On a Software Framework for Automated Pore Identification and Quantification for SEM Images of Metals

Abstract

1. Introduction

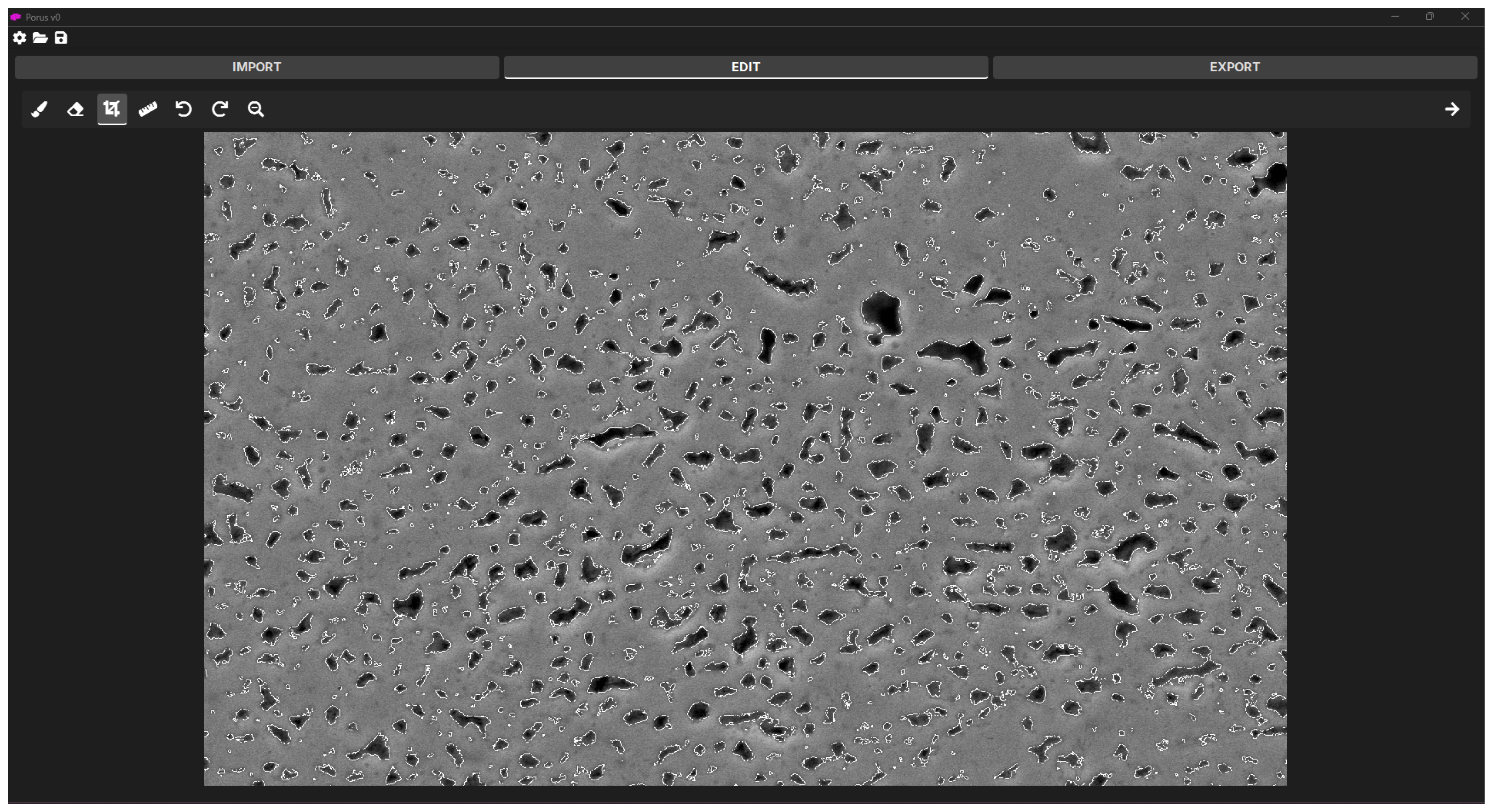

