Abstract

In this study, a series of Ni10MoxAl composite metal oxide (Ni10MoxAl, NiO = 10 wt.%, x = 2.5, 5, 10, 15, 20 wt.%) catalysts with different Mo content were prepared by a solvothermal method using a water—ethanol system. By employing various characterization technologies, it was confirmed that the suitable amount of the Mo element can not only promote the dispersion of the Ni species but also inhibit the formation of the inactive NiAl2O4 phase. Consequently, the hydrogenation activity of the Ni10MoxAl catalysts was affected by the particle size of the active components and the amount of the NiAl2O4 phase. As a result, the Ni10Mo10Al catalyst showed the best catalytic performance on methyl acrylate hydrogenation, and the yield of methyl propionate can be increased from 53.7% to 89.5% at 100 °C and 1 MP H2, compared with the Ni10Mo10/γ–Al2O3 catalyst prepared by a traditional impregnation method. The stability of the Ni10Mo10Al catalyst was also investigated, and the catalyst can run stably for 23 h. The novel strategy adopted in this article provides a new direction for the preparation of high activity Ni–Mo catalysts.

1. Introduction

As an important industrial feedstock, methyl propionate (MP) is widely used in the production of nitro spray paint and varnish. In addition, MP is also an essential intermediate for pharmaceutical, pesticide and perfume products [1,2,3]. In recent years, the hydrogenation of methyl acrylate (MA) to MP has received increasing attention due to its high atomic utilization and simple production process. However, MA is easy to polymerize during hydrogenation at relatively high temperatures, and the reported catalysts are mainly focused on precious metal catalysts, which severely restrict industrial application [4,5,6,7,8]. Therefore, the development of non-noble metal catalysts with high hydrogenation activity under mild reaction conditions is significantly required.

At present, the catalysts reported for the hydrogenation of MA to MP are precious metal catalysts due to their high activity under mild conditions. Trzeciak et al. reported that the yield of MP could reach 100% with catalysis of rhodium triphenyl phosphite in a batch reaction system [7]. Shiraishi et al. found that the platinum nanocluster protected by poy(N-vinyl-2-pyrrolidone) exhibited excellent behavior in the hydrogenation of MA, which was affected by the metal particle size [8]. Chen et al. synthesized a kind of Pd(II) complex using polyfunctional phosphine ligands for MA hydrogenation under atmospheric pressure, and the conversion achieved was higher than 92% [9]. Chen et al. obtained 100% yield of MP from MA hydrogenation over a Pd catalyst [10]. However, the high cost and low storage of precious metals limit their application in industrial production. Ni-based catalysts have gained much more attention for their comparable hydrogenation activity with precious metal catalysts and relatively low cost of preparation [11,12].

It is well known that the dispersion and particle size of active species in catalysts are crucial to the activity [13,14]. For the Ni-based catalyst, the Ni species will easily agglomerate and sinter at high temperatures during calcination or reduction. Therefore, considerable efforts have been made to solve this problem. Zhang et al. discovered that the introduction of the Mo element could improve the dispersion of the Ni species on SiO2 support, and the catalyst shows relatively high activity with a Mo/Ni ratio of 0.1 [15]. Kordouli et al. prepared a Ni–Mo/γ–Al2O3 catalyst with hierarchical NiO flake-flower architectures by the coprecipitation method and found that the addition of Mo could decrease the size of nickel nanoparticles and inhibit the formation of catalytically inactive nickel aluminate. In addition, flake-flower architectures formed under a high content amount of nickel (49–52 wt.%) when the MoO3 content was below 7 wt.%, and the Mo-Ni/ASA catalyst displayed a two times higher yield than a commercial NiMoP/Al2O3 due to the higher Ni dispersion [16]. Lv et al. demonstrated that the Ni–Mo/γ–Al2O3 catalyst prepared by the thermal decomposition of the layered double hydroxides Ni–Al–[C6H4(COO)2]2−–LDHs/γ–Al2O3 showed a better dispersion of the NiO and MoO3 on the alumina surface, and the yield of the catalyst increased by 20% more than the catalyst prepared by an impregnation method, while the preparation process was complicated and required a long time [17]. Past research has demonstrated that the dispersion of the active species can be improved by optimizing the catalyst preparation method. However, the coprecipitation method and the hydrothermal method limited the content of the active components in the catalyst due to the fact that Ni ions precipitate in alkaline environments, and Mo ions precipitate in acidic conditions. According to our previous work, the Ni–Mo/γ–Al2O3 catalyst, prepared by the incipient wetness impregnation method, exhibited excellent activity in the MA hydrogenation to MP under mild conditions; however, it still needs to be improved for industrial application [18]. Stimulated by the effects of dispersion and the particle size of the active species on catalytic activity, solvothermal technology was employed for the modification of this Ni–Mo–Al catalyst.

In this study, the Ni10MoxAl composite metal oxide (Ni10MoxAl) catalysts with different Mo content (x = 2.5, 5, 10, 15, 20 wt.%) were prepared by a solvothermal method using a water–ethanol system. The physicochemical properties of the catalyst series were characterized using X-ray diffraction (XRD), Brunauer–Emmett–Teller analysis (BET), UV-vis diffuse reflectance spectroscopy (UV-vis DRS), hydrogen temperature programmed reduction (H2-TPR), X-ray photoelectron spectroscopy (XPS) and transmission electron microscopy (TEM). The relationship between the structure and catalytic hydrogenation activity in these Ni–Mo–Al composite oxides were analyzed. In addition, the effects of the reaction conditions were systematically investigated.

2. Results and Discussion

2.1. Characterization of Catalysts

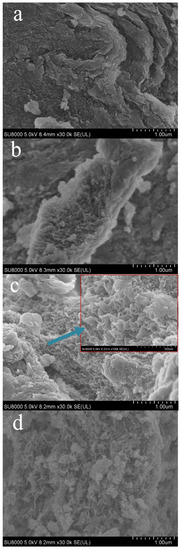

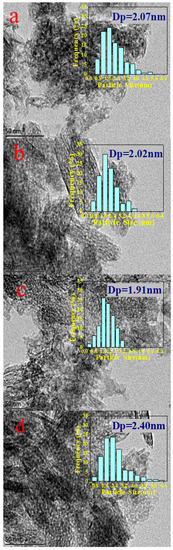

SEM analysis was carried out to study the morphological structure of the Ni10MoxAl catalyst precursors with different Mo content. For comparison, the SEM images of the Ni10Al and Mo10Al catalyst precursors were also obtained, as shown in Figure S1. Only small sheet structures were observed on the surface of the Ni10Al, while large block solids were found on the surface of the Mo10Al. For the Ni10MoxAl catalyst precursors, as shown in Figure 1, the Ni(OH)2 nano-flower architectures were observed; this is dependent on the content of molybdenum [19,20]. The formation and mechanistic route of the Ni(OH)2 nano-flower architectures and the maintenance of this structure after calcination (the transformation of Ni(OH)2 to NiO phase) has been reported [21,22,23]. It was also demonstrated that this structure promotes the diffusion and hydrogenation of the reactant. When the Mo content was 2.5 wt.% (Figure 1a), an outward diffusion sheet structure was seen on the surface. With the increase in Mo content, a hierarchical structure gradually formed on the surface, as shown in Figure 1b. The hierarchical structure was observed more obviously with a further increase in Mo content (Figure 1c), indicating that the introduction of the Mo element can promote the formation of hierarchical structures. However, when the Mo content attained 15 wt.% (Figure 1d), the hierarchical structure was covered by block solids. This phenomenon was more seriously observed with a further increase in Mo content to 20 wt.%, as shown in Figure 1e. In addition, the energy dispersive X-ray spectroscopy (EDS) elemental mapping of the Ni10Mo10Al catalyst precursor was also conducted. As shown in Figure 1f, the Mo and Ni displayed a uniform distribution on the surface [24]. In addition, the content of the Ni and Mo tested using EDS was 6.55 wt.% and 6.35 wt.%, respectively, which were consistent with the ICP–OES analysis, as presented in Table 1. In addition, it can be seen from Table 1 that the content of NiO was close to the theory design value, and MoO3 was also close to the theoretical design value when the content was below 15 wt.%.

