Hydrogen-Rich Gas Production with the Ni-La/Al2O3-CaO-C Catalyst from Co-Pyrolysis of Straw and Polyethylene

Abstract

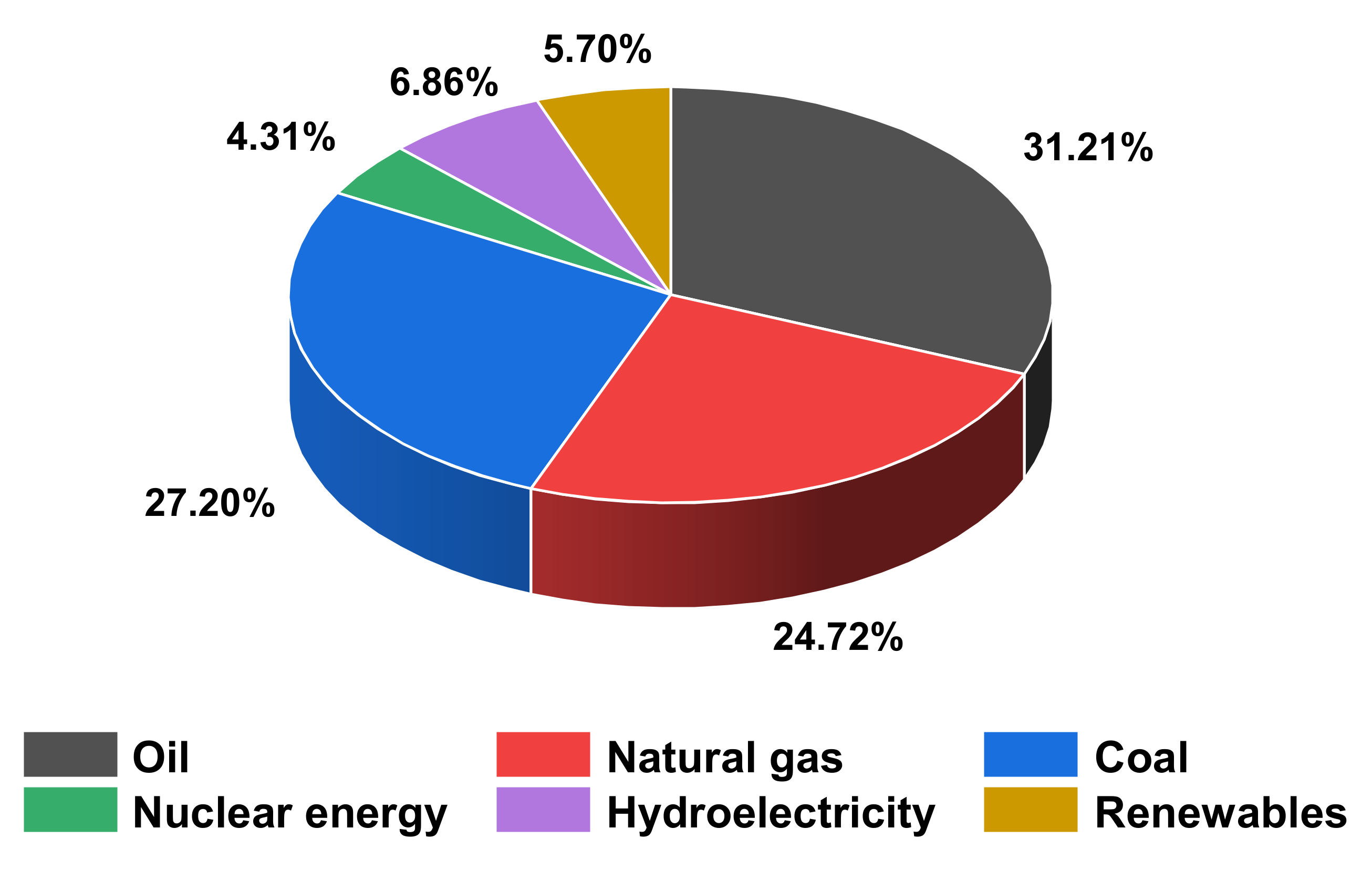

:1. Introduction

2. Results and Discussion

2.1. Characterization of Catalysts

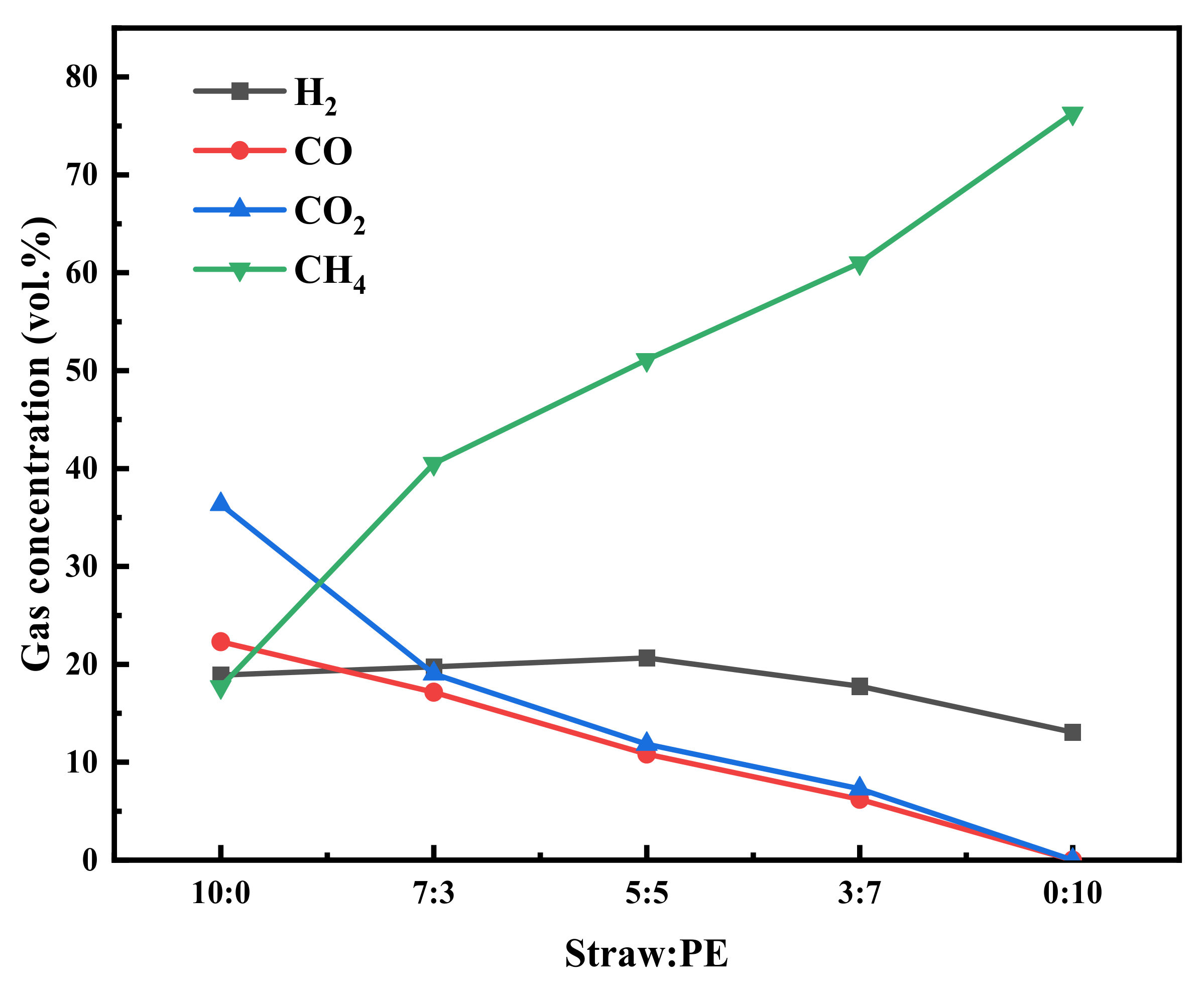

2.2. Effect of Raw Material Ratio on Gas Yieild

2.3. Effect of Composite Support Ratio on H2 Yield

2.4. Stability Test of Catalysts

3. Experiment

3.1. Chemicals and Materials

3.2. Catalysts Preparation

