Fast Pyrolysis of Sunflower Oil in the Presence of Microporous and Mesoporous Materials for Production of Bio-Oil

Abstract

1. Introduction

2. Results and Discussion

2.1. Characterization of the Catalysts Obtained

2.2. Catalytic Test

3. Materials and Methods

3.1. Synthesis of the Catalysts (Al-MCM-41 and ZSM-5)

3.2. Characterization of the Materials Obtained

3.3. Catalytic Test

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References and Note

- Han, Y.; Stankivikj, F.; Garcia-Perez, M. Co-hydrotreatment of tire pyrolysis oil and vegetable oil for the production of transportation fuels. Fuel Process. Technol. 2017, 159, 328–339. [Google Scholar] [CrossRef]

- Szklo, A.S.; Machado, G.; Schaeffer, R.; Simões, A.F.; Mariano, J.B. Placing Brazil’s heavy acid oils on international markets. Energy Policy 2006, 36, 692–705. [Google Scholar] [CrossRef]

- Jacobson, K.; Maheria, K.C.; Dalai, A.K. Bio-oil valorization: A review. Renew. Sustain. Energy Rev. 2013, 23, 91–106. [Google Scholar] [CrossRef]

- Wu, L.; Guo, S.; Wang, C.; Yang, Z. Production of alkanes (C7-C29) from different part of poplar tree via direct deoxy-liquefaction. Bioresour. Technol. 2009, 100, 2069–2076. [Google Scholar] [CrossRef] [PubMed]

- Qiang, L.; Wen-Zhi, L.; Xi-Feng, Z. Overview of fuel properties of biomass fast pyrolysis oils. Energy Convers. Manag. 2009, 50, 1376–1383. [Google Scholar]

- Demirbas, A. Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Convers. Manag. 2001, 42, 1357–1378. [Google Scholar] [CrossRef]

- Yaman, S. Pyrolysis of biomass to produce fuels and chemical feedstocks. Energy Convers. Manag. 2004, 45, 651–671. [Google Scholar] [CrossRef]

- Demirbas, A.; Arin, G. An overview of biomass pyrolysis. Energy Sources 2002, 24, 471–482. [Google Scholar] [CrossRef]

- Bridgwater, A.V. Catalysis in thermal biomass conversion. Appl. Catal. A Gen. 1994, 116, 5–47. [Google Scholar] [CrossRef]

- Bridgwater, A.V.; Peacoke, G.V.C. Fast pyrolysis processes for biomass. Renew. Sustain. Energy Rev. 2000, 4, 1–73. [Google Scholar] [CrossRef]

- Mohan, D.; Pittman, C.U.; Steele, P.H. Pyrolysis of wood/biomass for bio-oil: A critical review. Energy Fuels 2006, 20, 848–889. [Google Scholar] [CrossRef]

- Domínguez-Barroso, M.V.; Herrera, C.; Larrubia, M.A.; Alemany, L.J. Diesel oil-like hydrocarbn production from vegetable oil in a single process over Pt-Ni/Al2O3 and Pd/C combined catalysts. Fuel Process. Technol. 2016, 148, 110–116. [Google Scholar] [CrossRef]

- Silvério, F.O.; Barbosa, L.C.A. Pirólise como técnica analítica. Quím. Nova 2008, 31, 1543–1552. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, G. Supply chain design and operational planning models for biomass to drop-in fuel production. Biomass Bioenergy 2013, 58, 238–250. [Google Scholar] [CrossRef]

- Shouyun, C.; Wei, L.; Julson, J.; Muthukumarappan, K.; Kharel, P.R.; Boakye, E. Hidrocarbon bio-oil production from pyrolysis bio-oil using non-sulfide Ni-Zn/Al2O3 catalyst. Fuel Process. Technol. 2017, 162, 78–86. [Google Scholar]

- Koike, N.; Hosokai, S.; Takagaki, A.; Nishimura, S.; Kikuchi, R.; Ebitani, K.; Suzuki, Y.; Oyama, S.T. Upgrading of pyrolysis bio-oil using nickel phoshide catalysts. J. Catal. 2016, 333, 115–126. [Google Scholar] [CrossRef]

- Stefanidis, S.D.; Karakoulia, S.A.; Kalogiannis, K.G.; Iliopoulouil, E.F.; Delimitis, A.; Yannoulakis, H.; Zampetakis, T.; Lappas, A.A.; Triantafyllidis, K.S. Natural magnesium oxide (MgO) catalysts: A cost-effective sustainable alternative to acid zeolites for the in situ upgrading of biomass fast pyrolysis oil. Appl. Catal. B Environ. 2016, 196, 155–174. [Google Scholar] [CrossRef]

- Choi, S.J.; Park, S.H.; Jeon, J.; Lee, I.G.; Ryu, C.; Suh, D.J.; Park, Y. Catalytic conversion of particle board over microporous catalysts. Renew. Energy 2013, 54, 105–110. [Google Scholar] [CrossRef]

