2.2. Cracking FT Wax on Different Zeolite Catalysts

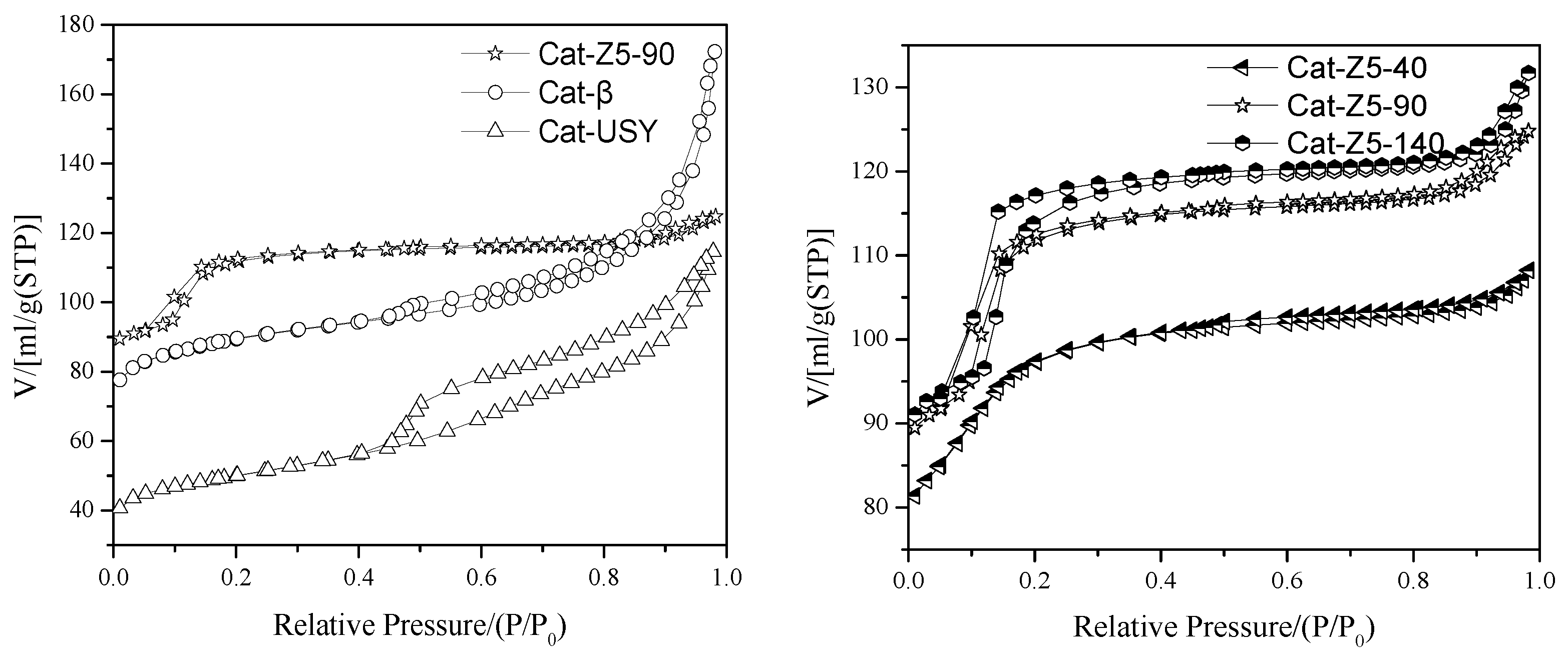

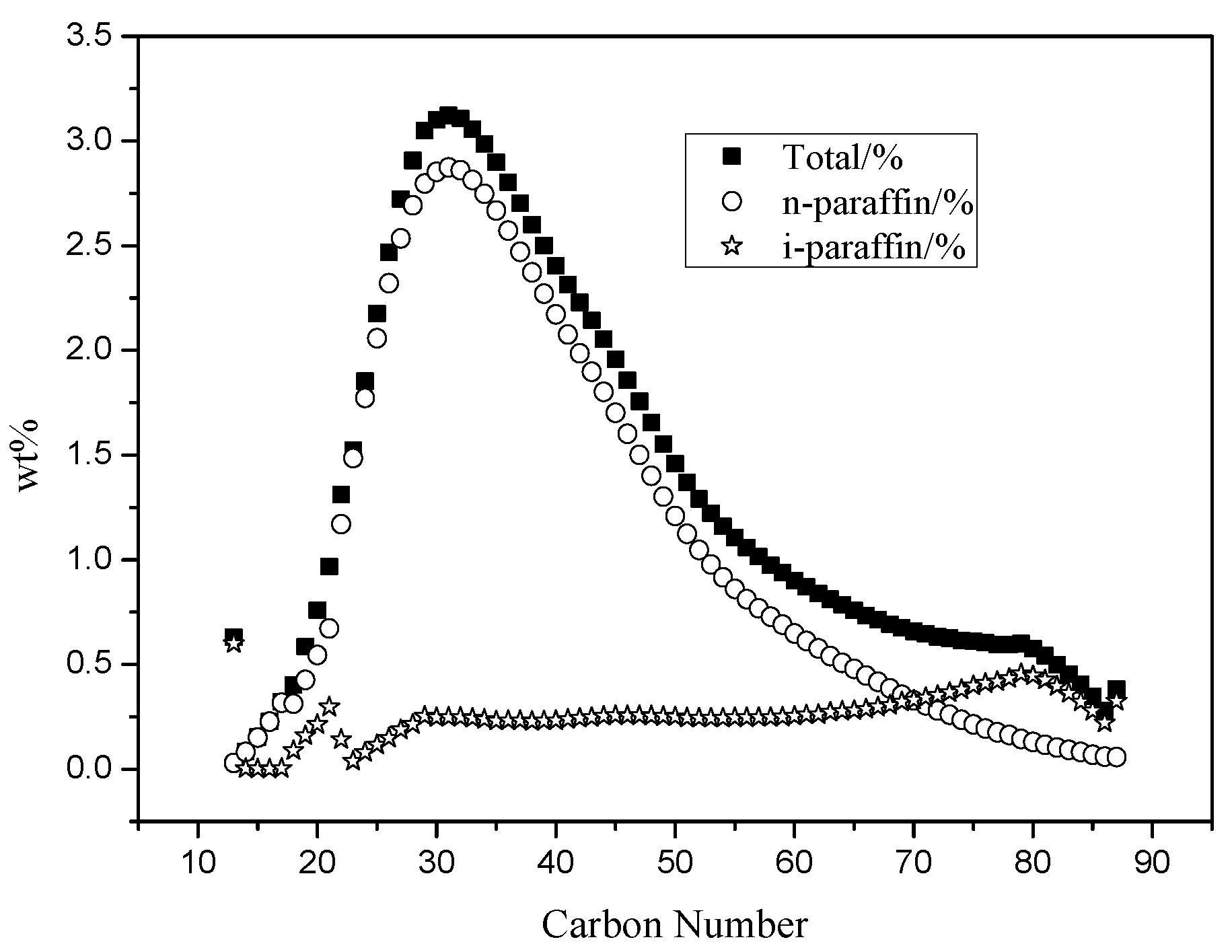

Table 3 presents the conversion and product distribution of cracking FT wax using catalysts with different zeolites. It can be seen that up to 90% of the conversions were obtained over all the studied catalysts. FT wax, which is mainly comprised of normal alkanes, has an average molecular dynamics diameter of between 0.43 nm~0.50 nm [

37]. The pore structure size of the zeolite of the catalysts was USY > β > ZSM-5, wherein the pore diameter of the ZSM-5 zeolite was 0.54 nm × 0.56 nm; thus, the FT wax could easily enter the pore channel of all three zeolites and could be cracked by the acid sites.

However, the product distribution varied dramatically. With Cat-USY, the yields of gasoline and diesel were 43.40 wt% and 7.97 wt%, respectively, which were much higher than those with Cat-β and Cat-Z5-90. The conversion of FT wax to light olefins on Cat-β was similar to that of Cat-Z5-90, and higher than that on Cat-USY. Compared to Cat-Z5-90, the dry gas yield on Cat-β was reduced by 4.30% and the butenes yield increased by 5.05%. With Cat-Z5-90, the yields of dry gas and LPG were 7.28 wt% and 56.55 wt%, of which the ethylene yield was 6.92 wt% and the propylene yield was 25.91 wt%.

