Non-Invasive Sensor Technology for the Development of a Dairy Cattle Health Monitoring System

Abstract

:1. Introduction

2. Background Study

3. Methodology

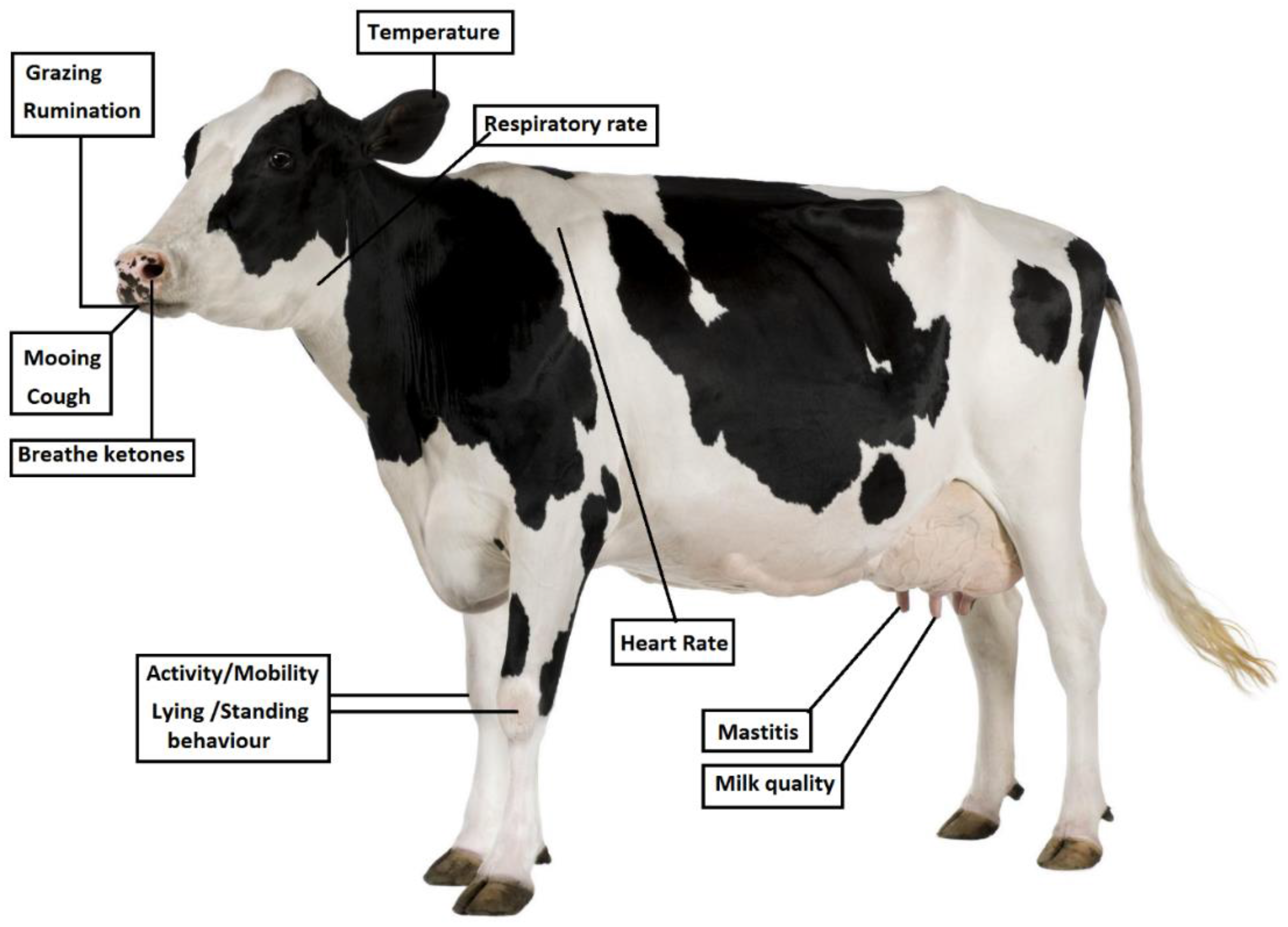

Ontological Relation Study of Diseases and Sensors

- Heartbeat sensor—It also occurs only once in the table. It is not feasible as it can be invasive. The pulse can be felt through an artery in the cow’s neck, near her jaw [31] and also through the facial artery which passes over the mandible near the angle of the jaw. However, this can be difficult to find and requires the animal to keep still [32]. The device will be moving around the neck and hence is not useful if the device has to be non-invasive.

