Abstract

The present review paper highlights recent progress in the processing of potential municipal solid waste (MSW) derived fuels. These wastes come from the sieved fraction (∅ < 40 mm), which, after sorting, can differ in biodegradable fraction content ranging from 5–60%. The fuels obtained from these wastes possess volumetric energy densities in the range of 15.6–26.8 MJL−1 and are composed mainly of methanol, ethanol, butanol, and carboxylic acids. Although these waste streams are a cheap and abundant source (and decrease the fraction going to landfills), syngas produced from MSW contains various impurities such as organic compounds, nitrogen oxides, sulfur, and chlorine components. These limit its use for advanced electricity generation especially for heat and power generation units based on high temperature fuel cells such as solid oxide fuel cells (SOFC) or molten carbonate fuel cells (MCFC). In this paper, we review recent research developments in the continuous MSW processing for syngas production specifically concentrating on dry reforming and the catalytic sorbent effects on effluent and process efficiency. A particular emphasis is placed on waste derived biofuels, which are currently a primary candidate for a sustainable biofuel of tomorrow, catalysts/catalytic sorbents with decreased amounts of noble metals, their long term activity, and poison resistance, and novel nano-sorbent materials. In this review, future prospects for waste to fuels or chemicals and the needed research to further process technologies are discussed.

1. Introduction

Each year millions of tons of potential valuable raw materials contained in municipal solid waste (MSW) are trapped in landfills. Potentially 44 million tons of MSW could be available in the European Union (EU) in 2030 [1,2]. Energy recovered by household refuse incineration plants in the EU only increased 0.7% in 2013 and reached 8.7 million tons. There has also been an increase in garbage export and storage prices. On the other hand, the waste management market could still be monopolized by waste incineration plants. Energy sector regulations urge better primary energy use and a significant increase of energy production from alternative fuels [2]. From the point of view of environmental protection, waste storage is undesirable because it could contaminate the source of air (greenhouse gas (GHG) emissions), soil, and nearby vegetation. Additionally, some components of unprocessed waste can make it into water reservoirs, which causes a threat to the aquatic environment. For example, garbage patches (clusters of garbage floating freely on the surface) in the oceans [3,4] are one threat to the aquatic environment.

Typically, waste management concentrates on materials recycling, recovery, and waste minimization in terms of waste volume. MSW processing involves separation at the source intorecyclable materials such as metals, paper and plastics used for recycled product manufacture, an organic fraction (biodegradable fraction), food waste, which can be converted to biogas via anaerobic digestion, and a refuse fraction (RF), which is the processed fraction of MSW that cannot be further recycled into shredded textiles, wood, paper, card, or plastics. Instead refuse derived fuels (RDF), also called solid recovered fuel (SRF), can be produced from this MSW fraction usually using the sieved fraction >50 mm [5]. Regardless of whether it is waste-derived or biomass-derived, it is typically treated via electromagnetic sorting and/or mechanical- and bio-stabilization and technically called an alternative fuel. This fraction of MSW can be converted into liquid and gaseous biofuels for production of heat and power or be used as a transport fuel. RDF usually can be combusted in specifically designed boilers, co-combusted (i.e., industrial boilers, cement industry), or converted to valuable chemicals or syngas, which then can be used for energy or processed into advanced biofuels [5,6]. Recognizing this potential, the EU imposes certain requirements on the level of MSW recycling and reuse. Today the limit is 15%, but in 2020, countries will have to reach a level of 50% and plans for 2030 assume MSW recycling and utilization at a level of 70% [2]. There are many concerns and an ongoing discussion about this plan and the associated requirements. The fuel obtained from the RF is beneficial in terms of energy recovery, can reduce global warming, and prevent acidification that can occur via leaching of metals in landfill storage. On the other hand, the MSW contains various contaminants that can lead to air pollution when combusted/co-combusted without proper control and design. This issue is not trivial and needs substantial industry and science involvement to overcome current technology obstacles.

The smaller, undersized ∅ = 20–50 mm MSW fraction, still contains potentially valuable components, which are mostly organic in nature (>30–60%) and plastics. Usually this fraction undergoes bio-stabilization or is directly sent for landfilling. Therefore, better methods of processing this fraction are sought. A current project with an industrial waste company (Waste2Fuel) is dedicated to methodology development for sieved MSW fraction processing. As mentioned, this fraction includes bio-wastes as well as plastic and textiles and has limited possibility for further processing. Usually, after bio-stabilization and decreasing the waste volume, it is landfilled. Using this fraction is concerning due to a high chlorine content, which fluctuates in concentration depending on the MSW composition. Here we briefly review possible technologies for its processing as well as the larger sieved fraction including reforming and syngas fuel production for FC applications instead of combustion or co-combustion.

2. Waste: Problems and Opportunities

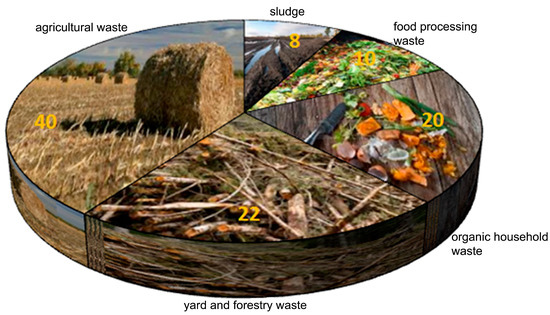

Waste can be classified on the basis of its source of origin, properties, harmfulness, or the amount of its production. It is mainly divided into five groups, which are agricultural waste, yard and forestry waste, sludge, food processing waste, and organic household waste [3]. In Figure 1, types of bio-wastes and the amounts (%) of their average annual production in Europe are shown. In general, waste treatment and recovery are complex processes and differ for the different waste types depending on the waste composition/stream, which is influenced by time, season, or production area. MSW composition could be generically described as having 40% recyclable content, 40% bio-waste, 10% bulky goods, and 10% other waste type. MSW contains different proportions of inorganic and organic-waste where the organic fraction contains mostly food and yard waste characterized by a high moisture content. Typically for undersized MSW fraction ∅ < 40 mm, the biodegradable fraction is about 30–40% but, in some cases, can reach more than 60%. The biodegradable fraction is usually separated from MSW and processed via composting or biological treatment such as anaerobic digestion to produce valuable soil fertilizer or a soil modifier. The process is also known as waste bio-stabilization and helps to minimize GHG emissions from landfills. There are also possibilities sought for unsorted MSW treatment in one combined process. However, due to process complexity this area still needs substantial study.

Figure 1.

Annual bio-waste production in Europe.

Apart from compost usage and reduced chemical fertilizer application, additional environmental, social, and economic benefits have also been reported [6]. The environmental benefits of bio-waste processing are mostly related to reduced GHG emissions from treated MSW and reduced amounts and waste volume in landfills. Depending on the method selected for waste processing, an additional benefit includes producing renewable fuels from this waste type. The overall benefits depend on technology effectiveness and certain waste types. However, the best processing technology is sought to recycle or recover more of the available energy in a socially or locally socially acceptable way. In some cases local smart cities, or smart grids, are based on biogas retrieved from bio-wastes [7].

There are several problems related to waste collection, transportation, and storage. Sorting waste at the source is the best source for raw material recycling. Paper, glass, metals, and waste sorted before transport to a larger sorting facility will minimize waste landfilling probability. Waste landfilling should be avoided not only because of negative health and environmental impacts, but also because this waste has energy and recycling potential. Thus, the possibilities for waste use as a renewable, clean source of energy are of significant interest [5,8]. All mixed and chipped combustible waste in which no dangerous substances are present may be used as an alternative fuel. This includes selected municipal solid waste, waste plastics, wastepaper, worn tires and wood, and chemical and mining industry waste [5,8]. These are high-calorie waste streams and for this reason the fuel quality has high value potential. They can serve as an alternative for fossil fuels and can help in mitigating the environmental impact of fuel combustion as well as help fulfill world energy demand, which can be advantageous in terms of decreased dependence on fossil fuels and reduction in landfill waste while also controlling pollutant emissions [8].

