Aqueous-Phase Glycerol Conversion over Ni-Based Catalysts Synthesized by Nanocasting

Abstract

1. Introduction

2. Results

2.1. Catalysts Characterization

2.1.1. Surface Characteristics

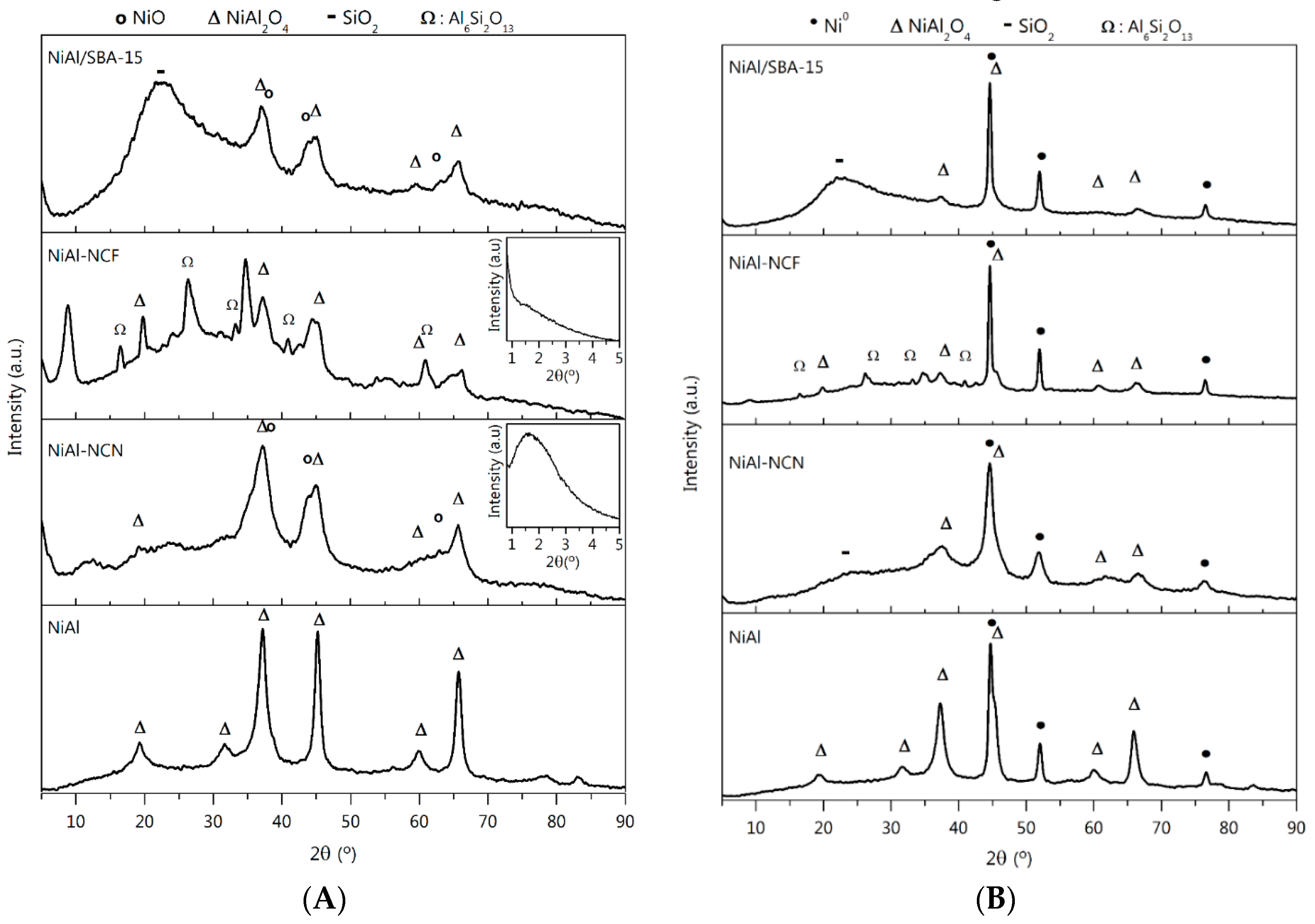

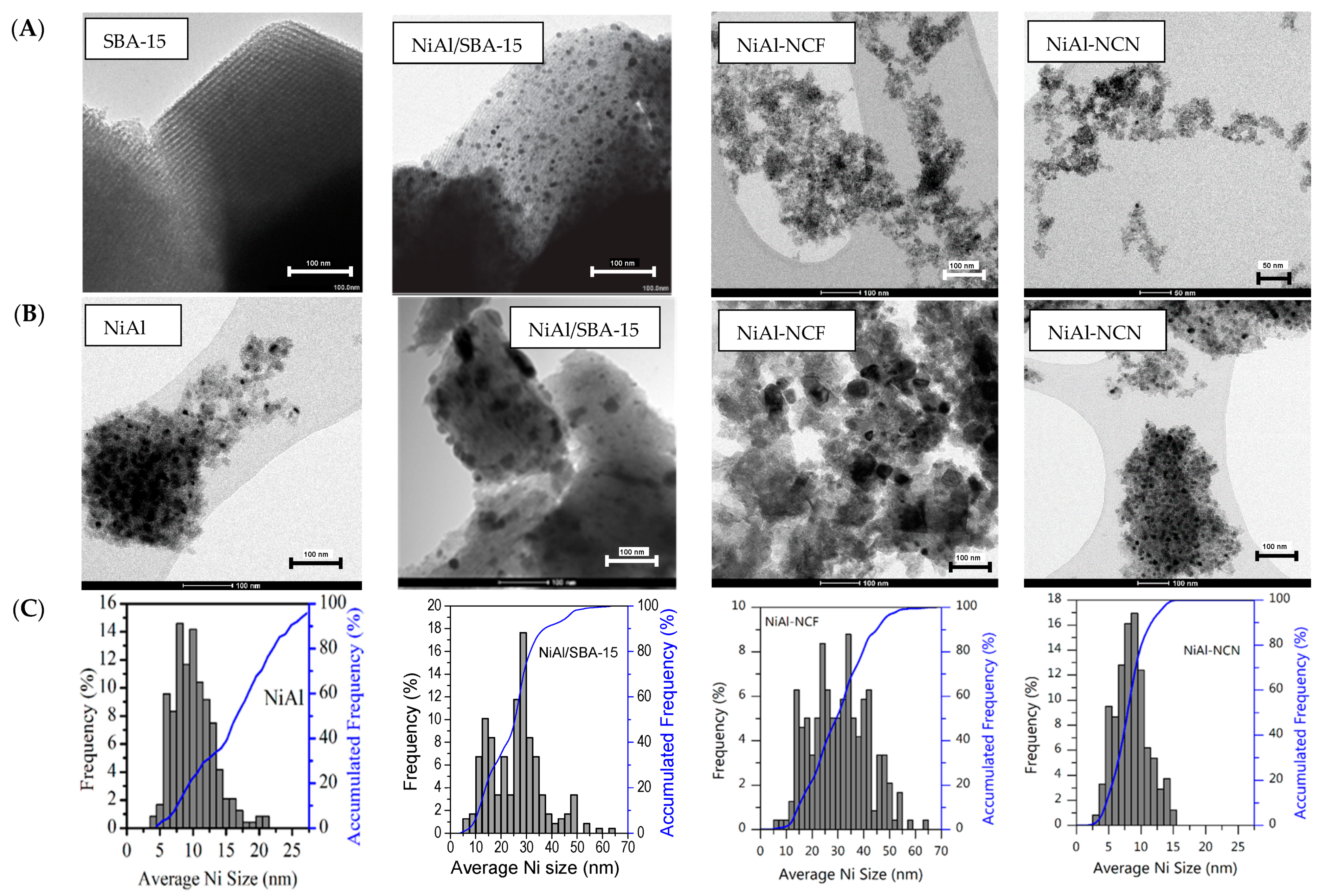

2.1.2. Morphological and Structural Characteristics

2.1.3. Reducibility and Speciation Analysis

