Enhanced Adhesion Strength of Pt/γ-Al2O3 Catalysts on STS-444 Substrate via γ-Al2O3 Intermediate Layer Formation: Application for CO and C3H6 Oxidation

Abstract

:1. Introduction

2. Results and Discussion

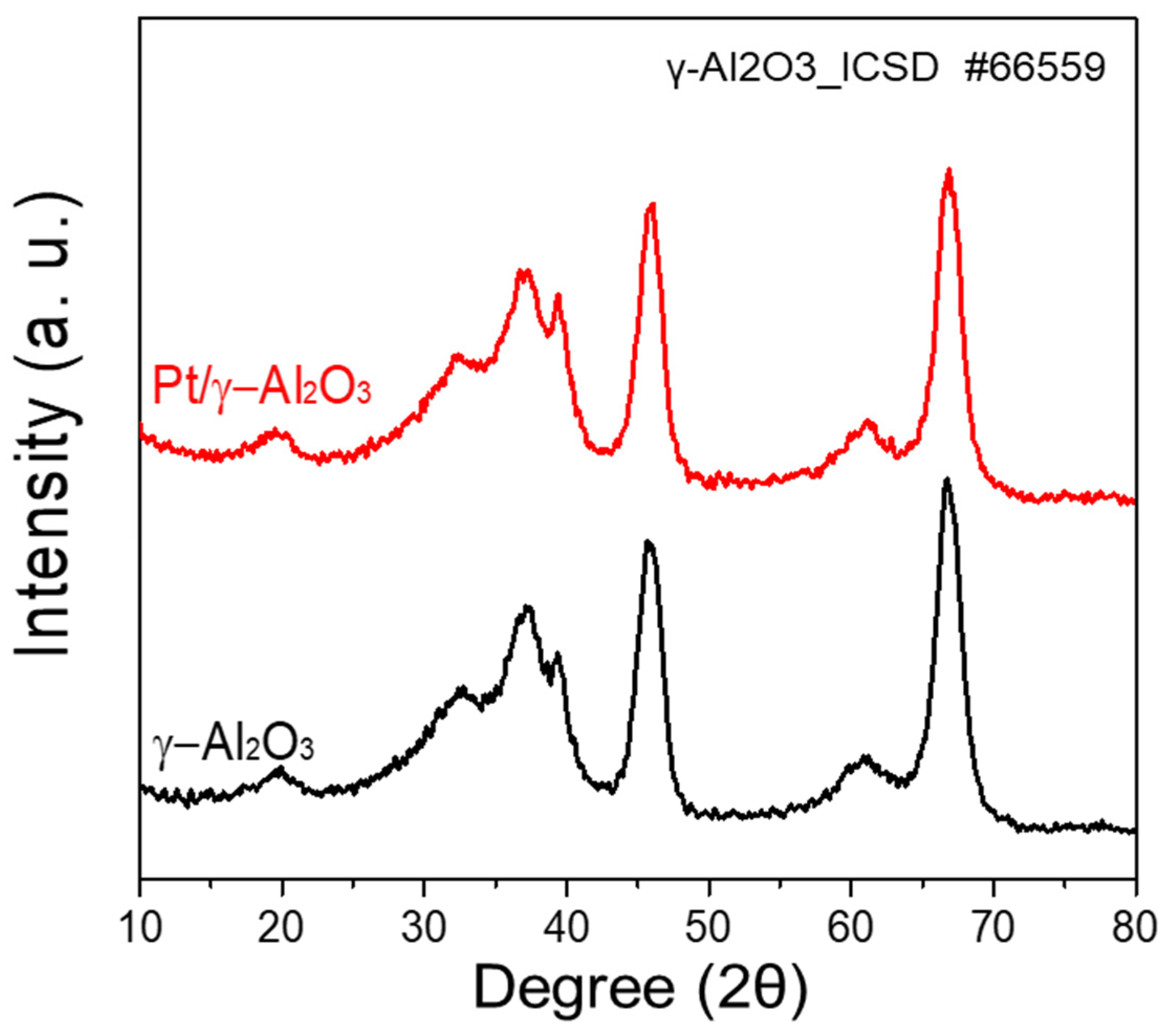

2.1. Characterization of γ-Al2O3 Intermediate Layer and Pt/γ-Al2O3 Catalyst

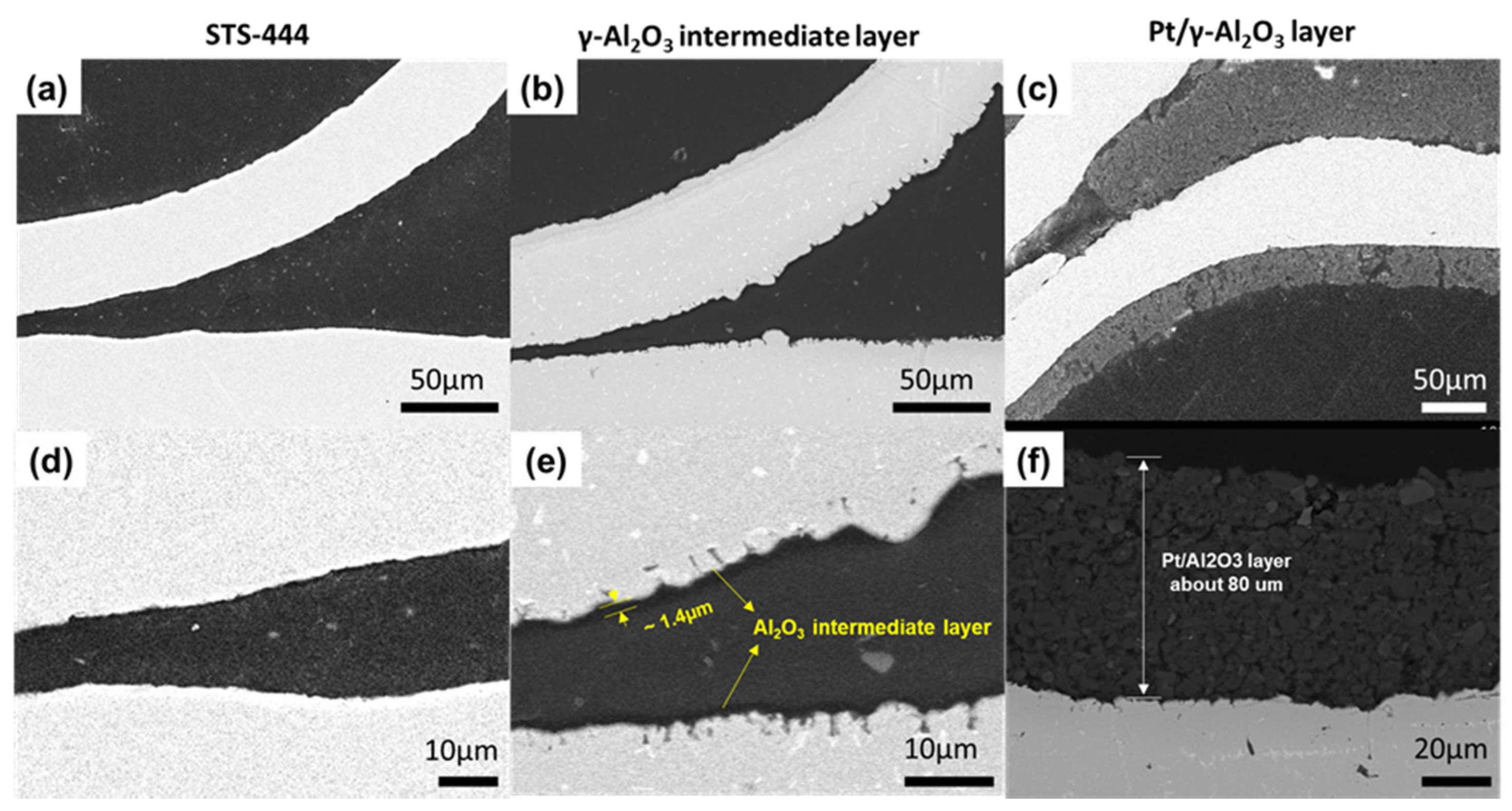

2.2. Morphology of γ-Al2O3 Intermediate Layer on the STS-444 Substrate

2.3. Adhesion Strength of Washcoated Pt/γ-Al2O3 Catalyst Layer

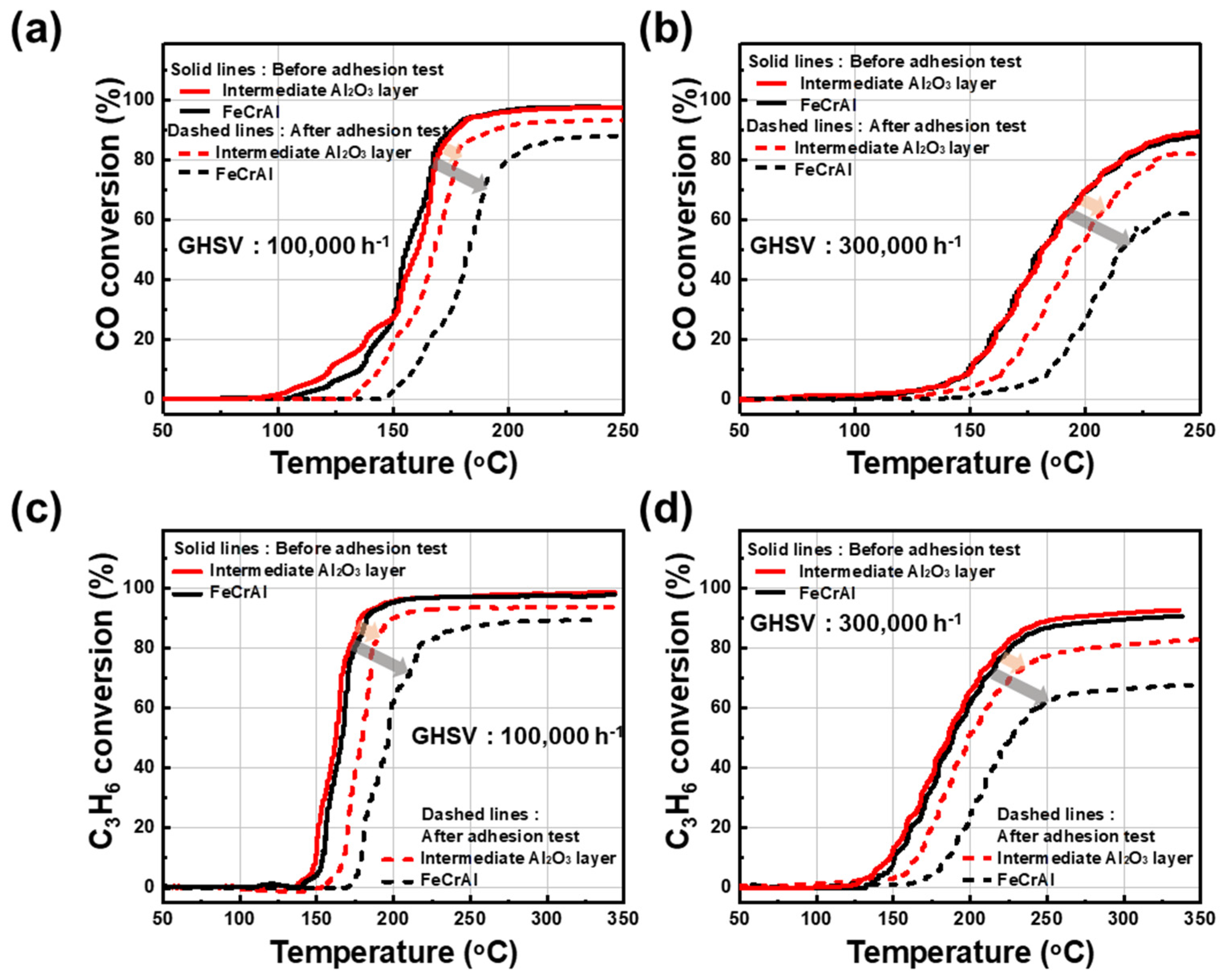

2.4. CO and C3H6 Oxidation over Pt/γ-Al2O3 Monolithic Catalysts with and without γ-Al2O3 Intermediate Layer

3. Materials and Methods

3.1. Formation of γ-Al2O3 Intermediate Layer on the STS-444 Substrate

3.2. Preparation of Pt-Based Monolithic Catalysts Coated on γ-Al2O3/STS-444 Substrate

3.3. Characterization of γ-Al2O3 Intermediate Layer and Pt/γ-Al2O3 Catalysts

3.4. Adhesive Strength Test of Washcoated Pt/γ-Al2O3 Catalysts