- ECG—It also occurs only once in the table. ECG records the electrical activity of the heart including the timing and duration of each electrical phase in your heartbeat. ECG electrodes have to be placed near to the heart of the cow, immediately behind the withers (third to fourth inter-rib space) and the second electrode in the pericardium area [33].ECG sensor is not included in the box because:

- (a)

- If we place the accelerometer and microphone near to cow’s heart so that we can also include them with ECG sensor in one sensor box, we will not receive good quality activity signal from accelerometer as compared to cow neck as the cow moves her neck more for nearly all activities (e.g., running, grazing etc.) compared to area near cows’ heart (its more static), similarly microphone will also receive less signal (mooing, grazing, rumination etc.) as now it has been placed far away as compared to neck, moreover, as in Table 4, ECG signals appears only once hence it is chosen to keep the sensor box location at neck to receive maximum activity signals.

- (b)

- Smartex, Italy has developed a wearable wellness system for humans [34], which was also tested on horses. This unit has two textile ECG sensor and was able to remove 40% of movement artifacts from 7 h of data [35]. Although this data looks very promising but 7 h is very less testing duration for any conclusion, for our application, at least 720 h of testing is required. Additionally, there is still a huge possibility for the sensors to easily get damaged in mud or cow dung as an adult cow tend to sit more than a horse due to the fact that horses “only have to lie down for an hour or two every few days to meet their minimum REM sleep requirements” [33,36].

- (c)

- Even if one could get a continuously accurate signal from ECG electrodes, it would almost certainly be on a customizable basis only, and the wearability would be characterised as “extremely uncomfortable” for continuous donning.

- (d)

- ECG is only used to detect two diseases in Table 4, which can also be detected by Accelerometer, microphone and temperature sensor. Hence, to conclude we can say that it is possible to have an ECG but it can only be added as an add-on sensor for extra measurements. Though its addition will cause an increased cost [37,38,39].

- Gas sensor—In order to detect any gas, it will have to be placed near to the cows’ mouth, or if placed in the sensor box, it will need an opening, which is not a feasible option as the sensor box should be weather proof to avoid any damages to all other electronic components. Moreover, ketosis can also be monitored be feed intake (grazing and rumination) that an accelerometer and microphone can detect [41].

4. Results, Discussion and Conclusions

- Sensor technique: Measurement of raw data for a cow (e.g., activity, temperature);

- Data Interpretation: Interpretation that condenses change in the sensor data (e.g., increased activity) to fabricate information about the status of the cow (e.g., Oestrus);

- Information Integration: Information can be integrated from other sensors (e.g., data from milking parlour or load cells) as an add-on for decision making; and

Author Contributions

Conflicts of Interest

Abbreviations

| BRD | Bovine Respiratory Disease or Pneumonia |

| BVD | Bovine Viral Diarrhea |

| COD | Cystic Ovarian Disease |

References

- Helwatkar, A.; Riordan, D.; Walsh, J. Sensor Technology for Animal Health Monitoring. In Proceedings of the 8th International Conference on Sensing Technology, Liverpool, UK, 2–4 September 2014.

- Murray, B. Finding the Tools to Achieve Longevity in Canadian Dairy Cows: What Is Longevity? How Do We Measure and What Are the Benchmarks. Available online: http://www.milkproduction.com/Library/Scientific-articles/Management/Finding-the-tools-to-achieve-longevity-in-canadian-dairy-cows/ (accessed on 12 October 2016).