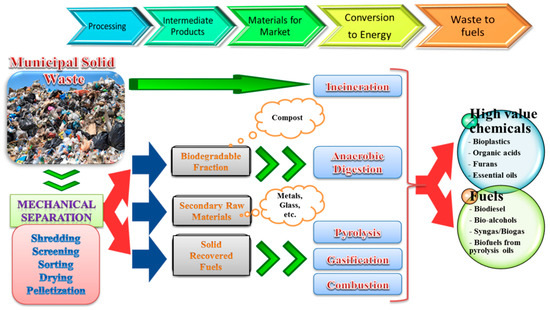

Overall, waste processing into energy is a method of obtaining a valuable product and simultaneously a way to eliminate a waste storage problem [9]. Waste into fuel recovers energy in the form of electricity and/or heat with the focus here being from MSW via thermochemical treatment processes excluding MSW incineration. Figure 2 summarizes available technologies for municipal solid waste valorization into higher value-added chemicals and fuels. Depending on the MSW plant configuration, usually sorted MSW after electromagnetic treatment and metal recovery undergoes further drying, stabilization, and separation into several fractions including a biodegradable fraction, a secondary recycled and recovered fraction, and an RF fraction, which is shown in Figure 2. The biodegradable fraction can be anaerobically digested and through biochemical pathways, highly valuable chemicals (bioplastic, furans, organic acids, etc.) and fuels (biodiesel, biogas, bio-alcohols etc.) can be produced. Biomass fermentation and other biochemical routes can produce liquid biofuels. These processes are often complex and include raw material pretreatment, hydrolysis, fermentation, and distillation. In one example, approximately 11 g of ethanol can be obtained from 100 g of raw material on a dry basis (32 g of cellulose) [10].

Figure 2.

Processing of MSW.

The RDF fraction can be thermochemically treated via catalytic and uncatalyzed routes known as pyrolysis (thermal decomposition in the limited oxygen flow), gasification (waste processing with CO2 or H2O as a gasifying agent) or combustion.

3. Waste Processing

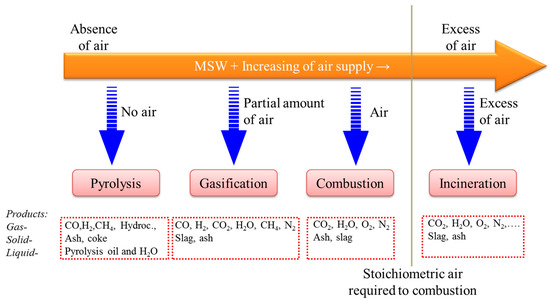

MSW can be converted into higher value gaseous or liquid fuels such as syngas or alcohols [11] and the RDF through three routes, which is described by Figure 2 and Figure 3. These include gasification to produce syngas, pyrolysis to produce bio-oil, or biomass liquefaction and hydrolysis to produce sugars [5]. Besides incineration, MSW processing technologies such as pyrolysis, gasification, and plasma-based methods have been under development since the 1970s [3]. These technologies often use higher temperatures and have higher conversion rates than other biochemical or physicochemical processes. They are used to treat different types of solid waste including unsorted residual waste that has significant energy content [5]. The process type and the final product, which can be retrieved from MSW processing, depends on the waste type and MSW contamination level. Solid waste feedstock characteristics depend on temperature, humidity, oxygen, sorting policy, and pretreatment techniques (shredding, screening, sorting, drying, or palletization) [12,13]. The price for such a fuel feedstock is low and is often supplied for free by waste management companies. This decreased input cost might offset the relatively high capital cost required for an integrated gasification system and downstream fuel or chemical production system such as Fischer-Tropsch or catalytic bio-syngas conversion to biodiesel, jet fuel, or biomethanol/bioethanol installations [12]. Also, the syngas obtained from MSW-based feedstocks can be used directly for heat and power generation units based on high temperature fuel cells such as solid oxide fuel cells (SOFC), which can mitigate the emission problem of noxious pollutants [12]. Considering the above arguments, it seems reasonable to strive for a wider use of this energy source.

Figure 3.

Main characteristics of chemical processes for thermal treatment of MSW.

Among the possible gaseous fuel products, syngas and a mixture of CO and H2 is a nice alternative fuel or a feed for chemical synthesis routes [13]. Today, syngas is primarily produced via natural gas reforming, but can also be produced from other sources such as naphtha, residual oil, petroleum coke, coal, biomass, and biomass waste [12]. In terms of it being a fuel, mixtures of H2 and CO have been used for spark ignition (SI) engines and has been shown to have high anti-knock behavior in compression ignition (CI) engines [14,15]. Syngas or syngas derived synthetic fuel is also considered efficient fuel for high temperature fuel cell applications. Current development in solid oxide fuel cells SOFC concentrates mostly on switching to operating temperatures in the 900–1000 K range and on the use of fuels other than hydrogen. When promising performance was reported for a biogas fueled SOFC, increased research of potential SOFC fuels including biogas (from fermentation or landfills and the gasification of biomass, agricultural wastes, and MSW), bio-derived synthetic hydrocarbons, bio-diesel, and others have been explored [16]. The syngas produced from hydrocarbon (HC) reforming is inconsistent in content, the H2:CO ratio varies. Additionally, different ratios are required depending on the downstream technology/process of engines. Beyond syngas, biofuels and high value chemicals derived from biomass are also of significant interest to scientists, engineers, and policymakers [15]. Among liquid fuels, ethanol production from cellulosic biomass is the most developed technology [11] with new fuel molecules including methanol [17,18], butanol [19,20], longer-chain alcohols [21,22], furan-based molecules [23,24], and bio-derived synthetic hydrocarbons [11] being investigated.

Reforming. MSW is a cheap and abundant source of biomass (typically MSW contains ca 40% and some sieved MSW fractions contain more than 60% organics), and is therefore an attractive alternative fuel or fuel blend for a feed stream for reforming. Currently syngas is mainly produced via methane steam reforming (Equation (1)).

CH4 + H2O ⇌ CO + 3H2 ΔH0298 = 206 kJ mol−1

The efficiency of the process rises and then decreases with increasing pressure as a result of the water-gas (WGS) and reverse water-gas shift (RWGS) reactions, which is shown in Equation (2).

CO + H2O ⇌ CO2 + H2 ΔH0298 = −42.2 kJ mol−1

With increased concern of the CO2 contribution to the greenhouse gas effect, there has been interest in replacing steam with CO2 as the reactant [25]. Dry reforming (DR) could produce H2 on an industrial scale using otherwise wasted CO2 [26,27]. Previous investigations related to DR mainly focused on feeds such as natural gas, methane, and ethane while the MSW-based fuel for DR is understudied while similar catalysts systems can be used for its conversion. Catalytic conversion of biofuels via reforming with CO2 provides synthesis gas with a low H2/CO ratio. DR of methane to syngas consumes more energy than steam reforming, which is an already energy intensive process. Even with the WGS reaction being mildly exothermic, the overall reaction will be endothermic due to the enthalpy change differences noted in Equations (1) and (2) [27] and DR is even more so. The possibility of using CO2, a major greenhouse gas, to produce valuable products could outweigh that energy-need increase [28]. Another issue is that DR product quality depends on feedstock composition/purity. Catalyst durability and efficiency is also an issue. The typical Ni-based catalysts used in methane reforming have good conversion performance, but they degrade via several paths including sintering, coke formation, and poisoning. Therefore, there is ongoing research focused on designing and developing new, more durable catalysts including for example nanomaterials/nanocomposites that have high activity, durability, and are economical, which are necessary to overcome the disadvantages of waste-derived biofuels via DR using Ni-based catalysts [11].