Figure 1.

SEM images of (a) Ni10Mo2.5Al, (b) Ni10Mo5Al, (c) Ni10Mo10Al, (d) Ni10Mo15Al and (e) Ni10Mo20Al catalyst precursor; and (f) EDS mapping of Ni, Mo, Al elements for Ni10Mo10Al catalyst precursor.

Table 1.

ICP–OES results for the fresh Ni10MoxAl catalysts.

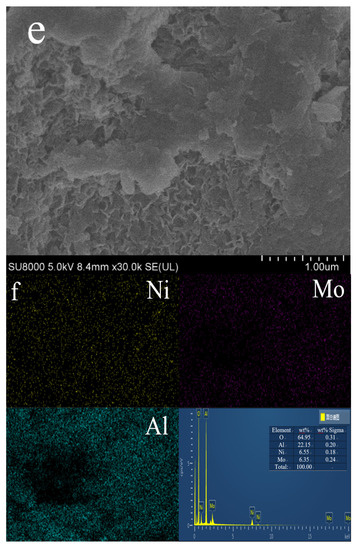

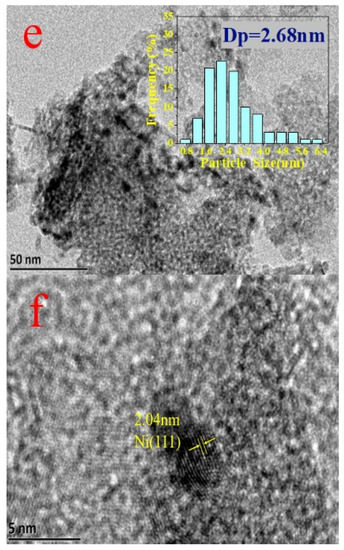

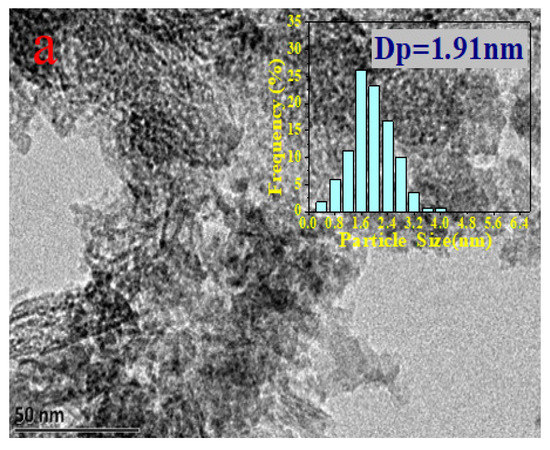

Figure 2 shows the TEM images of the reduced Ni10MoxAl catalyst series and the HRTEM image of the reduced Ni10Mo10Al catalyst. It was noticed that the Ni species in the catalyst showed a smaller particle size with the increase in MoO3 content in the region of 2.5–10 wt.%, suggesting that the introduction of Mo promotes the dispersion of the Ni species. A previous study also demonstrated that the introduction of Mo onto a Ni-based catalyst can inhibit the aggregation of the Ni species [25]. However, an excessive amount of the Mo element (15 wt.% and 20 wt.%) results in the growth of particle size because of the coverage of the Ni species by the excess Mo element, which was also demonstrated by the SEM results [26]. Figure 2f shows the HRTEM image of the Ni10Mo10Al catalyst. An Ni particle with a lattice spacing of 0.204 nm was found, which corresponded to the plane of Ni (111). For comparison, a TEM image of Ni10Mo10/γ–Al2O3 catalyst was also obtained, as shown in Figure S2. The aggregation of the Ni species with a wide range of particle distribution ranging from 1 to 11 nm was clearly observed. In addition, the mean particle size was twice as large as that of the Ni10Mo10Al catalyst, indicating that the solvothermal method is effective for the dispersion of the active components in the catalyst.

Figure 2.

TEM images of (a) Ni10Mo2.5Al, (b) Ni10Mo5Al, (c) Ni10Mo10Al, (d) Ni10Mo15Al and (e) Ni10Mo20Al; and (f) HRTEM image of Ni10Mo10Al catalyst after reduction at 450 °C.

Figure 3 shows the TEM images of the reduced Ni10Mo10Al catalysts obtained under different calcination temperatures (450–750 °C). It was observed that the agglomeration of the active components, together with a wider distribution in particle size, became more obvious with the enhancement of the calcination temperature, indicating that a higher calcination temperature is unfavorable for the distribution of active components.

Figure 3.

TEM images of Ni10Mo10Al catalysts calcined at (a) 450 °C, (b) 550 °C, (c) 650 °C and (d) 750 °C after reduction at 450 °C.

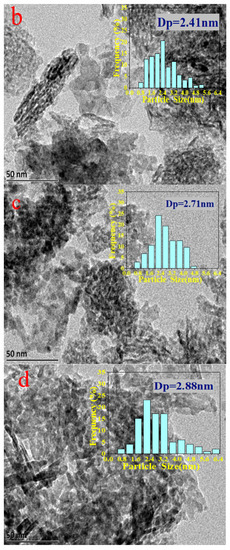

Figure 4 shows the N2 adsorption–desorption isotherms and pore size distribution curves of the Ni10MoxAl catalysts. All the catalysts showed the typical IV N2 adsorption–desorption isotherms, as shown in Figure 4a, indicating that the mesoporous structure existed in these catalysts [27]. The pore size distribution curves, as shown in Figure 4b, also identified the mesoporous structure in these catalysts, and the average pore size gradually decreased with the increase in Mo content.

Figure 4.

The N2 adsorption–desorption isotherms (a) and the distributions of pore size (b) of Ni10MoxAl catalysts.

For the Ni10MoxAl catalyst, as presented in Table 2, the N2-BET surface area (SBET) showed little change with the increase in Mo content from 2.5 to 10 wt.% and then decreased with a further increase in MoO3 content. This was due to the excess Mo content resulting in the agglomeration of the active components on the catalyst surface. The pore volume decreased from 0.48 to 0.29 cm3/g, while the average pore diameter of the catalysts decreased from 4.81 to 3.17 nm.

Table 2.

Texture properties of Ni10MoxAl catalysts.

