Applications and Perspectives of Life Cycle Assessment in the Green Design of Single-Atom Catalysts

Abstract

1. Introduction

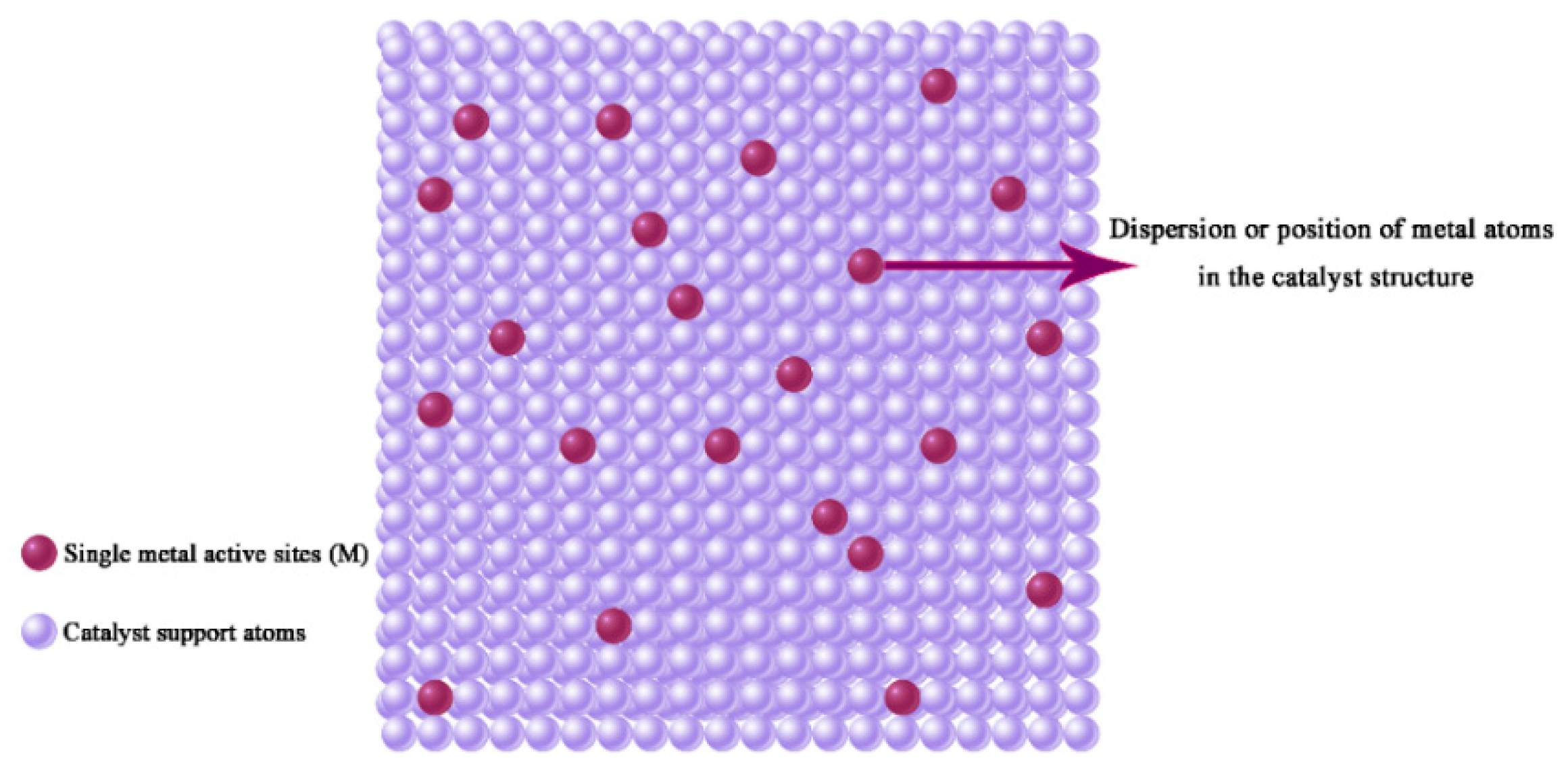

2. SACs and Their Environmental Implications

2.1. Performance Advantages

2.2. Synthetic Strategies

2.3. Practical Applications

2.4. Potential Ecological and Health Risks

3. LCA Methods and Applications in Catalyst Research

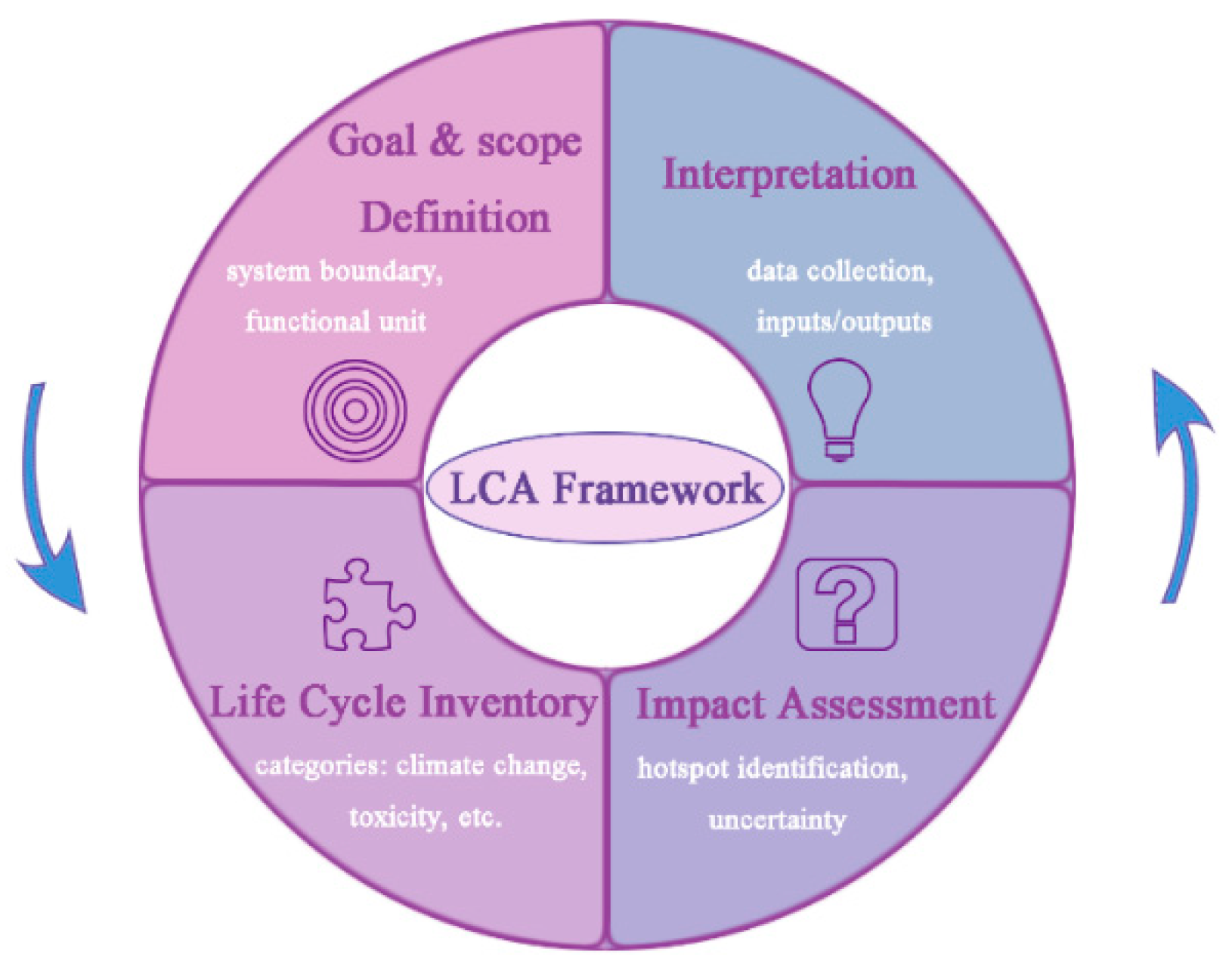

3.1. Fundamentals of LCA

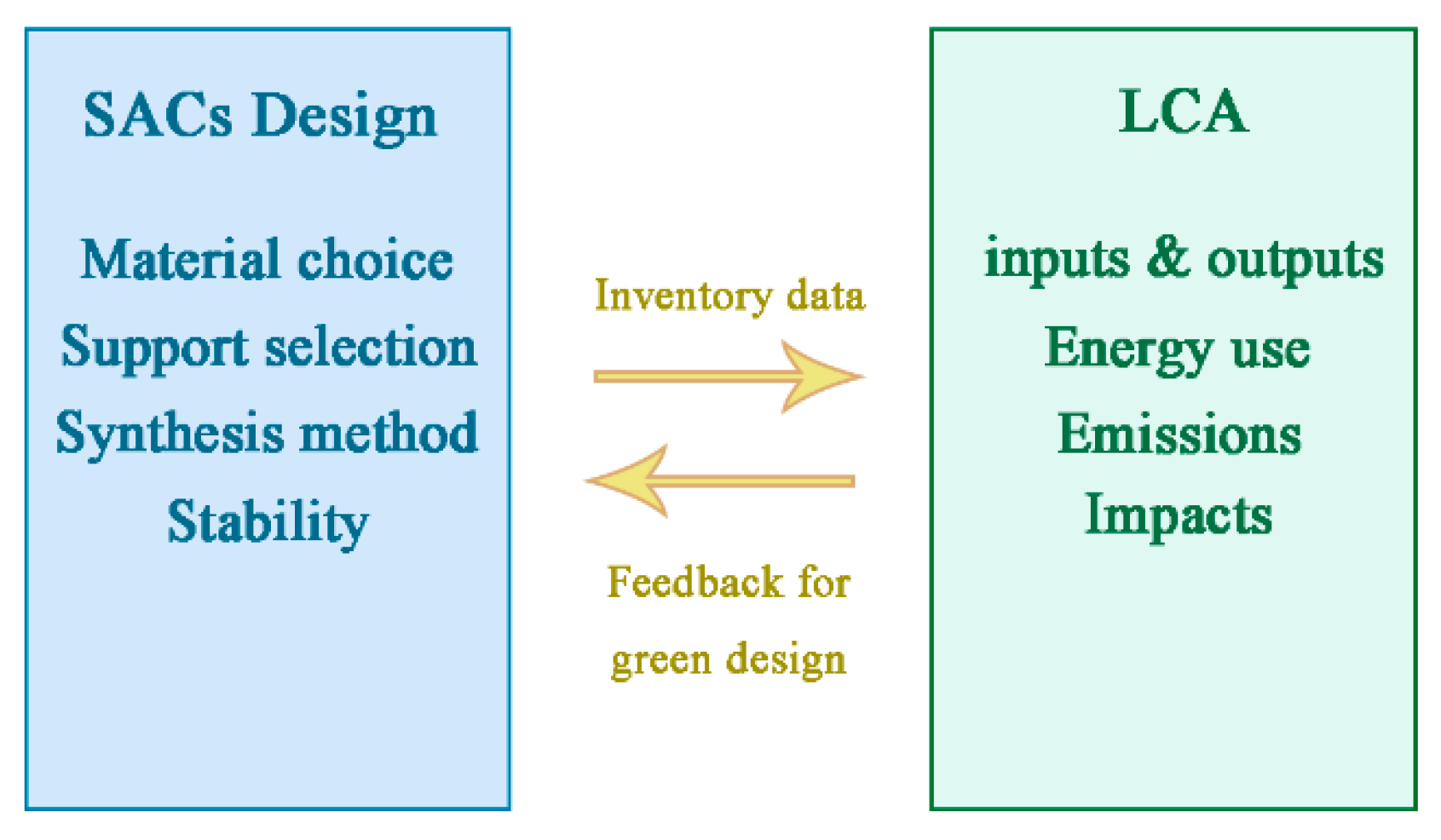

3.2. Feasibility of Applying LCA to SACs

3.3. The Necessity of LCA in SAC Research

4. Exploring an LCA Framework for the Sustainable Design of SACs

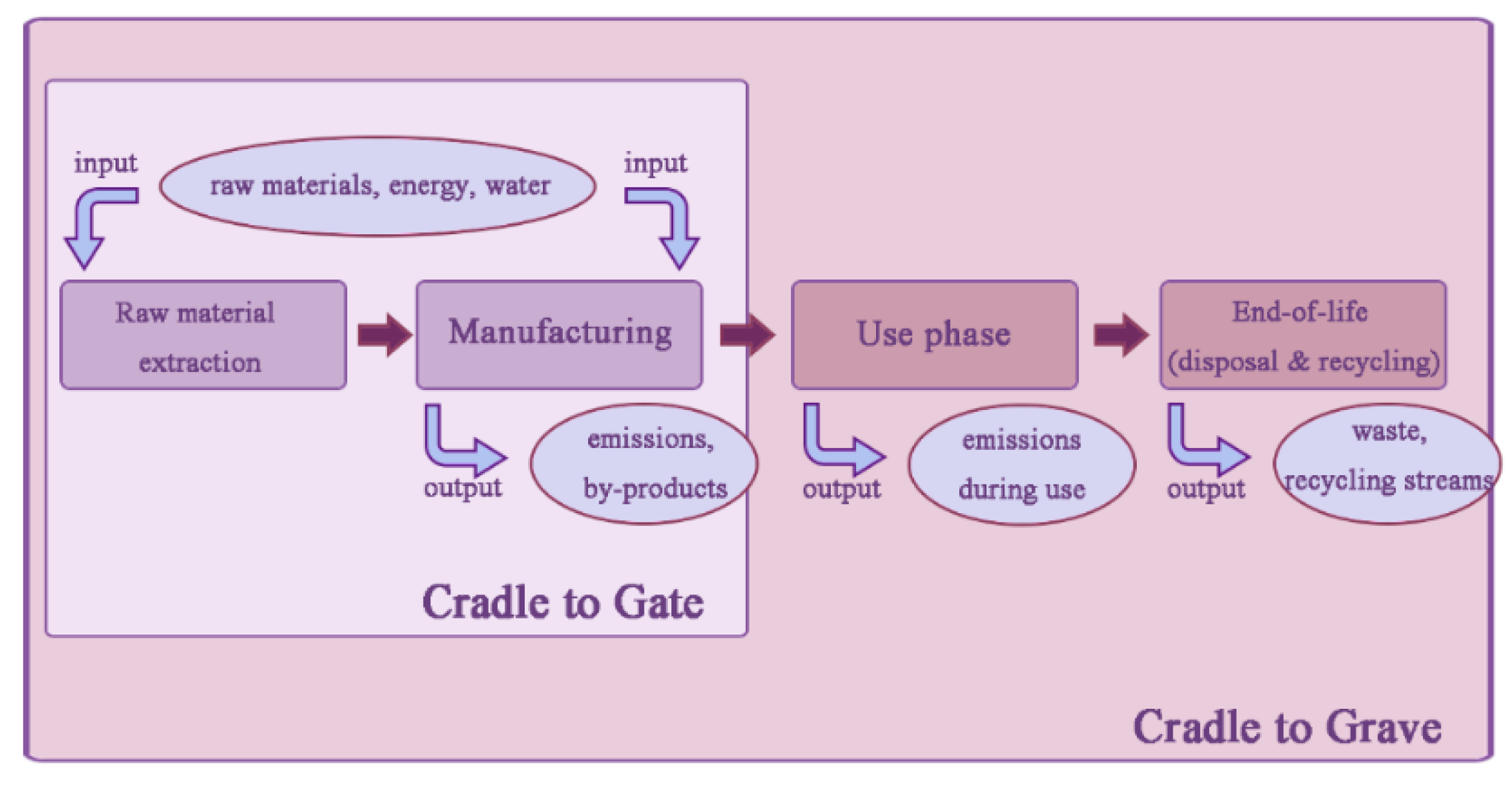

4.1. Defining System Boundaries and Functional Units

4.2. Building the Life Cycle Inventory (LCI)

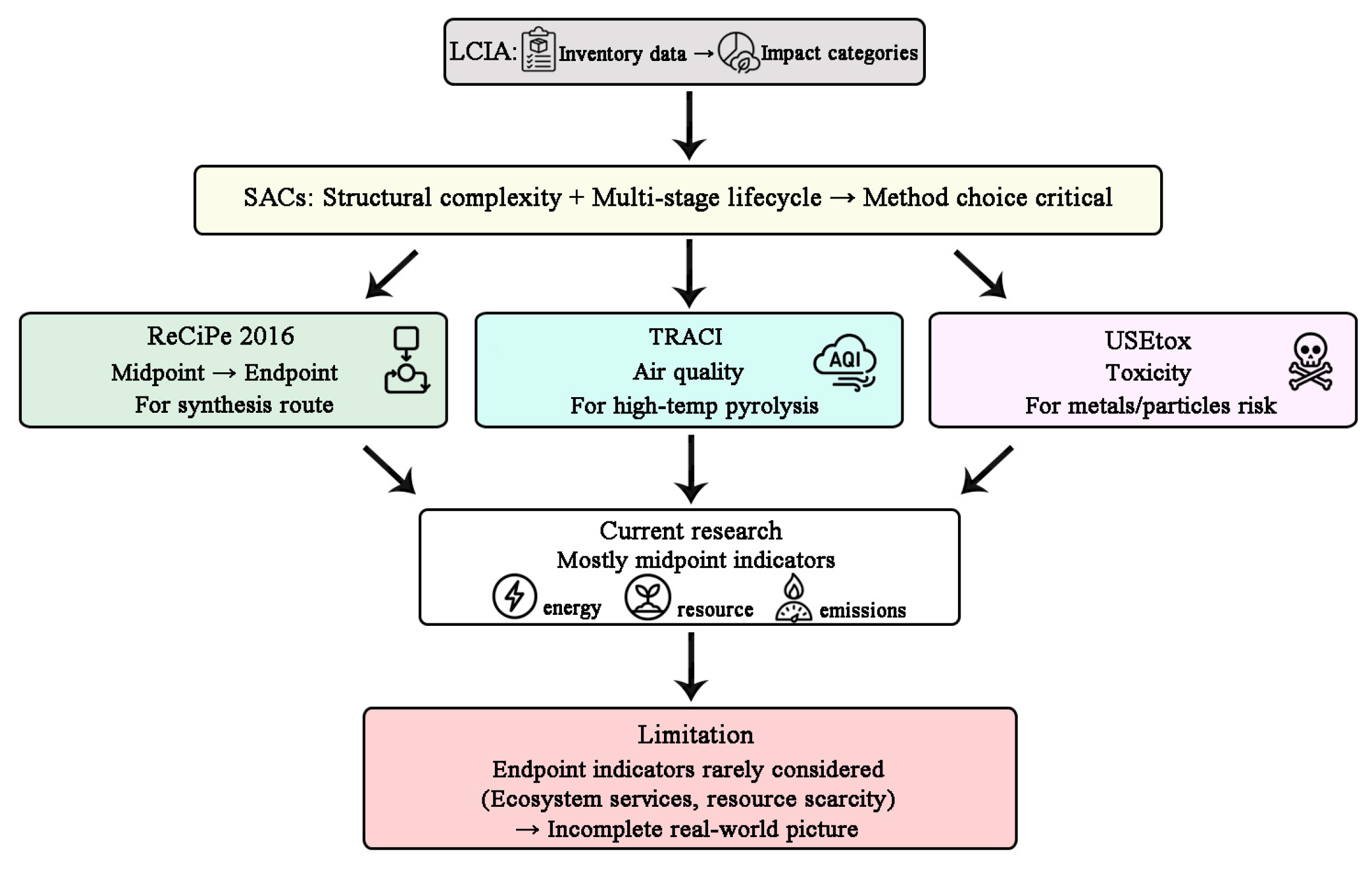

4.3. Life Cycle Impact Assessment (LCIA)

4.4. Interpretation and Its Role in SAC Design

5. Prospects and Limitations

5.1. Prospects

5.2. Limitations

