Mitigation of Air Pollutants by UV-A Photocatalysis in Livestock and Poultry Farming: A Mini-Review

Abstract

:1. Introduction

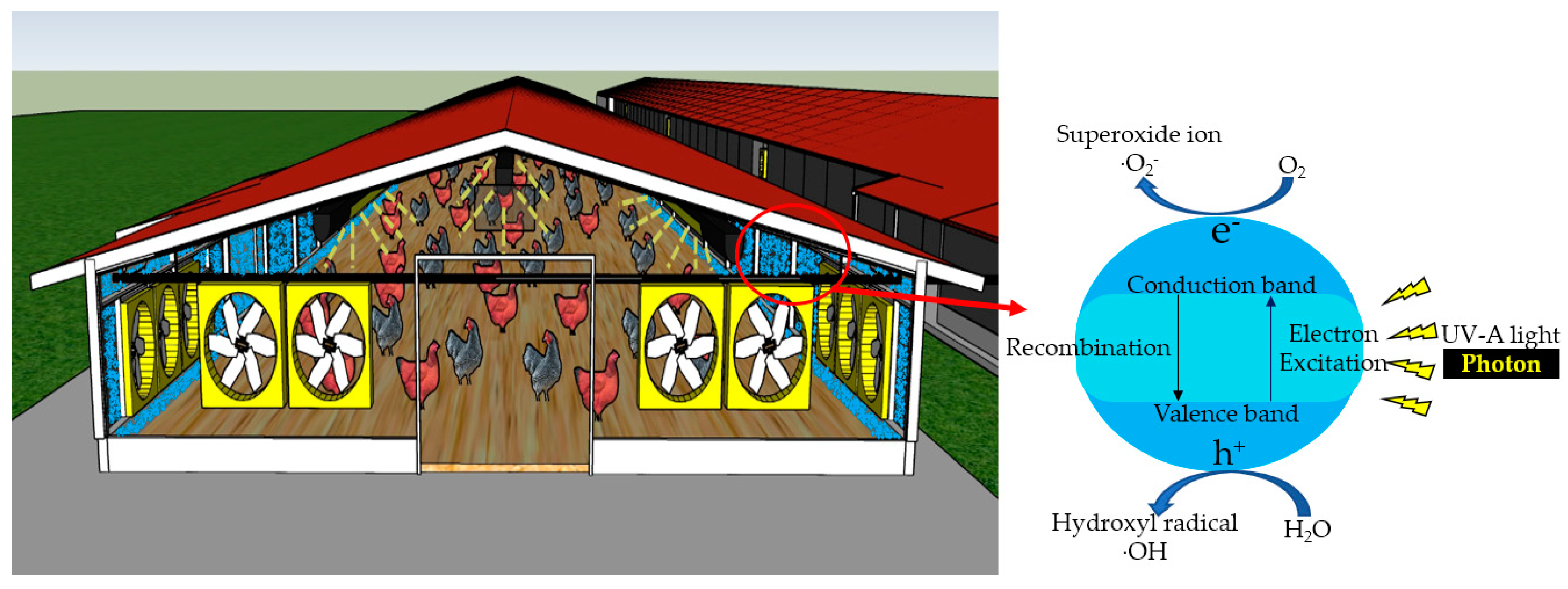

2. Mechanism of UV-A Photocatalysis

3. The Concept of UV Dose for UV-A Photocatalysis Evaluation

4. UV-A Photocatalysis Technology’s Effectiveness in Mitigating Targeted Air Pollutants in Livestock and Poultry Barns

4.1. Mitigation of NH3 and H2S

4.2. Mitigation of VOCs and Odor

4.3. Mitigation of GHGs

4.4. Mitigation of Pollutants

5. Discussion

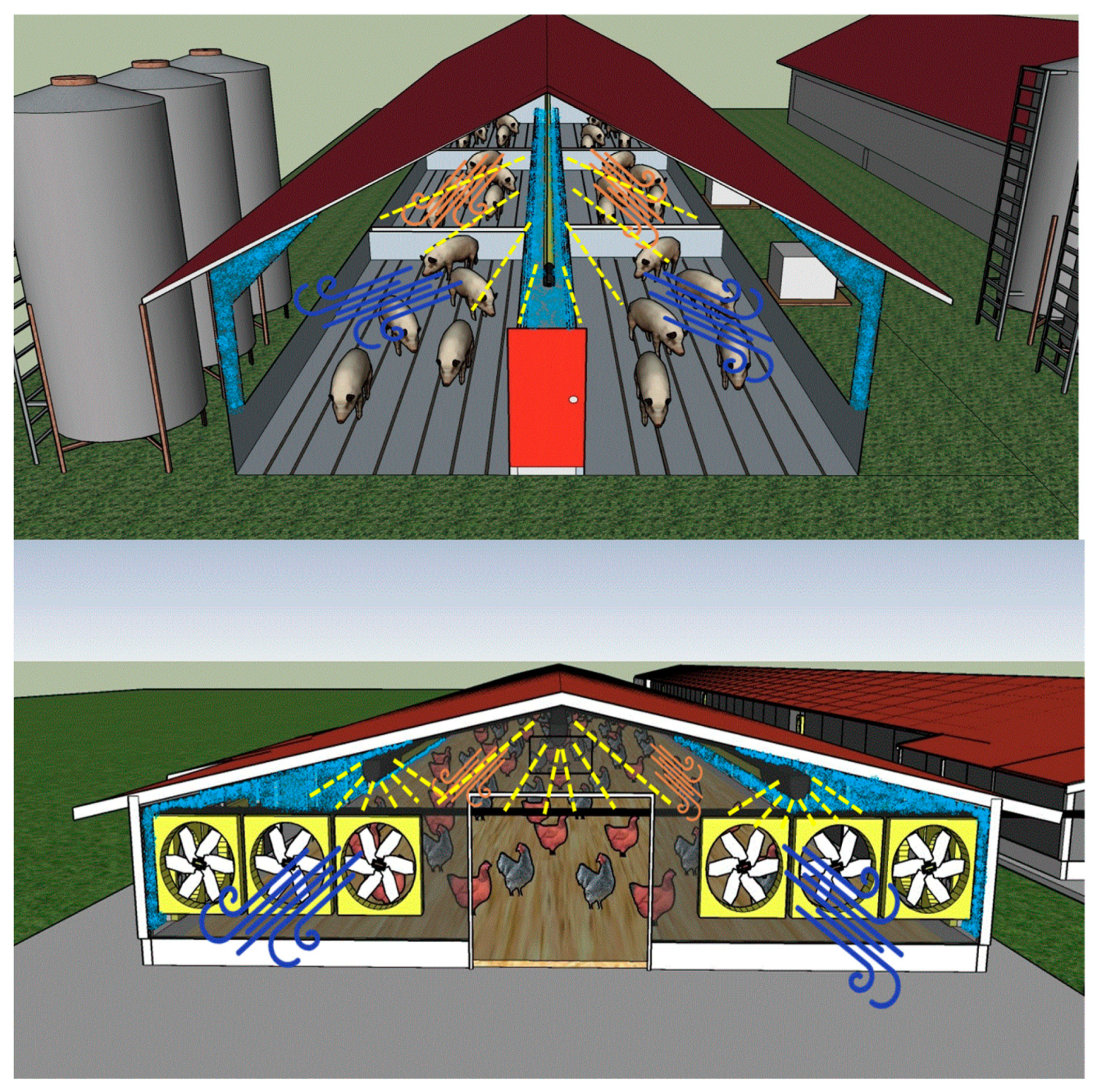

5.1. Expected Advantage of UV-A Photocatalysis in the Livestock and Poultry Barn

5.2. Improvements Needed to UV-A Photocatalysis in Livestock and Poultry Barns

5.3. Cost Effectiveness of UV-A Photocatalysis Application in the Livestock and Poultry Housing

5.4. Possible Future Trends in UV-A Photocatalysis Applications for Livestock Facilities

6. Materials and Methods

- (1)

- the mitigation method with UV light (photolysis and photocatalysis);

- (2)

- the mitigation rate of odorous gases;

- (3)

- coating thickness of catalyst and UV dose.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Maurer, D.L.; Koziel, J.A. On-farm pilot-scale testing of black ultraviolet light and photocatalytic coating for mitigation of odor, odorous VOCs, and greenhouse gases. Chemosphere 2019, 221, 778–784. [Google Scholar] [CrossRef] [PubMed]

- Buijsman, E.; Erisman, J.-W. Wet deposition of ammonium in Europe. J. Atmos. Chem. 1988, 6, 265–280. [Google Scholar] [CrossRef]

- Casey, J.A.; Kim, B.F.; Larsen, J.; Price, L.B.; Nachman, K.E. Industrial food animal production and community health. Curr. Environ. Health Rep. 2015, 2, 259–271. [Google Scholar] [CrossRef] [PubMed]

- Herrero, M.; Gerber, P.; Vellinga, T.; Garnett, T.; Leip, A.; Opio, C.; Westhoek, H.; Thornton, P.K.; Olesen, J.; Hutchings, N. Livestock and greenhouse gas emissions: The importance of getting the numbers right. Anim. Feed. Sci. Technol. 2011, 166, 779–782. [Google Scholar] [CrossRef] [Green Version]

