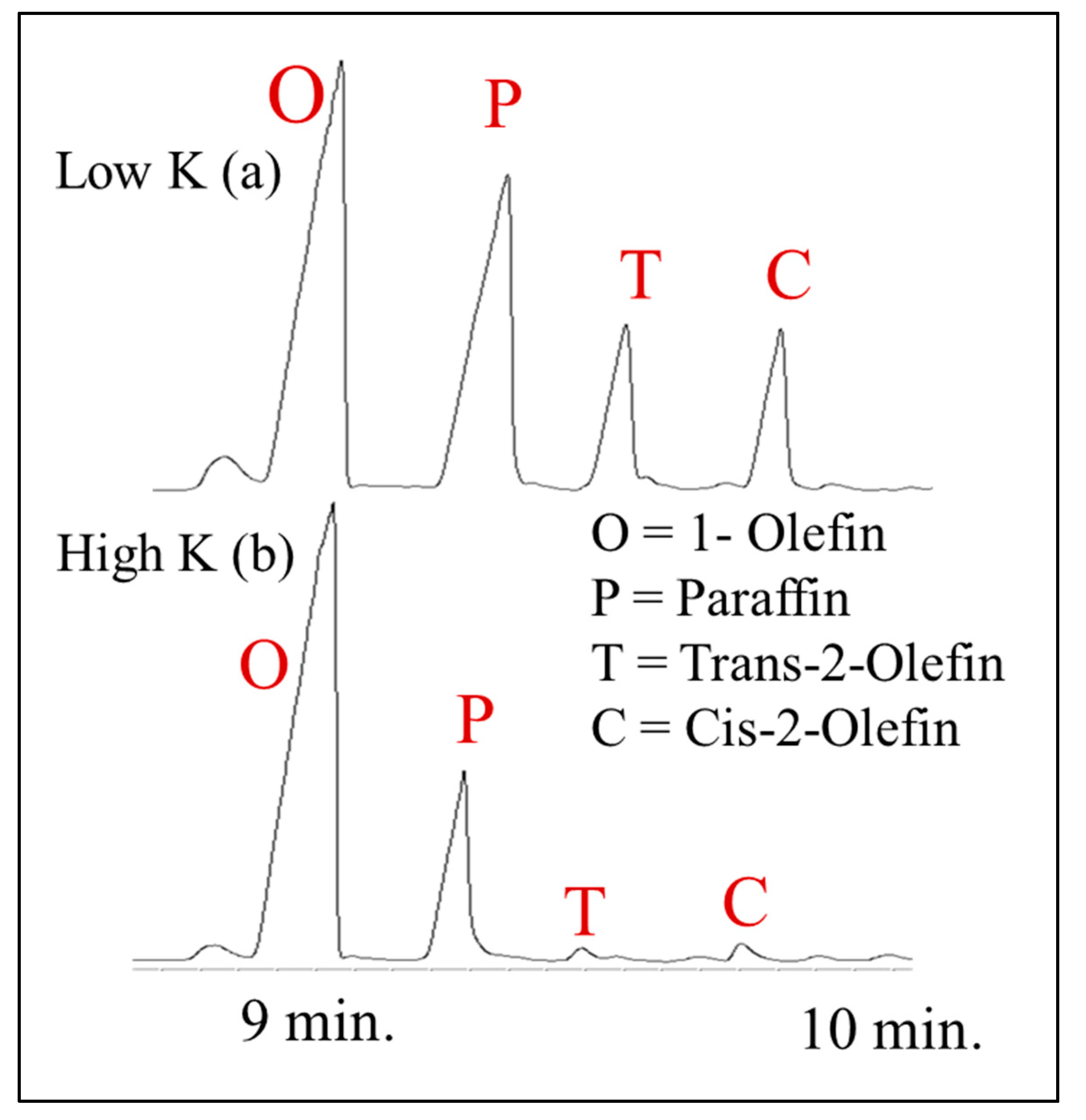

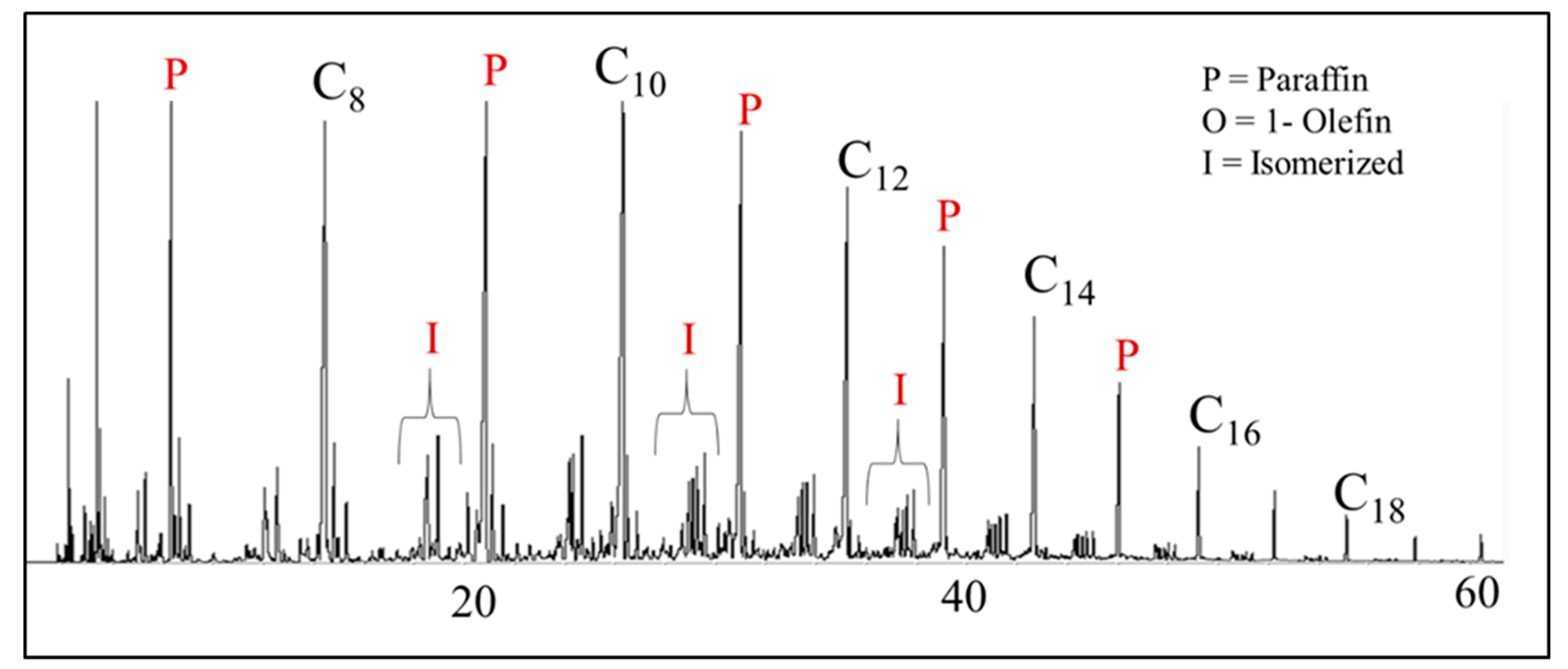

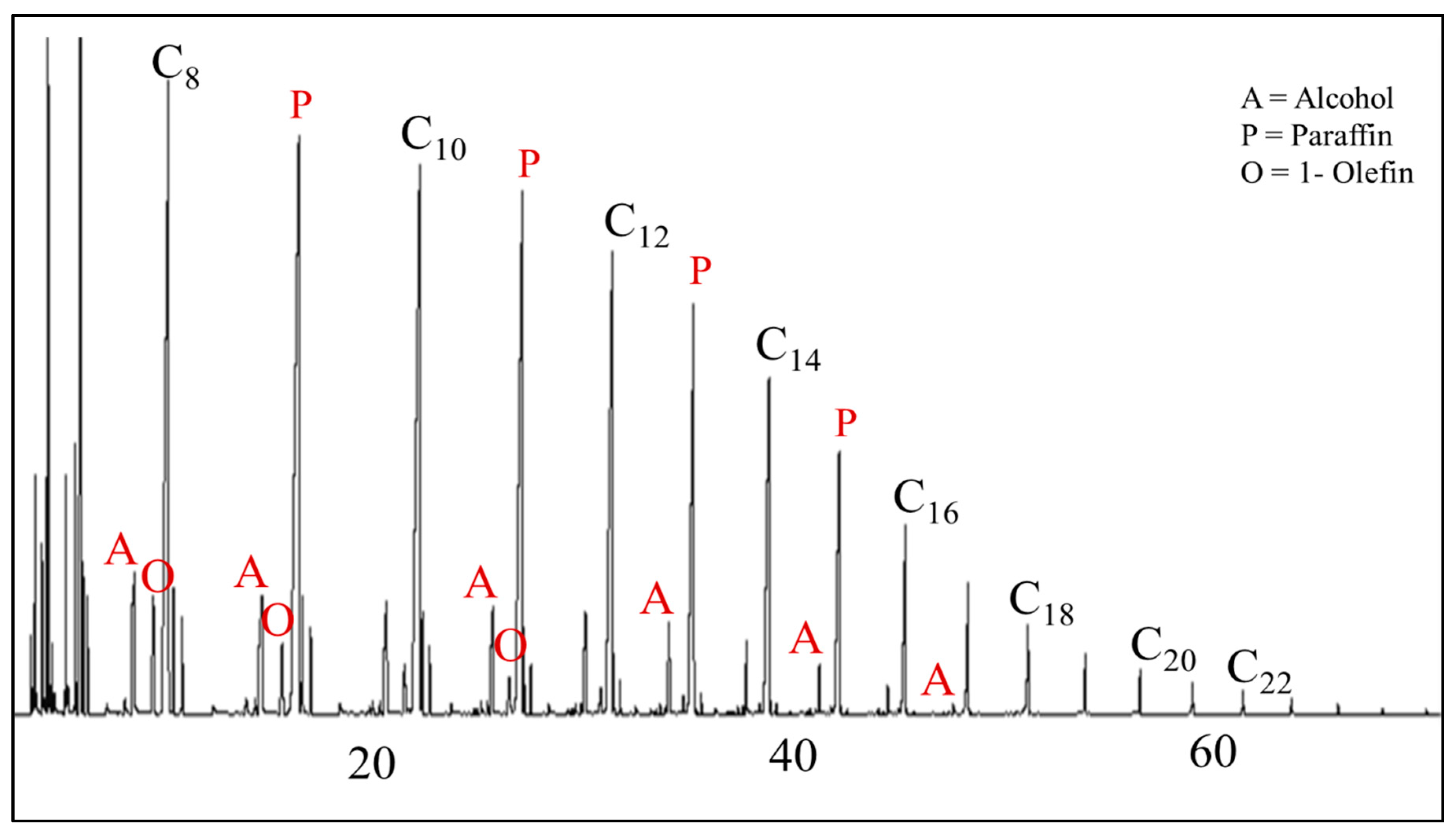

3.1. Product Selectivity Separation and Identification

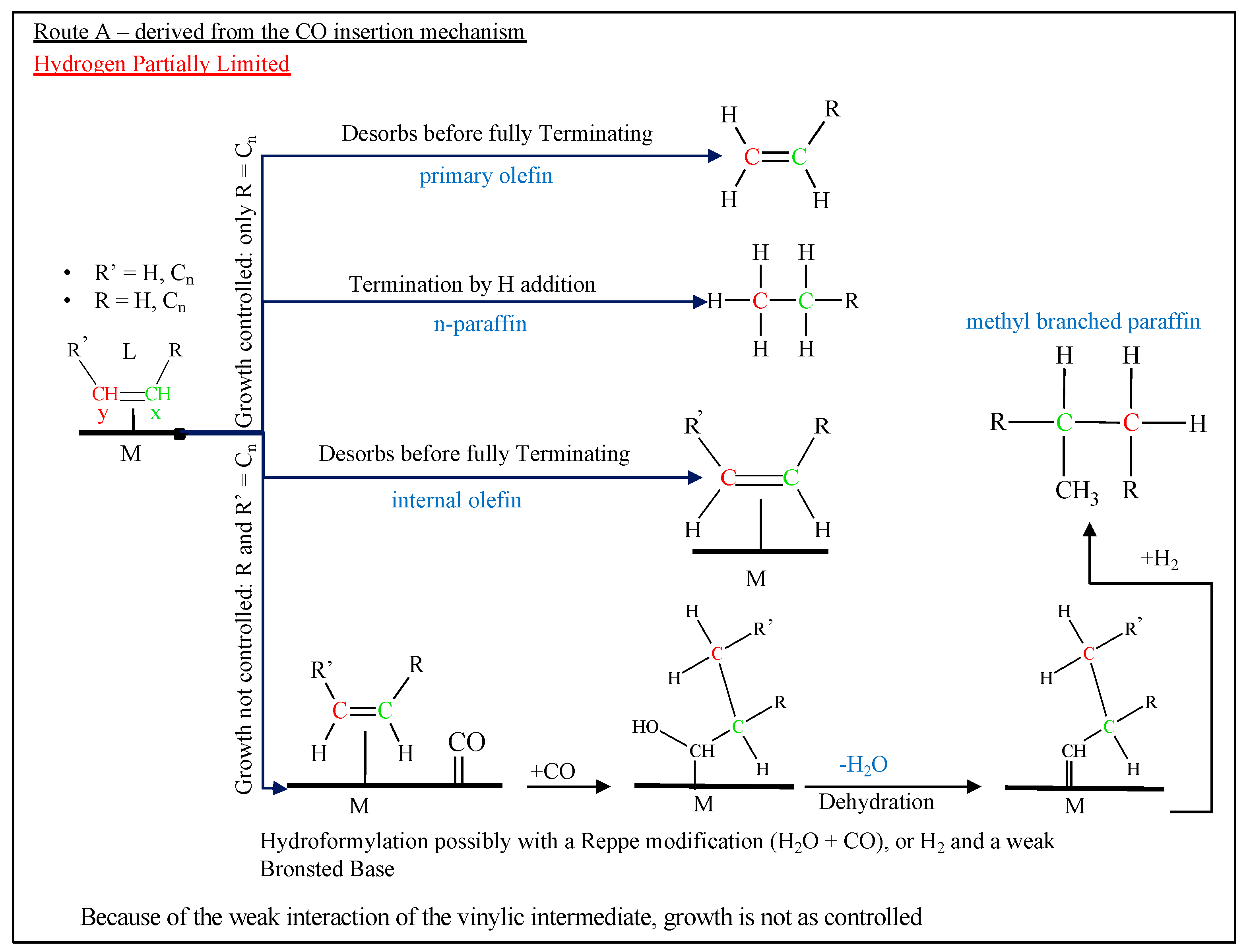

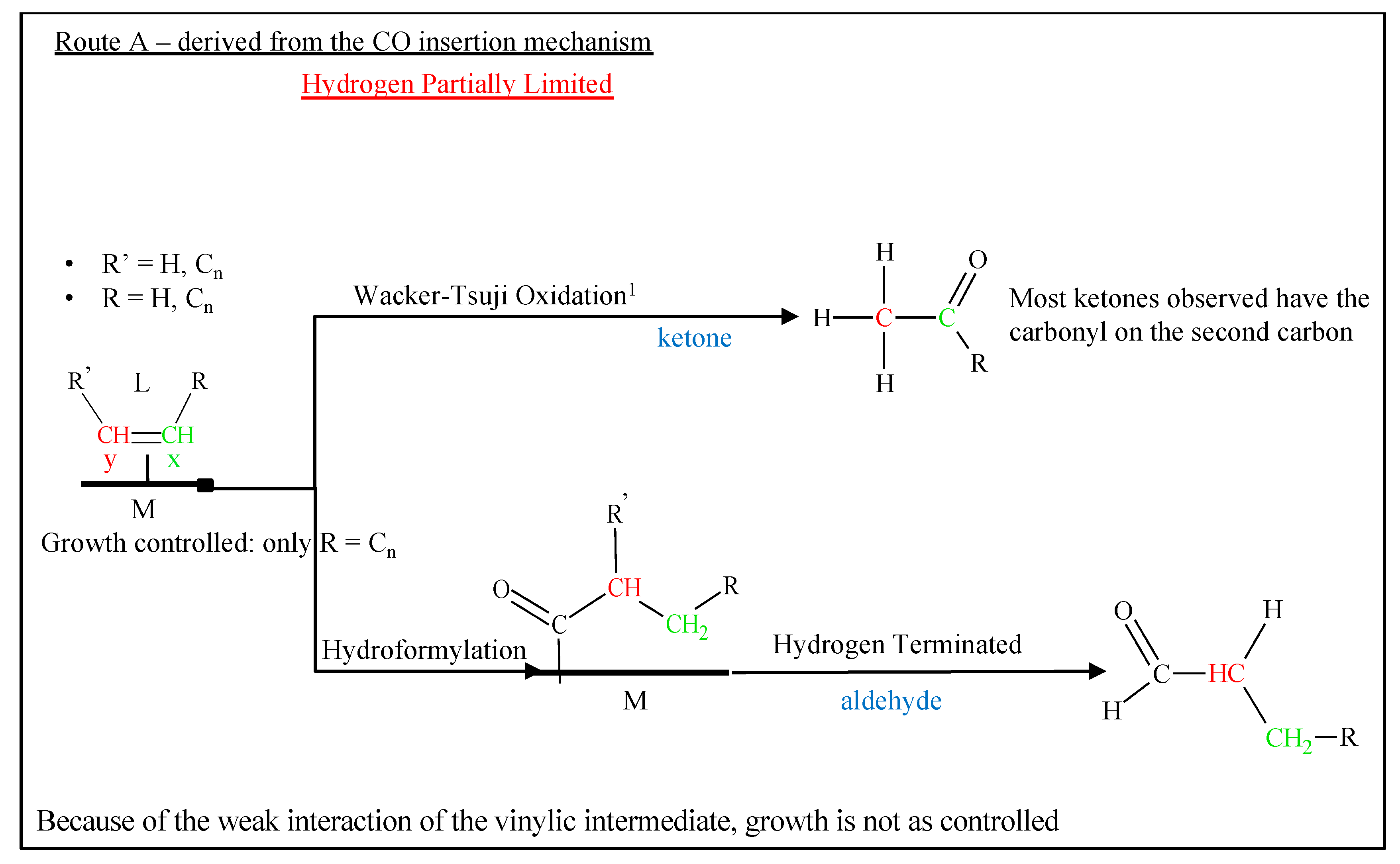

- The ketone regularly falls near the 1-olefin and, as the carbon number increases, the peak moves toward the 1-olefin and it eventually merges with it. The major ketone observed is where the carbonyl is on the second carbon; every ketone that was observed in the GC-MS for Figure 5 and Figure 9 has the second carbon as the carbonyl.

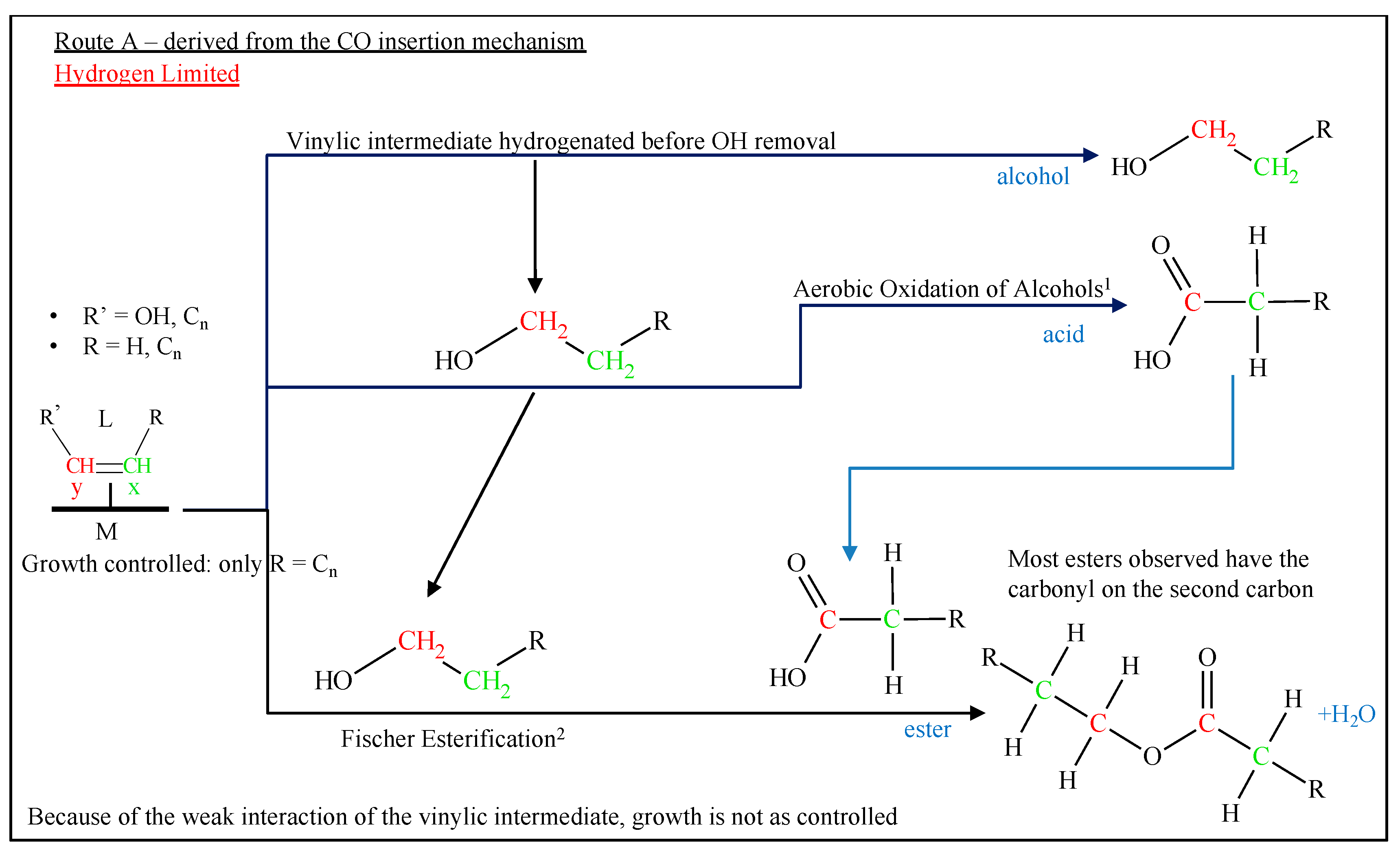

- Esters, by and large, appear between the trans-2-olefins and cis-2-olefins and, with increasing carbon number, move toward the cis-2-olefin. The major ester observed is also where the carbonyl is on the second carbon; again, every observed ester in the GC-MS for Figure 5 and Figure 9 has the second carbon as the carbonyl and the oxygen between the second and third carbons.