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; Feng, C.; Li, X.; Liu, C.; Wang, D.; Si, R.; Yang, J.; Zhou, S.; Zeng, J. In-Situ Generated High-Valent Iron Single-Atom Catalyst for Efficient Oxygen Evolution. Nano Lett. 2021, 21, 4795–4801. [Google Scholar] [CrossRef]

- Chen, Z.; Vorobyeva, E.; Mitchell, S.; Fako, E.; Ortuño, M.A.; López, N.; Collins, S.M.; Midgley, P.A.; Richard, S.; Vilé, G.; et al. A heterogeneous single-atom palladium catalyst surpassing homogeneous systems for Suzuki coupling. Nat. Nanotechnol. 2018, 13, 702–707. [Google Scholar] [CrossRef]

- Chu, P.; Zhang, L.; Wang, Z.; Wei, L.; Liu, Y.; Dai, H.; Guo, G.; Duan, E.; Zhao, Z.; Deng, J. Regulation Lattice Oxygen Mobility via Dual Single Atoms for Simultaneously Enhancing VOC Oxidation and NOx Reduction. Environ. Sci. Technol. 2024, 58, 17475–17484. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Wang, Z.; Lin, H.; Liu, Y.; Dai, H.; Deng, J. Catalytic oxidation of volatile organic compounds over supported noble metal and single atom catalysts: A review. J. Environ. Sci. 2025, 155, 858–888. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Feng, C.; Wang, D.; Zhou, S.; Wang, R.; Hu, S.; Li, H.; Zuo, M.; Kong, Y.; Bao, J.; et al. Selectively anchoring single atoms on specific sites of supports for improved oxygen evolution. Nat. Commun. 2022, 13, 2473. [Google Scholar] [CrossRef] [PubMed]

- Wang, A.; Li, J.; Zhang, T. Heterogeneous single-atom catalysis. Nat. Rev. Chem. 2018, 2, 65–81. [Google Scholar] [CrossRef]

- Ji, S.; Chen, Y.; Wang, X.; Zhang, Z.; Wang, D.; Li, Y. Chemical Synthesis of Single Atomic Site Catalysts. Chem. Rev. 2020, 120, 11900–11955. [Google Scholar] [CrossRef]

- Li, X.; Pereira-Hernández, X.I.; Chen, Y.; Xu, J.; Zhao, J.; Pao, C.-W.; Fang, C.-Y.; Zeng, J.; Wang, Y.; Gates, B.C.; et al. Functional CeOx nanoglues for robust atomically dispersed catalysts. Nature 2022, 611, 284–288. [Google Scholar] [CrossRef]

- Luo, H.; Tyrrell, H.; Bai, J.; Muazu, R.I.; Long, X. Fundamental, technical and environmental overviews of plastic chemical recycling. Green Chem. 2024, 26, 11444–11467. [Google Scholar] [CrossRef]

- Aromaa-Stubb, R.; Rinne, M.; Lundström, M. Life Cycle Assessment of Cobalt Catalyst Production and Recycling. J. Sustain. Metall. 2024, 10, 1795–1806. [Google Scholar] [CrossRef]

- Jiao, H.; Ali, S.S.; Alsharbaty, M.H.M.; Elsamahy, T.; Abdelkarim, E.; Schagerl, M.; Al-Tohamy, R.; Sun, J. A critical review on plastic waste life cycle assessment and management: Challenges, research gaps, and future perspectives. Ecotoxicol. Environ. Saf. 2024, 271, 115942. [Google Scholar] [CrossRef]

- Matzen, M.; Demirel, Y. Methanol and dimethyl ether from renewable hydrogen and carbon dioxide: Alternative fuels production and life-cycle assessment. J. Clean. Prod. 2016, 139, 1068–1077. [Google Scholar] [CrossRef]

- Bajada, M.A.; Tschulkow, M.; Vilé, G. Sustainability assessment of single-atom catalysts in the transition to greener chemical processes. Cell Rep. Sustain. 2025, 2, 100286. [Google Scholar] [CrossRef]