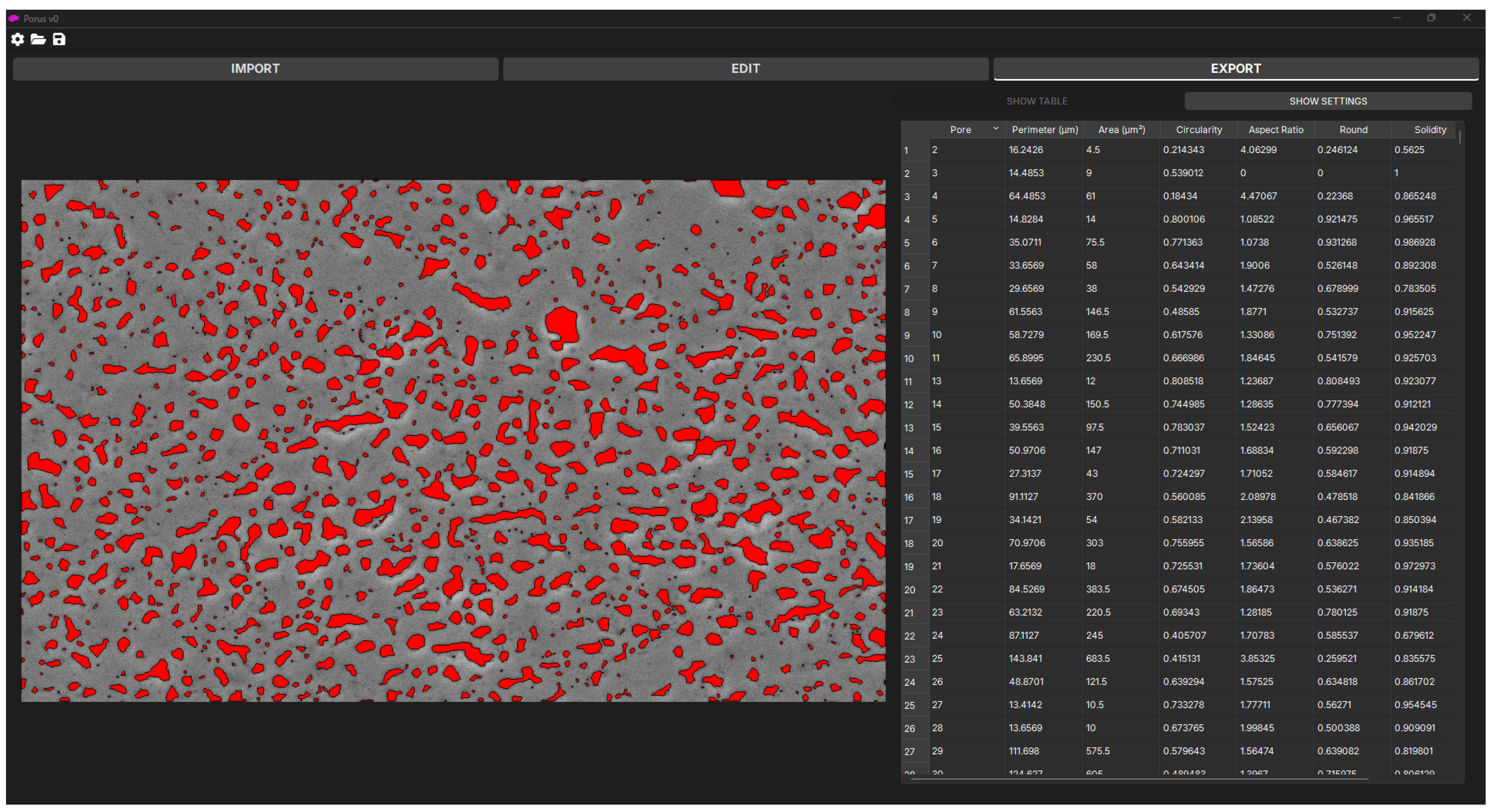

2. PORUS User Interface and Functionalities

3. Methodology

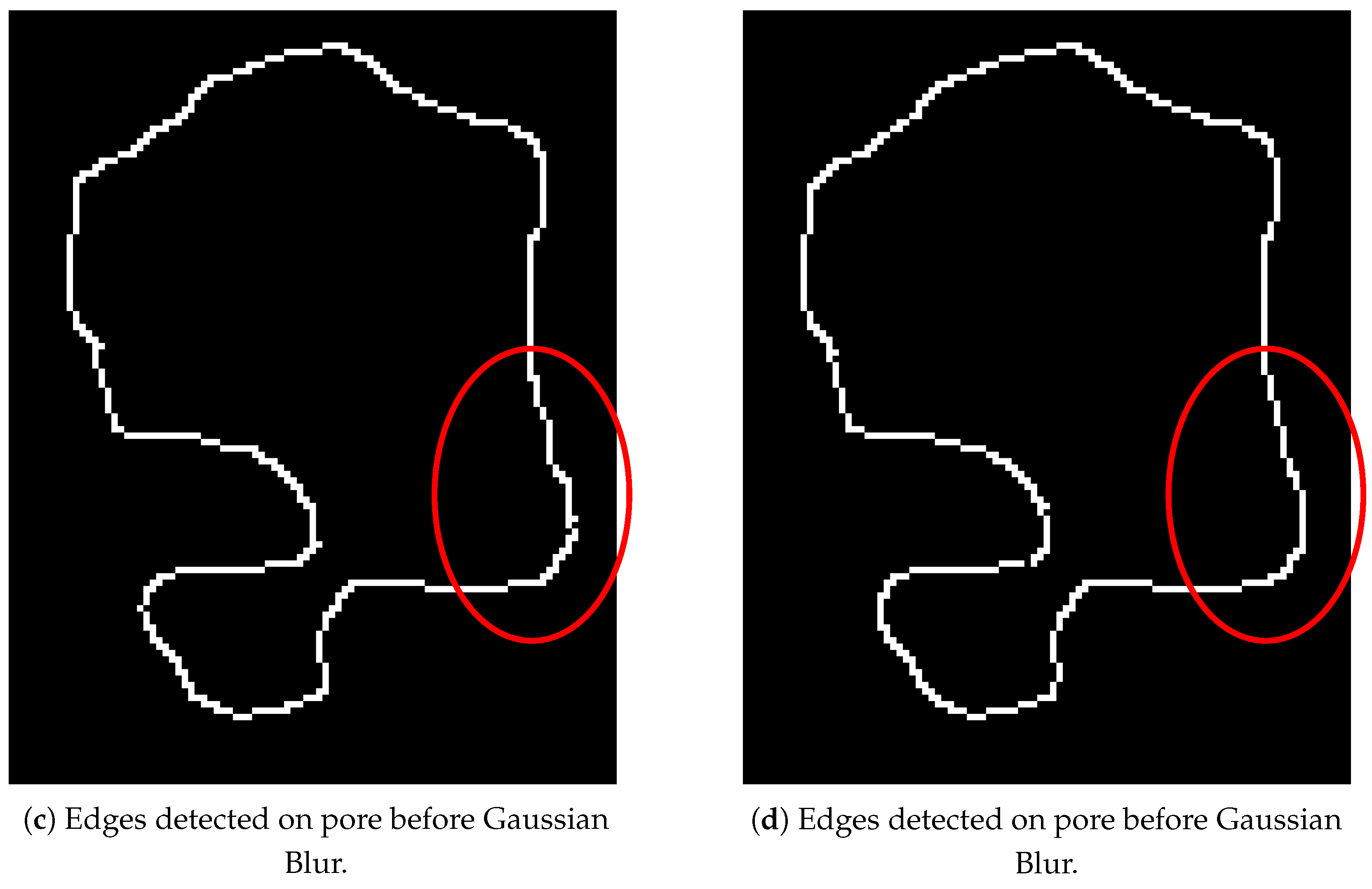

3.1. Material Preparation