3.3. Catalysts Characterization

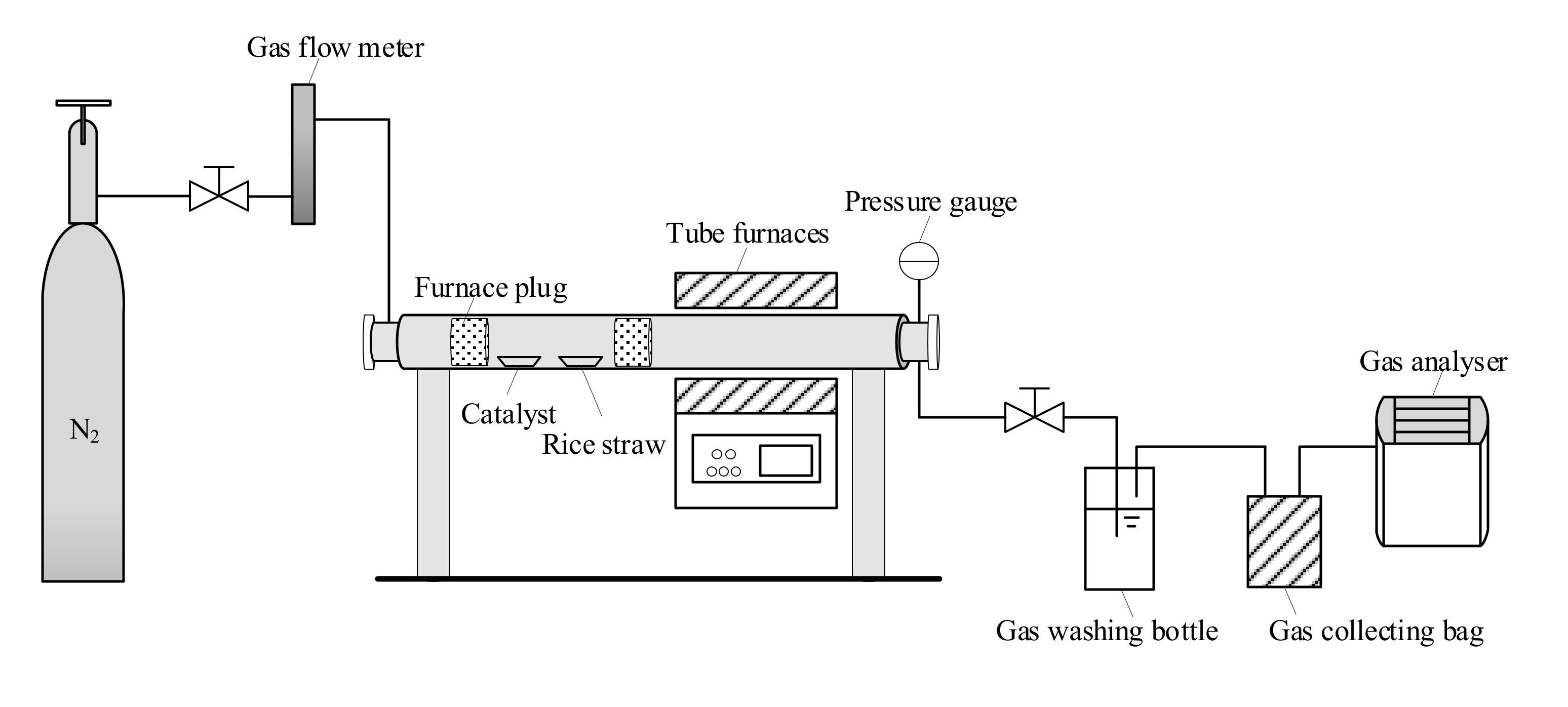

3.4. Experimental Process

3.5. Calculation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- bp. bp Statistical Review of World Energy 2021. 2021. Available online: https://www.bp.com/en/global/corporate/energy-economics/statistical-review-of-world-energy.html (accessed on 15 October 2021).

- Veziroğlu, T.N.; Şahin, S. 21st Century’s energy: Hydrogen energy system. Energy Convers. Manag. 2008, 49, 1820–1831. [Google Scholar] [CrossRef]

- Stefanidis, S.D.; Kalogiannis, K.G.; Iliopoulou, E.F.; Michailof, C.M.; Pilavachi, P.A.; Lappas, A.A. A study of lignocellulosic biomass pyrolysis via the pyrolysis of cellulose, hemicellulose and lignin. J. Anal. Appl. Pyrolysis 2014, 105, 143–150. [Google Scholar] [CrossRef]

- Goyal, H.B.; Seal, D.; Saxena, R.C. Bio-fuels from thermochemical conversion of renewable resources: A review. Renew. Sustain. Energy Rev. 2008, 12, 504–517. [Google Scholar] [CrossRef]