- Weber, M.; Boysen, N.; Graniel, O.; Sekkat, A.; Dussarrat, C.; Wiff, P.; Devi, A.; Muñoz-Rojas, D. Assessing the Environmental Impact of Atomic Layer Deposition (ALD) Processes and Pathways to Lower It. ACS Mater. Au 2023, 3, 274–298. [Google Scholar] [CrossRef] [PubMed]

- Kong, L.; Wang, L.; Li, F.; Guo, J. Toward product green design of modeling, assessment, optimization, and tools: A comprehensive review. Int. J. Adv. Manuf. Technol. 2022, 122, 2217–2234. [Google Scholar] [CrossRef]

- Qiao, B.; Wang, A.; Yang, X.; Allard, L.F.; Jiang, Z.; Cui, Y.; Liu, J.; Li, J.; Zhang, T. Single-atom catalysis of CO oxidation using Pt1/FeOx. Nat. Chem. 2011, 3, 634–641. [Google Scholar] [CrossRef]

- Liang, X.; Fu, N.; Yao, S.; Li, Z.; Li, Y. The Progress and Outlook of Metal Single-Atom-Site Catalysis. J. Am. Chem. Soc. 2022, 144, 18155–18174. [Google Scholar] [CrossRef]

- Liu, J. Catalysis by Supported Single Metal Atoms. ACS Catal. 2017, 7, 34–59. [Google Scholar] [CrossRef]

- Liu, D.; He, Q.; Ding, S.; Song, L. Structural Regulation and Support Coupling Effect of Single-Atom Catalysts for Heterogeneous Catalysis. Adv. Energy Mater. 2020, 10, 2001482. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, W.; Cao, D.; Cheng, D. Carbon-based material-supported single-atom catalysts for energy conversion. iScience 2022, 25, 104367. [Google Scholar] [CrossRef]

- Rocha, G.F.S.R.; da Silva, M.A.R.; Rogolino, A.; Diab, G.A.A.; Noleto, L.F.G.; Antonietti, M.; Teixeira, I.F. Carbon nitride based materials: More than just a support for single-atom catalysis. Chem. Soc. Rev. 2023, 52, 4878–4932. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Shen, K.; Chen, F.; Li, Y. Metal–Organic Frameworks as a Good Platform for the Fabrication of Single-Atom Catalysts. ACS Catal. 2020, 10, 6579–6586. [Google Scholar] [CrossRef]

- Mitchell, S.; Pérez-Ramírez, J. Single atom catalysis: A decade of stunning progress and the promise for a bright future. Nat. Commun. 2020, 11, 4302. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; Han, W.; Han, W.; Dong, F.; Tang, Z. Recent advances and future perspectives in MOF-derived single-atom catalysts and their application: A review. J. Mater. Chem. A 2023, 11, 3315–3363. [Google Scholar] [CrossRef]

- Mashkovsky, I.S.; Markov, P.V.; Rassolov, A.V.; Patil, E.D.; Stakheev, A.Y. Progress in single-atom methodology in modern catalysis. Russ. Chem. Rev. 2023, 92, RCR5087. [Google Scholar] [CrossRef]

- Zhao, S.; Cheng, Y.; Veder, J.-P.; Johannessen, B.; Saunders, M.; Zhang, L.; Liu, C.; Chisholm, M.F.; De Marco, R.; Liu, J.; et al. One-Pot Pyrolysis Method to Fabricate Carbon Nanotube Supported Ni Single-Atom Catalysts with Ultrahigh Loading. ACS Appl. Energy Mater. 2018, 1, 5286–5297. [Google Scholar] [CrossRef]

- Luo, J.; Waterhouse, G.I.N.; Peng, L.; Chen, Q. Recent progress in high-loading single-atom catalysts and their applications. Ind. Chem. Mater. 2023, 1, 486–500. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, H.; Li, C.; Wang, X.; Liu, J.; Zhang, X. Non-noble metal single-atom catalysts prepared by wet chemical method and their applications in electrochemical water splitting. J. Energy Chem. 2020, 47, 333–345. [Google Scholar] [CrossRef]

- Guo, J.; Liu, H.; Li, D.; Wang, J.; Djitcheu, X.; He, D.; Zhang, Q. A minireview on the synthesis of single atom catalysts. RSC Adv. 2022, 12, 9373–9394. [Google Scholar] [CrossRef]

- Fonseca, J.; Lu, J. Single-Atom Catalysts Designed and Prepared by the Atomic Layer Deposition Technique. ACS Catal. 2021, 11, 7018–7059. [Google Scholar] [CrossRef]

- He, H.; Wang, H.H.; Liu, J.; Liu, X.; Li, W.; Wang, Y. Research Progress and Application of Single-Atom Catalysts: A Review. Molecules 2021, 26, 6501. [Google Scholar] [CrossRef] [PubMed]

- Han, G.-F.; Li, F.; Chen, Z.-W.; Coppex, C.; Kim, S.-J.; Noh, H.-J.; Fu, Z.; Lu, Y.; Singh, C.V.; Siahrostami, S.; et al. Mechanochemistry for ammonia synthesis under mild conditions. Nat. Nanotechnol. 2021, 16, 325–330. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Feng, C.; Liu, C.; Zuo, M.; Qin, L.; Yan, X.; Xing, Y.; Li, H.; Si, R.; Zhou, S.; et al. Electrochemical deposition as a universal route for fabricating single-atom catalysts. Nat. Commun. 2020, 11, 1215. [Google Scholar] [CrossRef] [PubMed]

- Ntouros, V.; Kousis, I.; Papadaki, D.; Pisello, A.L.; Assimakopoulos, M.N. Life Cycle Assessment on Different Synthetic Routes of ZIF-8 Nanomaterials. Energies 2021, 14, 4998. [Google Scholar] [CrossRef]

- Cheng, N.; Zhang, L.; Doyle-Davis, K.; Sun, X. Single-Atom Catalysts: From Design to Application. Electrochem. Energy Rev. 2019, 2, 539–573. [Google Scholar] [CrossRef]

