Study the Effect of Various Sulfonation Methods on Catalytic Activity of Carbohydrate-Derived Catalysts for Ester Production

Abstract

:1. Introduction

2. Results and Discussion

2.1. Characterization of Catalysts

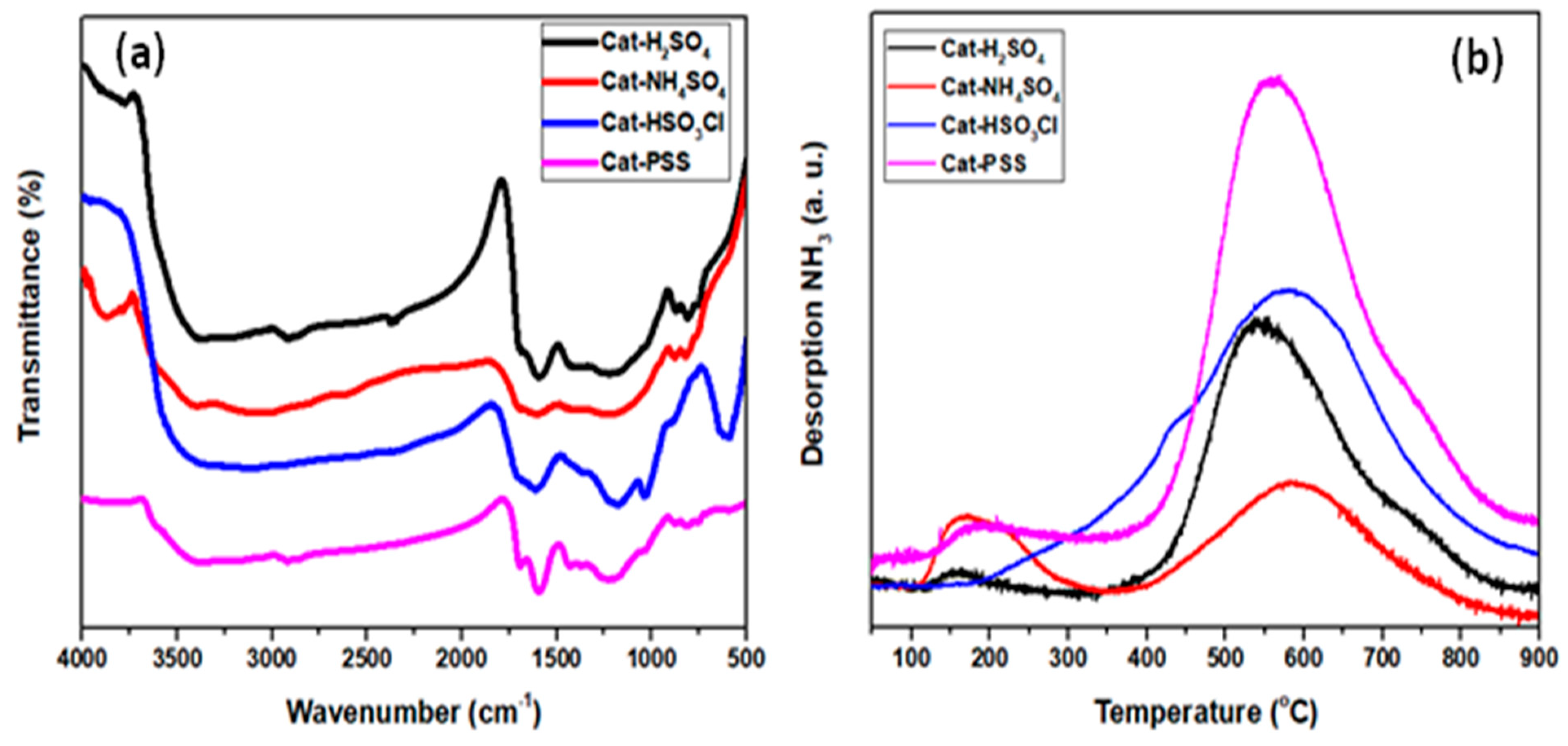

2.1.1. Fourier Transformation Infrared (FT-IR) Analysis

2.1.2. Ammonia Temperature Programmed Desorption (NH3-TPD) and Brunauer–Emmett–Teller (BET) Analysis

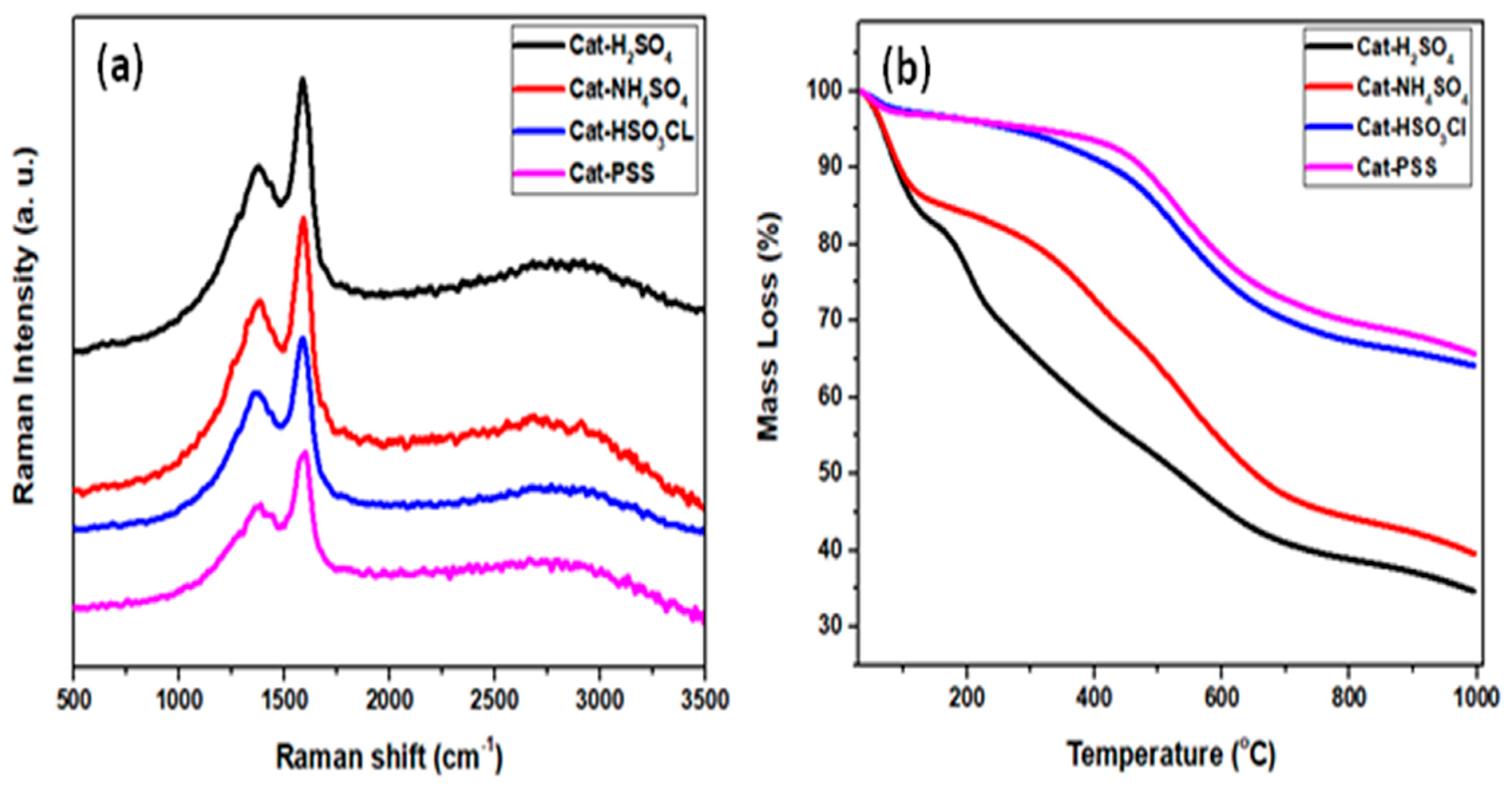