- Cui, B.; Chen, Z.; Wang, F.; Zhang, Z.; Dai, Y.; Guo, D.; Liang, W.; Liu, Y. Facile Synthesis of Magnetic Biochar Derived from Burley Tobacco Stems towards Enhanced Cr(VI) Removal: Performance and Mechanism. Nanomaterials 2022, 12, 678. [Google Scholar] [CrossRef]

- Cui, B.; Chen, Z.; Guo, D.; Liu, Y. Investigations on the pyrolysis of microalgal-bacterial granular sludge: Products, kinetics, and potential mechanisms. Bioresour. Technol. 2022, 349, 126328. [Google Scholar] [CrossRef]

- Jia, Y.; Wang, Y.; Zhang, Q.; Rong, H.; Liu, Y.; Xiao, B.; Guo, D.; Laghari, M.; Ruan, R. Gas-carrying enhances the combustion temperature of the biomass particles. Energy 2022, 239, 121956. [Google Scholar] [CrossRef]

- Hoang, A.T.; Ong, H.C.; Fattah, I.M.R.; Chong, C.T.; Cheng, C.K.; Sakthivel, R.; Ok, Y.S. Progress on the lignocellulosic biomass pyrolysis for biofuel production toward environmental sustainability. Fuel Process. Technol. 2021, 223, 106997. [Google Scholar] [CrossRef]

- Ambursa, M.M.; Juan, J.C.; Yahaya, Y.; Taufiq-Yap, Y.H.; Lin, Y.-C.; Lee, H.V. A review on catalytic hydrodeoxygenation of lignin to transportation fuels by using nickel-based catalysts. Renew. Sustain. Energy Rev. 2021, 138, 110667. [Google Scholar] [CrossRef]

- Kai, X.; Li, R.; Yang, T.; Shen, S.; Ji, Q.; Zhang, T. Study on the co-pyrolysis of rice straw and high density polyethylene blends using TG-FTIR-MS. Energy Convers. Manag. 2017, 146, 20–33. [Google Scholar] [CrossRef]

- Fan, H.; Gu, J.; Hu, S.; Yuan, H.; Chen, Y. Co-pyrolysis and co-gasification of biomass and polyethylene: Thermal behaviors, volatile products and characteristics of their residues. J. Energy Inst. 2019, 92, 1926–1935. [Google Scholar] [CrossRef]

- Yang, T.; Hu, K.; Li, R.; Sun, Y.; Kai, X. Cogasification of typical plastics and rice straw with carbon dioxide. Environ. Prog. Sustain. Energy 2015, 34, 789–794. [Google Scholar] [CrossRef]

- Sajdak, M. Impact of plastic blends on the product yield from co-pyrolysis of lignin-rich materials. J. Anal. Appl. Pyrolysis 2017, 124, 415–425. [Google Scholar] [CrossRef]

- Zhang, S.; Zhu, S.; Zhang, H.; Liu, X.; Xiong, Y. High quality H2-rich syngas production from pyrolysis-gasification of biomass and plastic wastes by Ni–Fe@Nanofibers/Porous carbon catalyst. Int. J. Hydrogen Energy 2019, 44, 26193–26203. [Google Scholar] [CrossRef]

- Chai, Y.; Wang, M.; Gao, N.; Duan, Y.; Li, J. Experimental study on pyrolysis/gasification of biomass and plastics for H2 production under new dual-support catalyst. Chem. Eng. J. 2020, 396, 125260. [Google Scholar] [CrossRef]

- Guo, D.; Hu, M.; Chen, Z.; Cui, B.; Zhang, Q.; Liu, Y.; Luo, S.; Ruan, R.; Liu, Y. Catalytic pyrolysis of rain tree biomass with nano nickel oxide synthetized from nickel plating slag: A green path for treating waste by waste. Bioresour. Technol. 2020, 315, 123831. [Google Scholar] [CrossRef]

- Gao, N.; Salisu, J.; Quan, C.; Williams, P. Modified nickel-based catalysts for improved steam reforming of biomass tar: A critical review. Renew. Sustain. Energy Rev. 2021, 145, 111023. [Google Scholar] [CrossRef]

- Chan, F.L.; Tanksale, A. Review of recent developments in Ni-based catalysts for biomass gasification. Renew. Sustain. Energy Rev. 2014, 38, 428–438. [Google Scholar] [CrossRef]