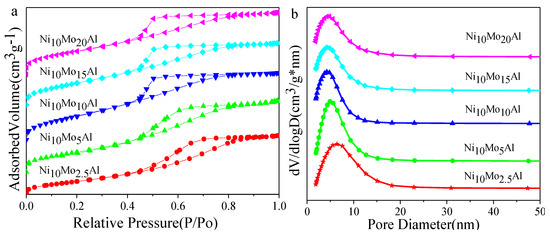

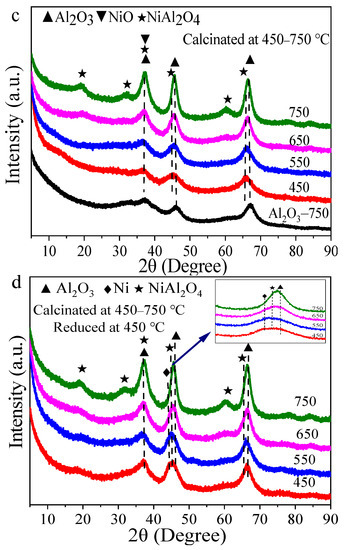

Figure 5a presents the XRD patterns of the Ni10MoxAl catalysts with different MoO3 content. The diffraction peaks at 2θ = 37.6, 45.9 and 67.0° are in respect to the (311), (400) and (440) crystal plane of γ–Al2O3, respectively (JCPDS card no. 10-0425). The peaks at 2θ = 37.2, 43.3 and 62.9° are attributed to the (111), (200) and (220) crystal planes of NiO (JCPDS card no. 47-1049). The peaks at 2θ = 19.1, 37.0, 45.0 and 65.5° belong to the (111), (311), (400) and (440) crystal planes of NiAl2O4 (JCPDS card no. 10-0339) [28,29,30]. It was observed that the diffraction peaks of NiO and NiAl2O4 overlapped with the diffraction peak of γ–Al2O3. In addition, the intensity of the characteristic peaks at 2θ = 37.6, 45.9 and 67.0° gradually decreased with increasing MoO3 content; this change may be due to the decrease in the γ–Al2O3 and NiAl2O4 phase content. It was noticed that no significant diffraction peak related to MoO3 was observed, indicating that amorphous molybdenum oxide is formed on the catalyst surface in relation to the MoO3 content. For the reduced Ni10MoxAl catalysts, as shown in Figure 5b, the characteristic peaks around 2θ = 44.5 and 51.8° corresponded to the (111) and (200) crystal planes of Ni0 (JCPDS card no. 04-0850). The characteristic peak at 2θ = 44.5° also overlapped with the diffraction peaks of the NiAl2O4 and γ–Al2O3 phases. However, the intensity of the characteristic peaks of Ni0 at 2θ = 51.8° gradually increased with the increase in MoO3 content, indicating that the introduction of MoO3 can increase the content of the reducible NiO which may be due to the decrease in the NiAl2O4 phase.

Figure 5.

XRD patterns of Ni10MoxAl catalysts (a) before and (b) after reduction at 450 °C; Ni10Mo10Al catalysts calcined at 450–750 °C (c) before and (d) after reduction at 450 °C.

Figure 5c shows the XRD spectra of Ni10Mo10Al catalysts calcined at different temperatures (450–750 °C). With the increase in the calcination temperature, the diffraction peaks of the γ–Al2O3 and NiAl2O4 phases gradually became intense and narrow. The new diffraction peaks around 2θ = 19.1, 31.4 and 60.9°, which were the overlapping peaks of NiAl2O4 and Al2O3, were observed when the catalyst was calcined under 750 °C. Compared with the diffraction peaks of Al2O3 calcinated at 750 °C, it can be concluded that the new diffraction peaks are mainly due to the formation of NiAl2O4 at a higher calcination temperature [31,32]. Regarding the reduced Ni10Mo10Al catalysts, as shown in Figure 5d, the intensity of the characteristic peaks was attributed to Ni0 decreases, while the peaks of the NiAl2O4 phase gradually became intense and narrow with the enhancement of the calcination temperature, demonstrating that the higher calcination temperature favors the formation of NiAl2O4.

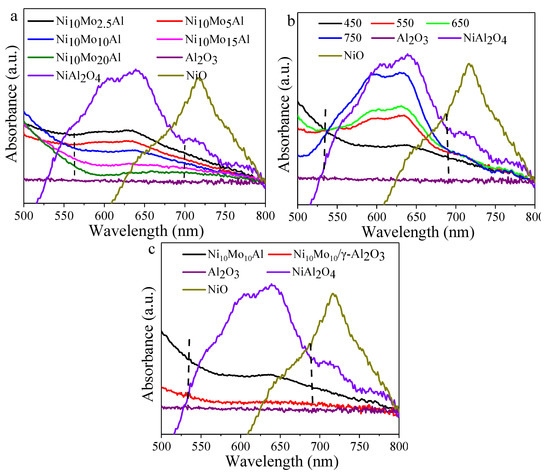

Due to the overlap of the characteristic peaks between the γ–Al2O3 and NiAl2O4 phase in the XRD patterns, the UV-vis diffuse reflectance spectroscopic characterization was utilized to study the influence of the Mo element on the formation of the NiAl2O4 phase in the catalyst. For comparison, the pure NiAl2O4 compound was prepared and confirmed by XRD characterization (Figure S4). As shown in Figure 6, it was observed that the broad absorption band of the NiAl2O4 and NiO phases appeared around 580–670 nm and 670–765 nm, respectively [33,34]. It can be seen from Figure 6a that the adsorption band of the NiAl2O4 phase became weaker with the increase in the Mo content in the catalyst. Therefore, it can be concluded that the introduction of the Mo element can inhibit the formation of the NiAl2O4 phase. Regarding the effect of the calcination temperature, as shown in Figure 6b, the absorption band of the NiAl2O4 phase became intense with the increase in the calcination temperature, indicating that the high temperature leads to the formation of the NiAl2O4 phase. The catalyst color changed from gray to green also demonstrating this change. For comparison, the Ni10Mo10/γ–Al2O3 catalyst was also performed, as shown in Figure 6c. The band of the Ni10Mo10Al catalysts was stronger than the Ni10Mo10/γ–Al2O3 catalysts, indicating that more NiAl2O4 phase was formed in the solvothermal preparation process.

Figure 6.

UV-vis DRS spectra of (a) Ni10MoxAl catalysts, (b) Ni10Mo10Al catalysts calcined at 450–750 °C and (c) Ni10Mo10Al and Ni10Mo10/γ–Al2O3 catalysts calcined at 450 °C.