Gasification. Gasification is a complex process, but has been regarded as a key thermochemical route for the production of syngas from a renewable and CO2-neutral source [29,30,31]. The process is performed typically at 1000–1950 K in the presence of steam or CO2 as the gasification agent and with low oxygen content (below stoichiometric). Under such conditions, the carbon based material is converted to H2 and CO (syngas) and smaller amounts of CO2 and CH4 are formed as co-products [6]. Inorganic materials present in gasified fuel can be converted to bottom ash or slag depending on gasification conditions. [6]. Since MSW contains a variety of components and impurities apart from syngas, other undesired compounds are formed or are contained in the product stream, which are namely halogens, heavy metals, tars, alkaline compounds, and SO2, which are considered to be harmful and can cause health, environmental, and technical/installation problems.

The synthesis gas or product gas produced during gasification can be used for generating electricity and heat by direct combustion in internal engines while high quality synthesis gas can also be used as a chemical feedstock for the synthesis of a variety of valuable fuels and chemicals [32]. Gasification studies concentrate mostly on platform molecules, biomass, and sieved organic fraction with considerable caloric value, which gives gas with low or medium heating value [30,31,32,33]. Steam gasification in a fluidized bed can lead to high gaseous product yield with its high heating rate, short residence time, and relatively low tar formation. The drawbacks include fluctuating syngas CO:H2 ratios and typically low yield in the overall biomass conversion to syngas. One study reported that 0.62 kg of gas from 1 kg of biomass can be produced via gasification of switch grass with H2/CO gas yield 0.54 (kg/kg weight of dry gas produced per unit weight of feedstock) [33]. It would be advantageous to produce syngas of specific composition dependent on downstream use as well as increase its yield and some of this tuning might come via catalytic methane and tar reforming, which are components formed in the gasification process [34]. One way to reduce tars that form is through catalytic decomposition and ideally at temperatures similar to those being used in the gasifier [35]. This would increase formation of synthesis gas and ultimately reduce the organics emitted with the wastewater originating from cooled raw gas to remove steam. Further along this line, in terms of separation efficiency, reforming methane before the gas is cooled would allow any CO2 formed to be removed along with other inorganic gas impurities [35].

For this type of technology, catalytic and non-catalytic waste processing are possible [5,11,36,37]. In terms of biomass conversion, there are two catalytic groupings, which include those added directly to the biomass and those in a downstream reactor post gasification [35]. The first group of catalysts (primary catalysts) are usually added directly to the biomass either by wet impregnation of the biomass material or by dry mixing the catalyst with it. This catalyst is responsible for catalyzing reactions such as combustion, partial combustion, the reverse Boudouard reaction, gasification with water, methanation, and water gas shift and its reverse reactions [35]. One primary role is also to reduce the tar content. They are usually non-renewable and consist of a cheap, disposable material. The second group of catalysts is not directly in contact with the biomass, but is downstream of the gasifier in a second reactor. This allows use of more optimal operating conditions than those for the primary catalysts that are in the gasification unit. This second group of catalysts are active in reforming hydrocarbons and methane [35].

Although gasification is a mature technology, MSW gasification is still under development. It is agreed that for effective MSW gasification towards valuable syngas, two consecutive processes are required. In the first process, at temperatures below 900 K pyrolysis occurs and volatile components are released and char is produced, which can further undergo gasification with steam or combustion with air or pure oxygen at 1050–1950 K under high pressure. As a result of gasification with pure oxygen, a mixture of CO and H2 is obtained with only trace or no nitrogen. When gasification is performed with air, obviously higher nitrogen content results. Gasification with steam is described as steam reforming where a mixture of CO2 and H2 (syngas) is produced [6]. For MSW gasification, fixed bed and fluidized bed reactors are used similarly to MSW combustion, but in case of MSW, larger gasifiers are preferred because they operate better with variable MSW composition and provide better conversion values [6]. As a cost effective technology especially for selected groups of wastes, gasification needs further development. Recently, this technology is receiving more attention due to diversification in power generation, more stringent environmental regulations, and higher landfilling fees [6].

Plasma gasification. Plasma gasification is a possibly effective MSW conversion to energy or a valuable substances method and is considered more efficient in terms of electricity production when compared to conventional gasification [6]. This technology is characterized by relatively low emissions. However, the technology investment costs are high. The costs are mostly related to high operating temperatures. Typically, MSW are exposed to 1500–2000 K to produce syngas and non-toxic vitreous slag. Steam, oxygen, or air hot plasmas are obtained using a plasma arc (>5500 K). A likely more effective use of plasma is to integrate the plasma process with heterogeneous catalysis. Such a combination of a non-thermal plasma and a selective catalyst is advantageous due to the fast and relatively lower-temperature reaction. The plasma-catalytic process has great synergy potential. This process is efficient because it lowers the activation energy via the catalyst, enhances the conversion of reactants, and provides selectivity and yield to desirable products [32].

Pyrolysis. Another MSW processing path is through a purely thermal treatment. Numerous studies have been performed to characterize pyrolysis and pyrolysis product properties from different MSW fractions [38,39]. Researchers have also studied interactions between different individual fractions and how these affect pyrolysis products [40,41]. To enhance pyrolysis efficiency, byproduct char can be used to reform the product volatiles including syngas and oil formed during the same pyrolysis process [42]. As an example, one study showed that contacting the product syngas and pyrolysis oil with hot char at 823 K in a downstream fixed bed reactor led to reforming of the volatiles and an increase in the dry syngas yield from 0.25 to 0.37 N m3 kg−1 MSW [42]. With this reforming, there was a higher carbon conversion ratio into syngas and energy content of the syngas. The pyrolysis liquid product yield including pyrolysis oil and water decreased by about 40% and the oil’s molecular weight decreased. Furthermore, about 60% of the water vapor was converted into syngas. Overall, these results show that reforming can increase yield and impact the pyrolysis process product composition while the char itself can have a catalytic reforming effect. For better process control, more consistent MSW compositions are required and, therefore, additional MSW pre-processing steps are needed. On the other hand there are existing MSW conversion technologies, which are able to work with raw, unprocessed, and unsorted MSW [6].

Conversion technology summary and comparisons. Reforming, gasification, plasma gasification, and pyrolysis are syngas producing processes, which differ from MSW incineration and are collectively considered “conversion technologies” [32]. Pushing the environmental benefit aspect further, using CO2 for the gasifying agent would provide a route for CO2 utilization and thus further the valorization of MSW. Indeed, previous research showed that increasing the CO2 content increased carbon conversion and mitigated tar production [43]. Using an air/CO2 mixture allows tailored H2/CO ratios such that catalyst-based Fischer-Tropsch synthesis could be used or to produce a feed gas for the production of other chemicals such as urea, methanol, and acetic acid.