- The aldehyde usually elutes between the paraffin and trans-2-olefin.

- Alcohol, which is the predominant oxygenate product in the oil phase, is the only oxygenate separated and verified for the higher carbon number fraction.

- The Co/ceria catalyst (Figure 19): the linear alcohol peaks are more dominant than the paraffin and there is the presence of the two methyl alcohols.

- The unsupported K/Fe catalyst (Figure 20): the aldehyde is more dominant than the linear alcohol for some of the shorter hydrocarbons.

- The NaY supported ruthenium catalyst (Figure 21): the peak that is assigned to 3-olefin is intense enough to be observable for several carbon numbers.

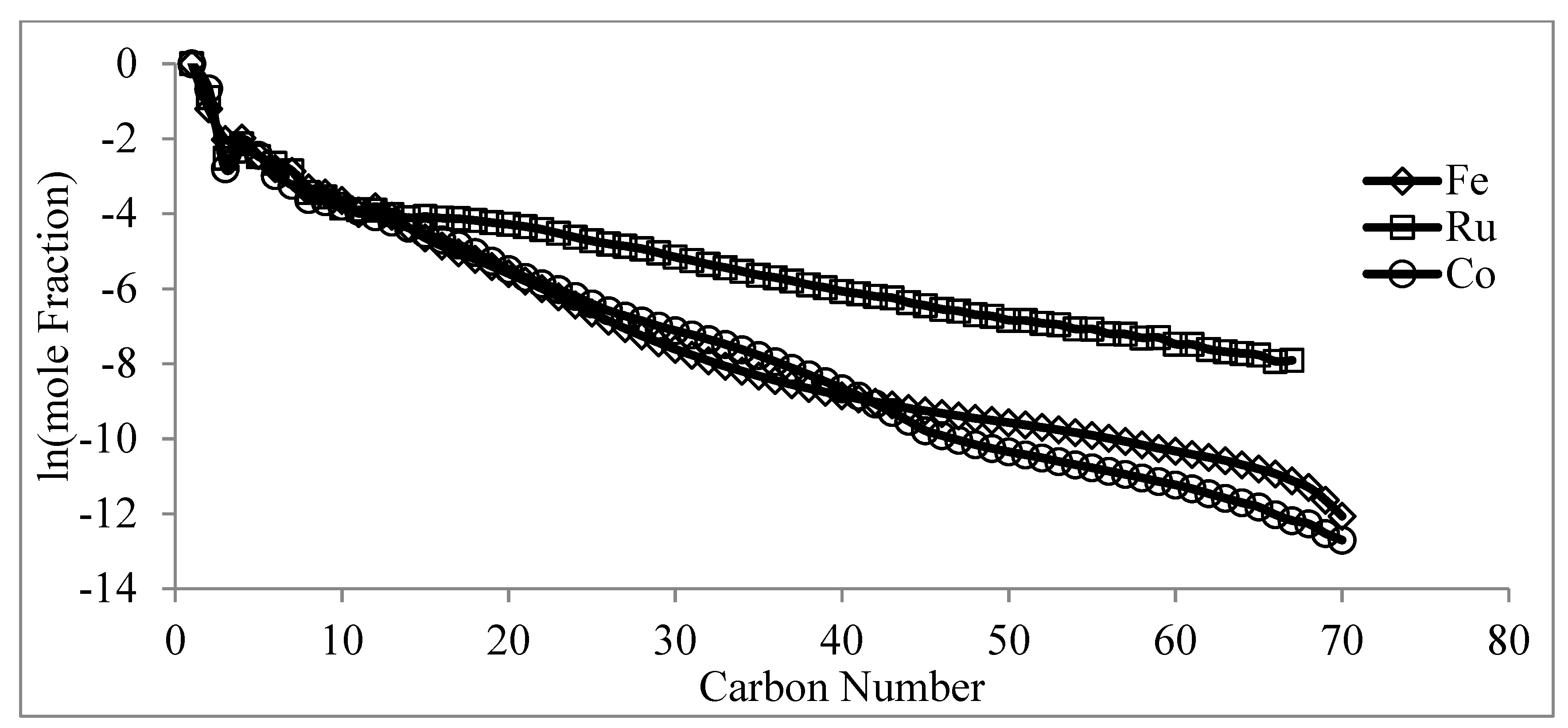

3.2. Mole Fraction

3.3. Chain Growth Probability Factor (α)

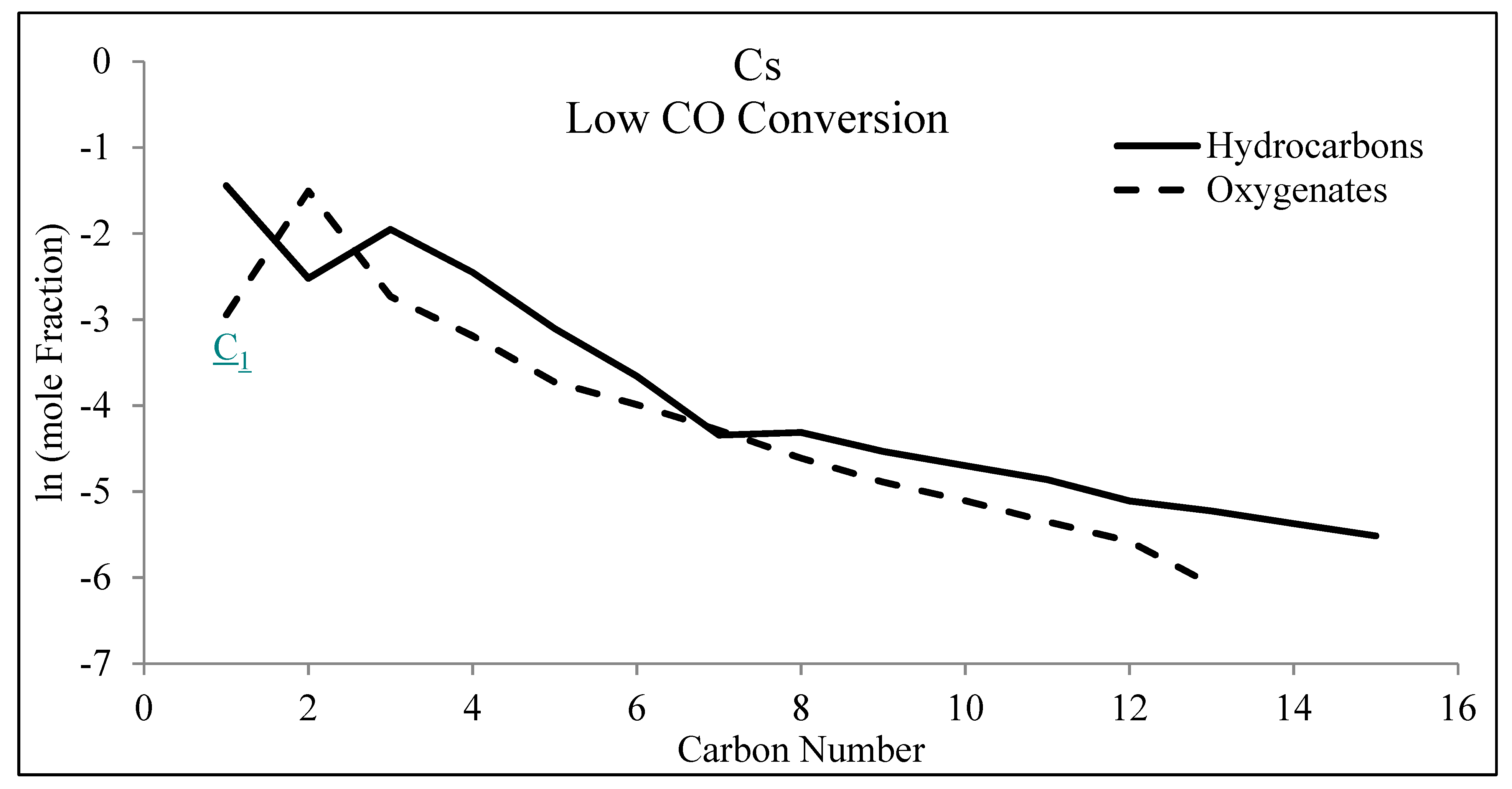

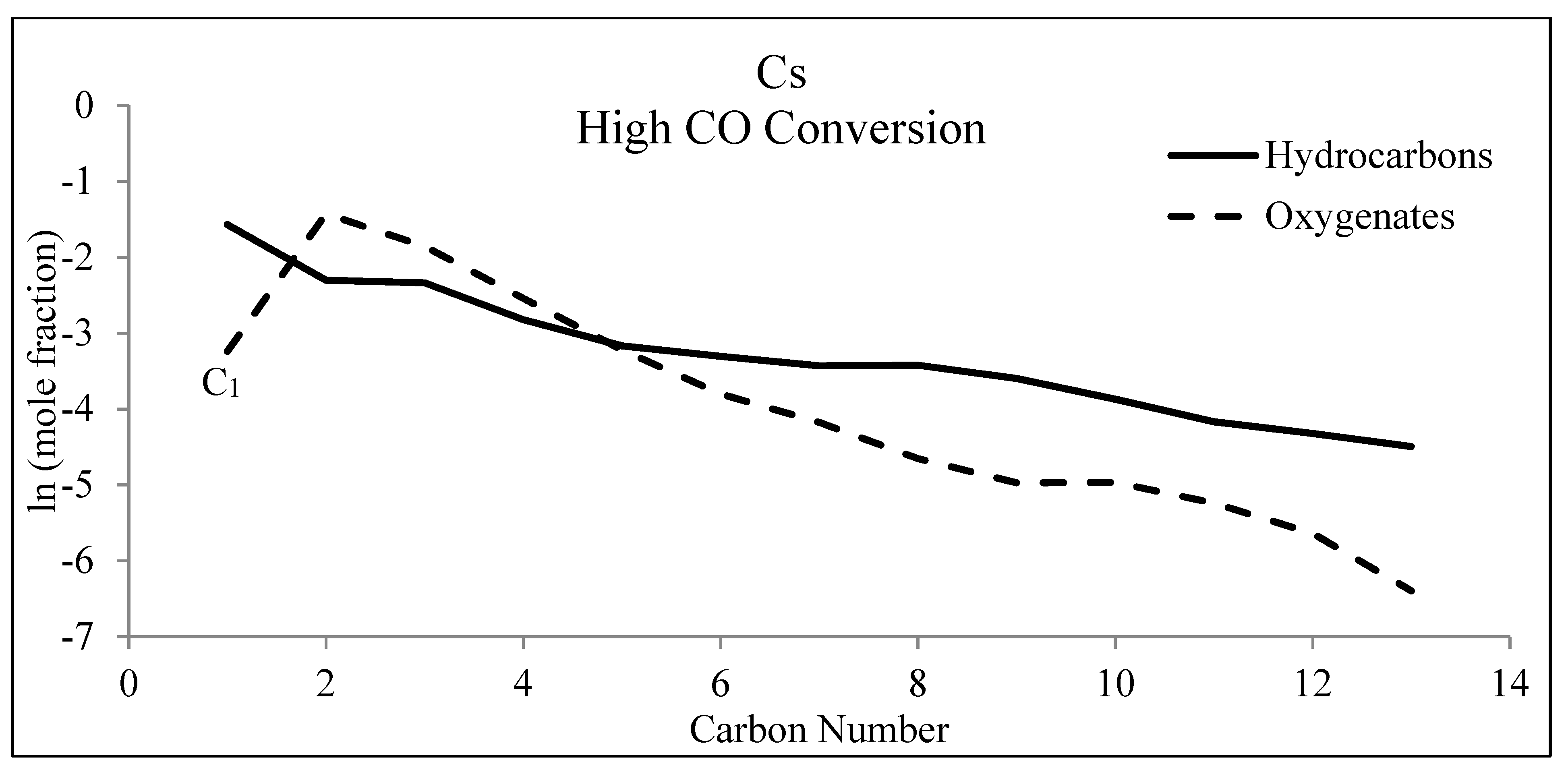

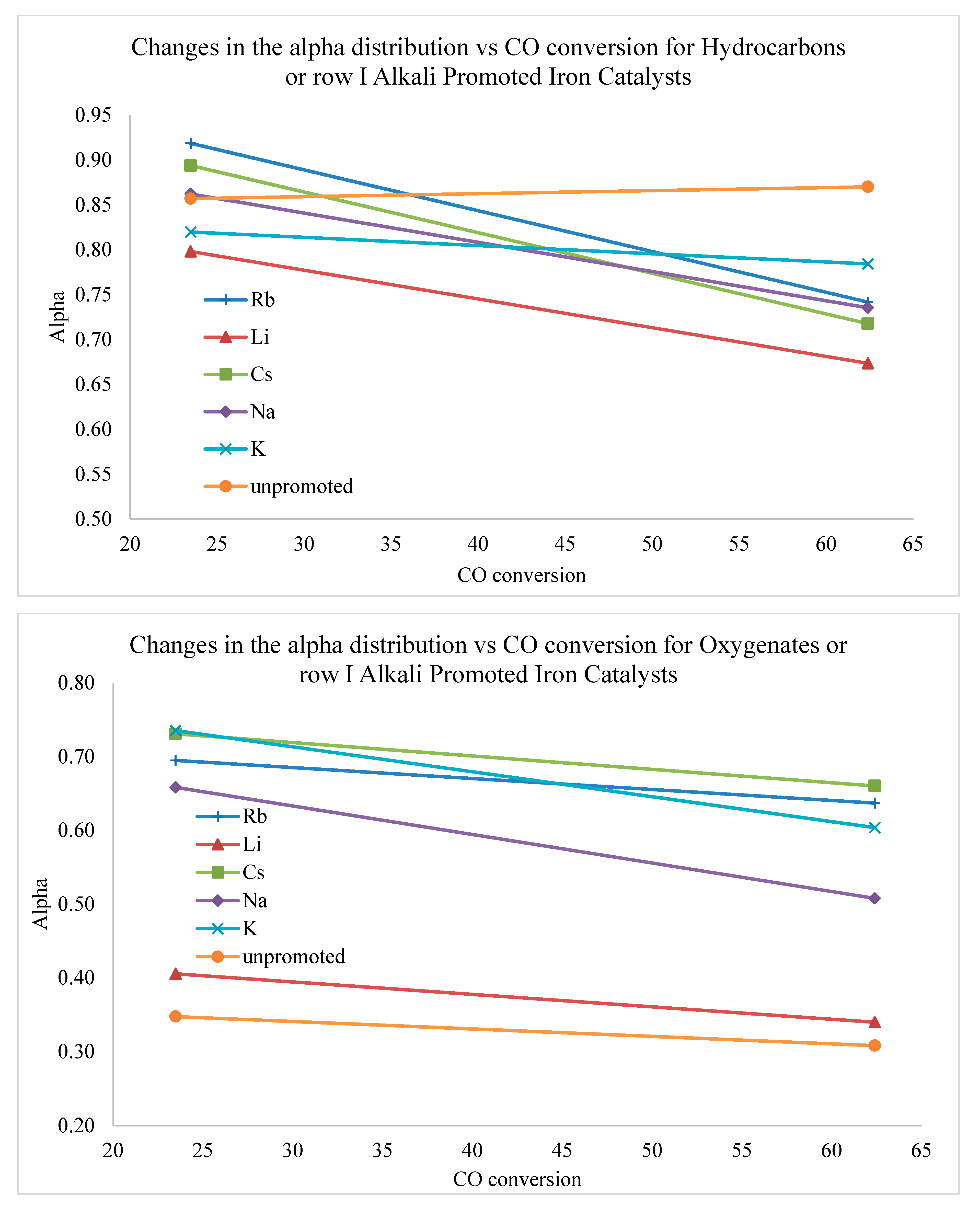

3.3.1. Iron

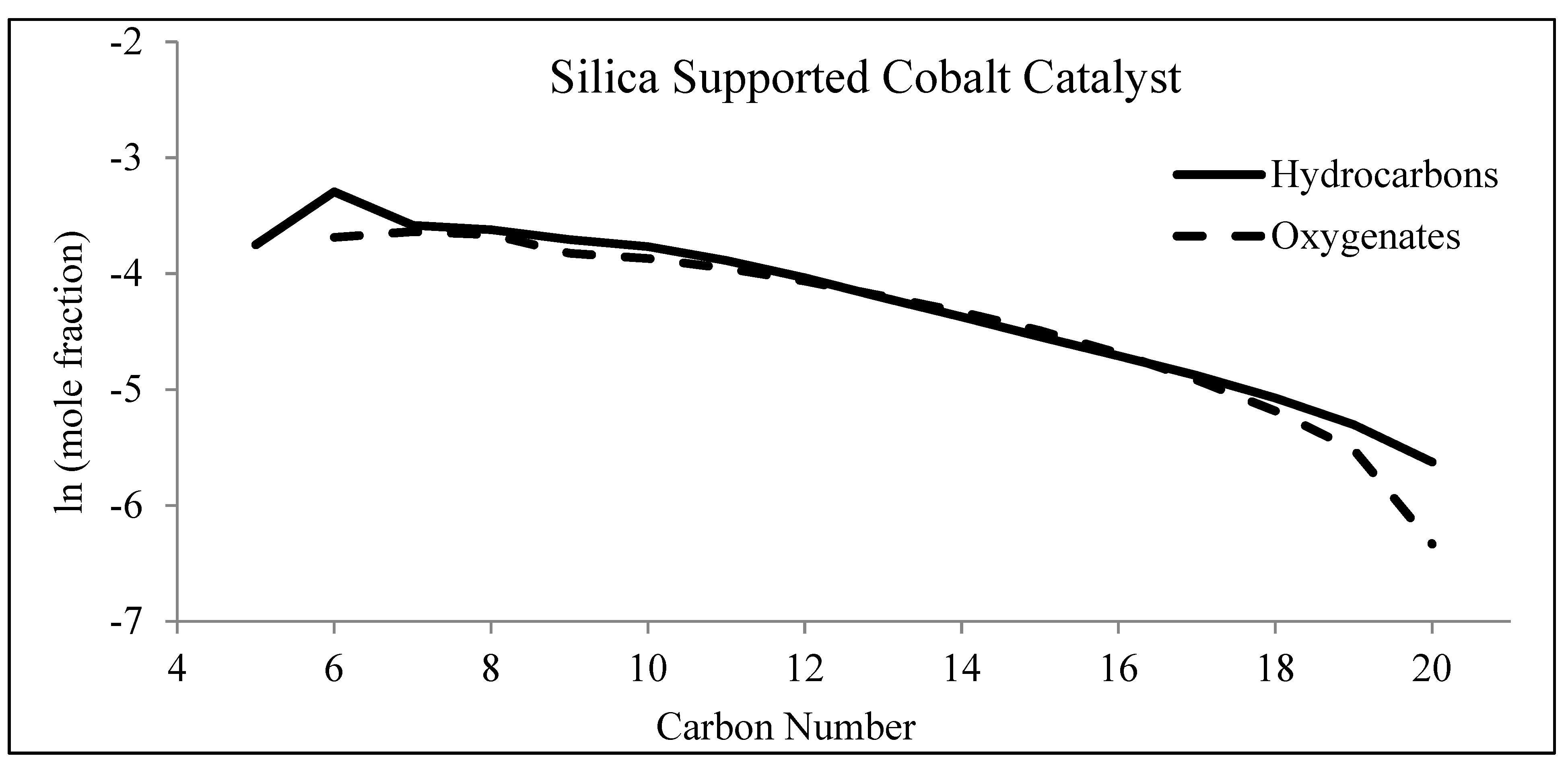

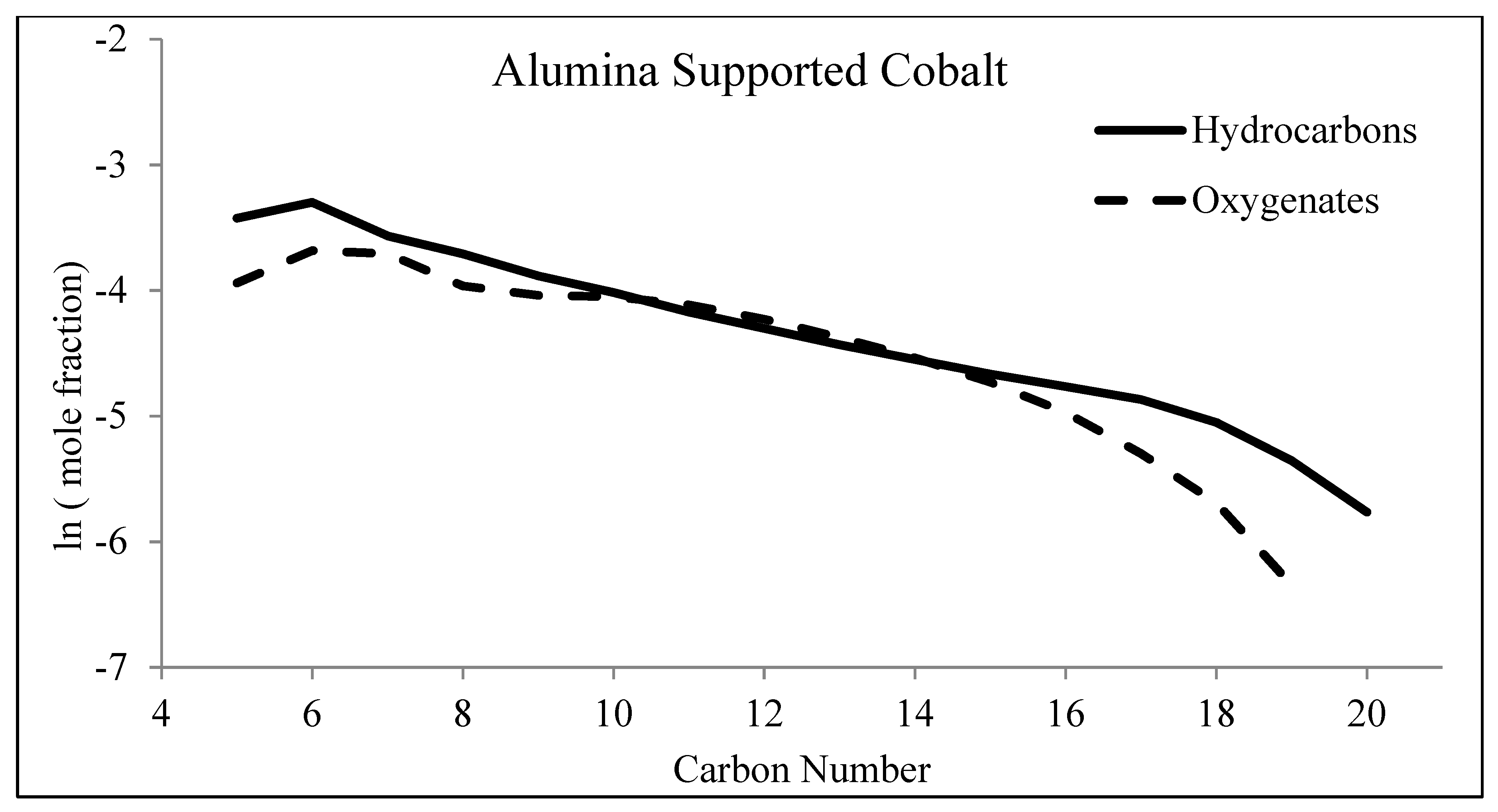

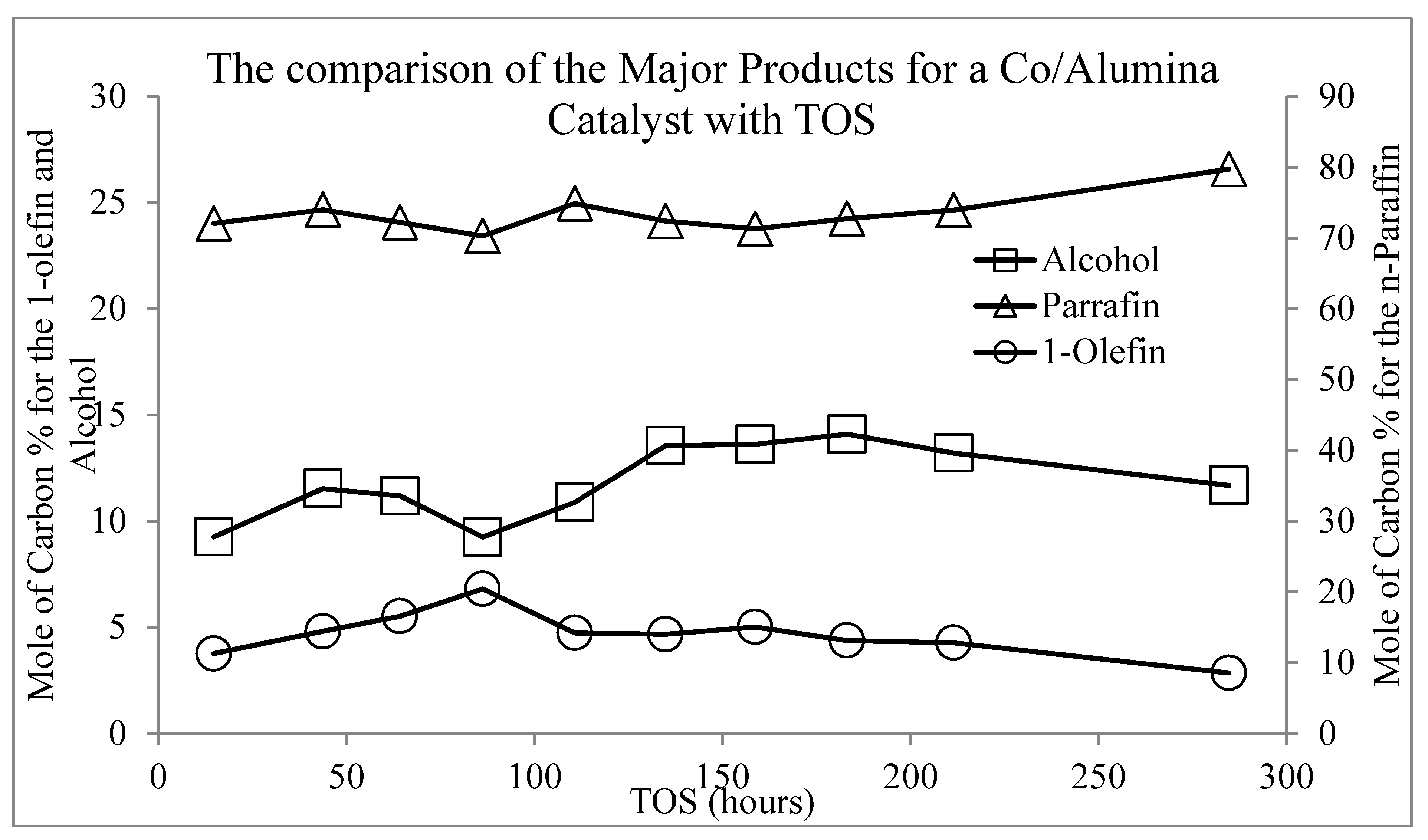

3.3.2. Cobalt

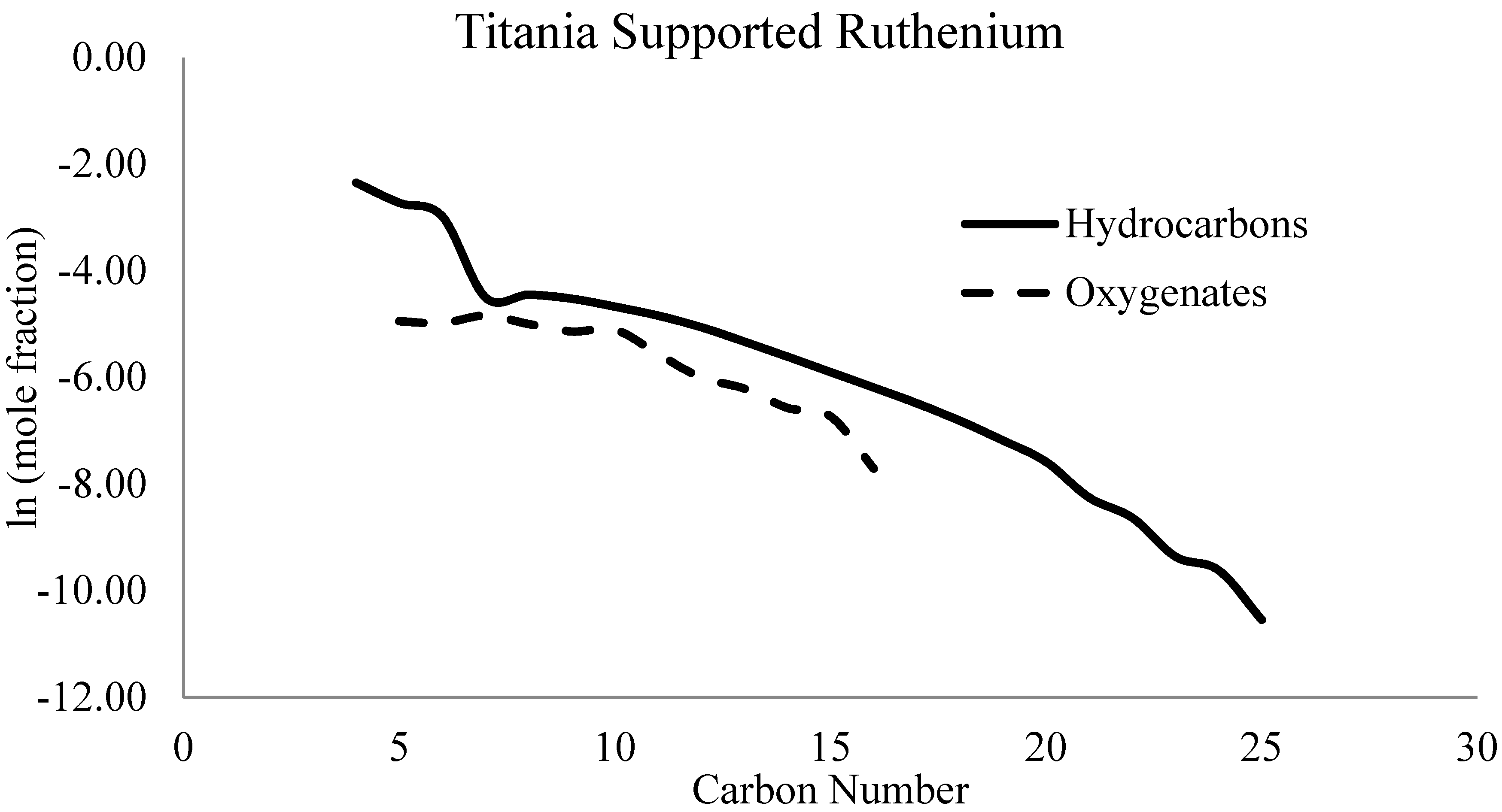

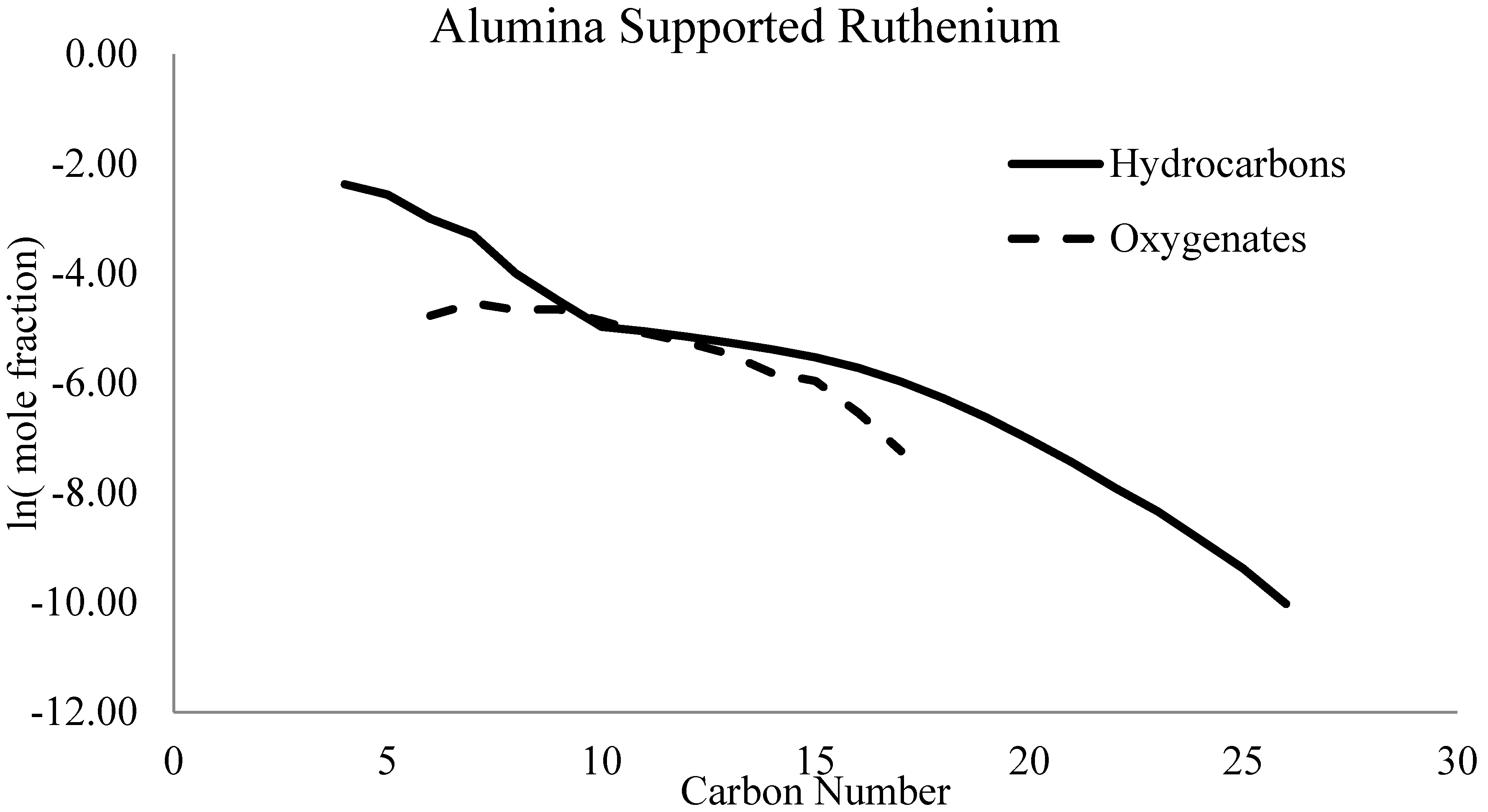

3.3.3. Ruthenium

3.4. Specific Product Selectivities

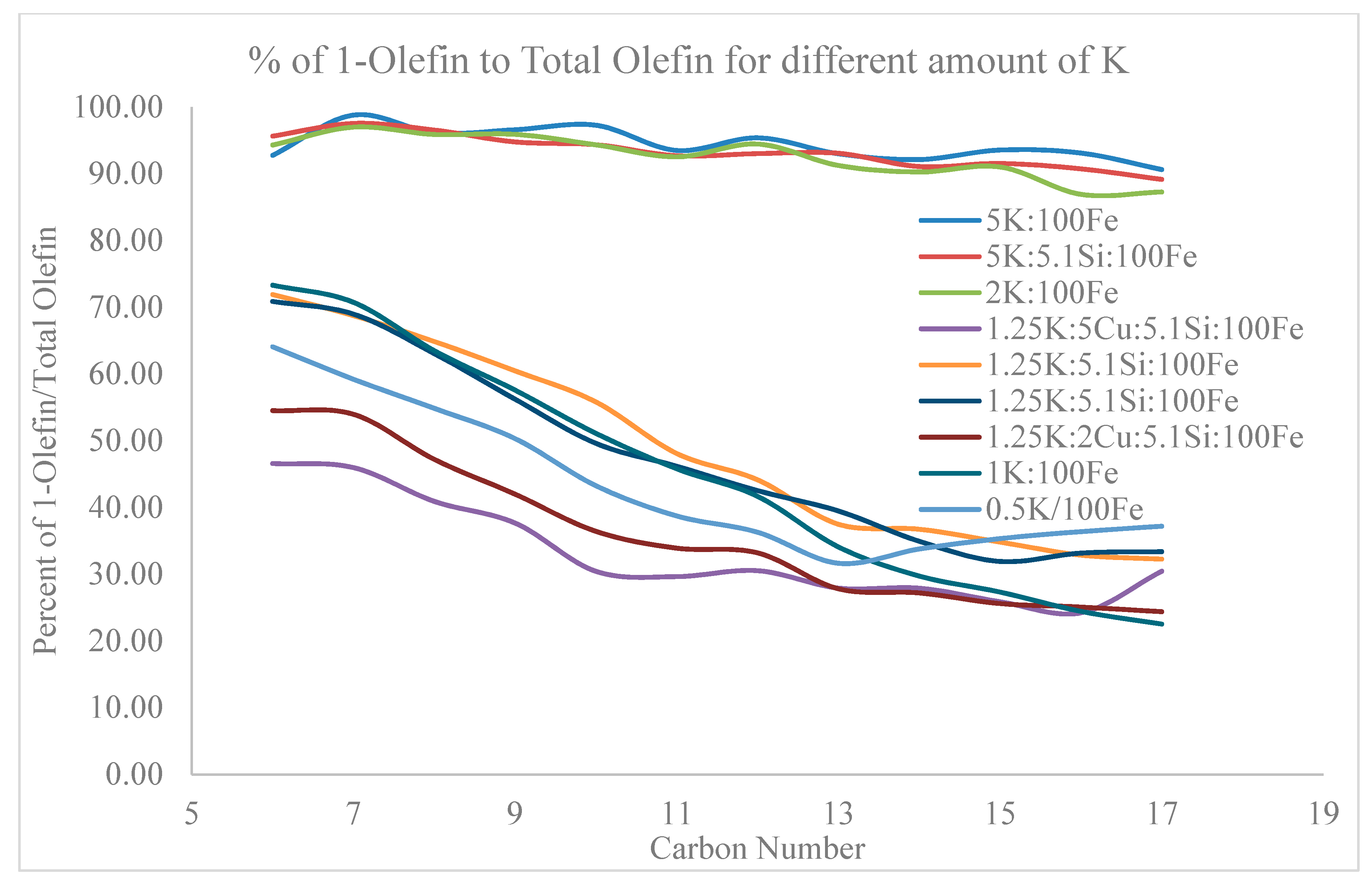

3.4.1. Iron

3.4.2. Cobalt

