Co-Production of Furfural, Xylo-Oligosaccharides, and Reducing Sugars from Waste Yellow Bamboo Through the Solid Acid-Assisted Hydrothermal Pretreatment

Abstract

1. Introduction

2. Results and Discussion

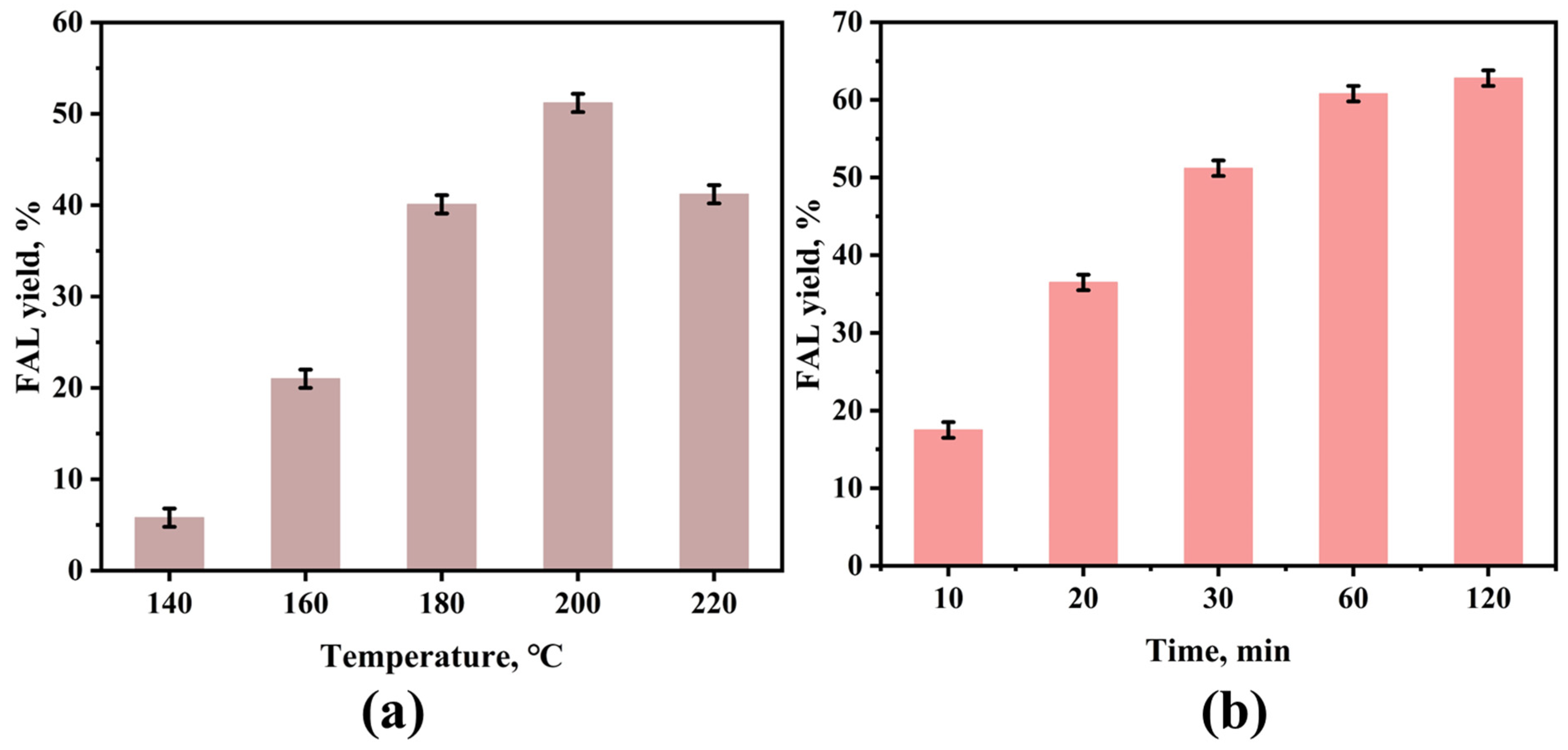

2.1. Solid Acid-Assisted Hydrothermal Pretreatment of Waste YB for Production of FAL

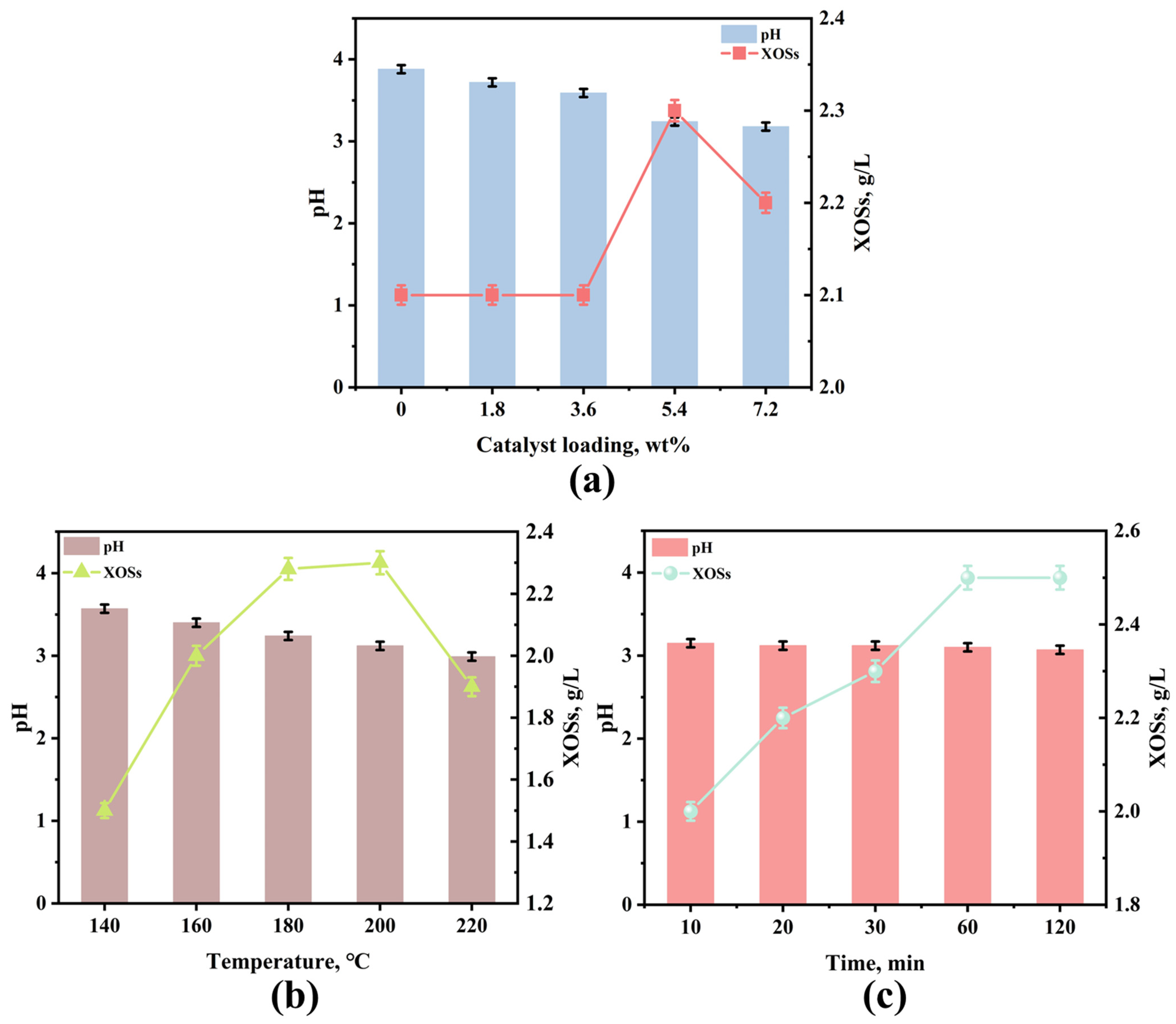

2.2. Formation of XOSs in Pretreatment Solution

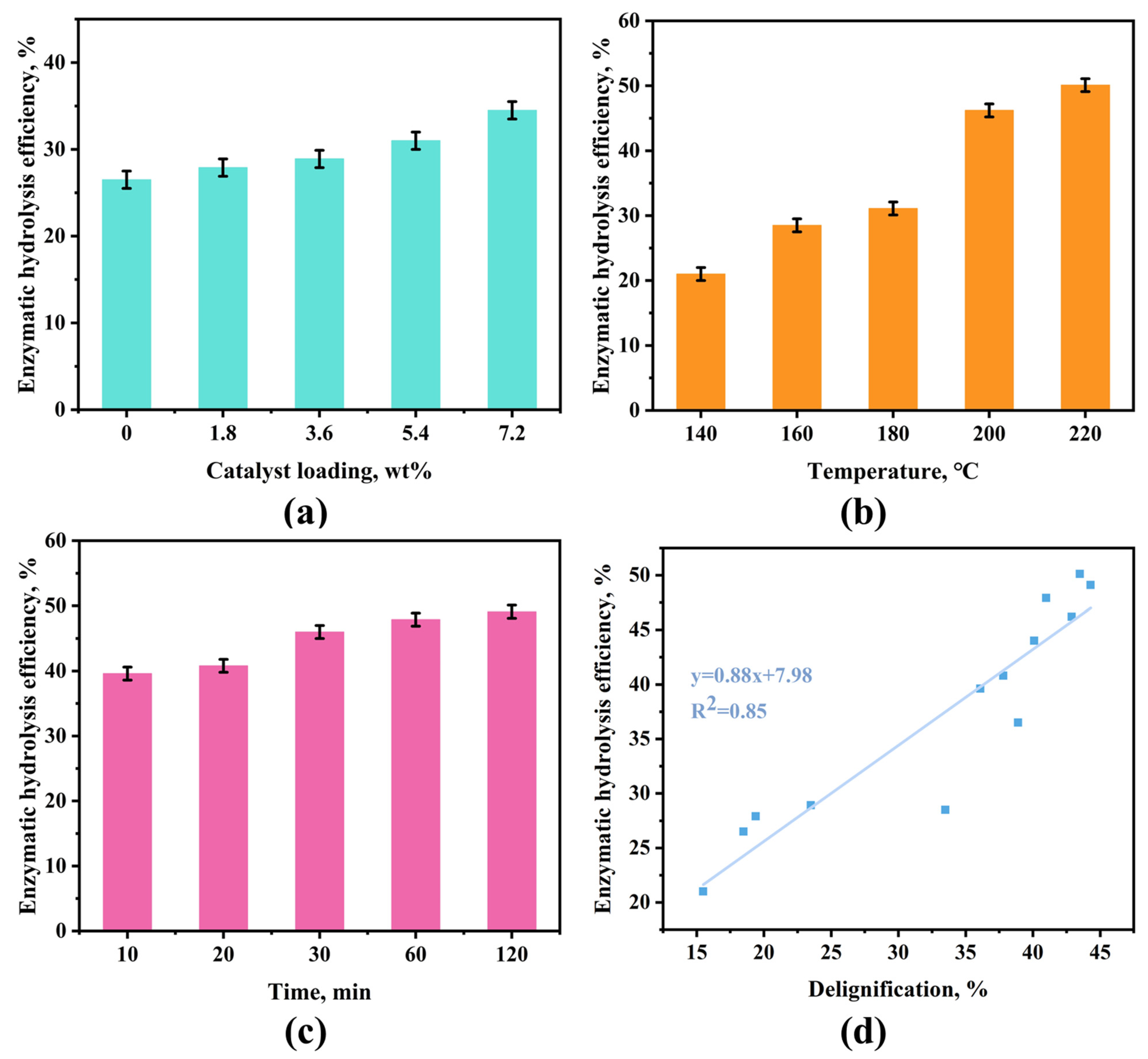

2.3. Enzymatic Hydrolysis of YB into Reducing Sugars

2.4. Analysis of Physicochemical Properties of Raw and Treated YB

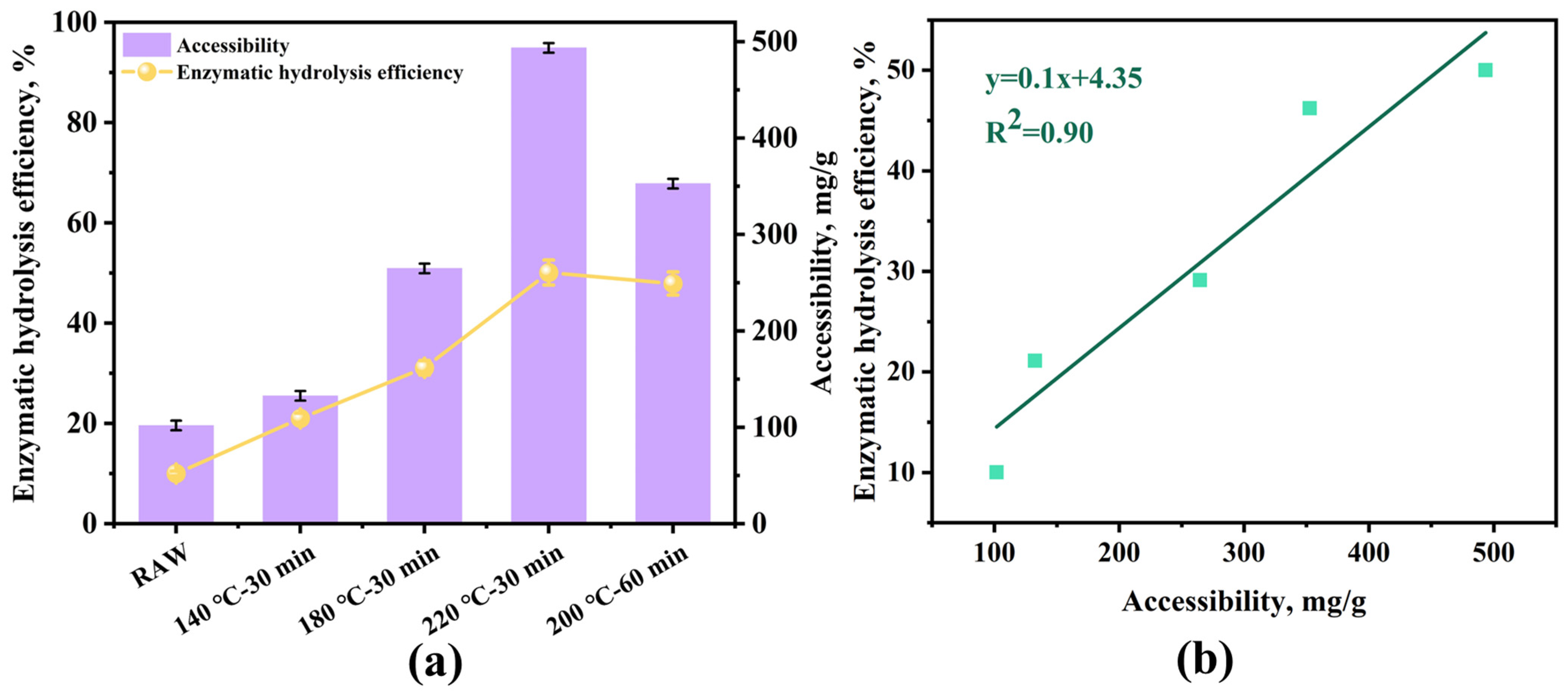

2.4.1. Accessibility

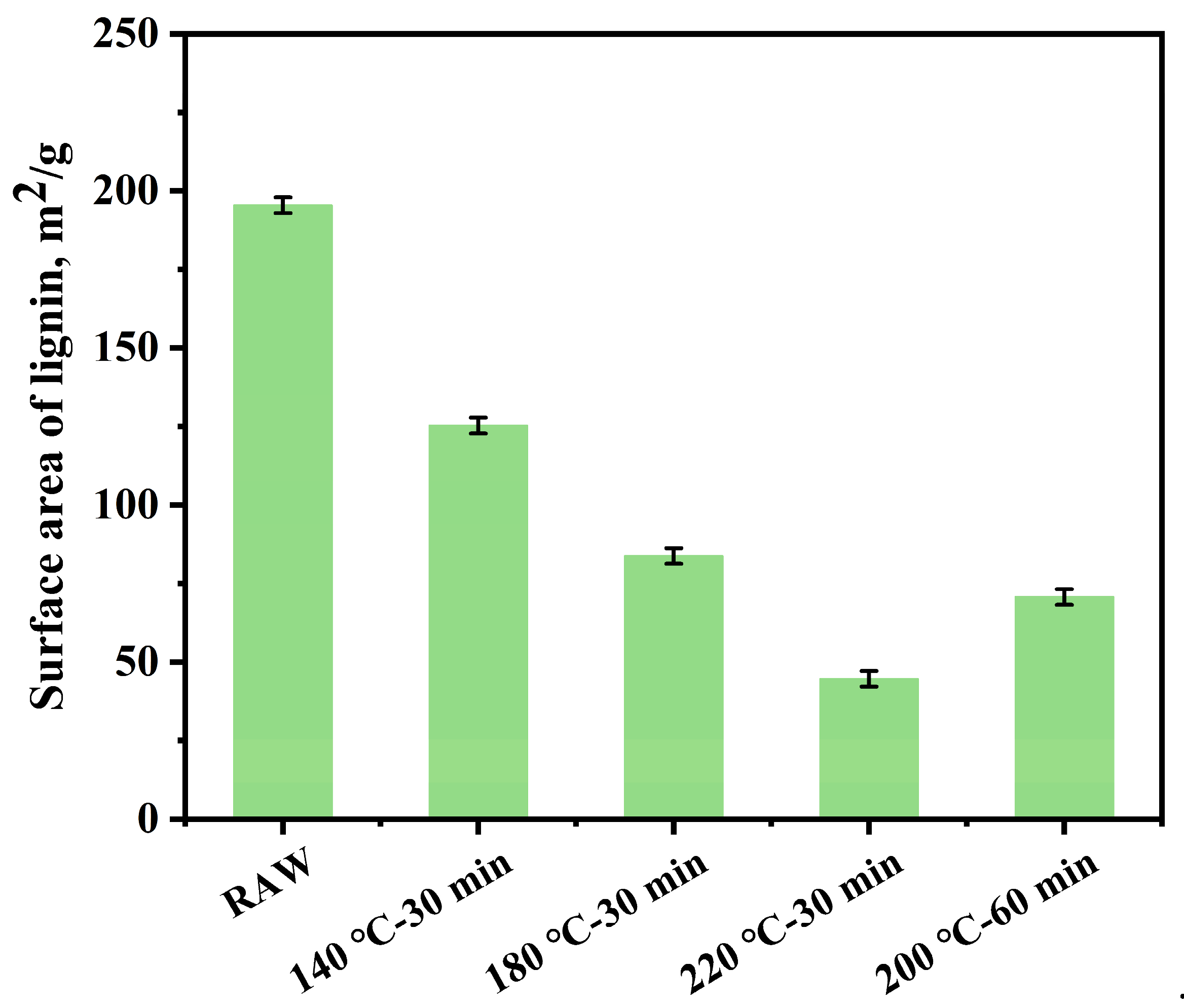

2.4.2. Lignin Surface Area

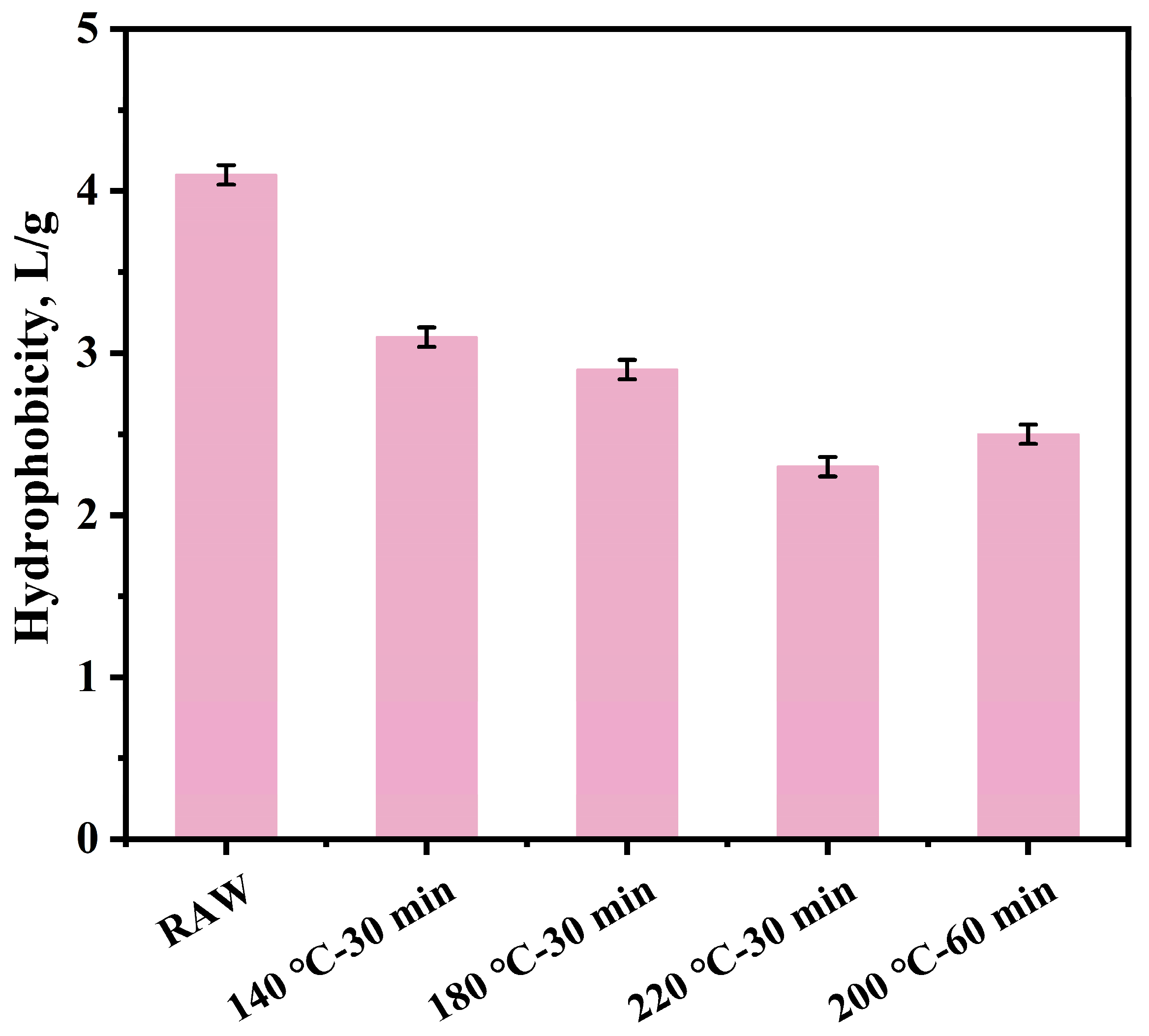

2.4.3. Hydrophobicity