2.1.3. Raman Spectroscopy Analysis

2.1.4. Thermogravimetric Analysis (TGA)

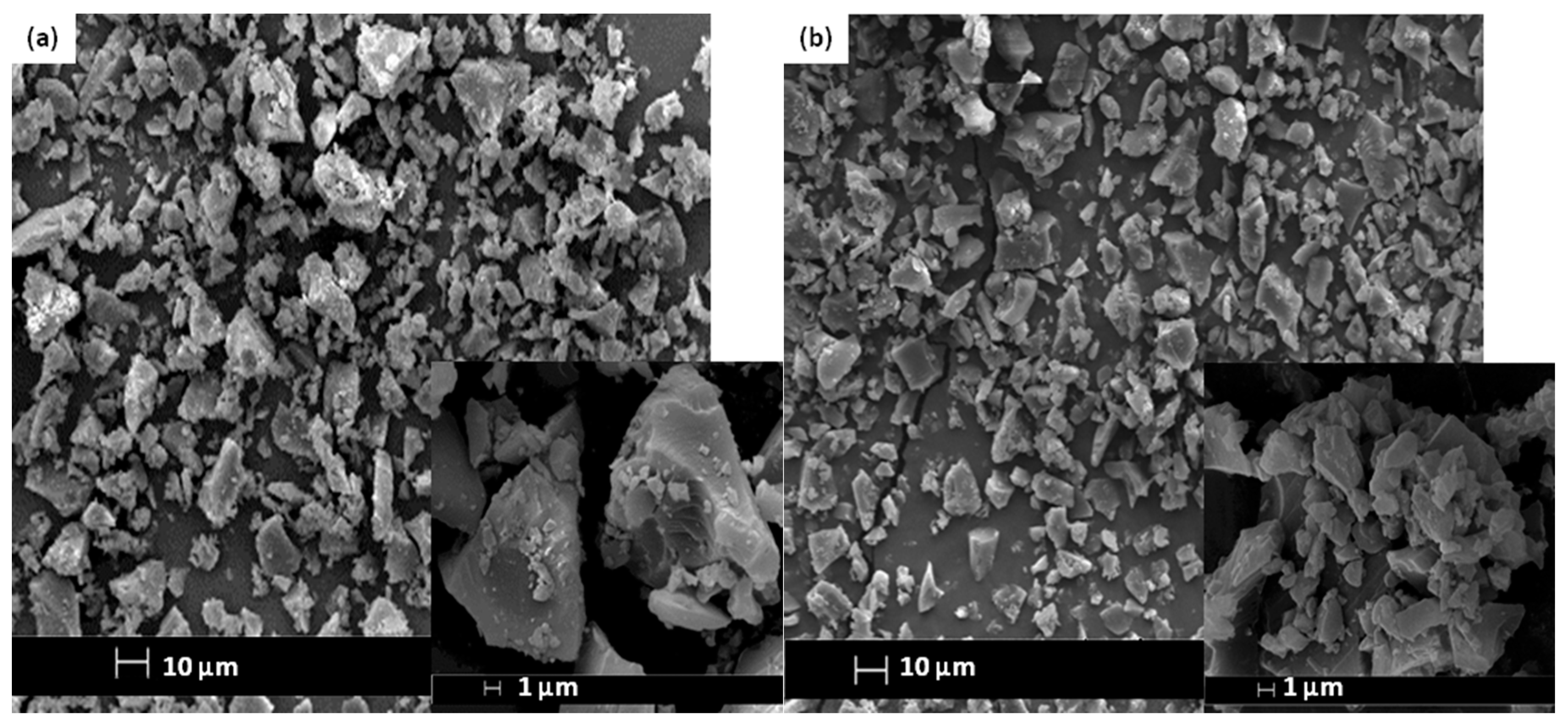

2.1.5. Scanning Election Microscopy (SEM) and Energy Dispersive X-ray (EDX) Analysis

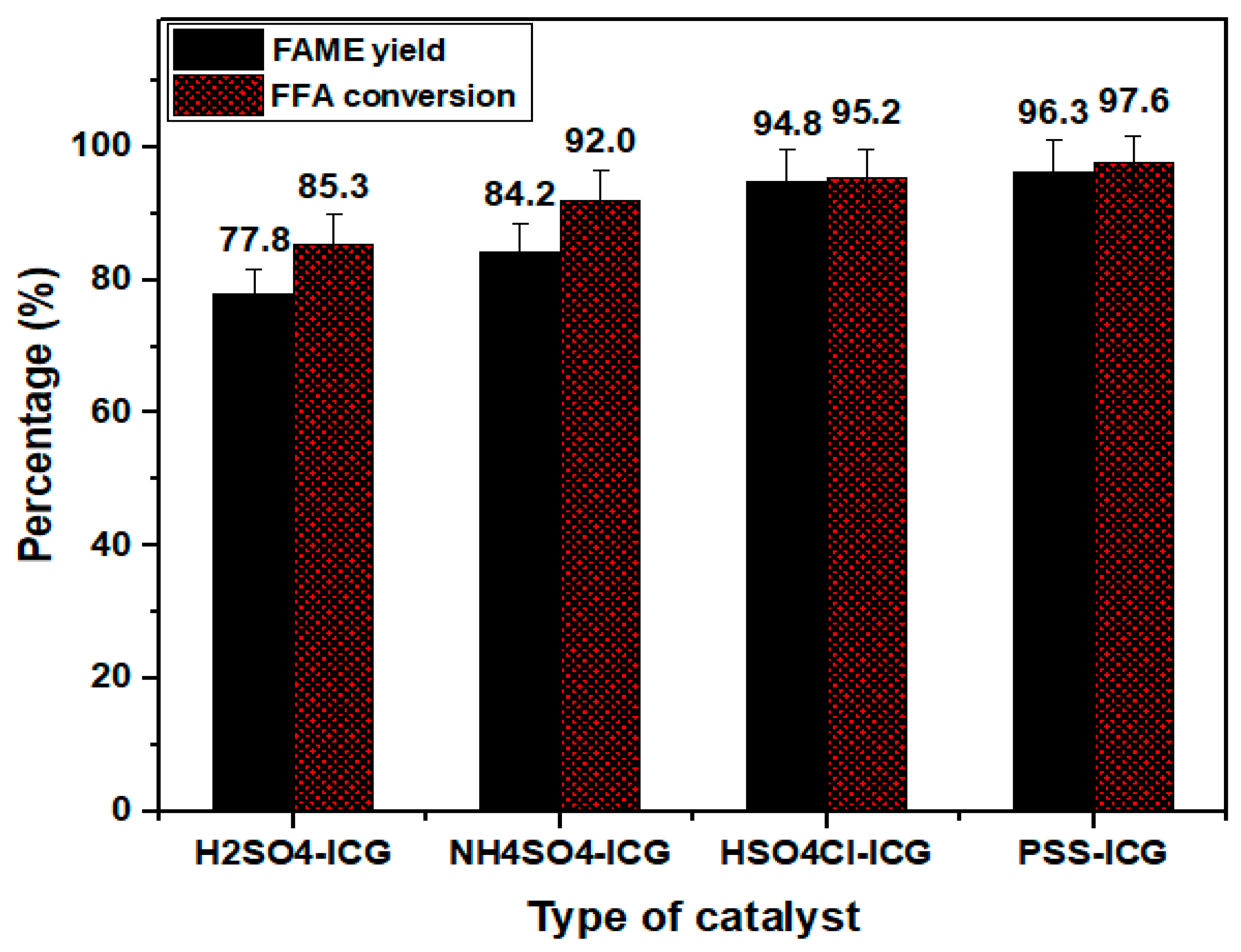

2.2. Comparisons of the Catalytic Activities using Different Sulfonation Methods

3. Materials and Methods

3.1. Materials

3.2. Methodology of the Catalyst Synthesis

3.2.1. Synthesis of Incomplete Carbonized Glucose (ICG)

3.2.2. Sulfonation by Thermal Treatment with Concentrated Sulfuric Acid

3.2.3. Sulfonation by Thermal Decomposition of Ammonium Sulphate

3.2.4. Sulfonation by Thermal Treatment with Chlorosulfonic Acid in Chloroform

3.2.5. Sulfonation by in situ Polymerization of Poly(Sodium4-styrene Sulfonate)

3.3. Characterization Methods

3.4. Catalytic Activity of the Catalysts

3.5. FAME Analysis and FFA Conversion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chongkhong, S.; Tongurai, C.; Chetpattananondh, P.; Bunyakan, C. Biodiesel production by esterification of palm fatty acid distillate. Biomass. Bioenergy 2007, 31, 563–568. [Google Scholar] [CrossRef]

- Al-Haj, L.; Al-Hinai, M.A.; Hellier, P.; Rashid, U. Optimization of oil extraction from waste “Date pits” for biodiesel production. Energ. Conver. Manag. 2016, 117, 264–272. [Google Scholar]

