Abstract

Valorization of the abundant renewable lignocellulose through an efficient chemoenzymatic strategy to produce the furan-based platform compounds has raised great interest in recent years. In this work, a newly prepared sulfonated tin-loaded rice husk-based heterogeneous chemocatalyst UST-Sn-RH was utilized to transform corncob (75.0 g/L) into furfural (72.1 mM) at 170 °C for 30 min in an aqueous system. To upgrade furfural into furfuryl alcohol, whole cells of recombinant E. coli KPADH harboring alcohol dehydrogenase were employed to transform corncob-derived furfural into furfuryl alcohol at 30 °C and pH 7.5. In the established chemoenzymatic cascade process, corncob was efficiently transformed to furfuryl alcohol with a productivity of 0.304 g furfuryl alcohol/(g xylan in corncob). In general, biomass could be efficiently valorized into valuable furan-based chemicals in this tandem reaction with the chemocatalyst (bio-based UST-Sn-RH) and the biocatalyst (KPADH cell) in an aqueous system, which has potential application.

1. Introduction

In the modern society, rapid depletion of fossil fuels and serious environment issues have raised concerns among scholars. The search for sustainable and eco-friendly energy sources which can be alternatives to fossil fuels has gained great interest [1,2]. Lignocellulose (LC) is a kind of sustainable and abundant energy source, generated from photosynthesis on earth, which is considered to be one of the most promising substitutes to fossil fuels. Biomass is consisted of three main components (such as hemicellulose, cellulose and lignin) [3,4,5]. The hemicellulose component in biomass is a kind of heteropolymer which is highly branched [5,6] and the reserve of xylan from hemicellulose is second only to cellulose in lignocellulose [7]. Hemicellulose-derived furfural (FAL) is a versatile bio-based platform molecule that is widely utilized in the manufacture of polymers, fuel additives, pharmaceutical intermediates, resins and agrochemicals [8,9].

Generally, homogeneous or heterogeneous catalysts are mainly utilized to catalyze the formation of FAL from biomass or D-xylose [10,11]. Because of high corrosivity and high pollution caused by some homogeneous acids, the high catalytic activity, low cost and good reusability of heterogeneous acid catalysts have been widely utilized in the production of FAL [12,13,14]. Using 45 mg SC-CaCt-700 as heterogeneous chemocatalyst, a 93% of FAL yield was obtained from 150 mg corn stover at 200 °C for 100 min in γ-valerolactone [10]. In a microwave oven (200 °C), solid acid S-DP (10 wt% load) was used as a catalyst, achieving a FAL yield of 76% after 50 min in a water-CPME (1:3, v/v) biphasic system [14]. Sn-graphite catalyst (3.6 wt% load) transformed bamboo shoot shell (75.0 g/L) into FAL in the yield of 41.1% in the aqueous phase after 30 min at 180 °C [15].

Furfuryl alcohol (FOL) is one of the most essential FAL derivatives, and has wide application in many fields such as the fabrication of foundry resins, the production of P-series fuels and the synthesis of lysine even vitamin C [16,17,18]. Traditionally, high temperature, long reaction time and the presence of heavy metal catalysts are used to prepare FOL [17,18,19]. Presently, the perspective of biocatalytic reduction is of great interest due to high catalytic selectivity, low energy consumption and sustainability [20,21,22]. Aldehyde reductase (ADH) is known as a member of a superfamily of NADPH-dependent aldo-keto reductases. Recently, coupling of ADH with glucose dehydrogenase (GDH) for coenzyme regeneration has been efficiently used for preparing biobased alcohols. GDH is capable of biotransformation of NAD(P)+ into NAD(P)H while co-substrate glucose is oxidizing for regeneration of coenzyme. To ensure the bioreduction process runs smoothly, GDH and the dehydrogenase can be coupled in one microbe [23,24,25,26]. Using glucose as co-substrates, 95.8% yield of FOL was obtained from 75 mM FAL by SF21 cells within 2 h in a CA:Betaine-water system [23]. KF2021 cells could effectively transform corncob-derived FAL into FOL at 98% yield in an aqueous medium [24]. The corncob-derived FAL was fully reduced with CG-19 cells co-expressing reductase and GDH in 3 h at 35 °C [27].

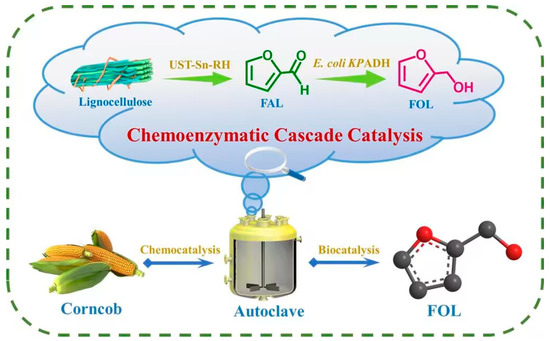

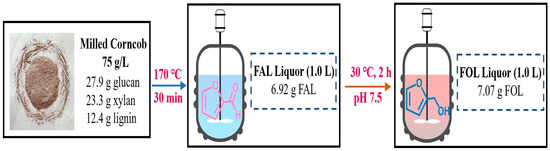

In this work, a new sulfonated tin-based heterogeneous chemocatalyst UST-Sn-RH was prepared using rice husk (RH) as the bio-based carrier to catalyze the formation of FAL from corncob (CCB) in an aqueous system. To explore the surface structure of solid acid and confirm the successful loading of Brönsted/Lewis acid sites, a serial of characterization of Fourier transform infrared spectroscopy (FT-IR), X-Ray Diffraction (XRD), Brunauer–Emmett–Teller (BET), NH3 Temperature-Programmed Desorption (NH3-TPD), and Thermogravimetric Analysis (TG) were applied to characterize the catalyst UST-Sn-RH. During the conversion of CCB into FAL, parameters including the reaction temperature, time and the catalysts loading were tested to evaluate their influence on the FAL generation. Moreover, the stability of UST-Sn-RH catalyst was investigated and the potential mechanism of CCB conversion to FAL was proposed. Furthermore, recombinant E. coli KPADH [28] containing reductase from Kluyveromyces polyspora (KP) and glucose dehydrogenase (GDH) from Bacillus subtilis was used for transforming FAL into FOL. Using KPADH cell as biocatalyst, the biological reaction parameters on the KPADH whole-cell reduction activity were tested (such as reaction temperature, pH, biocatalyst amount, NAD+ load and co-substrate glucose dosage). Finally, a chemoenzymatic route was established by bridging UST-Sn-RH-catalyzed chemical reaction and KPADH-catalyzed bioconversion for valorization of CCB to FOL with a high catalytic efficiency (Figure 1).

Figure 1.

A chemoenzymatic cascade strategy for synthesis of furfuryl alcohol (FOL) from corncob (CCB).

