An Efficient Strategy for Chemoenzymatic Conversion of Corn Stover to Furfuryl Alcohol in Deep Eutectic Solvent ChCl:PEG10000−Water Medium

Abstract

1. Introduction

2. Results and Discussion

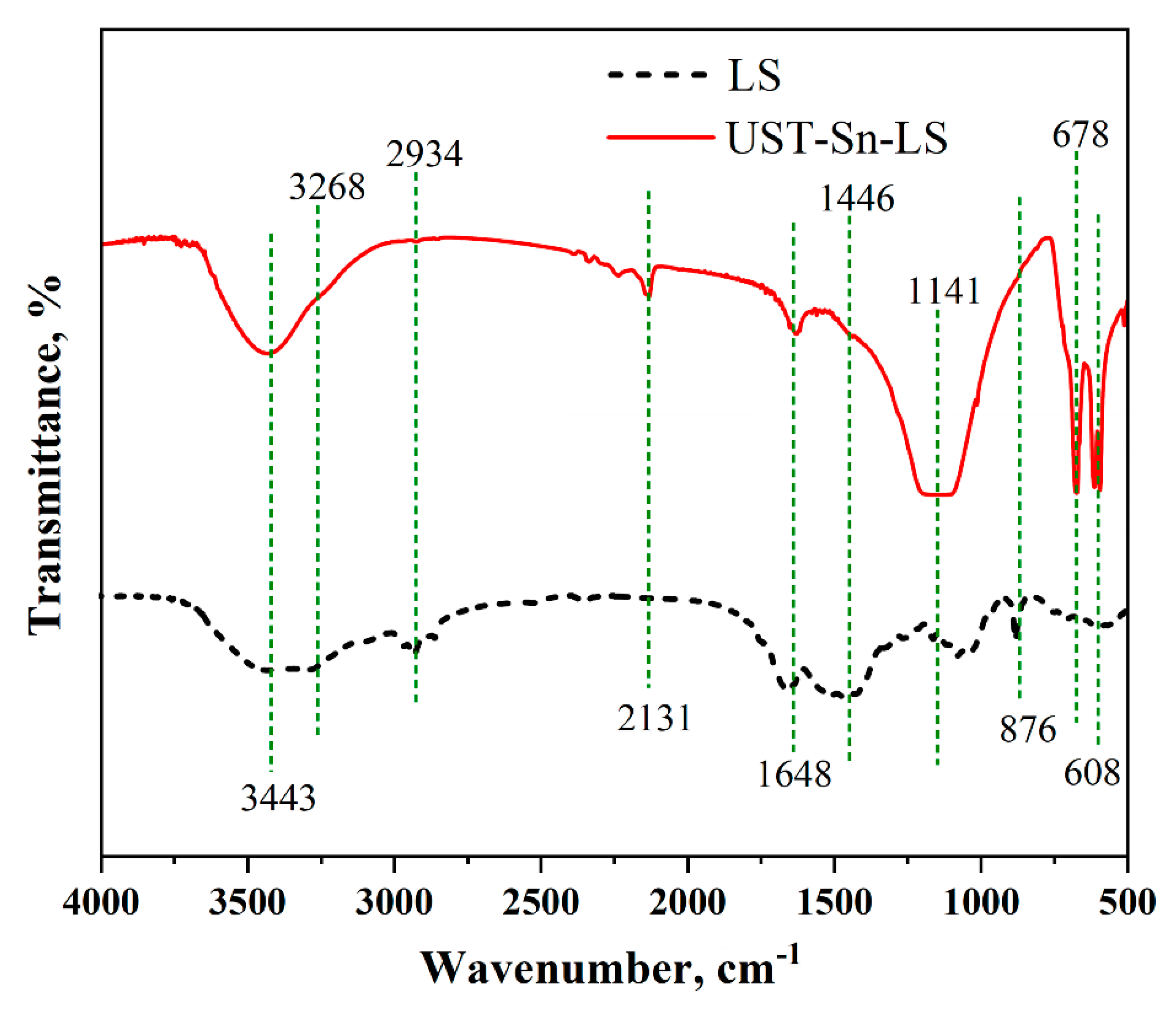

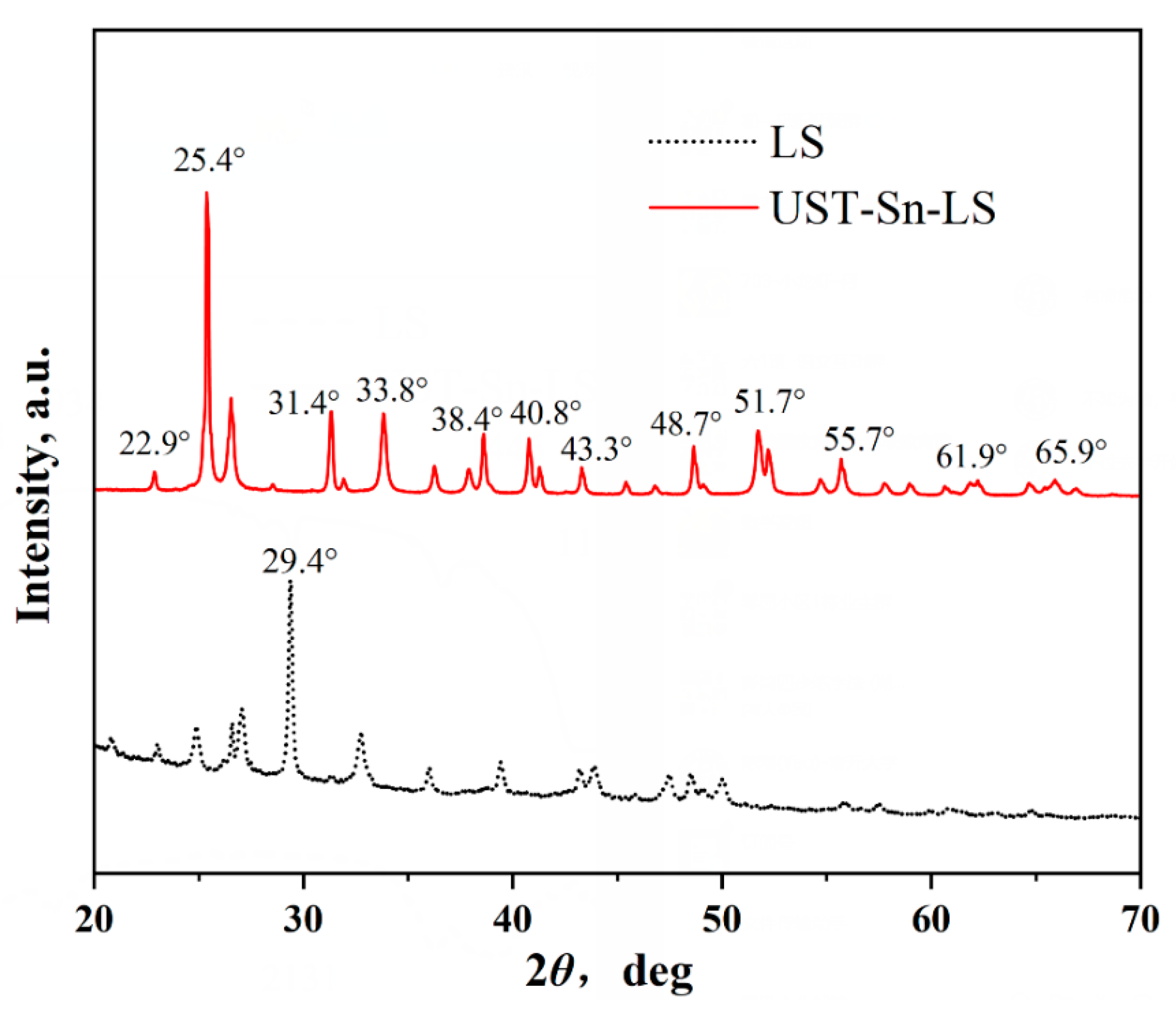

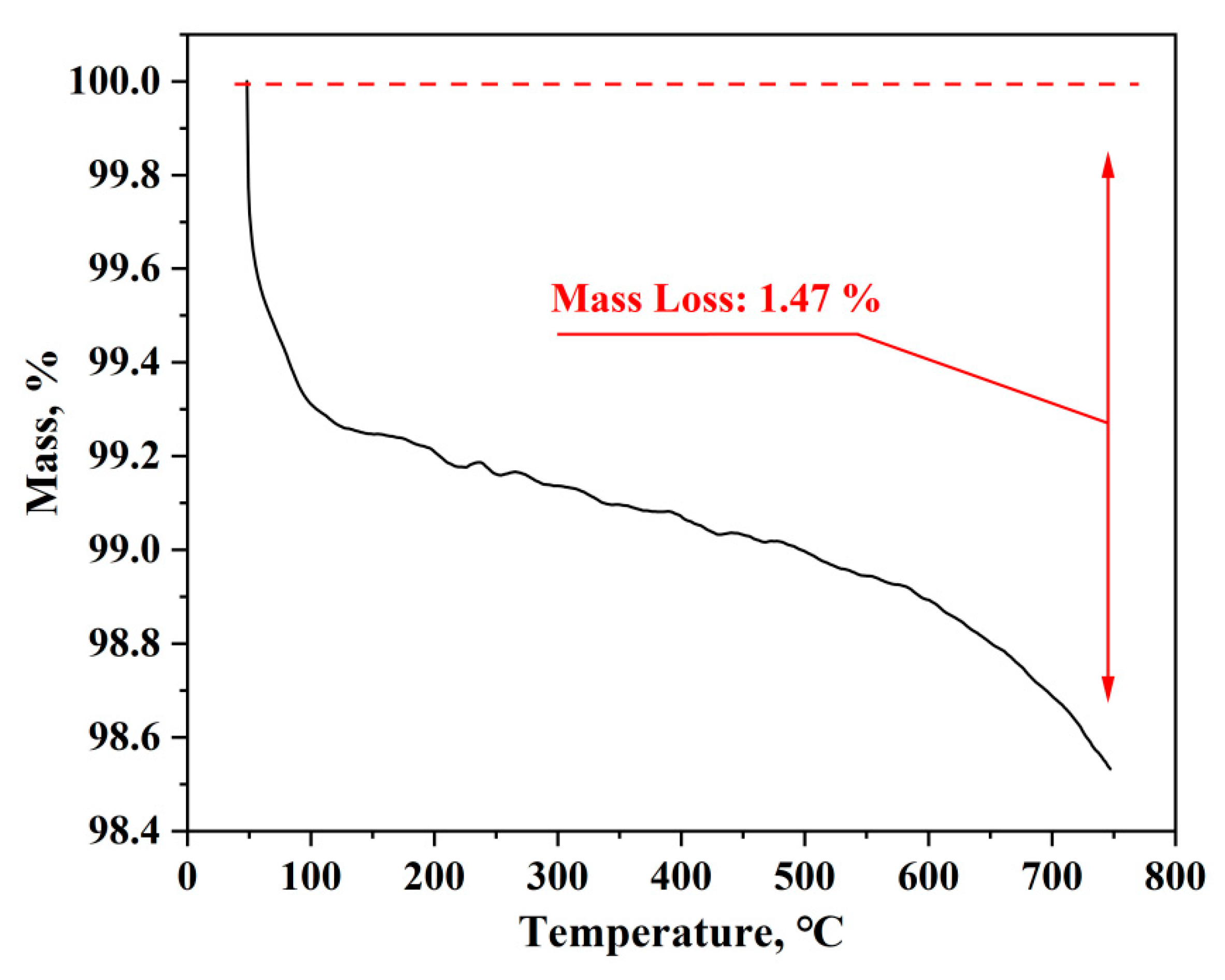

2.1. Characterization of Raw Corn Stover and UST-Sn-LS-Treated Corn Stover

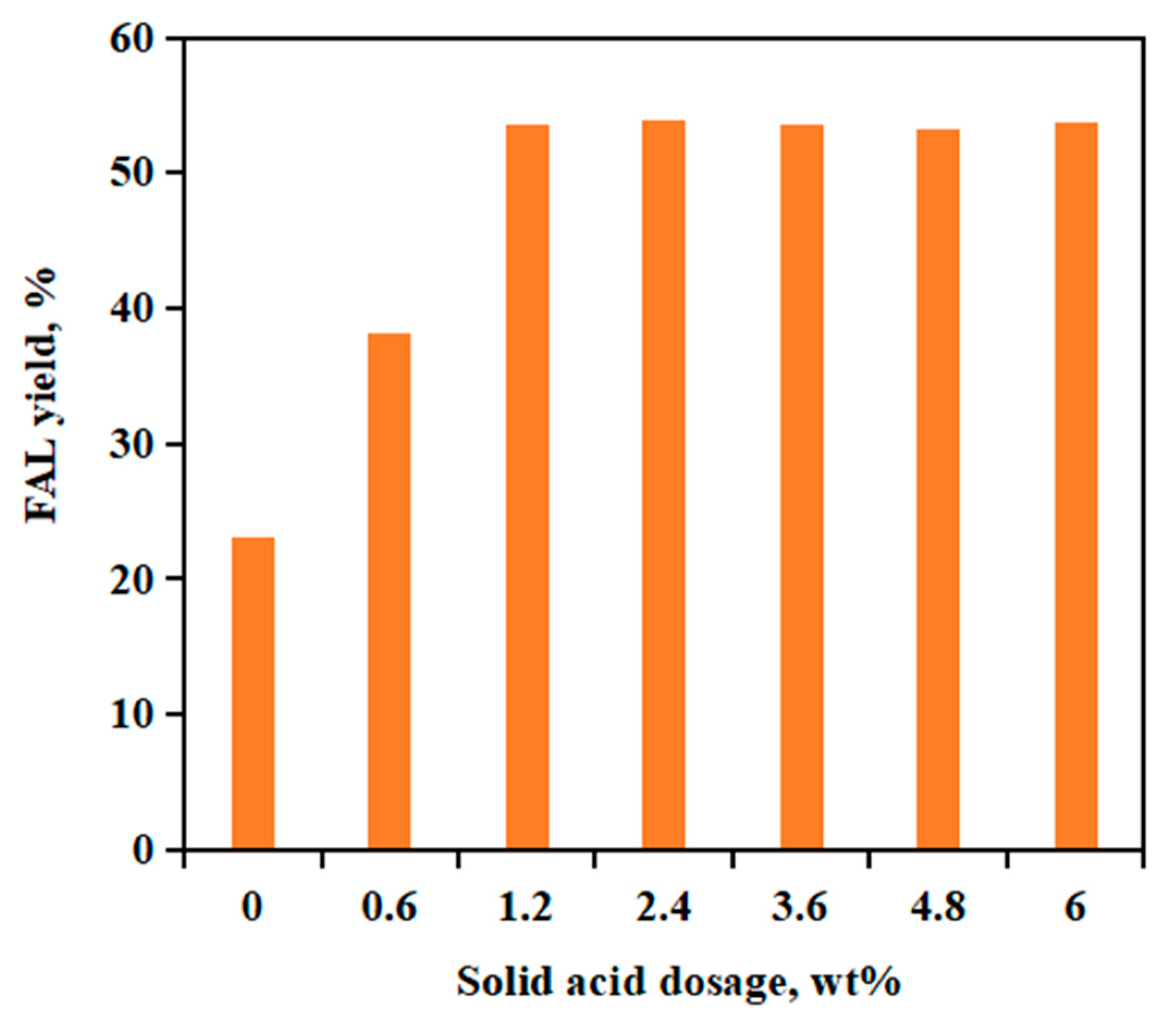

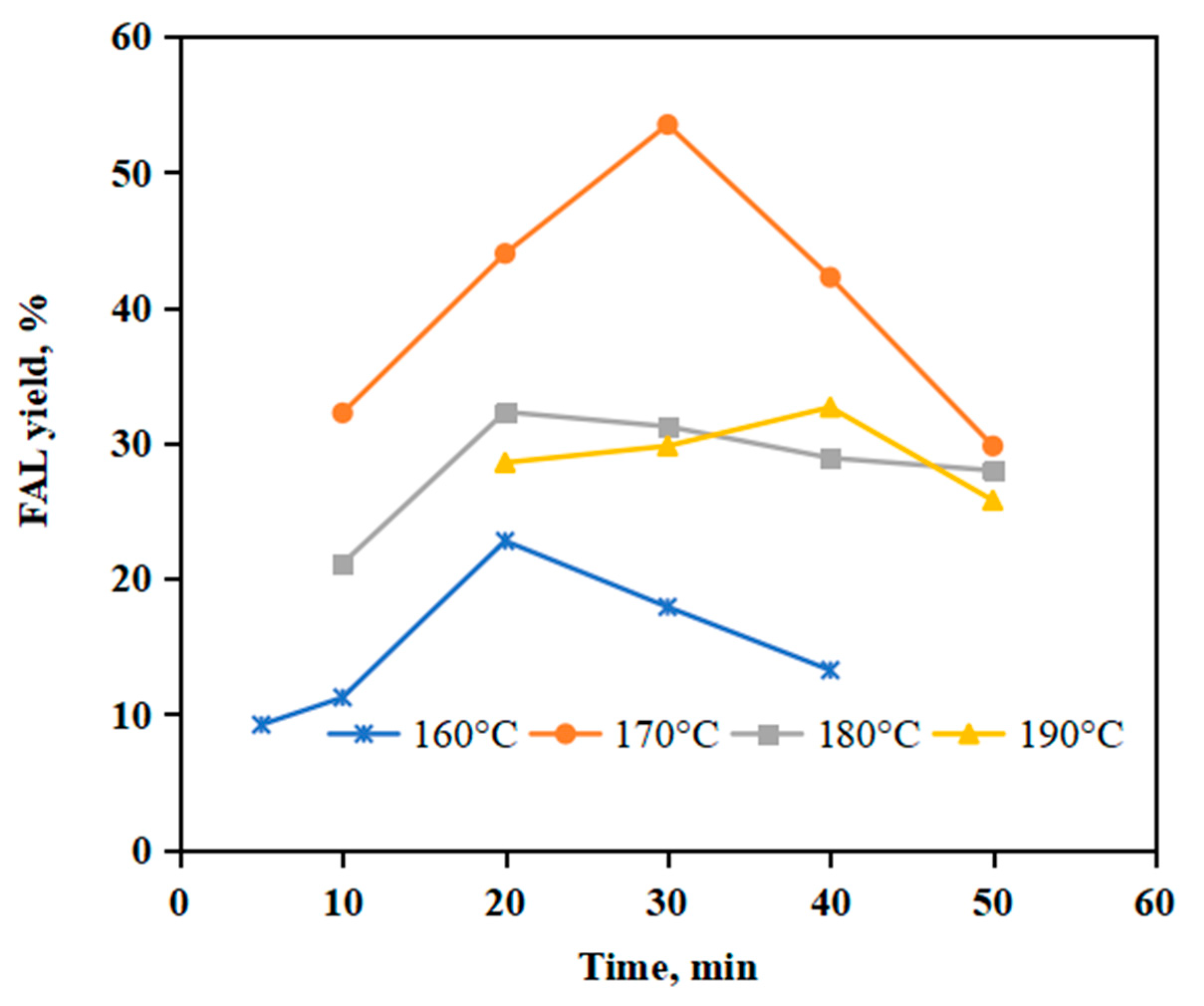

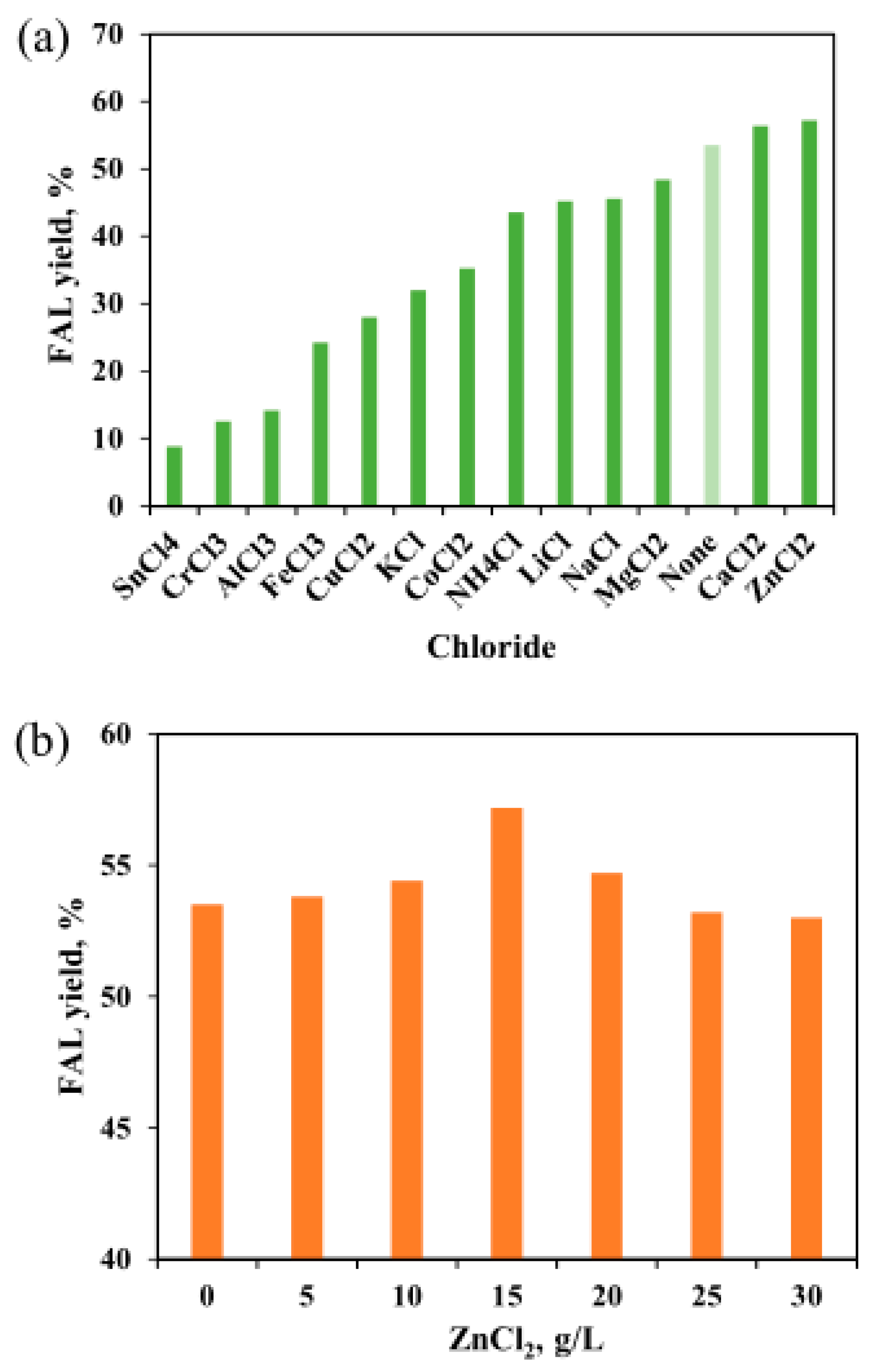

2.2. Synthesis of FAL from with UST-Sn-LS in ChCl:PEG10000–Water

2.3. Synthesis of FOL from FAL in ChCl:PEG10000–Water

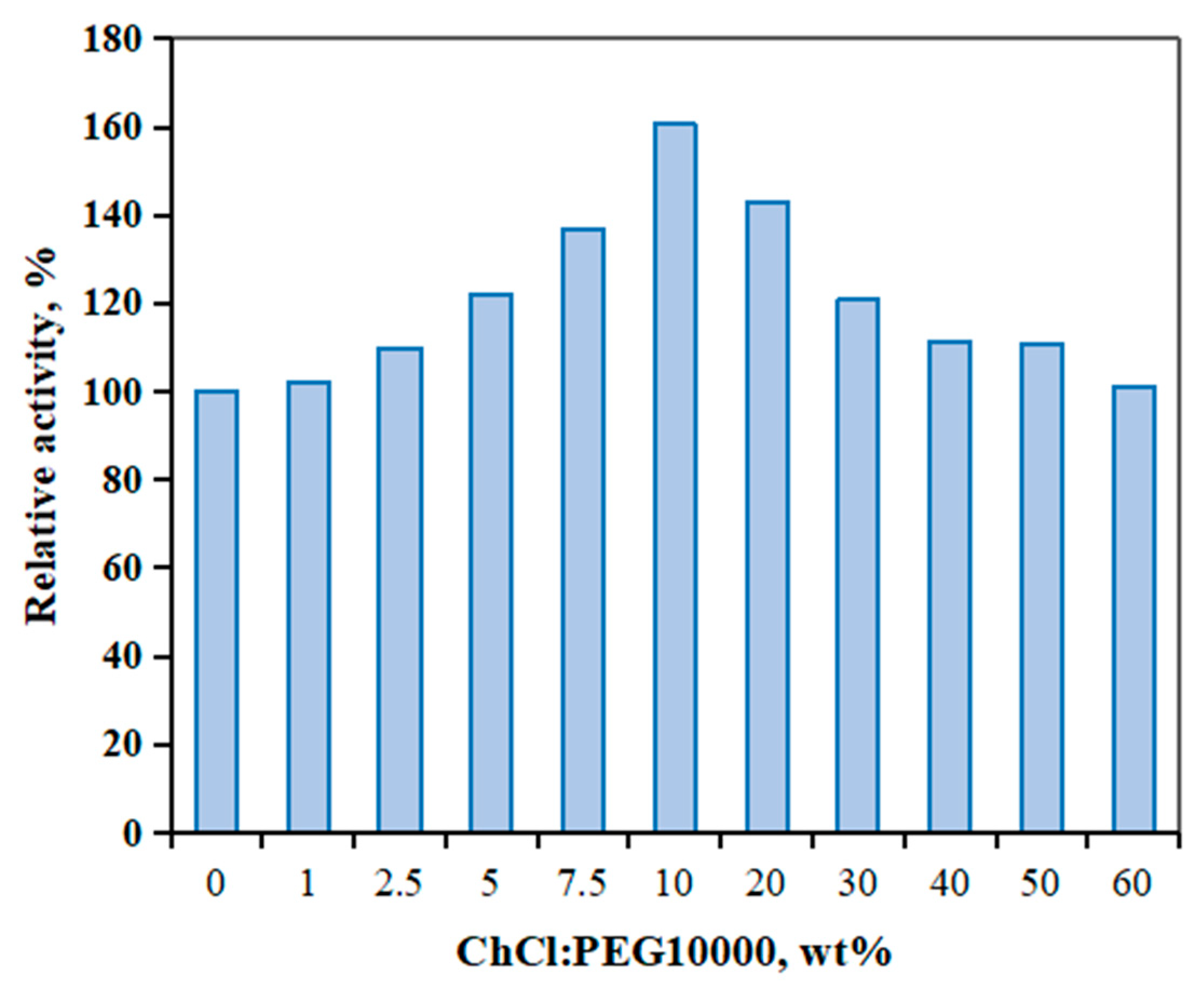

