Plasma-Catalytic Fischer–Tropsch Synthesis at Very High Pressure

Abstract

:1. Introduction

2. Results

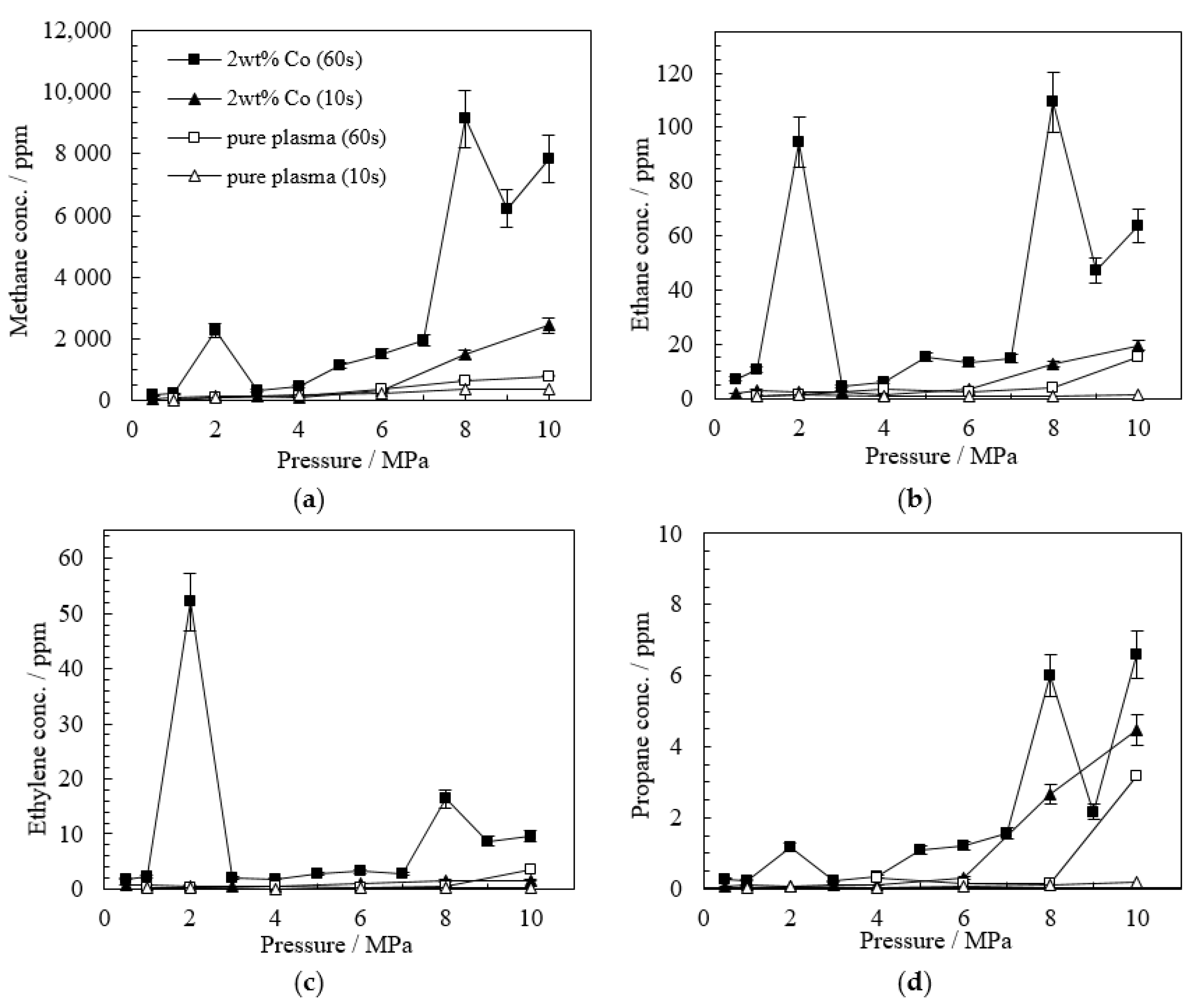

2.1. The Influence of Pressure on Plasma-Catalytic FTS

2.1.1. Pure Plasma

2.1.2. Plasma-Catalysis

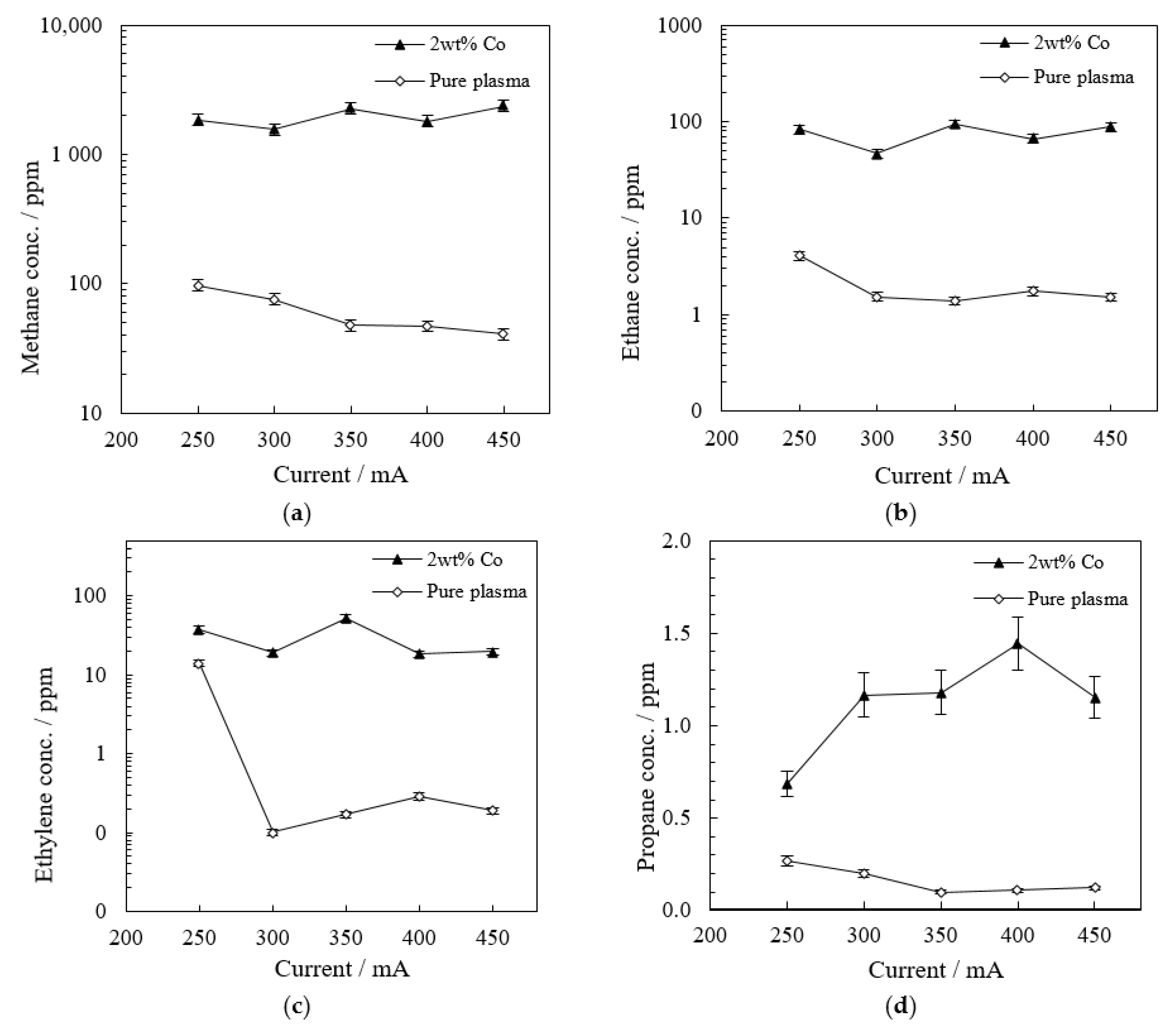

2.2. The Influence of Operating Current on Plasma-Catalytic FTS

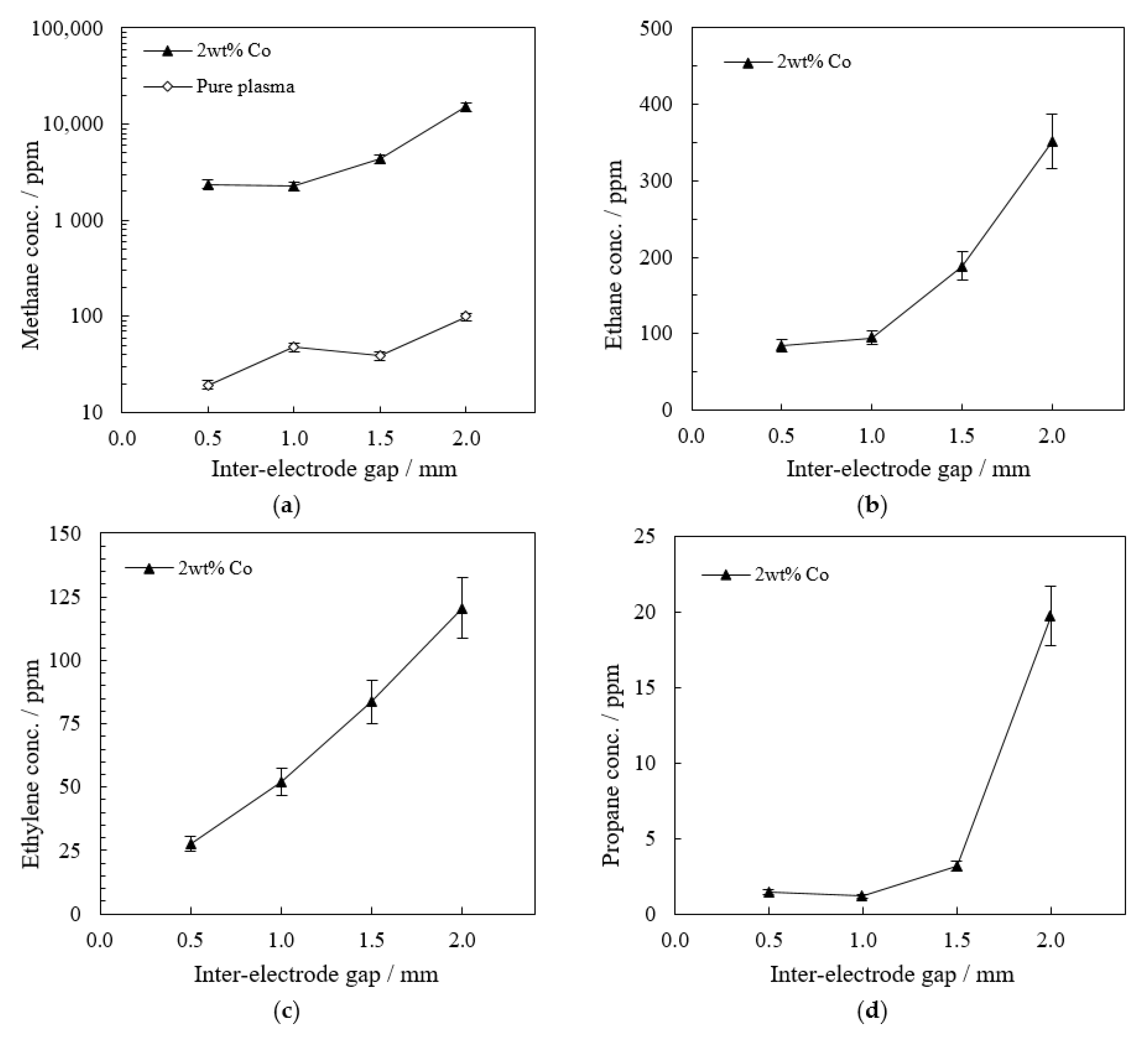

2.3. The Influence of the Inter-Electrode Gap on Plasma-Catalytic FTS

2.4. Catalyst Characterisation

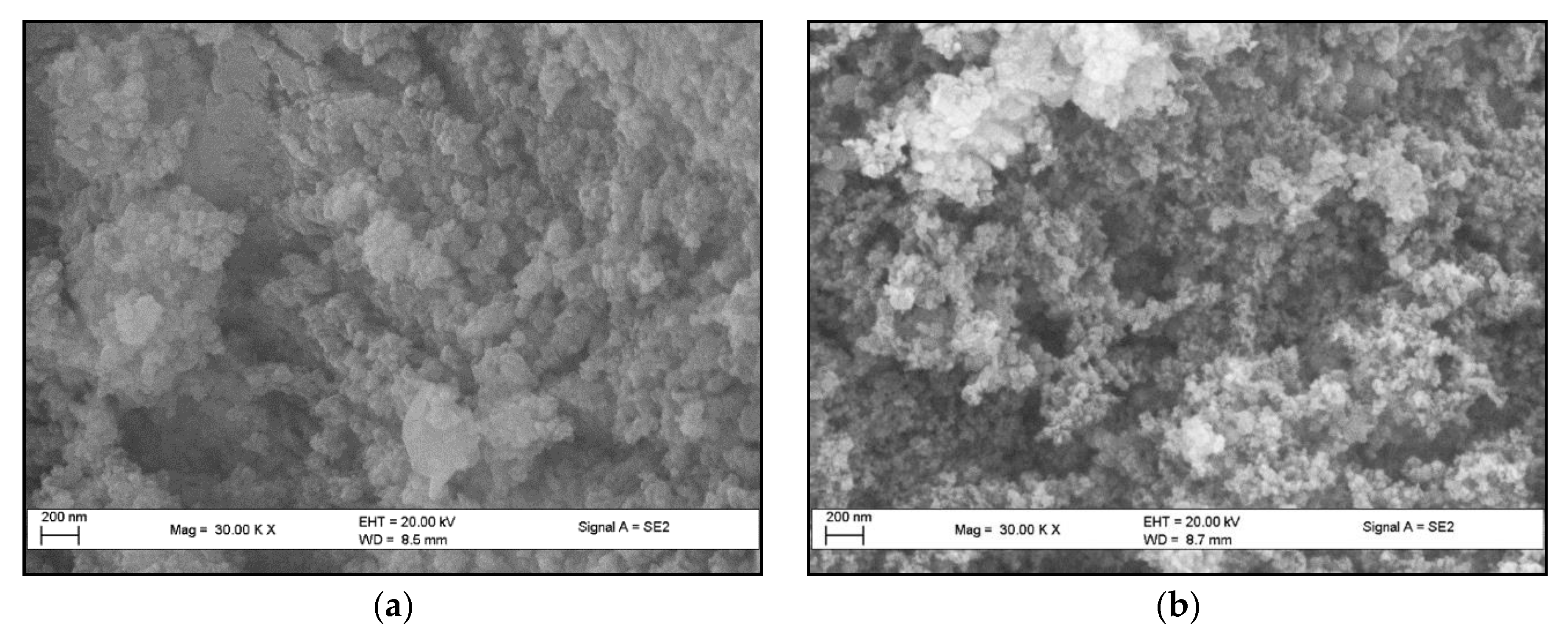

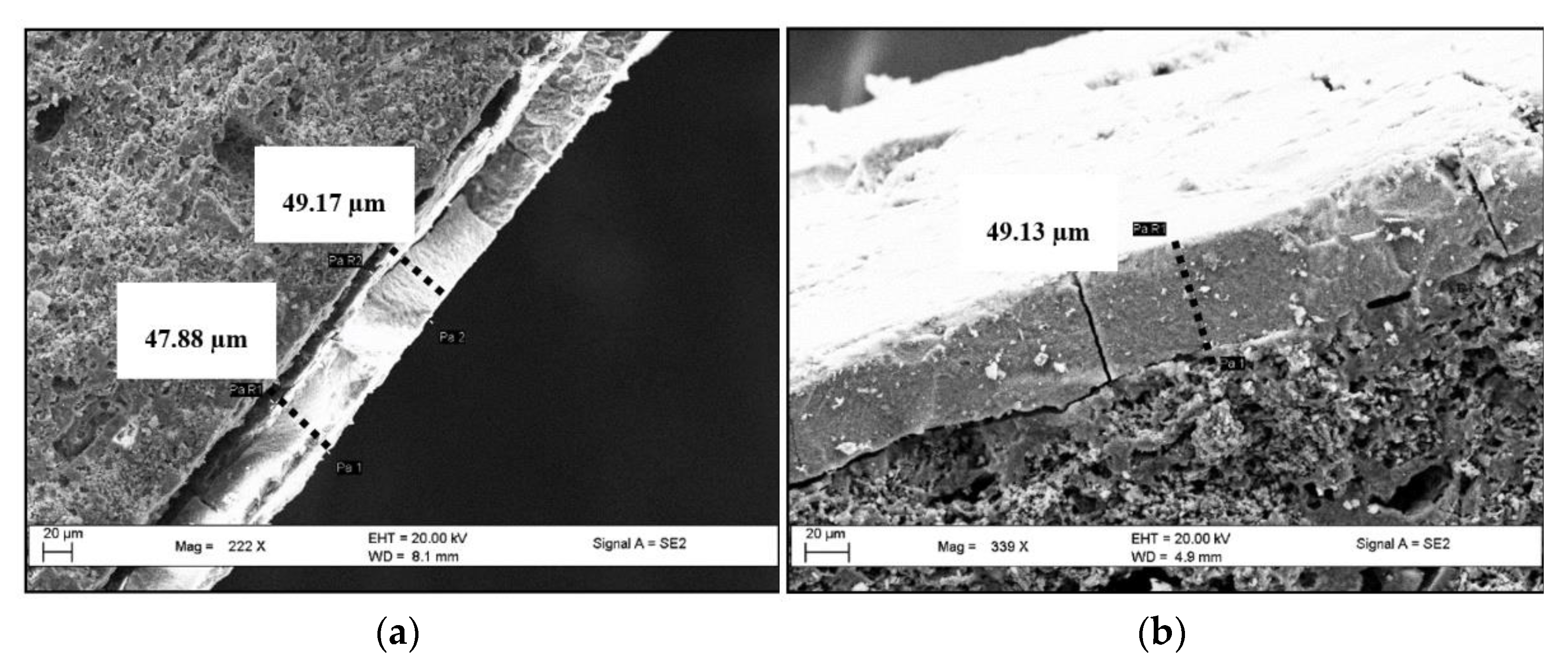

2.4.1. Scanning Electron Microscopy (SEM)

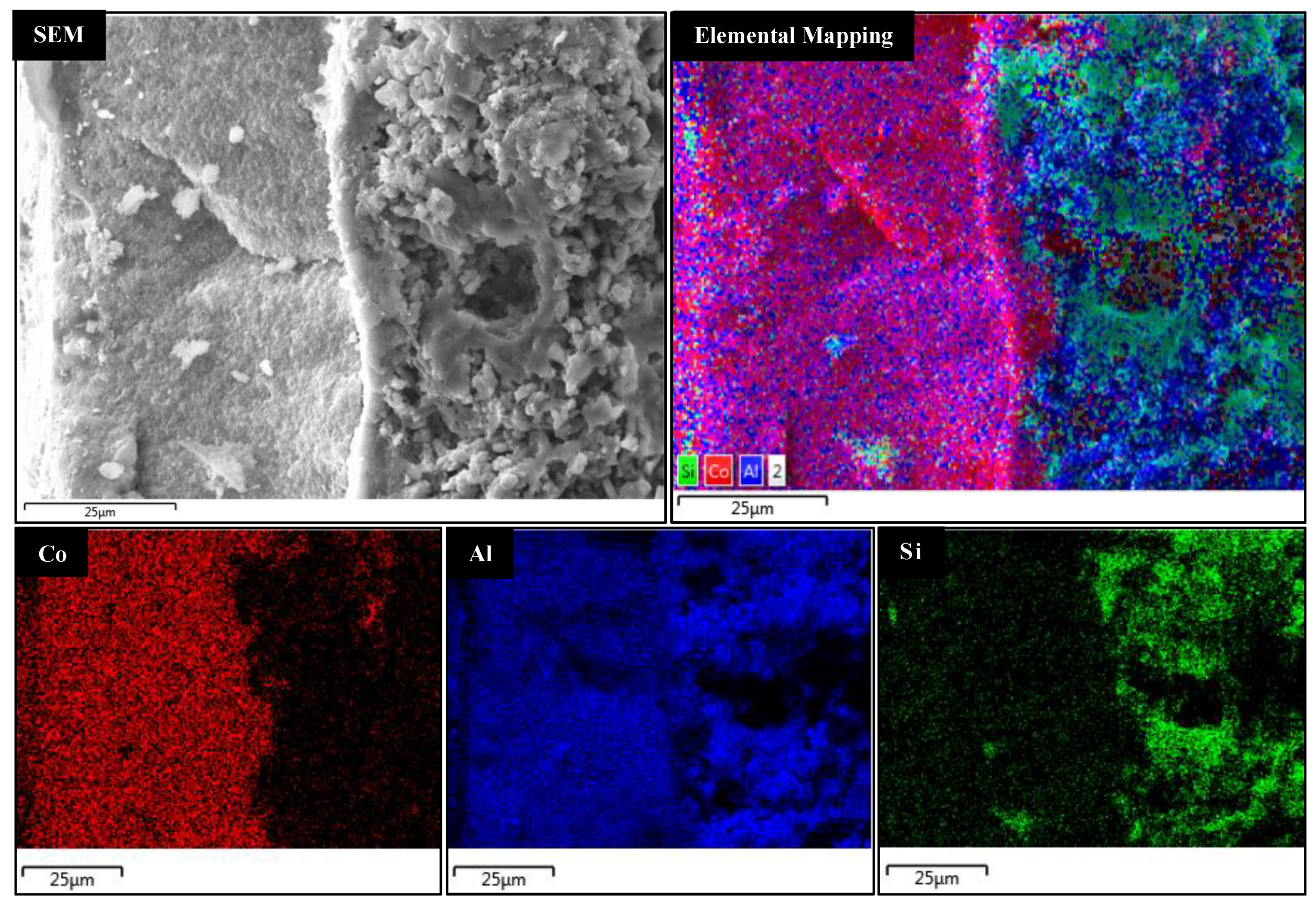

2.4.2. Energy-Dispersive X-ray Spectroscopy (EDX)

2.5. Plasma–Catalyst Interactions

3. Discussion

