Pyrolysis of Polyethylene Terephthalate over Carbon-Supported Pd Catalyst

Abstract

1. Introduction

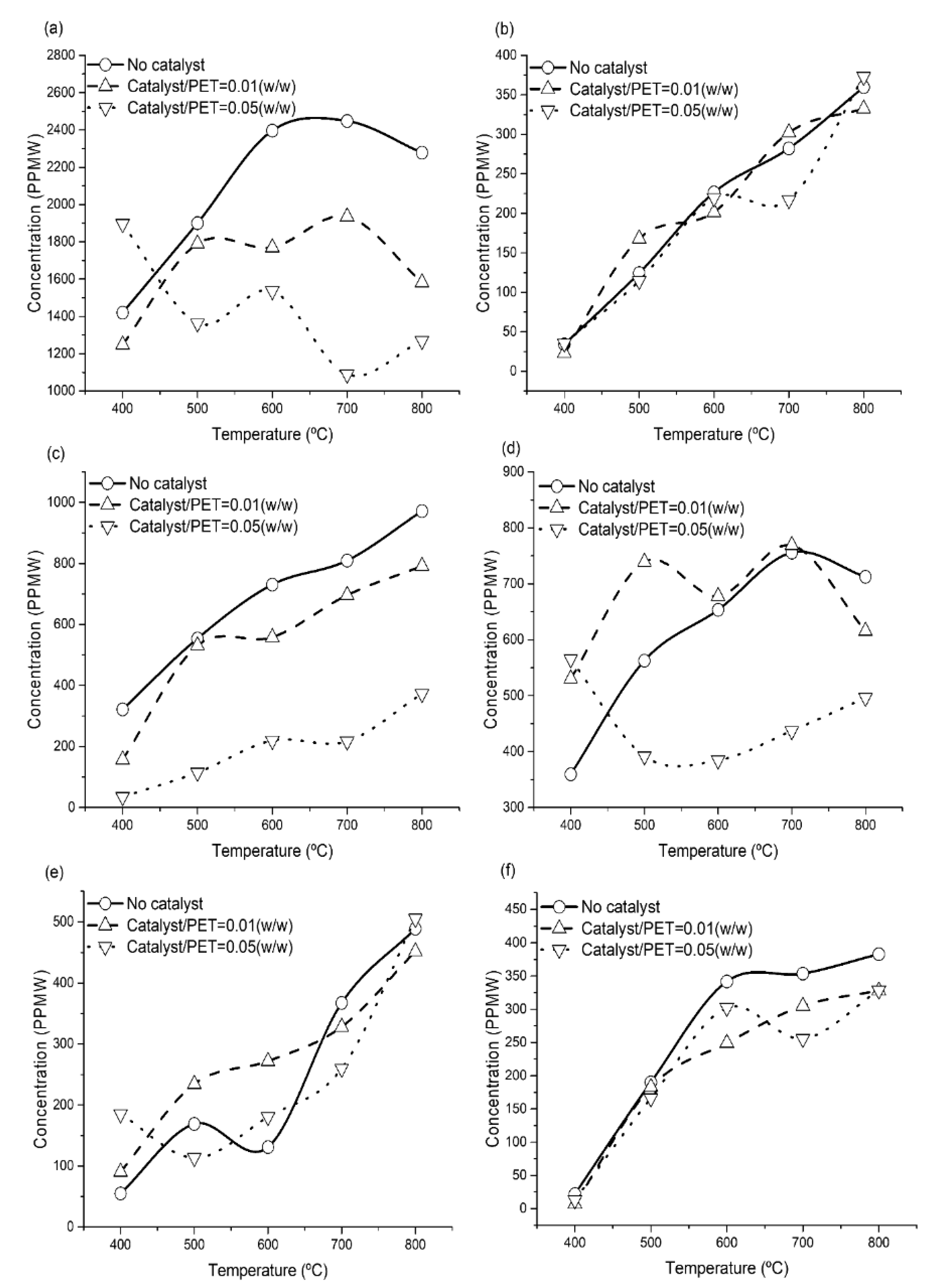

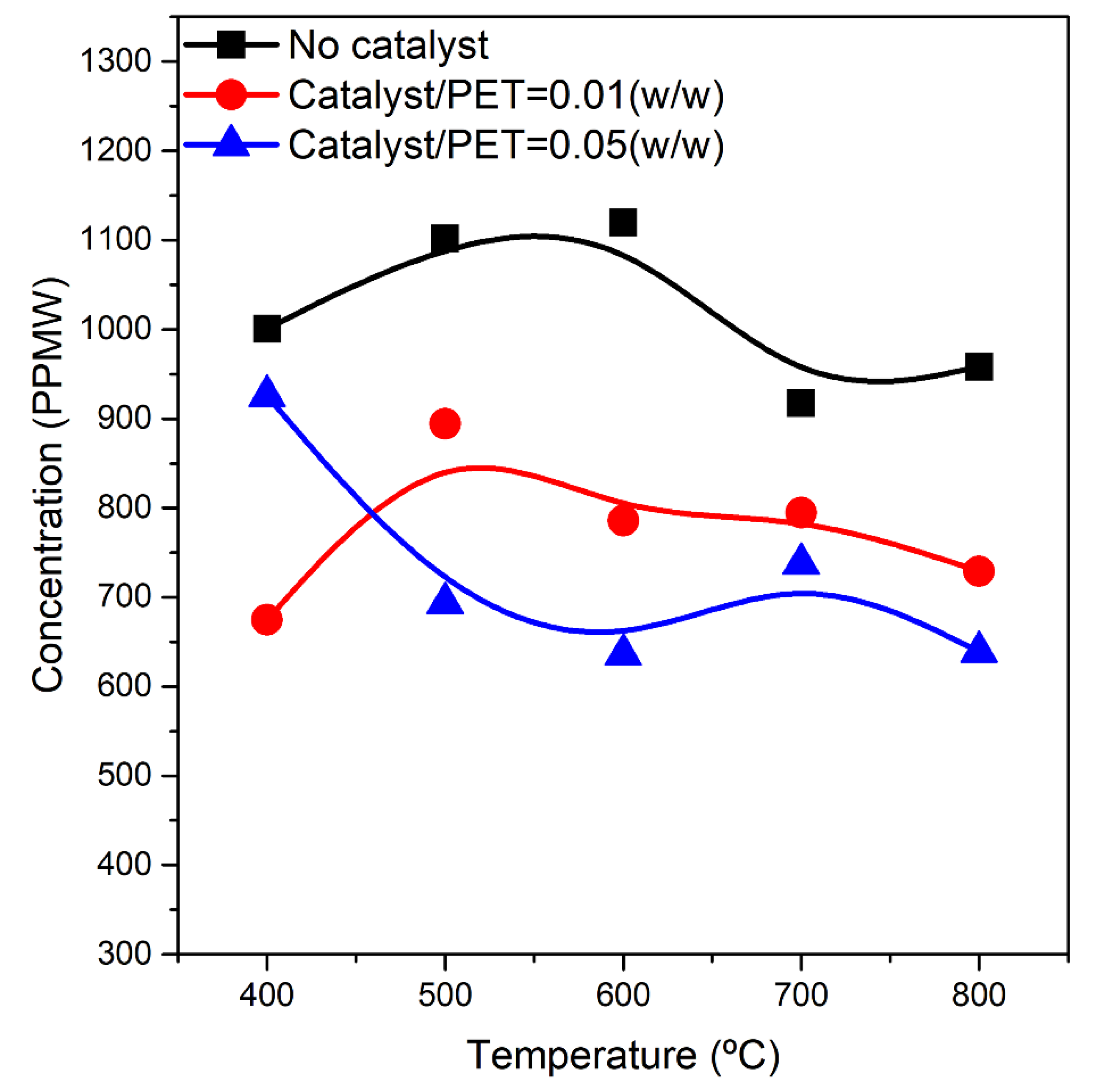

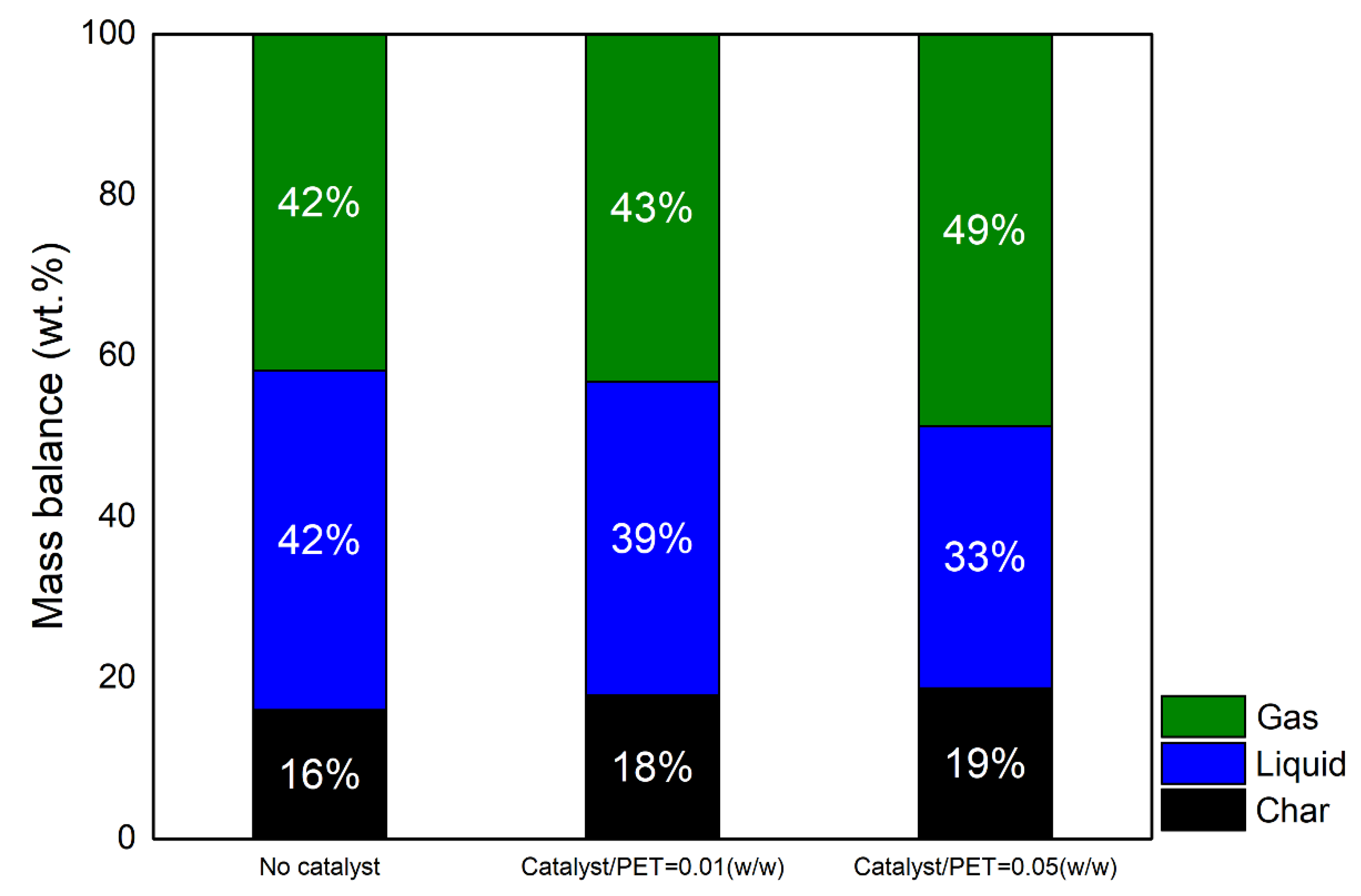

2. Results and Discussion

3. Experimental

3.1. Material and Chemical

3.2. Pd Catalyst Characterization

3.3. Thermogravimetric Analysis of PET

3.4. Pyrolysis of PET

3.5. Pyrolytic Products Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ghanbari, A.; Heuzey, M.; Carreau, P.; Ton-That, M. A novel approach to control thermal degradation of PET/organoclay nanocomposites and improve clay exfoliation. Polymer 2013, 54, 1361–1369. [Google Scholar] [CrossRef]