3.2. Current Methodology of Image Tracing and Processing

3.3. New Methodology for Image Processing

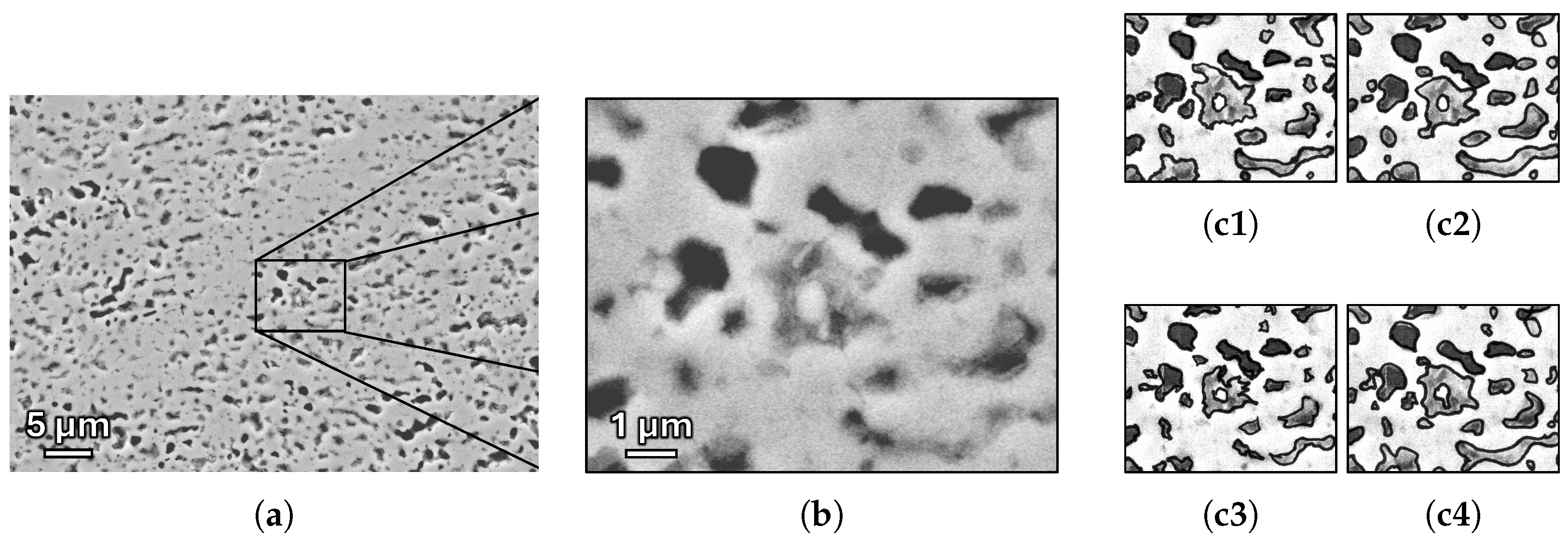

3.3.1. Image Manipulation