- Rappert, S.; Müller, R. Odor compounds in waste gas emissions from agricultural operations and food industries. Waste Manag. 2005, 25, 887–907. [Google Scholar] [CrossRef]

- Schiffman, S.S. Livestock odors: Implications for human health and well-being. J. Anim. Sci. 1998, 76, 1343–1355. [Google Scholar] [CrossRef] [Green Version]

- Van der Heyden, C.; Demeyer, P.; Volcke, E.I. Mitigating emissions from pig and poultry housing facilities through air scrubbers and biofilters: State-of-the-art and perspectives. Biosyst. Eng. 2015, 134, 74–93. [Google Scholar] [CrossRef]

- Lee, M.; Wi, J.; Koziel, J.A.; Ahn, H.; Li, P.; Chen, B.; Meiirkhanuly, Z.; Banik, C.; Jenks, W. Effects of UV-A Light Treatment on Ammonia, hydrogen sulfide, greenhouse gases, and ozone in simulated poultry barn conditions. Atmosphere 2020, 11, 283. [Google Scholar] [CrossRef] [Green Version]

- Maurer, D.L.; Koziel, J.A.; Harmon, J.D.; Hoff, S.J.; Rieck-Hinz, A.M.; Andersen, D.S. Summary of performance data for technologies to control gaseous, odor, and particulate emissions from livestock operations: Air management practices assessment tool (AMPAT). Data Brief 2016, 7, 1413–1429. [Google Scholar] [CrossRef] [Green Version]

- Bolton, J.R.; Cotton, C.A. The Ultraviolet Disinfection Handbook; American Water Works Association: Denver, CO, USA, 2011. [Google Scholar]

- Hashimoto, K.; Irie, H.; Fujishima, A. TiO2 photocatalysis: A historical overview and future prospects. Jpn. J. Appl. Phys. 2005, 44, 8269. [Google Scholar] [CrossRef]

- Schneider, J.; Matsuoka, M.; Takeuchi, M.; Zhang, J.; Horiuchi, Y.; Anpo, M.; Bahnemann, D.W. Understanding TiO2 photocatalysis: Mechanisms and materials. Chem. Rev. 2014, 114, 9919–9986. [Google Scholar] [CrossRef] [PubMed]

- Haque, M.M.; Bahnemann, D.; Muneer, M. Photocatalytic degradation of organic pollutants: Mechanisms and kinetics. In Organic Pollutants Ten Years after the Stockholm Convention–Environmental and Analytical Update; IntechOpen: London, UK, 2012; p. 293. [Google Scholar]