- Project Description|Rotabot. Available online: http://rotabot.eu/?page_id=46 (accessed on 9 October 2016).

- Wells, S.J.; Ott, S.L.; Seitzinger, A.H. Key Health Issues for Dairy Cattle—New and Old. J. Dairy Sci. 1998, 81, 3029–3035. [Google Scholar] [CrossRef]

- Geary, U.; Lopez-Villalobos, N.; O’Brien, B.; Garrick, D.J.; Shalloo, L. Examining the impact of mastitis on the profitability of the Irish dairy industry. Ir. J. Agric. Food Res. 2013, 52, 135–149. [Google Scholar]

- Three Rivers Vet Group. Lameness in Dairy Cows. Available online: http://threeriversvetgroup.co.uk/veterinary-services/farm-animals/info-for-farmers/lameness-in-dairy-cows/ (accessed on 12 October 2016).

- Baldock, C.; Forman, T.; Bill, G.; Taylor, B. New Technologies in the Fight against Transboundary Animal Diseases; FAO: Roma, Italy, 1999. [Google Scholar]

- Herdt, T.H. Ruminant adaptation to negative energy balance: Influences on the etiology of ketosis and fatty liver. Vet. Clin. N. Am. Food Anim. Pract. 2000, 16, 215–230. [Google Scholar] [CrossRef]

- Endres, M. Cow Sensor Technology—Are You Using It? Dairy Extension: University of Minnesota Extension. Available online: http://www.extension.umn.edu/agriculture/dairy/precision-dairy/cow-sensor-technology-are-you-using-it/index.html (accessed on 9 October 2016).

- Cusack, G.; Veterinary, C. Forage and Nutrition Guide 2012: Economic Cost of Lameness in Irish Dairy Herds. Available online: http://www.xlvets.ie/sites/xlvets.ie/files/press-article-files/XLVets%2520Article%2520Forage%2520Guide%25202012.pdf (accessed on 9 October 2016).

- Egan, M. Moorepark’13 Irish Dairying|Harvesting the Potential. Available online: https://www.teagasc.ie/media/website/publications/2013/2788/Moorepark2013.pdf (accessed on 9 October 2016).

- Johnson, C.J. Cystic Ovarian Disease in Cattle on Dairies in Central and Western Ohio: Ultrasonic, Hormonal, Histologic, and Metabolic Assessments. Ph.D. Thesis, The Ohio State University, Columbus, OH, USA, 2004. [Google Scholar]

- Carambeí, L.E.M. Economic impact of displaced abomasum on a dairy farm in carambeí, paraná. ARS Vet. Jaboticabal 2013, 29, 8–12. (In Portuguese) [Google Scholar]

- DairyCo. Displaced Abomasum. DairyCo Technical Information. Available online: http://dairy.ahdb.org.uk/technical-information/animal-health-welfare/biosecurity-and-diseases/diseases/displaced-abomasum/#.V_OKVvkrJD8 (accessed on 9 October 2016).

- Larven, R. Acetonaemia. NADIS—National Animal Disease Information Service. Available online: http://www.nadis.org.uk/bulletins/acetonaemia.aspx (accessed on 9 October 2016).

- The Cattle Site. Cattle Disease Guide—Acetonaemia (Ketosis). Available online: http://www.thecattlesite.com/diseaseinfo/194/acetonaemia-ketosis/ (accessed on 9 October 2016).

- Dupchak, K. Preventing Milk Fevers. Engormix. Available online: http://en.engormix.com/MA-dairy-cattle/health/articles/preventing-milk-fevers-t21/p0.htm (accessed on 9 October 2016).

- Queensland Government. Milk Fever: The State of Queensland (Department of Agriculture, Fisheries and Forestry). 2010. Available online: https://www.daf.qld.gov.au/animal-industries/dairy/health-management-and-diseases/milk-fever (accessed on 9 October 2016). [Google Scholar]

- Adams, R.; Ishler, V.; Moore, D. Trouble-Shooting Milk Fever and Downer Cow Problems. Available online: http://extension.psu.edu/animals/dairy/nutrition/nutrition-and-feeding/nutrition-and-health/trouble-shooting-milk-fever-and-downer-cow-problems (accessed on 9 October 2016).