- Hurley, R.; Woodward, J.; Rothwell, J.J. Microplastic contamination of river beds significantly reduced by catchment-wide flooding. Nat. Geosci. 2018, 11, 251–257. [Google Scholar] [CrossRef]

- Sharma, S.; Chatterjee, S. Microplastic pollution, a threat to marine ecosystem and human health: A short review. Environ. Sci. Pollut. Res. 2017, 24, 21530–21547. [Google Scholar] [CrossRef] [PubMed]

- Molina, J.C.; Eguia, I.; Racero, J. Reducing pollutant emissions in a waste collection vehicle routing problem using a variable neighborhood tabu search algorithm: A case study. Top 2019, 27, 253–287. [Google Scholar] [CrossRef]

- Chirayil, C.J.; Mishra, R.K.; Thomas, S. Materials Recovery, Direct Reuse and Incineration of PET Bottles. In Recycling of Polyethylene Terephthalate Bottles; Elsevier: Amsterdam, The Netherlands, 2019; pp. 37–60. [Google Scholar]

- Kim, S.B.; Yi, N.H.; Kim, H.Y.; Kim, J.-H.J.; Song, Y.-C. Material and structural performance evaluation of recycled PET fiber reinforced concrete. Cem. Concr. Compos. 2010, 32, 232–240. [Google Scholar] [CrossRef]

- Min, Y.; Liu, C.; Shi, P.; Qin, C.; Feng, Y.; Liu, B. Effects of the addition of municipal solid waste incineration fly ash on the behavior of polychlorinated dibenzo-p-dioxins and furans in the iron ore sintering process. Waste Manag. 2018, 77, 287–293. [Google Scholar] [CrossRef]

- Diaz-Silvarrey, L.S.; McMahon, A.; Phan, A.N. Benzoic acid recovery via waste poly (ethylene terephthalate)(PET) catalytic pyrolysis using sulphated zirconia catalyst. J. Anal. Appl. Pyrolysis 2018, 134, 621–631. [Google Scholar] [CrossRef]

- Demetrious, A.; Crossin, E. Life cycle assessment of paper and plastic packaging waste in landfill, incineration, and gasification-pyrolysis. J. Mater. Cycles Waste Manag. 2019, 21, 850–860. [Google Scholar] [CrossRef]

- Verma, R.; Vinoda, K.; Papireddy, M.; Gowda, A. Toxic pollutants from plastic waste—A review. Procedia Environ. Sci. 2016, 35, 701–708. [Google Scholar] [CrossRef]

- Raheem, A.B.; Noor, Z.Z.; Hassan, A.; Hamid, M.K.A.; Samsudin, S.A.; Sabeen, A.H. Current developments in chemical recycling of post-consumer polyethylene terephthalate wastes for new materials production: A review. J. Clean. Prod. 2019. [Google Scholar] [CrossRef]

- Jamdar, V.; Kathalewar, M.; Dubey, K.A.; Sabnis, A. Recycling of PET wastes using Electron beam radiations and preparation of polyurethane coatings using recycled material. Prog. Org. Coat. 2017, 107, 54–63. [Google Scholar] [CrossRef]

- Masmoudi, F.; Fenouillot, F.; Mehri, A.; Jaziri, M.; Ammar, E. Characterization and quality assessment of recycled post-consumption poly (ethylene terephthalate)(PET). Environ. Sci. Pollut. Res. 2018, 25, 23307–23314. [Google Scholar] [CrossRef] [PubMed]

- Mali, S.; Kadam, S.; Mane, S.; Panchal, K.; Kale, S.; Navkar, Y. Soil stabilization by using plastic waste. Int. Res. J. Eng. Technol. (IRJET) 2019, 6, 4056–4060. [Google Scholar]