Below are example comparisons of the different technologies or examples of combinations. A fixed bed reactor MSW catalytic steam gasification study showed that using a catalyst significantly improved tar cracking efficiency and hydrocarbon reforming [43]. Two types of techniques and catalysts can be applied, which are described elsewhere [30]. Primary methods attempt to clean gas inside the gasifier using dolomite, olivine or Ni/Al2O3, which are called a primary catalyst. The second technique is known as hot gas cleaning after gasifier using a secondary catalyst such as dolomite or Ni-based catalysts In a previous study, the highest H2 content (54%) and gas yield (1.75 N m3 kg−1) were achieved at 1173 K at a S/C = 2.41 with a NiO/γ-Al2O3 catalyst [43]. Increasing the reactor temperature improved reaction extents for the gasification of char, catalytic cracking, and tar reforming, which all resulted in a yield increase. Compared with regular pyrolysis, adding steam led to more steam gasification of tar and char, which again led to an increased syngas yield and carbon conversion [44]. In a similar study, but at a temperature 100 K lower, the optimum mass ratio of steam to MSW was ca 1.5 [45]. The gas yield and H2 concentration rapidly increased when the catalyst/MSW mass ratio passed 0.5. A smaller increase was observed with an increase in the catalyst/MSW up to 2.0 [45].

Previous MSW processing research, Table 1, showed that the highest syngas yield (153.67 mmol syngas g−1 in the presence of Ni/Al2O3 catalyst) was obtained from catalytic dry reforming of plastic waste from the agricultural industry [41,46]. For catalytic dry/steam reforming of simulated mixed waste plastics over Ni-Co/Al2O3 and Ni-Mg/Al2O3 catalysts, the optimum CO2/steam ratio was 4:1 with a very high syngas yield (133.87 and 146.77 mmol syngas g−1, respectively) [46,47,48]. While using the same Ni-Co-Al2O3 catalyst for pyrolysis-catalytic dry reforming, in a two-stage pyrolysis-catalytic reforming fixed bed reactor, optimal syngas production (148.6 mmol syngas g−1) was obtained at 1073 K [47]. For this process, increasing the CO2 flow rate promoted a higher syngas yield, which rose from 60.7 to 155.0 mmol g−1 [47]. The same CO2 effect was reported for dry reforming of high density polyethylene (HDPE) over Cu and Mg promoted Ni-Co/Al2O3 catalysts [49]. The authors showed that syngas production increased with CO2 addition, with 138.81 mmol syngas g−1 HDPE produced under their conditions, which was significantly higher than the amount made with no catalyst and no CO2. The Ni-Co-Al catalyst exhibited excellent anti-coking performance, which showed an overall very high resistance to catalyst deactivation and the highest CO2 conversion (57.62%) [49].

Table 1.

T Selected research studies of catalytic MSW/biomass processing under different reaction conditions (SR-steam reforming, DR-dry reforming).

4. Catalyst and Sorbents Screening for Chlorine Removal and Other Pollutant Considerations

As shown, waste processing for energy, fuels, and valuable chemicals production is a very promising technology. However, there are still issues that need to be resolved. Beyond concern over process efficiencies and for catalytic processes, catalyst durability as well other problems with MSW thermochemical processing include emissions of harmful compounds. The cleaning of product gas is still a difficult step in MSW to fuel processing. Apart from tars (sometimes also referred to as condensable organic compounds) and ash, the gas contains hydrocarbons and corrosive and toxic components such as carbonyl sulfide (COS), HCl, SO2, and H2S [57,58,59,60]. The gas cleaning techniques and installations for MSW incineration plants including SOx and NOx pollution control via selective catalytic reduction (SCR) is also problematic in this context since the SCR catalysts are sensitive to Cl and S compounds and get poisoned [58].

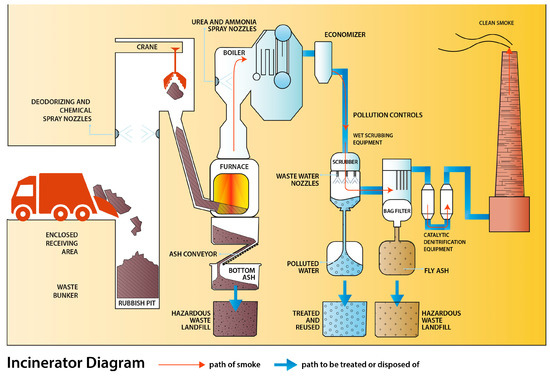

NOx removal during waste incineration. MSW incineration coupled with energy recovery can be incorporated into an integrated waste management system, but emissions control is required to prevent any negative health and environmental impacts [1,58]. MSW incineration plant NOx emission concentrations are similar to those for coal-fired power plants and, therefore, SCR technology seems applicable. SCR systems are used in MSW incineration plants in Japan, Denmark, and Sweden and a growing number of MSW incineration plants are equipped with SCR for NOx emissions mitigation [58]. Another important problem for these plants are pollutant emissions of HCl, H2S, CO, SO2, hydrocarbons (HC) heavy metals (e.g., Cd, Pb, and Hg), and toxic ashes [59]. These pollutants, besides being harmful and toxic to health and the environment, significantly affect the performance, efficiency, and lifetime of standard catalysts in incinerating plant installation. Thus, flue gases undergo different treatments to decrease the pollutant loading at the outlet and to protect the sensitive SCR catalytic part from the most harmful poisons, which is shown in Figure 4.

Figure 4.

Scheme of pollution control from MSW incineration plants.

The standard commercial SCR catalysts for stationary applications are V2O5-MoO3/TiO2 and V2O5-WO3/TiO2. These have a typical operating temperature window of 300–400 °C [5,6]. For MSW process flue gases, SO2 concentrations are normally relatively high and one can envision placing the SCR catalyst unit downstream of the desulfurizer. However, the exhaust gas temperature post desulfurizer is lower than the active operating window for these V-based SCR catalysts [7,8,9,10]. Reheating the exhaust is economically prohibitive. Furthermore, other poisons exist in the MSW flue gas that can inhibit V-based SCR catalyst performance such as alkali metals [11,12]. Therefore, current challenges would be developing lower-temperature SCR catalysts and/or catalysts that are insensitive to SO2 or alkali metal poisoning. Several types of low-temperature NH3-SCR catalysts have been reported including noble metal-based [13] and non-precious metal-based such as MnOx [16] and CuO [17,18] and zeolite-based catalysts [14,15]. Intuitively, cost may prohibit noble metal-based catalysts use and past research has shown that zeolite-based catalysts are not stable in the presence of HCl [19,20,21]. MnOx-based catalysts have been well studied but not commercialized. One reason may be due to the fact that they suffer from SO2 poisoning [22,23]. CuO catalysts supported on various supports show promise [24,25,26,27,28,29,30] with performance highly dependent on the preparation method [31].

The reduction of methane content is also an important step in the process since it decreases GHG emissions as well as increases the product gas value. Catalytic decomposition of byproduct hydrocarbons is also known as hot gas cleaning [35]. With such variability in feed type, these catalysts will need to be tailor designed. The catalysts would both purify and therefore alter the product gas composition. Fluidized-bed or fixed-bed reactors at temperatures and pressures matching those of the gasifier can be used. The catalyst would reform the hydrocarbons via steam reforming or dry reforming or both (mixed reforming). With condensable organic compound reforming as well as that of methane biomass conversion efficiency can increase by 10%. Hydrocarbon thermal cracking is also possible, but likely not practical since it requires high temperatures (>1373 K) and also produces soot [35].

Cl removal. Chlorine is found in many materials from different MSW fractions organic waste such as food, yard waste, or chlorinated plastics and its content usually determines the waste disposal and processing technology used. Another problem is formation of highly corrosive gases. For example, with a significant amount of Cl, a significant amount of HCl can form. HCl flue gas concentrations from gasification can range from 40–700 ppmv and, for biomass gasification, can be even greater [36]. Removing HCl from the feed gas is beneficial for any power generation plant as this avoids corrosion of metal components. For fuel cell applications, similarly HCl can corrode the cathode and react with the electrolyte. With these constraints it has been proposed that HCl concentrations not exceed 1 mg m−3 [60]. However, MSW can contain large amounts of chlorine and, during its conversion into energy, HCl might simply be emitted together with other impurities such as SO2 and NOx [61,62]. In terms of overall design outside of fuel cell applications, their presence in the reaction system has a negative impact on process equipment and plant effectiveness due to downtime associated with cleaning. With such a constraint, due to their high chlorine content, significant amounts of waste do not pass an initial selection screening that would allow their use as an alternative fuel. The possibility of realizing the full potential of waste-based input will need the development of a method to reduce the total chlorine content in the garbage or find a workable mechanism for HCl removal by a selective catalyst, sorbent, or other process at a suitable stage of waste processing.