- Vautier, M.; Guillard, C.; Herrmann, J.-M. Photocatalytic degradation of dyes in water: Case study of indigo and of indigo carmine. J. Catal. 2001, 201, 46–59. [Google Scholar] [CrossRef]

- Zaleska, A. Doped-TiO2: A review. Recent Pat. Eng. 2008, 2, 157–164. [Google Scholar] [CrossRef]

- Athanasekou, C.P.; Moustakas, N.G.; Morales-Torres, S.; Pastrana-Martínez, L.M.; Figueiredo, J.L.; Faria, J.L.; Silva, A.M.; Dona-Rodriguez, J.M.; Romanos, G.E.; Falaras, P. Ceramic photocatalytic membranes for water filtration under UV and visible light. Appl. Catal. B Environ. 2015, 178, 12–19. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.J.; Park, Y.G.; Lee, S.H.; Park, J.H. Photocatalytic properties of TiO2 according to manufacturing method. Korean Chem. Eng. Res. 2018, 56, 156–161. [Google Scholar]

- Chong, M.N.; Jin, B.; Chow, C.W.; Saint, C. Recent developments in photocatalytic water treatment technology: A review. Water Res. 2010, 44, 2997–3027. [Google Scholar] [CrossRef]

- Gomes, J.F.; Leal, I.; Bednarczyk, K.; Gmurek, M.; Stelmachowski, M.; Zaleska-Medynska, A.; Quinta-Ferreira, M.E.; Costa, R.; Quinta-Ferreira, R.M.; Martins, R.C. Detoxification of parabens using UV-A enhanced by noble metals—TiO2 supported catalysts. J. Environ. Chem. Eng. 2017, 5, 3065–3074. [Google Scholar] [CrossRef]

- Jia, J.; Li, D.; Wan, J.; Yu, X. Characterization and mechanism analysis of graphite/C-doped TiO2 composite for enhanced photocatalytic performance. J. Ind. Eng. Chem. 2016, 33, 162–169. [Google Scholar] [CrossRef]

- Abe, R. Recent progress on photocatalytic and photoelectrochemical water splitting under visible light irradiation. J. Photochem. Photobiol. C Photochem. Rev. 2010, 11, 179–209. [Google Scholar] [CrossRef]

- Maeda, K.; Domen, K. Photocatalytic water splitting: Recent progress and future challenges. J. Phys. Chem. Lett. 2010, 1, 2655–2661. [Google Scholar] [CrossRef]

- Costa, A.; Chiarello, G.L.; Selli, E.; Guarino, M. Effects of TiO2 based photocatalytic paint on concentrations and emissions of pollutants and on animal performance in a swine weaning unit. J. Environ. Manag. 2012, 96, 86–90. [Google Scholar] [CrossRef] [PubMed]

- Guarino, M.; Costa, A.; Porro, M. Photocatalytic TiO2 coating—To reduce ammonia and greenhouse gases concentration and emission from animal husbandries. Bioresour. Technol. 2008, 99, 2650–2658. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.; Koziel, J.A.; Macedo, N.R.; Li, P.; Chen, B.; Jenks, W.S.; Zimmerman, J.; Paris, R.V. Mitigation of particulate matter and airborne pathogens in swine barn emissions with filtration and UV-A photocatalysis. Catalysts 2021, 11, 1302. [Google Scholar] [CrossRef]

- Lee, M.; Koziel, J.A.; Murphy, W.; Jenks, W.S.; Chen, B.; Li, P.; Banik, C. Evaluation of TiO2 based photocatalytic treatment of odor and gaseous emissions from swine manure with UV-A and UV-C. Animals 2021, 11, 1289. [Google Scholar] [CrossRef]

- Lee, M.; Koziel, J.A.; Murphy, W.; Jenks, W.S.; Chen, B.; Li, P.; Banik, C. Mitigation of odor and gaseous emissions from swine barn with UV-A and UV-C photocatalysis. Atmosphere 2021, 12, 585. [Google Scholar] [CrossRef]

- Lee, M.; Koziel, J.A.; Murphy, W.; Jenks, W.S.; Fonken, B.; Storjohann, R.; Chen, B.; Li, P.; Banik, C.; Wahe, L. Design and testing of mobile laboratory for mitigation of gaseous emissions from livestock agriculture with photocatalysis. Int. J. Environ. Res. Public Health 2021, 18, 1523. [Google Scholar] [CrossRef]

- Lee, M.; Li, P.; Koziel, J.A.; Ahn, H.; Wi, J.; Chen, B.; Meiirkhanuly, Z.; Banik, C.; Jenks, W.S. Pilot-scale testing of UV-A light treatment for mitigation of NH3, H2S, GHGs, VOCs, odor, and O3 inside the poultry barn. Front. Chem. 2020, 8, 613. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Ma, J.; Li, Y.; Zhang, C.; He, H. Photocatalytic oxidation of gaseous ammonia over fluorinated TiO2 with exposed (0 0 1) facets. Appl. Catal. B Environ. 2014, 152, 82–87. [Google Scholar] [CrossRef]

- Yao, H.; Feilberg, A. Characterisation of photocatalytic degradation of odorous compounds associated with livestock facilities by means of PTR-MS. Chem. Eng. J. 2015, 277, 341–351. [Google Scholar] [CrossRef]

- Zhu, W.; Koziel, J.A.; Maurer, D.L. Mitigation of livestock odors using black light and a new titanium dioxide-based catalyst: Proof-of-concept. Atmosphere 2017, 8, 103. [Google Scholar] [CrossRef] [Green Version]

- Linsebigler, A.L.; Lu, G.; Yates, J.T., Jr. Photocatalysis on TiO2 surfaces: Principles, mechanisms, and selected results. Chem. Rev. 1995, 95, 735–758. [Google Scholar] [CrossRef]

- Cant, N.W.; Cole, J.R. Photocatalysis of the reaction between ammonia and nitric oxide on TiO2 surfaces. J. Catal. 1992, 134, 317–330. [Google Scholar] [CrossRef]