The difference of the product distribution was due to the physicochemical properties of the zeolite. The USY zeolite is composed of a series of spherical cavities with a diameter of about 1.2 nm, which is conducive to the diffusion of large wax molecules and reaction intermediates, thus improving the selectivity of the gasoline and diesel yields in the products. The β zeolite is composed of two types of channels, one with a pore diameter of about 0.73 nm × 0.60 nm in the horizontal direction and the other with a twisted channel with a diameter of about 0.56 nm × 0.56 nm in the vertical direction. The relatively large twelve-membered ring straight channels in the β zeolite are sterically favorable for the isomerization of hydrocarbon molecules, thereby promote the formation of butenes. ZSM-5 is a mesoporous zeolite, characterized by a 10-membered ring pore structure which greatly strengthens the cracking and isomerization reaction of hydrocarbon molecules. It has been widely used as a promoter for increasing propylene and high-octane additives. From

Table 2, it can be seen that Cat-Z5-90 had a much higher ratio of Brønsted acid sites to Lewis acid sites than both Cat-USY and Cat-β, which would also influence the cracking reaction. The high strong/weak acid ratio was beneficial for increasing the light olefins yield as the order of the ratio was Cat-Z5-90 > Cat-β > Cat-USY, showing a similar tend to the change in the light olefins yield. Thus, it can be concluded that the different pore structures and the acid characters were the crucial factors to determine the product distribution of FT wax cracking. In addition, the size and morphologies of the zeolites’ crystals can also affect the product distribution during catalytic cracking [

38,

39]. Y. Hirota et al. reported that 75 nm-sized SAPO-34 nanocrystals showed a longer catalyst lifetime in both MTO and dimethylether-to-olefins (DTO) reactions than the 800 nm-sized SAPO-34 [

40]. A multi-edge morphology and hierarchical porous structure are also found to be advantageous for the DTO reaction [

41]. The possible reason for the superior performance of the zeolite was a short residence time for products because of a shorter diffusion length. This might also influence the product distribution in FT wax cracking.

In addition to the differences in the fractions, the detailed composition also changed with the zeolite types. The compositions of the dry gas and LPG are shown in

Table 4. On Cat-Z5-90, 95.14 wt% of the dry gas was ethylene, 55.54 wt% of the LPG was C

3, of which 45.83 wt% was propylene; these rates were significantly higher than those on Cat-USY and Cat-β. The yield of propylene using Cat-β was slightly lower than that of Cat-Z5-90, but the mass fraction of butenes in its LPG was as high as 44.01 wt%, of which the isobutene fraction was 18.60 wt%. The yield and selectivity of butenes on Cat-β were significantly higher than those on Cat-Z5-90. Among the three catalysts, Cat-Z5-90 was suitable for producing ethylene and propylene, while Cat-β was suitable for propylene and butenes.

Table 5 lists the gasoline composition on different types of zeolite catalysts. With the decrease in the pore size of the zeolites, the mass fractions of

n-paraffins, olefins, naphthenes, and aromatics in the gasoline all increased, while the mass fraction of

i-paraffins decreased. The content of both weak and strong acid was higher on Cat-USY than Cat-β and Cat-Z5-90; additionally, its large cavity was conducive to the hydrogen transfer reaction. Although the total acid content of Cat-Z5-90 was less than Cat-USY, the fraction of strong acid was the highest, which was conducive to cracking, while the hydrogen transfer activity was relatively low. Compared with Cat-Z5-90, the fraction of strong acid over Cat-β was lower, resulting in a mild cracking performance of gasoline. The hydrogen transfer index of Cat-USY, Cat-β, and Cat-Z5-90 were 0.58, 0.37, and 0.35, respectively.

The mass fraction of aromatics in gasoline obtained by the three different types of zeolite catalysts were all less than 30%; this is much lower than the traditional DCC process’s gasoline, which is usually up to 50%. C. J. Mota summarized the previous understanding of gasoline aromatics and studied the reaction mechanism through experiments [

42]. It was found that in the initial stage of cracking, the aromatics in gasoline mainly came from the dealkylation reaction of monocyclic aromatics in the reactant. When the conversion increased, the olefins in the gasoline increased, and secondary reactions such as hydrogen transfer and cyclodehydrogenation increased to generate gasoline aromatics. FT wax does not contain cyclic compounds, such as aromatic and naphthenic hydrocarbons; thus, aromatics in gasoline should derive from the cyclodehydrogenation of olefins.