- Vetoquinol. How Much Are Retained Placentas Costing You? Vetoquinol UK Limited. Available online: https://www.yumpu.com/en/document/view/47622396/how-much-are-retained-placentas-costing-you-vetoquinol (accessed on 9 October 2016).

- Joosten, I.; Stelwagen, J.; Dijkhuizen, A.A. Economic and reproductive consequences of retained placenta in dairy cattle. Vet. Rec. 1988, 123, 53–57. [Google Scholar] [CrossRef] [PubMed]

- Guard, C. Retained Placenta: Causes and Treatments. Adv. Dairy Technol. 1999, 11, 81–86. [Google Scholar]

- The Cattle Site. Retained Placenta—The Cattle Site. 5m Publishing. Available online: http://www.thecattlesite.com/diseaseinfo/232/retained-placenta/ (accessed on 9 October 2016).

- Stott, A.W.; Humphry, R.W.; Gunn, G.J.; Higgins, I.; Hennessy, T.; O’Flaherty, J.; Graham, D.A. Predicted costs and benefits of eradicating BVDV from Ireland. Ir. Vet. J. 2012, 65. [Google Scholar] [CrossRef] [PubMed]

- Jain, D.A. Management of Diarrhoea in Dairy Animals. Engormix, Dairy Cattle, 2011. Available online: http://en.engormix.com/MA-dairy-cattle/dairy-industry/articles/diarrhoea-in-dairy-t1607/472-p0.htm (accessed on 9 October 2016).

- Zoetis. Management of Bovine Respiratory Disease (BRD). Available online: https://www.zoetisus.com/conditions/dairy/bovine-respiratory-disease-_brd_.aspx (accessed on 9 October 2016).

- McDonald’s Europe Flagship Farms. Beef—Upper House Farm, UK. Available online: http://www.flagshipfarms.eu/downloads/casestudies/case_Beef_UK.pdf (accessed on 9 October 2016).

- Zoetis, Dairy Zoetis Proud to Protect. Zoetis Blog, 2014. Available online: http://www.zoetis.ie/diseases-and-conditions/dairy-cattle/index.aspx (accessed on 9 October 2016).

- Wathes, C.M.; Kristensen, H.H.; Aerts, J.-M.; Berckmans, D. Is precision livestock farming an engineer’s daydream or nightmare, an animal’s friend or foe, and a farmer’s panacea or pitfall? Comput. Electron. Agric. 2008, 64, 2–10. [Google Scholar] [CrossRef]

- Porto, S.M.C.; Arcidiacono, C.; Anguzza, U.; Cascone, G. A computer vision-based system for the automatic detection of lying behaviour of dairy cows in free-stall barns. Biosyst. Eng. 2013, 115, 184–194. [Google Scholar] [CrossRef]

- University of Glasgow. Clinical Examination of the Cow—Clinical Examination Routine. Available online: http://www.gla.ac.uk/t4/~vet/files/teaching/clinicalexam/examination/tail.html (accessed on 9 October 2016).

- Freeman, A. Cow-Health-Facts. Cattleforum.com, 2014. Available online: http://www.cattleforum.com/Cow-Health-Facts.html (accessed on 12 Octomber 2016).

- Stoppa, M.; Chiolerio, A. Wearable electronics and smart textiles: A critical review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef] [PubMed]

- Pacelli, M.; Loriga, G.; Taccini, N.; Paradiso, R. Sensing fabrics for monitoring physiological and biomechanical variables: E-textile solutions. In Proceedings of the 3rd IEEE-EMBS International Summer School on Medical Devices and Biosensors, Cambridge, MA, USA, 4–6 September 2006; pp. 1–4.