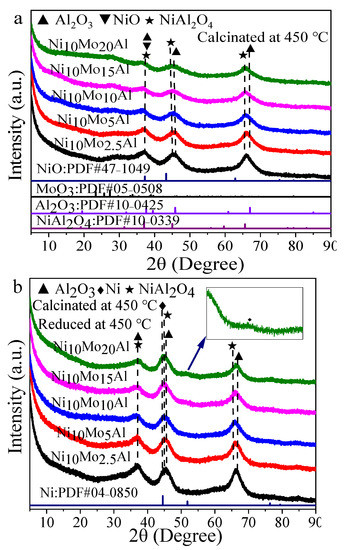

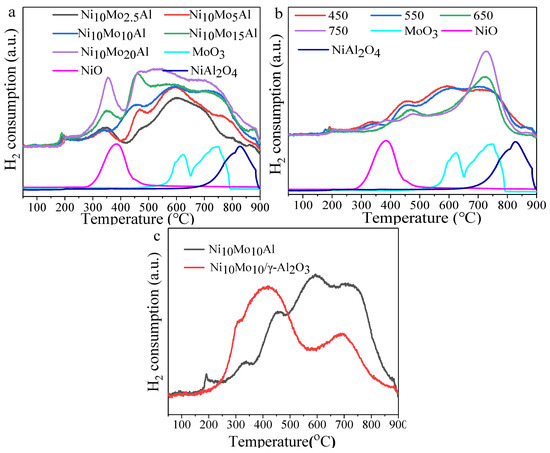

The reduction properties of the catalysts were studied using H2-TPR, and the results are shown in Figure 7. The reducibility of NiO depends on the interaction between NiO and γ–Al2O3. Regarding the Ni10Al catalyst, as shown in Figure S5, the H2 consumption peak around 340 °C is assigned to the reduction in NiO. The reduction peak range around 485 °C and 600 °C is in respect to the weak and strong interaction between NiO and γ–Al2O3, respectively. In addition, the peak at a temperature above 700 °C is assigned to the reduction in the NiAl2O4 phase. Regarding the Mo10Al catalyst, as shown in Figure S5, the reduction peak at 210–400 °C was lower than the bulk molybdena, indicating that well-dispersed oxomolybdenum-containing species are easier to reduce than bulk molybdena [24,35]. The reduction peak at 450 °C is assigned to the reduction in Mo6+ which interacted with the γ–Al2O3, and the peak at 660 °C is assigned to the reduction in Mo4+. Regarding the H2-TPR profiles of the Ni10MoxAl catalysts, the peak at 350 °C is corresponding to the NiO and MoO3 in the free state. The peak at 450 °C is ascribed to the reduction in Mo6+ and NiO, which showed a weak interaction with the γ–Al2O3 phase. The peak at 590 °C is assigned to the reducible NiO which showed a strong interaction with the γ–Al2O3 phase, while the hydrogen consumption peak at 750 °C is assigned to the overlap of the reduction peak of the NiAl2O4 phase and Mo4+. It was noticed that the reduction peaks of NiO at 590 °C became intense with the increase in Mo content. Meanwhile, the peak of the reducible NiO shifted to a lower temperature with the increase in Mo content. These results suggest that the interaction between NiO and Al2O3 becomes weak [36].

Figure 7.

H2-TPR profiles of (a) Ni10MoxAl, (b) Ni10Mo10Al catalysts calcined at 450–750 °C and (c) Ni10Mo10Al and Ni10Mo10/γ–Al2O3 catalysts calcined at 450 °C.

The H2-TPR profiles of Ni10Mo10Al catalysts calcined at different temperatures are shown in Figure 7b. The H2 consumption peaks (<600 °C) of reducible NiO and MoOx shifted to higher temperatures with the enhancement of the calcination temperature, indicating that the higher calcination temperature promotes the interaction between Ni–Al2O3 and Mo–Al2O3. In addition, the intensity of the reduction peaks (<600 °C) gradually decreased when the calcination temperature was raised from 450 to 750 °C. However, the reduction peak at 750 °C became gradually intense, indicating the formation of NiAl2O4 through the interaction between the Ni species and Al2O3 at a high calcination temperature, which is in agreement with the XRD and UV-vis characterization results.

The H2-TPR profiles of the Ni10Mo10/γ–Al2O3 catalysts prepared using the incipient wetness method are shown in Figure 7c. It was noted that the reduction peaks regarding NiO and MoO3 shifted towards a lower temperature than the Ni10Mo10Al catalyst. The change demonstrated that the catalyst prepared using the solvothermal method showed a stronger interaction between Ni–Al and Mo–Al, which is conductive to promote the dispersion of the active components in the catalyst. In addition, the intensity of the NiAl2O4 reduction peak in the Ni10Mo10Al catalyst was higher than that of the Ni10Mo10/γ–Al2O3 catalysts, indicating that more of the NiAl2O4 phase is in the Ni10Mo10Al catalyst, which is in full agreement with the UV-vis diffuse reflectance spectroscopic characterization.

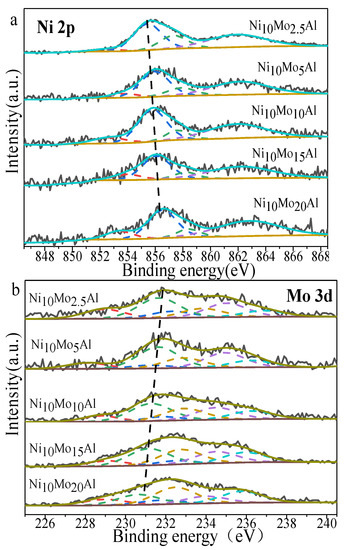

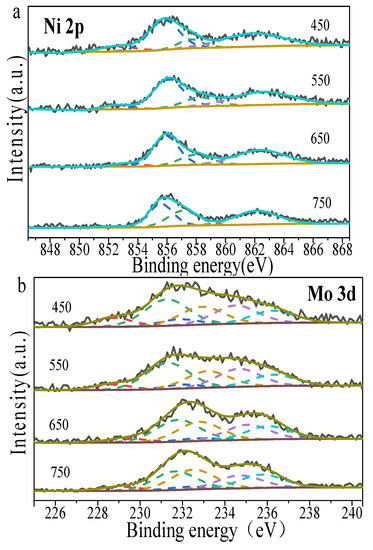

The reduced catalysts were measured by XPS analysis to investigate the chemical state of the Ni and Mo species on the catalyst surface, and their deconvolution are shown in Figure 8. All the results were corrected using the peak of C1s at 284.8 eV [37,38]. In addition, the related parameters are listed in Table 3. As shown in Figure 8a, the binding energy around 852.5 eV is attributed to Ni0, while 855.5 eV is assigned to Ni2+ in NiO, and 857.5 eV is ascribed to Ni2+ in NiAl2O4. The band at 862.2 eV is attributed to the satellite peak of Ni2p3/2 [25,36]. With the increase in Mo content, as showed in Figure 8a, the binding energy of Ni0 shifted to the higher binding energy, which may be related to the modification of the Ni0 surface by MoOx [26]. According to the XPS characterization results, as shown in Table 3, the Ni0 content on the catalyst surface rose, while the Ni–Al spinel content gradually decreased with the increase in Mo content, indicating that the introduction of the Mo element can inhibit the formation of the NiAl2O4 phase in the catalyst. This conclusion is also consistent with the UV-vis diffuse reflectance spectroscopic characterization results. Figure 8b depicts the Mo 3d spectra, and the quantitative analysis of the Mo species is listed in Table 3. The deconvolution results of the spectra show three different oxidation states around 228.8, 231.7 and 233.0 eV with respect to Mo4+, Mo5+ and Mo6+, respectively [39,40]. It is obvious that the binding energy of Mo shifted to a lower binding energy, and the percentage of the Mo6+ species increased with the increasing content of the Mo element.

Figure 8.

XPS spectra of Ni2p (a) and Mo3d (b) of Ni10MoxAl catalysts reduced at 450 °C.

Table 3.

Quantitative Ni 2p and Mo 3d XPS analysis for Ni10MoxAl catalysts a.