2. Results and Discussion

2.1. Characterization of UST-Sn-RH

As an available renewable biomass resource with huge reserves, rice husk (RH) is not utilized effectively. RH is not only utilized as the pentose source to produce FAL, it can also be used as biobased support to prepare the heterogeneous chemocatalyst for efficient conversion of lignocellulose. In this work, a new sulfonated tin-loaded heterogeneous solid acid UST-Sn-RH was first prepared using RH as a biobased carrier to transform RH into FAL. Different methods such as Fourier transform infrared spectroscopy (FT-IR), Scanning Electron Microscopy (SEM), X-Ray Diffraction (XRD), Brunauer–Emmett–Teller (BET) analysis, NH3 Temperature-Programmed Desorption (NH3-TPD) and Thermogravimetric Analysis (TG) were used to measure the microstructure and properties of UST-Sn-RH.

BET analysis was employed to determine the pore structure, surface area and porosity of carrier and catalyst [29]. Distinct from RH, the specific surface area (SSA) of UST-Sn-RH was largely enlarged from 0.78 to 98.6 m2/g (Table 1). Its pore volume was also expanded to 0.12 cm3/g, while the pore size decreased obviously from 31.6 nm to 6.16 nm. The contact opportunities between RH-derived D-xylose and active sites loaded on UST-Sn-RH would rise because of bigger SSA and larger pore sizes, which would result in the higher reaction rate and FAL yield [30]. Consequently, the efficiency for catalyzing CCB to FAL might be improved.

Table 1.

Surface and pore properties of LS and UST-Sn-RH via Brunauer–Emmett–Teller (BET) measurement.

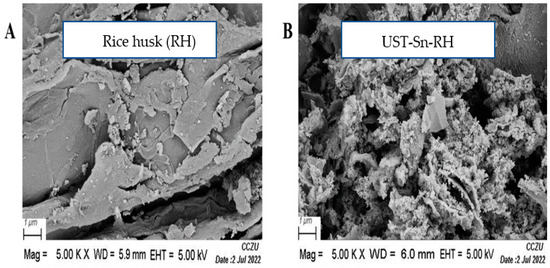

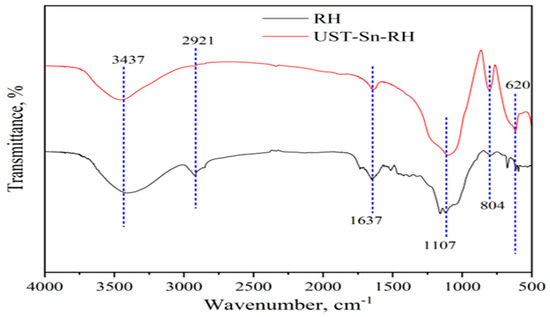

It was observed that UST-Sn-RH surface became much looser after raw material RH was used as a carrier for preparing solid acid (Figure 2A,B), verifying that original surface structure of RH was dramatically destroyed and became looser after a series of treatment (ultrasonic, ethanol, NaOH, H2SO4, etc.) [31]. FT-IR (Figure 3) showed that UST-Sn-RH exhibited diverse properties from raw material RH. The peak about 3437 cm−1 is assigned to the vibration of O-H stretching. The peak near 2921 cm−1 is ascribed to -CH which is prevalent to cellulose, and it was observed to be substantially weakened because of the removal of cellulose [32]. The preparation process of solid acid UST-Sn-RH may reshape the RH structure. As a result, the cellulose and some other structures would be cracked to some extent. The peak about 1637 cm−1 is attributed to aromatic skeletal vibration [33]. The peak near 1107 cm−1 is related to the stretching vibration of C-O and S=O [34]. The peak near 804 cm−1 is associated with carbonate [35]. The peak near 620 cm−1 is assigned the loaded SnO2 [30,33]. Overall, FT-IR verified that Brönsted/Lewis acid sites had been successfully loaded on UST-Sn-RH.

Figure 2.

Scanning Electron Microscopy (SEM) images of rice husk (RH) (A) and chemocatalyst UST-Sn-RH (B).

Figure 3.

Fourier transform infrared spectroscopy (FT-IR) images of chemocatalyst UST-Sn-RH. FT-IR was conducted by using Nicolet IS50 (Thermo Scientific, Waltham, MA, USA) in the range of 4000–500 cm−1.

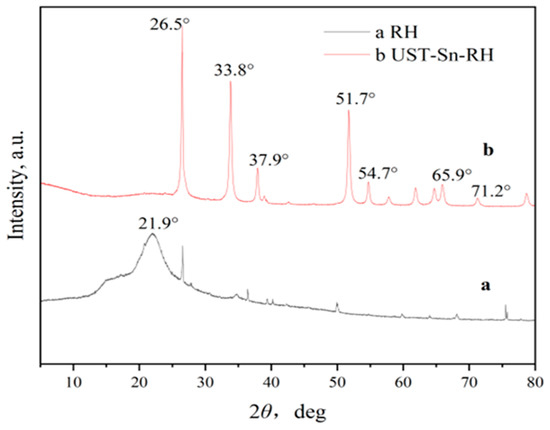

XRD technique can be employed to test the crystal structure of UST-Sn-RH. As revealed in XRD images (Figure 4), a broad diffraction peak at 21.9° ranging from 10° to 30° indicates the existence of amorphous structure in RH. Distinct from raw RH, the narrow diffraction peaks observed at 26.5°, 33.8°, 37.9°, 51.7°, 54.7°, 65.9° and 71.2° are attributed to the crystal structure of SnO2 loaded on UST-Sn-RH, which was consistent with the former report on SnO2 [36].

Figure 4.

X-Ray Diffraction (XRD) images of RH and chemocatalyst UST-Sn-RH [XRD was carried out by using a D/max-2500 (Japan) instrument (Rigaku Co., Akishima-shi, Japan) with CuKα radiation (λ = 1.5406) (40 kV, 30 mA). The 2θ angle was scanned between 5° and 80°.

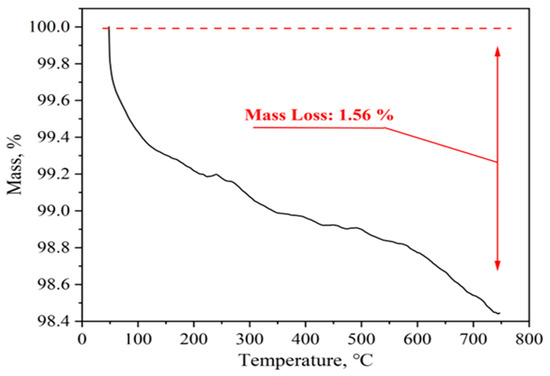

TG analysis can be used to test the thermal stability of catalysts, which is reflected by mass loss of the catalyst at high temperature [37]. Only 1.56% mass loss can be observed on the UST-Sn-RH prepared in this study after being heated to 750 °C, reflecting the good thermal stability of UST-Sn-RH (Figure 5). The NH3-TPD technique was used to measure the acid properties of Sn-DAT-SS. Depending on the desorption temperature of NH3, a heterogeneous catalyst is composed of the weak site (79.6 °C), medium site (383.8 °C), and strong site (577.5 °C and 737.5 °C) (Figure S1, in Supplementary Materials). From the above characterization, it can be seen that the Lewis/Brönsted acid sites are successfully loaded on the catalyst UST-Sn-RH using biomass waste RH as the carrier, which may efficiently transform biomass into FAL.

