Artificial Intelligence Approach for Waste-Printed Circuit Board Recycling: A Systematic Review

Abstract

1. Introduction

- RQ-1:

- What publicly available datasets are used in WPCB recycling, and what is their significance in deep learning-based computer vision systems?

- RQ-2:

- What are the current state-of-the-art methodologies and frameworks for the automatic disassembly and sorting of WPCBs?

- RQ-3:

- What are the main challenges and potential solutions for automating the disassembly and sorting of WPCBs using machine learning and computer vision?

- Focused Scope: It presents a systematic review specifically centered on AI-driven techniques for WPCB recycling, distinguishing it from broader studies on e-waste.

- Dataset-Centric Analysis: It highlights the role and limitations of available datasets, discussing their relevance, accessibility, and the challenges in training AI models for WPCB-specific tasks.

- Comparative Evaluation of Methods: The review critically compares various machine learning and computer vision approaches used in disassembly, sorting by component recognition, analyzing their suitability and limitations in practical settings.

- Discussion on Industrial Applicability: It examines real-world deployment potential, including scalability and cost-efficiency.

- Identification of Research Gaps: The paper outlines current limitations such as data scarcity, lack of model generalization, and integration issues, and proposes future directions to guide further research.

2. Critical Raw Materials

- Recovery of critical raw materials;

- Critical raw material diplomacy;

- Sustainable sourcing of raw materials.

3. Methodology

3.1. Search Strategies

3.2. Inclusion and Exclusion Criteria

- Articles that focus on WPCB recycling using AI and deep learning techniques.

- Articles that include research on the recovery of CRMs from electronic boards using AI and deep learning techniques.

- Articles that report on major advancements and recent developments in AI and deep learning for WEEE recycling.

- Articles that discuss the challenges and limitations of WEEE recycling techniques.

- Articles that were published in the past 10 years.

- Articles that do not focus on electronic board waste from WEEE.

- Articles that do not include research on AI and deep learning techniques for component level detection and localization of waste PCB.

- Articles that are not in the English language.

- Articles that are not peer-reviewed research papers or conference proceedings.

- Articles that are not published in the past 10 years.

- Articles that do not align with research questions and keywords used in this review.

3.3. Study Selection

3.4. Data Extraction Strategy

4. Datasets (RQ1)

4.1. Role of Artificial Intelligence in WEC Recycling

4.2. Datasets

- Pramerdorfer et al. [25] introduced a public dataset for computer vision-based PCB analysis with an emphasis on recycling-related tasks. It includes 748 high-resolution images of unique PCBs, captured using a DSLR camera under realistic conditions, and provides segmentation and bounding box information for integrated circuit (IC) chips, as well as textual annotations for some ICs.

- Mahalingam et al. [52] proposed a dataset for component-level classification. It includes 984 images from 123 boards, annotated with over 12,000 components: ICs (5844), capacitors (3175), resistors (2670), and inductors (542). This dataset is suitable for training models for WPCB component identification and classification.

- DeepPCB [28] consists of 1500 image pairs annotated for six major PCB defect types. The benchmark model achieved a mean average precision (mAP) of 98.6% at 62 FPS, highlighting its usefulness in high-speed defect detection tasks (https://github.com/tangsanli5201/DeepPCB, accessed on 12 March 2025).

- FICS-PCB [27] includes 9912 images across 31 PCB samples, with 77,347 labeled components spanning six classes. Images are provided in resolutions of 1600 × 1200 and 8256 × 440. The dataset supports both feature engineering and deep learning-based PCB classification.