4. Materials and Methods

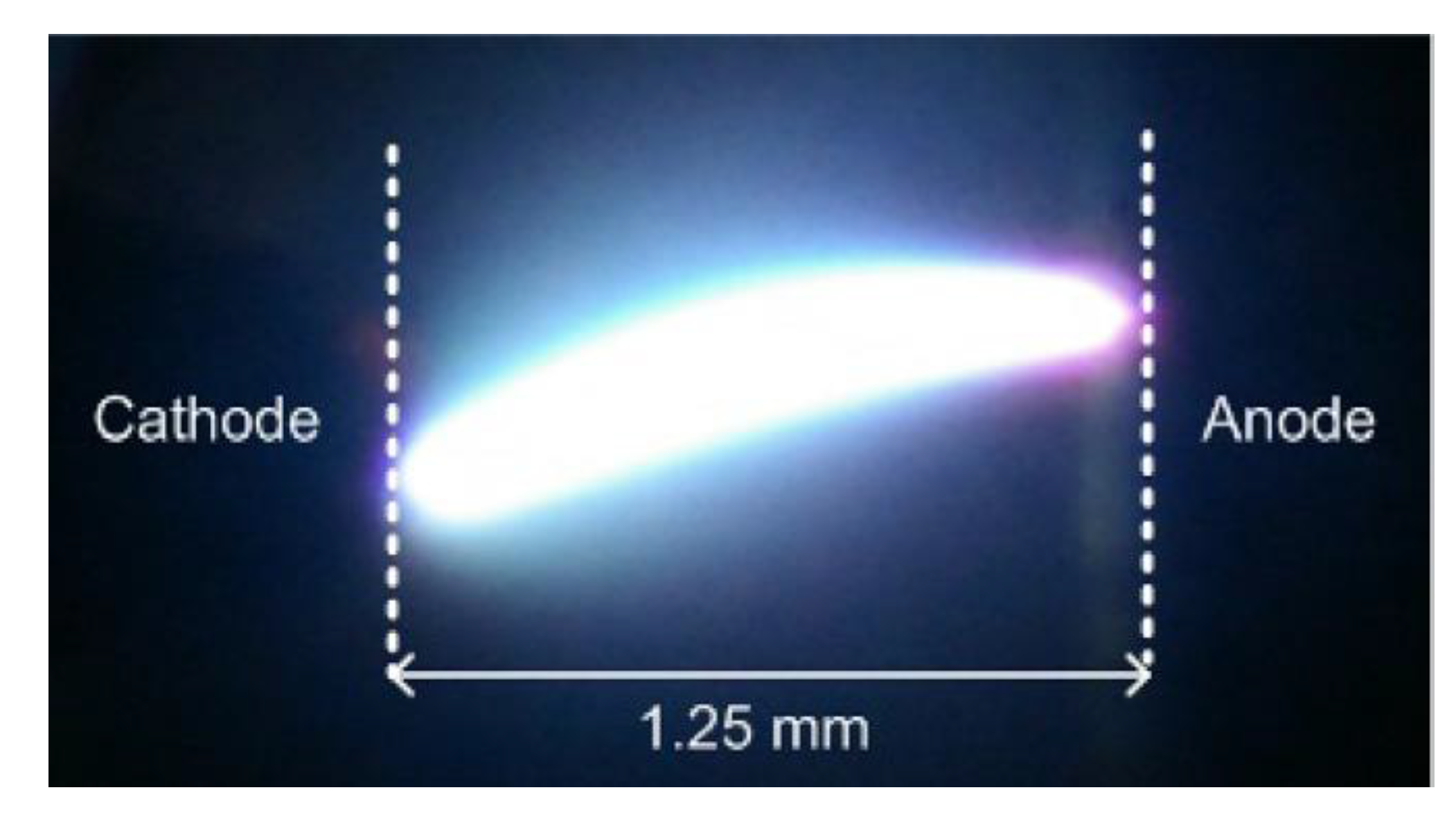

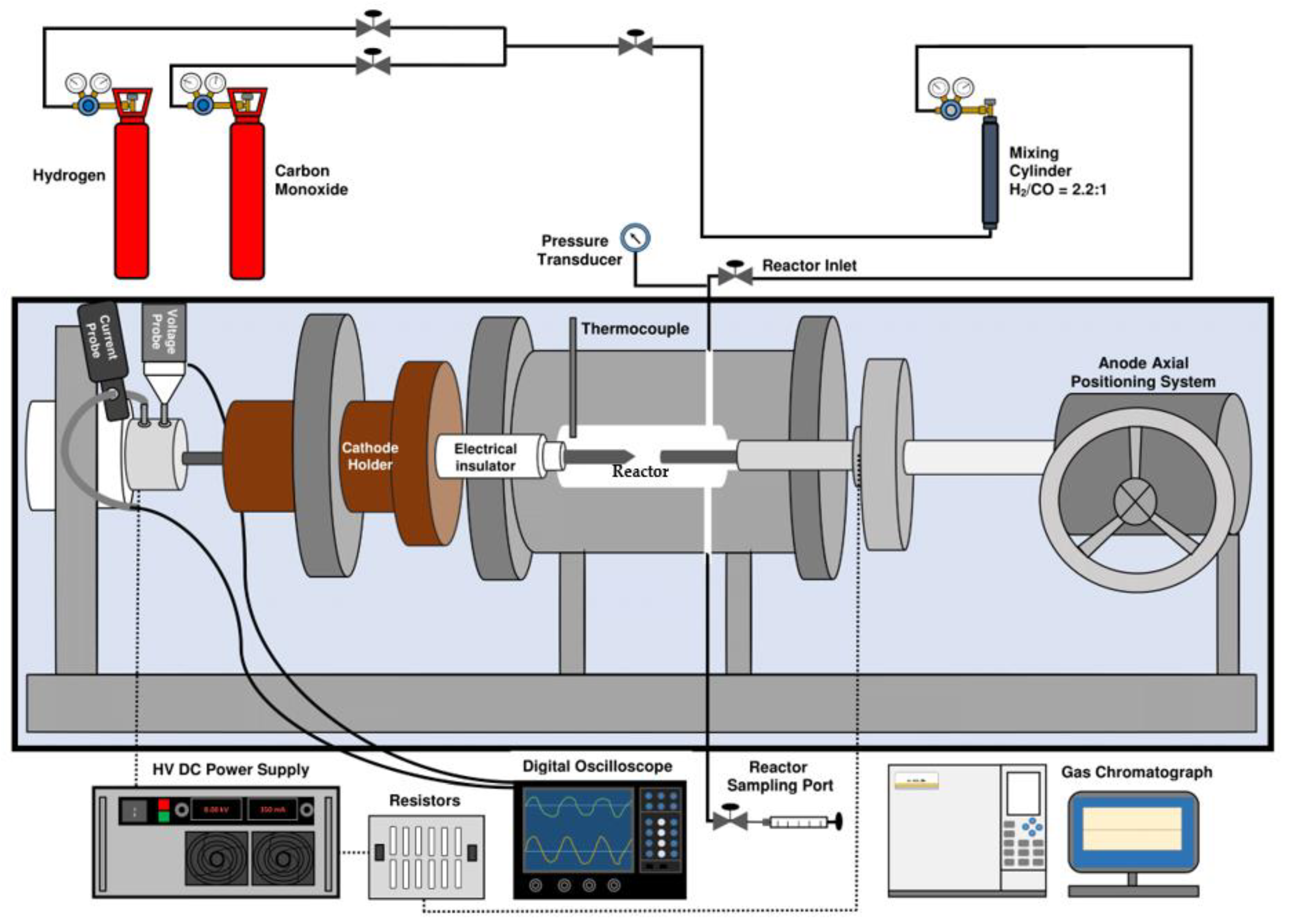

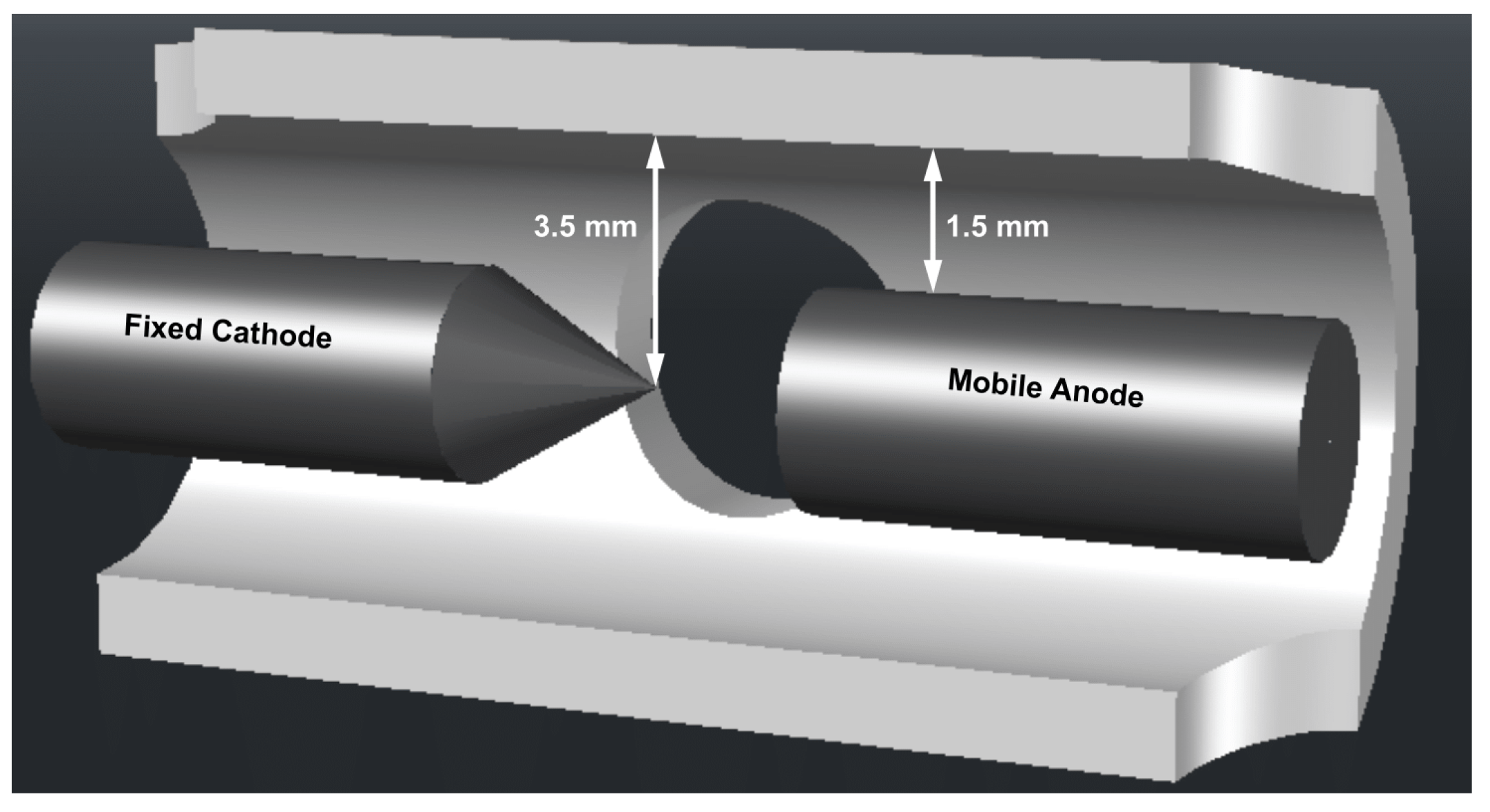

4.1. Plasma Reactor Setup

4.2. Reactor Experimental Procedure.

4.3. Catalyst Configuration and Preparation

4.4. Catalyst Characterisation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Takeshita, T.; Yamaji, K. Important roles of Fischer–Tropsch synfuels in the global energy future. Energy Policy 2008, 36, 2773–2784. [Google Scholar] [CrossRef]

- Morales, F.; Weckhuysen, B.M. Promotion Effects in Co-Based Fischer—Tropsch Catalysis. Catalysis 2006, 19, 1–40. [Google Scholar] [CrossRef] [Green Version]

- Aranda, G.; van der Drift, A.; Smit, R. The Economy of Large Scale Biomass to Substitute Natural Gas (bioSNG) Plants; Report ECN-E--14-008; ECN: Petten, The Netherlands, 2014. [Google Scholar]