Figure 5.

Thermogravimetric Analysis (TG) images of chemocatalyst UST-Sn-RH. TG was analyzed at a temperature ramping of 10 °C min−1 from 50 to 750 °C under nitrogen atmosphere to detect the weight loss of the sample.

2.2. Optimization of Transformation CCB into FAL with UST-Sn-RH

In recent years, the corrosion and contamination caused by some homogeneous acid catalysts have been recognized in the preparation of FAL. In this case, heterogeneous chemocatalysts have been widely studied by researchers due to its high catalytic activity, low price and easy preparation process [38,39,40]. In this study, the most important parameters, such as performance temperature (160–180 °C) and reaction duration (5–60 min), were optimized to obtain the highest FAL yield in UST-Sn-RH-catalyzed system.

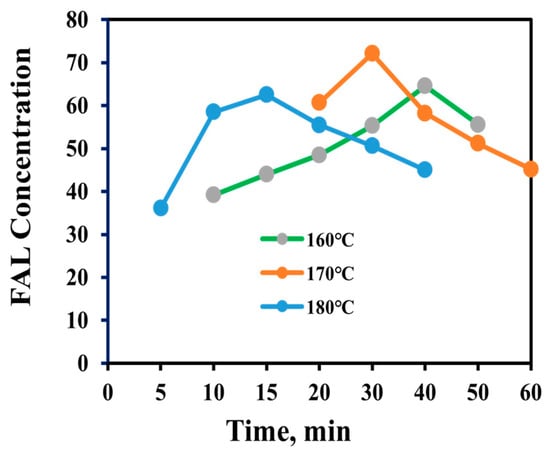

As revealed in Figure 6, highest yield of 40.9% was observed at 170 °C for 30 min, after exploring the effect of different temperatures and time on the FAL yield, the FAL could reach 72.1 mM. Too long reaction time could cause a lower FAL yield. Probably, the higher temperature and longer reaction time not only accelerated the formation of FAL, but also sped up the side reaction on FAL such as degradation. On the other hand, the reason why lower FAL yield was obtained under the condition of higher reaction temperature and long performance time was that more byproducts would deposit on the active site of catalyst UST-Sn-RH. The catalytic efficiency of the bifunctional solid acid NH2SO3H was optimized at 200 °C for 30 min [41]. After the reaction at 170 °C for 20 min, corn stover-derived pentose could be most effectively converted to FAL [42]. Under the above optimal reaction temperature and time, it was detected by HPLC that the formed FAL liquor contained 72.1 mM FAL, 20.2 mM cellobiose, 23.3 mM glucose, 14.3 mM formic acid, 6.1 mM levulinic acid and 1.2 mM HMF after the catalytic reaction (Figure S2, in Supplementary Materials). In order to test the performance on the effect of Sn content on solid acid, element analysis was made at the recycled UST-Sn-RH, the Sn ions bonded on the solid catalyst just decreased slightly from 9.57% to 8.21% after use.

Figure 6.

The performance time (5–60 min) and catalytic temperature (160–180 °C) on the influence on the FAL generation. In an autoclave containing 40 mL distilled water, 75 g/L of ground CCB (37.2% glucan, 31.1% xylan, and 16.5% lignin) was blended with UST-Sn-RH (1.5 wt%) and reacted at the designed temperature and reaction duration by stirring at 550 rpm.

As we all know, the structure of lignocellulosic biomass is quite compact and various ingredients (such as cellulose, hemicellulose and lignin) are intertwined together. During the reaction in autoclave, due to the thermal energy provided by high temperature and the Brönsted acid sites which were loaded on UST-Sn-RH, lignocellulose structure becomes loose. Therefore, the hemicellulose without a relatively tight structure is depolymerized into xylan. In the aqueous phase system, water can provide H+ to the reaction which would accelerate the breakdown of polymers [43]. In the presence of H+, xylan is hydrolyzed to monomeric xylose. Xylulose is then obtained by the isomerization of xylose, which is catalyzed by the Lewis acid sites on UST-Sn-RH. Then, three H2O molecules are removed from xylulose to form FAL catalyzed by the Brönsted acid sites loaded on the heterogenous catalyst [44]. During the reaction, the hemicellulose in biomass is hydrolyzed, the cellulose is also inevitably broken down into hexose sugars to some extent. The similar reaction of xylose also happened on hexose, which is then transformed into HMF in the aqueous phase. As HMF has excellent water solubility; it is easy for HMF to diffuse in the aqueous phase and react with water molecules. Subsequently, HMF is further degraded into formic acid and levulinic acid. Using bio-based UST-Sn-RH as a catalyst, CCB was catalyzed to FAL as well as HMF, formic acid and levulinic acid.

2.3. Biological Reduction of FAL with KPADH Cells

Compared with the chemical reduction, biological reduction has caught lots of attention from researchers; reactions could be catalyzed efficiently under mild conditions, avoiding the use of expensive heavy metal catalysts [19,22]. KPADH cells harboring ADH and GDH were employed to transform FAL into FOL in a MIBK-H2O biphasic system.