Several methods for reducing the amount of chlorine along the process have been investigated including dehydrochlorination, MaO, BaO, CaO, TiO2, and Fe2O3 adsorbents and composite catalysts especially hybrid composites and hierarchical porous composites [63,64,65]. Below, different adsorbent types are discussed.

Ca-based sorbents and calcined dolomites. Calcined dolomites (CaO·MgO), Ca- and Na-based sorbents, for example slaked lime (Ca(OH)2), limestone (CaCO3), lime (CaO), soda ash (Na2CO3) and nahcolite (NaHCO3) are commonly studied for HCl capture in flue gas in coal combustion plants [60]. CaO and MgO react with HCl, which forms CaCl2 and MgCl2. An HCl reaction with lime and limestone study, in the 330–1273 K temperature range, showed that the capacities for binding HCl is largest between 773–873 K [66]. At higher temperatures, the capacity is limited by chemical equilibrium [36]. Slaked lime exhibits high HCl sorption capacity below 423 K [66]. Therefore, there seems to be multiple temperature ranges where significant capture of HCl via formation of CaCl2 is possible. The reaction between HCl and Ca-based sorbents appear possible for HCl removal from the product gas of biomass, MSW, or coal processing [67]. The sorption process can be described by the equations listed below.

Ca(OH)2 + 2HCl → CaCl2 + 2H2O

CaCO3 + 2HCl → CaCl2 + 2H2O + CO2

CaO +2HCl → CaCl2 + 2H2O

A kinetic study in a fixed-bed reactor showed that treated sorbents (calcined and slaked) reveal the same reactivity as those obtained with pure Ca(OH)2. For this reason, the aforementioned sorbents could be used for dry injection, which reduce gas conditioning costs [68]. Another analysis involved simultaneous removal of HCl and H2S over limestone and lime sorbents at temperatures between 573–973 K in a fixed-bed reactor at the laboratory scale with varying residence times and concentrations of HCl, H2S, and H2O [69]. The results showed that CaO has excellent sorption properties for the simultaneous removal of HCl and H2S from the gas phase. The highest HCl capacity on CaO was achieved at 873 K, which was related to CaCl2 sintering at this temperature. It was also shown that chlorine contamination can be removed by calcium-based sorbents in a fluidized bed or via filtration accumulating in the filter cake which reduced the need for sorbent injection, but chlorine removal increased to 60% when slaked lime was added to the product gas line [70]. Moreover, it was reported that a CaO sorbent with small particle size (163 μm) has higher reactivity and greater chlorine capacity than the same sorbent with a mean particle size of 465 μm [62]. Both sorbents were able to reduce the initial HCl concentration (2000 ppm) to less than 40 ppm. However, the sorbent with the smaller particle size was insensitive to the reaction temperature. Lime addition to coal or waste during combustion helps not only with capturing chlorine but also with capturing sulphur, bromine, arsenic, and selenium [71].

The reaction between hydrogrossular (Ca3Al2-(SiO4) (OH)8) and gaseous HCl in a fixed-bed reactor was efficient in the 673–1223 K temperature range, which resulted in reducing HCl levels to almost zero [72]. The reaction products were Ca12-Al9.9Si4.05O32Cl5.9 and CaCl2 below 973 K or Ca12-Al9.9Si4.05O32Cl5.9 and CaO above 1073 K. In the summary of this article, the authors admitted that the described method of HCl removal is more expensive than the existing one based on Ca-based sorbents, but they planned to carry out further tests in order to match their methodology with the commercial application.

Na-based sorbents. Among alkali and alkaline earth metal carbonates, Na2CO3 and K2CO3, alone have equilibrium HCl pressures of 1 ppm at <773 K [36,60]. Furthermore, the adsorption of HCl on Ca-based sorbents depends on the concentration of CO2 in the product gas, but apparently such an influence has not been observed for Na-sorbents in the 573–873 K temperature range [73]. A thermodynamic study of Na-based and Ca-based sorbents for emission control in waste incinerators, mainly of HCl, NOx and SO2, has examined the effect of process temperature, molar ratio of the injected sorbents, and total content of the considered pollutants in the 373–873 K temperature range. The results predict that Na-based sorbents are more effective in the dry treatment of flue gas than Ca-based sorbents [73]. These types of sorbents have been demonstrated as active in the whole examined temperature range, which gives good results in minimizing HCl, NOx, and SO2 concentrations in flue gases from fossil fuel and solid waste combustion. In other studies, sorbents containing sodium, nahcolite (NaHCO3), and sodium aluminate (NaAlO2) have been evaluated [60]. Fixed-bed reactor tests at temperatures between 673 and 773 K revealed that with nahcolite injected into the product gas immediately after the gasifier, a reduction of HCl from 300 ppm to less than 1 ppm was observed. However, a secondary reactor to achieve lower HCl emission limits was necessary. For simulated coal-derived gas purification, sorbents like sodium aluminate in particle form and γ-alumina showed HCl removal from the gas phase at less than 1 ppm. However, very limited durability of these sorbents was shown for such high removal ability [74].

In another study, HCl removal using NaOH supported on activated carbon (NaOH/C) was evaluated [75]. Performance of the prepared catalyst was tested in a fixed-bed continuous up-flow reactor. This sorbent had a high capacity for HCl removal. Its efficiency was greater than that of alumina, which is often used in refineries to reduce HCl content in the gas stream [75,76]. Moreover, the NaOH/C sorbent can be easily regenerated without a significant decrease in its activity, which is advantageous relative to many other sorbents. Furthermore, some additives (crushed oyster shells and rice straw) inserted into the feed material during pyrolysis of wastes led to a reduction in HCl concentration in the product gas [77]. When the chlorine content of the feedstock was 11,300 ppm, the HCl emission dropped to 350–500 ppm depending on the process temperature. The addition of crushed oyster shells reduced this value to about 50 ppm.

Layered double hydroxide. Although several solutions to mitigate chlorine emissions are known and have been studied as shown above, more research is still required in the area of gas cleaning with some focusing on developing active, stable, and durable catalysts at low cost [6,36]. One solution for removal of HCl from incineration streams proposed is using a Mg-Al layered double hydroxide (LDH) intercalated with CO2−3 [59,77,78]. The effective sorption over this type of material was proposed to follow the reaction given by Equation (6) below.

Mg0.8Al0.2(OH)2(CO3)0.1 × 0.72 H2O + 0.2 HCl → Mg0.8Al0.2(OH)2Cl0.2 + 0.82 H2O + 0.1 CO2

This method might also be applied for gaseous HCl treatment. The same authors evaluated Mg-Al oxide in a slurry for sorption of HCl, SO2, and NOx [78]. It turned out that the degree of HCl removal surpassed 99% using 1.5, 1.75, and 2.0 times the stoichiometric quantities of the catalysts. The other material synthesized for HCl removal was a Ca-Mg-Al mixed oxide [61]. This sorbent was studied in the 573 to 973 K temperature range in a fixed-bed reactor. The results were compared with results for HCl removal by MgO, NaHCO3, and CaO and it was found that the binding capacity of HCl by Ca-Mg-Al mixed oxide was the highest.