- Lanata, A.; Guidi, A.; Baragli, P.; Paradiso, R.; Valenza, G.; Scilingo, E.P. Removing movement artifacts from equine ECG recordings acquired with textile electrodes. In Proceedings of the 2015 37th Annual International Conference of the IEEE on Engineering in Medicine and Biology Society (EMBC), Milan, Italy, 25–29 August 2015; pp. 1955–1958.

- An IAC Publishing Labs Company. Do Horses Sit Down? Reference. Available online: https://www.reference.com/pets-animals/horses-sit-down-e412c09b02e6fc54# (accessed on 9 October 2016).

- Cao, S.; Lei, J.; Li, T. A Bioimpedance Measurement System with Low-Power Compressive Sampling Time-Based A/D Converter. Available online: http://mgh-courses.ece.gatech.edu/ece6414/S13/Projects/Team4_Draft1_ECE6414_S13.pdf (accessed on 9 October 2016).

- Journal, A.; Darwish, A. The Impact of Implantable Sensors in Medical Applications. Auatin J. Biosens. Bioelectron. 2016, 2, 1016. [Google Scholar]

- Reinemann, D.J.; Rasmusssen, M.D.; Lemire, S.D. Milking performance of dairy cows subjected to electrical current and induced milking machine problems. Trans. ASAE 2002, 45, 833–838. [Google Scholar] [CrossRef]

- Pastell, M.; Hautala, M.; Poikalainen, V.; Praks, J.; Veermäe, I.; Kujala, M.; Ahokas, J. Automatic observation of cow leg health using load sensors. Comput. Electron. Agric. 2008, 62, 48–53. [Google Scholar] [CrossRef]

- Rutten, C.J.; Velthuis, A.G.J.; Steeneveld, W.; Hogeveen, H. Invited review: Sensors to support health management on dairy farms. Comput. Electron. Agric. 2013, 96, 1928–1952. [Google Scholar] [CrossRef] [PubMed]

- Steeneveld, W.; van der Gaag, L.C.; Ouweltjes, W.; Mollenhorst, H.; Hogeveen, H. Discriminating between true-positive and false-positive clinical mastitis alerts from automatic milking systems. J. Dairy Sci. 2010, 93, 2559–2568. [Google Scholar] [CrossRef] [PubMed]

- Mottram, T. Automatic monitoring of the health and metabolic status of dairy cows. Livest. Prod. Sci. 1997, 48, 209–217. [Google Scholar] [CrossRef]

- Diosdado, J.A.V.; Barker, Z.E.; Hodges, H.R.; Amory, J.R.; Croft, D.P.; Bell, N.J.; Codling, E.A. Classification of behaviour in housed dairy cows using an accelerometer-based activity monitoring system. Anim. Biotelem. 2015, 3. [Google Scholar] [CrossRef]

| Health Events | |

|---|---|

| 1. | Mastitis |

| 2. | Lameness |

| 3. | Cystic Ovarian Disease (COD) |

| 4. | Displaced Abomasum |

| 5. | Ketosis (Acetonaemia) |

| 6. | Milk fever |

| 7. | Retained Placenta |

| 8. | Bovine Viral Diarrhoea (BVD) |

| 9. | Heifer Pneumonia or Bovine Respiratory Disease (BRD) |

| Percentage of Cows by Health Problems | |||

|---|---|---|---|

| Problem | NHAMS Dairy 1996 | NHAMS Dairy | Trend |

| Mastitis | 13.40% | 16.50% | ↑ |

| Lameness | 10.50% | 14.00% | ↑ |

| Infertility problems | 11.60% | 12.90% | ↑ |

| Retained Placenta | 7.80% | 7.80% | ↔ |

| Milk fever | 5.90% | 4.60% | ↓ |

| Displaced abomasum | 2.80% | 3.50% | ↑ |

| Respiratory | 2.50% | 3.30% | ↑ |

| Impact to Farmer | Measurable Indicators | |

|---|---|---|

| Mastitis | €37.6 million (Nationally 2013) Total farm costs (€): 61,085–177,343 [5] | High temperature Reduced mobility Swelling, reddening and hardness of udder Irregularities in milk Diarrhoea, dehydration [5] |