3.4.3. Ruthenium

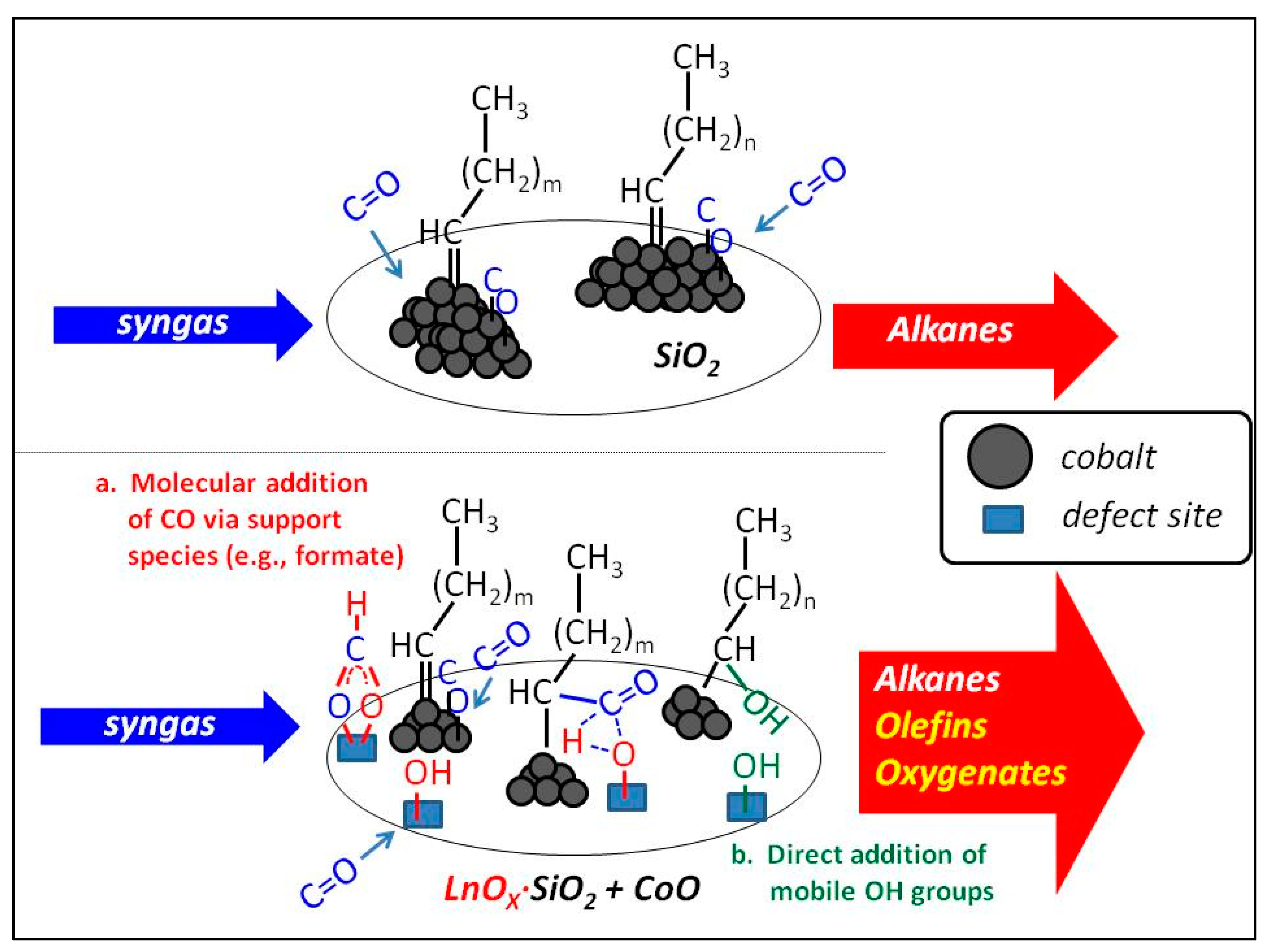

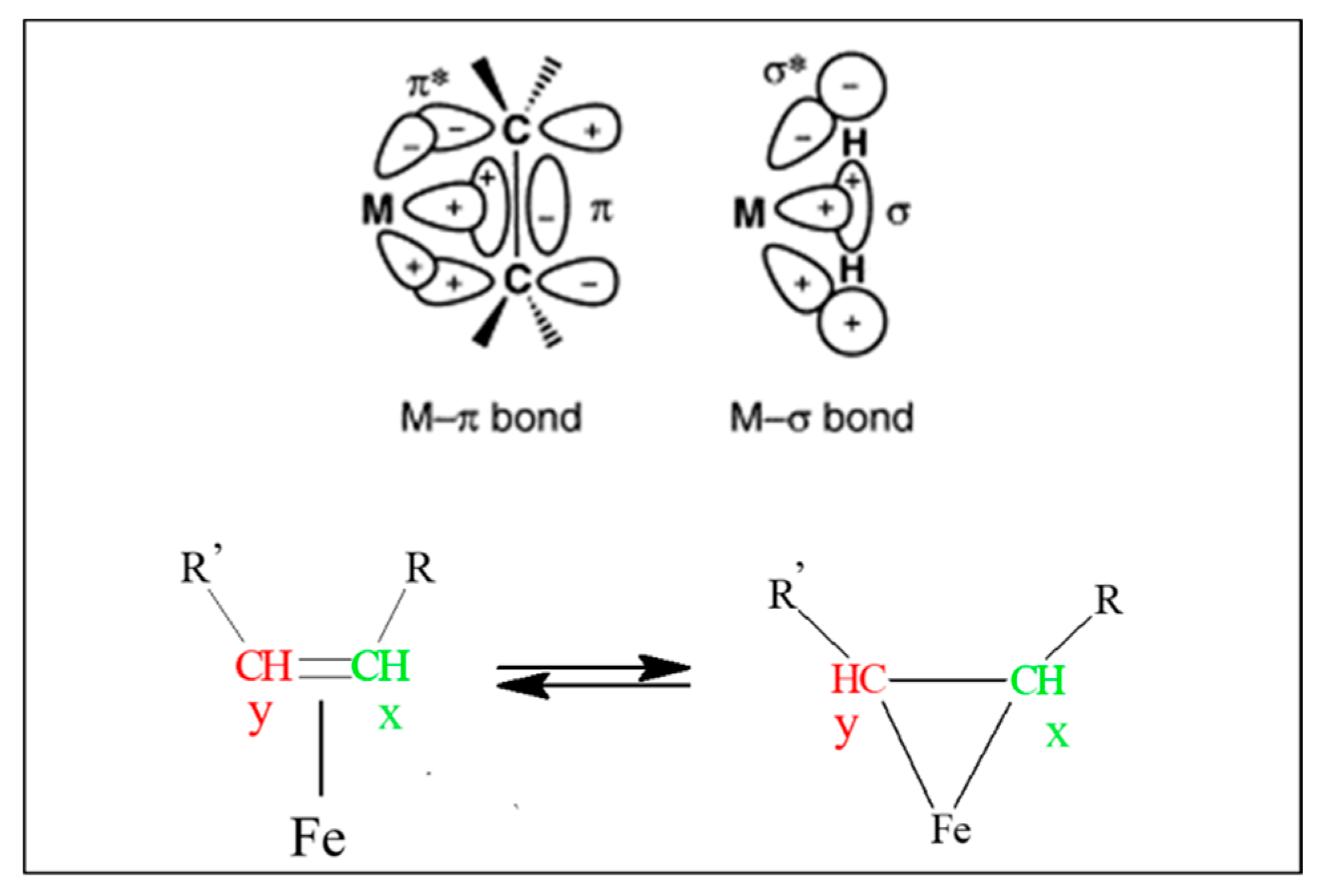

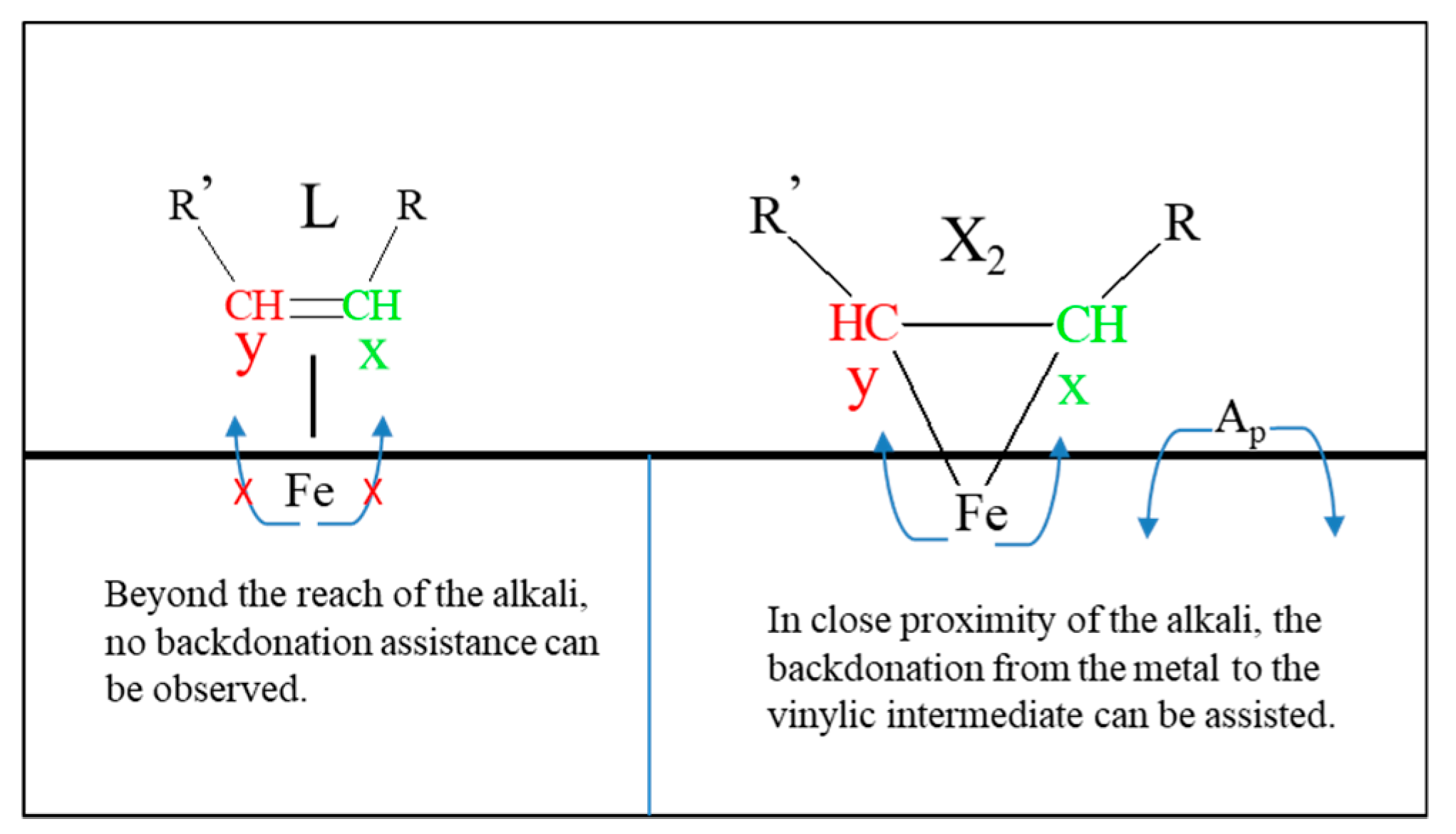

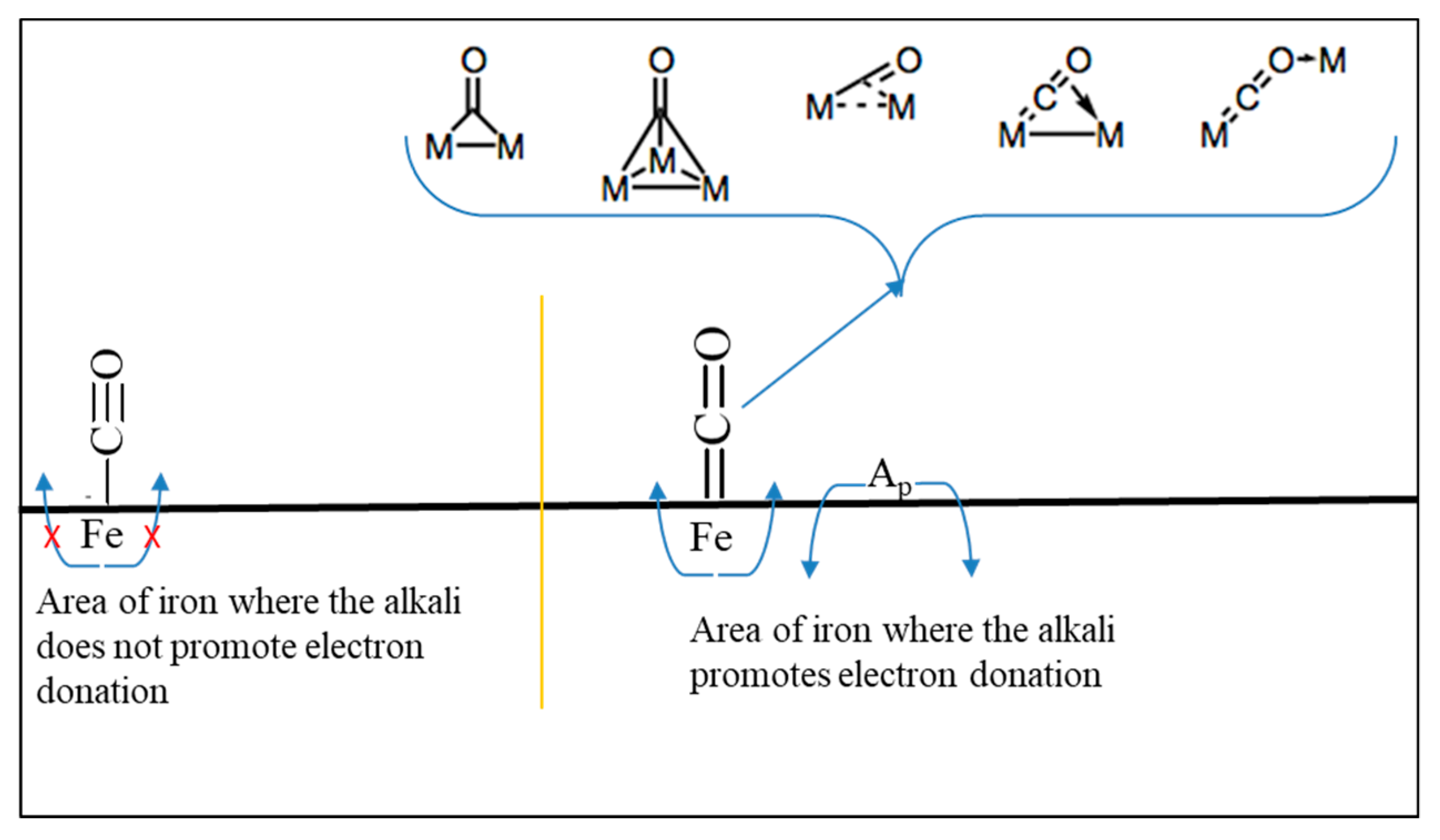

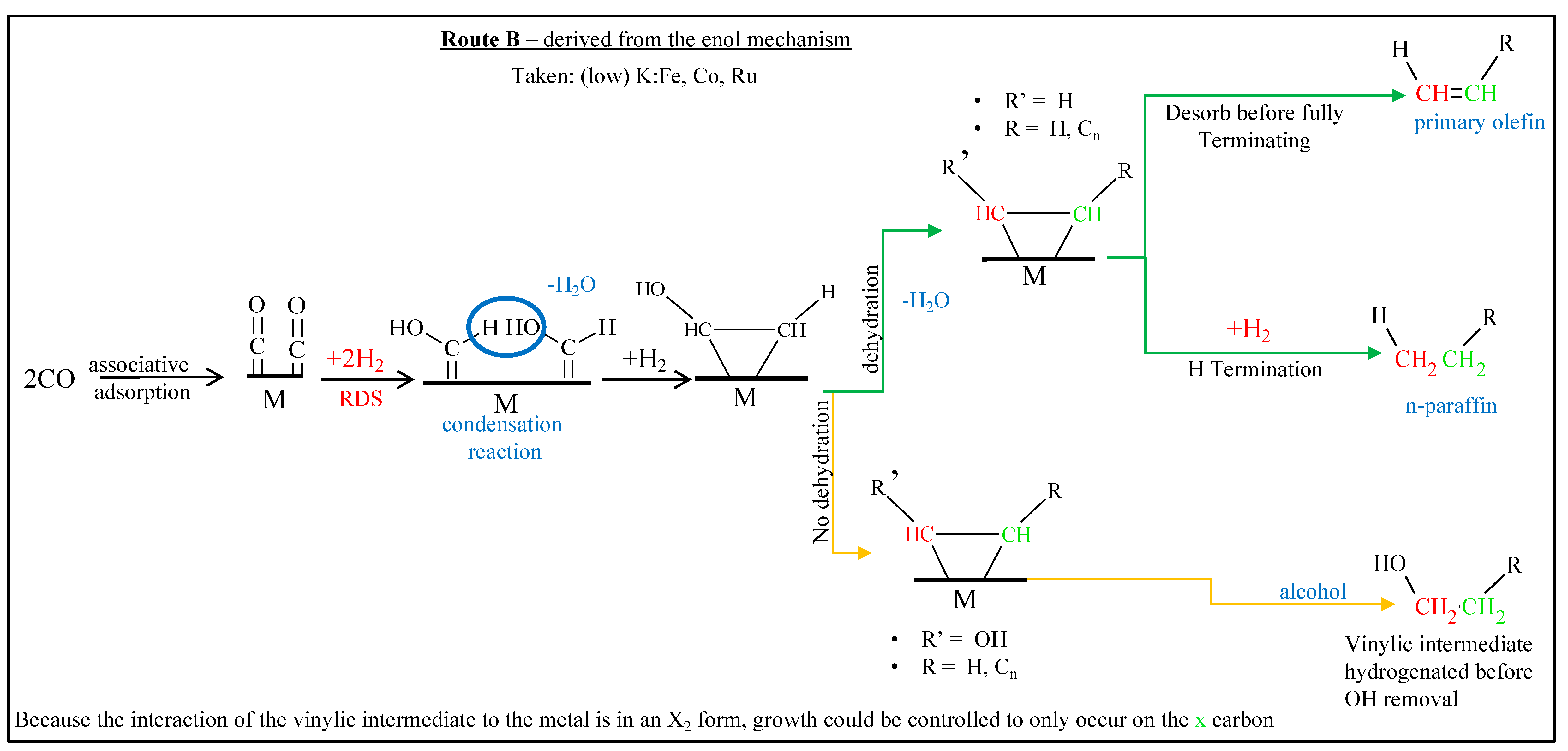

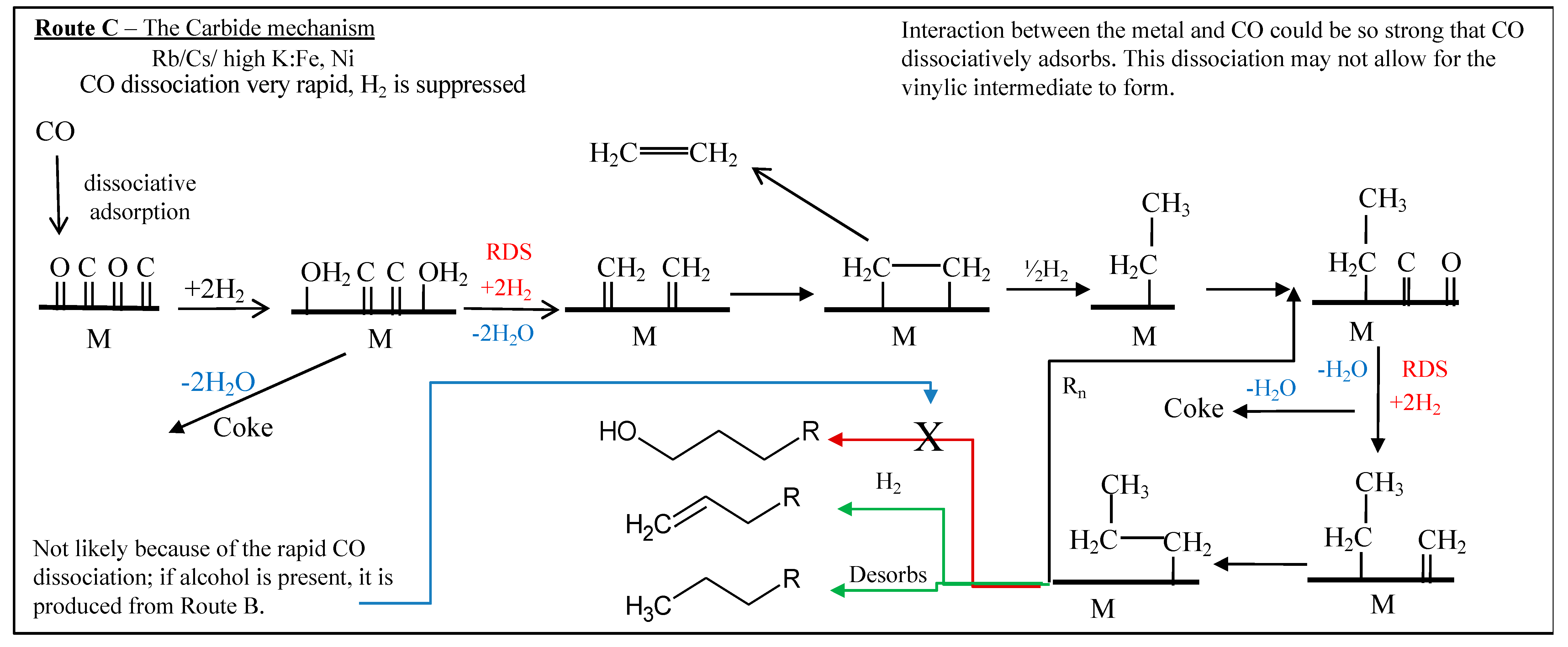

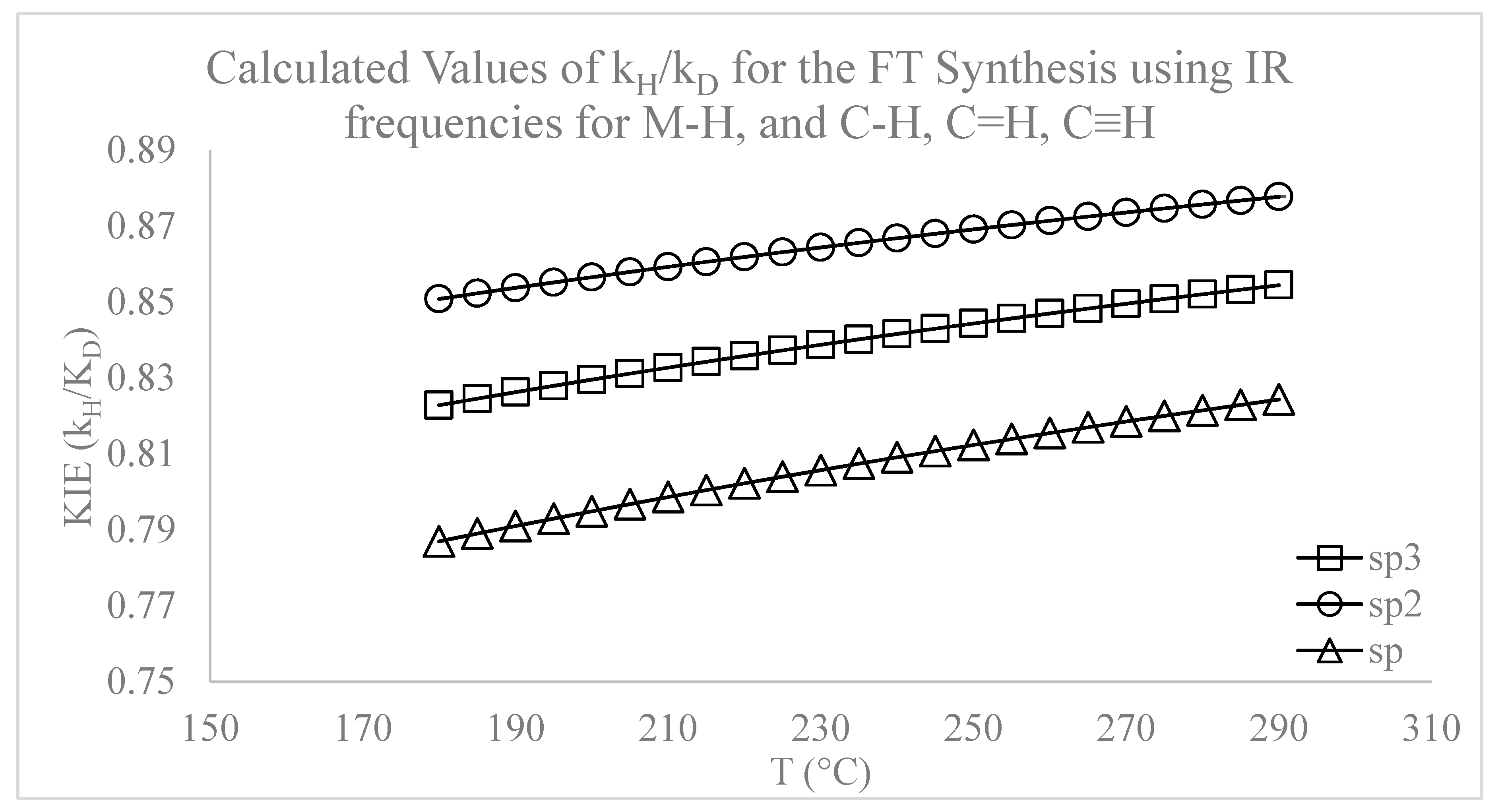

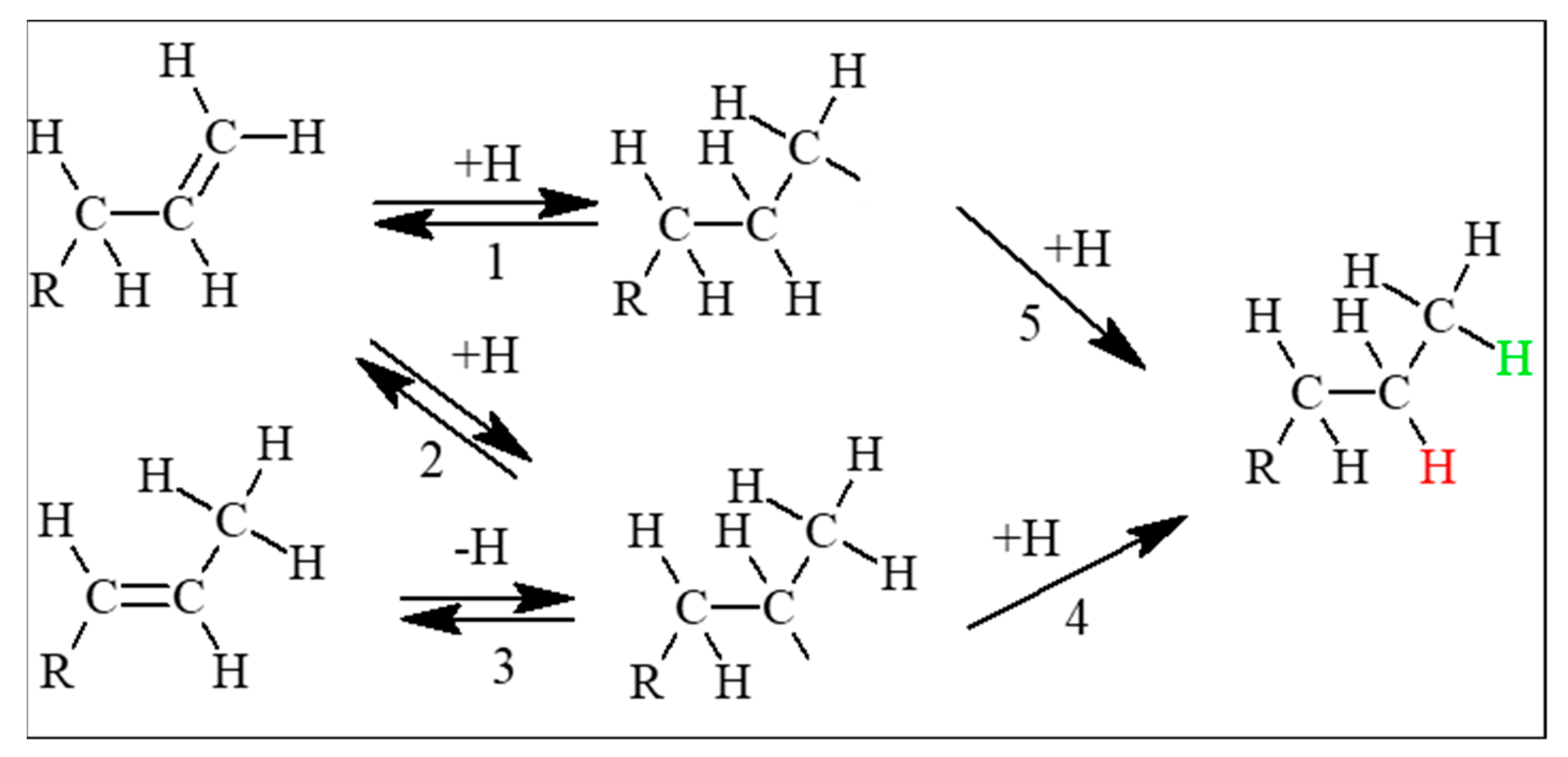

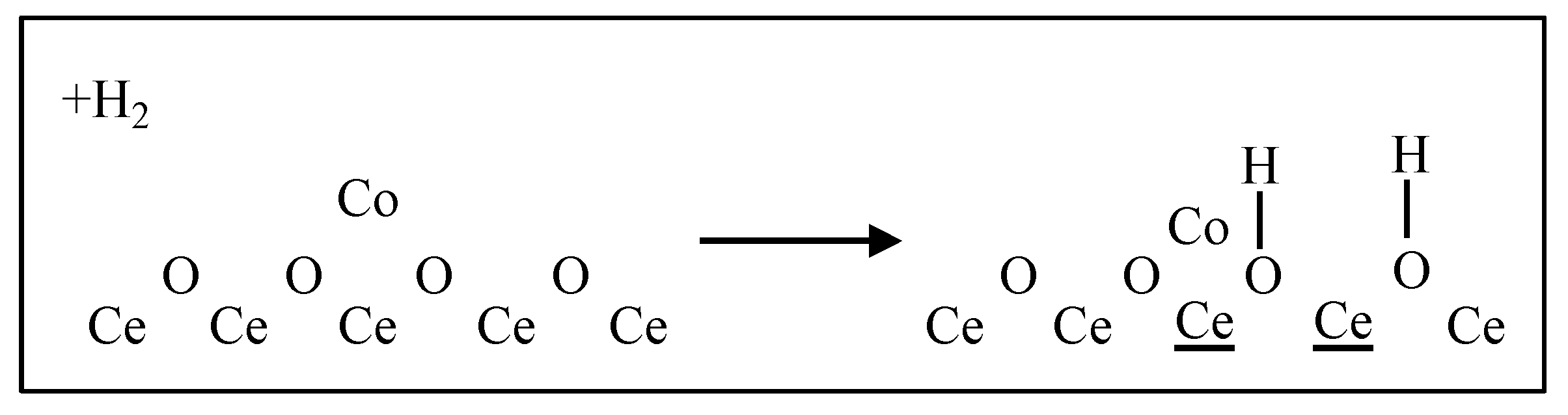

3.5. A Mechanistic Description

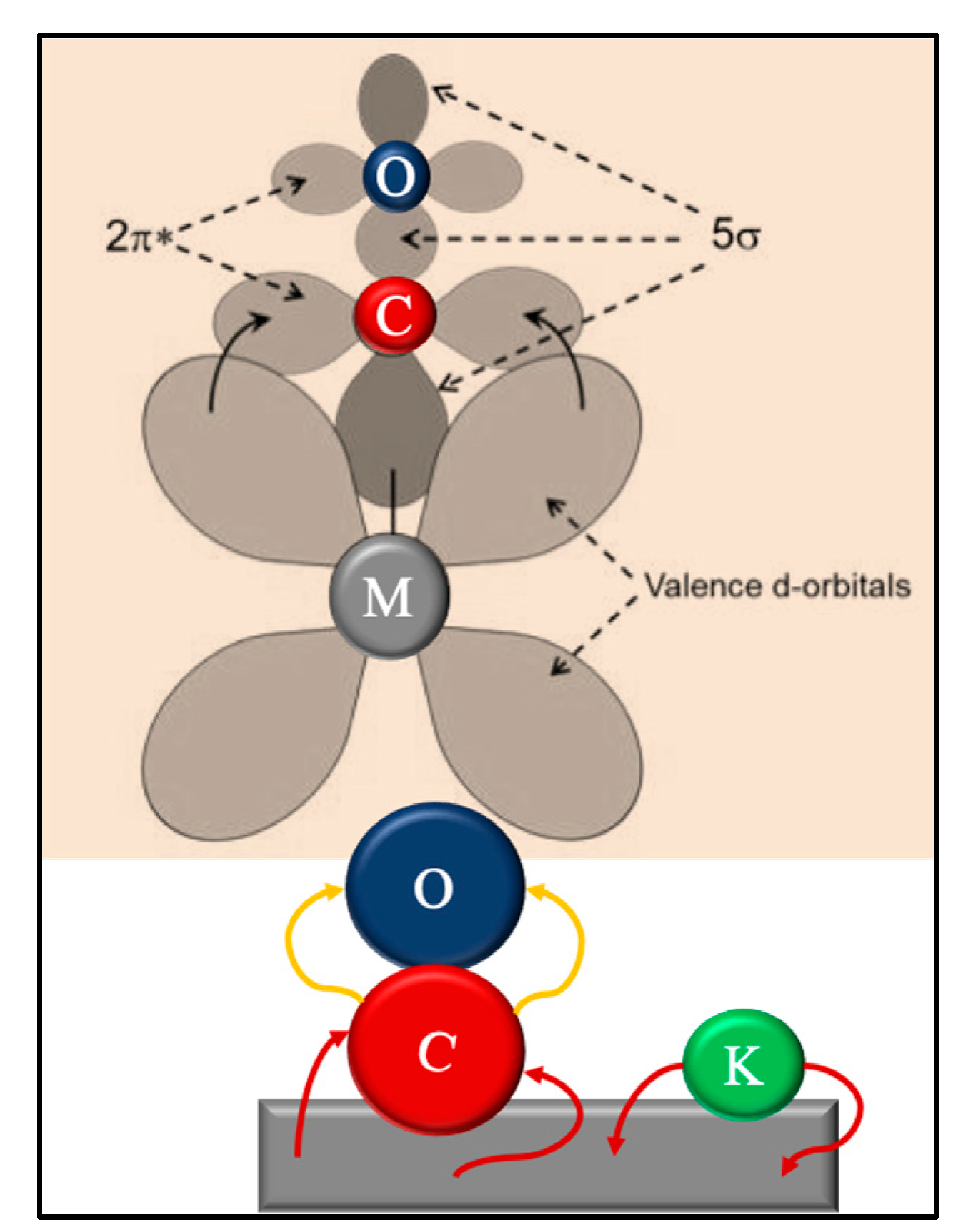

3.5.1. The Electronic Nature of the Active Metal

3.5.2. A General Mechanistic Explanation

- n-paraffins, 1-olefins, and linear alcohols are primary products. These products are observed through route B

- n-paraffins, 1-olefins and linear alcohols come from the same active X2-configuration, as depicted in Figure 35 and Figure 36. Furthermore, 1-olefins and 2-olefins are, for the most part, not produced from each other (i.e., 2-olefins are not derived from 1-olefins and vice versa). Deviations are also possible with longer chained material through secondary reactions, especially under conditions where there is considerable reactor holdup. When X2 is the dominant configuration, all other products, including branched paraffins, 2-olefins, etc., likely come from secondary reactions.