5. Future Prospects and Outlook

Waste-to-Energy technologies for MSW management are viable solutions to provide energy and prevent, reduce, reuse, and/or recycle waste. Developments in these technologies for recovering energy from MSW may emerge as a promising and sustainable approach to address growing global energy demands and new opportunities for environmental protection. However, complete separation and collection, composting of biodegradable waste, recycling, and recovery of different types of MSW can be tremendously difficult. Determining the exact composition of a municipal solid waste source can be nearly impossible and requires implementing a sustainable and effective municipal solid waste management system. There are many Waste-to-Energy challenges (e.g., abatement of chlorine emissions, waste-gas clean-up, tar formation, conversion efficiency, catalyst deactivation, regulatory hurdles, and high capital costs). Moreover, it is important to note that a large volume of gaseous emissions induced by various processes such as pyrolysis and thermal gasification may pose environmental health risks if not well cleaned from tars and particulates but this can be significantly reduced using known air pollution control equipment. The control of air pollution may be a key feature in processing agricultural residues, wood waste, and municipal solid waste into energy. Gasification or dry/steam reforming as well as anaerobic digestion for the generation of an upgraded biogas provides alternative syngas generation processes. It is well known that both syngas and biogas can then serve as a feedstock such as in Fischer–Tropsch synthesis to produce a number of subsequent chemical products and fuels. Additionally, biogas may be used for either electricity or combined heat and power (CHP) production. However, there is still much work to be done to provide sufficient and sustainable management of municipal solid waste. It is relatively early to suggest or converge on one processing strategy for MSW management especially with the wide variety of feedstock compositions including catalyst poisons and toxic chemicals. More knowledge could in turn stimulate better designs especially in regards to more highly efficient catalysts for production of fine chemicals and value-added products.

Acknowledgments

The authors want to acknowledge the Foundation for Polish Science the Financial support of POWROTY/2016-1/5.

Author Contributions

All authors equally contributed to literature analysis and discussion. I.S.P., W.S.E., A.K., and P.L. wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Malins, C.; Searle, S.; Malins, C.; Baral, A.; Turley, D.; Hopwood, L. Wasted: Europe’s Untrapped Resource: An Assessment of Advanced Biofuels from Wastes & Residues; International Council on Clean Transportation: Berlin, Germany, 2014. [Google Scholar]

- Uslu, A.; Pedersen, J.; Resch, G.; Fritsche, U. Maximising the Environmental Benefits of Europe’s Bioenergy Potential; European Environment Agency (EEA): Copenhagen, Denmark, 2008; ISSN 1725-2237. [Google Scholar]

- Fava, F.; Totaro, G.; Diels, L.; Reis, M.; Duarte, J.; Carioca, O.B.; Poggi-Varaldo, H.M.; Ferreira, B.S. Biowaste biorefinery in Europe: Opportunities and research & development needs. New Biotechnol. 2015, 32, 100–108. [Google Scholar]

- Ferrer-i-Carbonell, A.; Gowdy, J.M. Environmental degradation and happiness. Ecol. Econ. 2007, 60, 509–516. [Google Scholar] [CrossRef]

- Williams, R.B.; Zhang, T. Survey of MSW Conversion Options; CEC-500-11-020; California Biomass Collaborative, University of California: Davis, CA, USA, 2013. [Google Scholar]

- Jenkins, S.D.; Legrand, R. Conversion technologies: A new option for MSW management. In Proceedings of the 13th Annual North American Waste to Energy Conference (NAWTEC13-3153), Orlando, FL, USA, 23–25 May 2005; pp. 55–61. [Google Scholar]

- Persson, T.; Murphy, J.D.; Jannasch, A.-K.; Ahern, E.; Liebetrau, J.; Trommler, M.; Toyama, J.; Baxter, D.E. A Perspective on the Potential Role of Biogas in Smart Energy Grids; Technical Brochure; IEA Bioenergy: Paris, France, 2014. [Google Scholar]

- Omari, A.M.; Kichonge, B.N.; John, G.R.; Njau, K.N.; Mtui, P.L. Potential of Municipal solid waste, as renewable energy source- A case study of Arusha, Tanzania. Int. J. Renew. Energy Technol. Res. 2014, 3, 31–39. [Google Scholar]

- Eddine, B.T.; Salah, M.M. Solid waste as renewable source of energy: Current and future possibility in Algeria. Int. J. Energy Environ. Eng. 2012, 3, 1–12. [Google Scholar] [CrossRef]

- Cotana, F.; Cavalaglio, G.; Gelosia, M.; Nicolini, A.; Coccia, V.; Petrozzi, A. Production of bioethanol in a second generation prototype from pine wood chips. Energy Procedia 2014, 45, 42–51. [Google Scholar] [CrossRef]

- Colmenares, J.C.; Quintero, R.F.C.; Pieta, I.S. Catalytic Dry Reforming for Biomass-Based Fuels Processing: Progress and Future Perspectives. Energy Technol. 2016, 4, 881–890. [Google Scholar] [CrossRef]

- Bosmans, A.; Vanderreydt, I.; Geysen, D.; Helsen, L. The crucial role of Waste-to-Energy technologies in enhanced landfill mining: A technology review. J. Clean. Prod. 2013, 55, 10–23. [Google Scholar] [CrossRef]

- Quaghebeur, M.; Laenen, B.; Geysen, D.; Nielsen, P.; Pontikes, Y.; van Gerven, T.; Spooren, J. Characterization of landfilled materials: Screening of the enhanced landfill mining potential. J. Clean. Prod. 2013, 55, 72–83. [Google Scholar] [CrossRef]

- Sahoo, B.B.; Saha, U.K.; Sahoo, N. Theoretical performance limits of a syngas-diesel fueled compression ignition engine from second law analysis. Energy 2011, 36, 760–769. [Google Scholar] [CrossRef]

- Zinoviev, S.; Muller-Langer, F.; Das, P.; Bertero, N.; Fornasiero, P.; Kaltschmitt, M.; Centi, G.; Miertus, S. Next-Generation Biofuels: Survey of Emerging Technologies and Sustainability Issues. Chemsuschem 2010, 3, 1106–1133. [Google Scholar] [CrossRef] [PubMed]

- Pieta, I.S.; Resini, C.; Donazzi, A. Fuel processing for solid oxide fuel cells. In Modeling, Design, Construction, and Operation of Power Generators with Solid Oxide Fuel Cells: From Single Cell to Complete Power System; Springer: New York, NY, USA, 2017; Chapter 4; ISBN 978-973-319-75602-75608. [Google Scholar]

- Borgwardt, R.H. Transportation fuel from cellulosic biomass: A comparative assessment of ethanol and methanol options. J. Power Energy 1999, 213, 399–407. [Google Scholar] [CrossRef]

- Ptasinski, K.J. Thermodynamic efficiency of biomass gasification and biofuels conversion. Biofuels Bioprod. Biorefin. 2008, 2, 239–253. [Google Scholar] [CrossRef]

- Menon, V.; Rao, M. Trends in bioconversion of lignocellulose: Biofuels, platform chemicals & biorefinery concept. Prog. Energy Combust. 2012, 38, 522–550. [Google Scholar]

- Nigam, P.S.; Singh, A. Production of liquid biofuels from renewable resources. Prog. Energy Combust. 2011, 37, 52–68. [Google Scholar] [CrossRef]

- Bergthorson, J.M.; Thomson, M.J. A review of the combustion and emissions properties of advanced transportation biofuels and their impact on existing and future engines. Renew. Sustan. Energy Rev. 2015, 42, 1393–1417. [Google Scholar] [CrossRef]