- Lobo, P.; Hagen, D.E.; Whitefield, P.D. Comparison of PM Emissions from a Commercial Jet Engine Burning Conventional, Biomass, and Fischer–Tropsch Fuels. Environ. Sci. Technol. 2011, 45, 10744–10749. [Google Scholar] [CrossRef]

- Schihl, P.; Hoogterp-Decker, L.; Gingrich, E. The Ignition Behavior of a Coal to Liquid Fischer-Tropsch Jet Fuel in a Military Relevant Single Cylinder Diesel Engine. SAE Int. J. Fuels Lubr. 2012, 5, 785–802. [Google Scholar] [CrossRef]

- Wang, H.; Oehlschlaeger, M.A. Autoignition studies of conventional and Fischer–Tropsch jet fuels. Fuel 2012, 98, 249–258. [Google Scholar] [CrossRef]

- Beyersdorf, A.; Timko, M.; Ziemba, L.; Bulzan, D.; Corporan, E.; Herndon, S.; Howard, R.; Miake-Lye, R.; Thornhill, K.; Winstead, E. Reductions in aircraft particulate emissions due to the use of Fischer–Tropsch fuels. Atmos. Chem. Phys. 2014, 14, 11–23. [Google Scholar] [CrossRef] [Green Version]

- Best, L.M.; Ana, B.; Bradford, R.L.; Hepp, A.F. Characterization of Catalyst Materials for Production of Aerospace Fuels; NASA/TM—2012-217403; National Aeronautics and Space Administration: Washington, DC, USA, 2012. [Google Scholar]

- Oukaci, R.; Singleton, A.H.; Goodwin, J.G. Comparison of patented Co F–T catalysts using fixed-bed and slurry bubble column reactors. Appl. Catal. A Gen. 1999, 186, 129–144. [Google Scholar] [CrossRef]

- Rytter, E.; Holmen, A. Deactivation and Regeneration of Commercial Type Fischer-Tropsch Co-Catalysts—A Mini-Review. Catalysts 2015, 5, 478–499. [Google Scholar] [CrossRef] [Green Version]

- Dry, M.E. The Fischer–Tropsch process: 1950–2000. Catal. Today 2002, 71, 227–241. [Google Scholar] [CrossRef]

- Dry, M.E. Practical and theoretical aspects of the catalytic Fischer-Tropsch process. Appl. Catal. A Gen. 1996, 138, 319–344. [Google Scholar] [CrossRef]

- Dry, M.E. High quality diesel via the Fischer-Tropsch process—A review. J. Chem. Technol. Biotechnol. 2002, 77, 43–50. [Google Scholar] [CrossRef]

- Al-Harrasi, W.S.; Zhang, K.; Akay, G. Process intensification in gas-to-liquid reactions: Plasma promoted Fischer-Tropsch synthesis for hydrocarbons at low temperatures and ambient pressure. Green Process. Synth. 2013, 2, 479–490. [Google Scholar] [CrossRef]