4. Product Distribution

4.1. Iron Catalysts

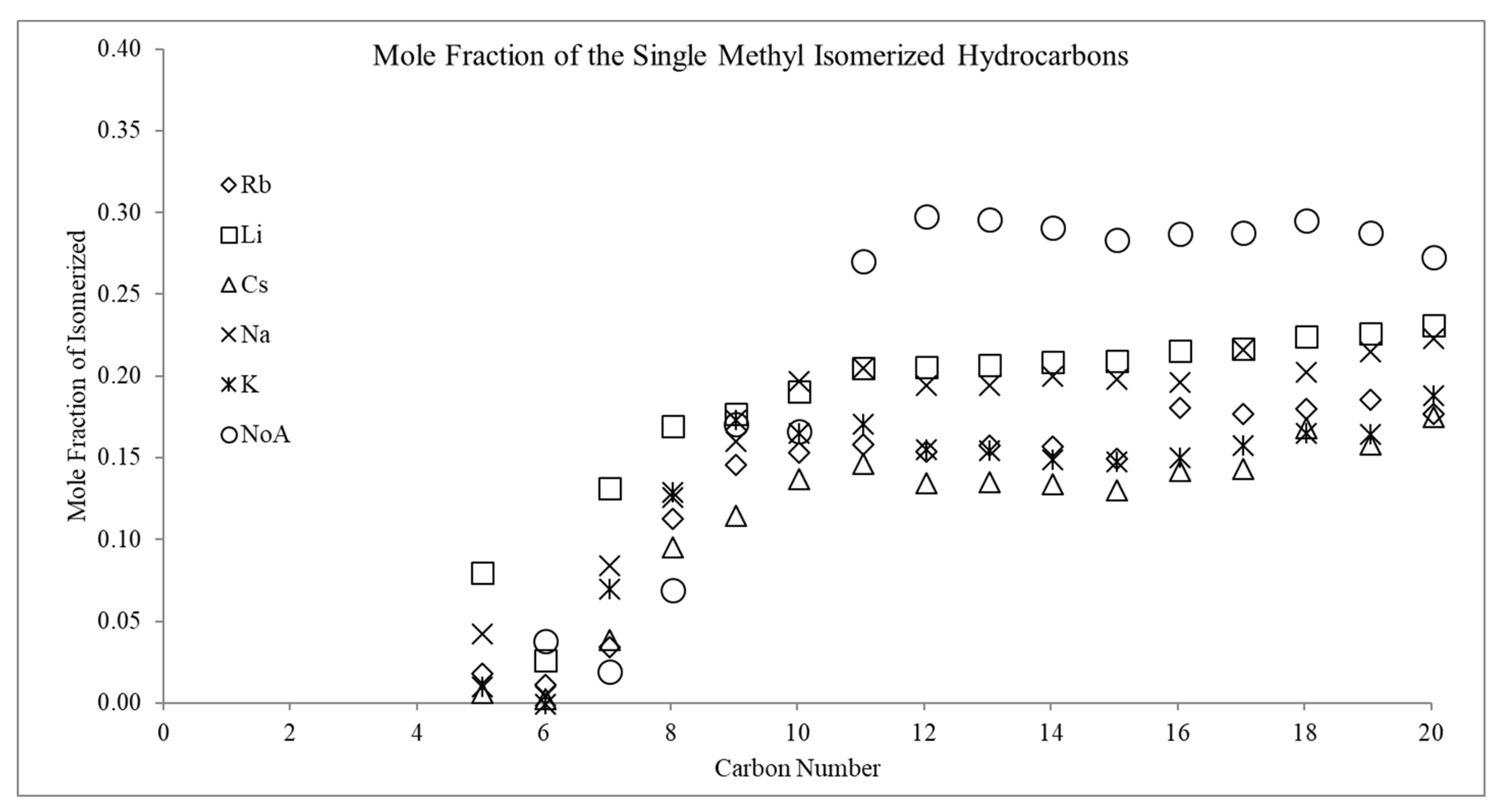

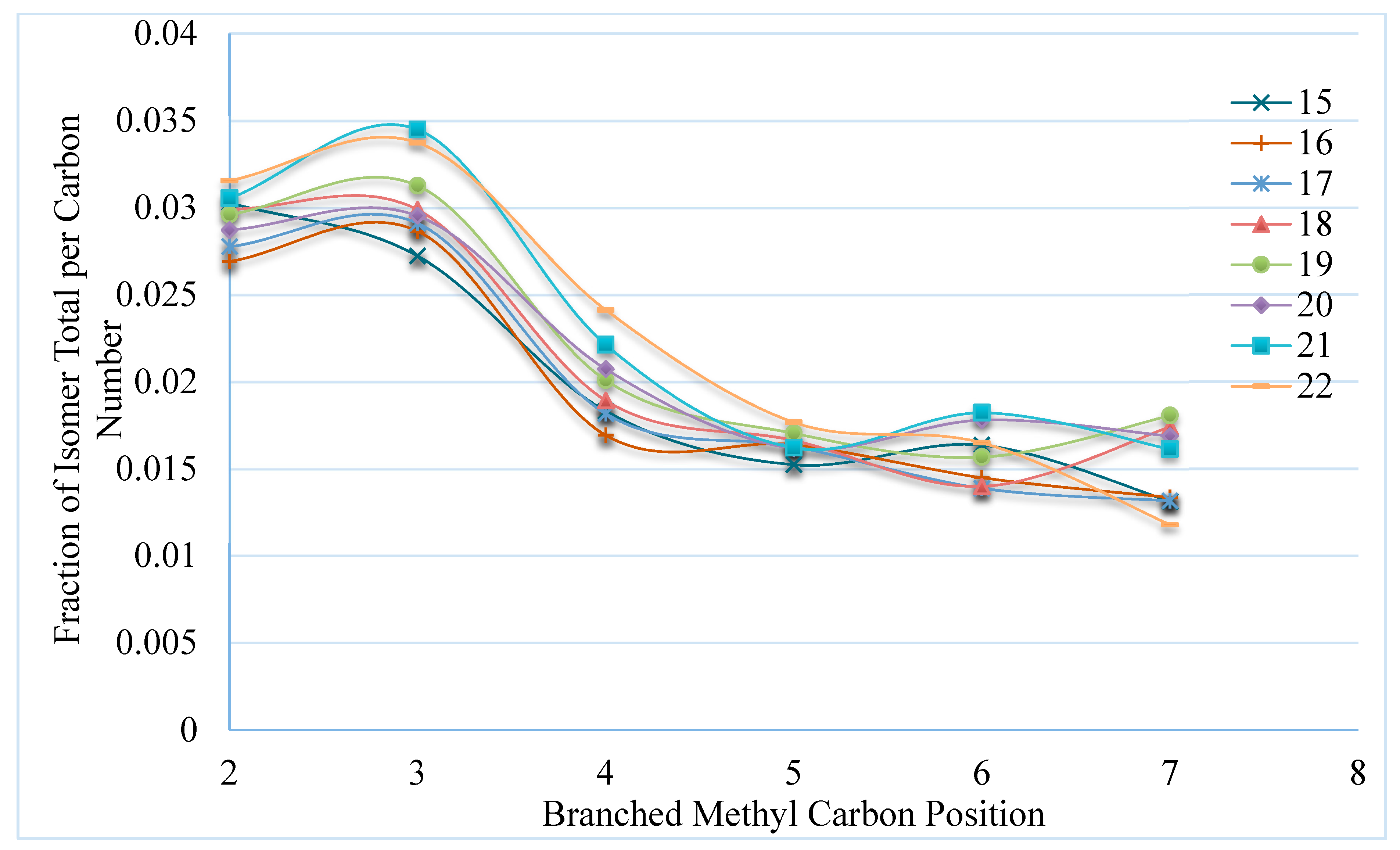

4.1.1. Hydrocarbons

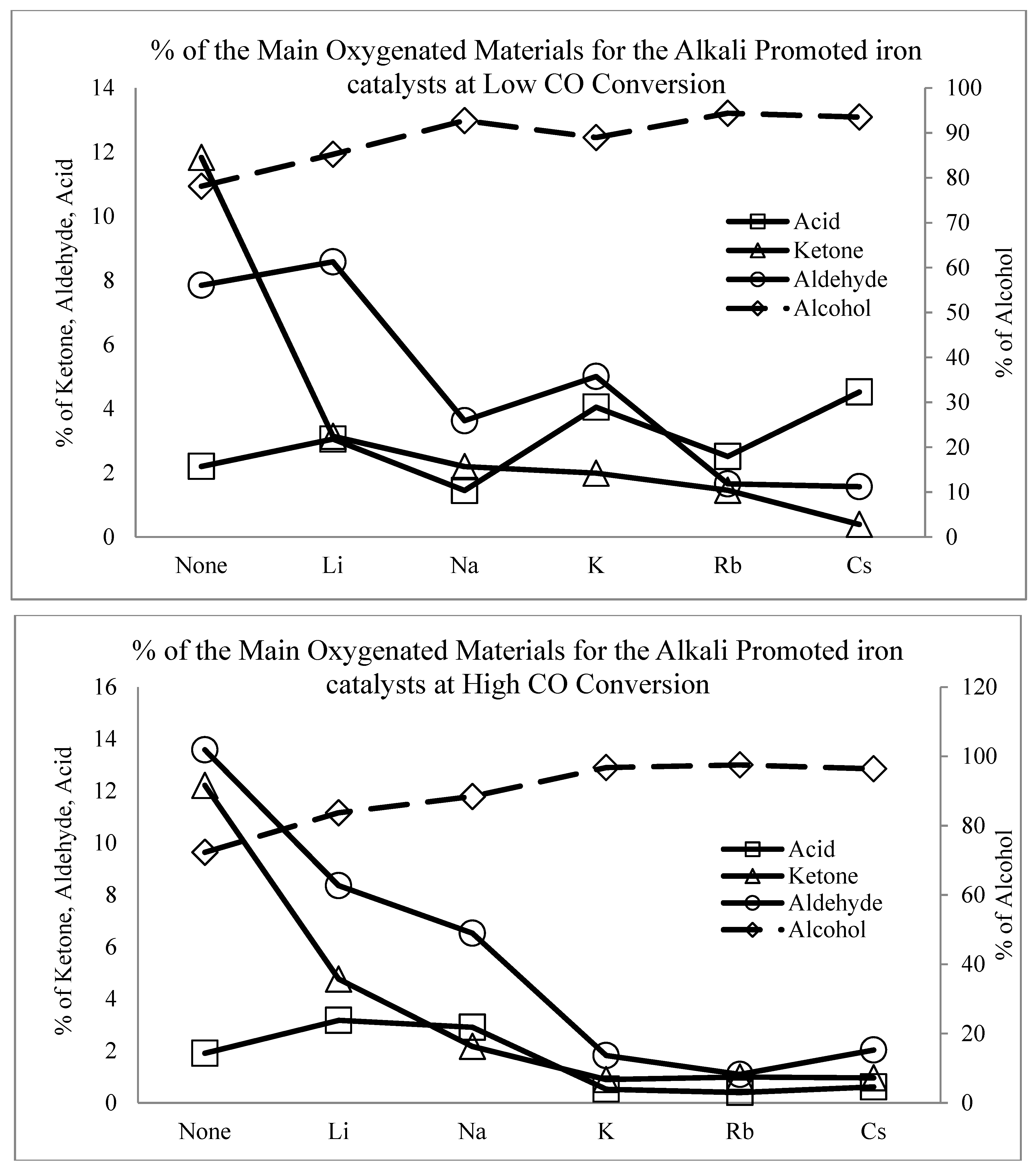

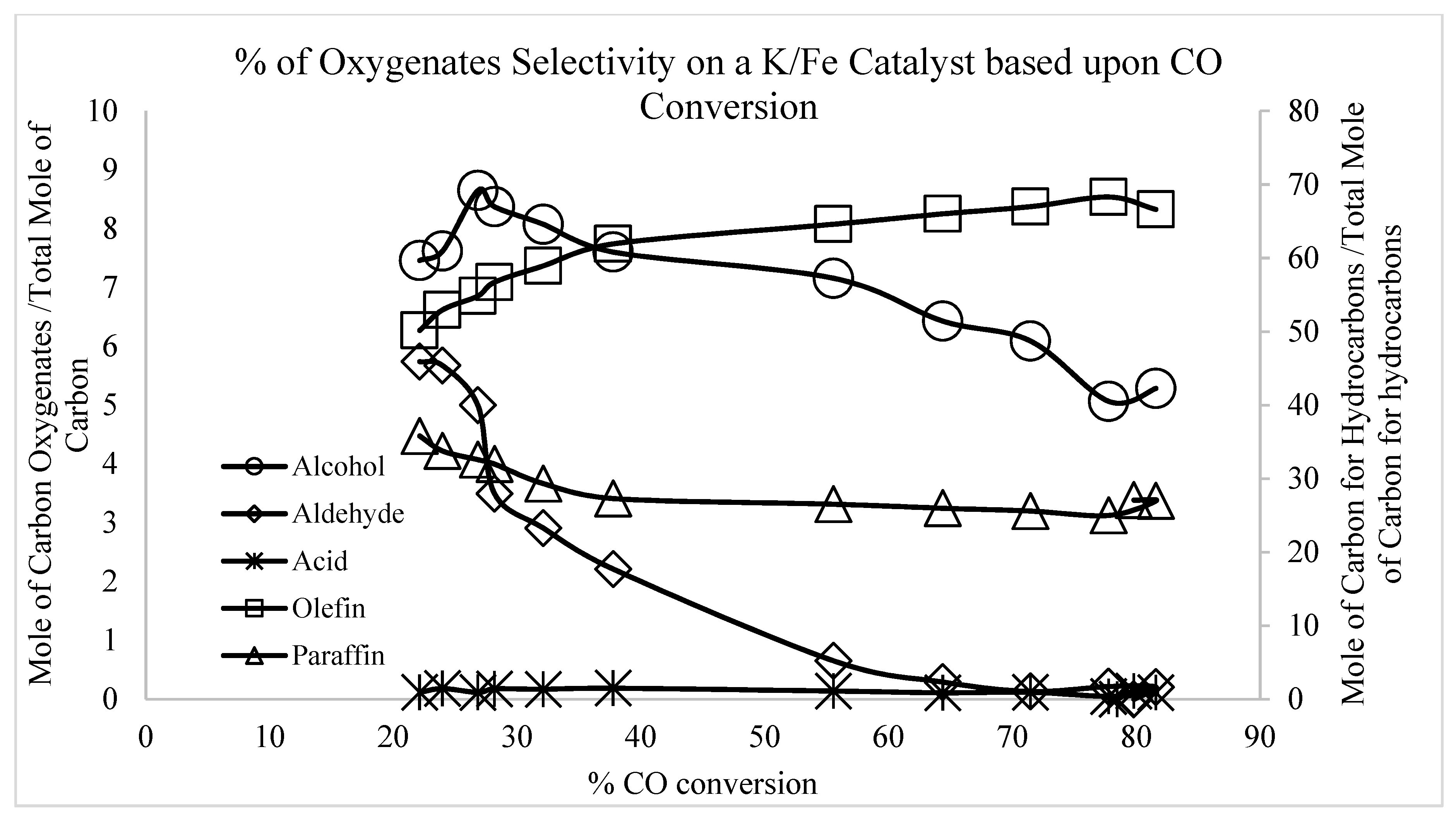

4.1.2. Oxygenates

4.1.3. ASF Factors

4.1.4. Manganese Supported Iron Catalysts

4.2. Cobalt and Ruthenium

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Glossary

| ASF | Anderson-Schulz-Flory Plot |

| CSTR | Continuously Stirred Tank Reactor |

| EI | Electron Impact |

| FID | Flame Ionization Detector |

| FTS | Fischer–Tropsch Synthesis |

| GC | Gas Chromatograph |

| GHSV | Gas Hourly Space Velocity |

| HC | High CO Conversion |

| H2/CO- | Hydrogen to Carbon Monoxide Ratio |

| IWI | Incipient Wetness Impregnation |

| LC | Low CO Conversion |

| LOD | Limit of Detection |

| MSD | Mass Selective Detector |

| O/P | Total Olefin to Paraffin Ratio |

| RT | Retention Time |

| SIM | Single Ion Monitoring |

| TCD | Thermal-conductivity Detector |

| WF | Weight Fraction |

| WHSV | Weight Hourly Space Velocity |

| VLE | Vapor Liquid Equilibrium |

References

- Wilhelm, D.J.; Simbeck, D.R.; Karp, A.D.; Dickenson, R.L. Syngas production for gas-to-liquids applications: Technologies, issues and outlook. Fuel Process. Technol. 2001, 71, 139–148. [Google Scholar] [CrossRef]

- Wood, D.A.; Nwaoha, C.; Towler, B.F. Gas-to-liquids (GTL): A review of an industry offering several routes for monetizing natural gas. J. Nat. Gas Sci. Eng. 2012, 9, 196–208. [Google Scholar] [CrossRef]

- Jessop, P.G.; Subramaniam, B. Gas-Expanded Liquids. Chem. Rev. 2007, 107, 2666–2694. [Google Scholar] [CrossRef]

- Davis, B.H. Clean fuels from coal: The path to 1972. Prepr. Symp. Am. Chem. Soc. Div. Fuel Chem. 2003, 48, 141–143. [Google Scholar]

- Zhang, Y.; Davis, B.H. Indirect coal liquefaction—Where do we stand? Prepr. Am. Chem. Soc. Div. Pet. Chem. 1999, 44, 20–24. [Google Scholar]

- Whitehurst, D.D.; Mitchell, T.O.; Farcasiu, M. Coal Liquefaction: The Chemistry and Technology of Thermal Processes; Academic Press, Inc.: New York, NY, USA, 1980; 390p. [Google Scholar]

- Liu, Z.; Shi, S.; Li, Y. Coal liquefaction technologies—Development in China and challenges in chemical reaction engineering. Chem. Eng. Sci. 2010, 65, 12–17. [Google Scholar] [CrossRef]

- Horne, P.A.; Williams, P.T. Influence of temperature on the products from the flash pyrolysis of biomass. Fuel 1996, 75, 1051–1059. [Google Scholar] [CrossRef]

- Swanson, R.M.; Platonc, A.; Satrio, J.A.; Brown, R.C. Techno-economic analysis of biomass-to-liquids production based on gasification. Fuel 2010, 89, S11–S19. [Google Scholar] [CrossRef]

- Medrano, J.A.; Oliva, M.; Ruiz, J.; García, L.; Arauzo, J. Hydrogen from aqueous fraction of biomass pyrolysis liquids by catalytic steam reforming in fluidized bed. Energy 2011, 36, 2215–2224. [Google Scholar] [CrossRef]

- Higman, C.; van der Burgt, M. Gasification; Gulf Professional Publishing: Houston, TX, USA, 2008; pp. 1–456. [Google Scholar]

- Nikrityuk, P.A.; Meye, B. Gasification Processes: Modeling and Simulation; Wiley-VCH: New York, NY, USA, 2014; pp. 1–360. [Google Scholar]

- Jacobs, G.; Crawford, A.C.; Davis, B.H. Water-gas shift: Steady state isotope switching study of the water-gas shift reaction over Pt/ceria using in-situ DRIFTS. Catal. Lett. 2005, 100, 147–152. [Google Scholar] [CrossRef]

- Jacobs, G.; Crawford, A.; Williams, L.; Patterson, P.M.; Davis, B.H. Low temperature water-gas-shift: Comparison of thoria and ceria catalysts. Appl. Catal. A Gen. 2004, 267, 27–33. [Google Scholar] [CrossRef]

- Martinelli, M.; Jacobs, G.; Graham, U.M.; Shafer, W.D.; Cronauer, D.C.; Kropf, J.A.; Marshall, C.L.; Khalid, S.; Visconti, C.G.; Lietti, L.; et al. Water-gas-shift: Characterization and testing of nanoscale YSZ supported Pt catalysts. Appl. Catal. A Gen. 2015, 497, 184–197. [Google Scholar] [CrossRef]

- Fu, Q. Howard Saltsburg, Maria Flytzani-Stephanopoulos, Active Nonmetallic Au and Pt Species on Ceria-Based Water-Gas Shift Catalysts. Science 2003, 301, 935–938. [Google Scholar] [CrossRef] [PubMed]

- Scherzer, J.; Gruia, A.J. Hydrocracking Science and Technology; Marcell Dekker Inc.: New York, NY, USA, 1996. [Google Scholar]

- Fischer, F.; Tropsch, H. Synthesis of Petroleum at Atmospheric Pressure from Gasification Products of Coal. Brennstoff-Chemie 1926, 7, 97–104. [Google Scholar]

- Fischer, F.; Tropsch, H. Development of the Benzene Synthesis from Carbon Monoxide and Hydrogen at Atmospheric Pressure. Brennstoff-Chemie 1930, 11, 489–500. [Google Scholar]

- Yang, J.; Shafer, W.D.; Pendyala, V.R.R.; Jacobs, G.; Chen, D.; Holmen, A.; Davis, B.H. Fisher-Tropsch Synthesis: Using Deuterium as a Tool to Investigate Primary Product Distribution. Catal. Lett. 2014, 144, 524–530. [Google Scholar] [CrossRef]

- Shi, B.; Davis, B.H. Fischer–Tropsch synthesis: Accounting for chain-length related phenomena. Appl. Catal. A 2004, 277, 61–69. [Google Scholar] [CrossRef]

- Davis, B.H. Fischer–Tropsch synthesis: Current mechanism and futuristic needs. Fuel Proc. Technol. 2001, 71, 157–166. [Google Scholar] [CrossRef]

- Tuxen, A.; Carenco, S.; Chintapalli, M.; Chuang, C.; Escudero, C.; Pach, E.; Jiang, P.; Borondics, F.; Beberwyck, B.; Alivisatos, A.P.; et al. Size-Dependent Dissociation of Carbon Monoxide on Cobalt Nanoparticles. J. Am. Chem. Soc. 2013, 135, 2273–2278. [Google Scholar] [CrossRef]

- Qi, Y.; Yang, J.; Chen, D.; Holmen, A. Recent Progresses in Understanding of Co-Based Fischer–Tropsch Catalysis by Means of Transient Kinetic Studies and Theoretical Analysis. Catal. Lett. 2015, 145, 145–161. [Google Scholar] [CrossRef]

- Jacobs, G.; Davis, B.H. Applications of isotopic tracers in Fischer–Tropsch synthesis. Catal. Sci. Technol. 2014, 4, 3927–3944. [Google Scholar] [CrossRef]

- Shi, B.; Jacobs, G.; Sparks, D.E.; Davis, B.H. Fischer-Tropsch Synthesis: 14C Labeled 1-alkene conversion using supercritical conditions with Co/Al2O3. Fuel 2005, 84, 1093–1098. [Google Scholar] [CrossRef]

- Dry, M.E. The Fischer–Tropsch process: 1950–2000. Catal. Today 2002, 71, 227–241. [Google Scholar] [CrossRef]

- Enger, B.C.; Holmen, A. Nickel and Fischer-Tropsch Synthesis. Catal. Rev. 2012, 54, 437–488. [Google Scholar] [CrossRef]

- Milburn, D.R.; Chary, V.R.K.; Davis, B.H. Promoted iron Fischer-Tropsch catalysts: Characterization by nitrogen sorption. Appl. Catal. A Gen. 1996, 144, 121–132. [Google Scholar] [CrossRef]

- Luo, M.; Hamdeh, H.; Davis, B.H. Potassium promoted iron Fischer-Tropsch Synthesis catalyst activation study with Mossbauer spectroscopy. Prepr. Am. Chem. Soc. Div. Pet. Chem. 2007, 52, 73–76. [Google Scholar]

- Pendyala, V.R.R.; Jacobs, G.; Gnanamani, M.K.; Hu, Y.; MacLennan, A.; Davis, B.H. Selectivity control of Cu promoted iron-based Fischer-Tropsch catalyst by tuning the oxidation state of Cu to mimic K. Appl. Catal. A Gen. 2015, 495, 45–53. [Google Scholar] [CrossRef]

- Rachid, O.; Singleton, A.H.; Goodwin, J.G., Jr. Comparison of patented Co F–T catalysts using fixed-bed and slurry bubble column reactors. Appl. Catal. A Gen. 1999, 186, 129–144. [Google Scholar]

- Girardona, J.-S.; Gribovala, A.Co.; Gengembre, L.; Chernavskii, P.A.; Khodakov, A.Y. Optimization of the pretreatment procedure in the design of cobalt silica supported Fischer–Tropsch catalysts. Catal. Today 2005, 106, 161–165. [Google Scholar] [CrossRef]

- Jacobs, G.; Das, T.K.; Zhang, Y.; Li, J.; Racoillet, G.; Davis, B.H. Fischer–Tropsch synthesis: Support, loading, and promoter effects on the reducibility of cobalt catalysts. Appl. Catal. A Gen. 2002, 233, 263–281. [Google Scholar] [CrossRef]

- Ribeiro, M.C.; Jacobs, G.; Davis, B.H.; Cronauer, D.C.; Kropf, A.J.; Marshall, C.L. Fischer–Tropsch Synthesis: An In-Situ TPR-EXAFS/XANES Investigation of the Influence of Group I Alkali Promoters on the Local Atomic and Electronic Structure of Carburized Iron/Silica Catalysts. J. Phys. Chem. C 2010, 114, 7895–7903. [Google Scholar] [CrossRef]

- Jacobs, G.; Ji, Y.; Davis, B.H.; Cronauer, D.; Kropf, A.J.; Marshall, C.L. Fischer–Tropsch synthesis: Temperature programmed EXAFS/XANES investigation of the influence of support type, cobalt loading, and noble metal promoter addition to the reduction behavior of cobalt oxide particles. Appl. Catal. A 2007, 333, 177–191. [Google Scholar] [CrossRef]

- Wang, W.J.; Chen, Y.W. Influence of metal loading on the reducibility and hydrogenation activity of cobalt/alumina catalysts. Appl. Catal. 1991, 77, 223–233. [Google Scholar] [CrossRef]

- Luo, M.; Shafer, W.D.; Davis, B.H. Fischer–Tropsch Synthesis: Branched Paraffin Distribution for Potassium Promoted Iron Catalysts. Catal. Lett. 2014, 144, 1031–1041. [Google Scholar] [CrossRef]

- Davis, B.H. Technology Development for Iron and Cobalt Fischer–Tropsch Catalysts; Quarterly Report #1, Contract #DE-FC26-98FT40308; Department of Energy (DOE): Commonwealth of Kentucky, USA, 2002. [Google Scholar]

- Gnanamani, M.K.; Jacobs, G.; Graham, U.M.; Ribeiro, M.C.; Noronha, F.B.; Shafer, W.D.; Davis, B.H. Influence of carbide formation on oxygenates selectivity during Fischer-Tropsch synthesis over Ce-containing Co catalysts. Catal. Today 2016, 261, 40–47. [Google Scholar] [CrossRef]

- Ribeiro, M.C.; Gnanamani, M.K.; Rabelo-Neto, R.C.; Azevedo, I.R.; Pendyala, V.R.R.; Jacobs, G.; Davis, B.H.; Noronha, F.B. Fischer-Tropsch Synthesis: Studies on the effect of support reducibility on the selectivity to n-alcohols in Co/CeO2.MOy (M = Si, Mn, Cr) catalysts. Top. Catal. 2014, 57, 550–560. [Google Scholar] [CrossRef]

- Gnanamani, M.K.; Jacobs, G.; Shafer, W.D.; Ribeiro, M.C.; Pendyala, V.R.R.; Ma, W.; Davis, B.H. Fischer-Tropsch synthesis: Deuterium isotopic study for the formation of oxygenates over CeO2-supported Pt-Co catalysts. Catal. Commun. 2012, 25, 12–17. [Google Scholar] [CrossRef]

- Gaube, J.; Klein, H.F. Studies on the reaction mechanism of the Fischer–Tropsch synthesis on iron and cobalt. J. Mol. Catal. A 2008, 283, 60–68. [Google Scholar] [CrossRef]

- Van Santen, R.A.; Markvoort, A.J.; Ghouri, M.M.; Hilbers, P.A.J.; Hensen, E.J.M. Monomer Formation Model versus Chain Growth Model of the Fischer–Tropsch Reaction. J. Phys. Chem. C 2013, 117, 4488–4504. [Google Scholar] [CrossRef]

- Ojeda, M.; Li, A.; Nabar, R.; Nilekar, A.U.; Mavrikakis, M.; Iglesia, E. Kinetically Relevant Steps and H2/D2 Isotope Effects in Fischer−Tropsch Synthesis on Fe and Co Catalysts. J. Phys. Chem. C 2010, 114, 19761–19770. [Google Scholar] [CrossRef]

- Kummer, J.T.; Podgurski, H.H.; Spencer, W.B.; Emmett, P.H. Mechanism studies of the Fischer-Tropsch synthesis. The addition of radioactive alcohol. J. Am. Chem. Soc. 1951, 73, 564–569. [Google Scholar] [CrossRef]

- Kummer, J.T.; Dewitt, W.; Emmett, P.H. Some Mechanism Studies on the Fischer-Tropsch Synthesis Using C14. J. Am. Chem. Soc. 1948, 70, 3632–3643. [Google Scholar] [CrossRef]

- Storch, H.H.; Golumbic, N.; Anderson, R.B. The Fischer–Tropsch and Related Syntheses; Wiley: New York, NY, USA, 1951. [Google Scholar]

- Pichler, H.; Schulz, H. Neuere Erkenntnisse auf dem Gebiet der Synthese von Kohlenwasserstoffen aus CO und H2. Chem. Ing. Tech. 1970, 42, 1162–1174. [Google Scholar] [CrossRef]

- Luo, M.; Bao, S.; Keogh, R.A.; Sarkar, A.; Jacobs, G.; Davis, B.H. Fischer-Tropsch Synthesis: A Comparison of Iron and Cobalt Catalysts. In Proceedings of the AIChE 2006 National Meeting, SanFrancisco, CA, USA, 12–17 November 2006. [Google Scholar]

- Schulz, H. Principles of Olefin Selectivity in Fischer-Tropsch Synthesis on Iron and Cobalt Catalysts. In Fischer-Tropsch Synthesis, Catalysts, and Catalysis: Advances and Applications; Davis, B.H., Occelli, M.L., Eds.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2015. [Google Scholar]

- Jennifer, N. Deuterium Enrichment and the Kinetic Isotope Effect during Ruthenium Catalyzed Fischer-Tropsch Synthesis. Online Theses and Dissertations, Eastern Kentucky University, Lexington, Kentucky, 2015; p. 408. [Google Scholar]

- Chakrabarti, D.; Gnanamani, M.K.; Shafer, W.D.; Ribeiro, M.C.; Sparks, D.E.; Prasad, V.; de Klerk, A.; Davis, B.H. Fischer–Tropsch Mechanism: 13C18O Tracer Studies on a Ceria–Silica Supported Cobalt Catalyst and a Doubly Promoted Iron Catalyst. Ind. Eng. Chem. Res. 2015, 54, 6438–6453. [Google Scholar] [CrossRef]