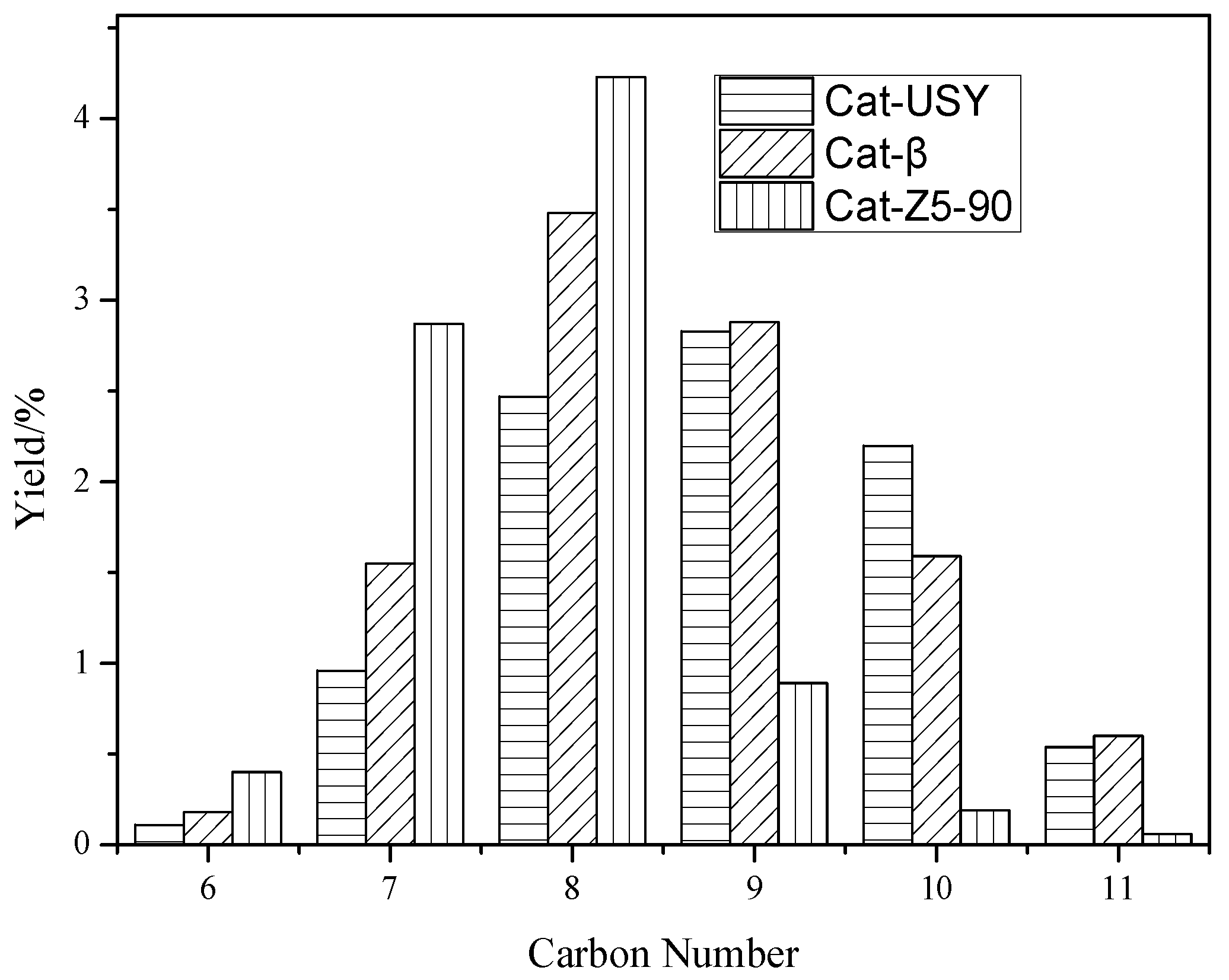

Figure 2 shows the yields of aromatic hydrocarbons with different carbon numbers in gasoline. It can be seen that compared with Cat-USY and Cat-β, the yield of C6~C8 aromatics using Cat-Z5-90 was substantially improved, and the C9~C11 aromatics were remarkably reduced. The larger pore size of USY and β was beneficial for the formation of heavy aromatics, and Cat-Z5-90 was beneficial for producing light aromatics-BTX.