- Vijayakumar, A.; Sebastian, J. Pyrolysis process to produce fuel from different types of plastic–a review. In Proceedings of the IOP Conference Series: Materials Science and Engineering, International Conference on Recent Advancements and Effectual Researches in Engineering Science and Technology (RAEREST), Kerala State, India, 20–21 April 2018; p. 012062. [Google Scholar]

- Gurgul, A.; Szczepaniak, W.; Zabłocka-Malicka, M. Incineration and pyrolysis vs. steam gasification of electronic waste. Sci. Total Environ. 2018, 624, 1119–1124. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Lee, Y.; Andrew Lin, K.-Y.; Hong, E.; Kwon, E.E.; Lee, J. The valorization of food waste via pyrolysis. J. Clean. Prod. 2020, 259, 120816. [Google Scholar] [CrossRef]

- Lee, Y.; Kim, S.; Kwon, E.E.; Lee, J. Effect of carbon dioxide on thermal treatment of food waste as a sustainable disposal method. J. Co2 Util. 2020, 36, 76–81. [Google Scholar] [CrossRef]

- Dhyani, V.; Bhaskar, T. A comprehensive review on the pyrolysis of lignocellulosic biomass. Renew. Energy 2018, 129, 695–716. [Google Scholar] [CrossRef]

- Sipra, A.T.; Gao, N.; Sarwar, H. Municipal solid waste (MSW) pyrolysis for bio-fuel production: A review of effects of MSW components and catalysts. Fuel Process. Technol. 2018, 175, 131–147. [Google Scholar] [CrossRef]

- Kwon, E.E.; Kim, S.; Lee, J. Pyrolysis of waste feedstocks in CO2 for effective energy recovery and waste treatment. J. Co2 Util. 2019, 31, 173–180. [Google Scholar] [CrossRef]

- Payne, J.L.; Bhakta, N.N.; Lyons, S.; Mohamed, R.A.; Carroll, K.C.; Brewer, C.E. Potential of pyrolysis of spacecraft solid waste for water recovery and plant-growth media production. J. Anal. Appl. Pyrolysis 2018, 135, 184–188. [Google Scholar] [CrossRef]

- Ding, K.; Zhong, Z.; Zhong, D.; Zhang, B.; Qian, X. Pyrolysis of municipal solid waste in a fluidized bed for producing valuable pyrolytic oils. Clean Technol. Environ. Policy 2016, 18, 1111–1121. [Google Scholar] [CrossRef]

- Kim, S.; Lee, J. Pyrolysis of food waste over a Pt catalyst in Co2 atmosphere. J. Hazard. Mater. 2020, 393, 122449. [Google Scholar] [CrossRef] [PubMed]

- Lam, S.S.; Liew, R.K.; Jusoh, A.; Chong, C.T.; Ani, F.N.; Chase, H.A. Progress in waste oil to sustainable energy, with emphasis on pyrolysis techniques. Renew. Sustain. Energy Rev. 2016, 53, 741–753. [Google Scholar] [CrossRef]

- Miandad, R.; Rehan, M.; Nizami, A.-S.; Barakat, M.A.E.-F.; Ismail, I.M. The energy and value-added products from pyrolysis of waste plastics. In Recycling of Solid Waste for Biofuels and Bio-Chemicals; Springer: Berlin/Heidelberg, Germany, 2016; pp. 333–355. [Google Scholar]

- Doğan-Sağlamtimur, N.; Bilgil, A.; Güven, A.; Ötgün, H.; Yıldırım, E.D.; Arıcan, B. Producing of qualified oil and carbon black from waste tyres and pet bottles in a newly designed pyrolysis reactor. J. Therm. Anal. Calorim. 2019, 135, 3339–3351. [Google Scholar] [CrossRef]

- Bridgwater, A.; Peacocke, G. Fast pyrolysis processes for biomass. Renew. Sustain. Energy Rev. 2000, 4, 1–73. [Google Scholar] [CrossRef]

