1. Introduction

The rapid evolution of Industry 4.0 has created a paradigm shift in the engineering sector, demanding a workforce equipped not only with foundational theoretical knowledge but also with advanced digital literacy and practical skills, reflecting a new human-centric perspective for the “Operator 4.0” [

1,

2,

3,

4].

Traditional pedagogical models in engineering education, long reliant on static textbooks, 2D schematics, and passive classroom lectures, are increasingly struggling to bridge the gap between abstract concepts and the complex, interconnected systems students will encounter in their careers [

5,

6,

7]. This disconnect is especially clear when students face the dual challenge of designing tangible, high-precision hardware, such as metrological equipment for torque sensors [

8], while also mastering the methodologies needed to optimize the complex automated processes in which such hardware is used, like industrial welding [

9]. This disconnect is a significant challenge, as it can hinder the development of crucial spatial reasoning and problem-solving abilities, which are fundamental to engineering practice [

10,

11]. The limitations of these conventional methods have been further highlighted by the global shift towards remote and hybrid learning models, which necessitate educational resources that are not only informative but also accessible and interactive [

12,

13,

14,

15].

Consequently, there is a growing demand for digital tools that bridge theoretical and practical aspects of engineering education. Among these, web-based visualization and interactive simulation environments have shown strong potential to enhance learning outcomes and support the competencies required by Industry 4.0 engineers.

However, the widespread adoption of advanced visualization technologies in education remains limited due to the need for specialized hardware, costly licenses, and complex installation procedures [

16,

17]. To overcome these barriers, there is a strong demand for lightweight, platform-independent, and universally accessible tools that can deliver rich interactive experiences directly through a standard web browser.

Addressing this gap, the present work introduces a web-based Digital Twin framework designed to make high-quality technical education accessible to a broad audience of students and professionals [

18]. The proposed system leverages modern web technologies to provide a comprehensive suite of e-learning tools including an interactive 3D parts explorer, a centralized document hub, animated procedural guides, and a real-time data dashboard—without requiring any client-side installation. The primary objective of this work is to detail the architecture of this framework and to present the results of a qualitative exploratory pilot study with engineering professionals to assess its perceived effectiveness and potential. This paper is structured as follows:

Section 2 reviews the relevant literature.

Section 3 describes the system architecture and outlines the methodology.

Section 4 presents the results, which are discussed in

Section 5. Finally,

Section 6 provides concluding remarks and suggests directions for future research. [

19].

2. Related Work

In response to the aforementioned challenges, the role of digital transformation in creating dynamic and effective learning experiences is well-documented. According to Mamun et al. [

20], immersive technologies have the potential to significantly improve comprehension and retention in technical disciplines. The development of specialized educational applications has also enabled new ways to teach complex subjects, such as software engineering [

21,

22]. For instance, augmented reality has been used to overcome limitations of traditional 2D representations in engineering graphics, allowing learners to better visualize geometric relations [

23]. These applications are proving effective in fields as diverse as engineering and history, as confirmed by systematic reviews [

24,

25,

26]. By allowing students to interact with 3D models and simulated environments, these tools enhance comprehension and provide a safe space for hands-on experimentation, such as with active thermography, without the risk of damaging expensive equipment [

27,

28,

29,

30].

This pedagogical shift towards interactivity is supported by a significant body of research focused on educational software design. For instance, studies on mobile learning applications have shown that including interactive features and tailored feedback is an effective strategy for advancing the cognitive abilities of learners [

31]. This principle is validated by broader trends, as highlighted in a systematic mapping study by Dicheva et al., which provides a comprehensive overview of how gamification techniques are successfully applied to increase student motivation [

32]. The practical benefits of these technologies have also been demonstrated in complex engineering disciplines; a case study by Pàmies-Vilà et al. used augmented reality to significantly improve students’ understanding of mechanism and machine theory, further underscoring the value of immersive tools [

33].