2.2. Catalytic Performance Tests

2.2.1. Gas-Phase Products

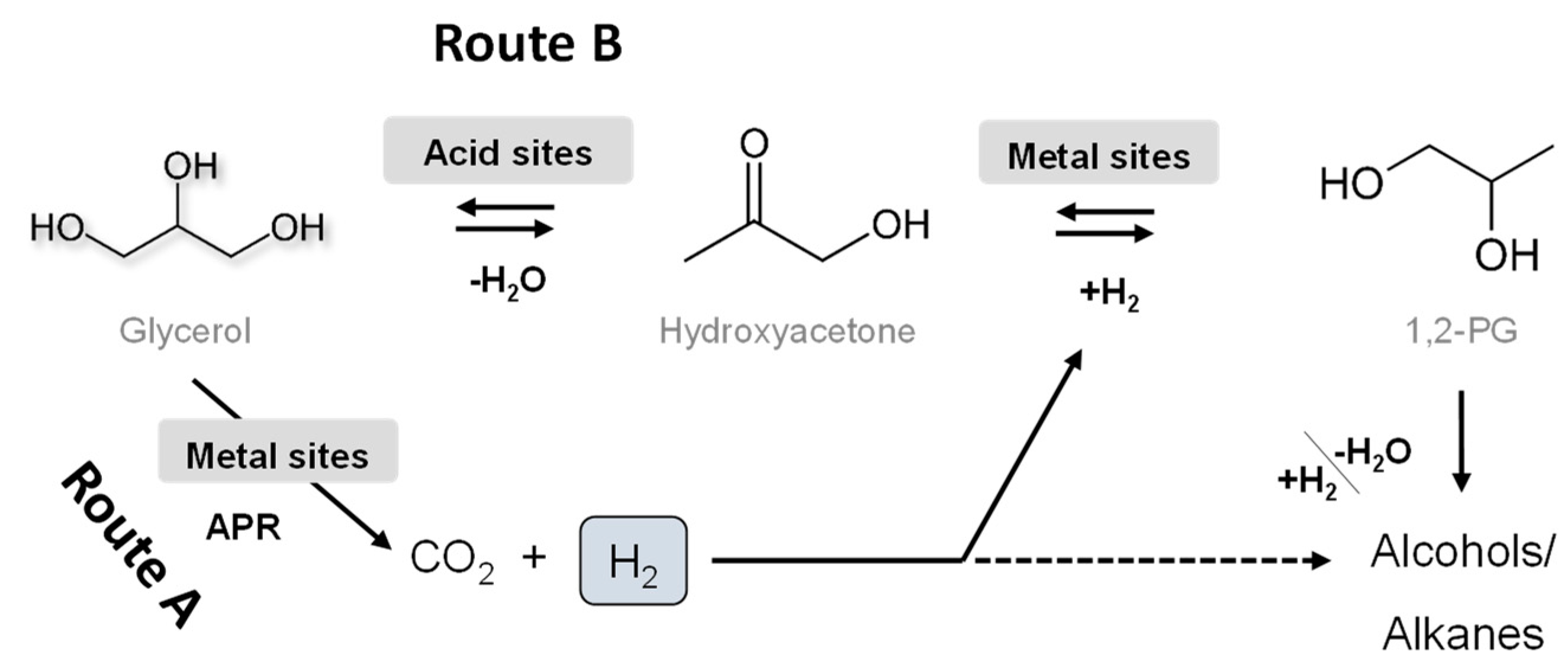

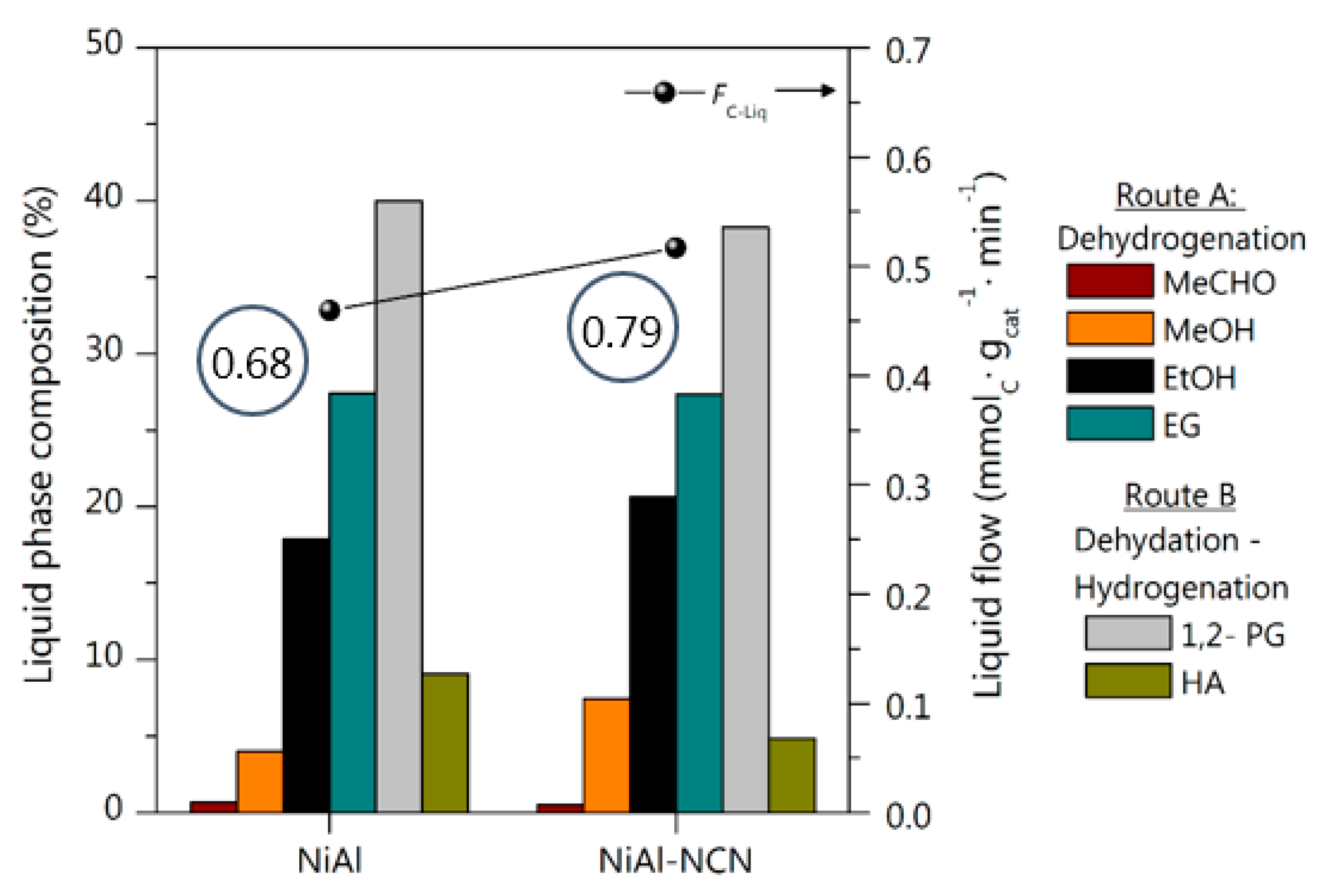

2.2.2. Liquid-Phase Products

2.2.3. Effect of Residence Time

2.3. Spent Catalysts Characterization

3. Materials and Methods

3.1. Catalysts Synthesis

3.2. Catalysts Characterization

3.3. Catalytic Performance Evaluation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chen, D.; Rojas, M.; Samset, B.H.; Cobb, K.; Diongue Niang, A.; Edwards, P.; Emori, S.; Faria, S.H.; Hawkins, E.; Hope, P.; et al. Framing, Context, and Methods. In Climate Change 2021: The Physical Science Basis; Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2021; pp. 147–286. [Google Scholar]