- Hu, H.; Wang, J.; Tao, P.; Song, C.; Shang, W.; Deng, T.; Wu, J. Stability of single-atom catalysts for electrocatalysis. J. Mater. Chem. A 2022, 10, 5835–5849. [Google Scholar] [CrossRef]

- Su, R.; Wang, Z.; Liu, Z.; Chen, Y.; Wang, H.; Dai, X.; Ge, X.; Luo, Y. Single atoms in environmental catalysis: Breakthroughs in synthesis and application. J. Water Process Eng. 2024, 68, 106319. [Google Scholar] [CrossRef]

- Ding, G.; Hao, L.; Xu, H.; Wang, L.; Chen, J.; Li, T.; Tu, X.; Zhang, Q. Atomically dispersed palladium catalyses Suzuki–Miyaura reactions under phosphine-free conditions. Commun. Chem. 2020, 3, 43. [Google Scholar] [CrossRef]

- Yu, X.; Deng, J.; Liu, Y.; Jing, L.; Hou, Z.; Pei, W.; Dai, H. Single-Atom Catalysts: Preparation and Applications in Environmental Catalysis. Catalysts 2022, 12, 1239. [Google Scholar] [CrossRef]

- Teng, J.; Xu, J.H.; Liu, X.F.; Xu, X.; Sun, W.X.; Liu, G. Single-atom catalysis for advanced oxidation and reduction systems in water decontamination. Rare Met. 2024, 43, 3576–3606. [Google Scholar] [CrossRef]

- Wu, Z.; Xiong, Z.; Huang, B.; Yao, G.; Zhan, S.; Lai, B. Long-range interactions driving neighboring Fe–N4 sites in Fenton-like reactions for sustainable water decontamination. Nat. Commun. 2024, 15, 7775. [Google Scholar] [CrossRef]

- Ye, Q.; Wang, P.; Liang, Y.; Li, R.; Shi, Z. Modeling the equilibrium and kinetics of heavy metals reactions with dissolved organic matter. Appl. Geochem. 2025, 181, 106300. [Google Scholar] [CrossRef]

- Liu, S.; Shi, J.; Wang, J.; Dai, Y.; Li, H.; Li, J.; Liu, X.; Chen, X.; Wang, Z.; Zhang, P. Interactions Between Microplastics and Heavy Metals in Aquatic Environments: A Review. Front. Microbiol. 2021, 12, 652520. [Google Scholar] [CrossRef]

- Zimmermann, S.; Wolff, C.; Sures, B. Toxicity of platinum, palladium and rhodium to Daphnia magna in single and binary metal exposure experiments. Environ. Pollut. 2017, 224, 368–376. [Google Scholar] [CrossRef]

- Neu-Baker, N.M.; Eastlake, A.; Hodson, L. Results of the 2019 Survey of Engineered Nanomaterial Occupational Health and Safety Practices. Int. J. Environ. Res. Public Health 2022, 19, 7676. [Google Scholar] [CrossRef] [PubMed]

- Cui, Y.; Ren, C.; Wu, M.; Chen, Y.; Li, Q.; Ling, C.; Wang, J. Structure–Stability Relation of Single-Atom Catalysts under Operating Conditions of CO2 Reduction. J. Am. Chem. Soc. 2024, 146, 29169–29176. [Google Scholar] [CrossRef] [PubMed]

- ISO 14040:2006(en); Environmental Management—Life Cycle Assessment—Principles and Framework [EB/OL]. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:14040:ed-2:v1:en (accessed on 4 July 2025).

- ISO 14044:2006(en); Environmental Management—Life Cycle Assessment—Requirements and Guidelines [EB/OL]. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:14044:ed-1:v1:en (accessed on 4 July 2025).

- Crawford, R.H.; Bontinck, P.A.; Stephan, A.; Wiedmann, T.; Yu, M. Hybrid life cycle inventory methods—A review. J. Clean. Prod. 2018, 172, 1273–1288. [Google Scholar] [CrossRef]

- Yang, Y.; Heijungs, R.; Brandão, M. Hybrid life cycle assessment (LCA) does not necessarily yield more accurate results than process-based LCA. J. Clean. Prod. 2017, 150, 237–242. [Google Scholar] [CrossRef]

- Neupane, B.; Belkadi, F.; Formentini, M.; Rozière, E.; Hilloulin, B.; Abdolmaleki, S.F.; Mensah, M. Machine learning algorithms for supporting life cycle assessment studies: An analytical review. Sustain. Prod. Consum. 2025, 56, 37–53. [Google Scholar] [CrossRef]

- Life Cycle Assessment (LCA) Explained [EB/OL]. (17 July 2022). Available online: https://pre-sustainability.com/articles/life-cycle-assessment-lca-basics/ (accessed on 7 October 2025).

- Kralisch, D.; Ott, D.; Gericke, D. Rules and benefits of Life Cycle Assessment in green chemical process and synthesis design: A tutorial review. Green Chem. 2015, 17, 123–145. [Google Scholar] [CrossRef]

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkeler, D.; Norris, G.; Rydberg, T.; Schmidt, W.-P.; Suh, S.; Werdema, B.P.; Pennington, D.W. Life cycle assessment. Environ. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef]

- Nizam, N.U.M.; Hanafiah, M.M.; Woon, K.S. A Content Review of Life Cycle Assessment of Nanomaterials: Current Practices, Challenges, and Future Prospects. Nanomaterials 2021, 11, 3324. [Google Scholar] [CrossRef] [PubMed]

- Faust Akl, D.; Poier, D.; D’Angelo, S.C.; Araújo, T.P.; Tulus, V.; Safonova, O.V.; Mitchell, S.; Marti, R.; Guillén-Gosálbez, G.; Pérez-Ramírez, J. Assessing the environmental benefit of palladium-based single-atom heterogeneous catalysts for Sonogashira coupling. Green Chem. 2022, 24, 6879–6888. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, S.; Esteves Da Silva, J.C.G.; Pinto Da Silva, L. Comparative life cycle assessment of high-yield synthesis routes for carbon dots. NanoImpact 2021, 23, 100332. [Google Scholar] [CrossRef] [PubMed]