- Wang, Y.; He, T.; Liu, K.; Wu, J.; Fang, Y. From biomass to advanced bio-fuel by catalytic pyrolysis/hidro-processing: Hydrodeoxygenation of bio-oil derived from biomass catalytic pyrolysis. Bioresour. Technol. 2012, 108, 280–284. [Google Scholar] [CrossRef] [PubMed]

- Ramli, A.; Razak, R.A. Analysis of the organic liquid produced from catalytic cracking of crude palm oil in the presence of alumina supported catalysts. AIP Conf. Proc. 2012, 1482, 643–648. [Google Scholar]

- Araújo, A.M.M.; Lima, R.O.; Gondim, A.D.; Diniz, J.; Souza, L.D.; Araujo, A.S. Thermal and catalytic pyrolysis of sunflower oil using AlMCM-41. Renew. Energy 2017, 101, 900–906. [Google Scholar] [CrossRef]

- Mâncio, A.A.; Costa, K.M.B.; Ferreira, C.C.; Santos, M.C.; Lhamas, D.E.L.; da Mota, S.A.P.; Leão, R.A.C.; de Souza, R.O.M.A.; Araújo, M.E.; Borges, L.E.P.; et al. Process analysis of physicochemical properties and chemical composition of organic liquid products obtained by thermochemical conversion of palm oil. J. Anal. Appl. Pyrolysis 2017, 123, 284–295. [Google Scholar] [CrossRef]

- Hu, X.; Gunawan, R.; Mourant, D.; Hasan, M.D.M.; Wu, L.; Song, Y.; Lievens, C.; Li, C.Z. Upgrading of bio-oil via acid-catalyzed reactions in alcohols—A mini review. Fuel Process. Technol. 2017, 155, 2–19. [Google Scholar] [CrossRef]

- Kubicka, D.; Kaluza, L. Deoxygenation of vegetable oils over sulfide Ni, Mo and NiMo catalysts. Appl. Catal. A Gen. 2010, 372, 199–208. [Google Scholar] [CrossRef]

- Beck, J.S.; Vartuli, J.G.; Roth, W.J.; Leonowicz, M.E.; Kresge, C.T.; Schmitt, K.D.; Chu, C.T.W.; Olson, D.H.; Sheppard, E.W.; Mcculen, S.B.; et al. A new family of mesoporous molecular-sieves prepared with liquid-crystal templates. J. Am. Chem. Soc. 1992, 114, 10834–10843. [Google Scholar] [CrossRef]

- Araújo, A.M.M.; Figueiredo, A.L.; Gondim, A.D.; Guedes, A.P.M.A.; Di Souza, L.; de Araujo, A.S. Thermal and catalytic pyrolysis of vacum gas oil using HZSM-5: TG and PY-GC/MS. Pet. Sci. Technol. 2016, 34, 247–252. [Google Scholar] [CrossRef]

- Costa, M.J.F.; Araujo, A.S. Zeólitas Sintetizadas na Ausência Total de Direcionador Orgânico e Respectivo Processo de Síntese. Rev. Propr. Ind. 2010, 2083, 76. [Google Scholar]

- EMBRAPA, Agroenergia, Biorrefinarias 2012. Acesso em 05 de maio de 2017.

- Zhao, X.S.; Lu, G.Q.; Millar, G.J. Advances in Mesoporous Molecular Sieve MCM-41. Ind. Eng. Chem. Res. 1996, 35, 2075–2090. [Google Scholar] [CrossRef]

- Araujo, A.S.; Jaroniec, M. Synthesis and properties of lanthanide incorporated mesoporous molecular sieves. J. Colloid Interface Sci. 1999, 218, 462–467. [Google Scholar] [CrossRef] [PubMed]

- Silva, A.O.S. Síntese e Caracterização de Catalisadores de Ferro e Cobalto Suportados nas Zeólitas HZSM-12 e HZSM-5 para a Conversão de gás de Síntese em Hidrocarbonetos. Tese (Doutorado em Engenharia Química) Programa de Pós-Graduação em Engenharia Química, Programa de Recursos Humanos da Agência Nacional do petróleo para o Setor de Petróleo e Gás—PRH/ANP-14, Universidade Federal do Rio Grande do Norte, Natal, Brazil, 2004. [Google Scholar]

- Sang, S.; Chang, F.; Liu, Z.; He, C.; He, Y.; Xu, L. Difference of ZSM-5 zeolites synthesized with various templates. Catal. Today 2004, 93, 729–734. [Google Scholar] [CrossRef]

- Kruk, M.; Jaroniec, M.; Sayari, A. Adsorption study of surface properties of MCM-41 materials with different pore sizes. J. Phys. Chem. 1997, 101, 583–589. [Google Scholar] [CrossRef]

- Maciel, S.T.A.; Wisniewski, A.; Souza, M.J.B. Use of micropyrolysis and Tg to sudy the termal catalytic conversion of onshore crude oil using the zeolite catalysts type Y and ferrite. J. Therm. Anal. Calorim. 2015, 122, 369–377. [Google Scholar] [CrossRef]

