Model Study of CNT-Based PEMFCs’ Electrocatalytic Layers

Abstract

:1. Introduction

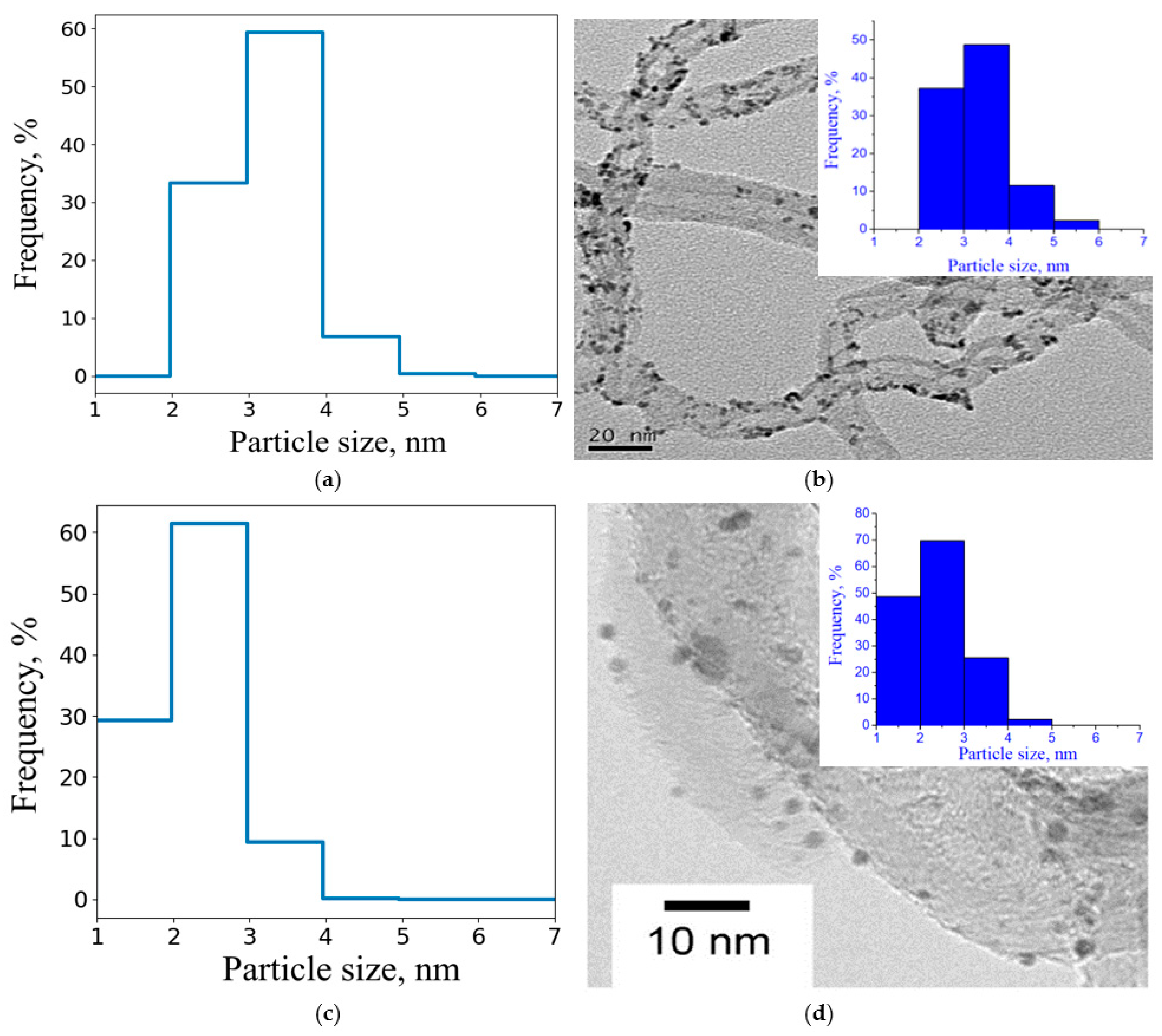

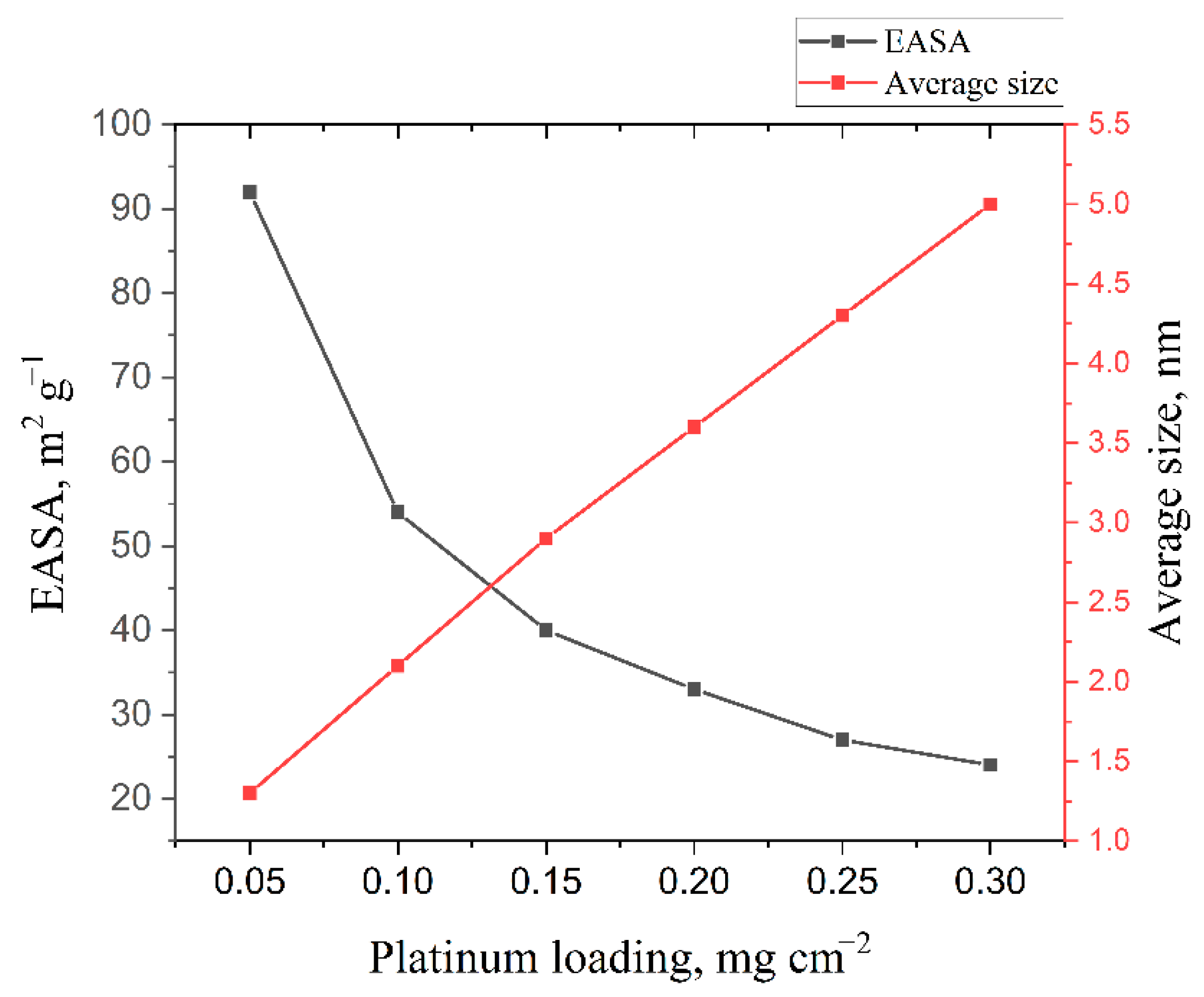