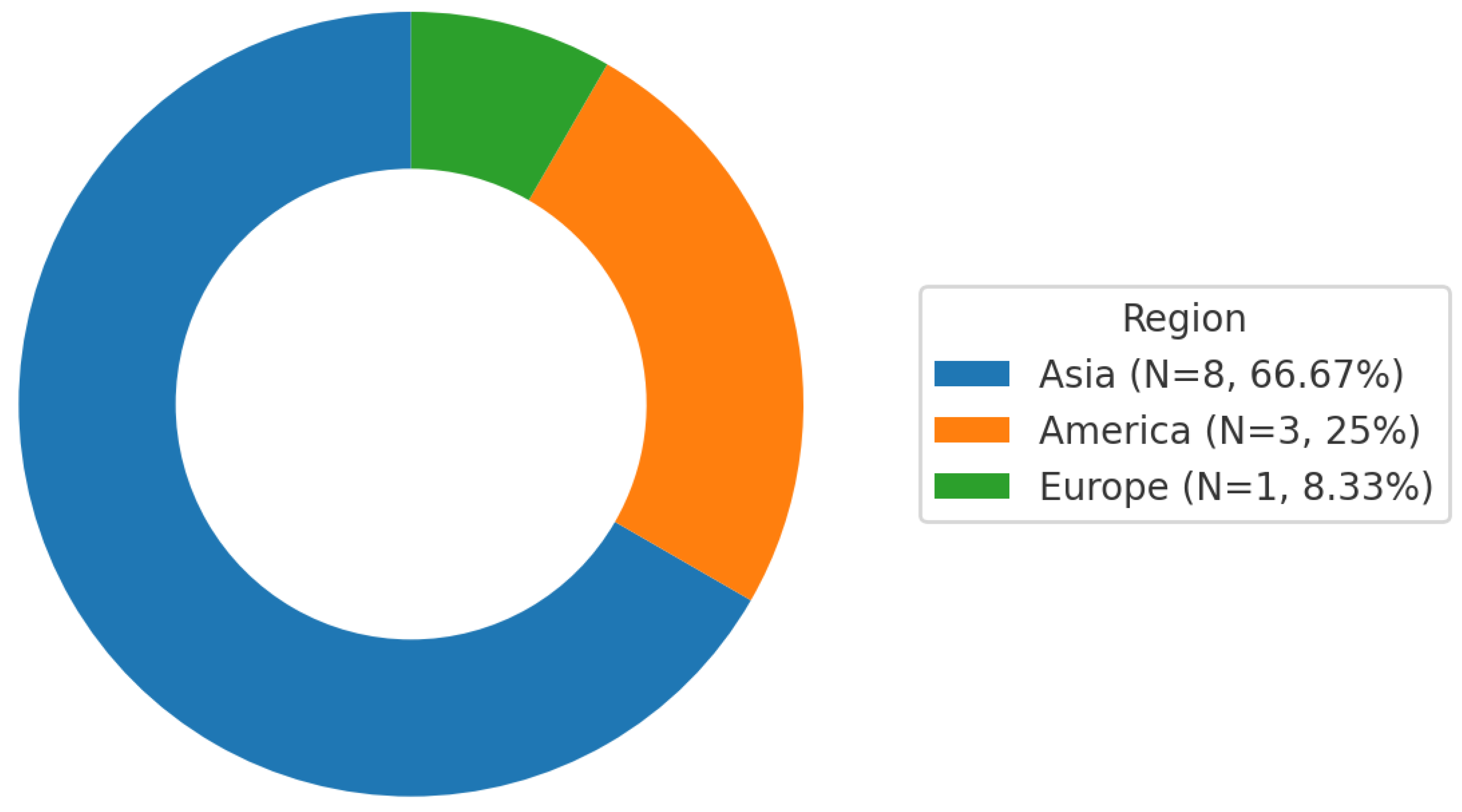

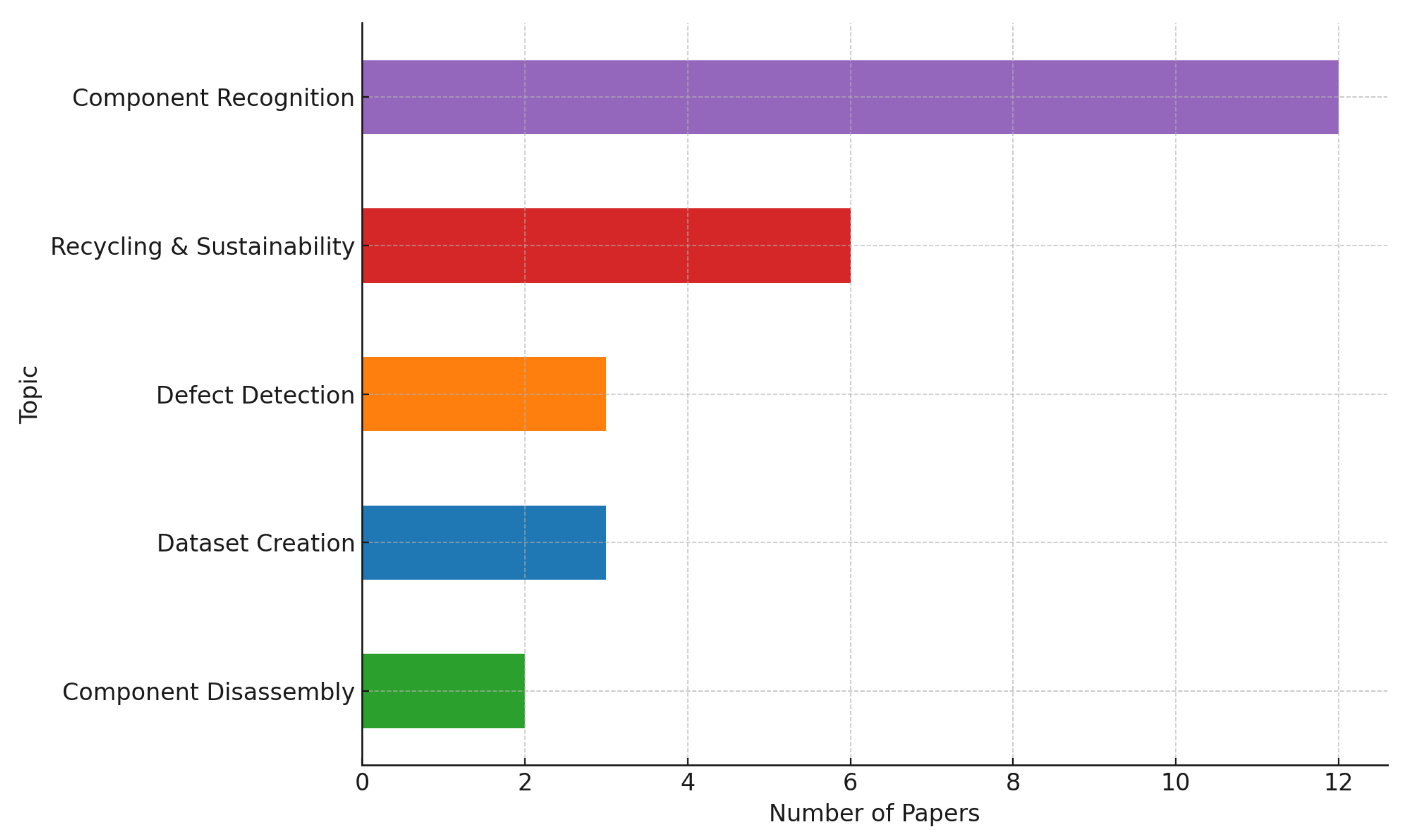

4.3. Results and Discussion

5. Current State of the Art for WPCB Recycling (RQ2)

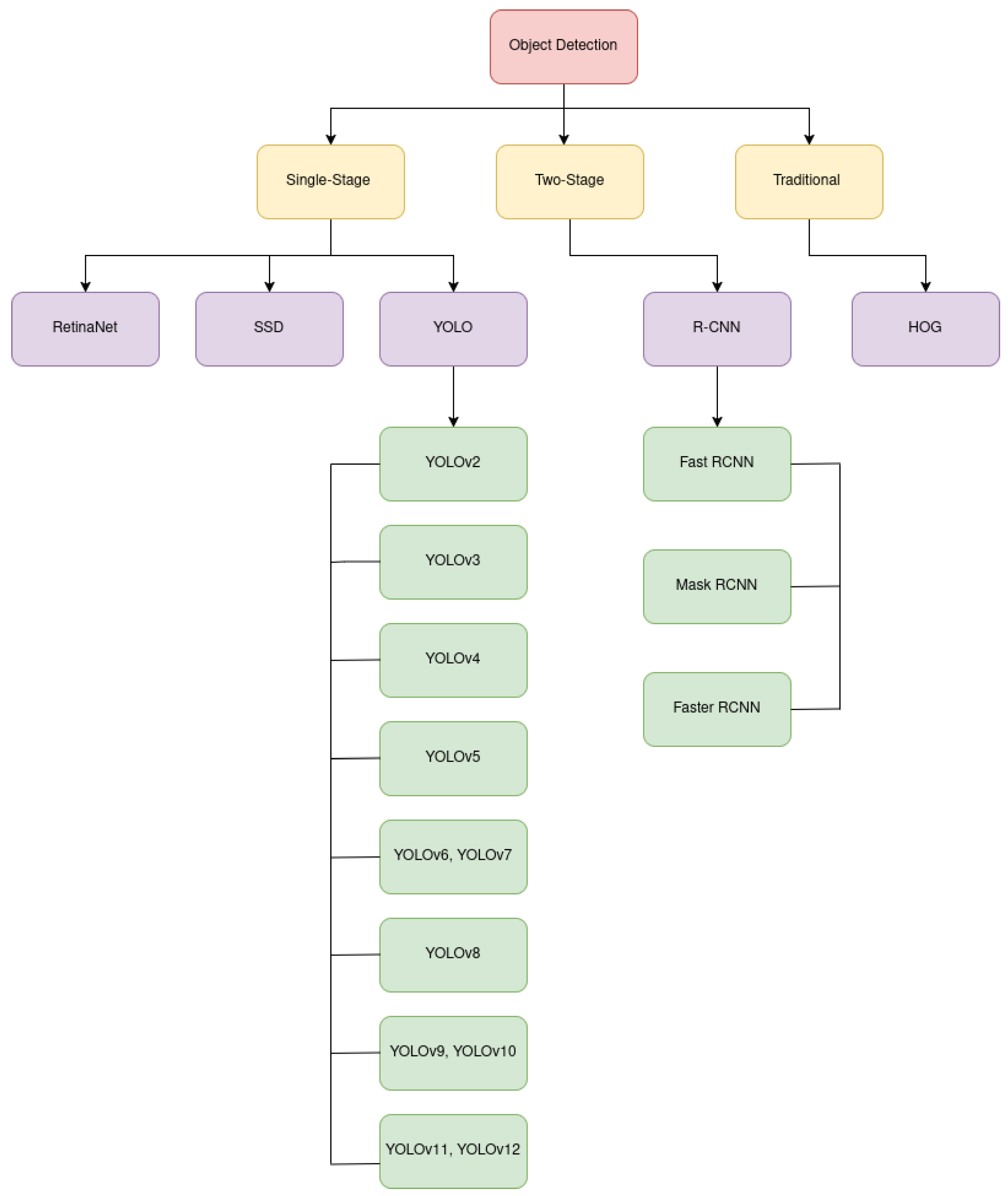

5.1. Object Detection: A Brief Overview

5.1.1. You Only Look Once (YOLO)

5.1.2. Single-Shot MultiBox Detector (SSD)

5.1.3. Region-Based Convolutional Neural Networks (R-CNNs)

5.1.4. RetinaNet

5.1.5. HOG

5.1.6. Automatic Methods for WPCB Recycling

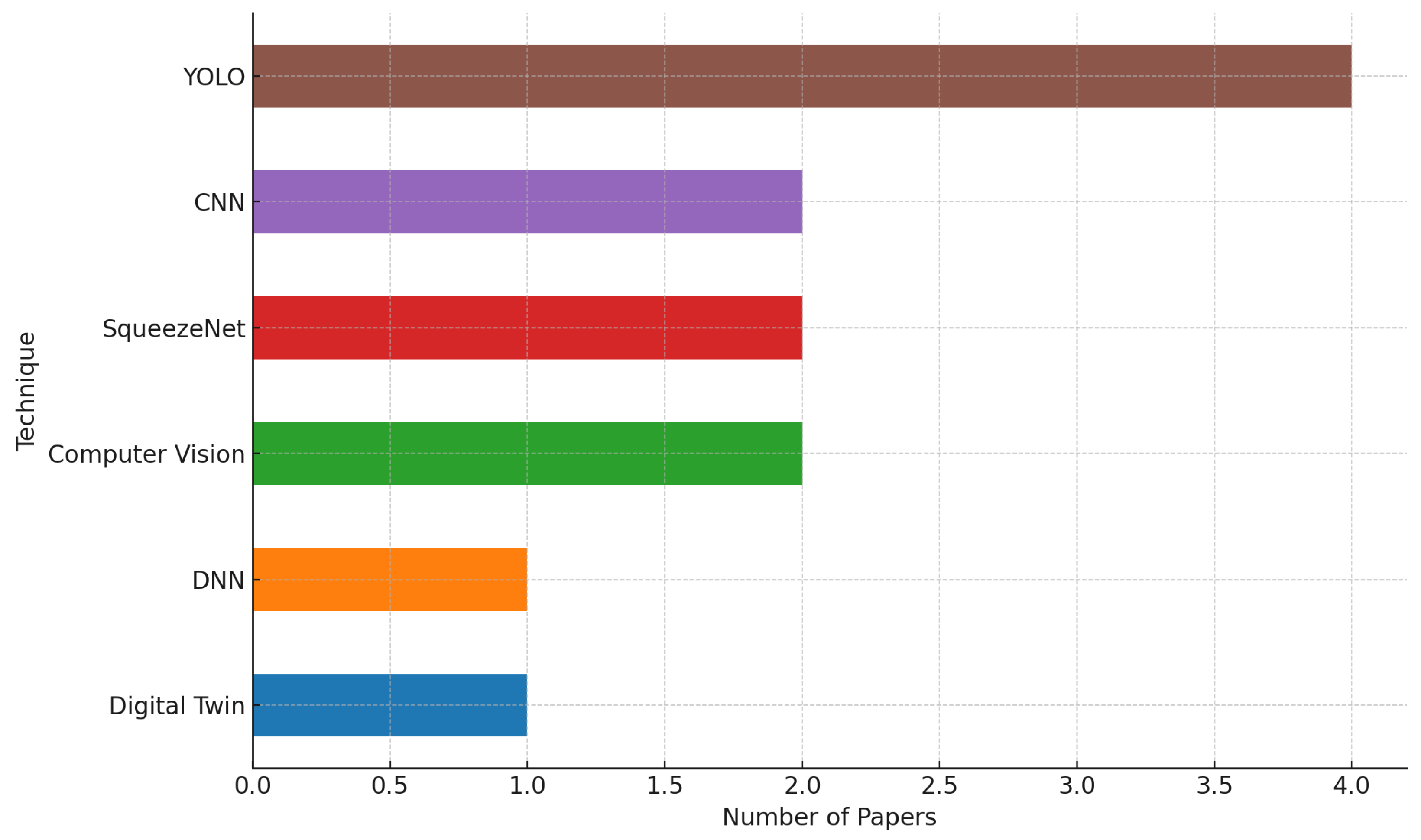

5.2. Results and Discussion

5.3. Critical Analysis of AI Techniques in WPCB Recycling

6. Challenges in the Adaptation of AI-Based Systems in WEC Recycling (RQ3)

6.1. Challenges: Survey of the Literature

6.2. Industrial Adoption and Feasibility

7. Conclusions and Future Directions

7.1. General Conclusions

- Datasets: A review of publicly available datasets relevant to deep learning–based WPCB analysis that highlights their role in supporting electronic component detection, automated disassembly and sorting.

- Methods: An evaluation of state-of-the-art AI techniques used for visual analysis and automatic detection of electronic components, including object detection models and robotic integration.

- Challenges and Solutions: A discussion of the primary technical and practical challenges in vision-based recycling systems and potential AI-driven solutions to improve accuracy, efficiency, and scalability.

7.2. Limitations and Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jung, Y.H.; Zhang, H.; Gong, S.; Ma, Z. High-performance green semiconductor devices: Materials, designs, and fabrication. Semicond. Sci. Technol. 2017, 32, 063002. [Google Scholar] [CrossRef]

- Forti, V.; Baldé, C.P.; Kuehr, R.; Bel, G. The Global e-Waste Monitor 2020. Quantities, Flows, and the Circular Economy Potential; International Telecommunication Union: Geneva, Switzerland, 2020; pp. 1–119. [Google Scholar]