- Cellura, M.; Luu, L.Q.; Guarino, F.; Longo, S. A review on life cycle environmental impacts of emerging solar cells. Sci. Total Environ. 2024, 908, 168019. [Google Scholar] [CrossRef]

- Quan, J.; Zhao, S.; Song, D.; Wang, T.; He, W.; Li, G. Comparative life cycle assessment of LFP and NCM batteries including the secondary use and different recycling technologies. Sci. Total Environ. 2022, 819, 153105. [Google Scholar] [CrossRef]

- Chen, W.; Bao, M.; Meng, F.; Ma, B.; Feng, L.; Zhang, X.; Qiu, Z.; Gao, S.; Zhong, R.; Xi, S.; et al. Designer topological-single-atom catalysts with site-specific selectivity. Nat. Commun. 2025, 16, 574. [Google Scholar] [CrossRef]

- Wang, K.H.; Wen, C.P.; Long, H.; Moldovan, N.C. Towards sustainable development: Exploring the spillover effects of green technology innovation on energy markets and economic cycles. Technol. Forecast. Soc. Change 2024, 203, 123368. [Google Scholar] [CrossRef]

- Nuss, P.; Eckelman, M.J. Life Cycle Assessment of Metals: A Scientific Synthesis. PLoS ONE 2014, 9, e101298. [Google Scholar] [CrossRef]

- Rinne, M.; Elomaa, H.; Lundström, M. Life cycle assessment and process simulation of prospective battery-grade cobalt sulfate production from Co-Au ores in Finland. Int. J. Life Cycle Assess. 2021, 26, 2127–2142. [Google Scholar] [CrossRef]

- Yuan, W.; Ma, Y.; Wu, H.; Cheng, L. Single-atom catalysts for CO oxidation, CO2 reduction, and O2 electrochemistry. J. Energy Chem. 2022, 65, 254–279. [Google Scholar] [CrossRef]

- Farnesi Camellone, M.; Dvořák, F.; Vorokhta, M.; Tovt, A.; Khalakhan, I.; Johánek, V.; Skála, T.; Matolínová, I.; Fabris, S.; Mysliveček, J. Adatom and Nanoparticle Dynamics on Single-Atom Catalyst Substrates. ACS Catal. 2022, 12, 4859–4871. [Google Scholar] [CrossRef]

- Chen, Z.; Song, J.; Zhang, R.; Li, R.; Hu, Q.; Wei, P.; Xi, S.; Zhou, X.; Nguyen, P.T.T.; Duong, H.M.; et al. Addressing the quantitative conversion bottleneck in single-atom catalysis. Nat. Commun. 2022, 13, 2807. [Google Scholar] [CrossRef] [PubMed]

- Pedersen, A.; Pandya, J.; Leonzio, G.; Serov, A.; Bernardi, A.; Stephens, I.E.L.; Titirici, M.-M.; Petit, C.; Chachuat, B. Comparative techno-economic and life-cycle analysis of precious versus non-precious metal electrocatalysts: The case of PEM fuel cell cathodes. Green Chem. 2023, 25, 10458–10471. [Google Scholar] [CrossRef]

- Li, T.; Zhang, H.; Liu, Z.; Ke, Q.; Alting, L. A system boundary identification method for life cycle assessment. Int. J. Life Cycle Assess. 2014, 19, 646–660. [Google Scholar] [CrossRef]

- Amin, M.; Shah, H.H.; Naveed, A.B.; Iqbal, A.; Gamil, Y.; Najeh, T. Life cycle assessment of iron-biomass supported catalyst for Fischer Tropsch synthesis. Front. Chem. 2024, 12, 1374739. [Google Scholar] [CrossRef]

- Agarski, B.; Nikolić, V.; Kamberović, Ž.; Anđić, Z.; Kosec, B.; Budak, I. Comparative life cycle assessment of Ni-based catalyst synthesis processes. J. Clean. Prod. 2017, 162, 7–15. [Google Scholar] [CrossRef]

- Gandiglio, M.; De Sario, F.; Lanzini, A.; Bobba, S.; Santarelli, M.; Blengini, G.A. Life Cycle Assessment of a Biogas-Fed Solid Oxide Fuel Cell (SOFC) Integrated in a Wastewater Treatment Plant. Energies 2019, 12, 1611. [Google Scholar] [CrossRef]

- Righi, S.; Baioli, F.; Pozzo, A.D.; Tugnoli, A. Integrating Life Cycle Inventory and Process Design Techniques for the Early Estimate of Energy and Material Consumption Data. Energies 2018, 11, 970. [Google Scholar] [CrossRef]

- Herrmann, I.T.; Moltesen, A. Does it matter which Life Cycle Assessment (LCA) tool you choose?—A comparative assessment of SimaPro and GaBi. J. Clean. Prod. 2015, 86, 163–169. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Igos, E.; Benetto, E.; Meyer, R.; Baustert, P.; Othoniel, B. How to treat uncertainties in life cycle assessment studies? Int. J. Life Cycle Assess. 2019, 24, 794–807. [Google Scholar] [CrossRef]

- Loy, A.C.M. Elucidation of single atom catalysts for energy and sustainable chemical production: Synthesis, characterization and frontier science. Prog. Energy Combust. Sci. 2023, 96, 101074. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- USEPAO. Tool for Reduction and Assessment of Chemicals and Other Environmental Impacts (TRACI) [EB/OL]. (17 December 2015). Available online: https://www.epa.gov/chemical-research/tool-reduction-and-assessment-chemicals-and-other-environmental-impacts-traci (accessed on 21 August 2025).