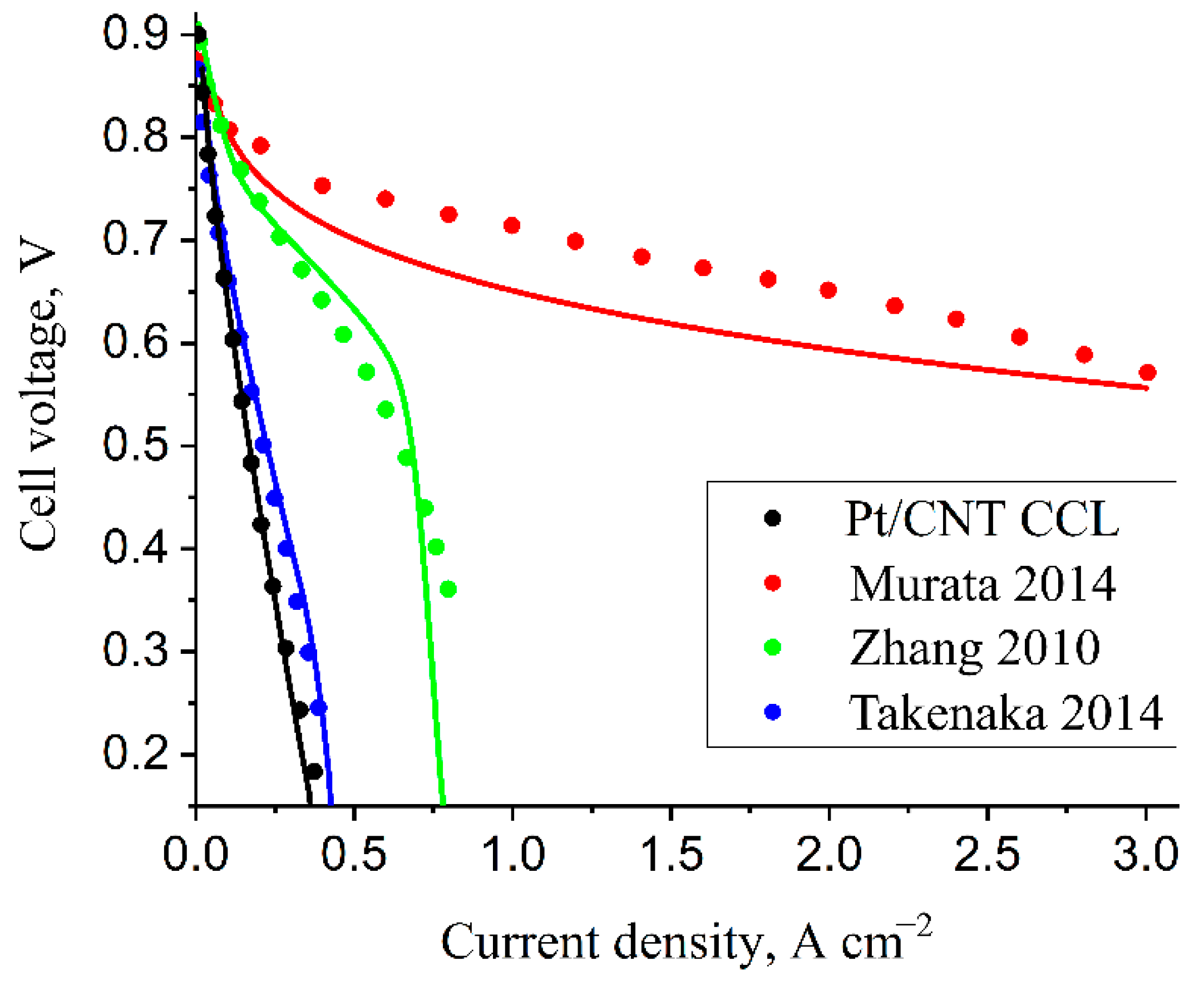

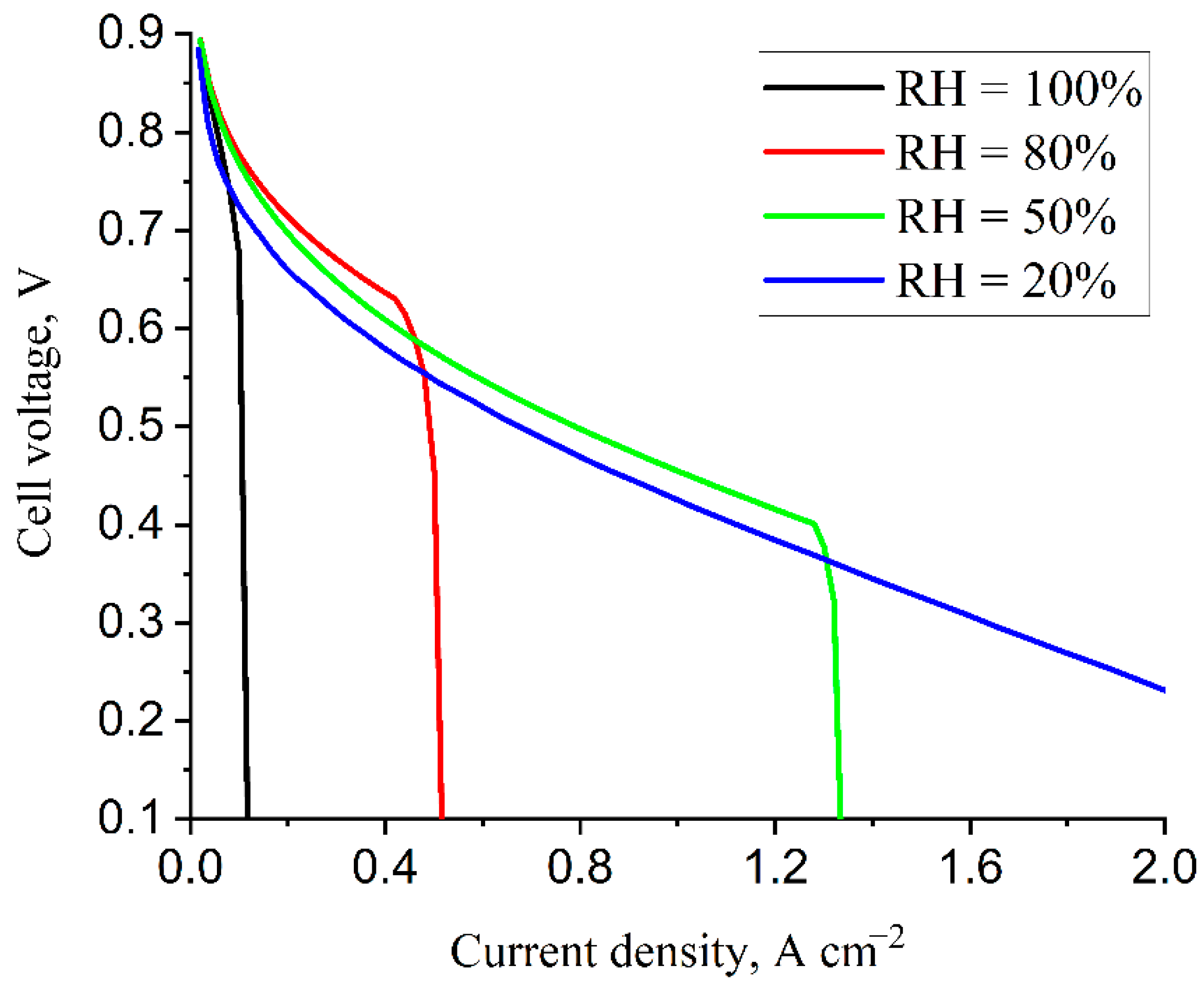

2. Results and Discussion

3. Model Description

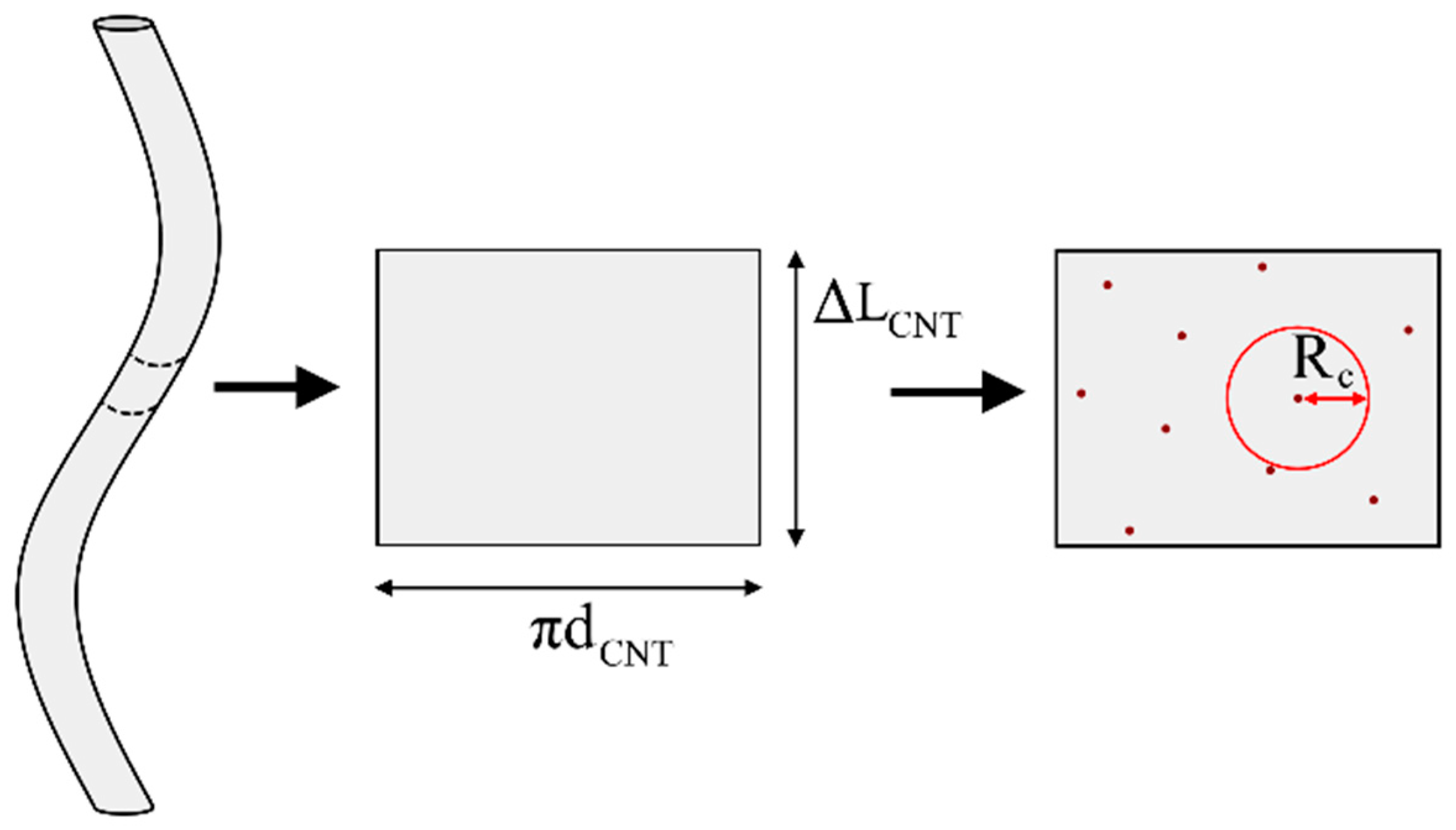

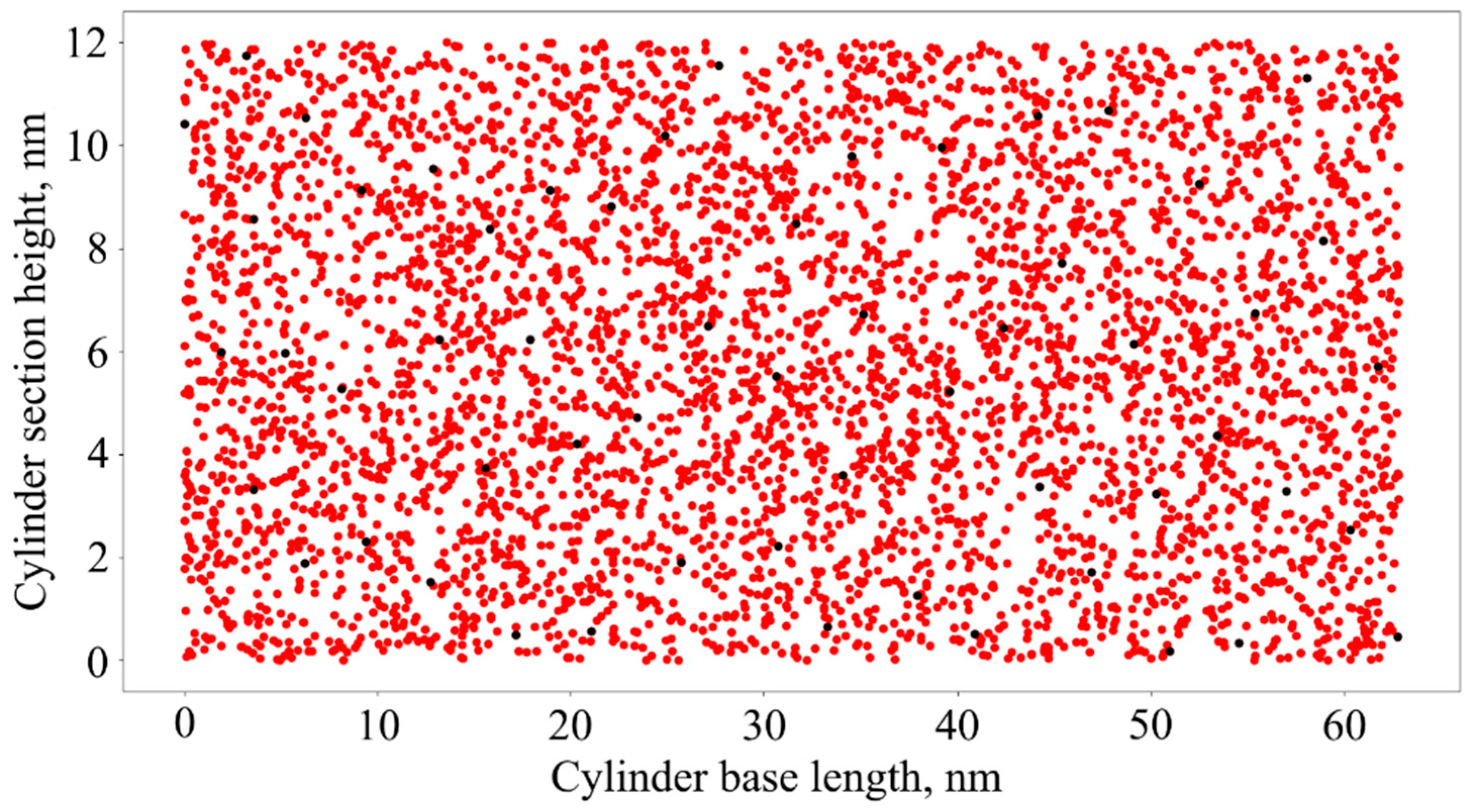

3.1. Calculation of Catalytic Layer Parameters

- The CNTs are evenly distributed over the surface with a given density.

- The CNTs have a fixed diameter and length.

- Platinum particles are uniformly and randomly distributed over the CNT surface.

- The probabilities of adsorption of platinum particles at any of the CNT sites are equal.

- Platinum particles located at a distance of less than Rc agglomerate and form a larger particle.

- Nanoparticles have the smallest possible size, i.e., the critical size of the nucleus dn.