- Levine, S.Z.; Calvert, J.G. The mechanism of the photooxidation of ammonia. Chem. Phys. Lett. 1977, 46, 81–84. [Google Scholar] [CrossRef]

- Mozzanega, H.; Herrmann, J.M.; Pichat, P. Ammonia oxidation over UV-irradiated titanium dioxide at room temperature. J. Phys. Chem. 1979, 83, 2251–2255. [Google Scholar] [CrossRef]

- Rockafellow, E.M.; Koziel, J.A.; Jenks, W.S. Laboratory--Scale Investigation of UV treatment of ammonia for livestock and poultry barn exhaust applications. J. Environ. Qual. 2012, 41, 281–288. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alonso-Tellez, A.; Robert, D.; Keller, N.; Keller, V. A parametric study of the UV-A photocatalytic oxidation of H2S over TiO2. Appl. Catal. B Environ. 2012, 115, 209–218. [Google Scholar] [CrossRef]

- Canela, M.C.; Alberici, R.M.; Jardim, W.F. Gas-phase destruction of H2S using TiO2/UV-VIS. J. Photochem. Photobiol. A Chem. 1998, 112, 73–80. [Google Scholar] [CrossRef]

- Portela, R.; Canela, M.C.; Sánchez, B.; Marques, F.C.; Stumbo, A.M.; Tessinari, R.F.; Coronado, J.M.; Suárez, S. H2S photodegradation by TiO2/M-MCM-41 (M= Cr or Ce): Deactivation and by-product generation under UV-A and visible light. Appl. Catal. B Environ. 2008, 84, 643–650. [Google Scholar] [CrossRef] [Green Version]

- Portela, R.; Suárez, S.; Rasmussen, S.B.; Arconada, N.; Castro, Y.; Durán, A.; Ávila, P.; Coronado, J.M.; Sánchez, B. Photocatalytic-based strategies for H2S elimination. Catal. Today 2010, 151, 64–70. [Google Scholar] [CrossRef]

- Chen, X.; Li, Y.; Pan, X.; Cortie, D.; Huang, X.; Yi, Z. Photocatalytic oxidation of methane over silver decorated zinc oxide nanocatalysts. Nat. Commun. 2016, 7, 12273. [Google Scholar] [CrossRef] [Green Version]

- Feng, N.; Lin, H.; Song, H.; Yang, L.; Tang, D.; Deng, F.; Ye, J. Efficient and selective photocatalytic CH4 conversion to CH3OH with O2 by controlling overoxidation on TiO2. Nat. Commun. 2021, 12, 4652. [Google Scholar] [CrossRef] [PubMed]

- Taylor, C.E. Methane conversion via photocatalytic reactions. Catal. Today 2003, 84, 9–15. [Google Scholar] [CrossRef]

- Yuliati, L.; Yoshida, H. Photocatalytic conversion of methane. Chem. Soc. Rev. 2008, 37, 1592–1602. [Google Scholar] [CrossRef] [PubMed]

- Paramasivam, I.; Jha, H.; Liu, N.; Schmuki, P. A review of photocatalysis using self-organized TiO2 nanotubes and other ordered oxide nanostructures. Small 2012, 8, 3073–3103. [Google Scholar] [CrossRef]

- Tan, S.S.; Zou, L.; Hu, E. Photocatalytic reduction of carbon dioxide into gaseous hydrocarbon using TiO2 pellets. Catal. Today 2006, 115, 269–273. [Google Scholar] [CrossRef]

- Blyholder, G.; Tanaka, K. Photocatalytic reactions on semiconductor surfaces. I. Decomposition of nitrous oxide on zinc oxide. J. Phys. Chem. 1971, 75, 1037–1043. [Google Scholar] [CrossRef]

- Obalová, L.; Reli, M.; Lang, J.; Matějka, V.; Kukutschová, J.; Lacný, Z.; Kočí, K. Photocatalytic decomposition of nitrous oxide using TiO2 and Ag-TiO2 nanocomposite thin films. Catal. Today 2013, 209, 170–175. [Google Scholar] [CrossRef] [Green Version]

- Lin, J.; Kawai, A.; Nakajima, T. Effective catalysts for decomposition of aqueous ozone. Appl. Catal. B Environ. 2002, 39, 157–165. [Google Scholar] [CrossRef]

- Koziel, J.; Yang, X.; Cutler, T.; Zhang, S.; Zimmerman, J.; Hoff, S.; Jenks, W.; Laor, Y.; Ravid, U.; Armon, R. Mitigation of odor and pathogens from CAFOs with UV/TiO2: Exploring the cost effectiveness. In Proceedings of the Mitigating Air Emissions from Animal Feeding Operations, Des Moines, IA, USA, 19–21 May 2008; pp. 169–173. [Google Scholar]

- Lighting Science: Nomenclature and Definitions for Illuminating Engineering. (ANSI/IES LS-1-21). In Proceedings of The IES Nomenclature Committee, 2021. Available online: https://www.ies.org/standards/definitions/ (accessed on 14 June 2022).