- Zholobenko, V.L.; Holmes, S.M.; Cundy, C.S.; Dwyer, J. Synthesis of MCM-41 materials: In situ FTIR study. Microporous Mater. 1997, 11, 83–86. [Google Scholar] [CrossRef]

- Silverstein, R.M.; Webster, F.X.; Kiemle, D.J. Identificação Espectrométrica de Compostos Orgânicos, 7th ed.; LTC: Rio de Janeiro, Brazil, 2007; ISBN 9788521615217. [Google Scholar]

- Narayanan, S.; Sultan, A.; Le, Q.T.; Aurox, A. A comparative and multitechnical approach to the acid character of template and non-template ZSM-5 zeolites. Appl. Catal. A Gen. 1998, 168, 373–384. [Google Scholar] [CrossRef]

- Han, W.; Jia, Y.; Xiong, G.; Yang, W. Synthesis of hierarchical porous materials with ZSM-5 structures via template-free sol-gel method. Sci. Technol. Adv. Mater. 2007, 8, 101–105. [Google Scholar] [CrossRef]

- Sing, K.S.W.; Everett, D.H.; Haul, R.A.W.; Moscou, L.; Pierotti, R.A.; Rouquérol, J.; Siemieniewska, T. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Biligetu, T.; Wang, Y.; Nishitoba, T.; Otomo, R.; Park, S.; Mochizuki, H.; Kondo, J.N.; Tatsumi, T.; Yokoi, T. Al distribution and catalytic performance of ZSM-5 zeolites synthesized with various alcohols. J. Catal. 2017, 353, 1–10. [Google Scholar] [CrossRef]

- Coriolano, A.C.F.; Silva, C.G.C.; Costa, M.J.F.; Pergher, S.B.C.; Caldeira, V.P.S.; Araujo, A.S. Development of HZSM-5/AlMCM-41 hybrid micro-mesoporous material and application for pyrolysis of vacuum gas oil. Microporous Mesoporous Mater. 2013, 172, 206–212. [Google Scholar] [CrossRef]

- Kraiem, T.; Hassen, A.B.; Belayouni, H.; Jeguirim, M. Production and characterization of bio-oil from the pyrolysis of waste frying oil. Environ. Sci. Pollut. Res. 2017, 24, 9951–9961. [Google Scholar] [CrossRef] [PubMed]

- Kloestra, K.R.; Zandbergen, H.W.; Jansen, J.C.; Bekkum, H.V. Overgrowth of mesoporous MCM-41 on faujasite. Microporous Mater. 1996, 6, 287–293. [Google Scholar] [CrossRef]

- Adjane, J.D.; Bakhshi, N.N. Production of hydrocarbons by catalytic upgrading of a fast pyrolysis bio-oil. Part I: Conversion over various catalysts. Fuel Process. Technol. 1995, 45, 185–202. [Google Scholar]

- Chew, T.L.; Bhatia, S. Catalytic processes towards the production of biofuels in a palm oil and oil palm biomass-based biorefinery. Bioresour. Technol. 2008, 99, 7911–7922. [Google Scholar] [CrossRef] [PubMed]

- Santos, C.D.; Bofim, L.M.; Motta, J.A.S.; Rodrigues, G.; Nascimento, A.R.; Araujo, A.S.; Pedrosa, A.M.G.; Souza, M.J.B. Estudo da pirólise de óleo de soja sobre peneiras moleculares micro e mesoporosas. Sci. Plena 2009, 5, 1–14. [Google Scholar]

- Idem, R.O.; Bakhshi, N.N. Kinetic modeling of the production of hydrogen from the metanol-steam reforming process over Mn-promoted coprecipitated Cu-Al catalyst. Chem. Eng. Sci. 1996, 51, 3697–3708. [Google Scholar] [CrossRef]