- Rehan, M.; Gardy, J.; Demirbas, A.; Rashid, U.; Budzianowski, W.M.; Pant, D.; Nizami, A.S. Waste to biodiesel: A preliminary assessment for Saudi Arabia. Bioresour. Technol. 2018, 250, 17–25. [Google Scholar] [CrossRef] [Green Version]

- Cho, H.J.; Kim, J.-K.; Ahmed, F.; Yeo, Y.-K. Life-cycle greenhouse gas emissions and energy balances of a biodiesel production from palm fatty acid distillate (PFAD). Appl. Energy 2013, 111, 479–488. [Google Scholar] [CrossRef]

- Soltani, S.; Rashid, U.; Yunus, R.; Taufiq-Yap, Y.H.; Al-Resayes, S.I. Post-functionalization of polymeric mesoporous C@Zn core–shell spheres used for methyl ester production. Renew. Energy 2016, 99, 1235–1243. [Google Scholar] [CrossRef]

- Roschat, W.; Siritanon, T.; Yoosuk, B.; Sudyoadsuk, T.; Promarak, V. Rubber seed oil as potential non-edible feedstock for biodiesel production using heterogeneous catalyst in Thailand. Renew. Energy 2017, 101, 937–944. [Google Scholar] [CrossRef]

- Lokman, I.M.; Rashid, U.; Taufiq-Yap, Y.H.; Yunus, R. Methyl ester production from palm fatty acid distillate using sulfonated glucose-derived acid catalyst. Renew. Energy 2015, 81, 347–354. [Google Scholar] [CrossRef]

- Issariyakul, T.; Dalai, A.K. Biodiesel from vegetable oils. Renew. Sustain. Energy Rev. 2014, 31, 446–471. [Google Scholar] [CrossRef]

- Ashraful, A.M.; Masjuki, H.H.; Kalam, M.A.; Rizwanul Fattah, I.M.; Imtenan, S.; Shahir, S.A.; Mobarak, H.M. Production and comparison of fuel properties, engine performance, and emission characteristics of biodiesel from various non-edible vegetable oils: A review. Energy. Convers. Manag. 2014, 80, 202–228. [Google Scholar] [CrossRef]

- Dawodu, F.A.; Ayodele, O.; Xin, J.; Zhang, S.; Yan, D. Effective conversion of non-edible oil with high free fatty acid into biodiesel by sulphonated carbon catalyst. Appl. Energy 2014, 114, 819–826. [Google Scholar] [CrossRef]

- Baskar, G.; Soumiya, S. Production of biodiesel from castor oil using iron (II) doped zinc oxide nanocatalyst. Renew. Energy 2016, 98, 101–107. [Google Scholar] [CrossRef]

- Al-Hamamre, Z.; Al-Salaymeh, A. Physical properties of (jojoba oil + biodiesel), (jojoba oil + diesel) and (biodiesel + diesel) blends. Fuel 2014, 123, 175–188. [Google Scholar] [CrossRef]

- Martínez, G.; Sánchez, N.; Encinar, J.M.; González, J.F. Fuel properties of biodiesel from vegetable oils and oil mixtures. Influence of methyl esters distribution. Biomass. Bioenergy 2014, 63, 22–32. [Google Scholar] [CrossRef]

- Lou, W.-Y.; Zong, M.-H.; Duan, Z.-Q. Efficient production of biodiesel from high free fatty acid-containing waste oils using various carbohydrate-derived solid acid catalysts. Bioresour. Technol. 2008, 99, 8752–8758. [Google Scholar] [CrossRef]

- Sani, Y.M.; Daud, W.M.A.W.; Abdul Aziz, A.R. Solid acid-catalyzed biodiesel production from microalgal oil—The dual advantage. J. Environ. Chem. Eng. 2013, 1, 113–121. [Google Scholar] [CrossRef]

- Hidayat, A.; Wijaya, K.; Nurdiawati, A.; Kurniawan, W.; Hinode, H.; Yoshikawa, K.; Budiman, A. Esterification of palm fatty acid distillate with high amount of free fatty acids using coconut shell char based catalyst. Energy. Procedia 2015, 75, 969–974. [Google Scholar] [CrossRef] [Green Version]

- Nakajima, K.; Hara, M. Amorphous carbon with SO3H groups as a solid brønsted acid catalyst. ACS Catal. 2012, 2, 1296–1304. [Google Scholar] [CrossRef]