2.3.1. Effects of ChCl:PEG10000 Load on Whole-Cell Bioreduction Activity

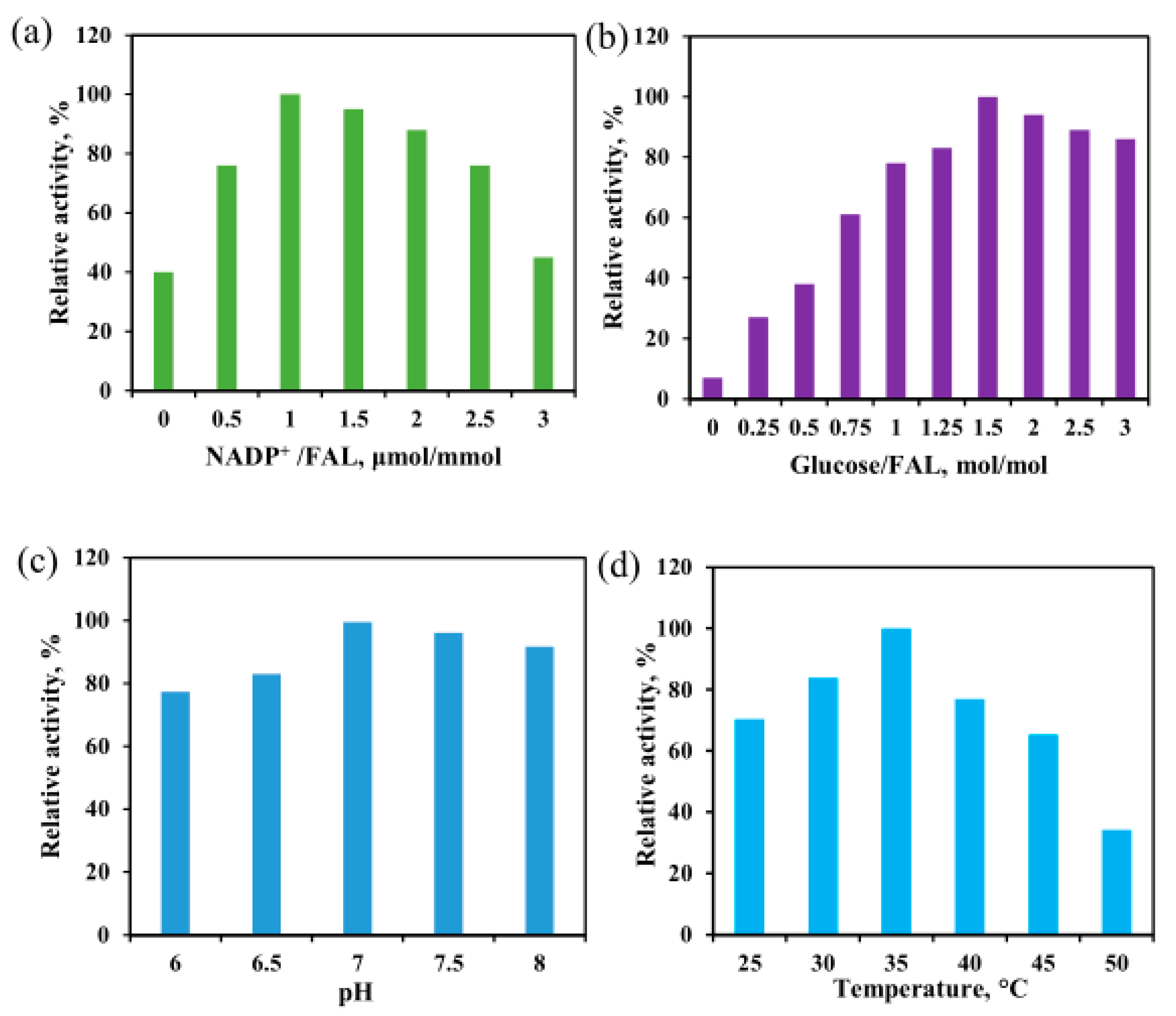

2.3.2. Effects of NADP+ Load and Co-Substrate Glucose Dosage on Whole-Cell Bioreduction

2.3.3. Effects of Reaction Temperature and Medium pH on Whole-Cell Bioreduction Activity

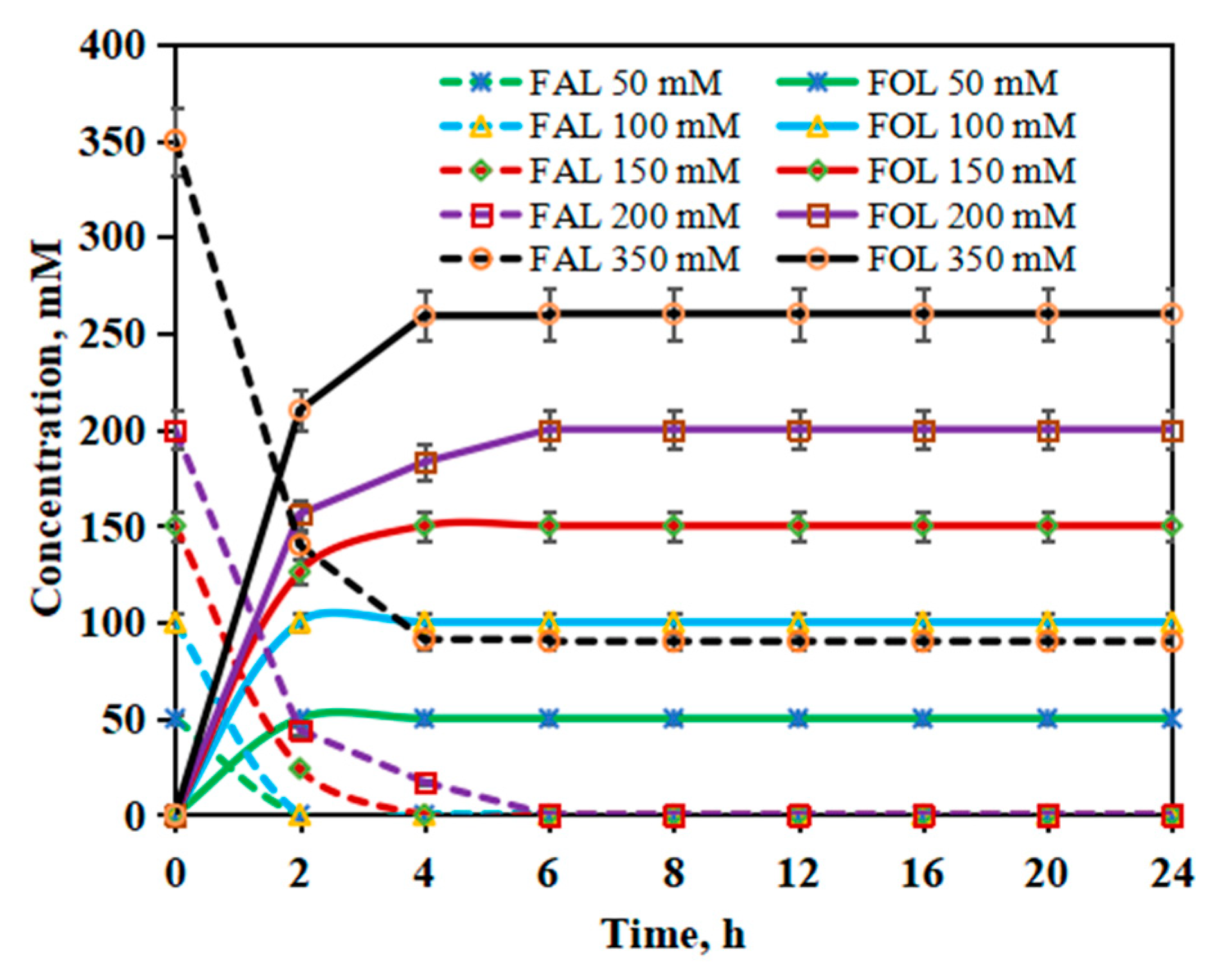

2.3.4. Effects of FAL Dosage on Whole-Cell Bioreduction Activity

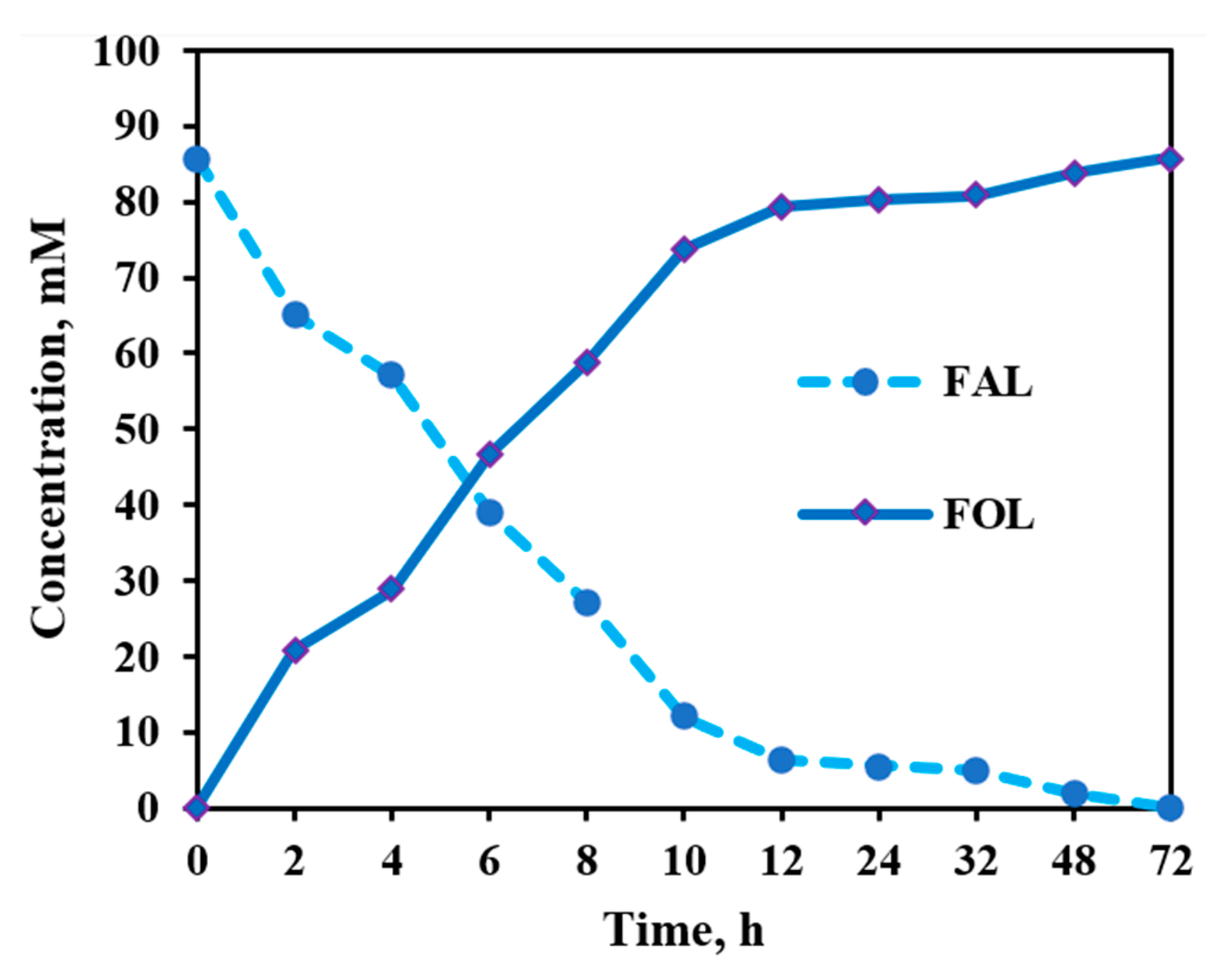

2.4. Transformation of Corn Stover to FOL in ChCl:PEG10000–Water

3. Materials and Methods

3.1. Chemicals

3.2. Synthesis of FAL from Corn Stover

3.3. Whole-Cell Bioreduction of FAL into FOL

3.4. Analytical Method

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| WLS | waste lobster shell |