3.5. Simultaneous CO and C3H6 Oxidation Reactions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bowker, M. Automotive catalysis studied by surface science. Chem. Soc. Rev. 2008, 37, 2204–2211. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.-H.; Hwang, J.; Kim, G.; Choi, J.-J.; Ahn, C.-W.; Kim, J.-W.; Hahn, B.-D.; Yoon, W.-H.; Min, Y. Catalyst adhesion enhancement by porous TiO2 layer formed on anodized titanium honeycomb substrate. Ceram. Int. 2021, 47, 7241–7247. [Google Scholar] [CrossRef]

- Carberry, B.; Grasi, G.; Guerin, S.; Jayat, F.; Konieczny, R. Pre-Turbocharger Catalyst–Fast Catalyst Light-Off Evaluation; 2005-01-2142; SAE: Warrendale, PA, USA, 2005. [Google Scholar]

- Hwang, J.; Ha, H.-J.; Ryu, J.; Choi, J.-J.; Ahn, C.-W.; Kim, J.-W.; Hahn, B.-D.; Yoon, W.-H.; Lee, H.; Choi, J.-H. Enhancement of washcoat adhesion for SCR catalysts to convert nitrogen oxide using powder spray coating of TiO2 on metallic honeycomb substrate. Catal. Commun. 2017, 94, 1–4. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, L.; Liang, B.; Li, Y. Effect of acid treatment on the high-temperature surface oxidation behavior of FeCrAlloy foil used for methane combustion catalyst support. Ind. Eng. Chem. Res. 2009, 48, 5117–5122. [Google Scholar] [CrossRef]

- Tomašíc, V.; Jovíc, F. State-of-the-art in the monolithic catalysts/reactors. Appl. Catal. A 2006, 311, 112–121. [Google Scholar] [CrossRef]

- Johnson, B.R.; Canfield, N.L.; Tran, D.N.; Dagle, R.A.; Li, X.S.; Holladay, J.D.; Wang, Y. Engineered SMR catalysts based on hydrothermally stable, porous, ceramic supports for microchannel reactors. Catal. Today 2007, 120, 54–62. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, J.; Weng, D.; Wu, X. A method to form well-adhered γ-Al2O3 layers on FeCrAl metallic supports. Surf. Coat. Technol. 2003, 167, 97–105. [Google Scholar] [CrossRef]

- Ismail, N.H.; Salleh, W.N.W.; Sazali, N.; Ismail, A.F. Effect of intermediate layer on gas separation performance of disk supported carbon membrane. Sep. Sci. Technol. 2017, 52, 2137–2149. [Google Scholar] [CrossRef]

- Lee, P.-S.; Kim, D.; Nam, S.-E.; Bhave, R.R. Carbon molecular sieve membranes on porous composite tubular supports for high performance gas separations. Micropor. Mesopor. Mater. 2016, 224, 332–338. [Google Scholar] [CrossRef]

- Wey, M.-Y.; Tseng, H.-H.; Chiang, C.-K. Effect of MFI zeolite intermediate layers on gas separation performance of carbon molecular sieve (CMS) membranes. J. Membr. Sci. 2013, 446, 220–229. [Google Scholar] [CrossRef]

- Wang, C.; Ling, L.; Huang, Y.; Yao, Y.; Song, Q. Decoration of porous ceramic substrate with pencil for enhanced gas separation performance of carbon membrane. Carbon 2015, 84, 151–159. [Google Scholar] [CrossRef]

- Tseng, H.-H.; Wang, C.-T.; Zhuang, G.-L.; Uchytil, P.; Reznickova, J.; Setnickova, K. Enhanced H2/CH4 and H2/CO2 separation by carbon molecular sieve membrane coated on titania modified alumina support: Effects of TiO2 intermediate layer preparation variables on interfacial adhesion. J. Membr. Sci. 2016, 510, 391–404. [Google Scholar] [CrossRef]