- Adrados, A.; De Marco, I.; Caballero, B.; López, A.; Laresgoiti, M.; Torres, A. Pyrolysis of plastic packaging waste: A comparison of plastic residuals from material recovery facilities with simulated plastic waste. Waste Manag. 2012, 32, 826–832. [Google Scholar] [CrossRef]

- Zhou, H.; Wu, C.; Onwudili, J.A.; Meng, A.; Zhang, Y.; Williams, P.T. Polycyclic aromatic hydrocarbons (PAH) formation from the pyrolysis of different municipal solid waste fractions. Waste Manag. 2015, 36, 136–146. [Google Scholar] [CrossRef]

- Kim, S.; Park, C.; Lee, J. Reduction of polycyclic compounds and biphenyls generated by pyrolysis of industrial plastic waste by using supported metal catalysts: A case study of polyethylene terephthalate treatment. J. Hazard. Mater. 2020, 392, 122464. [Google Scholar] [CrossRef]

- Lee, J.; Lee, T.; Tsang, Y.F.; Oh, J.-I.; Kwon, E.E. Enhanced energy recovery from polyethylene terephthalate via pyrolysis in CO2 atmosphere while suppressing acidic chemical species. Energy Convers. Manag. 2017, 148, 456–460. [Google Scholar] [CrossRef]

- Gbeddy, G.; Goonetilleke, A.; Ayoko, G.A.; Egodawatta, P. Transformation and degradation of polycyclic aromatic hydrocarbons (PAHs) in urban road surfaces: Influential factors, implications and recommendations. Environ. Pollut. 2019, 113510. [Google Scholar] [CrossRef]

- Abdel-Shafy, H.I.; Mansour, M.S. A review on polycyclic aromatic hydrocarbons: Source, environmental impact, effect on human health and remediation. Egypt. J. Pet. 2016, 25, 107–123. [Google Scholar] [CrossRef]

- Martínez, J.D.; Puy, N.; Murillo, R.; García, T.; Navarro, M.V.; Mastral, A.M. Waste tyre pyrolysis—A review. Renew. Sustain. Energy Rev. 2013, 23, 179–213. [Google Scholar] [CrossRef]

- Lee, J.; Kwon, E.E.; Park, Y.-K. Recent advances in the catalytic pyrolysis of microalgae. Catal. Today 2019. [Google Scholar] [CrossRef]

- Kim, S.; Kwon, E.E.; Kim, Y.T.; Jung, S.; Kim, H.J.; Huber, G.W.; Lee, J. Recent advances in hydrodeoxygenation of biomass-derived oxygenates over heterogeneous catalysts. Green Chem. 2019, 21, 3715–3743. [Google Scholar] [CrossRef]

- Kim, S.; Tsang, Y.F.; Kwon, E.E.; Lin, K.-Y.A.; Lee, J. Recently developed methods to enhance stability of heterogeneous catalysts for conversion of biomass-derived feedstocks. Korean J. Chem. Eng. 2019, 36, 1–11. [Google Scholar] [CrossRef]

- Kobayashi, H.; Fukuoka, A. Chapter 2 - Current Catalytic Processes for Biomass Conversion. In New and Future Developments in Catalysis; Suib, S.L., Ed.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 29–52. [Google Scholar]

- Kim, S.; Lee, C.-G.; Kim, Y.T.; Kim, K.-H.; Lee, J. Effect of Pt catalyst on the condensable hydrocarbon content generated via food waste pyrolysis. Chemosphere 2020, 248, 126043. [Google Scholar] [CrossRef]

- He, C.; Li, J.; Zhang, X.; Yin, L.; Chen, J.; Gao, S. Highly active Pd-based catalysts with hierarchical pore structure for toluene oxidation: Catalyst property and reaction determining factor. Chem. Eng. J. 2012, 180, 46–56. [Google Scholar] [CrossRef]