- Touma, D.; Stevenson, S.; Lehner, F.; Coats, S. Human-driven greenhouse gas and aerosol emissions cause distinct regional impacts on extreme fire weather. Nat. Commun. 2021, 12, 212. [Google Scholar] [CrossRef] [PubMed]

- Pachauri, R.K.; Allen, M.R.; Barros, V.R.; Broome, J.; Cramer, W.; Christ, R.; Church, J.A.; Clarke, L.; Dahe, Q.; Dasgupta, P.; et al. Climate Change 2014: Synthesis Report; Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2014; 151p. [Google Scholar]

- IEA Net Zero by 2050. IEA 2021. Available online: https://www.iea.org/reports/net-zero-by-2050 (accessed on 26 May 2022).

- Checa, M.; Nogales-Delgado, S.; Montes, V.; Encinar, J.M. Recent advances in glycerol catalytic valorization: A review. Catalysts 2020, 10, 1279. [Google Scholar] [CrossRef]

- Cortright, R.D.; Davda, R.R.; Dumesic, J.A. Hydrogen from catalytic reforming of biomass-derived hydrocarbons in liquid water. Nature 2002, 418, 964–967. [Google Scholar] [CrossRef]

- Chheda, J.N.; Huber, G.W.; Dumesic, J.A. Liquid-phase catalytic processing of biomass-derived oxygenated hydrocarbons to fuels and chemicals. Angew. Chem. Int. Ed. 2007, 46, 7164–7183. [Google Scholar] [CrossRef]

- Coronado, I.; Stekrova, M.; Reinikainen, M.; Simell, P.; Lefferts, L.; Lehtonen, J. A review of catalytic aqueous-phase reforming of oxygenated hydrocarbons derived from biorefinery water fractions. Int. J. Hydrogen Energy 2016, 41, 11003–11032. [Google Scholar] [CrossRef]

- Meryemoglu, B.; Kaya, B.; Irmak, S.; Hesenov, A.; Erbatur, O. Comparison of batch aqueous-phase reforming of glycerol and lignocellulosic biomass hydrolysate. Fuel 2012, 97, 241–244. [Google Scholar] [CrossRef]

- Remón, J.; Ruiz, J.; Oliva, M.; García, L.; Arauzo, J. Cheese whey valorisation: Production of valuable gaseous and liquid chemicals from lactose by aqueous phase reforming. Energy Convers. Manag. 2016, 124, 453–469. [Google Scholar] [CrossRef]

- Coronado, I.; Arandia, A.; Reinikainen, M.; Karinen, R.; Puurunen, R.L.; Lehtonen, J. Kinetic Modelling of the Aqueous-Phase Reforming of Fischer-Tropsch Water over Ceria-Zirconia Supported Nickel-Copper Catalyst. Catalysts 2019, 9, 936. [Google Scholar] [CrossRef]

- Pendem, C.; Sarkar, B.; Siddiqui, N.; Sivakumar Konathala, N.L.; Baskar, C.; Bal, R. K-Promoted Pt-Hydrotalcite Catalyst for Production of H2 by Aqueous Phase Reforming of Glycerol. ACS Sustain. Chem. Eng. 2018, 6, 2122–2131. [Google Scholar] [CrossRef]

- Zoppi, G.; Pipitone, G.; Pirone, R.; Bensaid, S. Aqueous phase reforming process for the valorization of wastewater streams: Application to different industrial scenarios. Catal. Today 2022, 387, 224–236. [Google Scholar] [CrossRef]

- El Doukkali, M.; Iriondo, A.; Gandarias, I. Enhanced catalytic upgrading of glycerol into high value-added H2 and propanediols: Recent developments and future perspectives. Mol. Catal. 2020, 490, 110928. [Google Scholar] [CrossRef]

- Davda, R.R.; Shabaker, J.W.; Huber, G.W.; Cortright, R.D.; Dumesic, J.A. A review of catalytic issues and process conditions for renewable hydrogen and alkanes by aqueous-phase reforming of oxygenated hydrocarbons over supported metal catalysts. Appl. Catal. B Environ. 2005, 56, 171–186. [Google Scholar] [CrossRef]

- Pipitone, G.; Zoppi, G.; Pirone, R.; Bensaid, S. A critical review on catalyst design for aqueous phase reforming. Int. J. Hydrogen Energy 2022, 47, 151–180. [Google Scholar] [CrossRef]

- Fasolini, A.; Cespi, D.; Tabanelli, T.; Cucciniello, R.; Cavani, F. Hydrogen from Renewables: A Case Study of Glycerol Reforming. Catalysts 2019, 9, 722. [Google Scholar] [CrossRef]

- Morales-Marín, A.; Ayastuy, J.L.; Iriarte-Velasco, U.; Gutiérrez-Ortiz, M.A. Nickel aluminate spinel-derived catalysts for the aqueous phase reforming of glycerol: Effect of reduction temperature. Appl. Catal. B Environ. 2019, 244, 931–945. [Google Scholar] [CrossRef]