From the screening of the zeolite types above, among the three catalysts, Cat-Z5-90 had the highest yield of light olefins and light aromatics.

2.3. Effect of Si/Al Ratio on Cracking

To further improve the yield of light olefins, cracking the olefins and paraffins in gasoline and suppressing the hydrogen transfer reaction would be the two feasible ways. As ZSM-5 had shown the highest light olefins yield in the above tests, we continued to study the effect of the Si/Al ratio of ZSM-5 on FT wax cracking.

The cracking performance of FT wax on ZSM-5 catalysts with different Si/Al ratios was investigated at 560 °C. The product distribution is given in

Table 6. It can be seen that as the Si/Al ratio of ZSM-5 increased, the yield of diesel and heavy oil in the product increased, while the conversion decreased. This was attributed to the fact that with a higher Si/Al ratio, the acid content of ZSM-5 declined, leading to a lower conversion. The dry gas yield in the product significantly decreased, especially for the ethylene yield. It is generally believed that some parts of ethylene are produced by high-temperature thermal reactions from a free radical mechanism [

43,

44] and some are catalyzed by acids [

45]. As the Si/Al ratio increased, the yield of LPG slightly increased, but the yield of propylene and butenes in the product notably increased. Using Cat-Z5-140, the yield of propylene was as high as 26.83%, and that of butenes reached 20.10%. The hydrogen transfer index was also reduced. Low acid density is conducive to inhibiting the hydrogen transfer reaction. On the whole, a high Si/Al ratio was favorable for increasing the yield and selectivity of light olefins. It can also be seen that the coke yield decreased with the Si/Al ratio. This was because a low acid density was conducive to inhibiting the hydrogen transfer reaction, which was the crucial reaction for coke formation. Nevertheless, the coke yields on the three catalysts were only ~0.1%, which is much lower than the traditional FCC process. As the coke deposit was one of the major factors for catalyst deactivation, it was reasonable to deduce that the deactivation would be minor.

In addition to the yield of individual fractions, their compositions were also important as they determined the downstream upgrading of the primary products. The detailed compositions of dry gas and LPG are given in

Table 7. The ethylene concentration was above 90% in all cases, which is much higher than using VGO/HVGO derived from petroleum as feedstocks [

10]. The mass fraction of paraffin in LPG decreased with the increasing Si/Al ratio, while the olefins, namely propylene and butenes, increased significantly. However, the mass fraction of the total C

3 and total C

4 hydrocarbons in the LPG remained almost unchanged.

Table 8 presents the group composition of gasoline. The mass fraction of alkanes and olefins in the gasoline increased with the increase in the Si/Al ratio, while the mass fraction of aromatics decreased. This indicated that the cyclization and dehydrogenation of olefins to aromatics were suppressed when the zeolite had a low acid density. This was consistent with the changes in the composition of the LPG.