- Peralta-Yahya, P.P.; Keasling, J.D. Advanced biofuel production in microbes. Biotechnol. J. 2010, 5, 147–162. [Google Scholar] [CrossRef] [PubMed]

- Alonso, D.M.; Bond, J.Q.; Dumesic, J.A. Catalytic conversion of biomass to biofuels. Green Chem. 2010, 12, 1493–1513. [Google Scholar] [CrossRef]

- Roman-Leshkov, Y.; Barrett, C.J.; Liu, Z.Y.; Dumesic, J.A. Production of dimethylfuran for liquid fuels from biomass-derived carbohydrates. Nature 2007, 447, U982–U985. [Google Scholar] [CrossRef] [PubMed]

- Abdollahifar, M.; Haghighi, M.; Babaluo, A.A. Syngas production via dry reforming of methane over Ni/Al2O3-MgO nanocatalyst synthesized using ultrasound energy. J. Ind. Energy Chem. 2014, 20, 1845–1851. [Google Scholar] [CrossRef]

- Garcia-Dieguez, M.; Pieta, I.S.; Herrera, M.C.; Larrubia, M.A.; Alemany, L.J. Nanostructured Pt- and Ni-based catalysts for CO2-reforming of methane. J. Catal. 2010, 270, 136–145. [Google Scholar] [CrossRef]

- Huber, G.W.; Dumesic, J.A. An overview of aqueous-phase catalytic processes for production of hydrogen and alkanes in a biorefinery. Catal. Today 2006, 111, 119–132. [Google Scholar] [CrossRef]

- Pakhare, D.; Spivey, J. A review of dry (CO2) reforming of methane over noble metal catalysts. Chem. Soc. Rev. 2014, 43, 7813–7837. [Google Scholar] [CrossRef] [PubMed]

- Andersen, V.F.; Anderson, J.E.; Wallington, T.J.; Mueller, S.A.; Nielsen, O.J. Distillation Curves for Alcohol-Gasoline Blends. Energy Fuel 2010, 24, 2683–2691. [Google Scholar] [CrossRef]

- De Lasa, H.; Salaices, E.; Mazumder, J.; Lucky, R. Catalytic Steam Gasification of Biomass: Catalysts, Thermodynamics and Kinetics. Chem. Rev. 2011, 111, 5404–5433. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.H.; Xu, C.B.; Champagne, P. Overview of recent advances in thermo-chemical conversion of biomass. Energy Convers. Manag. 2010, 51, 969–982. [Google Scholar] [CrossRef]

- Liu, S.Y.; Mei, D.H.; Nahil, M.A.; Gadkari, S.; Gu, S.; Williams, P.T.; Tu, X. Hybrid plasma-catalytic steam reforming of toluene as a biomass tar model compound over Ni/Al2O3 catalysts. Fuel Process. Technol. 2017, 166, 269–275. [Google Scholar] [CrossRef]

- Carpenter, D.L.; Bain, R.L.; Davis, R.E.; Dutta, A.; Feik, C.J.; Gaston, K.R.; Jablonski, W.; Phillips, S.D.; Nimlos, M.R. Pilot-Scale Gasification of Corn Stover, Switchgrass, Wheat Straw, and Wood: 1. Parametric Study and Comparison with Literature. Ind. Eng. Chem. Res. 2010, 49, 1859–1871. [Google Scholar] [CrossRef]

- Courson, C.; Makaga, E.; Petit, C.; Kiennemann, A. Development of Ni catalysts for gas production from biomass gasification. Reactivity in steam- and dry-reforming. Catal. Today 2000, 63, 427–437. [Google Scholar] [CrossRef]

- Sutton, D.; Kelleher, B.; Ross, J.R.H. Review of literature on catalysts for biomass gasification. Fuel Process. Technol. 2001, 73, 155–173. [Google Scholar] [CrossRef]

- Dou, B.L.; Wang, C.; Chen, H.S.; Song, Y.C.; Xie, B.Z.; Xu, Y.J.; Tan, C.Q. Research progress of hot gas filtration, desulphurization and HCl removal in coal-derived fuel gas: A review. Chem. Eng. Res. Des. 2012, 90, 1901–1917. [Google Scholar] [CrossRef]

- Kowalik, P.; Antoniak-Jurak, K.; Blesznowski, M.; Herrera, M.C.; Larrubia, M.A.; Alemany, L.J.; Pieta, I.S. Biofuel steam reforming catalyst for fuel cell application. Catal. Today 2015, 254, 129–134. [Google Scholar] [CrossRef]

- Ates, F.; Miskolczi, N.; Borsodi, N. Comparision of real waste (MSW and MPW) pyrolysis in batch reactor over different catalysts. Part I: Product yields, gas and pyrolysis oil properties. Bioresour. Technol. 2013, 133, 443–454. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.N.; Islam, M.N.; Beg, M.R.A.; Islam, M.R. Pyrolytic oil from fixed bed pyrolysis of municipal solid waste and its characterization. Renew. Energy 2005, 30, 413–420. [Google Scholar] [CrossRef]

- Grieco, E.M.; Baldi, G. Pyrolysis of polyethylene mixed with paper and wood: Interaction effects on tar, char and gas yields. Waste Manag. 2012, 32, 833–839. [Google Scholar] [CrossRef] [PubMed]

- Sorum, L.; Gronli, M.G.; Hustad, J.E. Pyrolysis characteristics and kinetics of municipal solid wastes. Fuel 2001, 80, 1217–1227. [Google Scholar] [CrossRef]

- Wang, N.; Chen, D.Z.; Arena, U.; He, P.J. Hot char-catalytic reforming of volatiles from MSW pyrolysis. Appl. Energy 2017, 191, 111–124. [Google Scholar] [CrossRef]

- Couto, N.; Silva, V.; Rouboa, A. Municipal solid waste gasification in semi-industrial conditions using air-CO2 mixtures. Energy 2016, 104, 42–52. [Google Scholar] [CrossRef]

- Luo, S.Y.; Zhou, Y.M.; Yi, C.J. Syngas production by catalytic steam gasification of municipal solid waste in fixed-bed reactor. Energy 2012, 44, 391–395. [Google Scholar] [CrossRef]

- Li, J.F.; Liao, S.Y.; Dan, W.Y.; Jia, K.L.; Zhou, X.R. Experimental study on catalytic steam gasification of municipal solid waste for bioenergy production in a combined fixed bed reactor. Biomass Bioenergy 2012, 46, 174–180. [Google Scholar] [CrossRef]

- Saad, J.M.; Williams, P.T. Catalytic dry reforming of waste plastics from different waste treatment plants for production of synthesis gases. Waste Manag. 2016, 58, 214–220. [Google Scholar] [CrossRef] [PubMed]

- Saad, J.M.; Williams, P.T. Pyrolysis-catalytic dry (CO2) reforming of waste plastics for syngas production: Influence of process parameters. Fuel 2017, 193, 7–14. [Google Scholar] [CrossRef]

- Saad, J.M.; Williams, P.T. Manipulating the H-2/CO ratio from dry reforming of simulated mixed waste plastics by the addition of steam. Fuel Process. Technol. 2017, 156, 331–338. [Google Scholar] [CrossRef]

- Saad, J.M.; Nahil, M.A.; Wu, C.F.; Williams, P.T. Influence of nickel-based catalysts on syngas production from carbon dioxide reforming of waste high density polyethylene. Fuel Process. Technol. 2015, 138, 156–163. [Google Scholar] [CrossRef]

- Fuentes-Cano, D.; Gomez-Barea, A.; Nilsson, S.; Ollero, P. Decomposition kinetics of model tar compounds over chars with different internal structure to model hot tar removal in biomass gasification. Chem. Eng. J. 2013, 228, 1223–1233. [Google Scholar] [CrossRef]