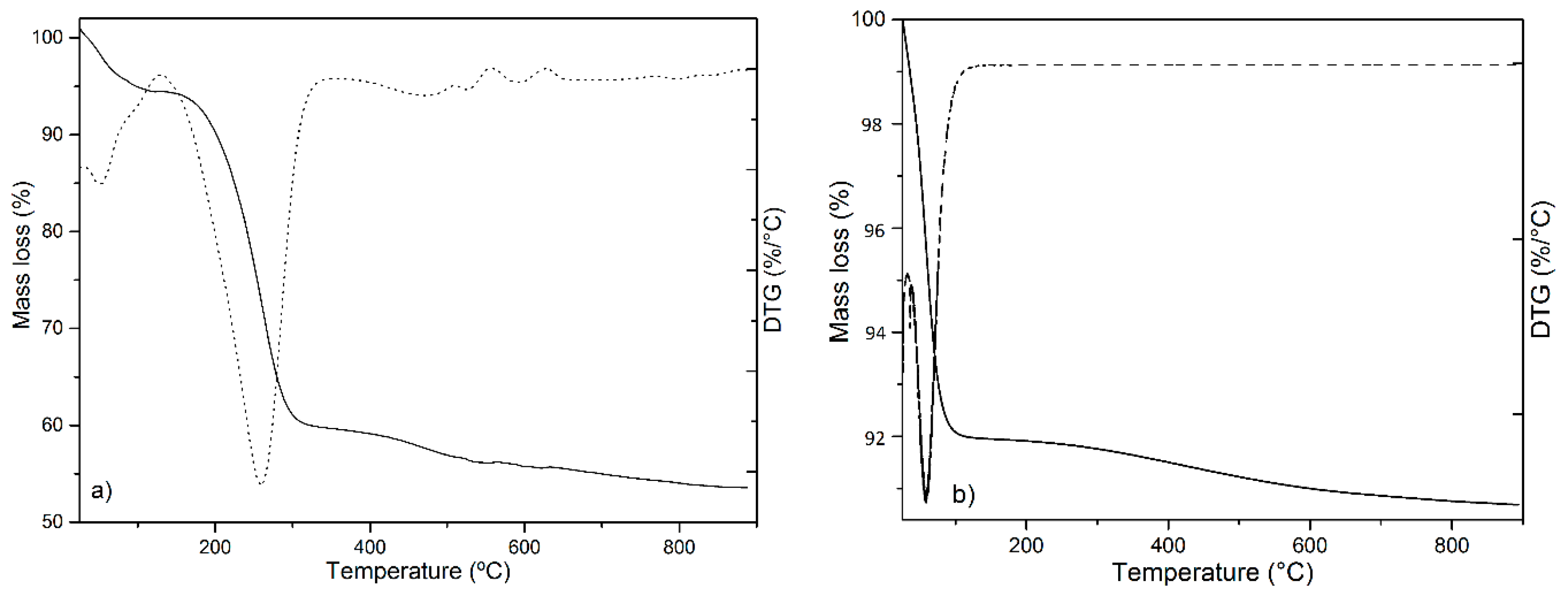

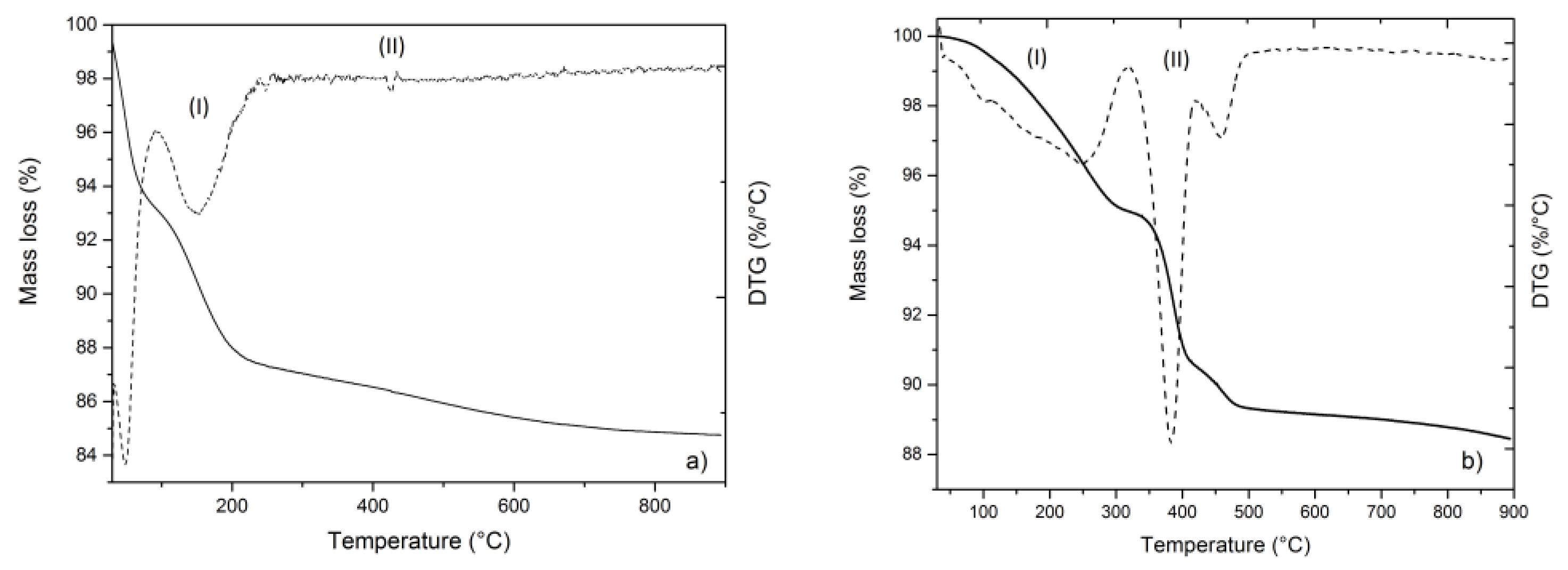

| Sample | STAGES | Temperature Ranges (°C) | Mass Losses (%) | Residues (%) |

|---|---|---|---|---|

| ALMCM | 1 | 50–127 | 3.93 | |

| (Non-calcined) | 2 | 128–350 | 34.82 | |

| 58.3 | ||||

| ALMCM | 1 | 351–653 | 2.92 | |