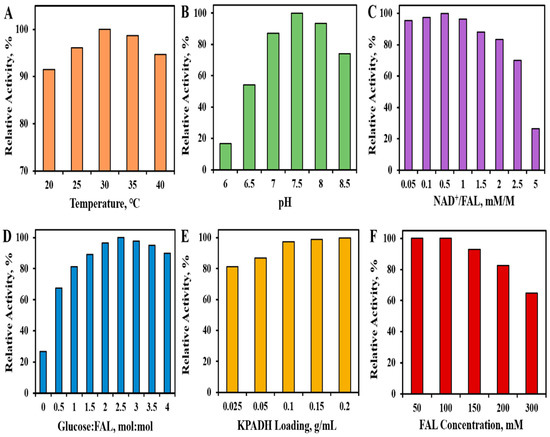

It is well known that the bioreduction activity can be greatly influenced by performance temperature, medium pH, NAD+ loading and glucose load [23,24,25,26]. As illustrated in the Figure 7A,B, the highest FAL-reducing activity was achieved when the temperature and pH reached 30 °C and 7.5, respectively. Consequently, the following experiments were performed under these conditions. The bioreduction activity of KPADH cells were greatly affected by the addition of the NAD+ (0.05–5.0 mM per mol FAL) in the existence of glucose (2.5 mol per mol FAL) and FAL (100 mM) (Figure 7C). The activity arrived at the maximum as the NAD+ load reached 0.5 mM per mol FAL [27]. As depicted in Figure 7D, the glucose dosage had significant influence on the FAL-reducing activity. As the glucose dosage increased from 0 to 2.5 mol glucose per mol FAL, FAL-reducing activities were raised gradually, and the maximum of biocatalytic activity was obtained when the glucose-to-FAL molar ratio was 2.5:1. Over this molar ratio, the bioreduction activity was inhibited. As a result, 2.5 mol glucose per mol FAL was the most proper dosage for bioreduction of FAL. The load of biocatalyst was also an important parameter in the bioreduction [45], and the formation of FOL was promoted by increasing the biocatalyst load (0.025–0.2 g/mL). As revealed in the Figure 7E, the bioconversion activity increased greatly as the load of KPADH was raised from 0.025 to 0.2 g/mL. When the load was increased over 0.1 g/mL, the enhancement of biocatalytic activity was slight. Therefore, the conclusion could be drawn that 0.1 g/mL biocatalyst was the most suitable load for FAL reduction. As we all know, too high FAL concentration could have a toxic effect on biological activity. To test the tolerance of KPADH towards FAL, 50–300 mM FAL was added to the reduction system. As shown in Figure 7F, 50 and 100 mM FAL was wholly transformed into FOL within 3 h. When FAL concentration ranged from 150–300 mM, the FAL conversion reached 93.0% to 64.9%. High concentration FAL obviously inhibited the bioreduction activity; however, the yield of 64.9% was still obtained with 300 mM FAL, which showed the great tolerance of KPADH [25,46].

Figure 7.

(A) Effects of bioreduction temperature (20–40 °C) on the FAL-reducing activity (FAL 100 mM, pH 7.5, NAD+/FAL 0.5:1 (mmol:mol), glucose/FAL 2.5:1 (mol:mol), KPADH cell wet weight 0.1 g/mL); (B) effects of bioreduction pH (100 mM KH2PO4-K2HPO4 buffer, pH 6.0–8.5) on the FAL-reducing activity (FAL 100 mM, 30 °C, NAD+/FAL 0.5:1 (mmol:mol), glucose/FAL 2.5:1 (mol:mol), KPADH cell wet weight 0.1 g/mL); (C) effects of NAD+ load (NAD+ to FAL molar ratio, 0.05–5:1, mmol: mol) on the FAL-reducing activity (FAL 100 mM, 30 °C, pH 7.5, glucose/FAL 2.5:1 (mol:mol), KPADH cell wet weight 0.1 g/mL); (D) effects of glucose load (glucose to FAL molar ratio, 0–4:1 mol: mol) on the FAL-reducing activity (FAL 100 mM, 30 °C, pH 7.5, NAD+/FAL 0.5:1 (mmol:mol), KPADH cell wet weight 0.025–0.2 g/mL); (E) effects of cell biocatalyst load (0.025–0.20 g/mL) on the FAL-reducing activity (FAL 100 mM, 30 °C, pH 7.5, NAD+/FAL 0.5:1 (mmol:mol), glucose/FAL 2.5:1 (mol:mol)); (F) effects of FAL concentration (50–300 mM) on the FAL-reducing activity (30 °C, pH 7.5, NAD+/FAL 0.5:1 (mmol:mol), glucose/FAL 2.5:1 (mol:mol), KPADH cell wet weight 0.1 g/mL).

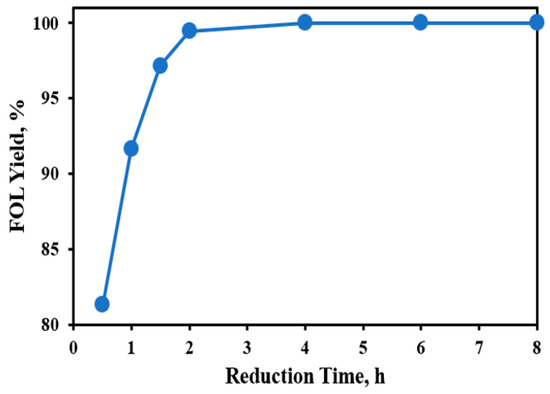

In this study, the biological reduction was carried out under optimized reaction conditions using KPADH cell as the biocatalyst, and 100 mM of FAL was efficiently converted to FOL in the analytical yield of 100%. Using S. cerevisiae NL22 as the biocatalyst, the maximal FOL yield of 98% was given at 30 °C in the presence of 62 mM FAL within 8 h [47]. In the conversion by B. coagulans NL01, about 98 mM FOL was synthesized from FAL in 24 h with the yield of 92% [48]. SF21 cells transformed CCB-derived FAL (74.6 mM) to FOL with a conversion of 95.8% at 40 °C [23]. Of FAL, 94.8% (66.0 mM) was reduced to FOL using CCZU-A13 cell as biocatalyst at 30 °C in 2 h [15]. Monitoring time course of FAL-reducing reaction is critical to learn about the biological reaction process. As depicted in Figure 8, 97.2% of FAL (100 mM) was transformed into FOL in 90 min. When the biological reaction was carried out for 2 h, the FOL yield reached nearly 100%. As a result, it was obviously that KPADH whole cells had excellent bioreduction activity towards FAL in the aqueous phase. This established bioreduction strategy had potential application in the production of FOL.

Figure 8.

Time course of 100 mM FAL into FOL by KPADH cells (FAL 100 mM, 30 °C, pH 7.5, NAD+/FAL 0.5:1 (mmol:mol), glucose/FAL 2.5:1 (mol:mol), cell wet weight 0.1 g/mL).