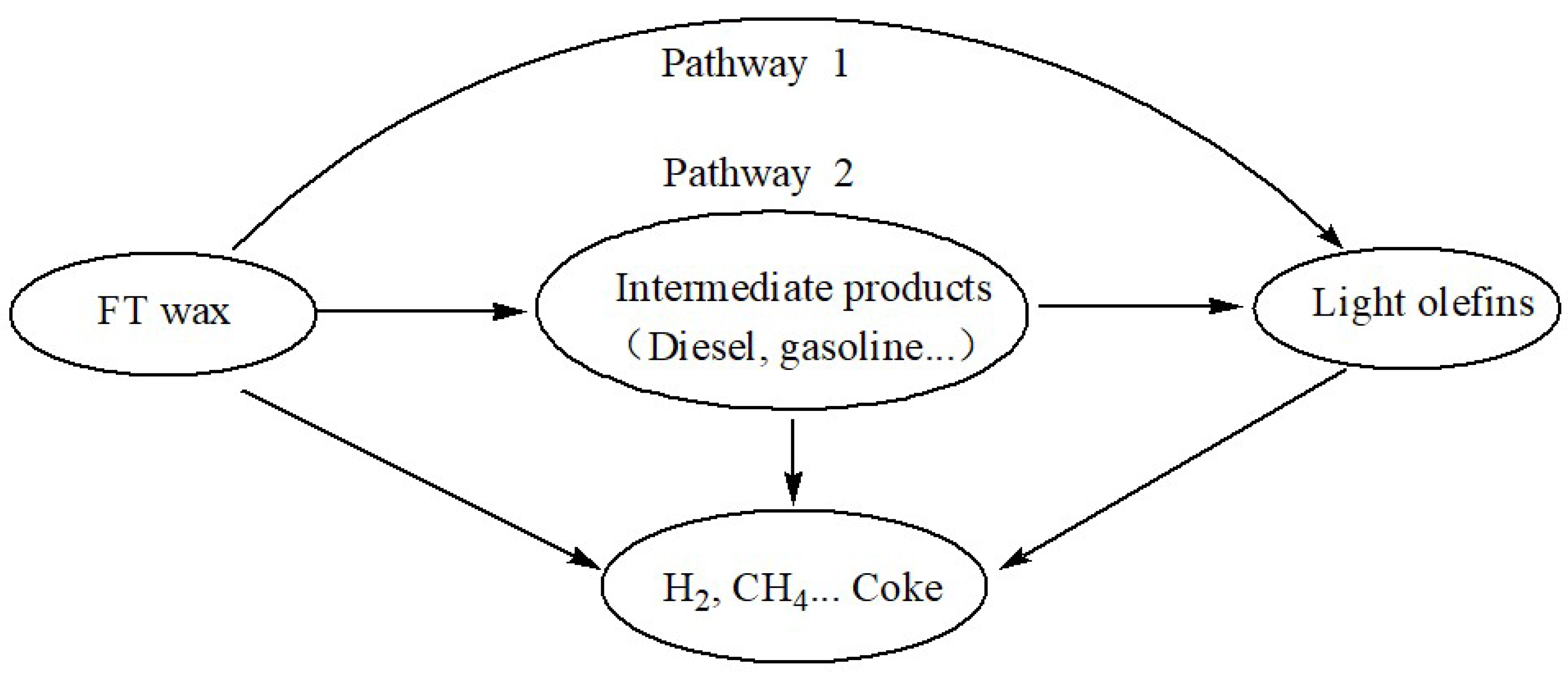

2.4. Effect of Space Velocity

During the catalytic cracking, the feedstock and intermediates underwent complex parallel and sequential reactions. The residence time, along with the temperature and other factors, determined the degree of cracking severity. A too-high space velocity might result in insufficient time for feedstock cracking and further conversion of the intermediates, which has a negative effect on increasing light olefins. On the other hand, hydrogen transfer, aromatization, and other undesired reactions would be unremarkable. A low space velocity led to a more sufficient time for the feeding molecules to make contact with the catalyst, facilitating further conversion to light olefins, but also intensified the undesired reactions.