- Huber, G.W.; Shabaker, J.W.; Dumseic, J.A. Raney Ni-Sn Catalyst for H2 Production from Biomass-Derived Hydrocarbons. Science 2003, 300, 2075–2077. [Google Scholar] [CrossRef]

- Zhu, J.; Gao, Q. Mesoporous MCo2O4 (M = Cu, Mn and Ni) spinels: Structural replication, characterization and catalytic application in CO oxidation. Microporous Mesoporous Mater. 2009, 124, 144–152. [Google Scholar] [CrossRef]

- Singh, D.K.; Krishna, K.S.; Harish, S.; Sampath, S.; Eswaramoorthy, M. No More HF: Teflon-assisted ultrafast removal of silica to generate high-surface-area mesostructured carbon for enhanced CO2 capture and supercapacitor performance. Angew. Chem. Int. Ed. 2016, 55, 2032–2036. [Google Scholar] [CrossRef]

- De Sousa, F.F.; de Sousa Helvio, S.A.; Oliveira, A.C.; Junior, M.C.C.; Ayala, A.P.; Barros, E.B.; Viana, B.C.; Filho, J.M.; Oliveira, A.C. Nanostructured Ni-containing spinel oxides for the dry reforming of methane: Effect of the presence of cobalt and nickel on the deactivation behaviour of catalysts. Int. J. Hydrogen Energy 2012, 37, 3201–3212. [Google Scholar] [CrossRef]

- Karam, L.; Reboul, J.; El Hassan, N.; Nelayah, J.; Massiani, P. Nanostructured nickel aluminate as a key intermediate for the production of highly dispersed and stable nickel nanoparticles supported within mesoporous alumina for dry reforming of methane. Molecules 2019, 24, 4107. [Google Scholar] [CrossRef]

- Gil, A.G.; Wu, Z.; Chadwick, D.; Li, K. Ni/SBA-15 Catalysts for combined steam methane reforming and water gas shift—Prepared for use in catalytic membrane reactors. Appl. Catal. A Gen. 2015, 506, 188–196. [Google Scholar]

- Carrero, A.; Calles, J.A.; García-Moreno, L.; Vizcaíno, A.J. Production of renewable hydrogen from glycerol steam reforming over bimetallic Ni-(Cu,Co,Cr) catalysts supported on SBA-15 silica. Catalysts 2017, 7, 55. [Google Scholar] [CrossRef]

- Kim, H.; Kim, T.; Park, H.J.; Jeong, K.; Chae, H.; Jeong, S.; Lee, C.; Kim, C. Hydrogen production via the aqueous phase reforming of ethylene glycol over platinum-supported ordered mesoporous carbon catalysts: Effect of structure and framework-configuration. Int. J. Hydrogen Energy 2012, 37, 12187–12197. [Google Scholar] [CrossRef]

- Al-Salihi, S.; Abrokwah, R.; Dade, W.; Deshmane, V.; Hossain, T.; Kuila, D. Renewable hydrogen from glycerol steam reforming using Co–Ni–MgO based SBA-15 nanocatalysts. Int. J. Hydrogen Energy 2020, 45, 14183–14198. [Google Scholar] [CrossRef]

- Calles, J.A.; Carrero, A.; Vizcaíno, A.J.; García-Moreno, L. Hydrogen production by glycerol steam reforming over SBA-15-supported nickel catalysts: Effect of alkaline earth promoters on activity and stability. Catal. Today 2014, 227, 198–206. [Google Scholar] [CrossRef]

- Azof, F.I.; Yang, Y.; Panias, D.; Kolbeinsen, L.; Safarian, J. Leaching characteristics and mechanism of the synthetic calcium-aluminate slags for alumina recovery. Hydrometallurgy 2019, 185, 273–290. [Google Scholar] [CrossRef]

- Galarneau, A.; Desplantier, D.; Dutartre, R.; Di Renzo, F. Micelle-templated silicates as a test bed for methods of mesopore size evaluation. Microporous Mesoporous Mater. 1999, 27, 297–308. [Google Scholar] [CrossRef]

- Remón, J.; Giménez, J.R.; Valiente, A.; García, L.; Arauzo, J. Production of gaseous and liquid chemicals by aqueous phase reforming of crude glycerol: Influence of operating conditions on the process. Energy Convers. Manag. 2016, 110, 90–112. [Google Scholar] [CrossRef]

- Estevez, R.; Lopez-Pedrajas, S.; Blanco-Bonilla, F.; Luna, D.; Bautista, F.M. Production of acrolein from glycerol in liquid phase on heterogeneous catalysts. Chem. Eng. J. 2015, 282, 179–186. [Google Scholar] [CrossRef]

- Jeon, S.; Roh, H.; Ju Moon, D.; Wook Bae, J. Aqueous phase reforming and hydrodeoxygenation of ethylene glycol on Pt/SiO2-Al2O3: Effects of surface acidity on product distribution. RSC Adv. 2016, 6, 68433–68444. [Google Scholar] [CrossRef]