2.4. Chemoenzymatic Cascade Catalysis with UST-Sn-RH and KPADH Cells

In this study, a chemoenzymatic cascade reaction route was established using UST-Sn-RH and KPADH whole cells as catalysts. In view of biomass components, UST-Sn-RH-catalyzed CCB conversion and KPADH cell-catalyzed FAL reduction, a mass balance was depicted in Figure 9. In a 2.5-L autoclave (170 °C) containing 75.0 g of CCB (27.9 g of glucan, 23.3 g of xylan, and 12.4 g of lignin) and 1.0 L of distilled water, FAL was obtained via the catalysis with UST-Sn-RH after 30 min. The FAL liquor contained 6.92 g of FAL which mainly existed in the upper layer of MIBK and by-products such as 6.9 g of cellobiose, 4.2 g of glucose, 0.71 g of levulinic acid, 0.66 g of formic acid and 0.15 g of HMF were dissolved mainly in the aqueous phase. The treated CCB (51.2% of glucan, 10.3% of xylan, and 8.5% of lignin) remained in this reactor. Sequentially, the CCB-derived FAL in liquid was biologically transformed to 7.07 g of FOL using KPADH at 30 °C within 2 h (Figure 9). The final FOL productivity was achieved at 0.304 g FOL per g xylan in biomass. In addition, the biological reduction did not happen on other CCB-derived by-products (such as HMF and levulinic acid) when KPADH cell was used as the biocatalyst. Lignocellulose is a kind of renewable material consisting of complex network composed of cellulose, hemicellulose and lignin. These materials have caught great interest from researchers and are used to produce biobased high-value chemicals [2,3,4,5,49,50]. In this study, hemicellulose in lignocellulose was catalyzed by Brönsted/Lewis acid sites on the surface of solid acid UST-Sn-RH to synthesize FAL. In the reaction, hemicellulose was rapidly hydrolyzed to xylose, and the majority of xylose was transformed to FAL whose concentration finally achieved 72.1 mM. This result showed that the synthesis of FAL from CCB was greatly promoted by the bio-based chemocatalyst UST-Sn-RH. In addition, KPADH cells had high bioreduction activity and transformed FAL into FOL in a high yield. Compared with the previous reports (Table 2), KPADH cells could efficiently transform higher concentrations of FAL in shorter time periods and obtain a relative high FOL productivity (0.304 g/g of xylan in CCB) an aqueous phase system. Compared to commercial FAL, corncob-derived FAL can also be efficiently transformed into FOL with reductase biocatalyst, indicating the feasibility of chemoenzymatically converting CCB into FOL.

Figure 9.

Mass balance for chemoenzymatic cascade transformation of milled CCB (75 g/L) into FLA in a tandem catalysis with UST-Sn-RH at 170 °C for 30 min and KPADH cells at 30 °C and pH 7.0 for 2 h in an aqueous phase system.

Table 2.

Examples of transforming FAL into FOL with the biocatalyst.

The conversion of lignocellulose into furan-based chemicals such as FOL by chemoenzymatic cascades is one of the research hotspots at present [15,23,25,27,49,50]. In this study, UST-Sn-RH, which used RH as the bio-based carrier, was employed to transform the chemical conversion of corncob (CCB) to FAL in an aqueous system. As we all know, CCB is a kind of lignocellulosic biomass, which is the largest renewable bioresource on earth. Using this biobased RH as carrier, UST-Sn-RH was easily prepared. The prepared heterogeneous catalyst UST-Sn-RH contained Lewis and Brönsted acid sites and could catalyze 75 g/L of CCB to promote the production of FAL (72.1 mM) in an aqueous system. To efficiently catalyze the biological reduction of FAL to FOL, the recombinant E. coli KPADH was used for the bioreduction. The FOL yield of 98% was given catalyzed by S. cerevisiae NL22 at 30 °C, with 62 mM FAL within 8 h [47]. When B. coagulans NL01 was used as biocatalyst, 92% of FOL yield was given in the presence of 98 mM FAL in 24 h [48]. In the DES-water system, biomass-derived FAL (74.6 mM) was converted into FOL with a conversion of 95.8% at 40 °C and pH 7.0 catalyzed by recombinant E. coli SF21 [23]. Within 2 h, 94.8% of FAL (66.0 mM) was converted into FOL using CCZU-A13 cell biocatalyst at 30 °C [15]. Compared with the former studies, KPADH cells transformed 100–300 mM of commercial FAL into FOL with the yield of 69.6–100% within 3 h, and 72.1 mM of CCB-derived FAL was completely converted into FOL after 2 h of bioreduction. Moreover, a hybrid strategy was newly constructed by bridging the chemocatalyst and biocatalyst and FOL could be effectively produced from CCB in this way. Although chemocatalyst UST-Sn-RH existed in the reaction system, the obvious inhibition to the reduction activity of KPADH whole cell was not observed. As a result, a chemoenzymatic cascade reaction was successfully constructed in this study to efficiently convert CCB into furan-based platform chemical FOL.

3. Materials and Methods

3.1. Chemicals and Materials

Corncob (CCB) and rice husk (RH) were obtained from the remote countryside in Xuzhou city, China. SnCl4·5H2O, sulphuric acid (H2SO4), NaOH, furfural (FAL), NaCl, methyl isobutyl ketone (MIBK), tetrahydrofuran (THF), cyclopentyl methyl ether (CPME), dichloromethane (DCM), ethanol and other reagents were bought from Aladdin (Shanghai, China) and other commercial sources.

3.2. Preparation of Solid Acid Catalysts UST-Sn-RH Using RH as the Carrier

UST-Sn-RH was prepared via the following steps: First, the ground RH (80.0 g) was immersed in 300 mL of NaOH (0.5 M) ethanol solution at room temperature for 4 h and placed in an ultrasonic processor (SB-5200DTS, Ningbo Science Biotechnology Co., Ltd., Ningbo, China) (300 W, 60 °C). The ultrasonic-treated RH was then separated by filtration and rinsed with distilled water until it became neutral. After drying, the obtained UST-RH was immersed in 300 mL of ethanol in which 20.0 g of SnCl4·5H2O was dissolved, and the pH was adjusted to 6.0 using ammonia (25.0%). The resulting colloidal solution was separately oven-dried at 70 °C and 90 °C for 48 h. Next, the dry gray powder was soaked in 4M H2SO4 at 60 °C for sulfonation. After 4 h, the sulfonated solid powder was filtered and further dried at 90 °C. Finally, the resulting black powder was calcined at 550 °C for 4 h. After calcining, the formed catalyst UST-Sn-RH was further used to transform biomass into FAL. Elemental analysis was conducted using a plasma spectrometer (Model#: Optima 5300DV, PerkinElmer, Waltham, MA, USA) to detect the changes of the content of different elements (Sn) in the solid acid catalyst before and after use.

3.3. Conversion of CCB to FAL with UST-Sn-RH

In an autoclave (Dantu Universal Electronic Equipment Components Factory, Zhenjiang, P.R. China) containing 40 mL distilled water, 75 g/L of ground CCB (37.2% glucan, 31.1% xylan, and 16.5% lignin) was mixed with UST-Sn-RH (1.5 wt%) and reacted at 160–170 °C and pH 1.1 for 5–60 min and 550 rpm. As soon as the reaction was finished, the autoclave was transferred to ice-water to quench the reaction. FAL yields were analyzed by high performance liquid chromatography (HPLC).

3.4. Biological Reduction of FAL into FOL with KPADH Whole Cells

KPADH cells harboring reductase from Kluyveromyces polyspora (KP) and glucose dehydrogenase (GDH) from Bacillus subtilis were constructed, cultivated and harvested as previously reported [28]. The biological reduction reactions were carried out at different pH (6.0–8.5) at 20–40 °C with KPADH wet cells (0.025–0.20 g/mL), FAL (50–300 mM), co-substrate glucose (0–4.0 mol glucose per mol FAL) and coenzyme NAD+ (0.05–5.0 mM).