| CS | corn stove |

| FAL | furfural |

| FOL | furfuryl alcohol |

| DES | deep eutectic solvent |

| PEG | poly ethylene glycol |

| ADH | aldehyde reductase |

| XRD | X-ray diffraction |

| TG | thermogravimetric analysis |

| SEM | scanning electron microscopy |

| FTIR | Fourier-transform infrared spectroscopy |

References

- Tuck, C.-O.; Pérez, E.; Horváth, I.-T.; Sheldon, R.-A.; Poliakoff, M. Valorization of biomass: Deriving more value from waste. Science 2012, 337, 695–699. [Google Scholar] [CrossRef] [PubMed]

- Kucherov, F.A.; Romashov, L.V.; Galkin, K.I.; Ananikov, V.P. Chemical transformations of biomass-derived C6-furanic platform chemicals for sustainable energy research, materials science, and synthetic building blocks. ACS Sustain. Chem. Eng. 2018, 6, 8064–8092. [Google Scholar] [CrossRef]

- Gallezot, P. Conversion of biomass to selected chemical products. Chem. Soc. Rev. 2012, 41, 1538–1558. [Google Scholar] [CrossRef] [PubMed]

- Isci, A.; Kaltschmitt, M. Recovery and recycling of deep eutectic solvents in biomass conversions: A review. Biomass Convers. Biorefinery 2022, 12, S197–S226. [Google Scholar] [CrossRef]

- Zhou, P.; Zhang, Z.H. One-pot catalytic conversion of carbohydrates into furfural and 5-hydroxymethylfurfural. Catal. Sci. Technol. 2016, 6, 3694–3712. [Google Scholar] [CrossRef]

- Li, Q.; Ma, C.; Di, J.; Ni, J.; He, Y.