- Rosenbaum, R.K.; Bachmann, T.M.; Gold, L.S.; Huijbregts, M.A.; Jolliet, O.; Juraske, R.; Koehler, A.; Larsen, H.F.; MacLeod, M.; Margni, M.; et al. USEtox—The UNEP-SETAC toxicity model: Recommended characterisation factors for human toxicity and freshwater ecotoxicity in life cycle impact assessment. Int. J. Life Cycle Assess. 2008, 13, 532–546. [Google Scholar] [CrossRef]

- Caldeira, C.; Abbate, E.; Moretti, C.; Mancini, L.; Sala, S. Safe and sustainable chemicals and materials: A review of sustainability assessment frameworks. Green Chem. 2024, 26, 7456–7477. [Google Scholar] [CrossRef]

- Stamp, A.; Althaus, H.-J.; Wäger, P.A. Limitations of applying life cycle assessment to complex co-product systems: The case of an integrated precious metals smelter-refinery. Resour. Conserv. Recycl. 2013, 80, 85–96. [Google Scholar] [CrossRef]

- Van Zelm, R.; Hennequin, T.; Huijbregts, M.A.J. Performing life cycle impact assessment with the midpoint and endpoint method ReCiPe. Nat. Protoc. 2025; ahead of print. [Google Scholar]

- Sala, S.; Laurent, A.; Vieira, M.; Van Hoof, G. Implications of LCA and LCIA choices on interpretation of results and on decision support. Int. J. Life Cycle Assess. 2020, 25, 2311–2314. [Google Scholar] [CrossRef]

- Adams, N.; Allacker, K. Parameter sensitivity and data uncertainty assessment of the cradle-to-gate environmental impact of state-of-the-art passive daytime radiative cooling materials. Environ. Sci. Eur. 2025, 37, 53. [Google Scholar] [CrossRef]

- Soleymani Angili, T.; Grzesik, K.; Jerzak, W. Comparative Life Cycle Assessment of Catalytic Intermediate Pyrolysis of Rapeseed Meal. Energies 2023, 16, 2004. [Google Scholar] [CrossRef]

- Kralisch, D.; Ott, D.; Kressirer, S.; Staffel, C.; Sell, I.; Krtschill, U.; Loeb, P. Bridging sustainability and intensified flow processing within process design for sustainable future factories. Green Process. Synth. 2013, 2, 465–478. [Google Scholar] [CrossRef]

- Kiemel, S.; Rietdorf, C.; Schutzbach, M.; Miehe, R. How to Simplify Life Cycle Assessment for Industrial Applications—A Comprehensive Review. Sustainability 2022, 14, 15704. [Google Scholar] [CrossRef]

- Kleinekorte, J.; Kleppich, J.; Fleitmann, L.; Beckert, V.; Blodau, L.; Bardow, A. APPROPRIATE Life Cycle Assessment: A PROcess-Specific, PRedictive Impact AssessmenT Method for Emerging Chemical Processes. ACS Sustain. Chem. Eng. 2023, 11, 9303–9319. [Google Scholar] [CrossRef]

- Mahmud, R.; Moni, S.M.; High, K.; Carbajales-Dale, M. Integration of techno-economic analysis and life cycle assessment for sustainable process design—A review. J. Clean. Prod. 2021, 317, 128247. [Google Scholar] [CrossRef]

- Zimmermann, A.W.; Langhorst, T.; Moni, S.; Schaidle, J.A.; Bensebaa, F.; Bardow, A. Life-Cycle and Techno-Economic Assessment of Early-Stage Carbon Capture and Utilization Technologies—A Discussion of Current Challenges and Best Practices. Front. Clim. 2022, 4, 841907. [Google Scholar] [CrossRef]

- Popowicz, M.; Katzer, N.J.; Kettele, M.; Schöggl, J.-P.; Baumgartner, R.J. Digital technologies for life cycle assessment: A review and integrated combination framework. Int. J. Life Cycle Assess. 2025, 30, 405–428. [Google Scholar] [CrossRef]

- Köck, B.; Friedl, A.; Loaiza, S.S.; Wukovits, W.; Mihalyi-Schneider, B. Automation of Life Cycle Assessment—A Critical Review of Developments in the Field of Life Cycle Inventory Analysis. Sustainability 2023, 15, 5531. [Google Scholar] [CrossRef]

- Smith, L.; Ibn-Mohammed, T.; Koh, L.; Reaney, I.M. Life cycle assessment of functional materials and devices: Opportunities, challenges, and current and future trends. J. Am. Ceram. Soc. 2019, 102, 7037–7064. [Google Scholar] [CrossRef]

- Wang, K.; Tong, R.; Zhai, Q.; Lyu, G.; Li, Y. A Critical Review of Life Cycle Assessments on Bioenergy Technologies: Methodological Choices, Limitations, and Suggestions for Future Studies. Sustainability 2025, 17, 3415. [Google Scholar] [CrossRef]

| Data Source | Type | Advantages | Limitations | Example Use |

|---|---|---|---|---|

| Experimental measurements | Primary | High accuracy | Limited scale | Lab-scale synthesis emissions |

| Ecoinvent/GaBi databases | Secondary | Comprehensive coverage | Poor specificity for SACs | Generic process modeling |

| Process simulations | Modeled | Enables extrapolation | Requires assumptions | Reactor-scale modeling |

| Hybrid models | Integrated | Combines accuracy and scope | Complex to calibrate | SAC synthesis route analysis |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, H.; Guo, R.; Guo, C.; Lv, N.; Xu, J. Applications and Perspectives of Life Cycle Assessment in the Green Design of Single-Atom Catalysts. Catalysts 2025, 15, 1007. https://doi.org/10.3390/catal15111007

Gao H, Guo R, Guo C, Lv N, Xu J. Applications and Perspectives of Life Cycle Assessment in the Green Design of Single-Atom Catalysts. Catalysts. 2025; 15(11):1007. https://doi.org/10.3390/catal15111007

Chicago/Turabian StyleGao, He, Ruonan Guo, Changsheng Guo, Ningqing Lv, and Jian Xu. 2025. "Applications and Perspectives of Life Cycle Assessment in the Green Design of Single-Atom Catalysts" Catalysts 15, no. 11: 1007. https://doi.org/10.3390/catal15111007

APA StyleGao, H., Guo, R., Guo, C., Lv, N., & Xu, J. (2025). Applications and Perspectives of Life Cycle Assessment in the Green Design of Single-Atom Catalysts. Catalysts, 15(11), 1007. https://doi.org/10.3390/catal15111007