To improve biocatalytic activity of KPADH cells, various biological reduction conditions were optimized. To test the effects of different biocatalytic temperatures and medium pH on the biotransformation activity, the reduction system containing KPADH cells (0.10 g/mL), FAL (100 mM), NAD+ (0.5 µM/mM FAL) and glucose (2.5 mol glucose/mol FAL) were incubated at 20–40 °C and pH 6.0–8.5. To test the effects of coenzyme NAD+ (0.05–5.0 mM) on the biotransformation activity, different amounts of NAD+ (0.05–5.0 mM) were supplemented into the reduction medium (30 °C, pH 7.5) containing KPADH wet cells (0.10 g/mL), FAL (100 mM) and glucose (2.5 mol glucose/mol FAL). To test different loads of glucose (as co-substrate) on influencing biotransformation activity, glucose (0–4.0 mol glucose/mol FAL), NAD+ (0.5 µM/mM FAL) and 100 mM FAL were supplemented into the reduction medium (30 °C, pH 7.5) containing 0.10 g/mL wet cells. To optimize the loading of KPADH cells, different amounts of KPADH wet cells (0.025–0.20 g/mL) was supplemented into the reduction medium (30 °C, pH 7.5) containing FAL (100 mM), NAD+ (0.5 µM/mM FAL) and glucose (2.5 mol glucose/mol FAL). To explore the tolerance of KPADH towards FAL, different amounts of FAL (50–300 mM) were supplemented into the reduction medium (30 °C, pH 7.5) containing KPADH wet cells (0.05 g/mL), NAD+ (0.5 µM/mM FAL) and glucose (2.5 mol glucose/mol FAL). After the transformation on a shaker (180 rpm) for 3 h, the substrate FAL and product FOL were determined with HPLC.

3.5. Analytical Methods

UST-Sn-RH was measured with XRD (X-ray Diffraction) (Rigaku Co., Akishima-shi, Japan), TG (Thermogravimetric Analysis) (Mettler-Toledo AG, Schwerzenbach, Switzerland), SEM (Scanning Electron Microscopy) (JEOL, Tokyo, Japan), and FT-IR (Fourier Transform Infrared Spectroscopy) (Thermo Electron Co., Waltham, MA, USA) to explore its microstructure and properties [24,49,51]. FAL and FOL were quantified with a Model 2695 HPLC (Waters Corporation, Milford, MA) equipped with a Waters Nova-Pak C18 column (3.9 mm × 150 mm, 4 µM) as reported in reference [23,24].

The yields of FAL and FOL are calculated as follows:

4. Conclusions

In this study, a novel heterogeneous catalyst UST-Sn-RH was prepared using rice husk as a bio-based carrier to catalyze the efficient conversion of lignocellulose into FAL. In addition, in order to efficiently convert FAL into FOL, recombinant E. coli KPADH were constructed. As a result, the FOL productivity was obtained at 0.304 g FOL/g xylan using the chemoenzymatic strategy which bridged the chemocatalyst UST-Sn-RH and the biocatalyst E. coli KPADH cells. Compared with chemical reduction, biological reduction is a clean and efficient approach for FOL production. Additionally, the established one-pot chemoenzymatic process could be conducted in a tandem reaction with chemocatalysis of available renewable and inexpensive lignocellulose into FAL and biocatalysis of FAL into FOL, which would reduce the equipment input and shorten the performance time. Clearly, this strategy provided an environment-friendly way to convert CCB to FOL and indicates a promising future in industrial application.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/catal13010037/s1, Figure S1: The NH3-TPD image of UST-Sn-RH, Figure S2: The HPLC image of FAL liquor after chemocatalysis.

Author Contributions

Methodology, software, validation, formal analysis, investigation, resources, data curation, writing—original draft preparation, Q.Y., Z.T. and J.X.; visualization, supervision, writing—review and editing, Y.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was kindly funded by Open Project Program of the State Key Laboratory of Bioreactor Engineering.

Data Availability Statement

Not applicable.

Acknowledgments

The authors thank the Analysis and Testing Center (Changzhou University) for analysis of solid acid with FT-IR, SEM, XRD, BET analysis and TG.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| LCB | Lignocellulosic biomass |

| RH | rice husk |

| CCB | corncob |

| FAL | furfural |

| OL | furfuryl alcohol |

| ADH | aldehyde reductase |

| GDH | glucose dehydrogenase |

| XRD | X-Ray Diffraction |

| BET | Brunner-Emmet--Teller Measurements |

| TG | Thermogravimetric Analysis |

| SEM | Scanning Electron Microscopy |

| FT-IR | Fourier Transform Infrared Spectroscopy |

References

- Prasad, R.K.; Chatterjee, S.; Mazumder, P.B.; Gupta, S.K.; Sharma, S.; Vairale, M.G.; Datta, S.; Dwivedi, S.K.; Gupta, D.K. Bioethanol production from waste lignocelluloses: A review on microbial degradation potential. Chemosphere 2019, 231, 588–606. [Google Scholar] [CrossRef] [PubMed]

- Brandt, B.A.; Jansen, T.; Görgens, J.F.; Zyl, W.H. Overcoming lignocellulose-derived microbial inhibitors: Advancing theSaccharomyces cerevisiaeresistance toolbox. Biofuel Bioprod. Biorefin. 2019, 13, 1520–1536. [Google Scholar] [CrossRef]

- Zhang, J.; Cai, D.; Qin, Y.; Liu, D.; Zhao, X. High value-added monomer chemicals and functional bio-based materials derived from polymeric components of lignocellulose by organosolv fractionation. Biofuel Bioprod. Biorefin. 2019, 14, 371–401. [Google Scholar] [CrossRef]

- Galkin, M.V.; Samec, J.S. Lignin valorization through catalytic lignocellulose fractionation: A fundamental platform for the future biorefinery. ChemSusChem 2016, 9, 1544–1558. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, D.; Zhao, X. Conversion of lignocellulose to biofuels and chemicals via sugar platform: An updated review on chemistry and mechanisms of acid hydrolysis of lignocellulose. Renew. Sustain. Energy Rev. 2021, 146, 111169. [Google Scholar] [CrossRef]

- Scapini, T.; Dos Santos, M.S.N.; Bonatto, C.; Wancura, J.H.C.; Mulinari, J.; Camargo, A.F.; Klanovicz, N.; Zabot, G.L.; Tres, M.V.; Fongaro, G.; et al. Hydrothermal pretreatment of lignocellulosic biomass for hemicellulose recovery. Bioresour. Technol. 2021, 342, 126033. [Google Scholar] [CrossRef]

- Hassan, S.S.; Williams, G.A.; Jaiswal, A.K. Emerging technologies for the pretreatment of lignocellulosic biomass. Bioresour. Technol. 2018, 262, 310–318. [Google Scholar] [CrossRef]

- Lee, C.B.T.L.; Wu, T.Y. A review on solvent systems for furfural production from lignocellulosic biomass. Renew. Sustain. Energy Rev. 2021, 137, 110172. [Google Scholar] [CrossRef]