- Waltersmann, L.; Kiemel, S.; Stuhlsatz, J.; Sauer, A.; Miehe, R. Artificial Intelligence Applications for Increasing Resource Efficiency in Manufacturing Companies—A Comprehensive Review. Sustainability 2021, 13, 6689. [Google Scholar] [CrossRef]

- Bressanelli, G.; Saccani, N.; Pigosso, D.C.; Perona, M. Circular Economy in the WEEE industry: A systematic literature review and a research agenda. Sustain. Prod. Consum. 2020, 23, 174–188. [Google Scholar] [CrossRef]

- Wu, C.; Awasthi, A.K.; Qin, W.; Liu, W.; Yang, C. Recycling value materials from waste PCBs focus on electronic components: A review on technologies, obstruction and prospects. J. Environ. Chem. Eng. 2022, 10, 108516. [Google Scholar] [CrossRef]

- Mohsin, M.; Rovetta, S.; Masulli, F.; Cabri, A. Adaptive Multi-Stage Transfer Learning Approach for Electronic Component Detection in Waste Printed Circuit Boards. In Proceedings of the 2025 International Conference on Advanced Sustainability Engineering and Technology (ICASET), Kenitra, Morocco, 17–18 April 2025; pp. 135–142. [Google Scholar]

- Mohsin, M.; Rovetta, S.; Masulli, F.; Cabri, A. Automated Disassembly of Waste Printed Circuit Boards: The Role of Edge Computing and IoT. Computers 2025, 14, 62. [Google Scholar] [CrossRef]

- Mohsin, M.; Rovetta, S.; Masulli, F.; Cabri, A. Virtual Mines–Component-level recycling of printed circuit boards using deep learning. In Proceedings of the 2023 Italian Workshop on Neural Networks (WIRN), Vietri sul Mare, Italy, 7–9 June 2023. [Google Scholar]

- Mohsin, M.; Rovetta, S.; Masulli, F.; Greco, D.; Cabri, A. Deep learning-powered computer vision system for selective disassembly of waste printed circuit boards. In Proceedings of the 2024 IEEE 8th Forum on Research and Technologies for Society and Industry Innovation (RTSI), Lecco, Italy, 18–20 September 2024; pp. 115–119. [Google Scholar]