-C. Catalytic valorization of biomass for furfuryl alcohol by novel deep eutectic solvent-silica chemocatalyst and newly constructed reductase biocatalyst. Bioresour. Technol. 2022, 347, 126376. [Google Scholar] [CrossRef]

- Kochermann, J.; Schreiber, J.; Klemm, M. Conversion of D-xylose and hemicellulose in water/ethanol mixtures. ACS Sustain. Chem. Eng. 2019, 7, 12323–12330. [Google Scholar] [CrossRef]

- Ni, J.; Di, J.; Ma, C.; He, Y.C. Valorisation of corncob into furfuryl alcohol and furoic acid via chemoenzymatic cascade catalysis. Bioresour. Bioprocess. 2021, 8, 113. [Google Scholar] [CrossRef]

- Liao, X.; Jia, P.; Wang, T. Furfural: A promising platform compound for sustainable production of C-4 and C-5 chemicals. ACS Catal. 2016, 6, 7621–7640. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, C.J.; Huang, C.X.; Fu, Y.; Chang, J. Efficient conversion of xylose into furfural using sulfonic acid-functionalized metal-organic frameworks in a biphasic system. Ind. Eng. Chem. Res. 2018, 57, 16628–16634. [Google Scholar] [CrossRef]

- Isikgor, F.H.; Becer, C.R. Lignocellulosic biomass: A sustainable platform for the production of bio-based chemicals and polymers. Polym. Chem. 2015, 6, 4497–4559. [Google Scholar] [CrossRef]

- Zhang, P.; Liao, X.; Ma, C.; Li, Q.; Li, A.; He, Y. Chemoenzymatic conversion of corncob to furfurylamine via tandem catalysis with tin-based solid acid and transaminase biocatalyst. ACS Sustain. Chem. Eng. 2019, 7, 17636–17642. [Google Scholar] [CrossRef]