3.2. PEMFC Performance Calculation

- The coefficient of water diffusion in the membrane does not depend on the water concentration (when the water content of the membrane is greater than five water molecules per SO3− group);

- The model is not applicable to low humidity conditions (when the water content of the membrane is less than five water molecules per SO3− group);

- There is no liquid water in the anode CL;

- The mass and charge transfer processes in the ACL do not significantly affect the PEMFC performance and are not considered in the model;

- The water evaporation and condensation rates are infinite;

- The processes of transfer of momentum, mass, and gas mixture components take place under isothermal conditions;

- The electrical resistivity of the CLs is negligible compared to the resistivity of the GDL;

- The rate of electrochemical reactions in the CCL is proportional to its water saturation (because water saturation determines the efficiency of the proton conductivity of the membrane);

- The cell temperature is constant and the same for all layers.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, Y.; Chen, S.; Wang, Y.; Ding, W.; Wu, R.; Li, L.; Wei, Z. Study of the degradation mechanisms of carbon-supported platinum fuel cells catalyst via different accelerated stress tests. J. Power Sources 2015, 273, 62–69. [Google Scholar] [CrossRef]

- Speder, J.; Zana, A.; Spanos, I.; Kirkensgaard, J.J.; Mortensen, K.; Hanzlik, M.; Arenz, M. Comparative degradation study of carbon supported proton exchange membrane fuel cell electrocatalysts–The influence of the platinum to carbon ratio on the degradation rate. J. Power Sources 2014, 261, 14–22. [Google Scholar] [CrossRef]

- Du, L.; Shao, Y.; Sun, J.; Yin, G.; Liu, J.; Wang, Y. Advanced catalyst supports for PEM fuel cell cathodes. Nano Energy 2016, 29, 314–322. [Google Scholar] [CrossRef] [Green Version]

- Mamat, M.S.; Grigoriev, S.A.; Dzhus, K.A.; Grant, D.M.; Walker, G.S. The performance and degradation of Pt electrocatalysts on novel carbon carriers for PEMFC applications. Int. J. Hydrogen Energy 2010, 35, 7580–7587. [Google Scholar] [CrossRef]

- Sharma, S.; Pollet, B.G. Support materials for PEMFC and DMFC electrocatalysts-A review. J. Power Sources 2012, 208, 96–119. [Google Scholar] [CrossRef]

- Kozlova, M.; Butrim, S.; Solovyev, M.; Pushkarev, A.; Pushkareva, I.; Kalinichenko, V.; Akelkina, S.; Grigoriev, S. Structural and Electrochemical Characteristics of Platinum Nanoparticles Supported on Various Carbon Carriers. C 2022, 8, 14. [Google Scholar] [CrossRef]

- Mink, J.E.; Hussain, M.M. Sustainable design of high-performance microsized microbial fuel cell with carbon nanotube anode and air cathode. ACS Nano 2013, 7, 6921–6927. [Google Scholar] [CrossRef]

- Deng, H.; Zhang, Y.; Zheng, X.; Li, Y.; Zhang, X.; Liu, X. A CNT (carbon nanotube) paper as cathode gas diffusion electrode for water management of passive μ-DMFC (micro-direct methanol fuel cell) with highly concentrated methanol. Energy 2015, 82, 236–241. [Google Scholar] [CrossRef]

- Kaushal, S.; Sahu, A.K.; Rani, M.; Dhakate, S.R. Multiwall carbon nanotubes tailored porous carbon fiber paper-based gas diffusion layer performance in polymer electrolyte membrane fuel cell. Renew. Energy 2019, 142, 604–611. [Google Scholar] [CrossRef]

- Xu, F.; Chang, L.; Duan, X.; Bai, W.; Sui, X.; Zhao, X. A novel layer-by-layer CNT/PbO2 anode for high-efficiency removal of PCP-Na through combining adsorption/electrosorption and electrocatalysis. Electrochim. Acta 2019, 300, 53–66. [Google Scholar] [CrossRef]

- Xie, Z.; Chen, G.; Yu, X.; Hou, M.; Shao, Z.; Hong, S.; Mu, C. Carbon nanotubes grown in situ on carbon paper as a microporous layer for proton exchange membrane fuel cells. Int. J. Hydrogen Energy 2015, 40, 8958–8965. [Google Scholar] [CrossRef]

- Jung, G.B.; Tzeng, W.J.; Jao, T.C.; Liu, Y.H.; Yeh, C.C. Investigation of porous carbon and carbon nanotube layer for proton exchange membrane fuel cells. Appl. Energy 2013, 101, 457–464. [Google Scholar] [CrossRef]

- Chinnasa, P.; Ponhan, W.; Swatsitang, E. Effects of electrodes CdS/CNT/C on performance of PEMFC. Mater. Today Proc. 2019, 17, 1344–1353. [Google Scholar] [CrossRef]

- Lin, S.Y.; Chang, M.H. Effect of microporous layer composed of carbon nanotube and acetylene black on polymer electrolyte membrane fuel cell performance. Int. J. Hydrogen Energy 2015, 40, 7879–7885. [Google Scholar] [CrossRef]