- Rohani, V.; Iwarere, S.; Fabry, F.; Mourard, D.; Izquierdo, E.; Ramjugernath, D.; Fulcheri, L. Experimental Study of Hydrocarbons Synthesis from Syngas by a Tip–Tip Electrical Discharge at Very High Pressure. Plasma Chem. Plasma Process. 2011, 31, 663–679. [Google Scholar] [CrossRef]

- Iwarere, S.; Rohani, V.; Ramjugernath, D.; Fabry, F.; Fulcheri, L. Hydrocarbons synthesis from syngas by very high pressure plasma. Chem. Eng. J. 2014, 241, 1–8. [Google Scholar] [CrossRef]

- Chen, H.L.; Lee, H.M.; Chen, S.H.; Chang, M.B.; Yu, S.J.; Li, S.N. Removal of Volatile Organic Compounds by Single-Stage and Two-Stage Plasma Catalysis Systems: A Review of the Performance Enhancement Mechanisms, Current Status, and Suitable Applications. Environ. Sci. Technol. 2009, 43, 2216–2227. [Google Scholar] [CrossRef]

- Roland, U.; Holzer, F.; Kopinke, F.-D. Improved oxidation of air pollutants in a non-thermal plasma. Catal. Today 2002, 73, 315–323. [Google Scholar] [CrossRef]

- Morent, R.; Dewulf, J.; Steenhaut, N.; Leys, C.; Van Langenhove, H. Hybrid Plasma-Catalyst System for the Removal of Trichloroethylene in Air. J. Adv. Oxid. Technol. 2006, 9, 53–58. [Google Scholar] [CrossRef]

- Nikoo, M.K.; Sharifi, M.A.; Amin, N.S. Carbon dioxide reforming of methane by catalytic-plasma reactor over Cu/Zn/γ-Al2O3. J. Teknol. Sci. Eng. 2011, 56, 75–86. [Google Scholar]

- Amouroux, J.; Cavadias, S.; Doubla, A. Carbon Dioxide reduction by non-equilibrium electrocatalysis plasma reactor. IOP Conf. Ser. Mater. Sci. Eng. 2011, 19, 012005. [Google Scholar] [CrossRef] [Green Version]

- Eliasson, B.; Kogelschatz, U.; Xue, B.; Zhou, L.-M. Hydrogenation of Carbon Dioxide to Methanol with a Discharge-Activated Catalyst. Ind. Eng. Chem. Res. 1998, 37, 3350–3357. [Google Scholar] [CrossRef]

- Li, M.-W.; Tian, Y.-L.; Xu, G.-H. Characteristics of Carbon Dioxide Reforming of Methane via Alternating Current (AC) Corona Plasma Reactions. Energy Fuels 2007, 21, 2335–2339. [Google Scholar] [CrossRef]

- Wallis, A.E.; Whitehead, J.; Zhang, K. The removal of dichloromethane from atmospheric pressure air streams using plasma-assisted catalysis. Appl. Catal. B Environ. 2007, 72, 282–288. [Google Scholar] [CrossRef]

- Nozaki, T.; Muto, N.; Kado, S.; Okazaki, K. Dissociation of vibrationally excited methane on Ni catalyst: Part 1. Application to methane steam reforming. Catal. Today 2004, 89, 57–65. [Google Scholar] [CrossRef]

- Nozaki, T.; Muto, N.; Kadio, S.; Okazaki, K. Dissociation of vibrationally excited methane on Ni catalyst: Part 2. Process diagnostics by emission spectroscopy. Catal. Today 2004, 89, 67–74. [Google Scholar] [CrossRef]

- Pietruszka, B.; Anklam, K.; Heintze, M. Plasma-assisted partial oxidation of methane to synthesis gas in a dielectric barrier discharge. Appl. Catal. A Gen. 2004, 261, 19–24. [Google Scholar] [CrossRef]

- Liu, C.-J.; Vissokov, G.P.; Jang, B.W.-L. Catalyst preparation using plasma technologies. Catal. Today 2002, 72, 173–184. [Google Scholar] [CrossRef]

- Guo, Y.F.; Ye, D.Q.; Chen, K.F.; He, J.C.; Chen, W.L. Toluene decomposition using a wire-plate dielectric barrier discharge reactor with manganese oxide catalyst in situ. J. Mol. Catal. A Chem. 2006, 245, 93–100. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Ma, P.S.; Zhu, X.; Liu, C.J.; Shen, Y. A novel plasma-treated Pt/NaZSM-5 catalyst for NO reduction by methane. Catal. Commun. 2004, 5, 35–39. [Google Scholar] [CrossRef]

- Cheng, D.-G.; Zhu, X.; Ben, Y.; He, F.; Cui, L.; Liu, C.-J. Carbon dioxide reforming of methane over Ni/Al2O3 treated with glow discharge plasma. Catal. Today 2006, 115, 205–210. [Google Scholar] [CrossRef]

- Whitehead, J.C. Plasma catalysis: A solution for environmental problems. Pure Appl. Chem. 2010, 82, 1329–1336. [Google Scholar] [CrossRef]

- Van Durme, J.; Dewulf, J.; Sysmans, W.; Leys, C.; Van Langenhove, H. Efficient toluene abatement in indoor air by a plasma catalytic hybrid system. Appl. Catal. B Environ. 2007, 74, 161–169. [Google Scholar] [CrossRef]

- Tu, X.; Whitehead, J. Plasma-catalytic dry reforming of methane in an atmospheric dielectric barrier discharge: Understanding the synergistic effect at low temperature. Appl. Catal. B Environ. 2012, 125, 439–448. [Google Scholar] [CrossRef]

- Gallon, H.J.; Tu, X.; Twigg, M.V.; Whitehead, J.C. Plasma-assisted methane reduction of a NiO catalyst—Low temperature activation of methane and formation of carbon nanofibres. Appl. Catal. B Environ. 2011, 106, 616–620. [Google Scholar] [CrossRef]

- Bromberg, L.; Cohn, D.; Rabinovich, A.; Alexeev, N.; Samokhin, A.; Hadidi, K.; Palaia, J.; Margarit-Bel, N. Onboard Plasmatron Hydrogen Production for Improved Vehicles; Report PSFC JA-06-3; MIT Plasma Fusion and Science Center: Cambridge, MA, USA, 2006. [Google Scholar]

- Chu, W.; Wang, L.-N.; Chernavskii, P.A.; Khodakov, A.Y. Glow-Discharge Plasma-Assisted Design of Cobalt Catalysts for Fischer-Tropsch Synthesis. Angew. Chem. Int. Ed. 2008, 47, 5052–5055. [Google Scholar] [CrossRef]

- Aluha, J.; Bere, K.; Abatzoglou, N.; Gitzhofer, F. Synthesis of Nano-catalysts by Induction Suspension Plasma Technology (SPS) for Fischer–Tropsch Reaction. Plasma Chem. Plasma Process. 2016, 36, 1325–1348. [Google Scholar] [CrossRef]

- Aluha, J.; Braidy, N.; Dalai, A.; Abatzoglou, N. Low-temperature Fischer–Tropsch synthesis using plasma-synthesised nanometric Co/C and Fe/C catalysts. Can. J. Chem. Eng. 2016, 94, 1504–1515. [Google Scholar] [CrossRef]

- Aluha, J.; Gutierrez, S.; Gitzhofer, F.; Abatzoglou, N. Use of Plasma-Synthesized Nano-Catalysts for CO Hydrogenation in Low-Temperature Fischer–Tropsch Synthesis: Effect of Catalyst Pre-Treatment. Nanomaterial 2018, 8, 822. [Google Scholar] [CrossRef] [Green Version]