- Zhang, T.; Li, W.; Xu, Z.; Liu, Q.; Ma, Q.; Jameel, H.; Chang, H.-M.; Ma, L. Catalytic conversion of xylose and corn stalk into furfural over carbon solid acid catalyst in gamma-valerolactone. Bioresour. Technol. 2016, 209, 108–114. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Qiu, M.; Tang, Y.; Yang, J.; Shen, F.; Qi, X.; Yu, Y. Synthesis of sulfonated lignin-derived ordered mesoporous carbon for catalytic production of furfural from xylose. Int. J. Biol. Macromol. 2021, 187, 232–239. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Reznicek, W.-D.; Wan, C. Aqueous Choline Chloride: A Novel Solvent for Switchgrass Fractionation and Subsequent Hemicellulose Conversion into Furfural. ACS Sustain. Chem. Eng. 2018, 6, 6910–6919. [Google Scholar] [CrossRef]

- Delbecq, F.; Wang, Y.; Muralidhara, A.; El Ouardi, K.; Marlair, G.; Len, C. Hydrolysis of hemicellulose and derivatives-A review of recent advances in the production of furfural. Front. Chem. 2018, 6, 146. [Google Scholar] [CrossRef] [PubMed]

- Choudhary, V.; Pinar, A.B.; Sandler, S.I.; Vlachos, D.G.; Lobo, R.F. Xylose isomerization to xylulose and its dehydration to furfural in aqueous media. ACS Catal. 2011, 1, 1724–1728. [Google Scholar] [CrossRef]

- Montes, V.; Miñambres, J.F.; Khalilov, A.N.; Boutonnet, M.; Marinas, J.M.; Urbano, F.J.; Maharramov, A.M.; Marinas, A. Chemoselective hydrogenation of furfural to furfuryl alcohol on ZrO2 systems synthesized through the microemulsion method. Catal. Today 2018, 306, 89–95. [Google Scholar] [CrossRef]

- Jiménez-Gómez, C.P.; Cecilia, J.A.; Durán-Martín, D.; Moreno-Tost, R.; Santamaría-González, J.; Mérida-Robles, J.; Mariscal, R.; Maireles-Torres, P. Gas-phase hydrogenation of furfural to furfuryl alcohol over Cu/ZnO catalysts. J. Catal. 2016, 336, 107–115. [Google Scholar] [CrossRef]

- Fulajtárova, K.; Soták, T.; Hronec, M.; Vávra, I.; Dobročka, E.; Omastová, M. Aqueous phase hydrogenation of furfural to furfuryl alcohol over Pd–Cu catalysts. Appl. Catal. A 2015, 502, 78–85. [Google Scholar] [CrossRef]

- Liu, X.; Li, B.; Han, G.-Q.; Liu, X.-W.; Cao, Z.; Jiang, D.-E.; Sun, Y.-J. Electrocatalytic synthesis of heterocycles from biomass-derived furfuryl alcohols. Nat. Commun. 2021, 8, 1868. [Google Scholar] [CrossRef] [PubMed]

- Hronec, M.; Fulajtarova, K.; Sotak, T. Highly selective rearrangement of furfuryl alcohol to cyclopentanone. Appl. Catal. B Environ. 2014, 154, 294–300. [Google Scholar] [CrossRef]

- Cao, Q.; Zhang, W.; Luo, S.-J.; Guo, R.-B.; Xu, D. Synthesis of furanic ethers from furfuryl alcohol for biofuel production. Energy Fuels 2021, 35, 12725–12733. [Google Scholar] [CrossRef]

- Salnikova, K.-E.; Matveeva, V.-G.; Larichev, Y.-V.; Bykov, A.-V.; Demidenko, G.-N.; Shkileva, I.P.; Sulman, M.-G. The liquid phase catalytic hydrogenation of furfural to furfuryl alcohol. Catal. Today 2019, 329, 142–148. [Google Scholar] [CrossRef]

- Ruelens, W.; Koolen, G.; Gricourt, B.; van Vuure, A.-W.; Smet, M. Co-polymerisation of furfuryl alcohol for furan resins with increased toughness. Mater. Lett. 2022, 328, 133025. [Google Scholar] [CrossRef]

- Maderuelo-Solera, R.; Lopez-Asensio, R.; Cecilia, J.-A.; Jimenez-Gomez, C.-P.; Garcia-Sancho, C.; Moreno-Tost, R.; Maireles-Torres, P. Catalytic transfer hydrogenation of furfural to furfuryl alcohol over calcined MgFe hydrotalcites. Appl. Clay Sci. 2019, 183, 105351. [Google Scholar] [CrossRef]

- Putrakumar, B.; Seelam, P.-K.; Srinivasarao, G.; Rajan, K.; Rajesh, R.; Rao, K.-R.; Liang, T. High performance and sustainable copper-modified hydroxyapatite catalysts for catalytic transfer hydrogenation of furfural. Catalysts 2020, 10, 1045. [Google Scholar] [CrossRef]

- Kuhaudomlap, S.; Mekasuwandumrong, O.; Praserthdam, P.; Lee, K.-M.; Jones, C.-W.; Panpranot, J. Influence of highly stable Ni2+ species in Ni phyllosilicate catalysts on selective hydrogenation of furfural to furfuryl alcohol. ACS Omega 2022, 8, 249–261. [Google Scholar] [CrossRef]

- Meng, X.; Yang, Y.; Chen, L.; Xu, M.; Zhang, X.; Wei, M.-A. Control over hydrogenation selectivity of furfural via tuning exposed facet of Ni catalysts. ACS Catal. 2019, 9, 4226–4235. [Google Scholar] [CrossRef]

- Xu, K.; Wang, J.; Li, C. Intelligent microbial cell factory with tolerance for green biological manufacturing. Synth. Biol. J. 2020, 1, 427–439. [Google Scholar] [CrossRef]

- Li, Q.; Di, J.; Liao, X.; Ni, J.; Li, Q.; He, Y.-C.; Ma, C.L. Exploration of benign deep eutectic solvent-water systems for the highly efficient production of furfurylamine from sugarcane bagasse via chemoenzymatic cascade catalysis. Green Chem. 2021, 23, 8154–8168. [Google Scholar] [CrossRef]

- Li, H.; Luan, Z.J.; Zheng, G.W.; Xu, J.H. Efficient Synthesis of Chiral Indolines using an Imine Reductase from Paenibacillus lactis. Adv. Synth. Catal. 2015, 357, 1692–1696. [Google Scholar] [CrossRef]

- Zhang, M.; Hu, P.F.; Zheng, Y.C.; Zheng, B.B.; Chen, Q.; Zhang, Z.J.; Xu, J.H. Structure-guided engineering of Pseudomonas dacunhae L-aspartate ß-decarboxylase for L-homophenylalanine synthesis. Chem. Commun. 2020, 56, 13876–13879. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Zhou, S.; Zhao, Y.; Xia, J.; Liu, X.; Xu, J.; He, B.; Wu, B.; Zhang, J. Asymmetric whole-cell bioreduction of sterically bulky 2-benzoylpyridine derivatives in aqueous hydrophilic ionic liquid media. Chem. Eng. J. 2017, 316, 919–927. [Google Scholar] [CrossRef]