- Mohsin, M.; Zeng, X.; Rovetta, S.; Masulli, F. Measuring the recyclability of electronic components to assist automatic disassembly and sorting waste printed circuit boards. arXiv 2024, arXiv:2406.16593. [Google Scholar] [CrossRef]

- European Commission. Roadmap to a Resource Efficient Europe; Communication of the European Commission; European Environment Agency: Copenhagen, Denmark, 2011.

- Commission of the European Communities. The Raw Materials Initiative—Meeting Our Critical Needs for Growth and Jobs in Europe; Communication of the European Commission; Commission of the European Communities: Brussels, Belgium, 2008. [Google Scholar]

- Urban Mine Platform. Weight of EEE per Capita. Available online: http://www.urbanmineplatform.eu/urbanmine/eee/weightpercapita (accessed on 15 April 2025).

- European Commission. Tackling the Challenges in Commodity Markets and on Raw Materials; Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; European Commission: Brussels, Belgium, 2011; 25.

- European Commission. On the Review of the List of Critical Raw Materials for the EU and the Implementation of the Raw Materials Initiative; Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; European Commission: Brussels, Belgium, 2014; 297.

- European Commission. On the 2017 List of Critical Raw Materials for the EU; Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; European Commission: Brussels, Belgium, 2017; 490.

- European Commission. Critical Raw Materials Resilience: Charting a Path Towards Greater Security and Sustainability; Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; European Commission: Brussels, Belgium, 2020; 474.

- Grohol, M.; Veeh, C. Study on the Critical Raw Materials for the EU 2023; Final Report DG GROW; European Commission: Brussels, Belgium, 2023.

- European Commission, Joint Research Centre (JRC). EU Critical Raw Materials. 2023. Available online: https://op.europa.eu/en/publication-detail/-/publication/57318397-fdd4-11ed-a05c-01aa75ed71a1 (accessed on 12 March 2025).