- Hong, J.; Du, J.; Wang, B.; Zhang, Y.; Liu, C.; Xiong, H.; Sun, F.; Chen, S.; Li, J. Plasma-Assisted Preparation of Highly Dispersed Cobalt Catalysts for Enhanced Fischer–Tropsch Synthesis Performance. ACS Catal. 2018, 8, 6177–6185. [Google Scholar] [CrossRef]

- Aluha, J.; Gitzhofer, F.; Abatzoglou, N. Application of Plasma Technology in Fischer-Tropsch Catalysis for the Production of Synthetic Fuels. Recent Adv. Petrochem. Sci. 2018, 5, 1–11. [Google Scholar] [CrossRef]

- Li, D.; Rohani, V.; Fabry, F.; Ramaswamy, A.P.; Sennour, M.; Fulcheri, L. Experimental study on plasma-catalytic synthesis of hydrocarbons from syngas. Appl. Catal. A Gen. 2019, 588, 117269. [Google Scholar] [CrossRef]

- Akay, G.; Zhang, K.; Al-Harrasi, W.S.S.; Sankaran, R.M. Catalytic Plasma Fischer–Tropsch Synthesis Using Hierarchically Connected Porous Co/SiO2 Catalysts Prepared by Microwave-Induced Co-assembly. Ind. Eng. Chem. Res. 2020, 59, 12013–12027. [Google Scholar] [CrossRef]

- Zabidi, N.A.M.; Ali, S.; Subbarao, D. Effects of Pressure on the Performance of CNTs-Supported Catalyst in a Fischer-Tropsch Reaction. J. Mater. Sci. Eng. B 2014, 4, 28–33. [Google Scholar]

- De la Pena O’Shea, V.; Alvarez-Galvan, M.; Campos-Martin, J.; Fierro, J. Strong dependence on pressure of the performance of a Co/SiO2 catalyst in Fischer–Tropsch slurry reactor synthesis. Catal. Lett. 2005, 100, 105–116. [Google Scholar] [CrossRef]

- Ma, W.; Jacobs, G.; Ji, Y.; Bhatelia, T.; Bukur, D.B.; Khalid, S.; Davis, B.H. Fischer–Tropsch Synthesis: Influence of CO Conversion on Selectivities, H2/CO Usage Ratios, and Catalyst Stability for a Ru Promoted Co/Al2O3 Catalyst Using a Slurry Phase Reactor. Top. Catal. 2011, 54, 757–767. [Google Scholar] [CrossRef]

- Borg, Ø.; Eri, S.; Blekkan, E.A.; Storsæter, S.; Wigum, H.; Rytter, E.; Holmen, A. Fischer–Tropsch synthesis over γ-alumina-supported cobalt catalysts: Effect of support variables. J. Catal. 2007, 248, 89–100. [Google Scholar] [CrossRef]

- Bukur, D.B.; Pan, Z.; Ma, W.; Jacobs, G.; Davis, B.H. Effect of CO Conversion on the Product Distribution of a Co/Al2O3 Fischer–Tropsch Synthesis Catalyst Using a Fixed Bed Reactor. Catal. Lett. 2012, 142, 1382–1387. [Google Scholar] [CrossRef]

- Botes, F.G. Influences of Water and Syngas Partial Pressure on the Kinetics of a Commercial Alumina-Supported Cobalt Fischer−Tropsch Catalyst. Ind. Eng. Chem. Res. 2009, 48, 1859–1865. [Google Scholar] [CrossRef]

- Deprez, N.; McLachlan, D. The analysis of the electrical conductivity of graphite conductivity of graphite powders during compaction. J. Phys. D Appl. Phys. 1988, 21, 101. [Google Scholar] [CrossRef]

- Fulcheri, L.; Rohani, V.; Fabry, F.; Traisnel, N. Experimental electrical characterization of a low-current tip–tip arc discharge in helium atmosphere at very high pressure. Plasma Sources Sci. Technol. 2010, 19, 045010. [Google Scholar] [CrossRef]

- Benilov, M.; Marotta, A. A model of the cathode region of atmospheric pressure arcs. J. Phys. D Appl. Phys. 1995, 28, 1869–1882. [Google Scholar] [CrossRef]

- Benilov, M.S. Understanding and modelling plasma–electrode interaction in high-pressure arc discharges: A review. J. Phys. D Appl. Phys. 2008, 41, 144001. [Google Scholar] [CrossRef] [Green Version]

- Lebouvier, A.; Iwarere, S.A.; Ramjugernath, D.; Fulcheri, L. 3D magnetohydrodynamic modelling of a dc low-current plasma arc batch reactor at very high pressure in helium. J. Phys. D Appl. Phys. 2013, 46, 145203. [Google Scholar] [CrossRef]

- Cheng, D.-G. Plasma Decomposition and Reduction in Supported Metal Catalyst Preparation. Catal. Surv. Asia 2008, 12, 145–151. [Google Scholar] [CrossRef]

- Bakhtiari, M.; Khorasheh, F.; Zamanian, A.; Nakhaeipour, A.; Irani, M. Preparation, Evaluation and Characterization of Monolithic Catalysts for Fischer-Tropsch Synthesis. Pet. Coal 2008, 50, 56–61. [Google Scholar]

- Khodakov, A.Y.; Chu, W.; Fongarland, P. Advances in the Development of Novel Cobalt Fischer—Tropsch Catalysts for Synthesis of Long-Chain Hydrocarbons and Clean Fuels. Chem. Rev. 2007, 107, 1692–1744. [Google Scholar] [CrossRef]

- Kim, H.H. Nonthermal Plasma Processing for Air-Pollution Control: A Historical Review, Current Issues, and Future Prospects. Plasma Process. Polym. 2004, 1, 91–110. [Google Scholar] [CrossRef]

- Chang, M.B.; Lee, H.M. Abatement of perfluorocarbons with combined plasma catalysis in atmospheric-pressure environment. Catal. Today 2004, 89, 109–115. [Google Scholar] [CrossRef]

- Yu, S.J.; Chang, M.B. Oxidative Conversion of PFC via Plasma Processing with Dielectric Barrier Discharges. Plasma Chem. Plasma Process. 2001, 21, 311–327. [Google Scholar] [CrossRef]

- Holzer, F.; Roland, U.; Kopinke, F.-D. Combination of non-thermal plasma and heterogeneous catalysis for oxidation of volatile organic compounds: Part 1. Accessibility of the intra-particle volume. Appl. Catal. B Environ. 2002, 38, 163–181. [Google Scholar] [CrossRef]

- Chen, X.; Rozak, J.; Lin, J.-C.; Suib, S.L.; Hayashi, Y.; Matsumoto, H. Oxidative decomposition of chlorinated hydrocarbons by glow discharge in PACT (plasma and catalyst integrated technologies) reactors. Appl. Catal. A Gen. 2001, 219, 25–31. [Google Scholar] [CrossRef]

- Rueangjitt, N.; Sreethawong, T.; Chavadej, S.; Sekiguchi, H. Non-Oxidative Reforming of Methane in a Mini-Gliding Arc Discharge Reactor: Effects of Feed Methane Concentration, Feed Flow Rate, Electrode Gap Distance, Residence Time, and Catalyst Distance. Plasma Chem. Plasma Process. 2011, 31, 517–534. [Google Scholar] [CrossRef]

- Rueangjitt, N.; Sreethawong, T.; Chavadej, S.; Sekiguchi, H. Plasma-catalytic reforming of methane in AC microsized gliding arc discharge: Effects of input power, reactor thickness, and catalyst existence. Chem. Eng. J. 2009, 155, 874–880. [Google Scholar] [CrossRef]

- Hilmen, A.-M.; Bergene, E.; Lindvåg, O.; Schanke, D.; Eri, S.; Holmen, A. Fischer–Tropsch synthesis on monolithic catalysts of different materials. Catal. Today 2001, 69, 227–232. [Google Scholar] [CrossRef]