- Lokman, I.M.; Rashid, U.; Taufiq-Yap, Y.H. Meso- and macroporous sulfonated starch solid acid catalyst for esterification of palm fatty acid distillate. Arab. J. Chem. 2016, 9, 179–189. [Google Scholar] [CrossRef] [Green Version]

- Chouhan, A.S.; Sarma, A.K. Modern heterogeneous catalysts for biodiesel production: A comprehensive review. Renew. Sustain. Energy Rev. 2011, 15, 4378–4399. [Google Scholar] [CrossRef]

- Toda, M.; Takagaki, A.; Okamura, M.; Kondo, J.N.; Hayashi, S.; Domen, K.; Hara, M. Biodiesel made with sugar catalyst. Nature 2005, 438, 178. [Google Scholar] [CrossRef]

- Roldán, L.; Pires, E.; Fraile, J.M.; García-Bordejé, E. Impact of sulfonated hydrothermal carbon texture and surface chemistry on its catalytic performance in esterification reaction. Catal. Today 2015, 249, 153–160. [Google Scholar] [CrossRef] [Green Version]

- Soltani, S.; Khanian, N.; Rashid, U.; Choong, T.S.Y. Core-shell ZnO-TiO2 hollow spheres synthesized by in-situ hydrothermal method for ester production application. Renew. Energy 2019, 151, 1076–1081. [Google Scholar] [CrossRef]

- Soltani, S.; Khanian, N.; Rashid, U.; Yaw Choong, T.S. Synthesis and characterization of sulfonated mesoporous NiO–ICG core–shell solid sphere catalyst with superior capability for methyl ester production. RSC Adv. 2019, 9, 31306–31315. [Google Scholar] [CrossRef] [Green Version]

- Shu, Q.; Nawaz, Z.; Gao, J.; Liao, Y.; Zhang, Q.; Wang, D.; Wang, J. Synthesis of biodiesel from a model waste oil feedstock using a carbon-based solid acid catalyst: reaction and separation. Bioresour. Technol. 2010, 101, 5374–5384. [Google Scholar] [CrossRef]

- Suganuma, S.; Nakajima, K.; Kitano, M.; Kato, H.; Tamura, A.; Kondo, H.; Yanagawa, S.; Hayashi, S.; Hara, M. SO3H-bearing mesoporous carbon with highly selective catalysis. Microporous. Mesoporous. Mater. 2011, 143, 443–450. [Google Scholar] [CrossRef]

- Santos, E.M.; de Carvalho Teixeira, A.P.; da Silva, F.G.; Cibaka, T.E.; Araújo, M.H.; Oliveira, W.X.C.; Medeiros, F.; Brasil, A.N.; de Oliveira, L.S.; Lago, R.M. New heterogeneous catalyst for the esterification of fatty acid produced by surface aromatization/sulfonation of oilseed cake. Fuel 2015, 150, 408–414. [Google Scholar] [CrossRef]

- Zong, M.-H.; Duan, Z.-Q.; Lou, W.-Y.; Smith, T.J.; Wu, H. Preparation of a sugar catalyst and its use for highly efficient production of biodiesel. Green. Chem. 2007, 9, 434. [Google Scholar] [CrossRef]

- Konwar, L.J.; Boro, J.; Deka, D. Review on latest developments in biodiesel production using carbon-based catalysts. Renew. Sustain. Energy. Rev. 2014, 29, 546–564. [Google Scholar] [CrossRef]

- Zhang, L.; Yan, J.; Zhou, M.; Yang, Y.; Liu, Y.-N. Fabrication and photocatalytic properties of spheres-in-spheres ZnO/ZnAl2O4 composite hollow microspheres. Appl. Surf. Sci. 2013, 268, 237–245. [Google Scholar] [CrossRef]

- Li, S.; Shen, Y.; Xiao, M.; Liu, D.; Fa, L.; Wu, K. Intercalation of 2,4-dihydroxybenzophenone-5-sulfonate anion into Zn/Al layered double hydroxides for UV absorption properties. J. Ind. Eng. Chem. 2014, 20, 1280–1284. [Google Scholar] [CrossRef]

- Bruno, J.E.; Dooley, K.M. Double-bond isomerization of hexadecenes with solid acid catalysts. Appl. Catal. A Gen. 2015, 497, 176–183. [Google Scholar] [CrossRef]