- Wang, C.; Hu, X.; Yu, J.; Wei, L.; Huang, Y. Intermediate gel coating on macroporous Al2O3 substrate for fabrication of thin carbon membranes. Ceram. Int. 2014, 40, 10367–10373. [Google Scholar] [CrossRef]

- Choi, K.; Yang, W.; Baik, K.H.; Kim, Y.; Lee, S.; Lee, S.; Park, J.S. Growth kinetics and isothermal oxidation behavior of a Si pack cementation-coated Mo-Si-B alloy. Appl. Surf. Sci. 2019, 489, 668–676. [Google Scholar] [CrossRef]

- Yang, W.C.; Lee, S.; Chung, C.-H.; Sakidja, R.; Park, J.S. Ablation stability of in situ Al2O3 layer in aluminized AISI 4130 steels under high-temperature plasma flame environments. J. Mater. Eng. Perform. 2021, 30, 7488–7493. [Google Scholar] [CrossRef]

- Ladd, D.M.; Volosin, A.; Seo, D.-K. Preparation of highly porous γ-alumina via combustion of bio renewableoil. J. Mater. Chem. 2010, 20, 5923–5929. [Google Scholar] [CrossRef]

- Samain, L.; Jaworski, A.; Edén, M.; Ladd, D.M.; Seo, D.-K.; Javier Garcia-Garcia, F.J.; Häussermann, U. Structural analysis of highly porous γ-Al2O3. J. Solid State Chem. 2014, 217, 1–8. [Google Scholar] [CrossRef]

- Bai, Q.; Li, D.; Hailian, L.H.; Sui, X.N.; Liu, M. Solvent-free selective hydrogenation of o-chloronitrobenzene to o-chloroaniline over alumina supported Pt nanoparticles. Prog. Nat. Sci. 2015, 25, 179–184. [Google Scholar] [CrossRef] [Green Version]

- Yang, X.-L.; Zhang, W.-Q.; Xia, C.-G.; Xiong, X.-M.; Mu, X.-Y.; Hu, B. Low temperature ruthenium catalyst for ammonia synthesis supported on BaCeO3 nanocrystals. Catal. Commun. 2010, 11, 867–870. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ryu, S.-H.; Hwang, C.H.; Jeong, H.; Kim, G.; Ahn, S.I.; Park, J.S.; Choi, J.-H. Enhanced Adhesion Strength of Pt/γ-Al2O3 Catalysts on STS-444 Substrate via γ-Al2O3 Intermediate Layer Formation: Application for CO and C3H6 Oxidation. Catalysts 2022, 12, 38. https://doi.org/10.3390/catal12010038

Ryu S-H, Hwang CH, Jeong H, Kim G, Ahn SI, Park JS, Choi J-H. Enhanced Adhesion Strength of Pt/γ-Al2O3 Catalysts on STS-444 Substrate via γ-Al2O3 Intermediate Layer Formation: Application for CO and C3H6 Oxidation. Catalysts. 2022; 12(1):38. https://doi.org/10.3390/catal12010038

Chicago/Turabian StyleRyu, Seung-Hee, Cheol Hong Hwang, Hojin Jeong, Giyeong Kim, Sung Il Ahn, Joon Sik Park, and Joon-Hwan Choi. 2022. "Enhanced Adhesion Strength of Pt/γ-Al2O3 Catalysts on STS-444 Substrate via γ-Al2O3 Intermediate Layer Formation: Application for CO and C3H6 Oxidation" Catalysts 12, no. 1: 38. https://doi.org/10.3390/catal12010038

APA StyleRyu, S.-H., Hwang, C. H., Jeong, H., Kim, G., Ahn, S. I., Park, J. S., & Choi, J.-H. (2022). Enhanced Adhesion Strength of Pt/γ-Al2O3 Catalysts on STS-444 Substrate via γ-Al2O3 Intermediate Layer Formation: Application for CO and C3H6 Oxidation. Catalysts, 12(1), 38. https://doi.org/10.3390/catal12010038