- Hilmen, A.-M.; Bergene, E.; Lindvåg, O.; Schanke, D.; Eri, S.; Holmen, A. Fischer-Tropsch synthesis using monolithic catalysts. Stud. Surf. Sci. Catal. 2000, 130, 1163–1168. [Google Scholar] [CrossRef]

- de Deugd, R.M.; Chougule, R.B.; Kreutzer, M.T.; Meeuse, F.M.; Grievink, J.; Kapteijn, F.; Moulijn, J.A. Is a monolithic loop reactor a viable option for Fischer–Tropsch synthesis? Chem. Eng. Sci. 2003, 58, 583–591. [Google Scholar] [CrossRef]

- De Deugd, R.M.; Kapteijn, F.; Moulijn, J.A. Using monolithic catalysts for highly selective Fischer–Tropsch synthesis. Catal. Today 2003, 79, 495–501. [Google Scholar] [CrossRef]

- Kapteijn, F.; de Deugd, R.M.; Moulijn, J.A. Fischer–Tropsch synthesis using monolithic catalysts. Catal. Today 2005, 105, 350–356. [Google Scholar] [CrossRef]

- Guettel, R.; Knochen, J.; Kunz, U.; Kassing, M.; Turek, T. Preparation and Catalytic Evaluation of Cobalt-Based Monolithic and Powder Catalysts for Fischer−Tropsch Synthesis. Ind. Eng. Chem. Res. 2008, 47, 6589–6597. [Google Scholar] [CrossRef]

- Liu, W.; Hu, J.; Wang, Y. Fischer–Tropsch synthesis on ceramic monolith-structured catalysts. Catal. Today 2009, 140, 142–148. [Google Scholar] [CrossRef]

- Avila, P.; Montes, M.; Miro, E.E. Monolithic reactors for environmental applications: A review on preparation technologies. Chem. Eng. J. 2005, 109, 11–36. [Google Scholar] [CrossRef]

- Panneerselvam, M.; Rao, K. Novel Microwave Method for the Synthesis and Sintering of Mullite from Kaolinite. Chem. Mater. 2003, 15, 2247–2252. [Google Scholar] [CrossRef]

- Chaudhuri, S.; Patra, S.; Chakraborty, A. Electrical resistivity of transition metal ion doped Mullite. J. Eur. Ceram. Soc. 1999, 19, 2941–2950. [Google Scholar] [CrossRef]

- Schneider, H.; Schreuer, J.; Hildmann, B. Structure and properties of mullite—A review. J. Eur. Ceram. Soc. 2008, 28, 329–344. [Google Scholar] [CrossRef]

- Villegas, L.; Masset, F.; Guilhaume, N. Wet impregnation of alumina-washcoated monoliths: Effect of the drying procedure on Ni distribution and on autothermal reforming activity. Appl. Catal. A Gen. 2007, 320, 43–55. [Google Scholar] [CrossRef]

- Holmen, A.; Venvik, H.J.; Myrstad, R.; Zhu, J.; Chen, D. Monolithic, microchannel and carbon nanofibers/carbon felt reactors for syngas conversion by Fischer-Tropsch synthesis. Catal. Today 2013, 216, 150–157. [Google Scholar] [CrossRef]

| Operating Parameters | Pressure Variation Study | Current Variation Study | Electrode Gap Variation Study | |

| Discharge time (s) | 10 | 60 | 60 | 60 |

| Operating current (mA) | 350 | 350 | 250, 300, 350, 400, 450 | 350 |

| Ignition voltage (kV) | 8 | 8 | 8 | 8 |

| Inter-electrode gap (mm) | 1 | 1 | 1 | 0.5, 1.0, 1.5, 2.0 |

| Pressure (MPa) | 0.5, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10 | 0.5, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10 | 2 | 2 |

| H2/CO ratio | 2.2:1 | 2.2:1 | 2.2:1 | 2.2:1 |

| Concentration/ppm | ||||||||

| 10 s | 60 s | |||||||

| Product | Pure plasma | Plasma-catalysis | Pure plasma | Plasma-catalysis | ||||

| 1 MPa | 10 MPa | 1 MPa | 10 MPa | 2 MPa | 10 MPa | 2 MPa | 10 MPa | |

| Methane | 17 | 342 | 68 | 2428 | 48 | 772 | 2266 | 7836 |

| C2 hydrocarbons | ||||||||

| Ethane | 0.6 | 1.3 | 2.8 | 19 | 1.4 | 16 | 95 | 64 |

| Ethylene | 0.1 | 0.3 | 0.7 | 1.6 | 0.2 | 3.4 | 52 | 9.6 |

| C3 hydrocarbons | ||||||||

| Propane | 0.0 | 0.2 | 0.1 | 4.5 | 0.1 | 2.8 | 1.2 | 6.6 |

| Propylene | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 1.2 | 0.0 | 0.0 |

| Product ratio | ||||||||

| Methane/ ethane | 29 | 270 | 24 | 125 | 34 | 47 | 24 | 123 |

| Ethane/ethylene | 5.6 | 4.4 | 4.0 | 12.2 | 8.2 | 4.8 | 1.8 | 6.6 |

| Channel 1 | Channel 2 | ||

|---|---|---|---|

| Analytes | Compound class | Permanent gases | Hydrocarbons |

| Gases | H2, CO | CH4, C2H6, C2H4, C3H8, C3H6 | |

| Injector | Type | SPL-2010 (Direct mode) | SPL-2010 (Split mode) |

| Carrier gas type | Nitrogen | Helium | |

| Carrier gas flow | 30 mL·min−1 | 83 mL·min−1 | |

| Temperature | 250 °C | 200 °C | |

| Split ratio | - | 15:1 | |

| Linear velocity | - | 38.4 cm·s−1 | |

| Gas volume injected | 500 µL | 500 µL | |

| Column | Type | Packed | Capillary |

| Make | Supelco | Hewlett-Packard | |

| Model | Carboxen 1000 (60/80) | Al2O3 PLOT | |

| Length | 4.5 m | 30 m | |

| Inner diameter | 2.10 mm | 0.53 mm | |

| Film thickness | - | 15 µm | |

| Maximum temperature | 400 °C | 200 °C | |

| Operating temperature | 40 °C (Isothermal) | 40 °C (10 min)–170 °C (ramp) | |

| Retention time | 10 min | 30 min | |

| Detector | Type | Thermal conductivity detector (TCD) | Flame ionisation detector (FID) |

| Temperature | 275 °C | 250 °C | |

| Flame | - | 35 mL·min−1 H2 | |

| - | 350 mL·min−1 Air |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Govender, B.B.; Iwarere, S.A.; Ramjugernath, D. Plasma-Catalytic Fischer–Tropsch Synthesis at Very High Pressure. Catalysts 2021, 11, 297. https://doi.org/10.3390/catal11030297

Govender BB, Iwarere SA, Ramjugernath D. Plasma-Catalytic Fischer–Tropsch Synthesis at Very High Pressure. Catalysts. 2021; 11(3):297. https://doi.org/10.3390/catal11030297

Chicago/Turabian StyleGovender, Byron Bradley, Samuel Ayodele Iwarere, and Deresh Ramjugernath. 2021. "Plasma-Catalytic Fischer–Tropsch Synthesis at Very High Pressure" Catalysts 11, no. 3: 297. https://doi.org/10.3390/catal11030297

APA StyleGovender, B. B., Iwarere, S. A., & Ramjugernath, D. (2021). Plasma-Catalytic Fischer–Tropsch Synthesis at Very High Pressure. Catalysts, 11(3), 297. https://doi.org/10.3390/catal11030297