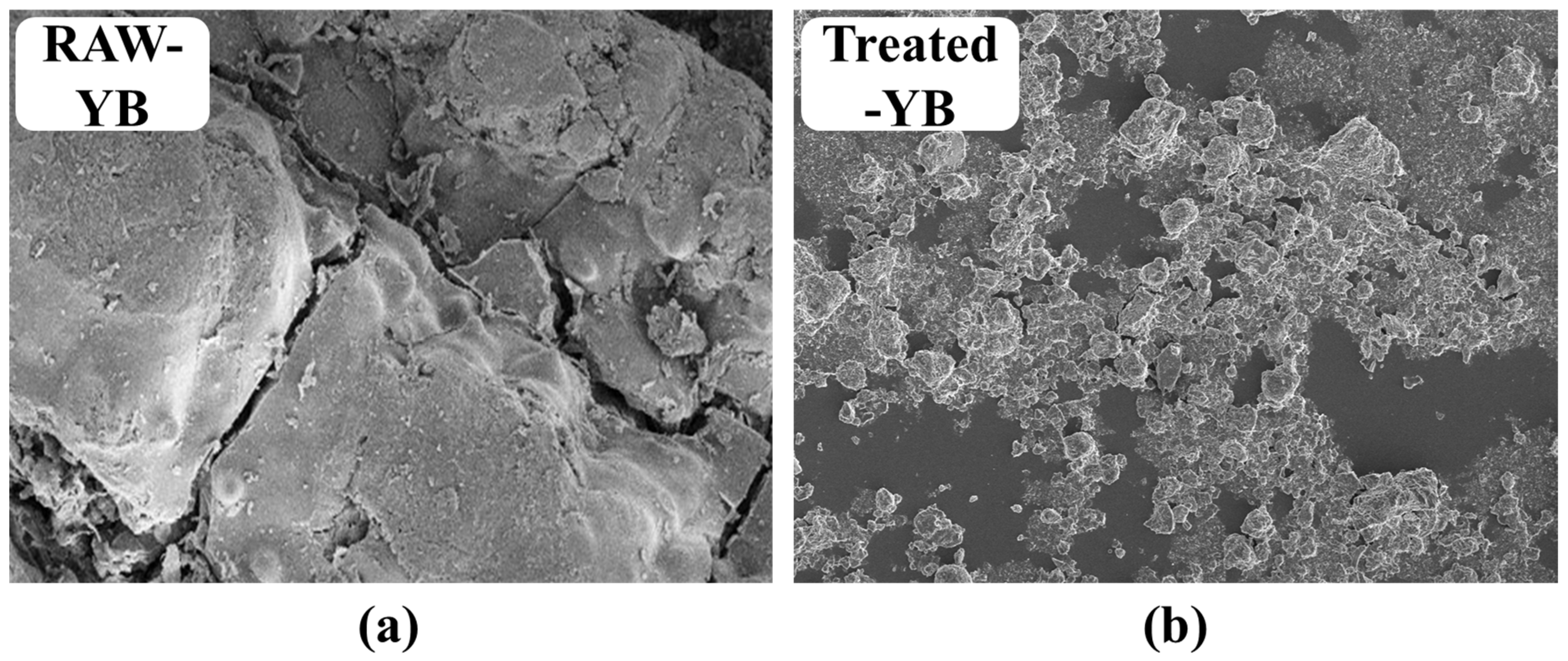

2.4.4. SEM

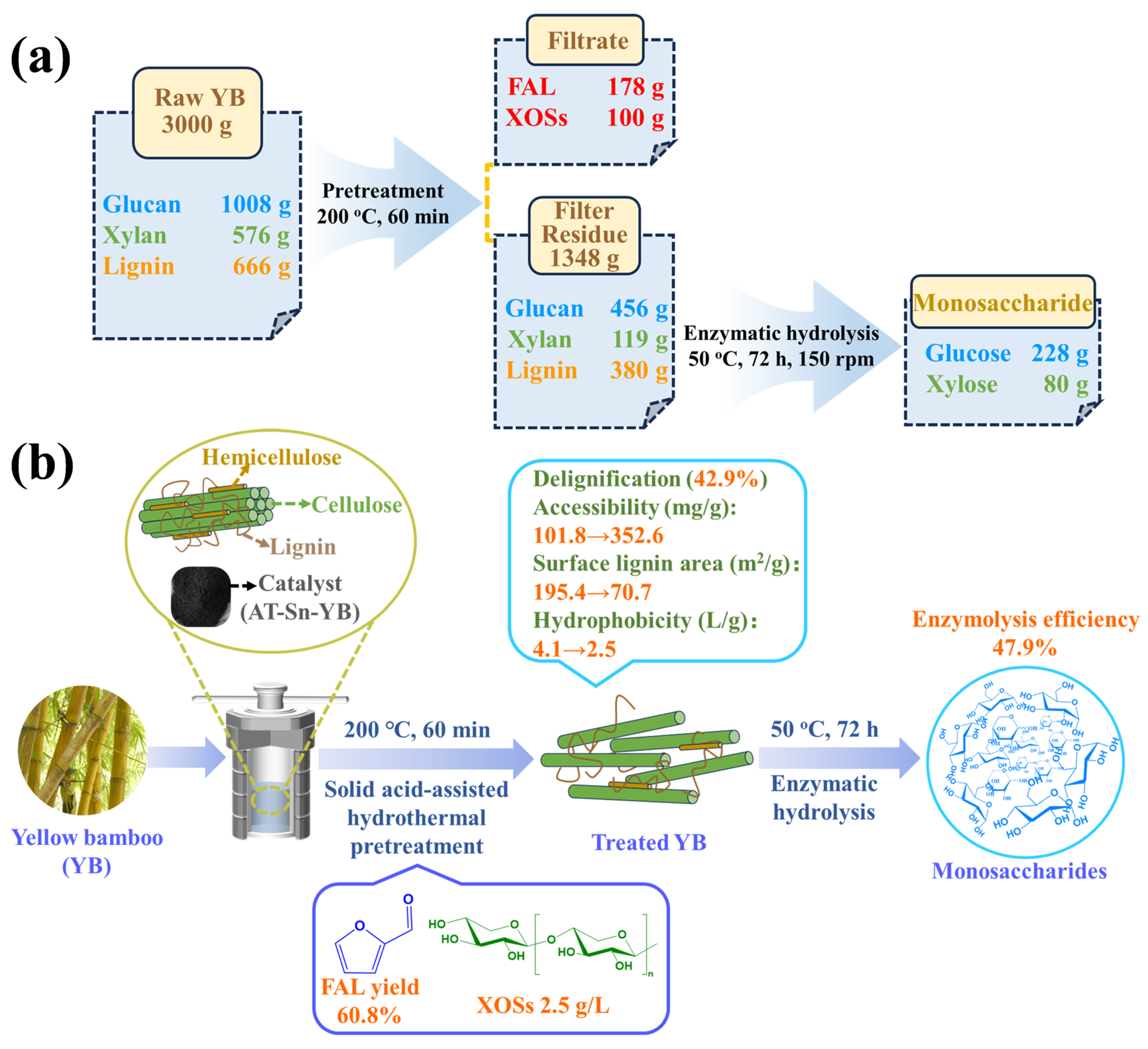

2.5. Comprehensive Evaluation of Coproducing FAL, XOSs, and Reducing Sugars Through the Solid Acid-Assisted Hydrothermal Pretreatment

3. Materials and Methods

3.1. Chemicals and Materials

3.2. Solid Acid Catalyst Assisted Hydrothermal Pretreatment of YB

3.3. Chemical Composition Analysis

3.4. Enzymatic Hydrolysis

3.5. Physicochemical Properties of Raw and Treated YB

3.5.1. Accessibility

3.5.2. Lignin Surface Area

3.5.3. Hydrophobicity

3.5.4. Scanning Electron Microscopy (SEM)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Deng, W.; Feng, Y.; Fu, J.; Guo, H.; Guo, Y.; Han, B.; Jiang, Z.; Kong, L.; Li, C.; Liu, H.; et al. Catalytic conversion of lignocellulosic biomass into chemicals and fuels. GEE 2023, 8, 10–114. [Google Scholar] [CrossRef]