Figure 9 presents the Ni 2p and Mo 3d spectra of the reduced (at 450 °C) Ni10Mo10Al catalyst after calcination at different temperature (450–750 °C), and the related analysis results are listed in Table 4. As shown in Figure 9a, the peak intensity of the Ni0 species gradually decreased with the increasing calcination temperature, while it gradually increased for the NiAl2O4, which is consistent with the H2-TPR characterization results. In addition, the increasing content of Mo6+ indicates that a higher calcination temperature promotes the interaction between Mo–Al.

Figure 9.

XPS spectra of (a) Ni 2p and (b) Mo 3d of Ni10Mo10Al catalysts after calcination at 450–750 °C.

Table 4.

Quantitative Ni 2p and Mo 3d XPS analysis for reduced Ni10Mo10Al catalysts after calcination at 450–750 °C a.

2.2. Catalytic Evaluation

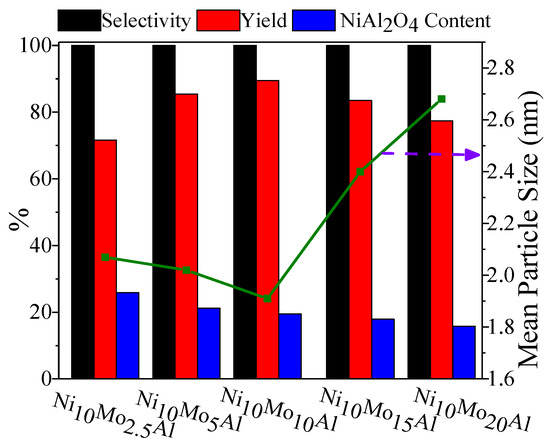

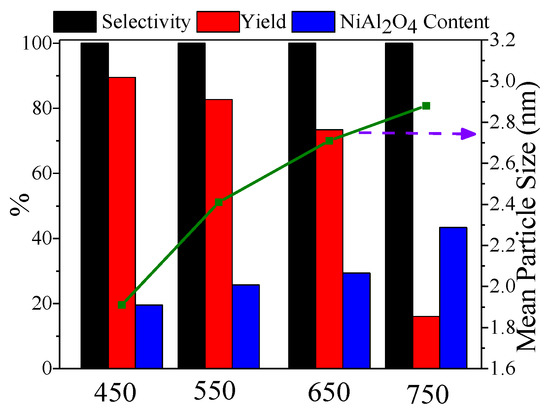

The effect of the Mo content on catalytic hydrogenation activity is shown in Figure 10. It was found that no byproducts were detected during the hydrogenation of MA under mild reaction conditions, which was consistent with the previous study [7,8,9,10]. So, the selectivity of MP remained stable at 100% in the wide range of Mo content from 2.5 to 20 wt.%. However, the yield of MP showed a volcanic pattern, and the Ni10Mo10Al catalyst existed at the peak position. According to the above TEM characterization results, the particle size of the Ni species on these catalyst series followed in the order of Ni10Mo10Al < Ni10Mo5Al < Ni10Mo2.5Al < Ni10Mo15Al < Ni10Mo20Al, which is consistent with the difference in the catalytic activity of Ni10Mo2.5Al, Ni10Mo5Al and Ni10Mo10Al. As for the Ni10Mo15Al and Ni10Mo20Al catalysts, their catalytic activities were still both higher than that of Ni10Mo2.5Al, although the particle size of the Ni species in them was larger, considering the lower content of the NiAl2O4 phase. In conclusion, the particle size of the Ni species and the content of the NiAl2O4 phase in this kind of Ni10MoxAl composite oxide catalyst are both crucial to the catalytic hydrogenation activity. This experimental phenomenon also demonstrates that the appropriate content of the Mo element not only promotes the dispersion of the Ni species but also decreases the formation of the NiAl2O4 phase; however, the excessive Mo covers the Ni particles and block the pore channels, which is consistent with the SEM and TEM characterization results [30,41].

Figure 10.

Catalytic evaluation of Ni10MoxAl catalyst series at the reaction conditions of 100 °C, 1 MPa H2, n(H2)/n(MA) = 4 and WHSV = 2 h−1.

For comparison, the catalytic activity of Ni10Mo10/γ–Al2O3 prepared using a traditional impregnation method was also evaluated under the same reaction conditions, and the yield of MP was only 53.7%, with a selectivity of 100%, as shown in Table S1. This is mainly due to the small particle size and better distribution of the active components in the catalyst prepared using the solvothermal method, although the solvothermal method tends to generate Ni–Al spinel, as demonstrated by the TEM and UV-vis characterization results.

First, the effect of a reduction in temperature was studied by reducing the Ni10Mo10Al catalyst to 300–500 °C, and the hydrogenation result is presented in Figure S5. It was observed that the highest yield of MP, 89.6%, was achieved at 450 °C. So, the catalytic activities of the Ni10Mo10Al catalysts calcinated at 450–750 °C and reduced at 450 °C were evaluated for the investigation of the effect of the calcination temperature, and the result is shown in Figure 11. With an increase in the calcination temperature, both the particle size of the Ni species and the content of the NiAl2O4 phase increased, and as a result, the catalytic hydrogenation activities on these Ni10Mo10Al catalysts decreased accordingly. This result also suggests that the high dispersion of the Ni species and the inhibition of NiAl2O4 phase in such Ni10Mo10Al catalysts promotes hydrogenation activity.

Figure 11.

Effect of calcination temperature on the catalytic activity of Ni10Mo10Al catalyst under the reaction conditions of 100 °C, 1 MPa H2, n(H2)/n(MA) = 4 and WHSV = 2 h−1.

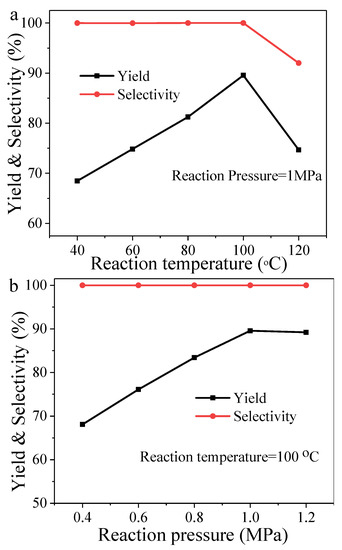

The effects of reaction conditions including temperature and pressure on MA hydrogenation were investigated, and the results are shown in Figure 12. As shown in Figure 12a, the selectivity of MP remained at 100%, while the yield increased from 68.5% to 89.6% when the reaction temperature was increased from 40 to 100 °C. However, both the yield and selectivity of MP tended to decrease when the temperature was above 100 °C due to the polymerization of MA. The influence of reaction pressure on the hydrogenation of MA is presented in Figure 12b. The selectivity of MP was stable at 100% with the increase in reaction pressure from 0.4 to 1.2 MPa, while the yield of MP increased from 68.1% to 89.6% and then remained unchanged with further increases. Therefore, the optimal reaction temperature is 100 °C, and the suitable reaction pressure of H2 is 1.0 MPa.

Figure 12.

Effect of (a) reaction temperature and (b) pressure on the yield and selectivity of MP.