- Zhang, T.; Li, W.; Xiao, H.; Jin, Y.; Wu, S. Recent progress in direct production of furfural from lignocellulosic residues and hemicellulose. Bioresour. Technol. 2022, 354, 127126. [Google Scholar] [CrossRef]

- Li, W.; Zhu, Y.; Lu, Y.; Liu, Q.; Guan, S.; Chang, H.M.; Jameel, H.; Ma, L. Enhanced furfural production from raw corn stover employing a novel heterogeneous acid catalyst. Bioresour. Technol. 2017, 245, 258–265. [Google Scholar] [CrossRef]

- Wang, L.; Chen, E.Y.X. An interchangeable homogeneous ⇔ heterogeneous catalyst system for furfural upgrading. Green Chem. 2015, 17, 5149–5153. [Google Scholar] [CrossRef]

- Pizzi, R.; van Putten, R.J.; Brust, H.; Perathoner, S.; Centi, G.; van der Waal, J. High-throughputscreening of heterogeneous catalysts for the conversion of furfural to bio-based fuel components. Catalysts 2015, 5, 2244–2257. [Google Scholar] [CrossRef]

- Li, X.; Xia, Q.; Nguyen, V.C.; Peng, K.; Liu, X.; Essayem, N.; Wang, Y. High yield production of HMF from carbohydrates over silica–alumina composite catalysts. Catal. Sci. Technol. 2016, 6, 7586–7596. [Google Scholar] [CrossRef]

- Delbecq, F.; Takahashi, Y.; Kondo, T.; Corbas, C.C.; Ramos, E.R.; Len, C. Microwave assisted efficient furfural production using nano-sized surface-sulfonated diamond powder. Catal. Commun. 2018, 110, 74–78. [Google Scholar] [CrossRef]

- Feng, X.Q.; Li, Y.Y.; Ma, C.L.; Xia, Y.; He, Y.C. Improved conversion of bamboo shoot shells to furfuryl alcohol and furfurylamine by a sequential catalysis with sulfonated graphite and biocatalysts. RSC Adv. 2020, 10, 40365–40372. [Google Scholar] [CrossRef]

- Gómez Millán, G.; Sixta, H. Towards the green synthesis of furfuryl alcohol in a one-pot system from xylose: A review. Catalysts 2020, 10, 1101. [Google Scholar] [CrossRef]

- Gong, W.; Chen, C.; Zhang, Y.; Zhou, H.; Wang, H.; Zhang, H.; Zhang, Y.; Wang, G.; Zhao, H. Efficient synthesis of furfuryl alcohol from H2-hydrogenation/transfer hydrogenation of furfural using sulfonate group modified Cu catalyst. ACS Sustain. Chem. Eng. 2017, 5, 2172–2180. [Google Scholar] [CrossRef]

- Audemar, M.; Ciotonea, C.; De Oliveira Vigier, K.; Royer, S.; Ungureanu, A.; Dragoi, B.; Dumitriu, E.; Jerome, F. Selective hydrogenation of furfural to furfuryl alcohol in the presence of a recyclable Cobalt/SBA-15 catalyst. ChemSusChem 2015, 8, 1885–1891. [Google Scholar] [CrossRef]

- Li, H.; Zhang, S.; Luo, H. A Ce-promoted Ni–B amorphous alloy catalyst (Ni–Ce–B) for liquid-phase furfural hydrogenation to furfural alcohol. Mater. Lett. 2004, 58, 2741–2746. [Google Scholar] [CrossRef]

- Fukuda, H.; Kondo, A.; Tamalampudi, S. Bioenergy: Sustainable fuels from biomass by yeast and fungal whole-cell biocatalysts. Biochem. Eng. J. 2009, 44, 2–12. [Google Scholar] [CrossRef]

- Ribeiro, L.F.; Amarelle, V.; Alves, L.F.; Viana de Siqueira, G.M.; Lovate, G.L.; Borelli, T.C.; Guazzaroni, M.E. Genetically engineered proteins to improve biomass conversion: New advances and challenges for tailoring biocatalysts. Molecules 2019, 24, 2879. [Google Scholar] [CrossRef] [PubMed]

- Nagaraja, B.M.; Padmasri, A.H.; David Raju, B.; Rama Rao, K.S. Vapor phase selective hydrogenation of furfural to furfuryl alcohol over Cu–MgO coprecipitated catalysts. J. Mol. Catal. A Chem. 2007, 265, 90–97. [Google Scholar] [CrossRef]

- Pan, L.; Li, Q.; Tao, Y.; Ma, C.; Chai, H.; Ai, Y.; He, Y.-C. An efficient chemoenzymatic strategy for valorisation of corncob to furfuryl alcohol in CA:Betaine-water. Ind. Crops Prod. 2022, 186, 115203. [Google Scholar] [CrossRef]

- Li, Q.; Ma, C.; Di, J.; Ni, J.; He, Y.C. Catalytic valorization of biomass for furfuryl alcohol by novel deep eutectic solvent-silica chemocatalyst and newly constructed reductase biocatalyst. Bioresour. Technol. 2022, 347, 126376. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Ren, J.-Q.; Li, Q.; Di, J.-H.; Ma, C.; He, Y. Sustainable conversion of biomass-derived d-xylose to furfuryl alcohol in a deep eutectic solvent–water system. ACS Sustain. Chem. Eng. 2021, 9, 10299–10308. [Google Scholar] [CrossRef]

- Qin, L.Z.; He, Y.C. Chemoenzymatic synthesis of furfuryl alcohol from biomass in tandem reaction system. Appl. Biochem. Biotechnol. 2020, 190, 1289–1303. [Google Scholar] [CrossRef]

- Li, Y.Y.; Li, Q.; Zhang, P.Q.; Ma, C.L.; Xu, J.H.; He, Y.C. Catalytic conversion of corncob to furfuryl alcohol in tandem reaction with tin-loaded sulfonated zeolite and NADPH-dependent reductase biocatalyst. Bioresour. Technol. 2021, 320, 124267. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, Y.; Xu, G.; Wu, L.; Han, R.; Schwaneberg, U.; Rao, Y.; Zhao, Y.L.; Zhou, J.; Ni, Y. Structural insight into enantioselective inversion of an alcohol dehydrogenase reveals a “Polar Gate” in stereorecognition of diaryl ketones. J. Am. Chem. Soc. 2018, 140, 12645–12654. [Google Scholar] [CrossRef]

- Zhang, T.; Li, W.; Xu, Z.; Liu, Q.; Ma, Q.; Jameel, H.; Chang, H.M.; Ma, L. Catalytic conversion of xylose and corn stalk into furfural over carbon solid acid catalyst in gamma-valerolactone. Bioresour. Technol. 2016, 209, 108–114. [Google Scholar] [CrossRef]

- Ji, L.; Tang, Z.; Yang, D.; Ma, C.; He, Y.C. Improved one-pot synthesis of furfural from corn stalk with heterogeneous catalysis using corn stalk as biobased carrier in deep eutectic solvent-water system. Bioresour. Technol. 2021, 340, 125691. [Google Scholar] [CrossRef]