- Ubando, A.T.; Felix, C.B.; Chen, W.-H. Biorefineries in circular bioeconomy: A comprehensive review. Bioresour. Technol. 2020, 299, 122585. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Zhao, X.; Lin, W.; Yong, Q.; Huang, C. Revealing the performance of phenoxyethanol-acid pretreatment on the intercellular structure of bamboo and its enzymatic hydrolysis. Ind. Crops Prod. 2023, 199, 116663. [Google Scholar] [CrossRef]

- Shen, X.; Sun, R. Recent advances in lignocellulose prior-fractionation for biomaterials, biochemicals, and bioenergy. Carbohydr. Poly. 2021, 261, 117884. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Song, J.; Han, B. Catalytic transformation of lignocellulose into chemicals and fuel products in ionic liquids. Chem. Rev. 2017, 117, 6834–6880. [Google Scholar] [CrossRef] [PubMed]

- Yan, B.; Huang, C.; Lai, C.; Ling, Z.; Yong, Q. Production of prebiotic xylooligosaccharides from industrial-derived xylan residue by organic acid treatment. Carbohydr. Poly. 2022, 292, 119641. [Google Scholar] [CrossRef]

- Liu, Y.; Lyu, Y.; Tian, J.; Zhao, J.; Ye, N.; Zhang, Y.; Chen, L. Review of waste biorefinery development towards a circular economy: From the perspective of a life cycle assessment. Renew. Sust. Energ. Rev. 2021, 139, 110716. [Google Scholar] [CrossRef]

- Cherubini, F. The biorefinery concept: Using biomass instead of oil for producing energy and chemicals. Energy Convers. Manag. 2010, 51, 1412–1421. [Google Scholar] [CrossRef]

- Hronec, M.; Fulajtarová, K. Selective transformation of furfural to cyclopentanone. Catal. Commun. 2012, 24, 100–104. [Google Scholar] [CrossRef]

- Nardi, M.; Costanzo, P.; De Nino, A.; Di Gioia, M.L.; Olivito, F.; Sindona, G.; Procopio, A. Water excellent solvent for the synthesis of bifunctionalized cyclopentenones from furfural. Green Chem. 2017, 19, 5403–5411. [Google Scholar] [CrossRef]

- Zhang, Y.; Fan, G.; Yang, L.; Li, F. Efficient conversion of furfural into cyclopentanone over high performing and stable Cu/ZrO2 catalysts. Appl Catal. A Gen. 2018, 561, 117–126. [Google Scholar] [CrossRef]

- Bonacci, S.; Nardi, M.; Costanzo, P.; De Nino, A.; Di Gioia, M.L.; Oliverio, M.; Procopio, A. Montmorillonite K10-catalyzed solvent-free conversion of furfural into cyclopentenones. Catalysts 2019, 9, 301. [Google Scholar] [CrossRef]