- Brancher, M.; Franco, D.; de Melo Lisboa, H. Photocatalytic oxidation of H2S in the gas phase over TiO2-coated glass fiber filter. Environ. Technol. 2016, 37, 2852–2864. [Google Scholar] [CrossRef]

- Cybula, A.; Klein, M.; Zaleska, A. Methane formation over TiO2-based photocatalysts: Reaction pathways. Appl. Catal. B Environ. 2015, 164, 433–442. [Google Scholar] [CrossRef]

- Ohtani, B.; Zhang, S.-W.; Nishimoto, S.-I.; Kagiya, T. Catalytic and photocatalytic decomposition of ozone at room temperature over titanium (IV) oxide. J. Chem. Soc. Faraday Trans. 1992, 88, 1049–1053. [Google Scholar] [CrossRef]

- Černigoj, U.; Štangar, U.L.; Trebše, P. Degradation of neonicotinoid insecticides by different advanced oxidation processes and studying the effect of ozone on TiO2 photocatalysis. Appl. Catal. B Environ. 2007, 75, 229–238. [Google Scholar] [CrossRef]

- Hernández-Alonso, M.a.D.; Coronado, J.M.; Maira, A.J.; Soria, J.; Loddo, V.; Augugliaro, V. Ozone enhanced activity of aqueous titanium dioxide suspensions for photocatalytic oxidation of free cyanide ions. Appl. Catal. B Environ. 2002, 39, 257–267. [Google Scholar] [CrossRef]

- Pichat, P.; Cermenati, L.; Albini, A.; Mas, D.; Delprat, H.; Guillard, C. Degradation processes of organic compounds over UV-irradiated TiO2. Effect of ozone. Res. Chem. Intermed. 2000, 26, 161–170. [Google Scholar] [CrossRef]

- Pichat, P.; Disdier, J.; Hoang-Van, C.; Mas, D.; Goutailler, G.; Gaysse, C. Purification/deodorization of indoor air and gaseous effluents by TiO2 photocatalysis. Catal. Today 2000, 63, 363–369. [Google Scholar] [CrossRef]

- Rodrigues-Silva, C.; Miranda, S.M.; Lopes, F.V.; Silva, M.; Dezotti, M.; Silva, A.M.; Faria, J.L.; Boaventura, R.A.; Vilar, V.J.; Pinto, E. Bacteria and fungi inactivation by photocatalysis under UVA irradiation: Liquid and gas phase. Environ. Sci. Pollut. Res. 2017, 24, 6372–6381. [Google Scholar] [CrossRef]

- Fraser, D.; Duncan, I.J.; Edwards, S.A.; Grandin, T.; Gregory, N.G.; Guyonnet, V.; Hemsworth, P.H.; Huertas, S.M.; Huzzey, J.M.; Mellor, D.J. General principles for the welfare of animals in production systems: The underlying science and its application. Vet. J. 2013, 198, 19–27. [Google Scholar] [CrossRef] [Green Version]

- Ni, J.Q. Research and demonstration to improve air quality for the US animal feeding operations in the 21st century—A critical review. Environ. Pollut. 2015, 200, 105–119. [Google Scholar] [CrossRef]

- Ni, J.Q.; Erasmus, M.A.; Croney, C.C.; Li, C.; Li, Y. A critical review of advancement in scientific research on food animal welfare-related air pollution. J. Hazard. Mater. 2021, 408, 124468. [Google Scholar] [CrossRef]

- Ni, J.Q.; Heber, A.J.; Lim, T.T. Ammonia and hydrogen sulfide in swine production. In Air Quality and Livestock Farming; CRC Press: London, UK, 2018; pp. 29–47. [Google Scholar]

- Fukui, T.; Niikura, T.; Oda, T.; Kumabe, Y.; Ohashi, H.; Sasaki, M.; Igarashi, T.; Kunisada, M.; Yamano, N.; Oe, K.; et al. Exploratory clinical trial on the safety and bactericidal effect of 222-nm ultraviolet C irradiation in healthy humans. PLoS ONE 2020, 15, e0235948. [Google Scholar] [CrossRef]

- Pal, A.; Min, X.; Yu, L.E.; Pehkonen, S.O.; Ray, M.B. Photocatalytic inactivation of bioaerosols by TiO2 coated membrane. Int. J. Chem. React. Eng. 2005, 3. [Google Scholar] [CrossRef]

- Zacarías, S.M.; Manassero, A.; Pirola, S.; Alfano, O.M.; Satuf, M.L. Design and performance evaluation of a photocatalytic reactor for indoor air disinfection. Environ. Sci. Pollut. Res. 2021, 28, 23859–23867. [Google Scholar] [CrossRef] [PubMed]

- Kühn, K.P.; Chaberny, I.F.; Massholder, K.; Stickler, M.; Benz, V.W.; Sonntag, H.G.; Erdinger, L. Disinfection of surfaces by photocatalytic oxidation with titanium dioxide and UVA light. Chemosphere 2003, 53, 71–77. [Google Scholar] [CrossRef]

- Le, T.T.N.; Nagata, H.; Takahashi, A.; Aihara, M.; Okamoto, T.; Shimohata, T.; Mawatari, K.; Akutagawa, M.; Kinouchi, Y.; Haraguchi, M. Sterilization effect of UV light on Bacillus spores using TiO2 films depends on wavelength. J. Med. Investig. 2012, 59, 53–58. [Google Scholar]

- Scheberl, A.; Khalil, M.L.; Maghsoodi, F.; Strach, E.W.; Yang, J.; Chi, E.Y.; Schanze, K.S.; Reimhult, E.; Whitten, D.G. Quantitative Determination of Dark and Light-Activated Antimicrobial Activity of Poly(Phenylene Ethynylene), Polythiophene, and Oligo(Phenylene Ethynylene) Electrolytes. ACS Appl. Mater. Interfaces 2020, 12, 21322–21329. [Google Scholar] [CrossRef] [PubMed]

| Reference | Target Gases | Reported Products after Photocatalysis |

|---|---|---|

| [34,35,36,37] | NH3 | N2O and N2 |

| [38,39,40,41] | H2S | SO2 and SO42− |

| [42,43,44,45] | CH4 | CH3OH, H, C2H6, C2H4, HCO2H and CO2 |

| [46,47] | CO2 | CH4, CH3OH, HCHO and CO |

| [48,49] | N2O | N2 and O2 |

| [50] | O3 | O2 |

| [51] | VOCs | Partially oxidized species, CO2 and H2O |

| Reference | Experimental Setup | Light Intensity | UV Dose (Treatment Time) | Catalyst (Coating Dose) | Coating Surface Area |