| (Calcined) | 2 | 34–130 | 4.88 | 95.2 |

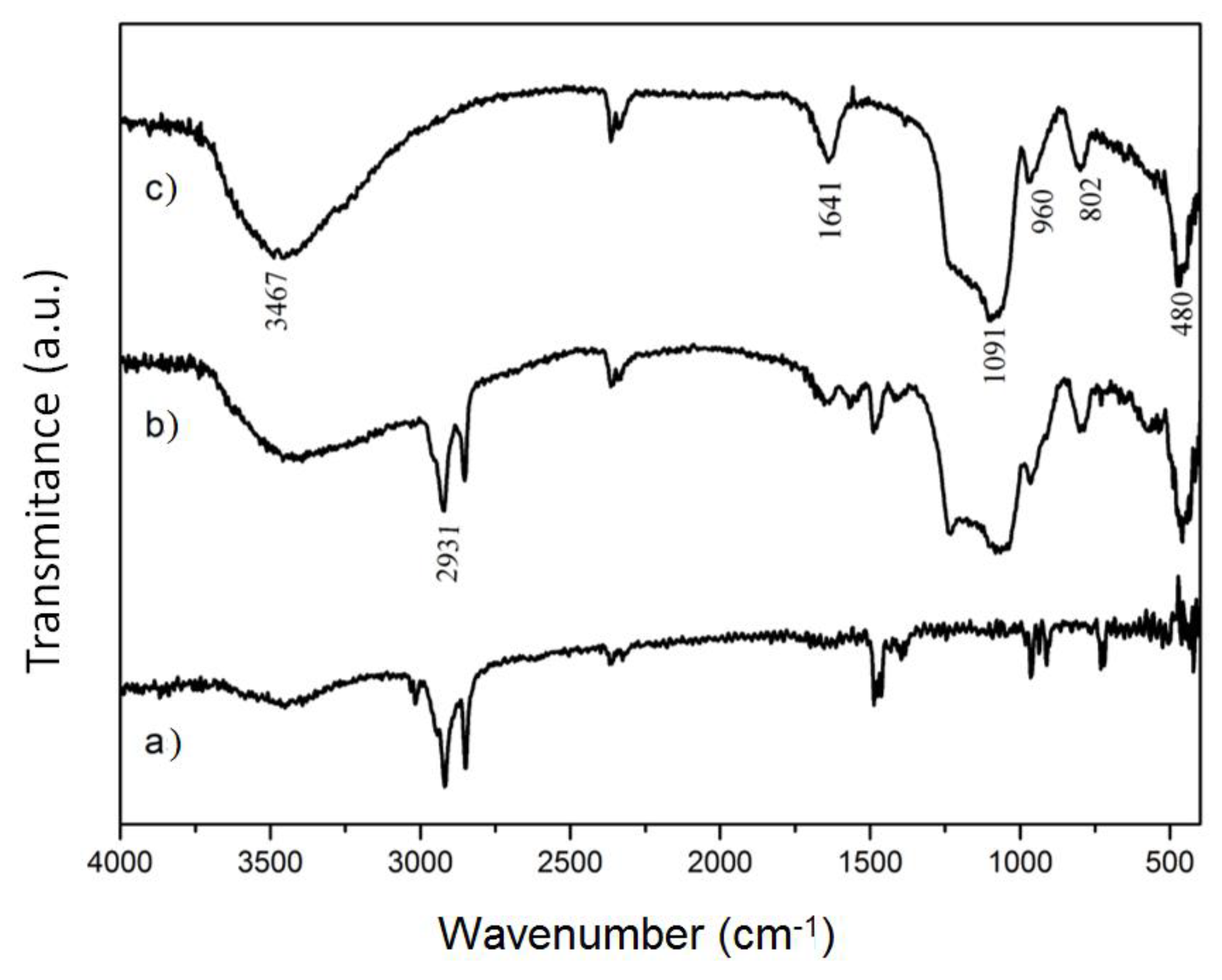

| Wave Number (cm−1) | Attributed to |

|---|---|

| 3750–2950 | Internal and external hydroxyl groups in the mesoporous structure |

| 2980–2820 | Stretching between the C-H of the CH2 and CH3 groups in the CTMA+ |