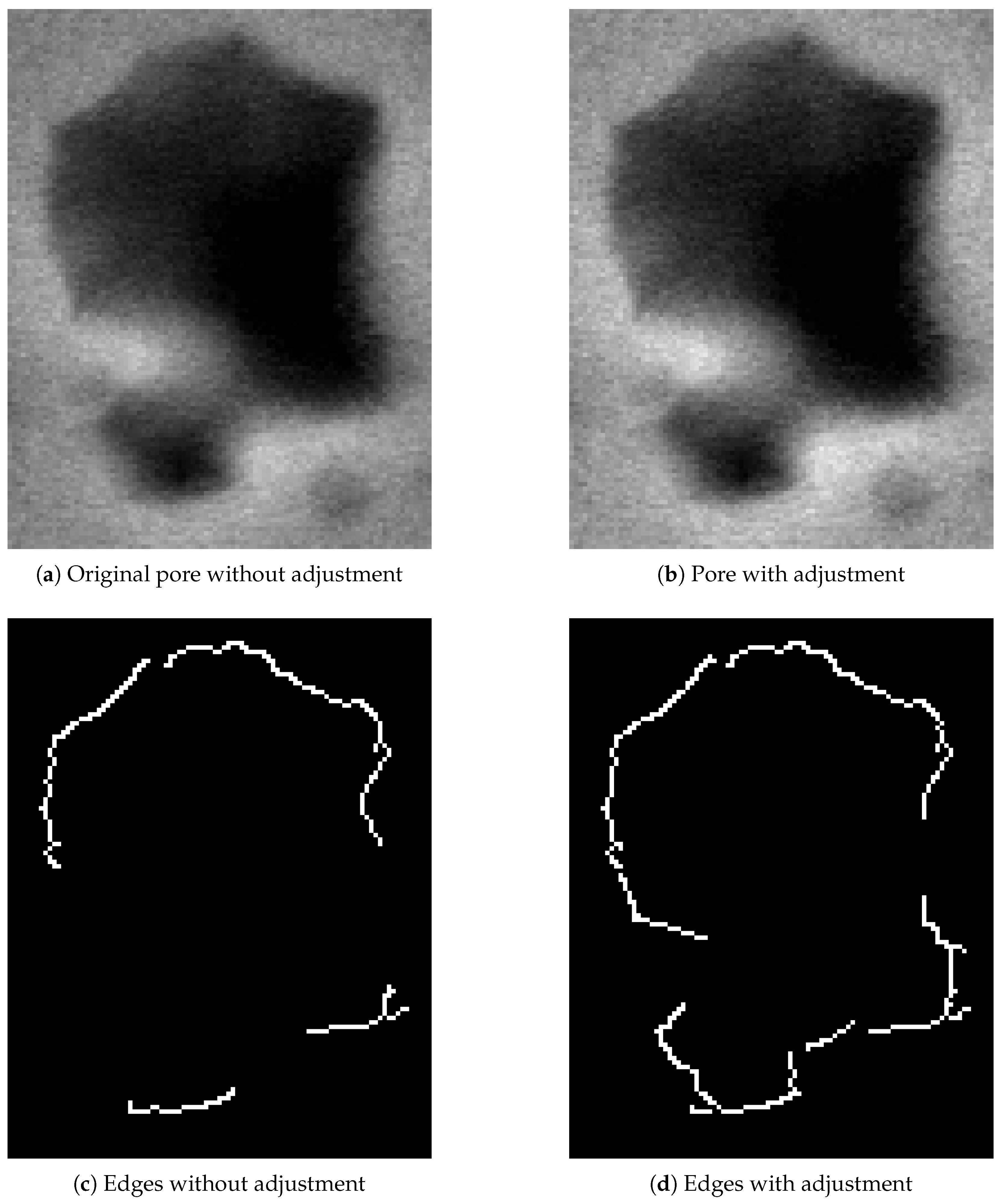

Intensity Clipping and Brightness/Contrast Adjustment

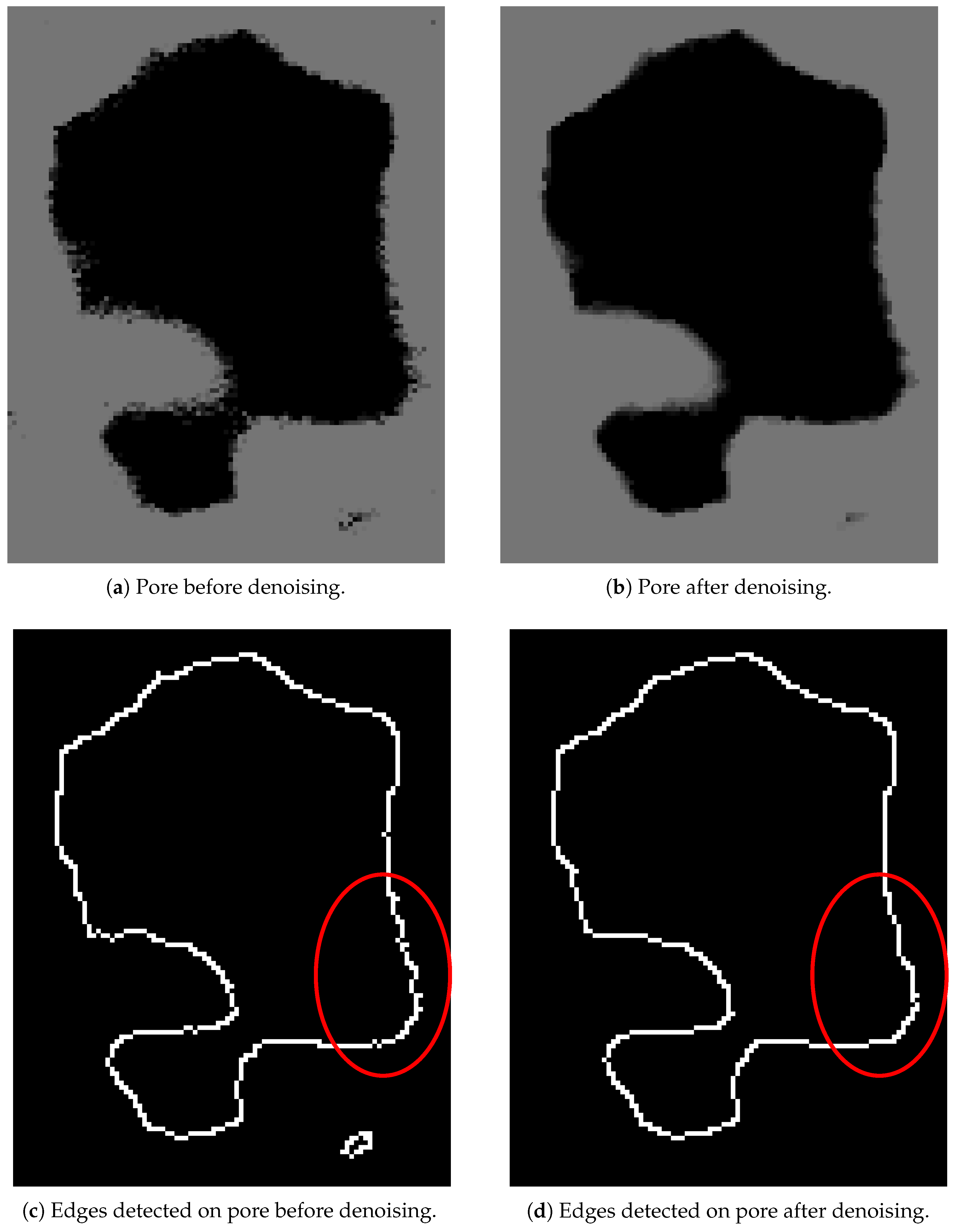

Median Blur (Denoising)