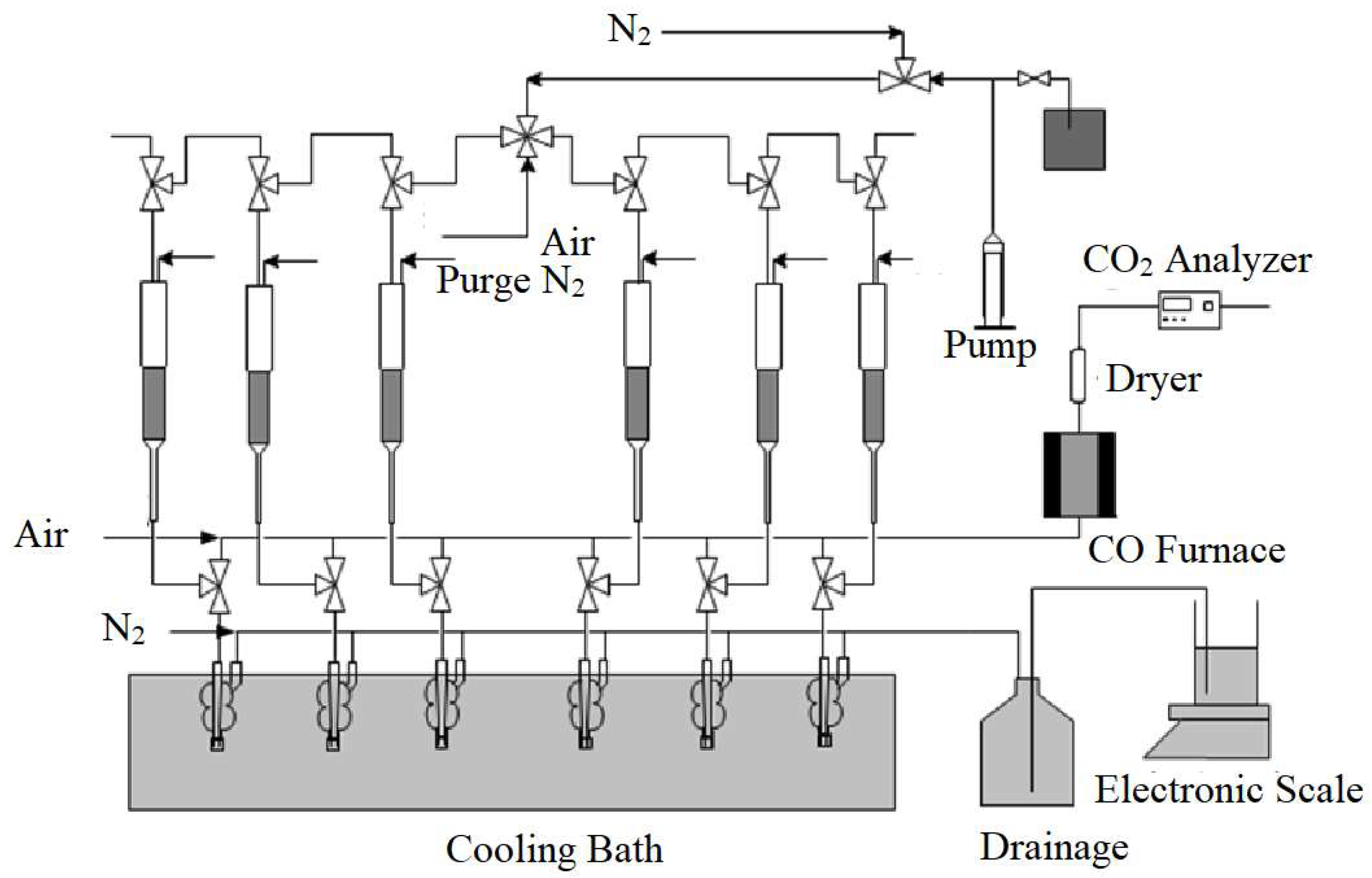

The catalytic cracking performance of FT wax under different weight hourly space velocities (WHSV) at 560 °C was investigated. The product distribution is shown in

Table 9. The decrease in the WHSV resulted in the increased conversion of FT wax. When the WHSV decreased from 41 h

−1 to 4 h

−1, the yield of dry gas and LPG both increased dramatically, much higher than the increasing ratio of the conversion. However, the yields of gasoline and diesel decreased. The opposite trend of changes illustrated that a large portion of dry gas and LPG were derived from gasoline and diesel. The coke yield remained almost unchanged, at around 1%.

As the WHSV decreased, the yields of ethylene, propylene, and butenes all increased, but their rates of increase were different. The yield of butenes increased sharply between WHSVs of 41 h−1 and 15 h−1, and the growth became sluggish between 15 h−1 and 4 h−1. At high WHSVs, the yield of butenes was higher than that of propylene. As the reaction time prolonged, the yield of propylene significantly increased, and the yield of propylene was higher than that of butenes. The yields of propylene and butenes were influenced by both generation and consumption. In the initial stage, as the reaction time prolonged, the concentrations of propylene and butenes were quite low; thus, the consumption rate was minor, and the generation rates of propylene and butenes dominated their yields. As the reaction time continued to extend, the concentration of reactants to produce propylene and butenes decreased, resulting in a decrease in the generation rate. At the same time, as the concentration of propylene and butenes increased, the rate of consumption increased.

The WHSV also impacted the composition of gasoline. As the WHSV decreased, the hydrogen transfer index increased, the yield of olefins decreased, and that of aromatics increased. The FT wax mainly underwent the cracking reaction in the early stage of the reaction, and as the reaction time prolonged, the cracking reaction of large molecules intensified, accompanied by an enhanced hydrogen transfer reaction. When the reaction time continued to extend, the cracking reaction of the middle fraction intensified, the yield of light olefins increased, while the hydrogen transfer reaction was strengthened, leading to high aromatic percentages.