Building on this momentum, the concept of the Digital Twin, a high-fidelity virtual representation of a physical asset or system, is emerging from its industrial origins as a revolutionary tool for education [

34,

35]. The core concepts of Digital Twin are now well-defined within the Industry 4.0 landscape, where it serves as a dynamic, data-rich virtual model for monitoring and simulation [

36,

37]. When this powerful industrial concept is repurposed for pedagogy, it can serve as a comprehensive learning object. A pedagogical Digital Twin allows students to not only visualize a complex assembly but also to understand its operational behavior, access integrated technical documentation, and practice procedural tasks in a realistic virtual environment [

38,

39]. As shown by Liu et al. [

40], such integrative approaches enable systems-level understanding that is difficult to achieve with passive instruction.

In summary, prior research has demonstrated the educational benefits of immersive visualization and Digital Twin technologies across various technical domains. Yet, these implementations often remain constrained by high computational demands or dependence on proprietary software ecosystems. The present study distinguishes itself by proposing a browser-based framework that eliminates such barriers while integrating real-time interaction, procedural guidance, and contextual documentation within a single unified environment.

3. Materials and Methods

This section details the methodology employed in this study, which is divided into two main parts. The first part describes the comprehensive development process of the interactive Digital Twin framework, including the selection of the subject asset, the technological stack, the core architecture, and the key e-learning features. The second part outlines the case study methodology used to assess the application’s usability and perceived educational impact among a group of engineering professionals.

3.1. Development of the Interactive Digital Twin Framework

The interactive web application presented and evaluated in this study is publicly available as

Supplementary Material. It is the culmination of an iterative development process, significantly refining and advancing the concepts from previous projects. This new framework is built upon a standardized development pipeline, a meticulously polished and intuitive user experience (UX), robust cross-platform performance, and flexible, data-driven architecture designed for scalability and ease of maintenance.

3.1.1. Conceptual Foundation and Asset Selection

The historical Wright J-5 “Whirlwind” 9-cylinder radial engine was strategically selected as the subject for this Digital Twin. Its pivotal role in aviation history provides a compelling narrative to engage learners, while its mechanical complexity is perfectly suited for demonstrating advanced engineering principles in an educational context. The high-fidelity 3D model, which serves as the visual and interactive core of the application, was expertly created by aerospace engineer and 3D artist Dave Goetsch and was sourced from the GrabCAD community, a valuable platform for engineering assets.

3.1.2. Development Pipeline and Core Technologies

A key innovation in this project is the establishment of a standardized, three-stage pipeline to ensure an efficient and repeatable workflow from the initial 3D asset to the final interactive web application.

The first stage is 3D Model Preparation, which takes place in Blender, an open-source 3D creation suite. The raw CAD model was meticulously optimized for real-time web performance. This critical process involved several techniques: the polygon count was reduced through careful decimation to ensure smooth rendering without sacrificing geometric fidelity; multiple materials were baked into a single Physically Based Rendering (PBR) texture atlas to minimize draw calls; and all components were professionally UV unwrapped for efficient texturing. Furthermore, the model was logically deconstructed, with each part separated into a distinct object and organized into a precise parent–child hierarchy that mirrors the real-world assembly structure (

Figure 1).

The second stage utilizes Verge3D, a real-time renderer and toolkit that serves as the bridge between the prepared 3D asset and the interactive web environment. Its visual programming environment, known as Puzzles, was instrumental in managing the core 3D interactivity. This event-driven logic handles all direct user interactions, including click-and-select events, camera manipulations (orbit, pan, zoom), and the triggering of animations. Puzzles were used to link user actions, such as clicking a button in the UI, to corresponding behaviors in the 3D scene, like initiating an explosion animation or isolating a component.

The final stage involves custom web development to build the sophisticated user interface (UI) and advanced application logic. This was done using standard web technologies in Visual Studio Code version 1.90. The structure of all UI panels, buttons, and informational containers was defined with HTML, while the visual styling, layout, and responsive design were managed by CSS. A suite of modular JavaScript files provides higher-level functionality that extends beyond the 3D viewport, such as managing the simulated state of the engine dashboard, dynamically populating data tables from external sources, and handling the overall application state (

Figure 2).

3.1.3. Framework Architecture and Data Integration

A fundamental architectural improvement in this framework is the exclusive use of JSON (JavaScript Object Notation) for all data management. This represents a significant improvement over previous methods that relied on less flexible formats like CSV. The hierarchical nature of JSON is perfectly suited to represent the nested structure of the engine’s bill of materials. All application content, from the parts list and document metadata to the sequential steps of the animated procedures, is dynamically loaded from external JSON files. This approach effectively decouples the application’s content from its logic, creating a “single source of truth”. This makes the framework exceptionally scalable, easily maintainable, and highly adaptable; it can represent any other complex asset simply by loading a new set of 3D models and corresponding JSON data files.