- Zhan, Y.; Wang, M.; Ma, T.; Li, Z. Enhancing the potential production of bioethanol with bamboo by γ-valerolactone/water pretreatment. RSC Adv. 2022, 12, 16942–16954. [Google Scholar] [CrossRef] [PubMed]

- Meenakshisundaram, S.; Fayeulle, A.; Leonard, E.; Ceballos, C.; Pauss, A. Fiber degradation and carbohydrate production by combined biological and chemical/physicochemical pretreatment methods of lignocellulosic biomass—A review. Bioresour. Technol. 2021, 331, 125053. [Google Scholar] [CrossRef]

- Huang, C.; Fang, G.; Zhou, Y.; Du, X.; Yu, L.; Meng, X.; Li, M.; Yoo, C.G.; Chen, B.; Zhai, S.; et al. Increasing the carbohydrate output of bamboo using a combinatorial pretreatment. ACS Sustain. Chem. Eng. 2020, 8, 7380–7393. [Google Scholar] [CrossRef]

- Zhang, F.; Lan, W.; Zhang, A.; Liu, C. Green approach to produce xylo-oligosaccharides and glucose by mechanical-hydrothermal pretreatment. Bioresour. Technol. 2022, 344, 126298. [Google Scholar] [CrossRef]

- Huang, C.; Wu, X.; Huang, Y.; Lai, C.; Li, X.; Yong, Q. Prewashing enhances the liquid hot water pretreatment efficiency of waste wheat straw with high free ash content. Bioresour. Technol. 2016, 219, 583–588. [Google Scholar] [CrossRef]

- Lu, H.; Liu, S.; Zhang, M.; Meng, F.; Shi, X.; Yan, L. Investigation of the strengthening process for liquid hot water pretreatments. Energy Fuels 2016, 30, 1103–1108. [Google Scholar] [CrossRef]

- Nitsos, C.K.; Lazaridis, P.A.; Mach-Aigner, A.; Matis, K.A.; Triantafyllidis, K.S. Enhancing lignocellulosic biomass hydrolysis by hydrothermal pretreatment, extraction of surface lignin, wet milling and production of cellulolytic enzymes. ChemSusChem 2019, 12, 1179–1195. [Google Scholar] [CrossRef]

- Su, Y.; Fang, L.; Wang, P.; Lai, C.; Huang, C.; Ling, Z.; Sun, S.; Yong, Q. Efficient production of xylooligosaccharides rich in xylobiose and xylotriose from poplar by hydrothermal pretreatment coupled with post-enzymatic hydrolysis. Bioresour. Technol. 2021, 342, 125955. [Google Scholar] [CrossRef]

- Li, X.; Jia, P.; Wang, T. Furfural: A promising platform compound for sustainable production of C4 and C5 chemicals. ACS Catal. 2016, 6, 7621–7640. [Google Scholar] [CrossRef]

- Lopes, M.; Dussan, K.; Leahy, J.J. Enhancing the conversion of D-xylose into furfural at low temperatures using chloride salts as co-catalysts: Catalytic combination of AlCl3 and formic acid. Chem. Eng. J. 2017, 323, 278–286. [Google Scholar] [CrossRef]

- Srinivasa Rao, B.; Krishna Kumari, P.; Koley, P.; Tardio, J.; Lingaiah, N. One pot selective conversion of furfural to γ-valerolactone over zirconia containing heteropoly tungstate supported on β-zeolite catalyst. J. Mol. Catal. 2019, 466, 52–59. [Google Scholar] [CrossRef]

- Zhang, T.; Li, W.; An, S.; Huang, F.; Li, X.; Liu, J.; Pei, G.; Liu, Q. Efficient transformation of corn stover to furfural using p-hydroxybenzenesulfonic acid-formaldehyde resin solid acid. Bioresour. Technol. 2018, 264, 261–267. [Google Scholar] [CrossRef]

- Li, H.; Ren, J.; Zhong, L.; Sun, R.; Liang, L. Production of furfural from xylose, water-insoluble hemicelluloses and water-soluble fraction of corncob via a tin-loaded montmorillonite solid acid catalyst. Bioresour. Technol. 2015, 176, 242–248. [Google Scholar] [CrossRef]

- Zha, J.; Fan, B.; He, J.; He, Y.-C.; Ma, C. Valorization of biomass to furfural by chestnut shell-based solid acid in methyl isobutyl ketone–water–sodium chloride system. Appl. Biochem. Biotechnol. 2022, 194, 2021–2035. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Li, W.; Xu, Z.; Liu, Q.; Ma, Q.; Jameel, H.; Chang, H.-M.; Ma, L. Catalytic conversion of xylose and corn stalk into furfural over carbon solid acid catalyst in γ-valerolactone. Bioresour. Technol. 2016, 209, 108–114. [Google Scholar] [CrossRef]

- Usha Rani, M.; Nanaji, K.; Rao, T.N.; Deshpande, A.S. Corn husk derived activated carbon with enhanced electrochemical performance for high-voltage supercapacitors. J. Power Sources 2020, 471, 228387. [Google Scholar] [CrossRef]

- Kim, H.; Yang, S.; Kim, D.H. One-pot conversion of alginic acid into furfural using Amberlyst-15 as a solid acid catalyst in γ-butyrolactone/water co-solvent system. Environ. Res. 2020, 187, 109667. [Google Scholar] [CrossRef]

- Yang, Q.; Tang, W.; Ma, C.; He, Y.-C. Efficient co-production of xylooligosaccharides, furfural and reducing sugars from yellow bamboo via the pretreatment with biochar-based catalyst. Bioresour. Technol. 2023, 387, 129637. [Google Scholar] [CrossRef]

- Imman, S.; Arnthong, J.; Burapatana, V.; Champreda, V.; Laosiripojana, N. Influence of alkaline catalyst addition on compressed liquid hot water pretreatment of rice straw. J. Chem. Eng. 2015, 278, 85–91. [Google Scholar] [CrossRef]

- Bittencourt, G.A.; Barreto, E.d.S.; Brandão, R.L.; Baêta, B.E.L.; Gurgel, L.V.A. Fractionation of sugarcane bagasse using hydrothermal and advanced oxidative pretreatments for bioethanol and biogas production in lignocellulose biorefineries. Bioresour. Technol. 2019, 292, 121963. [Google Scholar] [CrossRef]

- Dulie, N.W.; Woldeyes, B.; Demsash, H.D. Synthesis of lignin-carbohydrate complex-based catalyst from Eragrostis tef straw and its catalytic performance in xylose dehydration to furfural. Inter. J. Biol. Macromol. 2021, 171, 10–16. [Google Scholar] [CrossRef]