|---|---|---|---|---|---|

| [30] | <Lab scale> Volume: Not reported Airflow: 200 mL·min−1 Setup: (1) The targeted gas passed through the surface of a round stainless-steel sample dish with a diameter of 5.5 cm. (2) There was a fan above the lamp and a circulated cooling system. | 0.46 mW·cm−2 | Not reported | TiO2 (about 1 mg·cm−2) | 23.8 cm2 |

| [31] | <Lab scale> Volume: Not reported Airflow: <1000 m3·h−1 Setup: (1) TiO2-coated ceramic filters were used. (2) An exhaust fan was installed at the end of the outlet with a maximum capacity of 7700 m3·h−1 to provide a homogenous air stream. | <5.6 mW·cm−2 | <1.3 mJ·cm−2 (<0.32 s) | TiO2 (150 cm2·mg−1) | 0.65 m2 |

| [32] | <Lab scale> Volume: 200 mL Airflow: <300 mL·min−1 Setup: (1) The standard gases flowing through the UV reactor were irradiated with UV-A. (2) There was a fan above the lamp and a circulated cooling system. | 0.06 mW·cm−2 | 12 mJ·cm−2 (< 200 s) | TiO2 (10 μg·cm−2) | 193.5 cm2 |

| [8] | <4.85 mW·cm−2 | <0.97 J·cm−2 (< 200 s) | TiO2 (10 μg·cm−2) | ||

| [29] | <Pilot scale, tested at poultry and swine farm> Volume: 0.22 m3 Airflow: <0.008 m3·s−1 Setup: (1) A fan was installed in a 0.1 m diameter steel axial duct at the end of the reactor. | <4.85 mW·cm−2 | <0.82 J·cm−2 (<170 s) | TiO2 (10 μg·cm−2) | 2.9 m2 |

| [1] | <0.04 mW·cm−2 | <1.88 mJ·cm−2 (< 47 s) | TiO2 (10 μg·cm−2) | ||

| [25,26,27,28] | <Pilot and farm scale, tested at swine farm> Volume without walls: 14.4 m3 Airflow: <15.1 m3·min−1 Setup: (1) The mobile laboratory consisted of a series of 12 chambers. Untreated air was brought in through the inlet and treated while flowing in a serpentine pattern from the inlet to the outlet. (2) Fans at entry and near exit of the train of chambers control the airflow rate. | <0.41 mW·cm−2 | <5.8 mJ·cm−2 (<57 s) | TiO2 (10 μg·cm−2) | 61.2 m2 |

| [24] | <Swine farm, tested at swine farrowing rooms> Volume: 455 m3 Airflow: < 7666 m3·h−1 Setup: (1) TiO2 liquid solution was sprinkled on the inside walls of the treated room. (2) In each farrowing room, there were two chimneys. | Not reported | Not reported (<107 s) | TiO2 (7 mg·cm−2) | 150 m2 |

| [23] | <Swine farm, tested at swine weaning rooms> Volume: Not reported Airflow: <10,000 m3·h−1 Reactor characteristics: (1) TiO2 liquid suspension was sprinkled on the inside walls of the treated unit. (2) Fresh air came from the corridor of the building. The exhaust air was removed by two fans. | <0.45 lux | Not reported | TiO2 (7 mg·cm−2) | 260 m2 |

| Reference | Experimental Conditions | UV-A Type (Major Wavelength) | UV Dose (Light Intensity) | Catalyst (Dose) | Gas Mitigation (Mitigation %) |

|---|---|---|---|---|---|

| [30] | Lab scale Temp: 24 °C RH: 50% | Fluorescent (365 nm) | Not reported (0.46 mW·cm−2) | TiO2 (approx. 1 mg·cm−2) | NH3 (35) |

| [8] | Lab scale (simulated poultry farm) Temp: 25 ± 3 °C RH: 12% | Fluorescent (365 nm) | <88 mJ·cm−2 (<0.44 mW·cm−2) | TiO2 (10 μg·cm−2) | NH3 (9.4) H2S (N/S) |

| LED (365 nm) | <0.97 J·cm−2 (<4.85 mW·cm−2) | NH3 (19) H2S (N/S) | |||

| [29] | Pilot scale (layer poultry farm) Temp: 28 ± 3 °C RH: 56% | Fluorescent (365 nm) | <75 mJ·cm−2 (<0.44 mW·cm−2) | TiO2 (10 μg·cm−2) | NH3 (5.2) |

| LED (365 nm) | <0.82 J·cm−2 (<4.85 mW·cm−2) | NH3 (8.7) | |||

| [28] | Pilot scale (simulated swine farm) Temp: 11 ± 3 °C RH: 34 ± 6% | LED (367 nm) | 3.9 and 5.8 mJ·cm−2 (0.41 mW·cm−2) | TiO2 (10 μg·cm−2) | NH3 (9 and 11) |

| [26] | Pilot scale (simulated swine farm) Temp: 19 ± 2 °C RH: 45 ± 4% | LED (367 nm) | 5.8 mJ·cm−2 (0.41 mW·cm−2) | TiO2 (10 μg·cm−2) | NH3 (6.1) |

| [24] | Swine farm (farrowing rooms) Temp: 24 °C (19–27) RH: 54% | Not reported (315–400 nm) | Not reported | TiO2 (7 mg·cm−2) | NH3 (31) |

| [31] | Lab scale (simulated livestock farm) Temp: 20 ± 1 °C RH: 51% | Not reported (368 nm) | 0.6 and 1.3 mJ·cm−2 (2.3–5.6 mW·cm−2) | TiO2 (1.5 m2·g−1) | H2S (4.2 and 14) |

| [27] | Swine farm (finishing rooms) Temp: 29 ± 2 °C RH: 66 ± 4% | LED (367 nm) | 5.3 mJ·cm−2 (0.41 mW·cm−2) | TiO2 (10 μg·cm−2) | NH3 (N/S) H2S (26~40) |

| Reference | Experimental Conditions | UV-A Type (Major Wavelength) | UV Dose (Light Intensity) | Catalyst (Dose) | VOC Mitigation (Mitigation %) |