- Guo, G.; Usman, M.; Liu, X.; Wang, Y.; Lu, G. Effect of support’s basic properties on hydrogen production in aqueous-phase reforming of glycerol and correlation between WGS and APR. Appl. Energy 2012, 92, 218–223. [Google Scholar] [CrossRef]

- Ghosh, B.K.; Hazra, S.; Naik, B.; Ghosh, N.N. Preparation of Cu nanoparticle loaded SBA-15 and their excellent catalytic activity in reduction of variety of dyes. Powder Technol. 2015, 269, 371–378. [Google Scholar] [CrossRef]

- Zhao, D.; Feng, J.; Huo, Q.; Melosh, N.; Fredrickson, G.H.; Chmelka, B.F.; Stucky, G.D. Triblock copolymer syntheses of mesoporous silica with periodic 50 to 300 angstrom pores. Science 1998, 279, 548–552. [Google Scholar] [CrossRef] [PubMed]

- Song, K.H.; Jeong, S.K.; Jeong, B.H.; Lee, K.-Y.; Kim, H.J. Effect of the Ni/Al Ratio on the Performance of NiAl2O4 Spinel-Based Catalysts for Supercritical Methylcyclohexane Catalytic Cracking. Catalysts 2021, 11, 323. [Google Scholar] [CrossRef]

- Zhou, L.; Li, L.; Wei, N.; Li, J.; Basset, J.-M. Effect of NiAl2O4 Formation on Ni/Al2O3 Stability during Dry Reforming of Methane. ChemCatChem 2015, 7, 2508–2516. [Google Scholar] [CrossRef]

- Li, G.; Hu, L.; Hill, J.M. Comparison of reducibility and stability of alumina-supported Ni catalysts prepared by impregnation and co-precipitation. Appl. Catal. A Gen. 2006, 301, 16–24. [Google Scholar] [CrossRef]

- Godina, L.I.; Kirilin, A.V.; Tokarev, A.V.; Simakova, I.L.; Murzin, D.Y. Sibunit-Supported Mono- and Bimetallic Catalysts Used in Aqueous-Phase Reforming of Xylitol. Ind. Eng. Chem. Res. 2018, 57, 2050–2067. [Google Scholar] [CrossRef]

- Dietrich, P.J.; Lobo-Lapidus, R.J.; Wu, T.; Sumer, A.; Akatay, M.C.; Fingland, B.R.; Guo, N.; Dumesic, J.A.; Marshall, C.L.; Stach, E.; et al. Aqueous phase glycerol reforming by PtMo bimetallic nano-particle catalyst: Product selectivity and structural characterization. Top. Catal. 2012, 55, 53–69. [Google Scholar] [CrossRef]

- Seretis, A.; Tsiakaras, P. Aqueous phase reforming (APR) of glycerol over platinum supported on Al2O3 catalyst. Renew. Energy 2016, 85, 1116–1126. [Google Scholar] [CrossRef]

- Iriondo, A.; Cambra, J.F.; Güemez, M.B.; Barrio, V.L.; Requies, J.; Sánchez-Sánchez, M.C.; Navarro, R.M. Effect of ZrO2 addition on Ni/Al2O3 catalyst to produce H2 from glycerol. Int. J. Hydrogen Energy 2012, 37, 7084–7093. [Google Scholar] [CrossRef]

- Vaidya, P.D.; Lopez-Sanchez, J.A. Review of Hydrogen Production by Catalytic Aqueous-Phase Reforming. ChemistrySelect 2017, 2, 6563–6576. [Google Scholar] [CrossRef]

- Morales-Marín, A.; Ayastuy, J.L.; Iriarte-Velasco, U.; Gutiérrez-Ortiz, M.A. Biohydrogen production by glycerol Aqueous-Phase Reforming: Effect of promoters (Ce or Mg) in the NiAl2O4 spinel-derived catalysts. J. Environ. Chem. Eng. 2021, 9, 106433. [Google Scholar] [CrossRef]

- Li, D.; Li, Y.; Liu, X.; Guo, Y.; Pao, C.-W.; Chen, J.-L.; Hu, Y.; Wang, Y. NiAl2O4 Spinel Supported Pt Catalyst: High Performance and Origin in Aqueous-Phase Reforming of Methanol. ACS Catal. 2019, 9, 9671–9682. [Google Scholar] [CrossRef]

- García, L.; Valiente, A.; Oliva, M.; Ruiz, J.; Arauzo, J. Influence of operating variables on the aqueous-phase reforming of glycerol over a Ni/Al coprecipitated catalyst. Int. J. Hydrogen Energy 2018, 43, 20392–20407. [Google Scholar] [CrossRef]

- Kirilin, A.V.; Tokarev, A.V.; Murzina, E.V.; Kustov, L.M.; Mikkola, J.-P.; Murzin, D.Y. Reaction products and transformations of intermediates in the aqueous-phase reforming of sorbitol. ChemSusChem 2010, 3, 708–718. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Park, H.J.; Kim, T.; Jeong, K.; Chae, H.; Jeong, S.; Lee, C.; Kim, C. The effect of support and reaction conditions on aqueous phase reforming of polyol over supported Pt–Re bimetallic catalysts. Catal. Today 2012, 185, 73–80. [Google Scholar] [CrossRef]