- Alejandra, R.M.; Rache, L.Y.; Brijaldo, M.H.; Romanelli, G.P.; Martinez, J.J. Biocatalytic transformation of furfural into furfuryl alcohol using resting cells of Bacillus cereus. Catal. Today 2021, 372, 220–225. [Google Scholar] [CrossRef]

- Pan, L.; Li, Q.; Tao, Y.; Ma, C.; Chai, H.; Ai, Y.; He, Y. An efficient chemoenzymatic strategy for valorisation of corncob to furfuryl alcohol in CA: Betaine-water. Ind. Crop. Prod. 2022, 186, 115203. [Google Scholar] [CrossRef]

- Ji, L.; Tang, Z.Y.; Yang, D.; Ma, C.L.; He, Y.C. Improved one-pot synthesis of furfural from corn stalk with heterogeneous catalysis using corn stalk as biobased carrier in deep eutectic solvent–water system. Bioresour. Technol. 2021, 340, 125691. [Google Scholar] [CrossRef]

- Li, Y.Y.; Li, Q.; Zhang, P.Q.; Ma, C.L.; Xu, J.H.; He, Y.C. Catalytic conversion of corncob to furfuryl alcohol in tandem reaction with tin-loaded sulfonated zeolite and NADPH-dependent reductase biocatalyst. Bioresour. Technol. 2021, 320, 124267. [Google Scholar] [CrossRef]

- Li, X.-Y.; Lu, X.-B.; Hu, W.-X.; Hu, H.-C.; Chen, J.-G.; Xiong, j.; Lu, L.-F.; Yu, Z.-H.; Si, C.-L. Phosphotungstic acid functionalized biochar for furfural production from corncob. Fuel Process. Technol. 2022, 229, 107178. [Google Scholar] [CrossRef]

- He, Y.; Huang, M.; Tang, W.; Ma, C. Improving enzymatic hydrolysis of sunflower straw pretreated by deep eutectic solvent with different carboxylic acids as hydrogen bond donors. Ind. Crops Prod. 2023, 193, 116157. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, D.; Rodríguez-Padrón, D.; Len, C. Recent advances in catalytic hydrogenation of furfural. Catalysts 2019, 9, 796. [Google Scholar] [CrossRef]

- Wang, R.Q.; Liang, X.F.; Shen, F.; Qiu, M.; Yang, J.R.; Qi, X.H. Mechanochemical synthesis of sulfonated palygorskite solid acid catalysts for selective catalytic conversion of xylose to furfural. ACS Sustain. Chem. Eng. 2020, 8, 1163–1170. [Google Scholar] [CrossRef]

- Gao, R.; Li, Q.; Di, J.; Li, Q.; He, Y.; Ma, C. Improved 5-hydroxymethyl-2-furfurylamine production from D-fructose-derived 5-hydroxymethylfurfural by a robust double mutant Aspergillus terreus ω-transaminase biocatalyst in a betaine-formic acid medium. Ind. Crops Prod. 2023, 193, 116199. [Google Scholar] [CrossRef]

- Chen, Z.; Wan, C. A novel deep eutectic solvent/acetonebiphasic system for high-yield furfural production. Bioresour. Technol. Rep. 2019, 8, 100318. [Google Scholar] [CrossRef]

- Enslow, K.R.; Bell, A.T. The role of metal halides in enhancing the dehydration of xylose to furfural. ChemCatChem 2015, 7, 479–489. [Google Scholar] [CrossRef]

- Bodachivskyi, I.; Kuzhiumparambil, U.; Williams, D.-B.-G. Towards furfural from the reaction of cellulosic biomass in zinc chloride hydrate solvents. Ind. Crops Prod. 2020, 146, 112179. [Google Scholar] [CrossRef]

- Kumari, S.; Kumar Annamareddy, S.H.; Abanti, S.; Kumar Rath, P. Physicochemical properties and characterization of chitosan synthesized from fish scales, crab and shrimp shells. Int. J. Biol. Macromol. 2017, 104, 1697–1705. [Google Scholar] [CrossRef]

- Srinivasan, H.; Kanayairam, V.; Ravichandran, R. Chitin and chitosan preparation from shrimp shells Penaeus monodon and its human ovarian cancer cell line, PA-1. Int. J. Biol. Macromol. 2018, 107, 662–667. [Google Scholar] [CrossRef]

- Gavaskar, D.S.; Nagaraju, P.; Vijayakumar, Y.; Reddy, P.S.; Ramana Reddy, M.V. Low-cost ultra-sensitive SnO2-based ammonia sensor synthesized by hydrothermal method. J. Asian Ceram. Soc. 2020, 8, 605–614. [Google Scholar] [CrossRef]

- Li, C.; Wang, Z.; Liu, M.; Wang, B.; Xu, L.; Jiang, K.; Fan, S.; Sun, Y.; Li, J.; Liu, K. Ultrafast self-heating synthesis of robust heterogeneous nanocarbides for high current density hydrogen evolution reaction. Nat. Commun. 2022, 13, 3338. [Google Scholar] [CrossRef]

- He, Y.-C.; Liu, F.; Di, J.-H.; Ding, Y.; Gao, D.-Z.; Zhang, D.-P.; Tao, Z.-C.; Chong, G.-G.; Huang, M.-Z.; Ma, C.-L. Effective pretreatment of dilute NaOH-soaked chestnut shell with glycerol-HClO4-water media: Structural characterization, enzymatic saccharification, and ethanol fermentation. Bioprocess Biosyst. Eng. 2016, 39, 533–543. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.; Di, J.; Gong, L.; He, Y.; Ma, C.; Deng, Y. Enhanced adipic acid production from sugarcane bagasse by a rapid room temperature pretreatment. Chem. Eng. J. 2023, 452, 139320. [Google Scholar] [CrossRef]

- Pätzold, M.; Siebenhaller, S.; Kara, S.; Liese, A.; Syldatk, C.; Holtmann, D. Deep eutectic solvents as efficient solvents in biocatalysis. Trends Biotechnol. 2019, 37, 943–959. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, D.; Tang, W.; Tang, Z.; He, Y. An Efficient Strategy for Chemoenzymatic Conversion of Corn Stover to Furfuryl Alcohol in Deep Eutectic Solvent ChCl:PEG10000−Water Medium. Catalysts 2023, 13, 467. https://doi.org/10.3390/catal13030467

Xu D, Tang W, Tang Z, He Y. An Efficient Strategy for Chemoenzymatic Conversion of Corn Stover to Furfuryl Alcohol in Deep Eutectic Solvent ChCl:PEG10000−Water Medium. Catalysts. 2023; 13(3):467. https://doi.org/10.3390/catal13030467

Chicago/Turabian StyleXu, Daozhu, Wei Tang, Zhengyu Tang, and Yucai He. 2023. "An Efficient Strategy for Chemoenzymatic Conversion of Corn Stover to Furfuryl Alcohol in Deep Eutectic Solvent ChCl:PEG10000−Water Medium" Catalysts 13, no. 3: 467. https://doi.org/10.3390/catal13030467

APA StyleXu, D., Tang, W., Tang, Z., & He, Y. (2023). An Efficient Strategy for Chemoenzymatic Conversion of Corn Stover to Furfuryl Alcohol in Deep Eutectic Solvent ChCl:PEG10000−Water Medium. Catalysts, 13(3), 467. https://doi.org/10.3390/catal13030467