| 1730–1560 | Water adsorbed on the surface of the material |

| 1510–1450 | Deformations of the CTMA+ ion |

| 1260–1215 | Si-O asymmetric stretching |

| 1150–1010 | Vibrations in the tetrahedra of the TOT bonds (T = Si/Al) |

| 985–925 | Asymmetric stretching of the CH3-N + bond |

| 840–770 | Symmetric stretching of the T-O bonds (T = Si/Al) |

| 495–420 | Asymmetric stretching of the T-O bonds (T = Si/Al) |

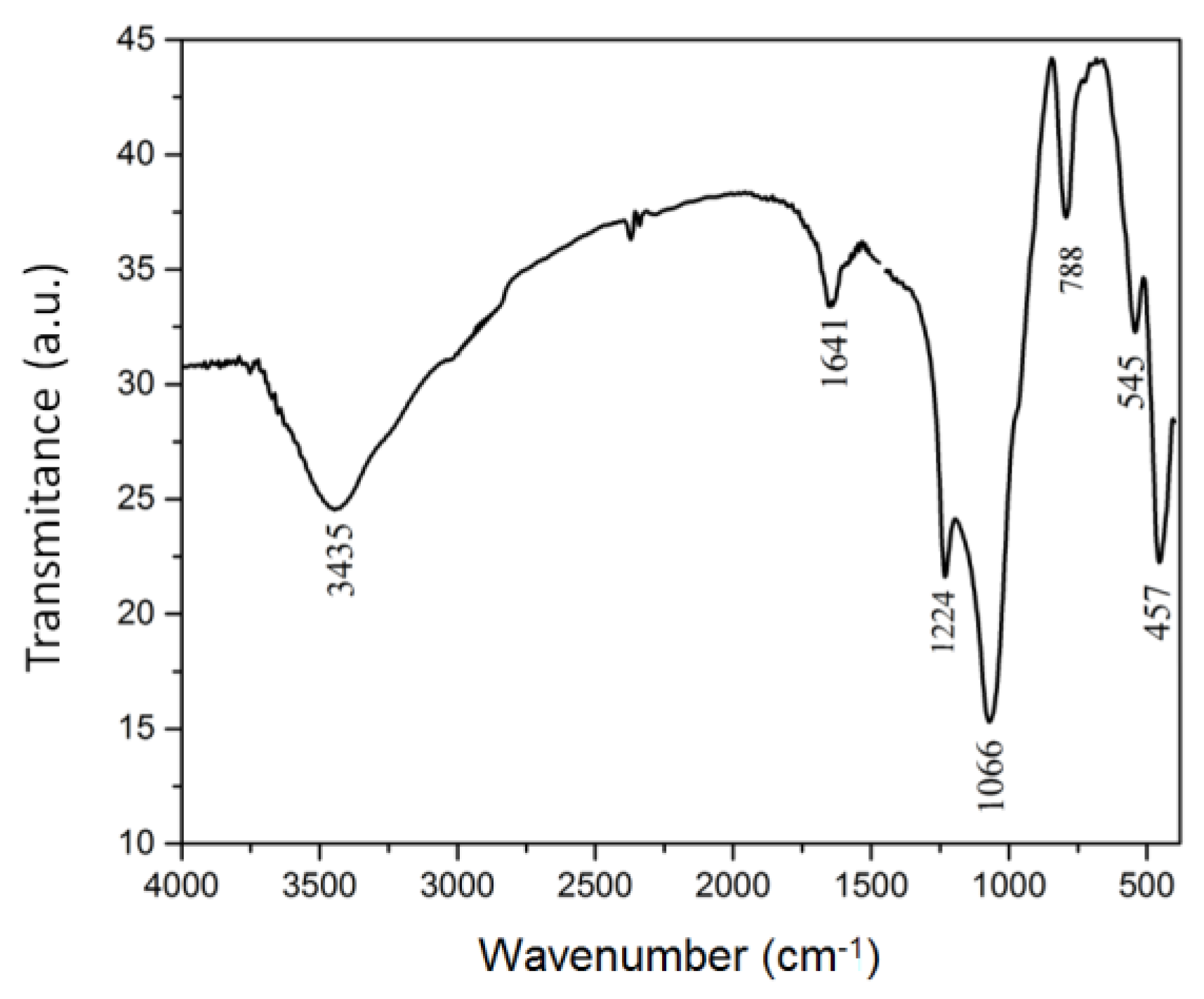

| Wave Number (cm−1) | Attributed to |

|---|---|

| 3640 | Internal and external OH groups |

| 1641 | Water adsorbed on the surface of the material |

| 1066 | Internal tetrahedral asymmetric stretching of the T-O (T = Si or Al) |

| 457 | Flexion (T-O, T = Si or Al) |

| 788 | External tetrahedral symmetrical stretching |

| 545 | Polyhedrons present in the structure |

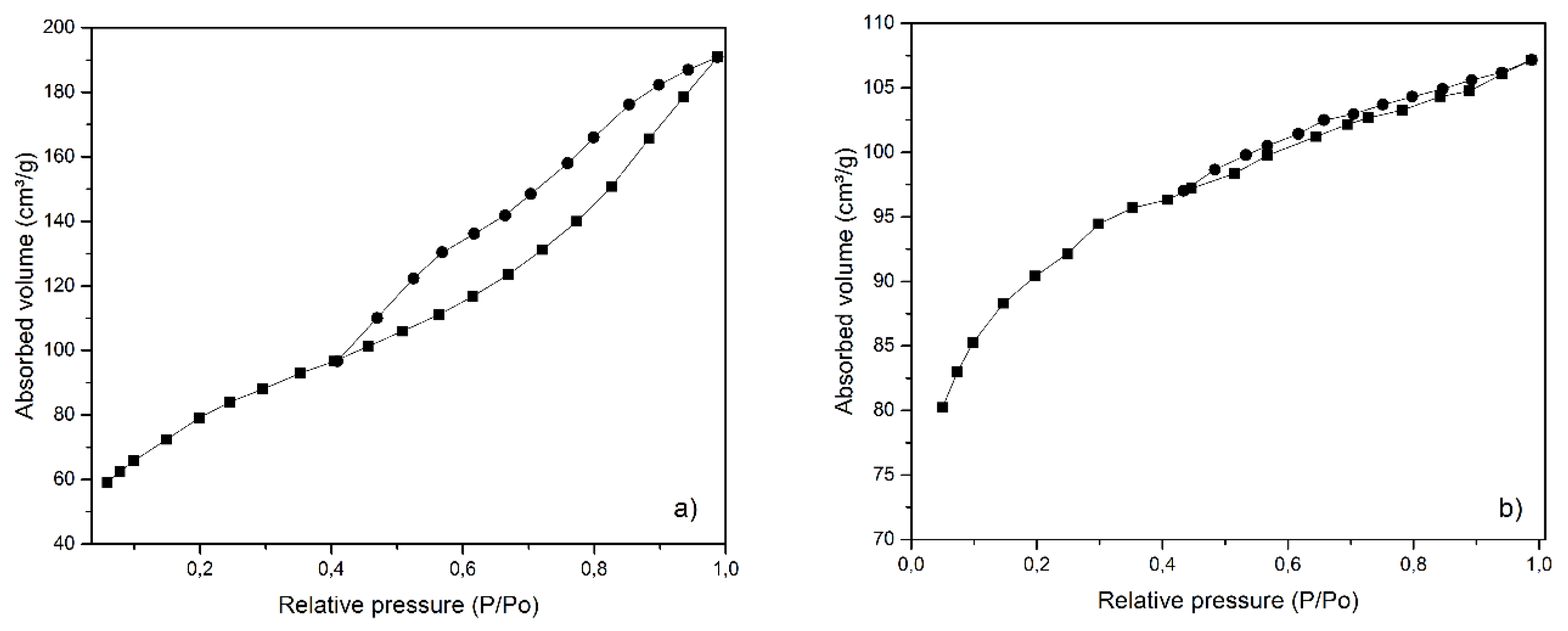

| Sample | a0 a (nm) | Dp b (nm) | Wt c (nm) | Vp d (cm3/g) | SBET e (m2/g) |

|---|---|---|---|---|---|

| ALMCM | 4.77 | 3.10 | 1.67 | 0.38 | 824.5 |