- Zhang, L.; Yu, H.; Wang, P.; Dong, H.; Peng, X. Conversion of xylan, d-xylose and lignocellulosic biomass into furfural using AlCl3 as catalyst in ionic liquid. Bioresour. Technol. 2013, 130, 110–116. [Google Scholar] [CrossRef] [PubMed]

- Zha, J.; Fan, B.; He, J.; He, Y.C.; Ma, C. Valorization of biomass to furfural by chestnut shell-based solid acid in methyl isobutyl ketone-water-sodium chloride system. Appl. Biochem. Biotechnol. 2022, 194, 2021–2035. [Google Scholar] [CrossRef] [PubMed]

- Gong, L.; Zha, J.; Pan, L.; Ma, C.; He, Y.C. Highly efficient conversion of sunflower stalk-hydrolysate to furfural by sunflower stalk residue-derived carbonaceous solid acid in deep eutectic solvent/organic solvent system. Bioresour. Technol. 2022, 351, 126945. [Google Scholar] [CrossRef]

- Kumari, S.; Kumar Annamareddy, S.H.; Abanti, S.; Kumar Rath, P. Physicochemical properties and characterization of chitosan synthesized from fish scales, crab and shrimp shells. Int. J. Biol. Macromol. 2017, 104, 1697–1705. [Google Scholar] [CrossRef]

- Li, Q.; Di, J.; Liao, X.; Ni, J.; Li, Q.; He, Y.-C.; Ma, C. Exploration of benign deep eutectic solvent–water systems for the highly efficient production of furfurylamine from sugarcane bagasse via chemoenzymatic cascade catalysis. Green Chem. 2021, 23, 8154–8168. [Google Scholar] [CrossRef]

- Gavaskar, D.S.; Nagaraju, P.; Vijayakumar, Y.; Reddy, P.S.; Ramana Reddy, M.V. Low-cost ultra-sensitive SnO2-based ammonia sensor synthesized by hydrothermal method. J. Asian Ceram. Soc. 2020, 8, 605–614. [Google Scholar] [CrossRef]

- Zhang, L.; Xi, G.; Zhang, J.; Yu, H.; Wang, X. Efficient catalytic system for the direct transformation of lignocellulosic biomass to furfural and 5-hydroxymethylfurfural. Bioresour. Technol. 2017, 224, 656–661. [Google Scholar] [CrossRef] [PubMed]

- Sudarsanam, P.; Zhong, R.; Van den Bosch, S.; Coman, S.M.; Parvulescu, V.I.; Sels, B.F. Functionalised heterogeneous catalysts for sustainable biomass valorisation. Chem. Soc. Rev. 2018, 47, 8349–8402. [Google Scholar] [CrossRef]

- Xue, Z.; Ma, M.-G.; Li, Z.; Mu, T. Advances in the conversion of glucose and cellulose to 5-hydroxymethylfurfural over heterogeneous catalysts. RSC Adv. 2016, 6, 98874–98892. [Google Scholar] [CrossRef]

- Kim, S.; Kwon, E.E.; Kim, Y.T.; Jung, S.; Kim, H.J.; Huber, G.W.; Lee, J. Recent advances in hydrodeoxygenation of biomass-derived oxygenates over heterogeneous catalysts. Green Chem. 2019, 21, 3715–3743. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, C.; Mao, J.; Ramaswamy, S.; Zhang, X.; Xu, F. Insights on the efficiency of bifunctional solid organocatalysts in converting xylose and biomass into furfural in a GVL-water solvent. Ind. Crops Prod. 2019, 138, 111454. [Google Scholar] [CrossRef]

- Mittal, A.; Black, S.K.; Vinzant, T.B.; O’Brien, M.; Tucker, M.P.; Johnson, D.K. Production of furfural from process-relevant biomass-derived pentoses in a biphasic reaction system. ACS Sustain. Chem. Eng. 2017, 5, 5694–5701. [Google Scholar] [CrossRef]

- Zhao, Y.; Lu, K.; Xu, H.; Zhu, L.; Wang, S. A critical review of recent advances in the production of furfural and 5-hydroxymethylfurfural from lignocellulosic biomass through homogeneous catalytic hydrothermal conversion. Renew. Sustain. Energy Rev. 2021, 139, 110706. [Google Scholar] [CrossRef]

- Xu, S.; Pan, D.; Wu, Y.; Song, X.; Gao, L.; Li, W.; Das, L.; Xiao, G. Efficient production of furfural from xylose and wheat straw by bifunctional chromium phosphate catalyst in biphasic systems. Fuel Process. Technol. 2018, 175, 90–96. [Google Scholar] [CrossRef]

- Qin, L.; Di, J.; He, Y. Efficient synthesis of furfuryl alcohol from corncob in a deep eutectic solvent system. Processes 2022, 10, 1873. [Google Scholar] [CrossRef]

- He, Y.C.; Jiang, C.X.; Jiang, J.W.; Di, J.H.; Liu, F.; Ding, Y.; Qing, Q.; Ma, C.L. One-pot chemo-enzymatic synthesis of furfuralcohol from xylose. Bioresour. Technol. 2017, 238, 698–705. [Google Scholar] [CrossRef]

- Yan, Y.; Bu, C.; Huang, X.; Ouyang, J. Efficient whole-cell biotransformation of furfural to furfuryl alcohol bySaccharomyces cerevisiaeNL22. J. Chem. Technol. Biotechnol. 2019, 94, 3825–3831. [Google Scholar] [CrossRef]

- Yan, Y.; Bu, C.; He, Q.; Zheng, Z.; Ouyang, J. Efficient bioconversion of furfural to furfuryl alcohol by Bacillus coagulans NL01. RSC Adv. 2018, 8, 26720–26727. [Google Scholar] [CrossRef]

- Ni, J.; Li, Q.; Gong, L.; Liao, X.-L.; Zhang, Z.-J.; Ma, C.; He, Y. Highly efficient chemoenzymatic cascade catalysis of biomass into furfurylamine by a heterogeneous shrimp shell-based chemocatalyst and an ω-transaminase biocatalyst in deep eutectic solvent–Water. ACS Sustain. Chem. Eng. 2021, 9, 13084–13095. [Google Scholar] [CrossRef]

- Li, N.; Zong, M.-H. (Chemo)biocatalytic upgrading of biobased furanic platforms to chemicals, fuels, and materials: A comprehensive review. ACS Catal. 2022, 12, 10080–10114. [Google Scholar] [CrossRef]

- Deng, A.; Lin, Q.; Yan, Y.; Li, H.; Ren, J.; Liu, C.; Sun, R. A feasible process for furfural production from the pre-hydrolysis liquor of corncob via biochar catalysts in a new biphasic system. Bioresour. Technol. 2016, 216, 754–760. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).