3.1.4. User Interface, Experience, and Key Features

The application’s design philosophy is centered on a polished and intuitive user experience. The UI is designed as a non-intrusive overlay on top of the central 3D viewport, which remains the primary focus of interaction. This ensures that the rich feature set is readily accessible without obscuring the main model. The entire interface is built with a responsive design, adapting seamlessly from large desktop monitors to the touch-based inputs of tablets and mobile phones.

The navigation logic is organized into several key components: a persistent Function Menu at the bottom of the screen serves as the main hub, providing one-click access to the core modules (Dashboard, Procedures, Documents, Parts, Section). An essential Navigation Menu provides view-management tools, including a Reset button to return the camera to its default state, a Return button to step back to a previous view, and a Fullscreen toggle for a more immersive experience. All informational side panels are draggable, allowing users to customize their workspace, and can be closed individually or all at once to maintain a clear view of the model.

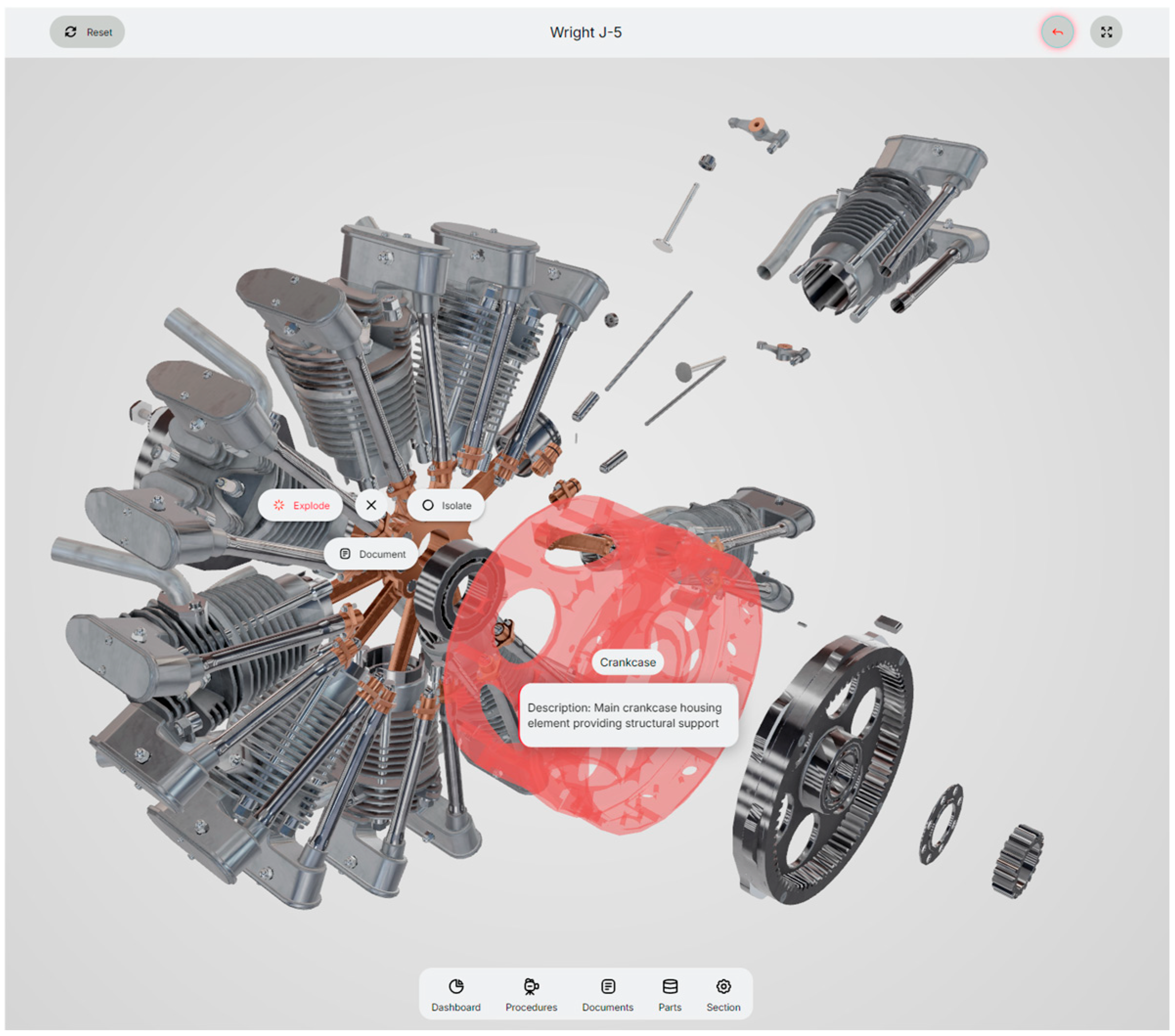

The core of the user experience is Direct Interaction. Users can click on any component in the 3D scene, which selects the part and reveals a Contextual Action Menu. This on-demand menu provides powerful, context-sensitive tools, such as Isolate and Explode, which allow the user to focus on a single part or to examine how an assembly fits together. The menu also includes a Documents button, providing a direct link to part-specific technical documentation.

This interaction model is complemented by the following key e-learning features:

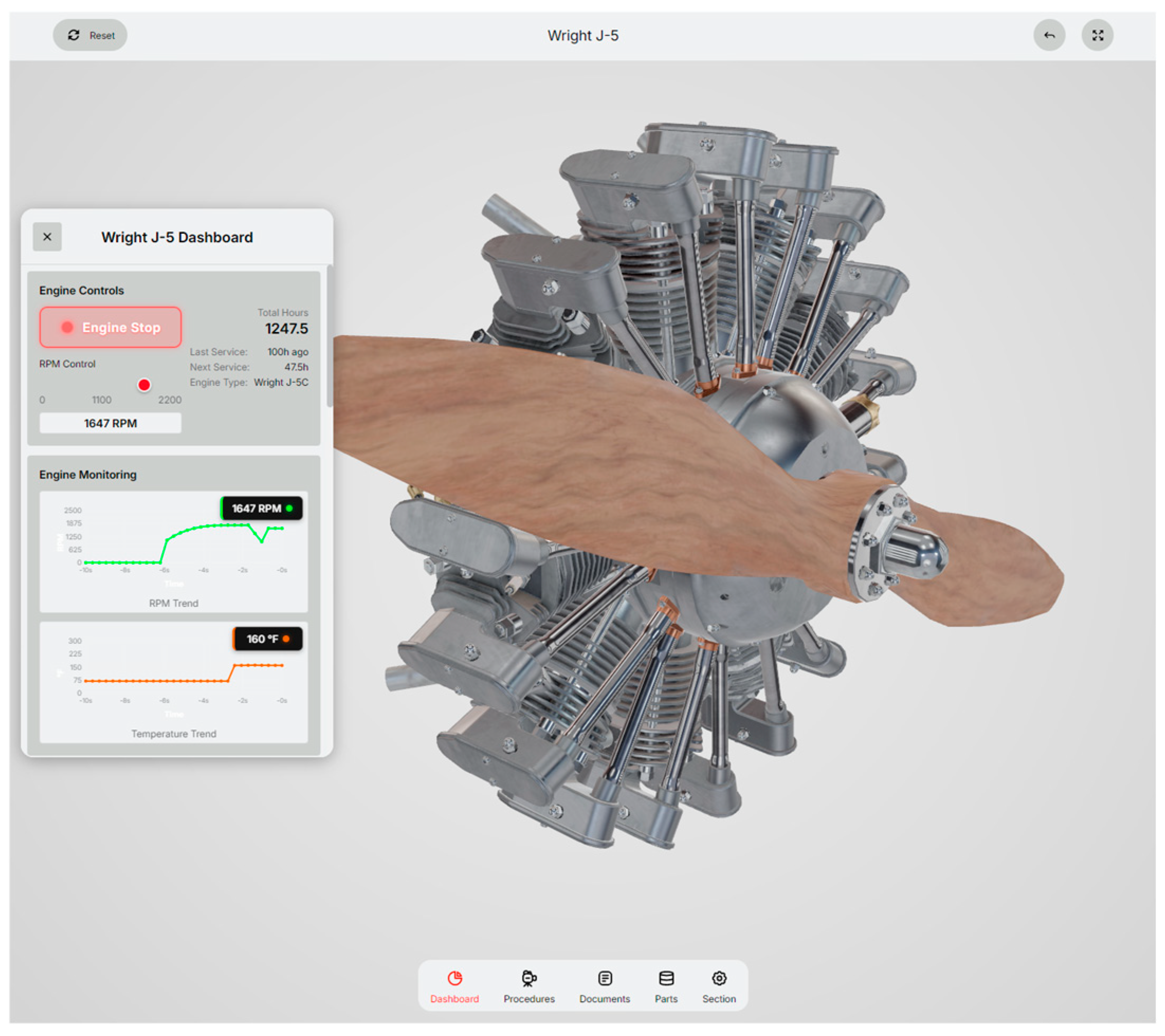

Illustrative Data Dashboard: The framework includes a dynamic dashboard that, for the purpose of this study, operates in an illustrative mode with simulated data, as a physical asset was not connected. However, the underlying JavaScript architecture and data-handling workflows have been designed and tested to be “digital twin-ready”, meaning the framework is fully capable of ingesting and displaying real-time data streams from physical sensors with future implementation. This module allows users to interact with engine controls, adjust RPM, and monitor key metrics on animated gauges and trend charts (

Figure 3).

Animated Procedures: The “Procedures” module transforms static instructions into interactive, step-by-step 3D guides. For tasks like the propeller installation, the application visually guides the user, highlighting the necessary parts and tools at each stage for a self-paced learning approach (

Figure 4).

Centralized Document Hub: The application provides immediate and interactive access to a comprehensive library of technical documentation. This is achieved through two distinct access points: the main “Documents” button in the primary menu provides access to a centralized repository of general documents, including operation manuals, inspection guidelines, and detailed assembly instructions. Additionally, a contextual “Document” button appears in the action menu when any specific part is selected, providing one-click access to its corresponding technical drawing. This dual system ensures that users can find both general and highly specific information exactly when and where they need it.

Contextual Part Explorer: This feature provides a dynamic bill of materials that is bidirectionally linked to the 3D model. Clicking a part in the scene highlights it in the list, and vice versa, allowing for intuitive exploration and rapid identification of every component (

Figure 5).