- Schulz, H. Principles of Fischer–Tropsch synthesis—Constraints on essential reactions ruling FT-selectivity. Catal. Today 2013, 214, 140–151. [Google Scholar] [CrossRef]

- Anderson, R.B.; Friedel, R.A.; Storch, H.H. Fischer-Tropsch Reaction Mechanism Involving Stepwise Growth of Carbon Chain. J. Chem. Phys. 1951, 19, 313. [Google Scholar] [CrossRef]

- Schulz, G.V. Über die Beziehung zwischen Reaktionsgeschwindigkeit und Zusammensetzung des Reaktionsproduktes bei Makropolymerisationsvorgängen. Z. Phys. Chem. 1935, 30, 379–398. [Google Scholar] [CrossRef]

- Flory, P.J. Molecular Size Distribution in Linear Condensation Polymers. J. Am. Chem. Soc. 1936, 58, 1877–1885. [Google Scholar] [CrossRef]

- Schliebs, B.; Gaube, J. The Influence of the Promoter K2CO3 in Iron Catalysts on the Carbon Number Distribution of Fischer-Tropsch Products. Ber. Der Bunsenges. Für Phys. Chem. 1985, 89, 68–73. [Google Scholar] [CrossRef]

- Graham, U.M.; Jacobs, G.; Gnanamani, M.K.; Lipka, S.M.; Shafer, W.D.; Swartz, C.R.; Jermwongratanachai, T.; Chen, R.; Rogers, F.; Davis, B.H. Fischer Tropsch synthesis: High oxygenate-selectivity of cobalt catalysts supported on hydrothermal carbons. ACS Catal. 2014, 4, 1662–1672. [Google Scholar] [CrossRef]

- Dictor, R.A.; Bell, A.T. Fischer-Tropsch synthesis over reduced and unreduced iron oxide catalysts. J. Catal. 1986, 97, 121–136. [Google Scholar] [CrossRef]

- Patzlaff, J.; Liu, Y.; Graffmann, C.; Gaube, J. Studies on product distributions of iron and cobalt catalyzed Fischer–Tropsch synthesis. Appl. Catal. A 1999, 186, 109. [Google Scholar] [CrossRef]

- Madon, R.J.; Taylor, W.F. Fischer-Tropsch synthesis on a precipitated iron catalyst. J. Catal. 1981, 69, 32–43. [Google Scholar] [CrossRef]

- Dictor, R.A.; Bell, A.T. Effects of potassium promotion on the activity and selectivity of iron Fischer-Tropsch catalysts. Ind. Eng. Chem. Proc. Des. Dev. 1983, 22, 97–103. [Google Scholar]

- Satterfield, C.N.; Huff, G.A.; Longwell, J.P. Product distribution from iron catalysts in Fischer-Tropsch slurry reactors. Ind. Eng. Chem. Process. Des. Dev. 1982, 21, 465–470. [Google Scholar] [CrossRef]

- Henrici-Olive, G.; Olive, S. The Fischer-Tropsch Synthesis: Molecular Weight Distribution of Primary Products and Reaction Mechanism. Angew. Chem. Int. Ed. Eng. 1976, 15, 136–141. [Google Scholar] [CrossRef]

- Huff, G.A., Jr.; Satterfield, C.N. Evidence for two chain growth probabilities on iron catalysts in the Fischer-Tropsch synthesis. J. Catal. 1984, 85, 370–379. [Google Scholar] [CrossRef]

- Donnelly, T.J.; Yates, I.C.; Satterfield, C.N. Analysis and prediction of product distributions of the Fischer-Tropsch synthesis. Energy Fuels 1988, 2, 734–739. [Google Scholar] [CrossRef]

- Herzog, K.; Gaube, J. Kinetic studies for elucidation of the promoter effect of alkali in Fischer-Tropsch iron catalysts. J. Catal. 1989, 115, 337–346. [Google Scholar] [CrossRef]

- Kuipers, E.W.; Vinkenburg, I.H.; Oosterbeek, H. Chain Length Dependence of α-Olefin Readsorption in Fischer-Tropsch Synthesis. J. Catal. 1995, 152, 137–146. [Google Scholar] [CrossRef]

- Bukur, B.D.; Mukesh, D.; Patel, S.A. Promoter effects on precipitated iron catalysts for Fischer-Tropsch synthesis. Ind. Eng. Chem. Res. 1990, 29, 194–204. [Google Scholar] [CrossRef]

- Masuku, C.M.; Hildebrandt, D.; Glasser, D. The role of vapour–liquid equilibrium in Fischer–Tropsch product distribution. Chem. Eng. Sci. 2011, 66, 6254–6263. [Google Scholar] [CrossRef]

- Satterfield, C.N.; Huff, G.A., Jr. Carbon number distribution of Fischer-Tropsch products formed on an iron catalyst in a slurry reactor. J. Catal. 1982, 73, 187–197. [Google Scholar] [CrossRef]

- Von Elbe, G. Internal Equilibria and Partial Vapor Pressures of Mixtures of Primary Normal Alcohols with Normal Paraffin Hydrocarbons. J. Chem. Phys. 1934, 2, 73–81. [Google Scholar] [CrossRef]

- Iglesia, E.; Reyes, S.C.; Madon, R.J. Transport-Enhanced a-Olefin Readsorption Pathways in Ru-Catalyzed Hydrocarbon Synthesis. J. Catal. 1991, 129, 238–256. [Google Scholar] [CrossRef]

- Davis, B.H. Fischer-Tropsch synthesis: relationship between iron catalyst composition and process variables. Catalysis Today 2003, 84, 83–98. [Google Scholar] [CrossRef]

- Zhang, C.H.; Yang, Y.; Teng, B.T.; Li, T.Z.; Zheng, H.Y.; Xiang, H.W.; Li, Y.W. Study of an iron-manganese Fischer–Tropsch synthesis catalyst promoted with copper. J. Catal. 2006, 237, 405–415. [Google Scholar] [CrossRef]

- Shi, B.; Davis, B.H. Fischer-Tropsch synthesis: The paraffin to olefin ratio as a function of carbon number. Catal. Today 2005, 106, 129–131. [Google Scholar] [CrossRef]

- Shi, B.; Wu, L.; Liao, Y.; Jin, C.; Montavon, A. Explanations of the formation of branched hydrocarbons during Fischer-Tropsch synthesis by alkylidene mechanism. Top. Catal. 2014, 57, 451–459. [Google Scholar] [CrossRef]

- Shi, B.; Davis, B.H. Fischer-Tropsch Synthesis: Evidence for Chain Initiation by Ethene and Ethanol for an Iron Catalyst. Top. Catal. 2003, 26, 157–161. [Google Scholar] [CrossRef]

- Gnanamani, M.K.; Keogh, R.A.; Shafer, W.D.; Shi, B.; Davis, B.H. Fischer–Tropsch synthesis: Deuterium labeled ethanol tracer studies on iron catalysts. Appl. Catal. A 2010, 385, 46–51. [Google Scholar] [CrossRef]

- Gnanamani, M.K.; Keogh, R.A.; Shafer, W.D.; Davis, B.H. Deutero-1-pentene tracer studies for iron and cobalt Fischer–Tropsch synthesis. Appl. Catal. A Gen. 2011, 393, 130–137. [Google Scholar] [CrossRef]

- Masuku, C.M.; Hildebrandt, D.; Glasser, D.; Davis, B.H. Steady-State Attainment Period for Fischer–Tropsch Products. Top. Catal. 2014, 57, 582–587. [Google Scholar] [CrossRef]

- Ao, M.; Pham, G.H.; Sunarso, J.; Tade, M.O.; Liu, S. Active Centers of Catalysts for Higher Alcohol Synthesis from Syngas: A Review. ACS Catal. 2018, 8, 7025–7050. [Google Scholar] [CrossRef]

- Wang, Y.; Davis, B.H. Fischer–Tropsch synthesis. Conversion of alcohols over iron oxide and iron carbide catalysts. Appl. Catal. A Gen. 1999, 180, 277–285. [Google Scholar] [CrossRef]

- Ngantsoue-Hoc, W.; Zhang, Y.; O’Brien, R.J.; Lou, M.; Davis, B.H. Fischer–Tropsch synthesis: Activity and selectivity for Group I alkali promoted iron-based catalysts. Appl. Catal. A Gen. 2002, 236, 77. [Google Scholar] [CrossRef]

- Espinoza, R.L.; Visagie, J.L.; van Berge, P.J.; Bolder, F.H. Catalysts. U.S. Patent 5,733,839, 31 March 1998. [Google Scholar]

- Yang, J.; Shafer, W.D.; Pendyala, V.R.R.; Jacobs, G.; Ma, W.; Chen, D.; Holmen, A.; Davis, B.H. Fischer-Tropsch synthesis: Deuterium kinetic isotopic effect for a 2.5%Ru/NaY catalysts. Top. Catal. 2014, 57, 508–517. [Google Scholar] [CrossRef]

- Deitz, W.A. Response Factors for Gas Chromatographic Analysis. J. Chromatogr. Sci. 1967, 5, 68–71. [Google Scholar] [CrossRef]

- Leveque, R.E. Determination of C3-C8 hydrocarbons in naphthas and reformates utilizing capillary column gas chromatography. Anal. Chem. 1967, 39, 1811–1818. [Google Scholar] [CrossRef]

- Ackman, R.G. The Flame lonization Detector: Further Comments on Molecular Breakdown and Fundamental Group Responses. J. Gas Chromatogr. 1968, 6, 497–5001. [Google Scholar] [CrossRef]

- Ackman, R.G. Fundamental Groups in the Response of Flame Ionization Detectors to Oxygenated Aliphatic Hydrocarbons. J. Gas Chromatogr. 1964, 2, 173. [Google Scholar] [CrossRef]

- Pendyala, V.R.R.; Jacobs, G.; Graham, U.M.; Shafer, W.D.; Martinelli, M.; Kong, L.; Davis, B.H. Fischer–Tropsch synthesis: Influence of acid treatment and preparation method on carbon nanotube supported ruthenium catalysts. Ind. Eng. Chem. Res. 2017, 56, 6408–6418. [Google Scholar] [CrossRef]

- Holm, T. Aspects of the mechanism of the flame ionization detector. J. Chromatogr. A 1999, 842, 221–227. [Google Scholar] [CrossRef]

- Down, R.D.; Lehr, J.H. (Eds.) Environmental Instrumentation and Analysis Handbook; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Noltingk, B.E. Measurement of Temperature and Chemical Composition: Jones’ Instrument Technology, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2013; p. 192. [Google Scholar]

- Barry, E.F.; Rosie, D.M. Response prediction of the thermal conductivity detector with light carrier gases. J. Chromatogr. A 1971, 59, 269–279. [Google Scholar] [CrossRef]

- Heftmann, E. Chromatography: A Laboratory Handbook of Chromatographic and Electrophoretic Methods, 3rd edition. J. Chromatogr. Sci. 1978, 16, 15A. [Google Scholar]

- Pendyala, V.R.R.; Chakrabarti, D.; de Klerk, A.; Keogh, R.A.; Sparks, D.E.; Davis, B.H. 14C-Labeled Alcohol Tracer Study: Comparison of Reactivity of Alcohols over Cobalt and Ruthenium Fischer–Tropsch Catalysts. Top. Catal. 2015, 58, 343–349. [Google Scholar]

- Masuku, C.M.; Hildebrandt, D.; Glasser, D. Olefin pseudo-equilibrium in the Fischer–Tropsch reaction. Chem. Eng. J. 2012, 181, 667–676. [Google Scholar] [CrossRef]

- Kellner, C.S.; Bell, A.T. Evidence for H2/D2 Isotope Effects on Fischer-Tropsch Synthesis over Supported Ruthenium Catalysts. J. Catal. 1981, 67, 175–185. [Google Scholar] [CrossRef]

- Jacobs, G.; Ribeiro, M.C.; Ma, W.; Ji, Y.; Khalid, S.; Sumodjo, P.T.A.; Davis, B.H. Group 11 (Cu, Ag, Au) promotion of 15%Co/Al2O3 Fischer-Tropsch synthesis catalysts. Appl. Catal. A Gen. 2009, 361, 137–151. [Google Scholar] [CrossRef]

- Ma, W.; Jacobs, G.; Keogh, R.A.; Bukur, D.B.; Davis, B.H. Fischer-Tropsch synthesis: Effect of Pd, Pt, Re, and Ru noble metal promoters on the activity and selectivity of a 25%Co/Al2O3 catalyst. Appl. Catal. A Gen. 2012, 437–438, 1–9. [Google Scholar] [CrossRef]

- Eliseev, O.L.; Tsapkina, M.V.; Dement’eva, O.S. Promotion of cobalt catalysts for the Fischer-Tropsch synthesis with alkali metals. Kinet. Catal. 2013, 54, 207–212. [Google Scholar] [CrossRef]

- Gnanamani, M.K.; Ribeiro, M.C.; Ma, W.; Shafer, W.D.; Jacobs, G.; Graham, U.M.; Davis, B.H. Fischer-Tropsch synthesis: Metal-support interfacial contact governs oxygenates selectivity over CeO2 supported Pt-Co catalysts. Appl. Catal. A Gen. 2011, 393, 17–23. [Google Scholar] [CrossRef]

- Ribeiro, M.C.; Gnanamani, M.K.; Garcia, R.; Jacobs, G.; Rabelo-Neto, R.C.; Noronha, F.B.; Gomes, I.G.; Davis, B.H. Tailoring the product selectivity of Co/SiO2 Fischer-Tropsch synthesis catalysts by lanthanide doping. Catal. Today 2018. [Google Scholar] [CrossRef]

- Blyholder, G.; Allen, M.C. Infrared spectra and molecular orbital model for carbon monoxide adsorbed on metals. J. Am. Chem. Soc. 1969, 91, 3158–3162. [Google Scholar] [CrossRef]

- Blyholder, G. Molecular Orbital View of Chemisorbed Carbon Monoxide. J. Phys. Chem. 1964, 68, 2772–2777. [Google Scholar] [CrossRef]

- Belosludov, R.V.; Sakahara, S.; Yajima, K.; Takami, S.; Kubo, M.; Miyamoto, A. Combinatorial computational chemistry approach as a promising method for design of Fischer–Tropsch catalysts based on Fe and Co. Appl. Surf. Sci. 2002, 189, 245–252. [Google Scholar] [CrossRef]

- Hocking, R.K.; Hambley, T.W. Database Analysis of Transition Metal Carbonyl Bond Lengths: Insight into the Periodicity of ð Back-Bonding, ó Donation, and the Factors Affecting the Electronic Structure of the TM-CtO Moiety. Organometallics 2007, 26, 2815–2823. [Google Scholar] [CrossRef]

- Betta, R.A.D.; Shelef, M. Heterogeneous Methanation: Absence of H2-D2, Kinetic Isotope Effect on Ni, Ru, and Pt. J. Catal. 1977, 49, 383–385. [Google Scholar] [CrossRef]

- Shelef, M.; Betta, R.A.D. Reply to comments on heterogeneous methanation: Absence of H2/D2 kinetic isotope effect on Ni, Ru, and Pt. J. Catal. 1979, 60, 169–170. [Google Scholar] [CrossRef]

- Van Nisselrooij, P.F.M.T.; Luttikholt, J.A.M.; van Meerten, R.Z.C.; de Croon, M.H.J.M.; Coenen, J.W.E. Hydrogen/deuterium kinetic isotope effect in the methanation of carbon monoxide on a nickel-silica catalyst. Appl. Catal. 1983, 6, 271–281. [Google Scholar] [CrossRef]

- McKee, E.W. Interaction of hydrogen and carbon monoxide on platinum group metals. J. Catal. 1967, 8, 240–249. [Google Scholar] [CrossRef]

- Shafer, W.D.; Jacobs, G.; Davis, B.H. Fischer–Tropsch Synthesis: Investigation of the Partitioning of Dissociated H2 and D2 on Activated Cobalt Catalyst. ACS Catal. 2012, 2, 1452–1456. [Google Scholar] [CrossRef]

- Shafer, W.D.; Jacobs, G.; Selegue, J.P.; Davis, B.H. An Investigation of the Partitioning of Dissociated H2 and D2 on Activated Nickel Catalysts. Catal. Lett. 2013, 143, 1368–1373. [Google Scholar] [CrossRef]

- Shafer, W.D.; Pendyala, V.R.R.; Gnanamani, M.K.; Jacobs, G.; Selegue, J.P.; Hopps, S.D.; Thomas, G.A.; Davis, B.H. Isotopic Apportioning of Hydrogen/Deuterium on the Surface of an Activated Iron Carbide Catalyst. Catal. Lett. 2015, 145, 1683–1690. [Google Scholar] [CrossRef]

- Shafer, W.D.; Pendyala, V.R.R.; Jacobs, G.; Selegue, J.; Davis, B.H. Fischer-Tropsch Synthesis, Catalysts, and Catalysis: Advances and Applications; Davis, B.H., Occelli, M.L., Eds.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2015. [Google Scholar]

- Shafer, W.D. Investigation into the Competitive Partitioning Of Dissociated H2 and D2 on Activated Fischer-Tropsch Catalysts. Ph.D. Theses, University of Kentucky, Lexington, Kentucky, 2015. [Google Scholar]

- Pendyala, V.R.R.; Shafer, W.D.; Jacobs, G.; Davis, B.H. Fischer-Tropsch synthesis: Effect of solvent on the H2-D2 isotopic exchange rate over an activated cobalt catalyst. Can. J. Chem. Eng. 2015, 94, 678–684. [Google Scholar] [CrossRef]

- Pendyala, V.V.R.R.; Shafer, W.D.; Jacobs, G.; Davis, B.H. Fischer-Tropsch synthesis: Effect of solvent on the H2-D2 isotopic exchange rate over an activated nickel catalyst. Catal. Today 2016, 270, 2–8. [Google Scholar] [CrossRef]

- Gnanamani, M.K.; Hamdeh, H.H.; Jacobs, G.; Shafer, W.D.; Sparks, D.E.; Davis, B.H. Fischer-Tropsch Synthesis: Activity and Selectivity of χ-Fe5C2 and θ-Fe3C Carbides. In Fischer-Tropsch Synthesis, Catalysts, and Catalysis: Advances and Applications; Davis, B.H., Occelli, M.L., Eds.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2015. [Google Scholar]

- Raye, A.; Davis, B.H. Fischer-Tropsch Synthesis. Mechanism Studies Using Isotopes. Catalysis 1996, 12, 52–131. [Google Scholar]

- Salvi, N.; Belpassi, L.; Tarantelli, F. On the Dewar–Chatt–Duncanson Model for Catalytic Gold(I) Complexes. Chem. A Eur. J. 2010, 16, 7231–7240. [Google Scholar] [CrossRef]

- Weststrate, C.J.; van Helden, P.; van de Loosdrecht, J.; Niemantsverdriet, J.W. Elementary steps in Fischer-Tropsch synthesis: CO bond scission, CO oxidation and surface carbiding on Co(0001). Surf. Sci. 2016, 648, 60–66. [Google Scholar] [CrossRef]

- Yang, J.; Frøseth, V.; Chen, D.; Holmen, A. Particle size effect for cobalt Fischer–Tropsch catalysts based on in situ CO chemisorption. Surf. Sci. 2016, 648, 67–73. [Google Scholar] [CrossRef]

- Ozbek, M.O.; Niemantsverdriet, J.H. Niemantsverdriet Elementary reactions of CO and H2 on C-terminated χ-Fe5C2(0 0 1) surfaces. J. Catal. 2014, 317, 158–166. [Google Scholar] [CrossRef]

- Nabaho, D.; Niemantsverdriet, J.H.; Claeys, M.; van Steen, E. Hydrogen spillover in the Fischer–Tropsch synthesis: An analysis of platinum as a promoter for cobalt–alumina catalysts. Catal. Today 2016, 261, 17–27. [Google Scholar] [CrossRef]

- Bartholomew, C.H. Hydrogen adsorption on supported cobalt, iron, and nickel. Catal. Lett. 1990, 7, 27–51. [Google Scholar] [CrossRef]

- Borg, Ø.; Frøseth, V.; Stors˦ter, S.; Rytter, E.; Holmen, A. Fischer-Tropsch synthesis recent studies on the relation between the properties of supported cobalt catalysts and the activity and selectivity. Surf. Sci. Catal. 2007, 167, 117. [Google Scholar]

- Zhang, R.; Hao, X.; Yong, Y.; Li, Y. Investigation of acetylene addition to Fischer–Tropsch Synthesis. Catal. Commun. 2011, 12, 1146–1148. [Google Scholar] [CrossRef]

- Krishnamoorthy, S.; Li, A.; Iglesia, E. Pathways for CO2 Formation and Conversion during Fischer–Tropsch Synthesis on Iron-Based Catalysts. Catal. Lett. 2002, 80, 77–86. [Google Scholar] [CrossRef]

- Shi, B.; Davis, B.H. 13C-tracer study of the Fischer–Tropsch synthesis: Another interpretation. Catal. Today 2000, 58, 255–261. [Google Scholar] [CrossRef]

- Mann, B.E.; Turner, M.L.; Quyoum, R.; Marsih, N.; Maitlis, P.M. Demonstration by 13C NMR Spectroscopy of Regiospecific Carbon−Carbon Coupling during Fischer−Tropsch Probe Reactions. J. Am. Chem. Soc. 1999, 121, 6497–6498. [Google Scholar] [CrossRef]