- Kitahara, T.; Nakajima, H.; Okamura, K. Gas diffusion layers coated with a microporous layer containing hydrophilic carbon nanotubes for performance enhancement of polymer electrolyte fuel cells under both low and high humidity conditions. J. Power Sources 2015, 283, 115–124. [Google Scholar] [CrossRef]

- Quinson, J.; Jensen, K.M. From platinum atoms in molecules to colloidal nanoparticles: A review on reduction, nucleation and growth mechanisms. Adv. Colloid Interface Sci. 2020, 286, 102300. [Google Scholar] [CrossRef]

- Bøjesen, E.D.; Iversen, B.B. The chemistry of nucleation. CrystEngComm 2016, 18, 8332–8353. [Google Scholar] [CrossRef]

- Sakurai, S.; Nishino, H.; Futaba, D.N.; Yasuda, S.; Yamada, T.; Maigne, A.; Hata, K. Role of subsurface diffusion and Ostwald ripening in catalyst formation for single-walled carbon nanotube forest growth. J. Am. Chem. Soc. 2012, 134, 2148–2153. [Google Scholar] [CrossRef]

- Tojo, C.; Blanco, M.C.; López-Quintela, M.A. Preparation of nanoparticles in microemulsions: A Monte Carlo study of the influence of the synthesis variables. Langmuir 1997, 13, 4527–4534. [Google Scholar] [CrossRef]

- Tandon, P.; Rosner, D.E. Monte Carlo simulation of particle aggregation and simultaneous restructuring. J. Colloid Interface Sci. 1999, 213, 273–286. [Google Scholar] [CrossRef]

- Kudinova, E.S.; Vorobyeva, E.A.; Ivanova, N.A.; Tishkin, V.V.; Alekseeva, O.K. A Magnetron Sputtering Method for the Application of the Ni Catalyst for the Synthesis Process of Carbon Nanotube Arrays. Nanotechnol. Russ. 2020, 15, 715–722. [Google Scholar] [CrossRef]

- Luo, F.; Guo, L.; Zhang, Q.; Ling, Y.; Yang, Z.; Grigoriev, S.A.; Cheng, H. Boosting CO tolerance and stability of Pt electrocatalyst supported on sulfonated carbon nanotubes. Int. J. Hydrogen Energy 2019, 44, 29671–29679. [Google Scholar] [CrossRef]

- Ivanova, N.A.; Spasov, D.D.; Zasypkina, A.A.; Alekseeva, O.K.; Kukueva, E.V.; Vorobyeva, E.A.; Grigoriev, S.A. Comparison of the performance and durability of PEM fuel cells with different Pt-activated microporous layers. Int. J. Hydrogen Energy 2021, 46, 18093–18106. [Google Scholar] [CrossRef]

- Chechenin, N.G.; Chernykh, P.N.; Vorobyeva, E.A.; Timofeev, O.S. Synthesis and electroconductivity of epoxy/aligned CNTs composites. Appl. Surf. Sci. 2013, 275, 217–221. [Google Scholar] [CrossRef]

- Murata, S.; Imanishi, M.; Hasegawa, S.; Namba, R. Vertically aligned carbon nanotube electrodes for high current density operating proton exchange membrane fuel cells. J. Power Sources 2014, 253, 104–113. [Google Scholar] [CrossRef]

- Baranov, I.E.; Nikolaev, I.I.; Pushkarev, A.S.; Pushkareva, I.V.; Kalinnikov, A.A.; Fateev, V.N. Numerical modeling of polymer electrolyte fuel cell catalyst layer with different carbon supports. Int. J. Hydrogen Energy 2018, 13, 8673–8685. [Google Scholar] [CrossRef]

- Bogdanovskaya, V.A.; Kuzov, A.V.; Radina, M.V.; Filimonov, V.Y.; Sudarev, G.M.; Osina, M.A. Stability against Degradation and Activity of Catalysts with Different Platinum Load Synthesized at Carbon Nanotubes. Russ. J. Electrochem. 2020, 56, 969–983. [Google Scholar] [CrossRef]

- Zhang, S.; Shao, Y.; Yin, G.; Lin, Y. Self-assembly of Pt nanoparticles on highly graphitized carbon nanotubes as an excellent oxygen-reduction catalyst. Appl. Catal. B Environ. 2011, 102, 372–377. [Google Scholar] [CrossRef]

- Onoe, T.; Iwamoto, S.; Inoue, M. Synthesis and activity of the Pt catalyst supported on CNT. Catal. Commun. 2007, 8, 701–706. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, J.; Swiegers, G.F.; Ma, Z.F.; Wallace, G.G. Microwave-assisted synthesis of Pt/CNT nanocomposite electrocatalysts for PEM fuel cells. Nanoscale 2010, 2, 282–286. [Google Scholar] [CrossRef]