- Xu, T.; Wang, X.; Wang, H.; Yao, J.; Kong, F.; Ren, J.; Wang, S. Efficient conversion of xylose and corncob to furfural using a novel carbon-based solid acid derived from black liquor lignin-tin complexes. J. Environ. Chem. Eng. 2024, 12, 114516. [Google Scholar] [CrossRef]

- Ji, L.; Tang, Z.; Yang, D.; Ma, C.; He, Y.-C. Improved one-pot synthesis of furfural from corn stalk with heterogeneous catalysis using corn stalk as biobased carrier in deep eutectic solvent–water system. Bioresour. Technol. 2021, 340, 125691. [Google Scholar] [CrossRef]

- Fuso, A.; Rosso, F.; Rosso, G.; Risso, D.; Manera, I.; Caligiani, A. Production of xylo-oligosaccharides (XOS) of tailored degree of polymerization from acetylated xylans through modelling of enzymatic hydrolysis. Int. Food Res. 2022, 162, 112019. [Google Scholar] [CrossRef]

- Amorim, C.; Silvério, S.C.; Prather, K.L.J.; Rodrigues, L.R. From lignocellulosic residues to market: Production and commercial potential of xylooligosaccharides. Biotechnol. Adv. 2019, 37, 107397. [Google Scholar] [CrossRef]

- Ali, K.; Niaz, N.; Waseem, M.; Ashraf, W.; Hussain, M.; Khalid, M.U.; Tahir, A.B.; Raza, A.; Khan, I.M. Xylooligosaccharides: A comprehensive review of production, purification, characterization, and quantification. Int. Food Res. 2025, 201, 115631. [Google Scholar] [CrossRef]

- Corim Marim, A.V.; Gabardo, S. Xylooligosaccharides: Prebiotic potential from agro-industrial residue, production strategies and prospects. Biocatal. Agri. Biotechnol. 2021, 37, 102190. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, S.; Shi, Y.; Zhang, P.; Huang, D.; Lin, C.; Wu, Y. Upgrading the wood vinegar prepared from the pyrolysis of biomass wastes by hydrothermal pretreatment. Energy 2022, 244, 122631. [Google Scholar] [CrossRef]

- Gundupalli, M.P.; Tantayotai, P.; Panakkal, E.J.; Chuetor, S.; Kirdponpattara, S.; Thomas, A.S.S.; Sharma, B.K.; Sriariyanun, M. Hydrothermal pretreatment optimization and deep eutectic solvent pretreatment of lignocellulosic biomass: An integrated approach. Bioresour. Technol. 2022, 17, 100957. [Google Scholar] [CrossRef]

- Yang, Q.; Tang, W.; Li, L.; Huang, M.; Ma, C.; He, Y.-C. Enhancing enzymatic hydrolysis of waste sunflower straw by clean hydrothermal pretreatment. Bioresour. Technol. 2023, 383, 129236. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Li, H.; Sun, S.; Cao, X.; Sun, R. Co-production of oligosaccharides and fermentable sugar from wheat straw by hydrothermal pretreatment combined with alkaline ethanol extraction. Ind. Crops Prod. 2018, 111, 78–85. [Google Scholar] [CrossRef]

- Mou, H.-Y.; Feng, L.; Huang, J.; Qin, C.-R.; Tang, L.; Fan, H.-M.; Liu, J.-A. Hydrothermal combined alkali pretreatment for fractionation the xylan from cotton stalk. Ind. Crops Prod. 2023, 197, 116592. [Google Scholar] [CrossRef]

- Sun, Q.; Chen, W.-J.; Pang, B.; Sun, Z.; Lam, S.S.; Sonne, C.; Yuan, T.-Q. Ultrastructural change in lignocellulosic biomass during hydrothermal pretreatment. Bioresour. Technol. 2021, 341, 125807. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Dong, Y.; Zhang, H.; Liu, J.; Renneckar, S.; Saddler, J. Reduced cellulose accessibility slows down enzyme-mediated hydrolysis of cellulose. Bioresour. Technol. 2023, 371, 128647. [Google Scholar] [CrossRef]

- Tan, X.; Yang, C.; Li, Y.; Zhang, Q.; Sheng, Y.; Lai, C. Lignin fractionation and condensation in aromatic-additive-assisted acidic pretreatment and their influence on lignin’s effect on the enzymatic hydrolysis. Int. J. Bio. Macromol. 2025, 295, 139471. [Google Scholar] [CrossRef]

- Chen, Y.; Ma, C.; Tang, W.; He, Y.-C. Comprehensive understanding of enzymatic saccharification of Betaine:Lactic acid-pretreated sugarcane bagasse. Bioresour. Technol. 2023, 386, 129485. [Google Scholar] [CrossRef]

- Tang, Z.; Wu, C.; Tang, W.; Huang, M.; Ma, C.; He, Y.-C. Enhancing enzymatic saccharification of sunflower straw through optimal tartaric acid hydrothermal pretreatment. Bioresour. Technol. 2023, 385, 129279. [Google Scholar] [CrossRef]

- Nordin, N.; Md Illias, R.; Manas, N.H.A.; Ramli, A.N.M.; Selvasembian, R.; Azelee, N.I.W.; Rajagopal, R.; Thirupathi, A.; Chang, S.W.; Ravindran, B. Highly sustainable cascade pretreatment of low-pressure steam heating and organic acid on pineapple waste biomass for efficient delignification. Fuel 2022, 321, 124061. [Google Scholar] [CrossRef]

- Lu, Y.; Zhang, L.; Zuo, X.; Yan, B.; Li, X.; Yuan, H. Depolymerization of corn stover by urea-hydrothermal pretreatment for efficient biomethane production and microbial community analysis of anaerobic digestion. J. Clean. Prod. 2022, 380, 134978. [Google Scholar] [CrossRef]

- Li, X.; Zheng, Y. Lignin-enzyme interaction: Mechanism, mitigation approach, modeling, and research prospects. Biotechnol. Adv. 2017, 35, 466–489. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Yang, D.; Tang, W.; Ma, C.; He, Y.-C. Improved enzymatic saccharification of bulrush via an efficient combination pretreatment. Bioresour. Technol. 2023, 385, 129369. [Google Scholar] [CrossRef]

- Tang, Z.; Wu, C.; Tang, W.; Ma, C.; He, Y.-C. A novel cetyltrimethylammonium bromide-based deep eutectic solvent pretreatment of rice husk to efficiently enhance its enzymatic hydrolysis. Bioresour. Technol. 2023, 376, 128806. [Google Scholar] [CrossRef]

- Qiu, B.; Shi, J.; Hu, W.; Gao, J.; Li, S.; Chu, H. Construction of hydrothermal liquefaction system for efficient production of biomass-derived furfural: Solvents, catalysts and mechanisms. Fuel 2023, 354, 129278. [Google Scholar] [CrossRef]