| HZSM5 | - | 1.80 | - | 0.23 | 286.8 |

| Sample | Concentration of Acid Sites (mmol/g) | ||

|---|---|---|---|

| Medium–I a | Strong–II b | Total | |

| ALMCM | 0.869 | 0.043 | 0.912 |

| HZSM5 | 0.640 | 0.903 | 1.543 |

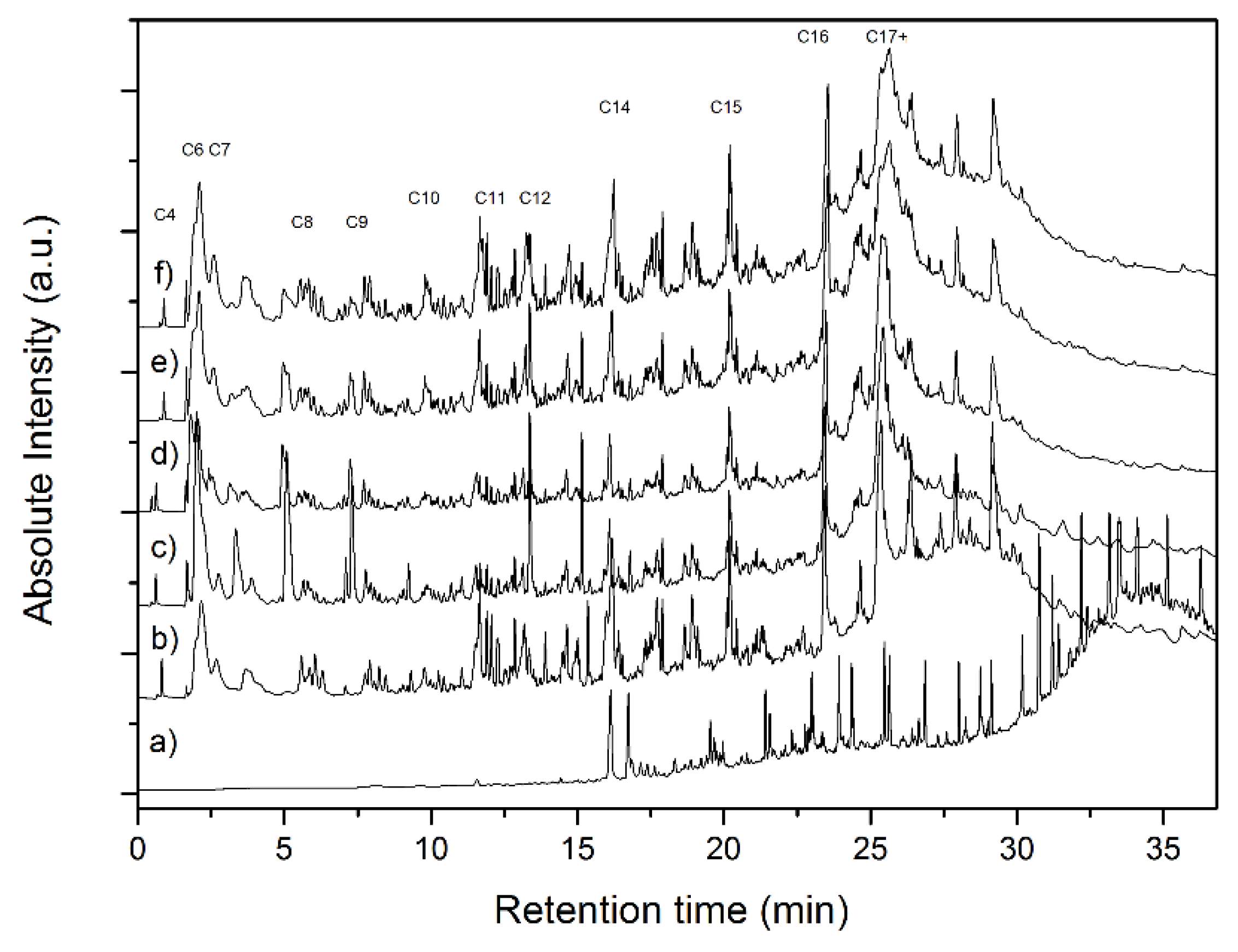

| SAMPLES | Classification | Fractions | ||||

|---|---|---|---|---|---|---|

| Hydrocarbons (%) | Oxygenates (%) | C2-C4 a | C5-C10 b | C11-C16 c | C16-C24 d | |

| OILSUN | 55.5 | 44.5 | 0.0 | 0.0 | 13.1 | 86.9 |

| OILSUN/ALMCM | 69.3 | 30.7 | 0.0 | 26.0 | 54.0 | 20.0 |

| OILSUN/HZSM5 | 78.8 | 21.2 | 12.0 | 46.0 | 26.0 | 16.0 |

| OILSUN/75HZSM5-25ALMCM | 77.6 | 22.4 | 4.2 | 45.8 | 37.5 | 12.5 |

| OILSUN/50HZSM5-50ALMCM | 71.7 | 28.3 | 2.6 | 44.7 | 42.2 | 10.5 |

| OILSUN/25HZSM5-75ALMCM | 58.5 | 41.5 | 0.0 | 40.0 | 48.9 | 11.1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Araújo, A.M.M.; Queiroz, G.S.M.; Maia, D.O.; Gondim, A.D.; Souza, L.D.; Fernandes, V.J., Jr.; Araujo, A.S. Fast Pyrolysis of Sunflower Oil in the Presence of Microporous and Mesoporous Materials for Production of Bio-Oil. Catalysts 2018, 8, 261. https://doi.org/10.3390/catal8070261

Araújo AMM, Queiroz GSM, Maia DO, Gondim AD, Souza LD, Fernandes VJ Jr., Araujo AS. Fast Pyrolysis of Sunflower Oil in the Presence of Microporous and Mesoporous Materials for Production of Bio-Oil. Catalysts. 2018; 8(7):261. https://doi.org/10.3390/catal8070261

Chicago/Turabian StyleAraújo, Aruzza M. M., Gabriella S. M. Queiroz, Danielle O. Maia, Amanda D. Gondim, Luiz D. Souza, Valter J. Fernandes, Jr., and Antonio S. Araujo. 2018. "Fast Pyrolysis of Sunflower Oil in the Presence of Microporous and Mesoporous Materials for Production of Bio-Oil" Catalysts 8, no. 7: 261. https://doi.org/10.3390/catal8070261

APA StyleAraújo, A. M. M., Queiroz, G. S. M., Maia, D. O., Gondim, A. D., Souza, L. D., Fernandes, V. J., Jr., & Araujo, A. S. (2018). Fast Pyrolysis of Sunflower Oil in the Presence of Microporous and Mesoporous Materials for Production of Bio-Oil. Catalysts, 8(7), 261. https://doi.org/10.3390/catal8070261