- He, Z.; Wang, X.; Gao, S.; Xiao, T. Effect of reaction variables on CO methanation process over NiO–La2O3–MgO/Al2O3 catalyst for coal to synthetic natural gas. Appl. Petrochem. Res. 2015, 5, 413–417. [Google Scholar] [CrossRef][Green Version]

- Nichele, V.; Signoretto, M.; Menegazzo, F.; Gallo, A.; Dal Santo, V.; Cruciani, G.; Cerrato, G. Glycerol steam reforming for hydrogen production: Design of Ni supported catalysts. Appl. Catal. B Environ. 2012, 111–112, 225–232. [Google Scholar] [CrossRef]

- De Vlieger, D.J.M.; Mojet, B.L.; Lefferts, L.; Seshan, K. Aqueous Phase Reforming of ethylene glycol—Role of intermediates in catalyst performance. J. Catal. 2012, 292, 239–245. [Google Scholar] [CrossRef]

- Park, J.C.; Lee, H.J.; Bang, J.U.; Park, K.H.; Song, H. Chemical transformation and morphology change of nickel-silica hybrid nanostructures via nickel phyllosilicates. Chem. Commun. 2009, 47, 7345–7347. [Google Scholar] [CrossRef]

- Van Haasterecht, T.; Ludding, C.C.I.; de Jong, K.P.; Bitter, J.H. Toward stable nickel catalysts for aqueous phase reforming of biomass-derived feedstock under reducing and alkaline conditions. J. Catal. 2014, 319, 27–35. [Google Scholar] [CrossRef]

- Melero, J.A.; Calleja, G.; Martínez, F.; Molina, R. Nanocomposite of crystalline Fe2O3 and CuO particles and mesostructured SBA-15 silica as an active catalyst for wet peroxide oxidation processes. Catal. Commun. 2006, 7, 478–483. [Google Scholar] [CrossRef]

- El Doukkali, M.; Iriondo, A.; Cambra, J.F.; Gandarias, I.; Jalowiecki-Duhamel, L.; Dumeignil, F.; Arias, P.L. Deactivation study of the Pt and/or Ni-based γ-Al2O3 catalysts used in the aqueous phase reforming of glycerol for H2 production. Appl. Catal. A Gen. 2014, 472, 80–91. [Google Scholar] [CrossRef]

- Sievers, C.; Scott, S.L.; Noda, Y.; Qi, L.; Albuquerque, E.M.; Rioux, R.M. Phenomena affecting catalytic reactions at solid−Liquid interfaces. ACS Catal. 2016, 6, 8286–8307. [Google Scholar] [CrossRef]

- Van Haasterecht, T.; Swart, M.; De Jong, K.P.; Bitter, J.H. Effect of initial nickel particle size on stability of nickel catalysts for aqueous phase reforming. J. Energy Chem. 2016, 25, 289–296. [Google Scholar] [CrossRef]

- Borodziński, A.; Bonarowska, M. Relation between crystallite size and dispersion on supported metal catalysts. Langmuir 1997, 13, 5613–5620. [Google Scholar] [CrossRef]

- Bastan, F.; Kazemeini, M.; Larimi, A.; Maleki, H. Production of renewable hydrogen through aqueous-phase reforming of glycerol over Ni/Al2O3–MgO nano-catalyst. Int J. Hydrogen Energy 2018, 43, 614–621. [Google Scholar] [CrossRef]

- El Doukkali, M.; Iriondo, A.; Arias, P.L.; Requies, J.; Gandarías, I.; Jalowiecki-Duhamel, L.; Dumeignil, F. A comparison of sol-gel and impregnated Pt or/and Ni based γ-alumina catalysts for bioglycerol aqueous phase reforming. Appl. Catal. B Environ. 2012, 125, 516–529. [Google Scholar] [CrossRef]

- Park, Y.H.; Kim, J.Y.; Moon, D.J.; Park, N.C.; Kim, Y.C. Effect of LaAlO3-supported modified Ni-based catalysts on aqueous phase reforming of glycerol. Res. Chem. Intermed 2015, 41, 9603–9614. [Google Scholar] [CrossRef]

- Rahman, M.M.; Church, T.L.; Variava, M.F.; Harris, A.T.; Minett, A.I. Bimetallic Pt-Ni composites on ceria-doped alumina supports as catalysts in the aqueous-phase reforming of glycerol. RSC Adv. 2014, 4, 18951–18960. [Google Scholar] [CrossRef]

- Manfro, R.L.; Pires, T.P.M.D.; Ribeiro, N.F.P.; Souza, M.M.V.M. Aqueous-phase reforming of glycerol using Ni-Cu catalysts prepared from hydrotalcite-like precursors. Catal. Sci. Technolog. 2013, 3, 1278–1287. [Google Scholar] [CrossRef]

- Rahman, M.M. Aqueous-Phase Reforming of Glycerol over Carbon-Nanotube-Supported Catalysts. Catal Lett. 2020, 150, 2674–2687. [Google Scholar] [CrossRef]