- Li, P.; He, C.; Cheng, J.; Ma, C.Y.; Dou, B.J.; Hao, Z.P. Catalytic oxidation of toluene over Pd/Co3AlO catalysts derived from hydrotalcite-like compounds: Effects of preparation methods. Appl. Catal. B Environ. 2011, 101, 570–579. [Google Scholar] [CrossRef]

- Baeckvall, J.E.; Bjoerkman, E.E.; Pettersson, L.; Siegbahn, P.; Strich, A. A theoretical study of the cyclopropane ring opening by palladium. J. Am. Chem. Soc. 1985, 107, 7408–7412. [Google Scholar] [CrossRef]

- Liu, F.; Audemar, M.; De Oliveira Vigier, K.; Clacens, J.M.; De Campo, F.; Jérôme, F. Palladium/carbon dioxide cooperative catalysis for the production of diketone derivatives from carbohydrates. ChemSusChem 2014, 7, 2089–2093. [Google Scholar] [CrossRef]

- Bartholomew, C.H.; Farrauto, R.J. Fundamentals of Industrial Catalytic Processes, 2nd ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2006. [Google Scholar]

- Nowicki, P. Effect of heat treatment on the physicochemical properties of nitrogen-enriched activated carbons. J. Therm. Anal. Calorim. 2016, 125, 1017–1024. [Google Scholar] [CrossRef]

- Reddy, G.K.; Ling, C.; Peck, T.C.; Jia, H. Understanding the chemical state of palladium during the direct NO decomposition – influence of pretreatment environment and reaction temperature. RSC Adv. 2017, 7, 19645–19655. [Google Scholar] [CrossRef]

- Xiong, H.; Lester, K.; Ressler, T.; Schlögl, R.; Allard, L.F.; Datye, A.K. Metastable Pd ↔ PdO structures during high temperature methane oxidation. Catal. Lett. 2017, 147, 1095–1103. [Google Scholar] [CrossRef]

- Ali, A.; Dreyer, B.; Renz, F.; Tegenkamp, C.; Sindelar, R. Electrospun Polyacrylonitrile Based Carbon Nanofibers: The Role of Creep Stress towards Cyclization and Graphitization. J. Mater. Sci. Eng. 2018, 7, 1000493. [Google Scholar]

- Dhahak, A.; Hild, G.; Rouaud, M.; Mauviel, G.; Burkle-Vitzthum, V. Slow pyrolysis of polyethylene terephthalate: Online monitoring of gas production and quantitative analysis of waxy products. J. Anal. Appl. Pyrolysis 2019, 142, 104664. [Google Scholar] [CrossRef]

- Kumagai, S.; Yamasaki, R.; Kameda, T.; Saito, Y.; Watanabe, A.; Watanabe, C.; Teramae, N.; Yoshioka, T. Aromatic hydrocarbon selectivity as a function of CaO basicity and aging during CaO-catalyzed PET pyrolysis using tandem µ-reactor-GC/MS. Chem. Eng. J. 2018, 332, 169–173. [Google Scholar] [CrossRef]

- Xue, Y.; Johnston, P.; Bai, X. Effect of catalyst contact mode and gas atmosphere during catalytic pyrolysis of waste plastics. Energy Convers. Manag. 2017, 142, 441–451. [Google Scholar] [CrossRef]

- Kumagai, S.; Yamasaki, R.; Kameda, T.; Saito, Y.; Watanabe, A.; Watanabe, C.; Teramae, N.; Yoshioka, T. Tandem μ-reactor-GC/MS for online monitoring of aromatic hydrocarbon production via CaO-catalysed PET pyrolysis. React. Chem. Eng. 2017, 2, 776–784. [Google Scholar] [CrossRef]

- Kharasch, N.; Alston, T.G.; Lewis, H.B.; Wolf, W. The photochemical conversion of o-terphenyl into triphenylene. Chem. Commun. 1965, 242–243. [Google Scholar] [CrossRef]

- Birnbaum, H.; Scott, R. X-Ray Diffraction Studies of the System: Zn2TiO4-NiTiO3. J. Am. Chem. Soc. 1950, 72, 1398–1399. [Google Scholar] [CrossRef]