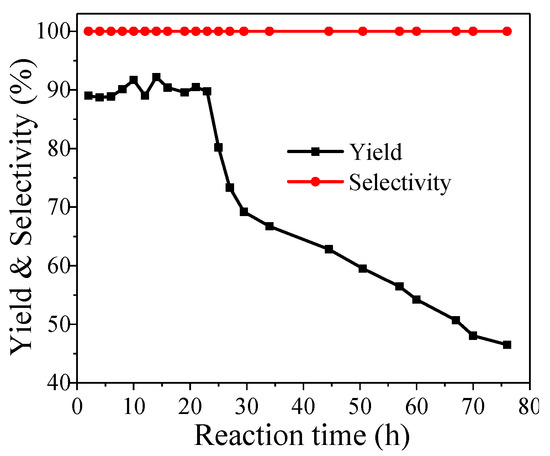

The catalytic stability of Ni10Mo10Al was tested under the optimal reaction conditions of 100 °C and 10 MPa, which is displayed in Figure 13. The selectivity of MP was still relatively stable at 100%; however, the yield of MP tended to decrease after 23 h time-on-stream. Comparing the ICP–OES analysis results of the fresh and deactivated catalysts, as listed in Table S2, it was observed that the Ni and Mo content reduced from 6.58 to 5.71 wt.% and from 6.07 to 5.81 wt.%, respectively. Moreover, the deactivated Ni10Mo10Al catalyst was characterized using TEM, as shown in Figure S6. The particle size of the Ni species in the deactivated catalyst was larger than that in the fresh catalyst. Therefore, the deactivation of the catalyst can be attributed to the loss of Ni and Mo elements and the agglomeration of active components during the hydrogenation reaction.

Figure 13.

Catalytic stability test for Ni10Mo10Al catalyst at the reaction conditions of 100 °C, 1 MPa H2, n(H2)/n(MA) = 4 and WHSV = 2 h−1.

3. Experimental Section

3.1. Catalyst Preparation

MA (≥99.0%) and absolute ethyl alcohol (≥99.7%) were offered by Damao Chemical Reagent Factory (Tianjin, China). NiC4H6O4·4H2O (≥99.0%), Na2CO3 (≥99.5%) and Al(NO3)3·9H2O (≥99.0%) were provided by Macklin Biochemical Co., Ltd. (Shanghai, China). NaOH (≥99.5%) was offered by Xilong Co., Ltd. (Shantou, China). n-Hexane (≥99.0%) and (NH4)6Mo7O24·4H2O (≥99.0%) were supported by the Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China). All reagents were used without any further purification.

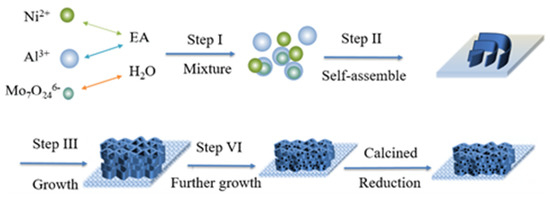

Ni10MoxAl catalysts were prepared using a solvothermal method (Figure 14). First, solution A was prepared by adding the required amount of NiC4H6O4·4H2O and Al(NO3)3·9H2O in 50 mL ethanol. Solution B was prepared by dissolving the desired amount of (NH4)6Mo7O24·4H2O, Na2CO3 and NaOH in 50 mL deionized water. Then the solution B was introduced dropwise in solution A under vigorous stirring for 30 min, during which the pH was controlled between 7–8. Then the mixture was transferred into 150 mL Teflon-lined autoclave and placed at 110 °C for 16 h. The obtained powders were washed with water and ethanol several times. Then the sample was dried at 60 °C for 8 h and calcined at 450 °C for 4 h to obtain Ni10MoxAl. For comparison, the Ni10Al and Mo10Al catalysts used as reference samples were prepared in the same conditions. The Ni10Mo10/γ–Al2O3 catalyst and NiAl2O4 were, respectively, prepared by the incipient impregnation and coprecipitation method, which has been reported in our previous work [18]. Before the hydrogenation experiments, the catalyst was reduced in situ at 450 °C for 4 h with a continuous flow of 10% H2/N2.

Figure 14.

Schematic illustrating for the preparation of Ni10MoxAl catalyst.

3.2. Catalyst Characterization

Scanning electron microscope (SEM) images of the catalysts were obtained on a Hitachi SUB8020 instrument. Transmission electron microscope (TEM) and high resolution transmission electron microscope (HRTEM) examination were performed on a FEI Talos F2000x instrument. Powder X-ray diffraction patterns (XRD) were examined on a Rigaku Smart Lab X-ray powder diffractometer with Cu Kα radiation. The diffraction patterns were recorded from 2θ = 5° to 90° under a 10°/min scanning speed. UV-vis diffusion reflectance spectroscopy (UV-vis DRS) was recorded on a UV-2550 spectrophotometer, and the diffractograms were carried out in the wavelength of 500–800 nm, with BaSO4 powder as background. N2 adsorption–desorption isotherms of the catalysts were performed on a micromeritics ASAP 2460 apparatus. The surface area was calculated using the Brunauer–Emmett–Teller (BET) method, and the pore size was obtained using the Barrett–Joyner–Halenda (BJH) model. The content of the Ni and Mo elements in the catalyst were analyzed by ICP-OES on a PerkinElmer Optima 8000 instrument. Before testing, the catalyst powder was ground to 200 mesh and dissolved in HF solution. Then the mixture was purified with a disposable syringe and appropriately diluted. Hydrogen temperature programmed reduction (H2-TPR) of the catalysts was carried out on the AutochemII 2920 chemisorption apparatus (Micromeritics, Norcross, GA, USA). The sample was placed in a U-shaped quartz reactor and treated under flowing He at 300 °C for 1 h to remove the adsorbed water and impurities and then cooled to 50 °C. Subsequently, the 10% H2/Ar gas was introduced to the sample, and the temperature was raised to 900 °C with a heating rate of 5 °C/min. X-ray photoelectron spectroscopy (XPS) analysis was obtained on an Escalab 250Xi electron spectrometer using Mg X-ray source. All the binding energies of the catalysts were corrected with C 1s (284.8 eV) as the reference.

3.3. Catalytic Testing

The hydrogenation of MA was carried out in a fixed bed reactor with a vertical tube (d = 8 mm). First, the catalyst samples were pretreated in 10% H2 flow at 450 °C for 4 h, and then the temperature was decreased to the reaction temperature. After that, the reactant of MA was introduced into the reactor using a constant flux pump under reaction conditions. The analysis of the products was performed on GC (SP-7890) equipped with an OV1701 column and a hydrogen flame detector, using n-hexane as internal standard substance. The catalytic activity was evaluated using MA conversion and MP yield and selectivity, which were calculated as Equations (1)–(3).