- Cui, X.; Ren, P.; Deng, D.; Deng, J.; Bao, X. Single layer graphene encapsulating non-precious metals as high-performance electrocatalysts for water oxidation. Energy Environ. Sci. 2016, 9, 123–129. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, J.; Li, B.; Li, Z.; He, Y.; Qin, Z.; Gao, R. Preparation of Ni-La/Al2O3-CeO2-Bamboo Charcoal Catalyst and Its Application in Co-pyrolysis of Straw and Plastic for Hydrogen Production. BioEnergy Res. 2021, 1–14. [Google Scholar] [CrossRef]

- Manera, C.; Perondi, D.; Barcellos, T.; Godinho, M. CO2 gasification of elephant grass: Effect of Ni/mayenite catalyst on dry reforming of tar. Biomass Bioenergy 2020, 143, 105829. [Google Scholar] [CrossRef]

- He, Z.; Wang, X.; Liu, R.; Gao, S.; Xiao, T. Perfomances of different additives on NiO/γ-Al2O3 catalyst in CO methanation. Appl. Petrochem. Res. 2016, 6, 235–241. [Google Scholar] [CrossRef] [Green Version]

- Jurado, L.; Papaefthimiou, V.; Thomas, S.; Roger, A.-C. Upgrading syngas from wood gasification through steam reforming of tars over highly active Ni-perovskite catalysts at relatively low temperature. Appl. Catal. B Environ. 2021, 299, 120687. [Google Scholar] [CrossRef]

- Lee, H.-S.; Lee, J.; Seo, H.; Kang, H.; Kim, D.H.; Lee, Y.-W. Evaluation of Pd/ZSM-5 catalyst for simultaneous reaction of transesterification and partial catalytic transfer hydrogenation of soybean oil under supercritical methanol. Fuel Process. Technol. 2021, 218, 106870. [Google Scholar] [CrossRef]

- Ren, J.; Liu, Y.-L. Boosting syngas production from corncob tar reforming over Ni/MgAl hydrotalcite-derived catalysts. Fuel 2022, 307, 121779. [Google Scholar] [CrossRef]

- Ma, H.; Zeng, L.; Tian, H.; Li, D.; Wang, X.; Li, X.; Gong, J. Efficient hydrogen production from ethanol steam reforming over La-modified ordered mesoporous Ni-based catalysts. Appl. Catal. B Environ. 2016, 181, 321–331. [Google Scholar] [CrossRef]

- Mo, W.; Ma, F.; Ma, Y.; Fan, X. The optimization of Ni–Al2O3 catalyst with the addition of La2O3 for CO2–CH4 reforming to produce syngas. Int. J. Hydrogen Energy 2019, 44, 24510–24524. [Google Scholar] [CrossRef]

- Takenaka, S.; Serizawa, M.; Otsuka, K. Formation of filamentous carbons over supported Fe catalysts through methane decomposition. J. Catal. 2004, 222, 520–531. [Google Scholar] [CrossRef]

- Xu, D.; Xiong, Y.; Zhang, S.; Su, Y. The synergistic mechanism between coke depositions and gas for H2 production from co-pyrolysis of biomass and plastic wastes via char supported catalyst. Waste Manag. 2021, 121, 23–32. [Google Scholar] [CrossRef]

- Liu, X.; Li, X.; Liu, J.; Wang, Z.; Kong, B.; Gong, X.; Yang, X.; Lin, W.; Guo, L. Study of high density polyethylene (HDPE) pyrolysis with reactive molecular dynamics. Polym. Degrad. Stab. 2014, 104, 62–70. [Google Scholar] [CrossRef]

- Zhang, G.; Liu, J.; Xu, Y.; Sun, Y. A review of CH4-CO2 reforming to synthesis gas over Ni-based catalysts in recent years (2010–2017). Int. J. Hydrogen Energy 2018, 43, 15030–15054. [Google Scholar] [CrossRef]

- Tathod, A.P.; Hayek, N.; Shpasser, D.; Simakov, D.S.A.; Gazit, O.M. Mediating interaction strength between nickel and zirconia using a mixed oxide nanosheets interlayer for methane dry reforming. Appl. Catal. B Environ. 2019, 249, 106–115. [Google Scholar] [CrossRef]