- Frenklach, M.; Clary, D.W.; Gardiner, W.C., Jr.; Stein, S.E. Effect of fuel structure on pathways to soot. Symp. (Int. ) Combust. 1988, 21, 1067–1076. [Google Scholar] [CrossRef]

- Richter, H.; Howard, J.B. Formation of polycyclic aromatic hydrocarbons and their growth to soot—A review of chemical reaction pathways. Prog. Energy Combust. Sci. 2000, 26, 565–608. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Z.; Chen, Z.; Xu, T.; Liu, Q. Bond cleavage and reactive radical intermediates in heavy tar thermal cracking. Fuel 2018, 233, 420–426. [Google Scholar] [CrossRef]

- Neufeldt, S.R.; Sanford, M.S. Combining Transition Metal Catalysis with Radical Chemistry: Dramatic Acceleration of Palladium-Catalyzed C—H Arylation with Diaryliodonium Salts. Adv. Synth. Catal. 2012, 354, 3517–3522. [Google Scholar] [CrossRef]

- Liu, C.; Qin, Z.-X.; Ji, C.-L.; Hong, X.; Szostak, M. Highly-chemoselective step-down reduction of carboxylic acids to aromatic hydrocarbons via palladium catalysis. Chem. Sci. 2019, 10, 5736–5742. [Google Scholar] [CrossRef]

- Anis, S.; Zainal, Z. Tar reduction in biomass producer gas via mechanical, catalytic and thermal methods: A review. Renew. Sustain. Energy Rev. 2011, 15, 2355–2377. [Google Scholar] [CrossRef]

- Koike, N.; Hosokai, S.; Takagaki, A.; Nishimura, S.; Kikuchi, R.; Ebitani, K.; Suzuki, Y.; Oyama, S.T. Upgrading of pyrolysis bio-oil using nickel phosphide catalysts. J. Catal. 2016, 333, 115–126. [Google Scholar] [CrossRef]

- Malapit, C.A.; Caldwell, D.R.; Sassu, N.; Milbin, S.; Howell, A.R. Pd-Catalyzed Acyl C–O Bond Activation for Selective Ring-Opening of α-Methylene-β-lactones with Amines. Org. Lett. 2017, 19, 1966–1969. [Google Scholar] [CrossRef]

| Metal Content | Metal Dispersion | BET Surface Area | Total Pore Volume | Average Pore Size |

|---|---|---|---|---|

| 5 wt.% | 42% | 1540 m2 g−1 | 0.9 cm3 g−1 | 4 nm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, C.; Kim, S.; Kwon, Y.; Jeong, C.; Cho, Y.; Lee, C.-G.; Jung, S.; Choi, K.-Y.; Lee, J. Pyrolysis of Polyethylene Terephthalate over Carbon-Supported Pd Catalyst. Catalysts 2020, 10, 496. https://doi.org/10.3390/catal10050496

Park C, Kim S, Kwon Y, Jeong C, Cho Y, Lee C-G, Jung S, Choi K-Y, Lee J. Pyrolysis of Polyethylene Terephthalate over Carbon-Supported Pd Catalyst. Catalysts. 2020; 10(5):496. https://doi.org/10.3390/catal10050496

Chicago/Turabian StylePark, Chanyeong, Soosan Kim, Yeonghwan Kwon, Chaehyeon Jeong, Yujin Cho, Chang-Gu Lee, Seungho Jung, Kwon-Young Choi, and Jechan Lee. 2020. "Pyrolysis of Polyethylene Terephthalate over Carbon-Supported Pd Catalyst" Catalysts 10, no. 5: 496. https://doi.org/10.3390/catal10050496

APA StylePark, C., Kim, S., Kwon, Y., Jeong, C., Cho, Y., Lee, C.-G., Jung, S., Choi, K.-Y., & Lee, J. (2020). Pyrolysis of Polyethylene Terephthalate over Carbon-Supported Pd Catalyst. Catalysts, 10(5), 496. https://doi.org/10.3390/catal10050496