- Matsuhara, T.; Hosokai, S.; Norinaga, K.; Matsuoka, K.; Li, C.Z.; Hayashi, J. In-Situ Reforming of Tar from the Rapid Pyrolysis of a Brown Coal over Char. Energy Fuel 2010, 24, 76–83. [Google Scholar] [CrossRef]

- Min, Z.H.; Yimsiri, P.; Asadullah, M.; Zhang, S.; Li, C.Z. Catalytic reforming of tar during gasification. Part II. Char as a catalyst or as a catalyst support for tar reforming. Fuel 2011, 90, 2545–2552. [Google Scholar] [CrossRef]

- Li, C.Z. Importance of volatile-char interactions during the pyrolysis and gasification of low-rank fuels—A review. Fuel 2013, 112, 609–623. [Google Scholar] [CrossRef]

- Wang, D.; Yuan, W.Q.; Ji, W. Char and char-supported nickel catalysts for secondary syngas cleanup and conditioning. Appl. Energy 2011, 88, 1656–1663. [Google Scholar] [CrossRef]

- Zhang, S.; Asadullah, M.; Dong, L.; Tay, H.L.; Li, C.Z. An advanced biomass gasification technology with integrated catalytic hot gas cleaning. Part II: Tar reforming using char as a catalyst or as a catalyst support. Fuel 2013, 112, 646–653. [Google Scholar] [CrossRef]

- Shen, Y.F.; Zhao, P.T.; Shao, Q.F.; Takahashi, F.; Yoshikawa, K. In situ catalytic conversion of tar using rice husk char/ash supported nickel-iron catalysts for biomass pyrolytic gasification combined with the mixing-simulation in fluidized-bed gasifier. Appl. Energy 2015, 160, 808–819. [Google Scholar] [CrossRef]

- Gilbert, P.; Ryu, C.; Sharifi, V.; Swithenbank, J. Tar reduction in pyrolysis vapours from biomass over a hot char bed. Bioresour. Technol. 2009, 100, 6045–6051. [Google Scholar] [CrossRef] [PubMed]

- Gallastegi-Villa, M.; Aranzabal, A.; Gonzalez-Marcos, J.A.; Gonzalez-Velasco, J.R. Tailoring dual redox-acid functionalities in VOx/TiO2/ZSM5 catalyst for simultaneous abatement of PCDD/Fs and NOx from municipal solid waste incineration. Appl. Catal. B 2017, 205, 310–318. [Google Scholar] [CrossRef]

- Yan, Q.H.; Nie, Y.; Yang, R.Y.; Cui, Y.H.; O’Hare, D.; Wang, Q. Highly dispersed CuyAlOx, mixed oxides as superior low-temperature alkali metal and SO2 resistant NH3-SCR catalysts. Appl. Catal. A 2017, 538, 37–50. [Google Scholar] [CrossRef]

- Krishnan, G.N.; Wood, B.J.; Brittain, R.D.; Lau, K.H. Vaporization of Alkali and Trace Metal Impurities in Coal Gasification and Combustion Systems; Universität Karlsruhe: Karlsruhe, Germany, 1996; pp. 651–663. [Google Scholar]

- Cao, J.; Zhong, W.Q.; Jin, B.S.; Wang, Z.F.; Wang, K. Treatment of Hydrochloric Acid in Flue Gas from Municipal Solid Waste Incineration with Ca-Mg-Al Mixed Oxides at Medium-High Temperatures. Energy Fuel 2014, 28, 4112–4117. [Google Scholar] [CrossRef]

- Chyang, C.; Han, Y.; Zhong, Z. Study of HCl Absorption by CaO at High Temperature. Energy Fuel 2009, 23, 3948–3953. [Google Scholar] [CrossRef]

- Blazso, M.; Jakab, E. Effect of metals, metal oxides, and carboxylates on the thermal decomposition processes of poly (vinyl chloride). J. Anal. Appl. Pyrolysis 1999, 49, 125–143. [Google Scholar] [CrossRef]

- Horikawa, S.; Takai, Y.; Ukei, H.; Azuma, N.; Ueno, A. Chlorine gas recovery from polyvinyl chloride. J. Anal. Appl. Pyrolysis 1999, 51, 167–179. [Google Scholar] [CrossRef]

- Miranda, R.; Pakdel, H.; Roy, C.; Vasile, C. Vacuum pyrolysis of commingled plastics containing PVC II. Product analysis. Polym. Degrad. Stab. 2001, 73, 47–67. [Google Scholar] [CrossRef]

- Weinell, C.E.; Jensen, P.I.; Damjohansen, K.; Livbjerg, H. Hydrogen-Chloride Reaction with Lime and Limestone—Kinetics and Sorption Capacity. Ind. Eng. Chem. Res. 1992, 31, 164–171. [Google Scholar] [CrossRef]

- Hofbauer, H.; Rauch, R.; Ripfel-Nitsche, K. Gas Cleaning for Synthesis Applications; Vienna University of Technology: Vienna, Austria, 2007. [Google Scholar]

- Wang, W.Y.; Ye, Z.C.; Bjerle, I. The kinetics of the reaction of hydrogen chloride with fresh and spent Ca-based desulfurization sorbents. Fuel 1996, 75, 207–212. [Google Scholar] [CrossRef]

- Fusch, Y.; Schwerdtfeger, K. Hot Dechlorination and Hot Desulfurization of Reducing Gases with Lime Pellets; Universität Karlsruhe: Karlsruhe, Germany, 1996; pp. 426–438. [Google Scholar]

- Mitchell, S.C. Hot Gas Cleanup of Sulphur, Nitrogen, Minor, and Trace Elements; Technical Report; IEA Coal Research: London, UK, 1998. [Google Scholar]

- Bartoňová, L. Effect of CaO, Al2O3 and Fe2O3 in coal ash on the retention of acidforming elements during coal combustion. WSEAS Trans. Power Syst. 2014, 9, 486–494. [Google Scholar]

- Fujita, S.; Suzuki, K.; Ohkawa, M.; Shibasaki, Y.; Mori, T. Reaction of hydrogrossular with hydrogen chloride gas at high temperature. Chem. Mater. 2001, 13, 2523–2527. [Google Scholar] [CrossRef]

- Dou, B.L.; Gao, J.S.; Sha, X.Z. A study on the reaction kinetics of HCl removal from high-temperature coal gas. Fuel Process. Technol. 2001, 72, 23–33. [Google Scholar] [CrossRef]

- Nunokawa, M.; Kobayashi, M.; Shirai, H. Halide compound removal from hot coal-derived gas with reusable sodium-based sorbent. Powder Technol. 2008, 180, 216–221. [Google Scholar] [CrossRef]

- Lee, M.T.; Wang, Z.Q.; Chang, J.R. Activated-carbon-supported NaOH for removal of HCl from reformer process streams. Ind. Eng. Chem. Res. 2003, 42, 6166–6170. [Google Scholar] [CrossRef]

- Cheng, L.S. Process for Removing HCl from Hydrocarbon Streams. U.S. Patent 6060033A, 22 April 1998. [Google Scholar]

- Kameda, T.; Uchiyama, N.; Yoshioka, T. Treatment of gaseous hydrogen chloride using Mg-Al layered double hydroxide intercalated with carbonate ion. Chemosphere 2010, 81, 658–662. [Google Scholar] [CrossRef] [PubMed]

- Kameda, T.; Uchiyama, N.; Yoshioka, T. Removal of HCl, SO2, and NO by treatment of acid gas with Mg-Al oxide slurry. Chemosphere 2011, 82, 587–591. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).