- Vafeas, N.; Slezak, P.; Hitzman, M. Analysis of critical raw materials policy for electrical and electronic equipment: Planning for a truly circular economy. Resour. Policy 2024, 99, 105380. [Google Scholar] [CrossRef]

- Bobba, S.; Carrara, S.; Huisman, J.; Mathieux, F.; Pavel, C. Critical Raw Materials for Strategic Technologies and Sectors in the EU. A Foresight Study; IRIS: Porto, Portugal, 2020. [Google Scholar]

- ComponentSense. Rare Earth Elements and Electronic Components: Your Questions Answered. 2023. Available online: https://www.componentsense.com/blog/rare-earth-elements-and-electronic-components-your-questions-answered (accessed on 7 March 2025).

- Resource Hub for Technical Documents and Datasheets. Available online: https://accuristech.com/resources/ (accessed on 10 May 2025).

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. Ann. Intern. Med. 2009, 151, 264–269. [Google Scholar] [CrossRef]

- Pramerdorfer, C.; Kampel, M. A dataset for computer-vision-based PCB analysis. In Proceedings of the 2015 14th IAPR International Conference on Machine Vision Applications (MVA), Tokyo, Japan, 18–22 May 2015; pp. 378–381. [Google Scholar]

- Huang, W.; Wei, P. A PCB dataset for defects detection and classification. arXiv 2019, arXiv:1901.08204. [Google Scholar] [CrossRef]

- Lu, H.; Mehta, D.; Paradis, O.; Asadizanjani, N.; Tehranipoor, M.; Woodard, D.L. Fics-pcb: A multi-modal image dataset for automated printed circuit board visual inspection. Cryptol. ePrint Arch. 2020. Available online: https://eprint.iacr.org/2020/366 (accessed on 20 March 2025).

- Tang, S.; He, F.; Huang, X.; Yang, J. Online PCB defect detector on a new PCB defect dataset. arXiv 2019, arXiv:1902.06197. [Google Scholar] [CrossRef]

- Hagelüken, C.; Lee-Shin, J.U.; Carpentier, A.; Heron, C. The EU circular economy and its relevance to metal recycling. Recycling 2016, 1, 242–253. [Google Scholar] [CrossRef]

- Herchenbach, D.; Li, W.; Breier, M. Segmentation and classification of THCs on PCBAs. In Proceedings of the 2013 11th IEEE International Conference on Industrial Informatics (INDIN), Bochum, Germany, 29–31 July 2013; pp. 59–64. [Google Scholar]

- Chen, J.; Bao, E.; Pan, J. Classification and Positioning of Circuit Board Components Based on Improved YOLOv5. Procedia Comput. Sci. 2022, 208, 613–626. [Google Scholar] [CrossRef]

- Li, J.; Gu, J.; Huang, Z.; Wen, J. Application research of improved YOLO V3 algorithm in PCB electronic component detection. Appl. Sci. 2019, 9, 3750. [Google Scholar] [CrossRef]

- Kopacek, B. Intelligent disassembly of components from printed circuit boards to enable re-use and more efficient recovery of critical metals. In Proceedings of the 2016 Electronics Goes Green 2016+(EGG), Berlin, Germany, 6–9 September 2016; pp. 1–8. [Google Scholar]

- Naito, K.; Shirai, A.; Kaneko, S.i.; Capi, G. Recycling of printed circuit boards by robot manipulator: A Deep Learning Approach. In Proceedings of the 2021 IEEE International Symposium on Robotic and Sensors Environments (ROSE), Virtual, 28–29 October 2021; pp. 1–5. [Google Scholar]

- Candido de Oliveira, D.; Nassu, B.T.; Wehrmeister, M.A. Image-Based Detection of Modifications in Assembled PCBs with Deep Convolutional Autoencoders. Sensors 2023, 23, 1353. [Google Scholar] [CrossRef]

- Li, D.; Li, C.; Chen, C.; Zhao, Z. Semantic segmentation of a printed circuit board for component recognition based on depth images. Sensors 2020, 20, 5318. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.V.; Wang, L. Digital twin-based WEEE recycling, recovery and remanufacturing in the background of Industry 4.0. Int. J. Prod. Res. 2019, 57, 3892–3902. [Google Scholar] [CrossRef]

- Kumar, S.; Yadav, D.; Gupta, H.; Verma, O.P.; Ansari, I.A.; Ahn, C.W. A novel yolov3 algorithm-based deep learning approach for waste segregation: Towards smart waste management. Electronics 2020, 10, 14. [Google Scholar] [CrossRef]

- Glučina, M.; Anđelić, N.; Lorencin, I.; Car, Z. Detection and Classification of Printed Circuit Boards Using YOLO Algorithm. Electronics 2023, 12, 667. [Google Scholar] [CrossRef]

- Zhao, W.; Gurudu, S.R.; Taheri, S.; Ghosh, S.; Mallaiyan Sathiaseelan, M.A.; Asadizanjani, N. Pcb component detection using computer vision for hardware assurance. Big Data Cogn. Comput. 2022, 6, 39. [Google Scholar] [CrossRef]

- Silva, L.H.d.S.; Júnior, A.A.; Azevedo, G.O.; Oliveira, S.C.; Fernandes, B.J. Estimating recycling return of integrated circuits using computer vision on printed circuit boards. Appl. Sci. 2021, 11, 2808. [Google Scholar] [CrossRef]

- Reza, M.A.; Chen, Z.; Crandall, D.J. Deep neural network–based detection and verification of microelectronic images. J. Hardw. Syst. Secur. 2020, 4, 44–54. [Google Scholar] [CrossRef]

- Adibhatla, V.A.; Shieh, J.S.; Abbod, M.F.; Chih, H.C.; Hsu, C.C.; Cheng, J. Detecting defects in PCB using deep learning via convolution neural networks. In Proceedings of the 2018 13th International Microsystems, Packaging, Assembly and Circuits Technology Conference (IMPACT), Taipei, Taiwan, 24–26 October 2018; pp. 202–205. [Google Scholar]