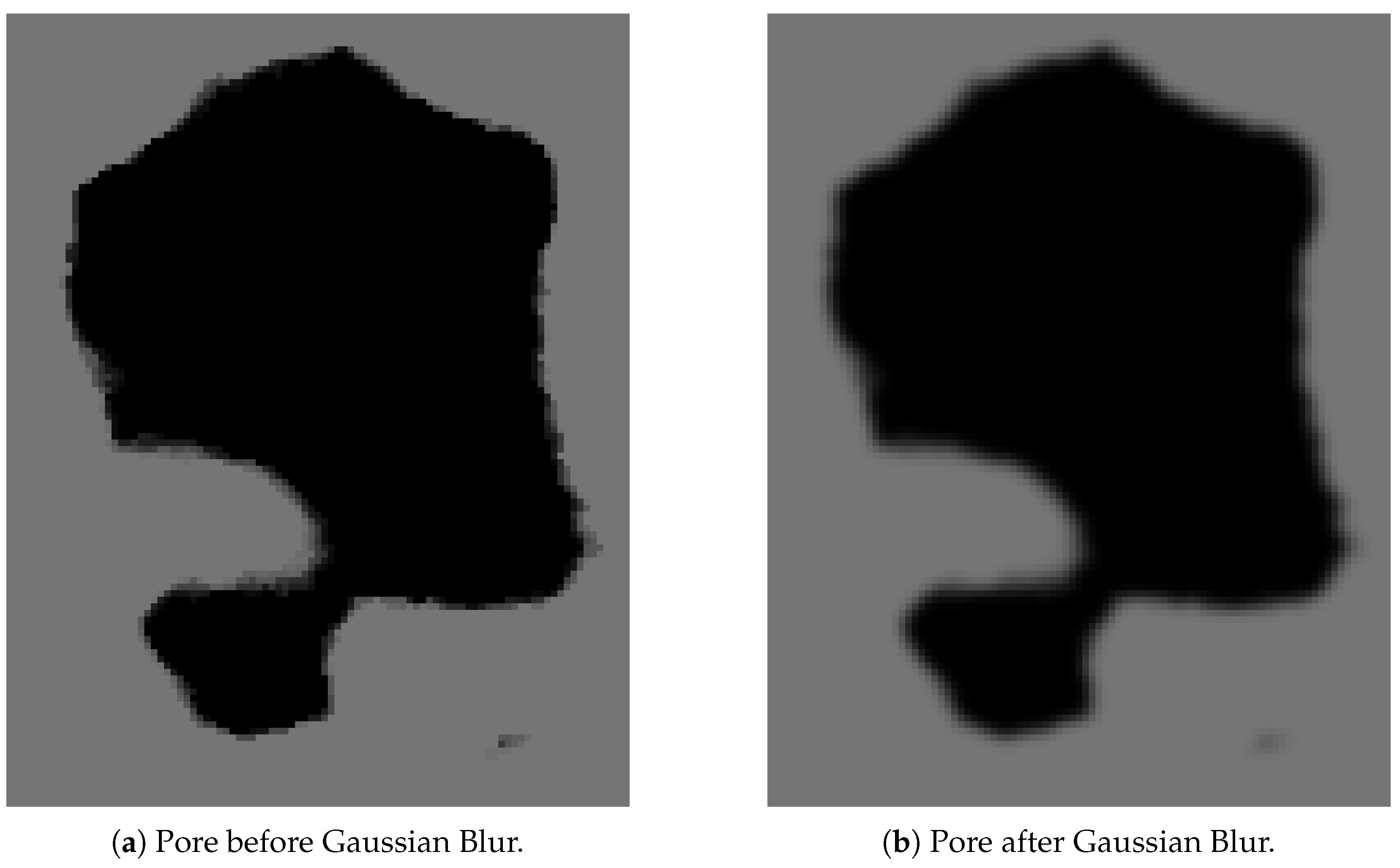

Gaussian Blur

3.3.2. Canny Edge Detection

3.3.3. Morphological Closing

3.3.4. Clean Up

3.4. Pore Characterization

3.4.1. Perimeter

3.4.2. Area

3.4.3. Circularity

3.4.4. Aspect Ratio

3.4.5. Roundness

3.4.6. Solidity

4. Results and Discussion

4.1. Discussion

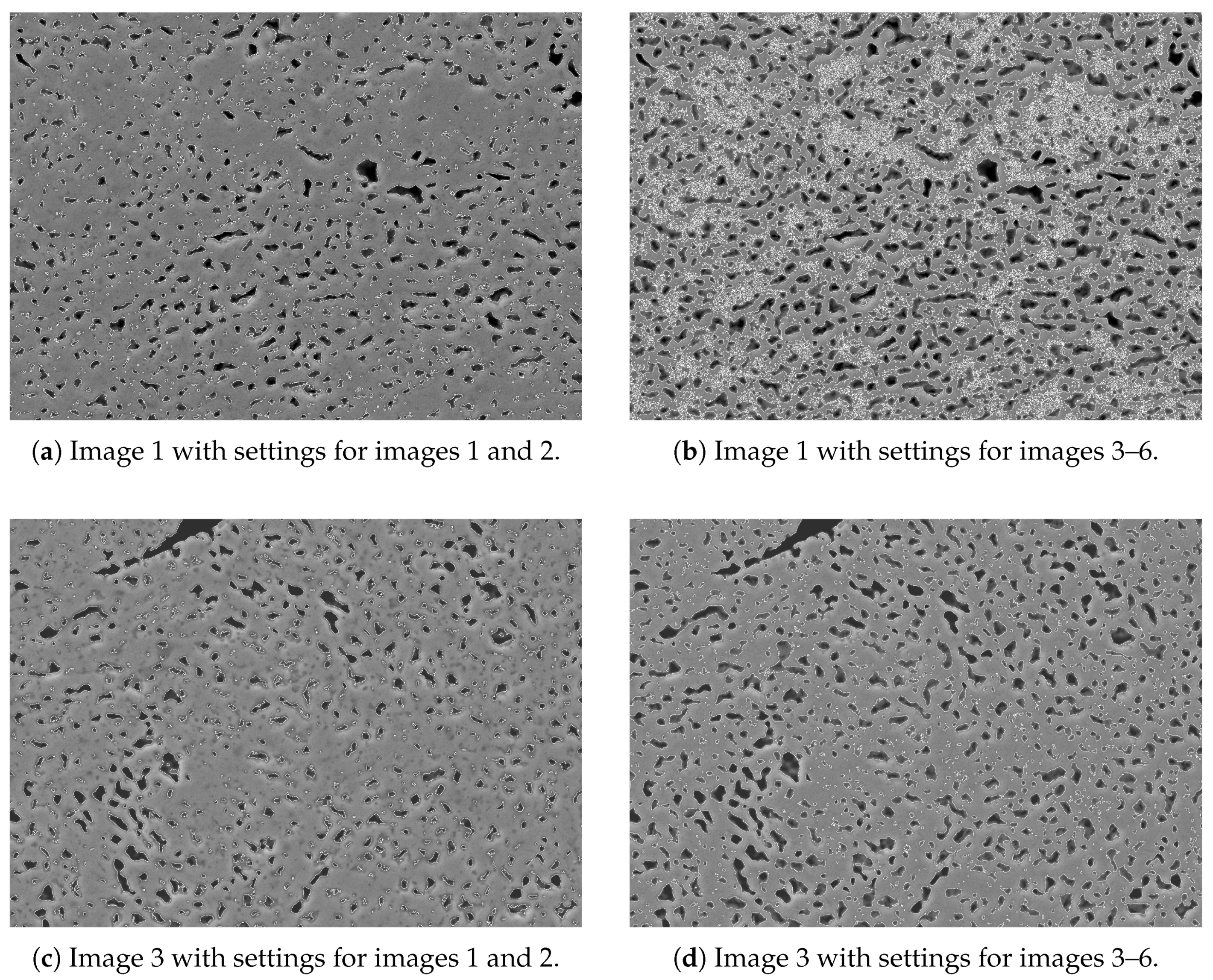

4.2. Qualitative Observations in Hand Tracing

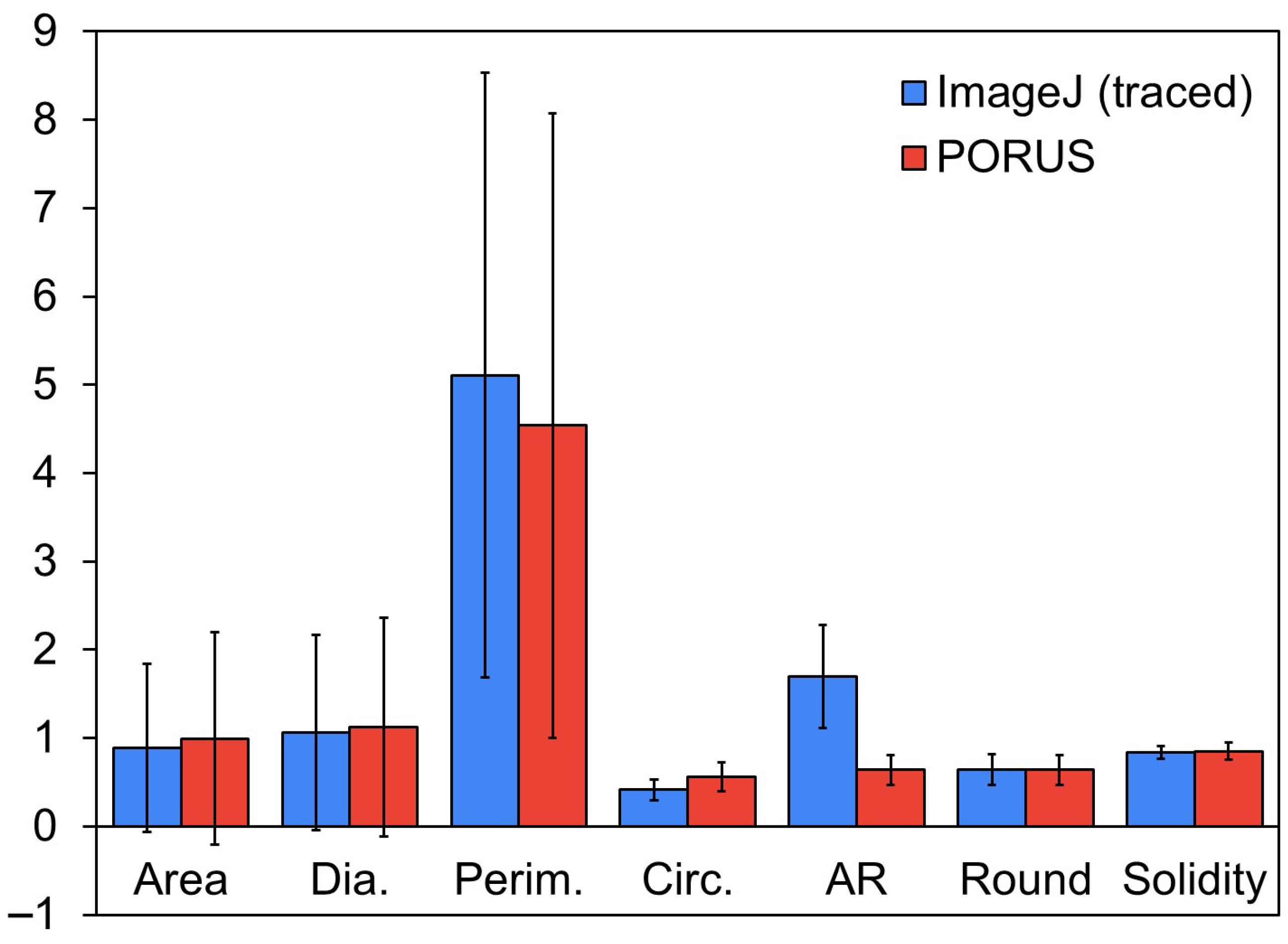

4.3. Quantitative Comparison of Manual and Automated Techniques

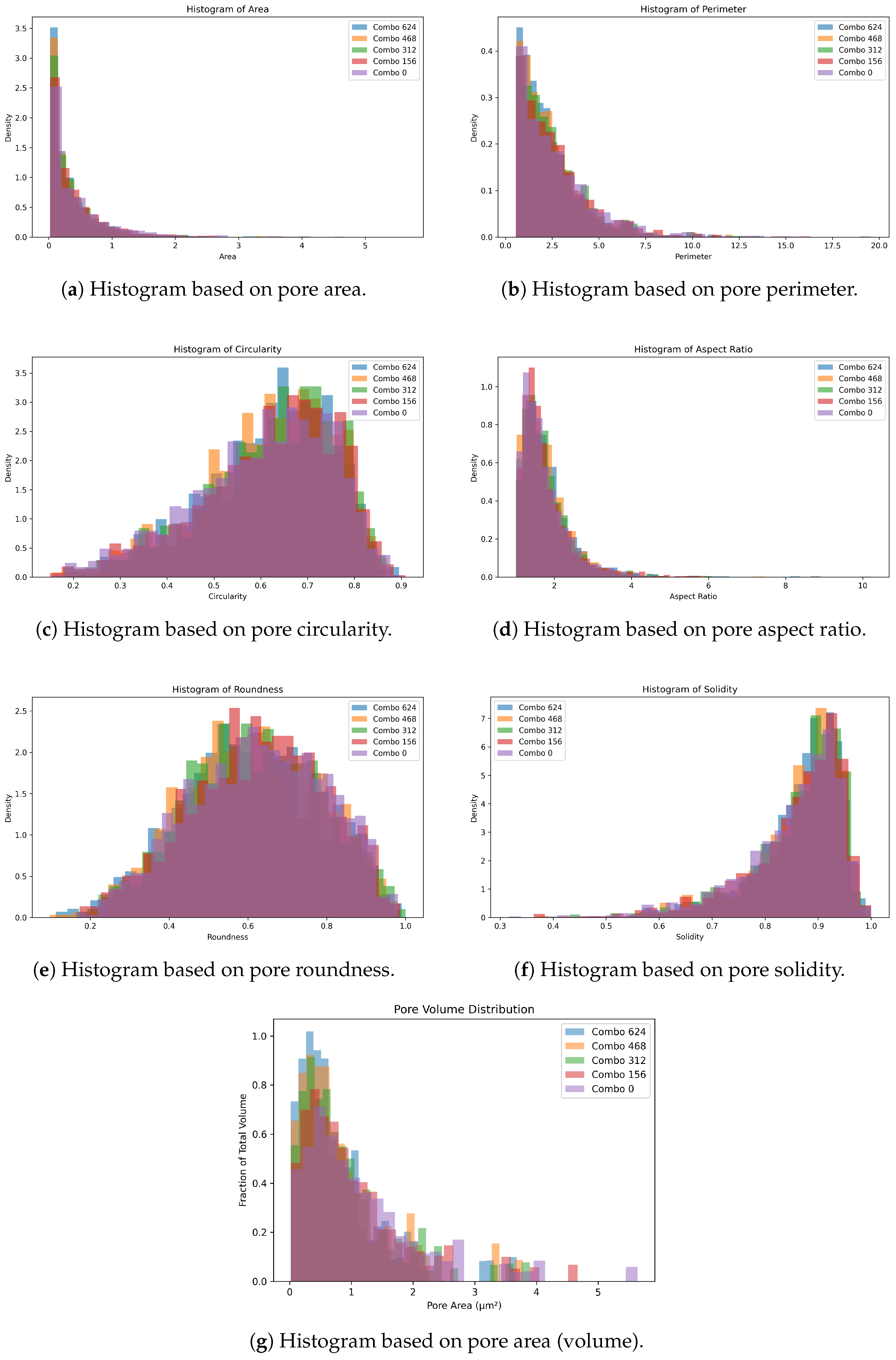

4.4. Sensitivity of Parameter Selection

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SEM | Scanning Electron Microscopy |

References

- García-Moreno, F. Commercial Applications of Metal Foams: Their Properties and Production. Materials 2016, 9, 85. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Mitra, I.; Avila, J.D.; Upadhyayula, M.; Bose, S. Porous metal implants: Processing, properties, and challenges. Int. J. Extrem. Manuf. 2023, 5, 032014. [Google Scholar] [CrossRef] [PubMed]

- Hassan, A.; Alnaser, I.A. A Review of Different Manufacturing Methods of Metallic Foams. ACS Omega 2024, 9, 6280–6295. [Google Scholar] [CrossRef] [PubMed]

- Banhart, J. Manufacture, characterisation and application of cellular metals and metal foams. Prog. Mater. Sci. 2001, 46, 559–632. [Google Scholar] [CrossRef]

- Atwater, M.A.; Guevara, L.N.; Darling, K.A.; Tschopp, M.A. Solid State Porous Metal Production: A Review of the Capabilities, Characteristics, and Challenges. Adv. Eng. Mater. 2018, 20, 1700766. [Google Scholar] [CrossRef]