| Lameness | The cost to a typical 100-cow herd are: No. Cows affected: 20 1.4 episodes of lameness @ €296.61 per cow [10] €200/lameness case [11] | Digital or hoof lameness (white line disease, solar haemorrhage, laminitis, slurry heel) Inter-digital infections (digital dermatitis, foul-in-the-foot, inter-digital dermatitis); and Solar ulcers [10] |

| Cystic Ovarian Disease (COD) | Each episode of COD costs the producer $137 per lactation [12] | Appearance of raised tailhead Formation of cyst(s) in the ovary/ovaries Bullying behavior Excessive mounting, standing and bawling with the noticeably deeper tone Inconsistent milk yielding General metabolic changes Rough, dry hair coat Nervous tension Disturbed feeding and rumination [12] |

| Displaced Abomasum | Daily losses of R$17.21 (US$10.12) per sick cow Each animal cost R$417.00 (US$248.00) [13] | Lack of appetite Milk production and rumination reduction are the primarily frequent symptoms Diarrhoea, a distended abdomen and mild colic Twisting (torsion) occurs—a difficulty common in Right Displaced Abomasum Distress Decreased temperature Elevated heart rate Ketones will be present [14] |

| Ketosis (Acetonaemia) | £23,000 per year for every 100 cows [15] | Reduced milk yield Weight loss Reduced appetite Dull coat Acetone (pear drop) smell of breath/or milk Fever Some develop nervous signs including excess salivation, licking, aggression [16] |

| Milk Fever | Exceeds $400 (~280 Euros) per cow [17] | Exhilaration or anxiety Muscle trembles in the head and limbs Stumble Lying Down and can’t stand Lethargy Low body temperature [18,19] |

| Retained Placenta | Total £s per affected cow: 274.00 [20] Loss was 2,139 pounds per year [21] Total average financial loss per case is $206, typical loss of $3,090 per 100 calvings per year [22] | Calf’s membranes fail to separate from the mother cow [23] |

| Bovine Viral Diarrhoea (BVD) | Cost per cow per year €63 Total costs €71.7 million Average of naïve herd costs at €57/cow/year and PI herd costs at €69/cow/year [24] | Weakness and thinning Inappetence Lose watery stool with mucus and sometimes blood Loss of milk production Death if not treated at the right time [25] |

| Heifer Pneumonia or Bovine Respiratory Disease (BRD) | £80 million annually [26] £82 per suckler calf, £43 per dairy bred calf [27,28] Long term cost of disease £243 per animal, £1,008 per annum [28] | Fever Depression Inappetence Serious nasal and eye discharge Purulent nasal discharge Bloody nasal discharge Stiff gait Mild diarrhea Rapid, shallow breathing Soft coughing [26] |

| Disease | Aspect of Animal Health | Behavioural Changes | Sensor |

|---|---|---|---|

| Fever | High temperature | - | Temperature (Neck) |

| Discomfort | Less activity | Accelerometer (Neck) | |

| Bellowing (Distress) | Mooing | Microphone (Neck) | |

| Lameness | Motion changes | Standing or sitting | Accelerometer (Neck, feet, udder) |

| Reduced feed intake | Less grazing | Accelerometer (Neck) | |

| - | Abnormal back arch | Camera (External location) | |

| - | Non-uniform weight division | Load sensor (Under Feet) | |

| Oestrus | Hormone level (e.g., Estrogen, Progesterone) | Restlessness | Accelerometer (around the neck, feet) |

| Yield (Decreased) | Less grazing | Accelerometer (neck, near tail or sacrum) | |

| Standing to be mounted | Increased activity | Accelerometer (around the neck, feet) | |