- Koganti, S.K.; Purnima, G.; Bhavana, P.; Raghava, Y.V.; Resmi, R. Deep Learning based Automated Waste Segregation System based on degradability. In Proceedings of the 2021 Second International Conference on Electronics and Sustainable Communication Systems (ICESC), Coimbatore, India, 4–6 August 2021; pp. 1953–1956. [Google Scholar]

- Soomro, I.A.; Ahmad, A.; Raza, R.H. Printed Circuit Board identification using Deep Convolutional Neural Networks to facilitate recycling. Resour. Conserv. Recycl. 2022, 177, 105963. [Google Scholar] [CrossRef]

- Xu, Y.; Yang, G.; Luo, J.; He, J. An Electronic component recognition algorithm based on deep learning with a faster SqueezeNet. Math. Probl. Eng. 2020, 2020, 2940286. [Google Scholar] [CrossRef]

- Chen, Z.; Yang, M.; Shi, Q.; Kuang, X.; Qi, H.J.; Wang, T. Recycling waste circuit board efficiently and environmentally friendly through small-molecule assisted dissolution. Sci. Rep. 2019, 9, 17902. [Google Scholar] [CrossRef]

- Mohsin, M.; Rovetta, S.; Masulli, F.; Cabri, A. Extraction of Critical Raw Materials from Waste Printed Circuit Boards Using Machine Learning and Computer Vision. TechRxiv 2025. [Google Scholar] [CrossRef]

- Van Yken, J.; Boxall, N.J.; Cheng, K.Y.; Nikoloski, A.N.; Moheimani, N.R.; Kaksonen, A.H. E-waste recycling and resource recovery: A review on technologies, barriers and enablers with a focus on oceania. Metals 2021, 11, 1313. [Google Scholar] [CrossRef]

- Sajwan, D.; Sharma, A.; Sharma, M.; Krishnan, V. Upcycling of Plastic Waste Using Photo-, Electro-, and Photoelectrocatalytic Approaches: A Way toward Circular Economy. ACS Catal. 2024, 14, 4865–4926. [Google Scholar] [CrossRef]

- Mohsin, M.; Shaukat, A.; Akram, U.; Zarrar, M.K. Automatic Prostate Cancer Grading Using Deep Architectures. In Proceedings of the 2021 IEEE/ACS 18th International Conference on Computer Systems and Applications (AICCSA), Tangier, Morocco, 30 November–3 December 2021; pp. 1–8. [Google Scholar]

- Mahalingam, G.; Gay, K.M.; Ricanek, K. Pcb-metal: A pcb image dataset for advanced computer vision machine learning component analysis. In Proceedings of the 2019 16th International Conference on Machine Vision Applications (MVA), Tokyo, Japan, 27–31 May 2019; pp. 1–5. [Google Scholar]

- Redmon, J.; Divvala, S.; Girshick, R.; Farhadi, A. You only look once: Unified, real-time object detection. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 26 June–1 July 2016; pp. 779–788. [Google Scholar]

- Girshick, R. Fast r-cnn. In Proceedings of the IEEE International Conference on Computer Vision, Santiago, Chile, 7–13 December 2015; pp. 1440–1448. [Google Scholar]

- Liu, W.; Anguelov, D.; Erhan, D.; Szegedy, C.; Reed, S.; Fu, C.Y.; Berg, A.C. Ssd: Single shot multibox detector. In Proceedings of the Computer Vision–ECCV 2016: 14th European Conference, Amsterdam, The Netherlands, 11–14 October 2016; Part I 14. Springer: Berlin/Heidelberg, Germany, 2016; pp. 21–37. [Google Scholar]

- He, K.; Gkioxari, G.; Dollár, P.; Girshick, R. Mask r-cnn. In Proceedings of the IEEE International Conference on Computer Vision, Venice, Italy, 22–29 October 2017; pp. 2961–2969. [Google Scholar]

- Dalal, N.; Triggs, B. Histograms of oriented gradients for human detection. In Proceedings of the 2005 IEEE Computer Society Conference on Computer Vision and Pattern Recognition (CVPR’05), San Diego, CA, USA, 20–25 June 2005; Volume 1, pp. 886–893. [Google Scholar]

- Zhao, Z.Q.; Zheng, P.; Xu, S.t.; Wu, X. Object detection with deep learning: A review. IEEE Trans. Neural Networks Learn. Syst. 2019, 30, 3212–3232. [Google Scholar] [CrossRef] [PubMed]

- Zou, X. A review of object detection techniques. In Proceedings of the 2019 International Conference on Smart Grid and Electrical Automation (ICSGEA), Xiangtan, China, 10–11 August 2019; pp. 251–254. [Google Scholar]

- Laroca, R.; Severo, E.; Zanlorensi, L.A.; Oliveira, L.S.; Gonçalves, G.R.; Schwartz, W.R.; Menotti, D. A robust real-time automatic license plate recognition based on the YOLO detector. In Proceedings of the 2018 International Joint Conference on Neural Networks (IJCNN), Rio de Janeiro, Brazil, 8–13 July 2018; pp. 1–10. [Google Scholar]

- Tian, Y.; Yang, G.; Wang, Z.; Wang, H.; Li, E.; Liang, Z. Apple detection during different growth stages in orchards using the improved YOLO-V3 model. Comput. Electron. Agric. 2019, 157, 417–426. [Google Scholar] [CrossRef]

- Jamtsho, Y.; Riyamongkol, P.; Waranusast, R. Real-time license plate detection for non-helmeted motorcyclist using YOLO. Ict Express 2021, 7, 104–109. [Google Scholar] [CrossRef]

- Han, J.; Liao, Y.; Zhang, J.; Wang, S.; Li, S. Target fusion detection of LiDAR and camera based on the improved YOLO algorithm. Mathematics 2018, 6, 213. [Google Scholar] [CrossRef]

- Jocher, G.; Chaurasia, A.; Qiu, J. Ultralytics YOLOv8. GitHub Repository. 2023. Available online: https://github.com/ultralytics/ultralytics (accessed on 22 October 2024).