- Davis, B.H. Fischer–Tropsch Synthesis: Reaction mechanisms for iron catalysts. Catal. Today 2009, 141, 25–33. [Google Scholar] [CrossRef]

- Bistoni, G.; Rampino, S.; Scafuri, N.; Ciancaleoni, G.; Zuccaccia, D.; Belpassi, L.; Tarantelli, F. How π back-donation quantitatively controls the CO stretching response in classical and non-classical metal carbonyl complexes. Chem. Sci. 2016, 7, 1174–1184. [Google Scholar] [CrossRef]

- Ojeda, M.; Nabar, R.; Nilekar, A.U.; Ishikawa, A.; Mavrikakis, M.; Iglesia, E. CO activation pathways and the mechanism of Fischer–Tropsch synthesis. J. Catal. 2010, 272, 287–297. [Google Scholar] [CrossRef]

- Schulz, H. Short history and present trends of Fischer–Tropsch synthesis. Appl Catal A Gen. 1999, 186, 3–12. [Google Scholar] [CrossRef]

- Kuipers, E.W.; Scheper, C.; Wilson, J.H.; Vinkenburg, I.H.; Oosterbeek, H. Non-ASF product distributions due to secondary reactions during Fischer–Tropsch synthesis. J. Catal. 1996, 158, 288–300. [Google Scholar] [CrossRef]

- Van der Laan, G.P.; Beenackers, A.A.C.M. Kinetics and Selectivity of the Fischer–Tropsch Synthesis: A Literature Review. Catal. Rev. 1999, 41, 255–318. [Google Scholar] [CrossRef]

- Madon, R.J.; Reyes, S.C.; Iglesia, E. Primary and secondary reaction pathways in ruthenium-catalyzed hydrocarbon synthesis. J. Phys. Chem. 1991, 95, 7795–7804. [Google Scholar] [CrossRef]

- Ji, Y.-Y.; Xiang, H.-W.; Yang, J.-L.; Xu, Y.-Y.; Li, Y.-W.; Zhong, B. Effect of reaction conditions on the product distribution during Fischer–Tropsch synthesis over an industrial Fe-Mn catalyst. Appl. Catal. A 2001, 214, 77–86. [Google Scholar] [CrossRef]

- Iglesia, E.; Soled, S.L.; Fiato, R.A. Fischer-Tropsch synthesis on cobalt and ruthenium. Metal dispersion and support effects on reaction rate and selectivity. J. Catal. 1992, 137, 212–224. [Google Scholar] [CrossRef]

- Novak, S.; Madon, R.J.; Suhl, H. Secondary effects in the Fischer-Tropsch synthesis. J. Catal. 1982, 77, 141–151. [Google Scholar] [CrossRef]

- Schulz, H.; Claeys, M. Reactions of α-olefins of different chain length added during Fischer–Tropsch synthesis on a cobalt catalyst in a slurry reactor. Appl. Catal. A 1999, 186, 71–90. [Google Scholar] [CrossRef]

- Kapteijn, F.; de Deugd, R.M.; Moulijn, J.A. Fischer–Tropsch synthesis using monolithic catalysts. Catal. Today 2005, 105, 350–356. [Google Scholar] [CrossRef]

- Soled, S.; Iglesia, E.; Fiato, R.A. Activity and selectivity control in iron catalyzed Fischer-Tropsch synthesis. Catal. Lett. 1990, 7, 271–280. [Google Scholar] [CrossRef]

- Bukur, D.B.; Nowicki, L.; Manne, R.K.; Lang, X.S. Activation Studies with a Precipitated Iron Catalyst for Fischer-Tropsch Synthesis: II. Reaction Studies. J. Catal. 1995, 155, 366–375. [Google Scholar] [CrossRef]

- Donnelly, T.J.; Satterfield, C.N. Product distributions of the Fischer-Tropsch synthesis on precipitated iron catalysts. Appl. Catal. 1989, 52, 93–114. [Google Scholar] [CrossRef]

- Tau, L.M.; Dabbagh, H.A.; Davis, B.H. Fischer-Tropsch synthesis: carbon-14 tracer study of alkene incorporation. Energy Fuels 1990, 4, 94–99. [Google Scholar] [CrossRef]

- Ma, W.; Shafer, W.D.; Martinelli, M.; Sparks, D.E.; Davis, B.H. Fischer-Tropsch synthesis: Using deuterium tracer coupled with kinetic approach to study the kinetic isotopic effects of iron, cobalt and ruthenium catalysts. Catal. Today 2019, in press. [Google Scholar] [CrossRef]

- Schulz, H. Comparing Fischer-Tropsch Synthesis on Iron- and Cobalt Catalysts: The dynamics of structure and function. Stud. Surf. Sci. Catal. 2007, 163, 177–199. [Google Scholar]

- Jacobs, G.; Ricote, S.; Patterson, P.M.; Graham, U.M.; Dozier, A.; Khalid, S.; Rhodus, E.; Davis, B.H.; Brookhaven National Laboratory. Low temperature water-gas shift: Examining the efficiency of Au as a promoter for ceria-based catalysts prepared by CVD of an Au precursor. Appl. Catal. A Gen. 2005, 292, 229–243. [Google Scholar] [CrossRef]

- Ricote, S.; Jacobs, G.; Milling, M.; Ji, Y.; Patterson, P.M.; Davis, B.H. Low temperature water-gas shift: Characterization and testing of binary mixed oxides of ceria and zirconia promoted with Pt. Appl. Catal. A Gen. 2006, 303, 35–47. [Google Scholar] [CrossRef]

- Jacobs, G.; Ricote, S.; Davis, B.H. Low temperature water-gas shift: Type and loading of metal impacts decomposition and hydrogen exchange rates of pseudo-stabilized formate over metal/ceria catalysts. Appl. Catal. A Gen. 2006, 302, 14–21. [Google Scholar] [CrossRef]

- Jacobs, G.; Graham, U.M.; Chenu, E.; Patterson, P.M.; Dozier, A.; Davis, B.H. Low temperature water-gas shift: Impact of Pt promoter loading on the partial reduction of ceria, and consequences for catalyst design. J. Catal. 2005, 229, 499–512. [Google Scholar] [CrossRef]

- Pendyala, V.R.R.; Jacobs, G.; Mohandas, J.C.; Luo, M.; Ma, W.; Gnanamani, M.K.; Davis, B.H. Fischer–Tropsch synthesis: Attempt to tune FTS and WGS by alkali promoting of iron catalysts. Appl. Catal. A Gen. 2010, 389, 131–139. [Google Scholar] [CrossRef]

- Pendyala, V.R.R.; Jacobs, G.; Mohandas, J.C.; Luo, M.; Hamdeh, H.H.; Ji, Y.; Ribeiro, M.C.; Davis, B.H. Fischer–Tropsch Synthesis: Effect of Water Over Iron-Based Catalysts. Catal. Lett. 2010, 140, 98–105. [Google Scholar] [CrossRef]

- Lia, J.; Cheng, X.; Zhang, C.; Chang, Q.; Wang, J.; Wang, X.; Lv, Z.; Dong, W.; Yang, Y.; Lia, Y. State Effect of alkalis on iron-based Fischer-Tropsch synthesis catalysts: Alkali-FeOx interaction, reduction, and catalytic performance. Appl. Catal. A Gen. 2016, 528, 131–141. [Google Scholar] [CrossRef]

- Lee, S.W.; Coulombe, S.; Glavincevski, B. Investigation of methods for determining aromatics in middle-distillate fuels. Energy Fuels 1990, 4, 20–33. [Google Scholar] [CrossRef]

- Tau, L.; Dabbagh, H.A.; Chawla, B.; Davis, B.H. Fischer-Tropsch synthesis with an iron catalyst: Incorporation of ethene into higher carbon number alkanes. Catal. Lett. 1990, 7, 141–150. [Google Scholar] [CrossRef]

- O’Brien, B.S.R.; Davis, S.B.B.H. Mechanism of the Isomerization of 1-Alkene during Iron-Catalyzed Fischer–Tropsch Synthesis. J. Catal. 2001, 199, 202–208. [Google Scholar]

- Shi, B.; Liao, Y.; Naumovitz, J.L. Formation of 2-alkenes as secondary products during Fischer–Tropsch synthesis. Appl. Catal. A Gen 2015, 490, 201–206. [Google Scholar] [CrossRef]

- Shi, B.; Chunfen, J. Inverse kinetic isotope effects and deuterium enrichment as a function of carbon number during formation of C–C bonds in cobalt catalyzed Fischer–Tropsch synthesis. J. Appl. Catal A Gen. 2011, 393, 178–183. [Google Scholar] [CrossRef]

- Van Dijk, W.L.; Niemantsverdriet, J.W.; Kraan, A.M.v.; van der Baan, H.S. Effects of Manganese Oxide and Sulphate on the Olefin Selectivity of Iron Catalysts in the Fischer Tropsch Reaction. Appl. Catal. 1982, 2, 273–288. [Google Scholar] [CrossRef]

- Kreitman, K.M.; Baerns, M.; Butt, J.B. Manganese-oxide-supported iron Fischer-Tropsch synthesis catalysts: Physical and catalytic characterization. J. Catal. 1987, 105, 319–334. [Google Scholar] [CrossRef]

- Ribeiro, M.C.; Jacobs, G.; Pendyala, R.; Davis, B.H.; Cronauer, D.C.; Kropf, A.J.; Marshall, C.L. Fischer-Tropsch Synthesis: Influence of Mn on the Carburization Rates and Activities of Fe-Based Catalysts by TPR-EXAFS/XANES and Catalyst Testing. J. Phys. Chem. C 2011, 115, 4783–4792. [Google Scholar] [CrossRef]

- Diehl, F.; Khodakov, A.Y. Promotion of Cobalt Fischer-Tropsch Catalysts with Noble Metals: A Review. Oil Gas Sci. Technol. 2009, 64, 11–24. [Google Scholar] [CrossRef]

- Hilmen, A.M.; Schanke, D.; Holmen, A. TPR study of the mechanism of rhenium promotion of alumina-supported cobalt Fischer-Tropsch catalysts. Catal. Lett. 1996, 38, 143–147. [Google Scholar] [CrossRef]

- Vada, S.; Hoff, A.; Ådnanes, E.; Schanke, D.; Holmen, A. Fischer-Tropsch synthesis on supported cobalt catalysts promoted by platinum and rhenium. Top. Catal. 1995, 2, 155–162. [Google Scholar] [CrossRef]

- Prins, R. Hydrogen Spillover. Facts and Fiction. Chem. Rev. 2012, 112, 2714–2738. [Google Scholar] [CrossRef]

- Karim, W.; Spreafico, C.; Kleibert, A.; Gobrecht, J.; VandeVondele, J.; Ekinci, Y.; van Bokhoven, J.A. Catalyst support effects on hydrogen spillover. Nature 2017, 541, 68–71. [Google Scholar] [CrossRef]

- Masuku, C.M.; Shafer, W.D.; Ma, W.; Gnanamani, M.K.; Jacobs, G.; Hildebrandt, D.; Glasser, D.; Davis, B.H. Variation of residence time with chain length for products in a slurry-phase Fischer–Tropsch reactor. J. Catal. 2012, 287, 93–101. [Google Scholar] [CrossRef]

| Support/Promoter | Hydrocarbons | Oxygenates | |

|---|---|---|---|

| Cobalt 220 °C, 27.6 bar, WHSV = 2–5 H2/CO = 2 | Unsupported | 0.82 | 0.68 |

| Alumina | 0.88 | 0.75 | |

| Silica | 0.86 | 0.79 | |

| Titania | 0.79 | 0.79 | |

| Carbon | 0.76 | 0.60 | |

| Ceria | 0.80 | 0.64 | |

| Ruthenium 220 °C, 19.2 bar, WHSV = 1.5, H2/CO = 2 | Alumina | 0.78 | 0.63 |

| Titania | 0.79 | 0.52 | |

| Silica | 0.80 | 0.70 | |

| NaY | 0.75 | 0.70 | |

| Iron at High CO conversion supported with 5.1 silica. Reaction Conditions 270 °C, 12.1 bar, WHSV = 2, H2/CO = 0.7 | Unsupported | 0.87 | 0.31 |

| LiHC | 0.67 | 0.34 | |

| NaHC | 0.74 | 0.51 | |

| KHC | 0.78 | 0.60 | |

| RbHC | 0.74 | 0.64 | |

| CsHC | 0.72 | 0.66 | |

| Iron at Low CO conversion supported with 5.1 silica 270 °C, 12.1 bar, WHSV = 2, H2/CO = 0.7 | Unsupported | 0.86 | 0.35 |

| LiLC | 0.80 | 0.41 | |

| NaLC | 0.86 | 0.66 | |

| KLC | 0.82 | 0.74 | |

| RbLC | 0.92 | 0.69 | |

| CsLC | 0.89 | 0.73 | |

| Iron 270 °C, 12.1 bar, WHSV = 2, H2/CO = 0.7 | Manganese | 0.78 | 0.56 |

| Hydrocarbons Alpha | Average | Standard Deviation | Coefficient of Variance |

| Cobalt | 0.82 | 0.04 | 5.49 |

| Ruthenium | 0.78 | 0.02 | 3.02 |

| Iron High CO | 0.75 | 0.07 | 8.93 |

| Iron Low CO | 0.86 | 0.04 | 5.22 |

| Oxygenates Alpha | Average | Standard Deviation | Coefficient of Variance |

| Cobalt | 0.71 | 0.08 | 11.34 |

| Ruthenium | 0.64 | 0.09 | 13.42 |

| Iron High CO | 0.51 | 0.15 | 30.05 |

| Iron Low CO | 0.60 | 0.17 | 29.02 |

| Support/Promoter | Methane | Oxygenate | Paraffin | 1-Olefin | Trans-2-Olefin | Cis-2-Olefin | O/P | A/P | |

|---|---|---|---|---|---|---|---|---|---|

| Cobalt 220 °C, 27.6 bar, WHSV = 2–5, H2/CO = 2 | Unsupported | 42.20 | 1.44 | 42.79 | 10.56 | 2.33 | 0.68 | 0.16 | 0.02 |

| Alumina | 14.98 | 2.51 | 66.10 | 13.12 | 1.00 | 2.30 | 0.20 | 0.03 | |

| Silica | 19.30 | 6.27 | 53.31 | 18.29 | 1.36 | 1.48 | 0.29 | 0.09 | |

| Titania | 19.40 | 2.93 | 41.03 | 30.26 | 3.57 | 2.81 | 0.61 | 0.05 | |

| Carbon | 18.00 | 10.07 | 58.38 | 7.89 | 3.26 | 2.40 | 0.18 | 0.13 | |

| Ceria | 28.80 | 46.59 | 11.92 | 8.81 | 2.04 | 1.84 | 0.31 | 1.14 | |

| Ruthenium 220 °C, 19.2 bar, WHSV = 1.5, H2/CO = 2 | Alumina | 7.99 | 3.85 | 59.96 | 26.32 | 1.17 | 0.72 | 0.42 | 0.06 |

| Titania | 8.36 | 3.40 | 54.90 | 24.64 | 4.90 | 3.80 | 0.53 | 0.05 | |

| Silica | 6.76 | 7.05 | 51.56 | 23.71 | 6.85 | 4.08 | 0.59 | 0.12 | |

| NaY | 7.53 | 2.24 | 53.70 | 25.13 | 7.11 | 4.30 | 0.60 | 0.04 | |

| Iron at High CO conversion supported with 5.1 silica. Reaction Conditions 270 °C, 12.1 bar, WHSV = 2, H2/CO = 0.7 | unsupported | 46.26 | 0.25 | 37.22 | 12.90 | 2.33 | 1.04 | 0.19 | 0.00 |

| LiHC | 12.46 | 2.50 | 33.71 | 40.19 | 6.92 | 4.22 | 1.11 | 0.05 | |

| NaHC | 12.87 | 3.81 | 34.69 | 44.27 | 2.51 | 1.83 | 1.02 | 0.08 | |

| KHC | 11.01 | 2.84 | 30.38 | 48.36 | 4.49 | 2.91 | 1.35 | 0.07 | |

| RbHC | 12.08 | 7.52 | 29.03 | 43.90 | 3.63 | 3.84 | 1.25 | 0.18 | |

| CsHC | 11.19 | 8.23 | 25.45 | 47.86 | 4.21 | 3.06 | 1.50 | 0.22 | |

| Iron at Low CO conversion supported with 5.1 silica 270 °C, 12.1 bar, WHSV = 2, H2/CO = 0.7 | Unsupported | 17.66 | 0.57 | 54.66 | 18.81 | 4.52 | 3.78 | 0.37 | 0.01 |

| LiLC | 13.41 | 5.01 | 29.99 | 45.11 | 3.73 | 2.75 | 1.19 | 0.12 | |

| NaLC | 10.43 | 3.16 | 31.24 | 45.19 | 5.51 | 4.48 | 1.32 | 0.08 | |

| KLC | 7.01 | 7.39 | 27.11 | 49.06 | 5.91 | 3.52 | 1.71 | 0.22 | |

| RbLC | 9.33 | 7.53 | 28.61 | 48.99 | 2.79 | 2.76 | 1.44 | 0.20 | |

| CsLC | 9.54 | 7.26 | 25.38 | 53.02 | 2.30 | 2.50 | 1.66 | 0.21 | |

| Iron 270 °C, 12.1 bar, WHSV = 2, H2/CO = 0.7 | Manganese | 4.53 | 4.69 | 19.90 | 65.82 | 1.63 | 3.43 | 2.90 | 0.19 |

| Alpha | Product Distribution | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Catalyst | Hydrocarbons | Oxygenates | Oxygenate | Paraffin | 1-Olefin | Trans-2-Olefin | Cis-2-Olefin | O/P | A/P | Methane |

| No Alkali | 0.01 | 0.03 | 0.23 | 7.90 | 4.18 | 1.54 | 1.94 | 0.13 | 0.00 | 20.22 |

| Li | 0.09 | 0.05 | 1.78 | 1.96 | 3.47 | 2.26 | 1.04 | 0.05 | 0.04 | 0.67 |

| Na | 0.09 | 0.11 | 0.46 | 4.17 | 0.65 | 2.12 | 1.87 | 0.21 | 0.00 | 1.73 |

| K | 0.03 | 0.09 | 3.22 | 5.14 | 0.49 | 1.00 | 0.43 | 0.26 | 0.10 | 2.83 |

| Rb | 0.13 | 0.04 | 0.01 | 2.25 | 3.60 | 0.59 | 0.76 | 0.13 | 0.01 | 1.95 |

| Cs | 0.12 | 0.05 | 0.69 | 1.22 | 3.65 | 1.34 | 0.39 | 0.11 | 0.01 | 1.17 |

| % Total Mole of Carbon | |||||

|---|---|---|---|---|---|

| Totals | 0%K | 2%K | 4%K | 6%K | 10%K |

| Ph | 79.80 | 76.86 | 78.13 | 76.60 | 62.79 |

| 2Me | 3.27 | 3.38 | 3.18 | 3.91 | 4.26 |

| 3Me | 3.53 | 3.28 | 3.03 | 3.99 | 4.37 |

| 4Me | 2.05 | 2.14 | 1.92 | 2.30 | 2.89 |

| 5Me | 1.34 | 1.20 | 1.72 | 1.48 | 2.10 |

| 6Me | 0.77 | 0.69 | 1.04 | 0.78 | 1.02 |

| 7Me | 0.34 | 0.30 | 0.54 | 0.32 | |

| Unseparated | 1.05 | 1.06 | 1.69 | 1.23 | 1.98 |

| Total | 12.35 | 10.98 | 13.12 | 14.01 | 16.61 |

| Iso/Normal Mole Fraction | |

|---|---|

| No Alkali | 0.21 |

| Li | 0.17 |

| Na | 0.16 |

| Rb | 0.16 |

| K | 0.16 |

| Cs | 0.13 |

| Oil and Wax | D | H |

|---|---|---|

| Alcohol | 3.96 | 3.25 |

| 1-Olefin | 11.30 | 10.21 |

| Paraffin | 82.34 | 84.40 |

| Cis-Olefin | 0.93 | 0.95 |

| Trans-Olefin | 1.46 | 1.19 |

| Total Olefin | 13.69 | 12.35 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shafer, W.D.; Gnanamani, M.K.; Graham, U.M.; Yang, J.; Masuku, C.M.; Jacobs, G.; Davis, B.H. Fischer–Tropsch: Product Selectivity–The Fingerprint of Synthetic Fuels. Catalysts 2019, 9, 259. https://doi.org/10.3390/catal9030259

Shafer WD, Gnanamani MK, Graham UM, Yang J, Masuku CM, Jacobs G, Davis BH. Fischer–Tropsch: Product Selectivity–The Fingerprint of Synthetic Fuels. Catalysts. 2019; 9(3):259. https://doi.org/10.3390/catal9030259

Chicago/Turabian StyleShafer, Wilson D., Muthu Kumaran Gnanamani, Uschi M. Graham, Jia Yang, Cornelius M. Masuku, Gary Jacobs, and Burtron H. Davis. 2019. "Fischer–Tropsch: Product Selectivity–The Fingerprint of Synthetic Fuels" Catalysts 9, no. 3: 259. https://doi.org/10.3390/catal9030259

APA StyleShafer, W. D., Gnanamani, M. K., Graham, U. M., Yang, J., Masuku, C. M., Jacobs, G., & Davis, B. H. (2019). Fischer–Tropsch: Product Selectivity–The Fingerprint of Synthetic Fuels. Catalysts, 9(3), 259. https://doi.org/10.3390/catal9030259