- JIANG, B.; ZHAO, N.; SHI, C.; LI, J. Processing of open cell aluminum foams with tailored porous morphology. Scr. Mater. 2005, 53, 781–785. [Google Scholar] [CrossRef]

- Gan, Y.X.; Zhang, Y.; Gan, J.B. Nanoporous metals processed by dealloying and their applications. AIMS Mater. Sci. 2018, 5, 1141–1183. [Google Scholar] [CrossRef]

- Jin, H.J.; Han, J.; Chen, Q. Nontraditional dealloying methods, novel nanoporous materials, and new opportunities. MRS Bull. 2025, 50, 608–617. [Google Scholar] [CrossRef]

- Rabiei, A.; Lattimer, B.Y.; Bearinger, E. Recent Advances in the Analysis, Measurement, and Properties of Composite Metal Foams. In Proceedings of the Metal-Matrix Composites; Srivatsan, T.S., Harrigan, W.C., Jr., Hunyadi Murph, S., Eds.; Springer: Cham, Switzerland, 2021; pp. 201–216. [Google Scholar]

- Elmoutaouakkil, A.; Salvo, L.; Maire, E.; Peix, G. 2D and 3D Characterization of Metal Foams Using X-ray Tomography. Adv. Eng. Mater. 2002, 4, 803–807. [Google Scholar] [CrossRef]

- Atwater, M.A.; Darling, K.A.; Tschopp, M.A. Synthesis, characterization and quantitative analysis of porous metal microstructures: Application to microporous copper produced by solid state foaming. AIMS Mater. Sci. 2016, 3, 573–590. [Google Scholar] [CrossRef]

- Yoshida, R.; Mizuta, Y.; Kato, T.; Kimura, T. Comparison of large-volume 3D reconstruction using plasma FIB-SEM and X-ray CT. Microscopy 2024, 73, 354–357. [Google Scholar] [CrossRef]

- Kun, J.E.T.L.; Rutherford, A.P.; Learn, R.S.; Atwater, M.A. Parametric Study of Planetary Milling to Produce Cu-CuO Powders for Pore Formation by Oxide Reduction. Materials 2023, 16, 5407. [Google Scholar] [CrossRef]

- Jones, B.; Kun, J.T.L.; Patterson, E.; Allapatt, N.; Atwater, M. Hybrid Pore Formation in Copper Spheres by Gas Entrapment and Oxide Reduction. Adv. Eng. Mater. 2024, 26, 2301198. [Google Scholar] [CrossRef]

- Canny, J. A Computational Approach to Edge Detection. IEEE Trans. Pattern Anal. Mach. Intell. 1986, PAMI-8, 679–698. [Google Scholar] [CrossRef]

- Cohen, D. Precalculus: A Problems-Oriented Approach; Cengage Learning; Brooks Cole: Pacific Grove, CA, USA, 2004. [Google Scholar]

- Braden, B. The Surveyor’s Area Formula. Coll. Math. J. 1986, 17, 326–337. [Google Scholar] [CrossRef]

- Cox, E.P. A Method of Assigning Numerical and Percentage Values to the Degree of Roundness of Sand Grains. J. Paleontol. 1927, 1, 179–183. [Google Scholar]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- Fitzgibbon, A.; Pilu, M.; Fisher, R. Direct least square fitting of ellipses. IEEE Trans. Pattern Anal. Mach. Intell. 1999, 21, 476–480. [Google Scholar] [CrossRef]

- Graham, R. An efficient algorith for determining the convex hull of a finite planar set. Inf. Process. Lett. 1972, 1, 132–133. [Google Scholar] [CrossRef]

- von Kleist-Retzow, F.T.; Tiemerding, T.; Elfert, P.; Haenssler, O.C. Automated Calibration of RF On-Wafer Probing and Evaluation of Probe Misalignment Effects Using a Desktop Micro-Factory. J. Comput. Commun. 2016, 4, 61–67. [Google Scholar] [CrossRef]

- Papia, E.M.; Kondi, A.; Constantoudis, V. Machine learning applications in SEM-based pore analysis: A review. Microporous Mesoporous Mater. 2025, 394, 113675. [Google Scholar] [CrossRef]

- Leng, Y. Materials Characterization; Wiley: Hoboken, NJ, USA, 2013; pp. 137–139. [Google Scholar] [CrossRef]

| Number | Brightness | Contrast | Minimum Threshold | Maximum Threshold |

|---|---|---|---|---|

| Combo 0 | 90 | 92 | 77 | 92 |

| Combo 156 | 95 | 97 | 81 | 97 |

| Combo 312 | 100 | 102 | 85 | 102 |

| Combo 468 | 105 | 107 | 89 | 94 |

| Combo 624 | 110 | 112 | 94 | 112 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mulligan, M.; Fowler, O.; Voell, J.; Atwater, M.; Fang, H. On a Software Framework for Automated Pore Identification and Quantification for SEM Images of Metals. Computers 2025, 14, 442. https://doi.org/10.3390/computers14100442

Mulligan M, Fowler O, Voell J, Atwater M, Fang H. On a Software Framework for Automated Pore Identification and Quantification for SEM Images of Metals. Computers. 2025; 14(10):442. https://doi.org/10.3390/computers14100442

Chicago/Turabian StyleMulligan, Michael, Oliver Fowler, Joshua Voell, Mark Atwater, and Howie Fang. 2025. "On a Software Framework for Automated Pore Identification and Quantification for SEM Images of Metals" Computers 14, no. 10: 442. https://doi.org/10.3390/computers14100442

APA StyleMulligan, M., Fowler, O., Voell, J., Atwater, M., & Fang, H. (2025). On a Software Framework for Automated Pore Identification and Quantification for SEM Images of Metals. Computers, 14(10), 442. https://doi.org/10.3390/computers14100442