- Wang, C.Y.; Liao, H.Y.M. YOLOv9: Learning What You Want to Learn Using Programmable Gradient Information. arXiv 2024, arXiv:2402.13616. [Google Scholar] [CrossRef]

- Wang, A.; Chen, H.; Liu, L.; Chen, K.; Lin, Z.; Han, J.; Ding, J. YOLOv10: Real-Time End-to-End Object Detection. arXiv 2024, arXiv:2405.14458. [Google Scholar]

- Jocher, G.; Qiu, J. Ultralytics YOLO11. 2024. Available online: https://github.com/ultralytics/ultralytics (accessed on 25 March 2025).

- Tian, Y.; Ye, Q.; Doermann, D. Yolov12: Attention-centric real-time object detectors. arXiv 2025, arXiv:2502.12524. [Google Scholar]

- Everingham, M.; Van Gool, L.; Williams, C.K.; Winn, J.; Zisserman, A. The pascal visual object classes (voc) challenge. Int. J. Comput. Vis. 2010, 88, 303–338. [Google Scholar] [CrossRef]

- Lin, T.Y.; Maire, M.; Belongie, S.; Hays, J.; Perona, P.; Ramanan, D.; Dollár, P.; Zitnick, C.L. Microsoft coco: Common objects in context. In Proceedings of the Computer Vision—ECCV 2014: 13th European Conference, Zurich, Switzerland, 6–12 September 2014; Part V 13. Springer: Berlin/Heidelberg, Germany, 2014; pp. 740–755. [Google Scholar]

- Girshick, R.; Donahue, J.; Darrell, T.; Malik, J. Region-based convolutional networks for accurate object detection and segmentation. IEEE Trans. Pattern Anal. Mach. Intell. 2015, 38, 142–158. [Google Scholar] [CrossRef]

- Lin, T.Y.; Goyal, P.; Girshick, R.; He, K.; Dollár, P. Focal loss for dense object detection. In Proceedings of the IEEE International Conference on Computer Vision, Venice, Italy, 22–29 October 2017; pp. 2980–2988. [Google Scholar]

- Huang, R.; Gu, J.; Sun, X.; Hou, Y.; Uddin, S. A rapid recognition method for electronic components based on the improved YOLO-V3 network. Electronics 2019, 8, 825. [Google Scholar] [CrossRef]

- Lee, J.; Kim, Y.; Lee, J.c. Disassembly and physical separation of electric/electronic components layered in printed circuit boards (PCB). J. Hazard. Mater. 2012, 241, 387–394. [Google Scholar] [CrossRef]

| Acronym | Definition |

|---|---|

| CE | Circular Economy |

| WPCBs | Waste-Printed Circuit Boards |

| e-waste | Electronic Waste |

| WEEE | Waste Electrical and Electronic Equipment |

| CRMs | Critical Raw Materials |

| BoM | Bill of Material |

| AI | Artificial Intelligence |

| DL | Deep Learning |

| ML | Machine Learning |

| CV | Computer Vision |

| 2-D | Two-Dimensional |

| CNN | Convolutional Neural Network |

| R-CNN | Region-Based Convolutional Neural Network |

| SSD | Single-Shot Detector |

| YOLO | You Only Look Once |

| Mineral | Element | Mineral | Element |

|---|---|---|---|

| Aluminium | Copper * | Bauxite | Nickel * |

| Lithium | Phosphorus | Antimony | Feldspar * |

| LREE | Scandium | Arsenic * | Fluorspar |

| Magnesium | Silicon Metal | Baryte | Gallium |

| Manganese * | Strontium | Beryllium | Germanium |

| Natural Graphite | Tantalum | Bismuth | Hafnium |

| Niobium | Titanium Metal | Boron/Borate | Helium * |

| PGM | Tungsten | Cobalt | HREE |

| Phosphate Rock | Vanadium |

| Electronic Component | Description | Common Critical Raw Materials (CRMs) |

|---|---|---|

| Integrated Circuits (ICs) | Microchips for processing, memory, control logic | Silicon, Gold, Tantalum, Palladium, Rare Earth Elements (REEs) |

| Capacitors | Store and release electrical energy | Tantalum, Aluminum, Manganese, Niobium |

| Resistors | Limit current flow in circuits | Tin, Nickel, Manganese |

| Inductors/Coils | Store energy in magnetic fields | Copper, Ferrite (Iron), Rare Earth Elements |

| Transistors | Signal amplification and switching | Silicon, Gallium, Germanium |

| Diodes | Allow current flow in one direction | Silicon, Germanium |

| Crystal Oscillators | Timing elements for clocks and frequencies | Quartz (Silicon Dioxide), Tantalum, REEs |

| Connectors/Terminals | Electrical connection points | Gold, Silver, Copper, Tin |

| Printed Wiring (Traces) | Conductive paths etched onto the PCB surface | Copper, Tin |

| Solder | Binds components to PCB | Tin, Silver, Lead (less common now due to RoHS), Antimony |

| LEDs | Light-emitting diodes for indicators | Gallium, Indium, Phosphorus |

| Relays and Switches | Mechanical/electromechanical control | Silver, Copper, Nickel |

| Transformers | Voltage conversion | Copper, Iron, Manganese |

| Heat Sinks | Dissipate heat from high-power components | Aluminum |

| Battery (on some PCBs) | Power backup or RTC battery | Lithium, Cobalt, Graphite |

| Database | Search Terms |

|---|---|

| IEEE Xplore, Scopus, Web of Science, Google Scholar | “Waste Printed Circuit Boards Disassembly” AND “Deep Learning”, |

| “Waste Printed Circuit Boards Recycling” AND “State-of-the-Art Computer Vision System for WPCBs disassembly”, | |

| “Printed Circuit Boards Dataset” AND “State-of-the-Art Computer Vision System PCBs Analysis”, | |

| “Resource Recovery from Waste Printed Circuit Boards” AND “Environmental Sustainability”, | |

| “Challenges in Waste Printed Circuit Boards Recycling” AND “Limitations of Waste Printed Circuit Boards Recycling Techniques” |

| Inclusion Criteria | Exclusion Criteria | |

|---|---|---|

| Focus Area | Articles that focus on WPCB recycling using AI and deep learning techniques. | Articles that do not focus on electronic board waste from WEEE. |