- Mennani, M.; Kasbaji, M.; Benhamou, A.A.; Boussetta, A.; Ablouh, E.-H.; Bayousfi, O.; Grimi, N.; Moubarik, A. Effects of direct sulfonation on the catalytic activity and recyclability of novel lignin-based solid acid catalysts from agri-food waste. Int. J. Biol. Macromol. 2023, 230, 123242. [Google Scholar] [CrossRef]

- Jiang, Q.; Yang, G.; Kong, F.; Fatehi, P.; Wang, X. High acid biochar-based solid acid catalyst from corn stalk for lignin hydrothermal degradation. Polymers 2020, 12, 1623. [Google Scholar] [CrossRef]

- Teng, X.; Si, Z.; Li, S.; Yang, Y.; Wang, Z.; Li, G.; Zhao, J.; Cai, D.; Qin, P. Tin-loaded sulfonated rape pollen for efficient catalytic production of furfural from corn stover. Ind. Crops Prod. 2020, 151, 112481. [Google Scholar] [CrossRef]

- Hu, Z.; Zhu, L.; Cai, H.; Huang, M.; Li, J.; Cai, B.; Chen, D.; Zhu, L.; Yang, Y.; Ma, Z. Enhancement of the production of bio-aromatics from bamboo pyrolysis: Wet torrefaction pretreatment coupled with catalytic fast pyrolysis. JAAP 2023, 169, 105818. [Google Scholar] [CrossRef]

- Shen, J.; Gao, R.; He, Y.-C.; Ma, C. Efficient synthesis of furfural from waste biomasses by sulfonated crab shell-based solid acid in a sustainable approach. Ind. Crops Prod. 2023, 202, 116989. [Google Scholar] [CrossRef]

- Xue, X.-X.; Ma, C.-L.; Di, J.-H.; Huo, X.-Y.; He, Y.-C. One-pot chemo-enzymatic conversion of D-xylose to furfuralcohol by sequential dehydration with oxalic acid plus tin-based solid acid and bioreduction with whole-cells. Bioresour. Technol. 2018, 268, 292–299. [Google Scholar] [CrossRef] [PubMed]

- Tang, W.; Wu, X.; Huang, C.; Ling, Z.; Lai, C.; Yong, Q. Natural surfactant-aided dilute sulfuric acid pretreatment of waste wheat straw to enhance enzymatic hydrolysis efficiency. Bioresour. Technol. 2021, 324, 124651. [Google Scholar] [CrossRef]

- Nglesby, M.K.; Zeronian, S.H. Direct dyes as molecular sensors to characterize cellulose substrates. Cellulose 2002, 9, 19–29. [Google Scholar] [CrossRef]

- Sipponen, M.H.; Pihlajaniemi, V.; Littunen, K.; Pastinen, O.; Laakso, S. Determination of surface-accessible acidic hydroxyls and surface area of lignin by cationic dye adsorption. Bioresour. Technol. 2014, 169, 80–87. [Google Scholar] [CrossRef]

| Pretreatment Condition | Glucan, % | Xylan, % | Lignin, % | Lignin Removal, % | ||

|---|---|---|---|---|---|---|

| Catalyst Loading, wt% | Temperature, °C | Time, min | ||||

| Raw | 33.6 ± 0.1 | 19.2 ± 0.2 | 22.2 ± 0.3 | / | ||

| 0 | 180 | 30 | 34.8 ± 0.2 | 13.1 ± 0.2 | 24.7 ± 0.2 | 18.5 ± 0.1 |

| 1.8 | 34.6 ± 0.3 | 12.6 ± 0.1 | 26.2 ± 0.1 | 19.4 ± 0.1 | ||

| 3.6 | 33.6 ± 0.2 | 12.1 ± 0.2 | 27.1 ± 0.1 | 23.5 ± 0.2 | ||

| 5.4 | 32.8 ± 0.3 | 10.9 ± 0.1 | 29.0 ± 0.2 | 36.2 ± 0.2 | ||

| 7.2 | 31.1 ± 0.2 | 10.6 ± 0.1 | 29.2 ± 0.2 | 38.9 ± 0.2 | ||

| 5.4 | 140 | 34.1 ± 0.2 | 15.3 ± 0.3 | 23.5 ± 0.3 | 15.5 ± 0.1 | |

| 160 | 33.6 ± 0.1 | 12.7 ± 0.3 | 26.0 ± 0.2 | 33.5 ± 0.1 | ||

| 180 | 32.8 ± 0.1 | 10.4 ± 0.1 | 27.0 ± 0.2 | 37.5 ± 0.3 | ||

| 200 | 31.6 ± 0.2 | 9.5 ± 0.2 | 29.6 ± 0.3 | 41.0 ± 0.2 | ||

| 220 | 21.5 ± 0.1 | 8.1 ± 0.1 | 31.5 ± 0.1 | 43.5 ± 0.2 | ||

| 200 | 10 | 33.9 ± 0.3 | 10.2 ± 0.3 | 26.6 ± 0.2 | 36.1 ± 0.3 | |

| 20 | 33.7 ± 0.2 | 9.9 ± 0.2 | 28.4 ± 0.2 | 37.8 ± 0.1 | ||

| 30 | 31.6 ± 0.1 | 9.5 ± 0.1 | 29.5 ± 0.3 | 40.1 ± 0.1 | ||

| 60 | 33.8 ± 0.2 | 8.8 ± 0.1 | 28.2 ± 0.2 | 42.9 ± 0.2 | ||

| 120 | 34.1 ± 0.2 | 8.3 ± 0.2 | 28.1 ± 0.2 | 44.3 ± 0.4 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, D.; Yang, Q.; Yang, R.; Zhou, Y.; He, Y. Co-Production of Furfural, Xylo-Oligosaccharides, and Reducing Sugars from Waste Yellow Bamboo Through the Solid Acid-Assisted Hydrothermal Pretreatment. Catalysts 2025, 15, 325. https://doi.org/10.3390/catal15040325

Yang D, Yang Q, Yang R, Zhou Y, He Y. Co-Production of Furfural, Xylo-Oligosaccharides, and Reducing Sugars from Waste Yellow Bamboo Through the Solid Acid-Assisted Hydrothermal Pretreatment. Catalysts. 2025; 15(4):325. https://doi.org/10.3390/catal15040325

Chicago/Turabian StyleYang, Dan, Qizhen Yang, Ruiqing Yang, Yifeng Zhou, and Yucai He. 2025. "Co-Production of Furfural, Xylo-Oligosaccharides, and Reducing Sugars from Waste Yellow Bamboo Through the Solid Acid-Assisted Hydrothermal Pretreatment" Catalysts 15, no. 4: 325. https://doi.org/10.3390/catal15040325

APA StyleYang, D., Yang, Q., Yang, R., Zhou, Y., & He, Y. (2025). Co-Production of Furfural, Xylo-Oligosaccharides, and Reducing Sugars from Waste Yellow Bamboo Through the Solid Acid-Assisted Hydrothermal Pretreatment. Catalysts, 15(4), 325. https://doi.org/10.3390/catal15040325