- Zhang, R.-J.; Xia, G.-F.; Li, M.-F.; Wu, Y.; Nie, H.; Li, D.-D. Effect of support on the performance of Ni-based catalyst in methane dry reforming. J. Fuel Chem. Technol. 2015, 43, 1359–1365. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, X.; Miller, J.B.; Huber, G.W. The Chemistry and Kinetics of Polyethylene Pyrolysis: A Process to Produce Fuels and Chemicals. ChemSusChem 2020, 13, 1764–1774. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Ashok, J.; Kawi, S. Smart Designs of Anti-Coking and Anti-Sintering Ni-Based Catalysts for Dry Reforming of Methane: A Recent Review. Reactions 2020, 1, 13. [Google Scholar] [CrossRef]

- Liang, S.; Guo, F.; Du, S.; Tian, B.; Dong, Y.; Jia, X.; Qian, L. Synthesis of Sargassum char-supported Ni-Fe nanoparticles and its application in tar cracking during biomass pyrolysis. Fuel 2020, 275, 117923. [Google Scholar] [CrossRef]

- Hu, J.; Jia, Z.; Zhao, S.; Wang, W.; Zhang, Q.; Liu, R.; Huang, Z. Activated char supported Fe-Ni catalyst for syngas production from catalytic gasification of pine wood. Bioresour. Technol. 2021, 340, 125600. [Google Scholar] [CrossRef]

| Samples | Main Composition and Content (wt%) | ||||

|---|---|---|---|---|---|

| Al2O3 | CaO | NiO | La2O3 | Others | |

| ACC(W) | 46.52 | 51.16 | - | - | 2.32 |

| ACC(M) | 63.73 | 33.52 | - | - | 2.75 |

| Ni/ACC(M) | 56.95 | 28.01 | 12.20 | - | 2.84 |

| Ni-La/ACC(M) | 48.28 | 21.53 | 13.37 | 14.32 | 2.50 |

| Samples | BET Surface Area (m2·g −1) | Pore Volume (cm3·g−1) | Pore Diameter (nm) |

|---|---|---|---|

| ACC(M) | 36.88 | 0.25 | 21.35 |

| Ni/ACC(M) | 168.09 | 0.28 | 7.51 |

| Ni-La/ACC(M) | 134.22 | 0.31 | 8.34 |

| Samples | Ultimate Analysis (wt%) | Proximate Analysis (wt%) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| C | H | O* | N | S | M | A | V | FC | |

| Soybean straw | 41.08 | 5.53 | 52.15 | 1.24 | 0.00 | 4.60 | 8.70 | 82.06 | 4.64 |

| PE | 85.78 | 14.22 | - | - | - | - | <0.05 | 99.95 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Gao, R.; Zhu, L.; Zhang, Y.; Li, Z.; Li, B.; Wang, J.; He, J.; He, Y.; Qin, Z.; et al. Hydrogen-Rich Gas Production with the Ni-La/Al2O3-CaO-C Catalyst from Co-Pyrolysis of Straw and Polyethylene. Catalysts 2022, 12, 496. https://doi.org/10.3390/catal12050496

Li J, Gao R, Zhu L, Zhang Y, Li Z, Li B, Wang J, He J, He Y, Qin Z, et al. Hydrogen-Rich Gas Production with the Ni-La/Al2O3-CaO-C Catalyst from Co-Pyrolysis of Straw and Polyethylene. Catalysts. 2022; 12(5):496. https://doi.org/10.3390/catal12050496

Chicago/Turabian StyleLi, Jianfen, Rongyi Gao, Longkai Zhu, Yiran Zhang, Zeshan Li, Bolin Li, Jiaxiang Wang, Ji He, Yun He, Zhenhua Qin, and et al. 2022. "Hydrogen-Rich Gas Production with the Ni-La/Al2O3-CaO-C Catalyst from Co-Pyrolysis of Straw and Polyethylene" Catalysts 12, no. 5: 496. https://doi.org/10.3390/catal12050496

APA StyleLi, J., Gao, R., Zhu, L., Zhang, Y., Li, Z., Li, B., Wang, J., He, J., He, Y., Qin, Z., Laghari, M., & Guo, D. (2022). Hydrogen-Rich Gas Production with the Ni-La/Al2O3-CaO-C Catalyst from Co-Pyrolysis of Straw and Polyethylene. Catalysts, 12(5), 496. https://doi.org/10.3390/catal12050496