- Takenaka, S.; Miyamoto, H.; Utsunomiya, Y.; Matsune, H.; Kishida, M. Catalytic activity of highly durable Pt/CNT catalysts covered with hydrophobic silica layers for the oxygen reduction reaction in PEFCs. J. Phys. Chem. C 2014, 118, 774–783. [Google Scholar] [CrossRef]

- Gan, J.; Luo, W.; Chen, W.; Guo, J.; Xiang, Z.; Chen, B.; Zhou, X. Mechanistic Understanding of Size-Dependent Oxygen Reduction Activity and Selectivity over Pt/CNT Nanocatalysts. Eur. J. Inorg. Chem. 2019, 27, 3210–3217. [Google Scholar] [CrossRef]

- Bharti, A.; Cheruvally, G.; Muliankeezhu, S. Microwave assisted, facile synthesis of Pt/CNT catalyst for proton exchange membrane fuel cell application. Int. J. Hydrogen Energy 2017, 42, 11622–11631. [Google Scholar] [CrossRef]

- Bharti, A.; Cheruvally, G. Influence of various carbon nano-forms as supports for Pt catalyst on proton exchange membrane fuel cell performance. J. Power Sources 2017, 360, 196–205. [Google Scholar] [CrossRef]

- Kalinnikov, A.A.; Grigoriev, S.A.; Bessarabov, D.G.; Bouzek, K. Two-phase mass transfer in porous transport layers of the electrolysis cell based on a polymer electrolyte membrane: Analysis of the limitations. Electrochim. Acta 2021, 387, 138541. [Google Scholar] [CrossRef]

- Springer, T.E.; Zawodzinski, T.A.; Gottesfeld, S. Polymer electrolyte fuel cell model. J. Electrochem. Soc. 1991, 138, 2334. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| CNT length (LCNT) | 60 μm |

| CNT diameter (dCNT) | 20 nm |

| CNT array density (NCNT) | 3 × 109 tubes cm−2 |

| Mass of platinum | 0.1 mg cm−2 |

| Average particle size | 2.0–2.5 nm |

| EASA | 77 m2·g−1 |

| Minimum particle spacing (Rc) | 0.5 nm |

| Minimum particle diameter (dw) | 0.5 nm |

| No. | Synthesis Method | Pt Loading, % (mg/cm2) | Average Particle Size of Pt, nm | Average Particle Size of Pt, nm (Model) | EASA, m2/g | EASA (Model), m2/g |

|---|---|---|---|---|---|---|

| 1 | EG [25] | 20 (0.1) | 2.0–2.5 | 2.1 | 77 | 81.0 |

| 2 | EG [28] | 20 (0.3) | 3.2 | 3.1 | 48.6 | 41.8 |

| 3 | EG [30] | 20 (0.55) | 2.5–4 | 3.3 | 40.2 | 39.4 |

| 4 | Imp. H2 [31] | 15 | 1–3 | 2.3 | 46–70 | 56.3 |

| 5 | Imp. H2 | 20 (0.3) | 5.2 | 5.2 | 27 | 25.0 |

| Parameters | Values |

|---|---|

| Cell temperature | 30 °C |

| Gas pressure on the anode and cathode sides | 1 bar |

| AGDL thickness | 420 μm |

| PEM thickness | 50 μm |

| CCL thickness | 10 μm |

| GDL porosity | 0.8 |

| CCL porosity | 0.8 |

| GDL electrical resistivity | 1.6 μΩ m2 |

| CCL platinum loading | 0.3 mg·cm−2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mensharapov, R.M.; Ivanova, N.A.; Zasypkina, A.A.; Spasov, D.D.; Sinyakov, M.V.; Grigoriev, S.A.; Fateev, V.N. Model Study of CNT-Based PEMFCs’ Electrocatalytic Layers. Catalysts 2022, 12, 1227. https://doi.org/10.3390/catal12101227

Mensharapov RM, Ivanova NA, Zasypkina AA, Spasov DD, Sinyakov MV, Grigoriev SA, Fateev VN. Model Study of CNT-Based PEMFCs’ Electrocatalytic Layers. Catalysts. 2022; 12(10):1227. https://doi.org/10.3390/catal12101227

Chicago/Turabian StyleMensharapov, Ruslan M., Nataliya A. Ivanova, Adelina A. Zasypkina, Dmitry D. Spasov, Matvey V. Sinyakov, Sergey A. Grigoriev, and Vladimir N. Fateev. 2022. "Model Study of CNT-Based PEMFCs’ Electrocatalytic Layers" Catalysts 12, no. 10: 1227. https://doi.org/10.3390/catal12101227

APA StyleMensharapov, R. M., Ivanova, N. A., Zasypkina, A. A., Spasov, D. D., Sinyakov, M. V., Grigoriev, S. A., & Fateev, V. N. (2022). Model Study of CNT-Based PEMFCs’ Electrocatalytic Layers. Catalysts, 12(10), 1227. https://doi.org/10.3390/catal12101227