| Research Scope | Articles including research on the recovery of CRMs from electronic boards using AI and deep learning. | Articles lacking research on AI/deep learning for component-level detection/localization in waste PCBs. |

| Technological Advancement | Articles reporting major advancements and developments in AI and deep learning for WEEE recycling. | Articles not aligned with research questions or keywords used in this review. |

| Challenges Covered | Articles discussing challenges and limitations of WEEE recycling techniques. | – |

| Language | English only. | Articles not written in English. |

| Type of Document | Peer-reviewed research papers or conference proceedings. | Articles that are not peer-reviewed or are editorial/opinion pieces. |

| Publication Period | Published in the past 10 years. | Articles not published in the past 10 years. |

| ID | Database | Title | References |

|---|---|---|---|

| P-1 | IEEE | A dataset for computer-vision-based PCB analysis | [25] |

| P-2 | Scopus | A PCB dataset for defects detection and classification | [26] |

| P-3 | Scopus | FICS-PCB: A multi-modal image dataset for automated printed circuit board visual inspection | [27] |

| P-4 | Scopus | Online PCB defect detector on a new PCB defect dataset | [28] |

| P-5 | MDPI | The EU Circular Economy and Its Relevance to Metal Recycling | [29] |

| P-6 | MDPI | Segmentation and classification of THCs on PCBAs | [30] |

| P-7 | Scopus | Classification and Positioning of Circuit Board Components Based on Improved YOLOv5 | [31] |

| P-8 | MDPI | Application research of improved YOLO V3 algorithm in PCB electronic component detection | [32] |

| P-9 | IEEE | Intelligent disassembly of components from printed circuit boards to enable re-use | [33] |

| P-10 | IEEE | Recycling of printed circuit boards by robot manipulator: A Deep Learning Approach | [34] |

| P-11 | IEEE | Image- based detection of modifications in assembled pcbs with deep convolutional autoencoders | [35] |

| P-12 | MDPI | Image-Based Detection of Modifications in Assembled PCBs with Deep Convolutional Autoencoders | [35] |

| P-13 | MDPI | Semantic segmentation of a printed circuit board for component recognition based on depth images | [36] |

| P-14 | Scopus | Classification and positioning of circuit board components based on improved yolov5 | [31] |

| P-15 | Scopus | Digital twin-based WEEE recycling, recovery and remanufacturing in the background of Industry 4.0 | [37] |

| P-16 | MDPI | A novel YOLOv3 algorithm-based deep learning approach for waste segregation: Towards smart waste management | [38] |

| P-17 | MDPI | Detection and Classification of Printed Circuit Boards Using YOLO Algorithm | [39] |

| P-18 | MDPI | PCB component detection using computer vision for hardware assurance | [40] |

| P-19 | MDPI | Estimating recycling return of integrated circuits using computer vision on printed circuit boards | [41] |

| P-20 | Scopus | Deep neural network-based detection and verification of microelectronic images | [42] |

| P-21 | IEEE | Detecting defects in PCB using deep learning via convolution neural networks | [43] |

| P-22 | IEEE | Deep Learning based Automated Waste Segregation System based on degradability | [44] |

| P-23 | IEEE | Printed circuit board identification using deep convolutional neural networks to facilitate recycling | [45] |

| P-24 | IEEE | An Electronic component recognition algorithm based on deep learning with a faster SqueezeNet | [46] |

| ID | Technique | Application Focus | Reference |

|---|---|---|---|

| P-7 | YOLOv5 | Classification and positioning of PCB components | [31] |

| P-8 | YOLOv3 | Detection of electronic components on PCBs | [32] |

| P-14 | SqueezeNet | Recognition of electronic components | [46] |

| P-15 | Digital Twin | Recycling and re-manufacturing in Industry 4.0 | [37] |

| P-16 | YOLOv3 | Smart waste segregation system | [38] |

| P-17 | YOLO | PCB classification and detection | [39] |

| P-18 | Computer Vision | Hardware assurance and component detection | [40] |

| P-20 | DNN | Microelectronic image verification | [42] |

| P-21 | CNN | Defect detection on PCBs | [43] |

| P-23 | CNN | PCB identification for recycling | [45] |

| P-24 | SqueezeNet | High-speed component recognition | [46] |

| ID | Year | Challenge | Proposed Solution |

|---|---|---|---|

| P-9 | 2016 | Manual disassembly is inefficient and damages components. | AI and robotics for precise, automated disassembly. |

| P-10 | 2021 | Traditional recycling methods are slow and hazardous. | Deep learning and robotic arms for automated component recovery. |

| P-19 | 2021 | Lack of precise methods to estimate recoverable material value. | Computer vision to detect ICs and estimate material value. |

| P-15 | 2019 | Poor integration of recycling data with product lifecycle. | Digital twin system for real-time data and product tracking. |

| P-16 | 2020 | Manual sorting lacks accuracy and scalability. | YOLOv3 model for real-time, automated waste classification. |

| P-22 | 2021 | Difficulty in classifying waste based on degradability. | SSD with MobileNet for degradability-based waste segregation. |

| P-23 | 2022 | Manual PCB sorting is error-prone and inefficient. | CNNs for automated PCB type identification and classification. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohsin, M.; Rovetta, S.; Masulli, F.; Cabri, A. Artificial Intelligence Approach for Waste-Printed Circuit Board Recycling: A Systematic Review. Computers 2025, 14, 304. https://doi.org/10.3390/computers14080304

Mohsin M, Rovetta S, Masulli F, Cabri A. Artificial Intelligence Approach for Waste-Printed Circuit Board Recycling: A Systematic Review. Computers. 2025; 14(8):304. https://doi.org/10.3390/computers14080304

Chicago/Turabian StyleMohsin, Muhammad, Stefano Rovetta, Francesco Masulli, and Alberto Cabri. 2025. "Artificial Intelligence Approach for Waste-Printed Circuit Board Recycling: A Systematic Review" Computers 14, no. 8: 304. https://doi.org/10.3390/computers14080304

APA StyleMohsin, M., Rovetta, S., Masulli, F., & Cabri, A. (2025). Artificial Intelligence Approach for Waste-Printed Circuit Board Recycling: A Systematic Review. Computers, 14(8), 304. https://doi.org/10.3390/computers14080304