|---|---|---|---|---|---|

| [31] | Lab scale (simulated livestock farm) Temp: 20 ± 1 °C RH: 51% | Not reported (368 nm) | 0.6 and 1.3 mJ·cm−2 (2.3–5.6 mW·cm−2) | TiO2 (1.5 m2·g−1) | MT (80–87) DMS (92–96) DMDS (83–91) Butan-1-ol (93–95) AA (81–89) PA (97–98) BA (98–99) VA (98–99) |

| [32] | Lab scale (simulated livestock farm) Temp: 40 °C R: 40% | Fluorescent (365 nm) | 12 mJ·cm−2 (0.06 mW·cm−2) | TiO2 (10 μg·cm−2) | DMDS (40) DEDS (81) DMTS (76) BA (87) Guaiacol (100) p-Cresol (94) |

| [1] | Pilot scale (swine finishing room) Temp: 22~26 °C RH: 36~80% | Fluorescent (365 nm) | <1.88 mJ·cm−2 (<0.04 mW·cm−2) | TiO2 (10 μg·cm−2) | p-Cresol (22) Odor (16) |

| [29] | Pilot scale (layer poultry farm) Temp: 28 ± 3 °C RH: 56% | LED (365 nm) | <0.82 J·cm−2 (<4.85 mW·cm−2) | TiO2 (10 μg·cm−2) | DEDS (47) BA (62) p-Cresol (49) Skatole (35) Odor (18) |

| [28] | Pilot scale (simulated swine farm) Temp: 11 ± 3 °C RH: 34 ± 6% | LED (367 nm) | 2.5 and 5.8 mJ·cm−2 (0.41 mW·cm−2) | TiO2 (10 μg·cm−2) | Butan-1-ol (19 and 41) |

| [26] | Pilot scale (simulated swine farm) Temp: 19 ± 2 °C RH: 45 ± 4% | LED (367 nm) | 1.3 and 3.9 mJ·cm−2 (0.41 mW·cm−2) | TiO2 (10 μg·cm−2) | AA (N/S and 49) BA (36 and 53) p-Cresol (N/S and 67) Indole (N/S and 32) Odor (N/S and 58) |

| [27] | Swine farm (finishing rooms) Temp: 29 ± 2 °C RH: 66 ± 4% | LED (367 nm) | 2.9 and 5.3 mJ·cm−2 (0.41 mW·cm−2) | TiO2 (10 μg·cm−2) | DMDS (22 and 62) IA (N/S and 44) BA (N/S and 32) p-Cresol (32 and 40) Indole (N/S and 66) Skatole (38 and 49) Odor (N/S and 40) |

| Reference | Experimental Conditions | UV-A Type (Major Wavelength) | UV Dose (Light Intensity) | Catalyst (Dose) | GHGs Mitigation (Mitigation %) |

|---|---|---|---|---|---|

| [8] | Lab scale (simulated poultry farm) Temp: 25 ± 3 °C RH: 12% | Fluorescent (365 nm) | <88 mJ·cm−2 (<0.44 mW·cm−2) | TiO2 (10 μg·cm−2) | N2O (3.3) |

| LED (365 nm) | <0.97 J·cm−2 (<4.85 mW·cm−2) | CO2 (3.8) N2O (10) | |||

| [1] | Pilot scale (swine finishing room) Temp: 22~26 °C RH: 36~80% | Fluorescent (365 nm) | <1.88 mJ·cm−2 (<0.04 mW·cm−2) | TiO2 (10 μg·cm−2) | CO2 (−3.1) N2O (8.7) |

| [29] | Pilot scale (layer poultry farm) Temp: 28 ± 3 °C RH: 56% | Fluorescent (365 nm) | <75 mJ·cm−2 (<0.44 mW·cm−2) | TiO2 (10 μg·cm−2) | N2O (7.5) |

| LED (365 nm) | <0.82 J·cm−2 (<4.85 mW·cm−2) | N2O (13) | |||

| [26] | Pilot scale (simulated swine farm) Temp: 19 ± 2 °C RH: 45 ± 4% | LED (367 nm) | 2.5 and 3.9 mJ·cm−2 (0.41 mW·cm−2) | TiO2 (10 μg·cm−2) | N2O (9.0 and 4.3) CO2 (N/S and −25.8) |

| [27] | Swine farm (finishing rooms) Temp: 29 ± 2 °C RH: 66 ± 4% | LED (367 nm) | 2.9 and 5.3 mJ·cm−2 (0.41 mW·cm−2) | TiO2 (10 μg·cm−2) | N2O (9.4 and 12) CO2 (−33.7 and −27.8) |

| [24] | Swine farm (farrowing rooms) Temp: 24 °C (19–27) RH: 54% | Not reported (315–400 nm) | Not reported | TiO2 (7 mg·cm−2) | CH4 (15) CO2 (11) N2O (4.2) |

| [23] | Swine farm (weaning rooms) Temp: 26 °C (24~30) RH: 56% (52~90) | Not reported (315–400 nm) | Not reported | TiO2 (7 mg·cm−2) | CH4 (27) |

| Reference | Experimental Conditions | UV-A Type (Major Wavelength) | UV Dose (Light Intensity) | Catalyst (Dose) | Mitigation (Mitigation %) |

|---|---|---|---|---|---|

| [8] | Lab scale (simulated poultry farm) Temp: 25 ± 3 °C RH: 12% | Fluorescent (365 nm) | <88 mJ·cm−2 (<0.44 mW·cm−2) | TiO2 (10 μg·cm−2) | O3 (24) |

| LED (365 nm) | <0.97 J·cm−2 (<4.85 mW·cm−2) | O3 (48) | |||

| [26] | Pilot scale (simulated swine farm) Temp: 19 ± 2 °C RH: 45 ± 4% | LED (367 nm) | 1.3 and 5.8 mJ·cm−2 (0.41 mW·cm−2) | TiO2 (10 μg·cm−2) | O3 (100 and 100) |