Yield of MP = Conversion of MA × selectivity of MP

4. Conclusions

A series of Ni10MoxAl catalysts were prepared using the solvothermal method in a water–ethanol system due to the characteristics that Ni ions precipitate in alkaline environments and Mo ions precipitate in acidic conditions, which also provides a new method for metal catalysts with opposite precipitation pH values. The introduction of Mo can improve the dispersion of the Ni species and inhibit the formation of Ni–Al spinel, which significantly affect the catalytic activity in the MA hydrogenation to MP. As a result, the Ni10Mo10Al catalyst exhibits 89.6% yield of MP with 100% selectivity under the optimized conditions of 100 °C and 1 MPa, which is higher than the 53.7% yield achieved by Ni10Mo10/γ–Al2O3 prepared using a traditional impregnation method. However, the deactivation behavior observed on this kind of Ni10Mo10Al composite catalyst is derived from the loss of Ni and Mo elements and the agglomeration of the Ni species. It is foreseeable that if the stability of the catalyst is improved, the catalyst prepared by the new strategy will have broader industrial application potential.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/catal12101118/s1, Figure S1. SEM images of (a) Mo10Al, (b) Ni10Al catalysts; Figure S2. TEM images of reduced Ni10Mo10/γ–Al2O3 catalyst after reduction at 450 oC; Figure S3. XRD patterns of NiAl2O4; Figure S4. H2-TPR profiles of Ni10Al, Mo10Al, Ni10Mo10Al catalysts; Figure S5. Effect of reduction temperature on the catalytic activity of Ni10Mo10Al catalyst at the reaction conditions of 100 °C, 1 MPa H2, n(H2)/n(MA) = 4 and WHSV =2 h–1; Figure S6. TEM images of the used Ni10Mo10Al catalyst; Table S1. Properties of NiAl2O4, Ni10Mo10Al and Ni10Mo10/γ–Al2O3 catalysts; Table S2. ICP–OES results for the fresh and used Ni10Mo10Al catalyst.

Author Contributions

Conceptualization, Z.L. and E.W.; formal analysis, T.S.; formal analysis, T.S.; data curation, T.S.; Original draft of the paper, T.S.; Review, G.W. and X.G.; writing—review and editing, T.S. and Z.L. Supervision and funding: Z.L. and C.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Fund for Distinguished Young Scholars (Grant number: 22025803), the National Natural Science Foundation of China (Grant number: 22178338), the Innovation Academy for Green Manufacture, Chinese Academy of Sciences (Grant number: IAGM-2019-A14) and the Key R&D Plans of Hebei Province (Grant number: 20374002D).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chen, Z.; Wu, D. Novel Route for the Synthesis of Methyl Propionate from 3-Pentanone with Dimethyl Carbonate over Solid Bases. Ind. Eng. Chem. Res. 2011, 50, 12343–12348. [Google Scholar] [CrossRef]

- Ai, M. Formation of methyl methacrylate from methyl propionate and methanol. Catal. Today 2006, 111, 398–402. [Google Scholar] [CrossRef]

- Dudu, W.; Zhi, C.; Shangde, L.; Zhenbin, J. Synthesis of Methyl Propionate from Dimethyl Carbonate and 3-Pentanone over Solid Base Catalyst. Petrochem. Technol. 2009, 38, 423–427. [Google Scholar]

- Breysse, E.; Fajula, F.; Finiels, A.; Frémy, G.; Lamotte, J.; Maugé, F.; Lavalley, J.-C.; Moreau, C. Kinetic and FT-IR study for the mechanism of addition of hydrogen sulfide to methyl acrylate over solid basic catalysts. J. Mol. Catal. A Chem. 2003, 198, 185–194. [Google Scholar] [CrossRef]

- Matsushita, T.; Shiraishi, Y.; Horiuchi, S.; Toshima, N. Synthesis and Catalysis of Polymer-Protected Pd/Ag/Rh Trimetallic Nanoparticles with a Core–Shell Structure. Bull. Chem. Soc. Jpn. 2007, 80, 1217–1225. [Google Scholar] [CrossRef]

- Girvin, Z.C.; Lampkin, P.P.; Liu, X.; Gellman, S.H. Catalytic Intramolecular Conjugate Additions of Aldehyde-Derived Enamines to α,β-Unsaturated Esters. Org. Lett. 2020, 22, 4568–4573. [Google Scholar] [CrossRef]

- Trzeciak, A.M.; Ziółkowski, J.J. New insight into role of ortho-metallation in rhodium triphenylphosphite complexes. Hydrogen mobility in hydrogenation and isomerization of unsaturated substrates. J. Organomet. Chem. 2000, 597, 69–76. [Google Scholar] [CrossRef]

- Shiraishi, Y.; Nakayama, M.; Takagi, E.; Tominaga, T.; Toshima, N. Effect of quantity of polymer on catalysis and superstructure size of polymer-protected Pt nanoclusters. Inorg. Chim. Acta 2000, 300, 964–969. [Google Scholar] [CrossRef]

- Chen, X.; Zuo, H.; Qing, L.U.; Liu, A. Studies on Catalyzed Hydrogenation of Olef ins by Palladium (II) Complexes with Polyfunctional(P,N,O) Phosphine Ligands. J. Mol. Catal. 2001, 15, 451–453. [Google Scholar]

- Chunfu, C.; Juntan, S.; Hong, L.; Binglin, H. Study on The Hydrogenation of Methyl Acrylate Catalyzed by Pd/dvb Crosslinked Poly-(N-Vinyl Pyrrolidone). Chin. J. Poly. Sci. 1990, 8, 295–301. [Google Scholar]

- Kuhaudomlap, S.; Praserthdam, P.; Shirai, M.; Panpranot, J. Highly active and stable Ni-incorporated spherical silica catalysts for CO2 methanation. Catal. Today 2020, 358, 30–36. [Google Scholar] [CrossRef]

- Zhang, H.; Dong, J.; Qiao, X.; Qin, J.; Sun, H.; Wang, A.; Niu, L.; Bai, G. In-Situ generated highly dispersed nickel nanoclusters confined in MgAl mixed metal oxide platelets for benzoic acid hydrogenation. J. Catal. 2019, 372, 258–265. [Google Scholar] [CrossRef]

- Prins, R. Catalytic Hydrodenitrogenation. Adv. Catal. 2000, 46, 399–464. [Google Scholar]

- Furimsky, E.; Massoth, F.E. Hydrodenitrogenation of Petroleum. Catal. Rev. 2005, 47, 297–489. [Google Scholar] [CrossRef]

- Zhang, R.; Wei, A.; Zhu, M.; Wu, X.; Wang, H.; Zhu, X.; Ge, Q. Tuning reverse water gas shift and methanation reactions during CO2 reduction on Ni catalysts via surface modification by MoOx. J. CO2 Util. 2021, 52, 101678. [Google Scholar] [CrossRef]

- Kordouli, E.; Pawelec, B.; Bourikas, K.; Kordulis, C.; Fierro, J.L.G.; Lycourghiotis, A. Mo promoted Ni–Al2O3 co-precipitated catalysts for green diesel production. Appl. Catal. B 2018, 229, 139–154. [Google Scholar] [CrossRef]

- Lv, L.; Bo, Y.; Ji, D.; Han, W.; Liu, H.; Gao, X.; Xu, C.; Liu, H. Layered Double Hydroxide Method for Preparing Ni–Mo/γ–Al2O Ultradeep Hydrodesulfurization Catalysts. Ind. Eng. Chem. Res. 2018, 57, 13889–13894. [Google Scholar] [CrossRef]

- Sun, T.; Wu, Z.; Wang, G.; Li, Z.; Li, C.; Wang, E. Efficient Promotional Effects of Mo on the Catalytic Hydrogenation of Methyl Acrylate over Ni-Based Catalysts under Mild Conditions. Ind. Eng. Chem. Res. 2021, 61, 152–163. [Google Scholar] [CrossRef]