| Mastitis | Lying behaviour | Less time lying down | Accelerometer (Neck) |

| Reactivity during milking | Stepping, lifting and kicking | Accelerometer (around the neck, feet) | |

| Weight distribution | Weakness/weight shifting | Load sensors (Under Feet) | |

| Pain, Discomfort, Bellowing | Restlessness | Accelerometer (around the neck, feet), Microphone | |

| Reduced feed intake | Less grazing | Accelerometer (Neck) | |

| Ovarian cysts | Hormone level (e.g., Progesterone) | Restlessness and increased activity | Accelerometer (around the neck, feet) |

| Yield | Less/more grazing | Accelerometer (neck, near tail or sacrum) | |

| Bellowing | Mooing | Microphone (Neck) | |

| Temperature | High/low temp | Temperature (Neck) | |

| Milk quality | Electrical conductivity | Electrical conductivity sensor (Udder) | |

| Displaced Abomasum, Ketosis | Feeding | Grazing | Accelerometer (Neck, feet) |

| - | Rumination | Microphone + Accelerometer (Neck) | |

| Breathe ketones | - | Gas sensor (Nose) | |

| Milk Fever, Retained Placenta | Movement/motion | Excitement/stiffness | Accelerometer (Neck) |

| Bellowing | Mooing | Microphone (Neck) | |

| Weight distribution | Weakness/weight shifting | Load sensors (Under Feet) | |

| - | Temperature | Temperature sensor (Neck) | |

| - | Pulse | Heartbeat sensor (Vein on neck), ECG (Near to the heart) | |

| Diarrhoea, Pneumonia | Fever | High temperature | Temperature sensor (Neck) |

| Nasal discharge | Running nose | - | |

| Cough | Coughing sound | Microphone (Neck) | |

| Increased respiratory rate | Sound of breathing | Microphone (Neck) | |

| Decreased appetite | Less grazing/feeding | Accelerometer (Neck) |

| Sensor | Category | Value | ||

|---|---|---|---|---|

| Temperature | Hypothermy | 36.5–38.5 °C (Cold) | ||

| Normothermia | 38.5–39.5 °C (Normal) | |||

| Febricula | 39–40 °C (High) | |||

| Middle fever | 40–41 °C (High) | |||

| Hyperthermy | Over 41 °C (High) | |||

| Posture | Posture Category | Three-Axis Accelerometer | ||

| x | y | z | ||

| Move freely | Variable | Variable | Variable | |

| Do not want to move | Constant | Constant | Constant | |

| Laid down and cannot move | Constant | Constant | Constant | |

| Keep standing | Constant | - | Constant | |

| Limp | Variable | - | Variable | |

| Lift leg up with neck movement | - | - | Variable | |

| S line posture | - | Variable | - | |

| Turn in one direction | Variable | - | - | |

| Stumble | Variable | Variable | - | |

| Cross legs, do not move | Constant | Constant | Constant | |

| Sound | Mooing | Yes | ||

| No | ||||

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Awasthi, A.; Awasthi, A.; Riordan, D.; Walsh, J. Non-Invasive Sensor Technology for the Development of a Dairy Cattle Health Monitoring System. Computers 2016, 5, 23. https://doi.org/10.3390/computers5040023

Awasthi A, Awasthi A, Riordan D, Walsh J. Non-Invasive Sensor Technology for the Development of a Dairy Cattle Health Monitoring System. Computers. 2016; 5(4):23. https://doi.org/10.3390/computers5040023

Chicago/Turabian StyleAwasthi, Amruta, Anshul Awasthi, Daniel Riordan, and Joseph Walsh. 2016. "Non-Invasive Sensor Technology for the Development of a Dairy Cattle Health Monitoring System" Computers 5, no. 4: 23. https://doi.org/10.3390/computers5040023

APA StyleAwasthi, A., Awasthi, A., Riordan, D., & Walsh, J. (2016). Non-Invasive Sensor Technology for the Development of a Dairy Cattle Health Monitoring System. Computers, 5(4), 23. https://doi.org/10.3390/computers5040023