- Shuit, S.H.; Tan, S.H. Feasibility study of various sulphonation methods for transforming carbon nanotubes into catalysts for the esterification of palm fatty acid distillate. Energy Convers. Manag. 2014, 88, 1283–1289. [Google Scholar] [CrossRef]

- Ngaosuwan, K.; Goodwin, J.G.; Prasertdham, P. A green sulfonated carbon-based catalyst derived from coffee residue for esterification. Renew. Energy 2016, 86, 262–269. [Google Scholar] [CrossRef]

- Fraile, J.M.; García-Bordejé, E.; Pires, E.; Roldán, L. New insights into the strength and accessibility of acid sites of sulfonated hydrothermal carbon. Carbon 2014, 77, 1157–1167. [Google Scholar] [CrossRef]

- Alhassan, F.H.; Yunus, R.; Rashid, U.; Sirat, K.; Islam, A.; Lee, H.V.; Taufiq-Yap, Y.H. Production of biodiesel from mixed waste vegetable oils using Ferric hydrogen sulphate as an effective reusable heterogeneous solid acid catalyst. Appl. Catal. A Gen. 2013, 456, 182–187. [Google Scholar] [CrossRef]

- Soltani, S.; Rashid, U.; Nehdi, I.A.; Al-Resayes, S.I. Esterification of palm fatty acid distillate using a sulfonated mesoporous CuO-ZnO mixed metal oxide catalyst. Chem. Eng. Technol. 2017, 40, 1931–1939. [Google Scholar] [CrossRef]

- Soltani, S.; Rashid, U.; Al-Resayes, S.I.; Nehdi, I.A. Sulfonated mesoporous ZnO catalyst for methyl esters production. J. Clean. Prod. 2017, 144, 482–491. [Google Scholar] [CrossRef]

| Catalysts | Sulfonation Method | Elemental Composition by Weight (%) | Total Acid Density (mmol g−1) | SBETm2g−1 | FAME Yield (%)* | FFA Conversion (%)* | ||

|---|---|---|---|---|---|---|---|---|

| Carbon | Oxygen | Sulphur | ||||||

| H2SO4-ICG | Thermal treatment with concentrated sulfuric acid | 64.25 | 33.83 | 1.91 | 4.408 | 4.27 | 77.8 | 85.3 |

| NHSO4-ICG | Thermal decomposition of ammonium sulphate | 59.33 | 36.16 | 4.51 | 5.299 | 4.83 | 84.2 | 89.8 |

| HSO3Cl-ICG | Thermal treatment with chlorosulfonic acid in chloroform | 83.92 | 9.82 | 6.26 | 7.461 | 8.09 | 94.8 | 95.2 |

| PSS-ICG | In situ polymerisation of poly(sodium4-styrenesulfonate) | 81.28 | 10.85 | 7.87 | 14.643 | 8.70 | 96.3 | 97.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deris, N.H.; Rashid, U.; Soltani, S.; Choong, T.S.Y.; Nehdi, I.A. Study the Effect of Various Sulfonation Methods on Catalytic Activity of Carbohydrate-Derived Catalysts for Ester Production. Catalysts 2020, 10, 638. https://doi.org/10.3390/catal10060638

Deris NH, Rashid U, Soltani S, Choong TSY, Nehdi IA. Study the Effect of Various Sulfonation Methods on Catalytic Activity of Carbohydrate-Derived Catalysts for Ester Production. Catalysts. 2020; 10(6):638. https://doi.org/10.3390/catal10060638

Chicago/Turabian StyleDeris, Nur Hidayah, Umer Rashid, Soroush Soltani, Thomas Shean Yaw Choong, and Imededdine Arbi Nehdi. 2020. "Study the Effect of Various Sulfonation Methods on Catalytic Activity of Carbohydrate-Derived Catalysts for Ester Production" Catalysts 10, no. 6: 638. https://doi.org/10.3390/catal10060638

APA StyleDeris, N. H., Rashid, U., Soltani, S., Choong, T. S. Y., & Nehdi, I. A. (2020). Study the Effect of Various Sulfonation Methods on Catalytic Activity of Carbohydrate-Derived Catalysts for Ester Production. Catalysts, 10(6), 638. https://doi.org/10.3390/catal10060638