- Wei, Q.; Gao, X.; Liu, G.; Yang, R.; Zhang, H.; Yang, G.; Yoneyama, Y.; Tsubaki, N. Facile one-step synthesis of mesoporous Ni–Mg–Al catalyst for syngas production using coupled methane reforming process. Fuel 2018, 211, 1–10. [Google Scholar] [CrossRef]

- Gao, L.; Luo, Y.; Wan, P.; Liu, Z. Theoretical and experimental investigations on mechanical properties of (Fe,Ni)Sn2 intermetallic compounds formed in SnAgCu/Fe-Ni solder joints. Mater. Charact. 2021, 178, 111195. [Google Scholar] [CrossRef]

- Miao, R.; Yu, X.; Zeng, W. Novel NiO flower-like microspheres with abundant nanoparticles adhering to the petals: Hydrothermal synthesis and their gas sensing properties. Mater. Lett. 2016, 173, 107–110. [Google Scholar] [CrossRef]

- Miao, R.; Zeng, W.; Gao, Q. SDS-assisted hydrothermal synthesis of NiO flake-flower architectures with enhanced gas-sensing properties. Appl. Surf. Sci. 2016, 384, 304–310. [Google Scholar] [CrossRef]

- Wang, J.; Zeng, W.; Wang, Z. Assembly of 2D nanosheets into 3D flower-like NiO: Synthesis and the influence of petal thickness on gas-sensing properties. Ceram. Int. 2016, 42, 4567–4573. [Google Scholar] [CrossRef]

- Li, J.; Li, J.; Yu, T.; Ding, F.; Xu, G.; Li, Z.; Zhao, Y.; Kang, F. Stabilizing the structure and suppressing the voltage decay of Li[Li0.2Mn0.54Co0.13Ni0.13]O2 cathode materials for Li-ion batteries via multifunctional Pr oxide surface modification. Ceram. Int. 2016, 42, 18620–18630. [Google Scholar] [CrossRef]

- Shen, Z.; Ke, M.; Yu, P.; Liu, S.; Song, Z.; Jiang, Q. Catalytic activities of Mo-modified Ni/Al2O3 catalysts for thioetherification of mercaptans and di-olefins in fluid catalytic cracking naphtha. Transit. Met. Chem. 2012, 37, 587–593. [Google Scholar] [CrossRef]

- Yang, F.; Libretto, N.J.; Komarneni, M.R.; Zhou, W.; Miller, J.T.; Zhu, X.; Resasco, D.E. Enhancement of m-Cresol Hydrodeoxygenation Selectivity on Ni Catalysts by Surface Decoration of MoOx Species. ACS Catal. 2019, 9, 7791–7800. [Google Scholar] [CrossRef]

- Ortega-Domínguez, R.A.; Vargas-Villagrán, H.; Peñaloza-Orta, C.; Saavedra-Rubio, K.; Bokhimi, X.; Klimova, T.E. A facile method to increase metal dispersion and hydrogenation activity of Ni/SBA-15 catalysts. Fuel 2017, 198, 110–122. [Google Scholar] [CrossRef]

- Yang, R.; Li, X.; Wu, J.; Zhang, X.; Zhang, Z.; Cheng, Y.; Guo, J. Hydrotreating of crude 2-ethylhexanol over Ni/Al2O3 catalysts: Surface Ni species-catalytic activity correlation. Appl. Catal. A Gen. 2009, 368, 105–112. [Google Scholar] [CrossRef]

- He, D.; Zhang, Y.; Wang, Z.; Mei, Y.; Jiang, Y. Bi-reforming of Methane with Carbon Dioxide and Steam on Nickel-Supported Binary Mg–Al Metal Oxide Catalysts. Energ Fuels 2020, 34, 4822–4827. [Google Scholar] [CrossRef]

- Fan, X.; Liu, D.; Zhao, Z.; Li, J.; Liu, J. Influence of Ni/Mo ratio on the structure-performance of ordered mesoporous Ni–Mo–O catalysts for oxidative dehydrogenation of propane. Catal. Today 2020, 339, 67–78. [Google Scholar] [CrossRef]

- Liu, Z.; Han, W.; Hu, D.; Sun, S.; Hu, A.; Wang, Z.; Jia, Y.; Zhao, X.; Yang, Q. Effects of Ni–Al2O3 interaction on NiMo/Al2O3 hydrodesulfurization catalysts. J. Catal. 2020, 387, 62–72. [Google Scholar] [CrossRef]

- Cheng, D.; Wang, Z.; Xia, Y.; Wang, Y.; Zhang, W.; Zhu, W. Catalytic amination of diethylene glycol with tertiarybutylamine over Ni–Al2O3 catalysts with different Ni/Al ratios. RSC Adv. 2016, 6, 102373–102380. [Google Scholar] [CrossRef]

- Kim, P.; Kim, Y.; Kim, H.; Song, I.K.; Yi, J. Synthesis and characterization of mesoporous alumina with nickel incorporated for use in the partial oxidation of methane into synthesis gas. Appl. Catal. A Gen. 2004, 272, 157–166. [Google Scholar] [CrossRef]

- Cárdenas-Lizana, F.; Gómez-Quero, S.; Baddeley, C.J.; Keane, M.A. Tunable gas phase hydrogenation of m-dinitrobenzene over alumina supported Au and Au–Ni. Appl. Catal. A Gen. 2010, 387, 155–165. [Google Scholar] [CrossRef]

- Sarbak, Z.; Jozwiak, W.K. Thermal characterisation of molybdenum and platinum-molybdenum catalysts. J. Therm. Anal. Calorim. 2007, 87, 229–232. [Google Scholar] [CrossRef]

- Kukushkin, R.G.; Bulavchenko, O.A.; Kaichev, V.V.; Yakovlev, V.A. Influence of Mo on catalytic activity of Ni-based catalysts in hydrodeoxygenation of esters. Appl. Catal. B 2015, 163, 531–538. [Google Scholar] [CrossRef]

- Fang, D.; He, F.; Xie, J.; Xue, L. Calibration of Binding Energy Positions with C1s for XPS Results. J. Wuhan Univ. Technol. 2020, 35, 711–718. [Google Scholar] [CrossRef]

- Ohana, T.; Nakamura, T.; Goto, A.; Tsugawa, K.; Tanaka, A.; Koga, Y. The characterization of nanocrystal graphite films deposited by ECR plasma sputtering. Diam. Relat. Mater. 2003, 12, 2011–2015. [Google Scholar] [CrossRef]

- Wang, X.; Ozkan, U.S. Effect of pre-treatment conditions on the performance of sulfided Ni–Mo/γ–Al2O3 catalysts for hydrogenation of linear aldehydes. J. Mol. Catal. A Chem. 2005, 232, 101–112. [Google Scholar] [CrossRef]

- Ameen, M.; Azizan, M.T.; Ramli, A.; Yusup, S.; Alnarabiji, M.S. Catalytic hydrodeoxygenation of rubber seed oil over sonochemically synthesized Ni–Mo/γ–Al2O3 catalyst for green diesel production. Ultrason. Sonochem. 2019, 51, 90–102. [Google Scholar] [CrossRef]

- Pillay, B.; Mathebula, M.R.; Friedrich, H.B. The oxidative dehydrogenation of n-hexane over Ni–Mo–O catalysts. Appl. Catal. A Gen. 2009, 361, 57–64. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).