- Bastan, F.; Kazemeini, M.; Larimi, A.S. Aqueous-phase reforming of glycerol for production of alkanes over Ni/CexZr1-xO2 nano-catalyst: Effects of the support's composition. Renew. Energy 2017, 108, 417–424. [Google Scholar] [CrossRef]

| Solid | Ni/Al (at./at.) | Si a (%) | SBET (m2/g) | Vpore (m3/g) | dpore (nm) | Acid/Base Ratio b (molNH3/molCO2) | dNi0 -XRD (nm) | dNi0 -TEM (nm) | DNi0 c (%) | ANi0 d (m2Ni /g) |

|---|---|---|---|---|---|---|---|---|---|---|

| NiAl | 0.49 | n.a. | 98 (83) | 0.27 (0.29) | 8.4 (10.8) | 1.7 | 16.0 | 12.0 | 10.0 | 14.1 |

| NiAl/SBA-15 | 0.60 | 55.8 | 210 (158) | 0.30 (0.26) | 4.7 (5.5) | 7.2 | 24.3 | 25.8 | 3.6 | 7.3 |

| NiAl-NCN | 0.74 | 1.2 | 306 (155) | 0.33 (0.15) | 3.9 (5.4) | 2.7 | 6.7 | 9.0 | 12.0 | 17.9 |

| NiAl-NCF | 0.48 | 2.9 | 81 (38) | 0.46 (0.22) | 22.1 (20.9) | 15.7 | 27.7 | 31.7 | 3.2 | 3.8 |

| Catalyst | Calcined | Fresh Reduced | ||||||

|---|---|---|---|---|---|---|---|---|

| TPR950 H2-Uptake (mmol H2/g) | Nickel Speciation (%) | TPR700–950 H2-Uptake (mmol H2/g) | DRNi (1) (%) | Ni0 Content (mmol H2/g) | ||||

| α | β1 | β2 | γ | |||||

| NiAl | 5.6 (5.6) | 1.5 | 21.3 | 23.4 | 53.8 | 0.56 | 79 | 4.4 |

| NiAl/SBA-15 | 2.0 (2.1) | 1.7 | 14.2 | 33.6 | 50.6 | 0.22 | 88 | 1.8 |

| NiAl-NCN | 5.2 (6.7) | 6.2 | 31.4 | 23.3 | 39.1 | 0.16 | 97 | 5.0 |

| NiAl-NCF | 4.0 (5.0) | 1.6 | 29.1 | 48.6 | 20.6 | 0.10 | 98 | 3.9 |

| Catalyst | FGas (mmol/gcat·min) | SGas (%) | Composition (vol.%) | H2/CO2 | CO2/CH4 | |||

|---|---|---|---|---|---|---|---|---|

| H2 | CO2 | CO | CH4 | |||||

| NiAl | 0.48 | 42 | 50.8 | 26.4 | 0.8 | 20.0 | 1.8 | 1.5 |

| NiAl/SBA-15 | 0.01 | 21 | 77.5 | 6.6 | 3.3 | 8.8 | 12.9 | 0.6 |

| NiAl-NCN | 0.66 | 50 | 42.1 | 31.1 | 0.5 | 24.0 | 1.4 | 1.3 |

| NiAl-NCF | 0.09 | 24 | 65.0 | 18.1 | 2.0 | 12.0 | 3.6 | 1.2 |

| Leaching (%) | |||||||

|---|---|---|---|---|---|---|---|

| Catalyst | Ni | Al | Si | ΔSBETa (%) | New Phases (XRD) | ΔdNi°a (%) | Ni oxidized (%) |

| NiAl | 0.7 | 0.05 | n.a. | +37 | AlO(OH) | −9 | 60 |

| NiAl/SBA-15 | 0.3 | 0.04 | 5.5 | −42 | Ni3Si2O5(OH)4 | +18 | 67 |

| NiAl-NCN | 0.1 | 0.06 | 94 | +33 | Ni(OH)2·0.75H2O | −6 | 60 |

| NiAl-NCF | 0.4 | 1.02 | 31 | +137 | n.d. | +30 | 44 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morales-Marín, A.; Iriarte-Velasco, U.; Gutiérrez-Ortiz, M.Á.; Ayastuy, J.L. Aqueous-Phase Glycerol Conversion over Ni-Based Catalysts Synthesized by Nanocasting. Catalysts 2022, 12, 668. https://doi.org/10.3390/catal12060668

Morales-Marín A, Iriarte-Velasco U, Gutiérrez-Ortiz MÁ, Ayastuy JL. Aqueous-Phase Glycerol Conversion over Ni-Based Catalysts Synthesized by Nanocasting. Catalysts. 2022; 12(6):668. https://doi.org/10.3390/catal12060668

Chicago/Turabian StyleMorales-Marín, Adriana, Unai Iriarte-Velasco, Miguel Ángel Gutiérrez-Ortiz, and Jose Luis Ayastuy. 2022. "Aqueous-Phase Glycerol Conversion over Ni-Based Catalysts Synthesized by Nanocasting" Catalysts 12, no. 6: 668. https://doi.org/10.3390/catal12060668

APA StyleMorales-Marín, A., Iriarte-Velasco, U., Gutiérrez-Ortiz, M. Á., & Ayastuy, J. L. (2022). Aqueous-Phase Glycerol Conversion over Ni-Based Catalysts Synthesized by Nanocasting. Catalysts, 12(6), 668. https://doi.org/10.3390/catal12060668