| [29] | Pilot scale (layer poultry farm) Temp: 28 ± 3 °C RH: 56% | Fluorescent (365 nm) | <75 mJ·cm−2 (<0.44 mW·cm−2) | TiO2 (10 μg·cm−2) | O3 (100) |

| LED (365 nm) | <0.82 J·cm−2 (<4.85 mW·cm−2) | O3 (100) | |||

| [23] | Swine farm (weaning rooms) Temp: 26 °C (24~30) RH: 56% (52~90) | Not reported (315–400 nm) | Not reported | TiO2 (7 mg·cm−2) | PM 10 (17) FCR (−12) |

| [27] | Swine farm (finishing rooms) Temp: 29 ± 2 °C RH: 66 ± 4% | LED (367 nm) | 5.3 mJ·cm−2 (0.41 mW·cm−2) | TiO2 (10 μg·cm−2) | O3 (100) |

| [25] | Swine farm (finishing rooms) Temp: 29 ± 2 °C RH: 66 ± 4% | LED (367 nm) | 5.3 mJ·cm−2 (0.41 mW·cm−2) | TiO2 (10 μg·cm−2) | CFU (49~51) PM (N/S) |

| Reference | Mitigated Gas (Maximum Mitigation 1 %) | Minimum UV Dose 2 | Catalyst (Dose) |

|---|---|---|---|

| [24] | NH3 (~35%) | Not reported | TiO2 (7 mg·cm−2) |

| [27] | VOCs (~66%) | 2.9 mJ·cm−2 | TiO2 (10 μg·cm−2) |

| [27] | Odor (~58%) | 4.0 mJ·cm−2 | TiO2 (10 μg·cm−2) |

| [24,26,27,28,29] | N2O (~13%) | 1.9 mJ·cm−2 | TiO2 (10 μg·cm−2) |

| [26,27,28,29] | O3 (~100%) | 1.3 mJ·cm−2 | TiO2 (10 μg·cm−2) |

| [25] | Airborne microbials (~51%) | 5.3 mJ·cm−2 | TiO2 (10 μg·cm−2) |

| Reference | Mitigated Gases (Maximum Mitigation %) | Light Intensity | UV Dose (Treatment Time) | Catalyst (Coating Dose) | Coating Surface Area | UV Energy |

|---|---|---|---|---|---|---|

| [30] | NH3 (35) | 0.46 mW·cm−2 | Not reported | TiO2 (~1 mg·cm−2) | 23.8 cm2 | Not available |

| [31] | H2S (14), MT (87), DMS (96), DMDS (91), Butan-1-ol (95), AA (89), PA (98), BA (99), VA (99) | 5.6 mW·cm−2 | 1.3 mJ·cm−2 (<0.32 s) | TiO2 (150 cm2·mg−1) | 0.65 m2 | 8.45 J |

| [32] | DMDS (40), DEDS (81), DMTS (76), BA (87), Guaiacol (100), p-Cresol (94) | 0.06 mW·cm−2 | 12 mJ·cm−2 (<200 s) | TiO2 (10 μg·cm−2) | 193.5 cm2 | 2.33 J |

| [8] | NH3 (19), N2O (10), O3 (48) | <4.85 mW·cm−2 | <0.97 J·cm−2 (<200 s) | TiO2 (10 μg·cm−2) | 188 J | |

| [29] | NH3 (8.7), DEDS (47), BA (62), p-Cresol (49), Skatole (35), Odor (18), N2O (13), O3 (100) | <4.85 mW·cm−2 | <0.82 J·cm−2 (<170 s) | TiO2 (10 μg·cm−2) | 2.9 m2 | 23,780 J |

| [1] | CO2 (−3.1), N2O (8.7), p-Cresol (22), Odor (16) | <0.04 mW·cm−2 | <1.88 mJ·cm−2 (<47 s) | TiO2 (10 μg·cm−2) | 54.5 J | |

| [25,26,27,28] * | NH3 (11), H2S (40), DMDS (62), IA (44), BA (32), Indole (66), Skatole (49), Butan-1-ol (41), Odor (40), CO2 (−27.8), N2O (12), O3 (100), CFU (51), | <0.41 mW·cm−2 | <5.8 mJ·cm−2 (<57 s) | TiO2 (10 μg·cm−2) | 61.2 m2 | 3550 J |

| [24] | NH3 (31), CH4 (15), CO2 (11), N2O (4.2) | Not reported | Not reported (<107 s) | TiO2 (7 mg·cm−2) | 150 m2 | Not available |

| [23] | CH4 (27), PM (17), FCR (−12) | <0.45 lux | Not reported | TiO2 (7 mg·cm−2) | 260 m2 | Not available |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, M.; Koziel, J.A.; Li, P.; Jenks, W.S. Mitigation of Air Pollutants by UV-A Photocatalysis in Livestock and Poultry Farming: A Mini-Review. Catalysts 2022, 12, 782. https://doi.org/10.3390/catal12070782

Lee M, Koziel JA, Li P, Jenks WS. Mitigation of Air Pollutants by UV-A Photocatalysis in Livestock and Poultry Farming: A Mini-Review. Catalysts. 2022; 12(7):782. https://doi.org/10.3390/catal12070782

Chicago/Turabian StyleLee, Myeongseong, Jacek A. Koziel, Peiyang Li, and William S. Jenks. 2022. "Mitigation of Air Pollutants by UV-A Photocatalysis in Livestock and Poultry Farming: A Mini-Review" Catalysts 12, no. 7: 782. https://doi.org/10.3390/catal12070782

APA StyleLee, M., Koziel, J. A., Li, P., & Jenks, W. S. (2022). Mitigation of Air Pollutants by UV-A Photocatalysis in Livestock and Poultry Farming: A Mini-Review. Catalysts, 12(7), 782. https://doi.org/10.3390/catal12070782