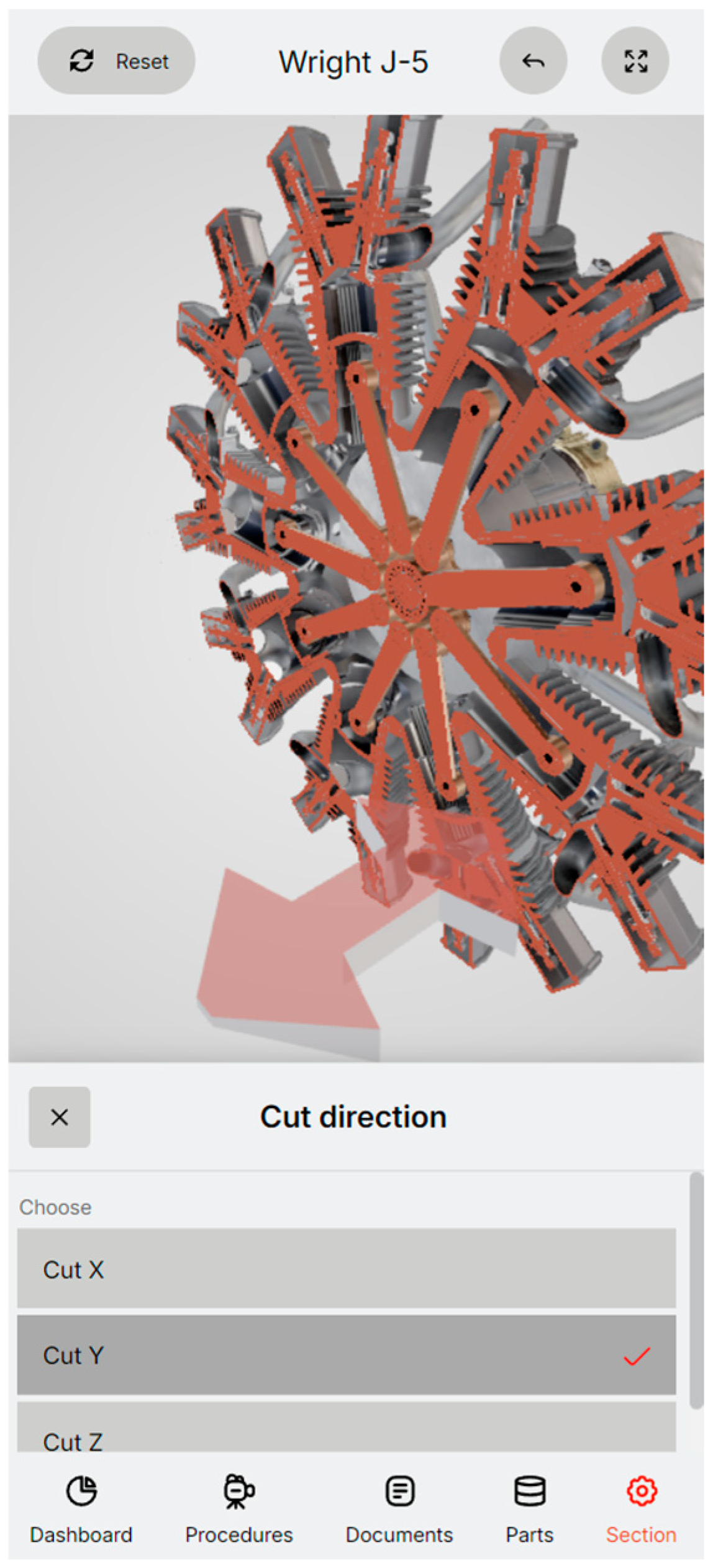

Interactive Cross-Section View: A powerful visualization tool allows users to dynamically slice through the 3D model. The cut plane is fully interactive and controlled by a simple slider, highlighting the resulting cut surfaces in red enabling the exploration of internal geometries from any angle, even on a mobile device (

Figure 6).

3.2. Case Study Methodology

As an exploratory pilot study, the primary goal of this research was not to produce statistically generalizable results, but rather to gather rich, in-depth feedback from a targeted expert group. To evaluate the framework’s effectiveness, a qualitative case study was conducted, designed to gather in-depth, expert feedback on the application’s features and its potential as a tool for both education and professional training. The study’s primary objectives were threefold: to assess the usability and intuitiveness of the user interface, to evaluate the perceived impact of the interactive features on understanding complex mechanical systems, and to gather expert feedback on the framework’s potential for professional development and on-the-job support. To this end, a group of seven professionals from a European company specializing in automotive technology were recruited. The purposefully selected group represented a cross-section of target users and included a technical manager, four mechanical design engineers, and two service technicians, all of whom had no prior experience with the application, ensuring an unbiased assessment.

Each participant engaged in an individual session lasting approximately 20–25 min. The session began with a brief introduction to the application’s purpose and interface, after which participants were asked to complete a series of comprehensive tasks. During this interactive portion, they were encouraged to use a “think-aloud” protocol to verbalize their actions, expectations, and thought processes in real-time. Immediately following the tasks, data was formally captured through a mixed-methods survey. This instrument contained quantitative questions using a 5-point Likert scale to rate usability and educational impact, alongside several open-ended questions designed to elicit detailed qualitative comments and suggestions. The data gathered was subsequently analyzed using a dual approach. The Likert scale responses were analyzed using descriptive statistics to identify general trends, while the rich qualitative data from the survey and the “think-aloud” session notes were analyzed using a thematic analysis method to identify recurring patterns and key insights. The analysis was conducted by the primary author through a systematic, multi-stage process. First, the author transcribed and repeatedly reviewed the ‘think-aloud’ protocols and open-ended survey responses to achieve deep familiarity with the data. Following this, an inductive coding process was performed, where the text was systematically analyzed to apply descriptive labels (codes) to key concepts and phrases.

To illustrate this process, specific participant comments were assigned multiple granular codes. For instance:

A statement on visualization, such as, “The cross-section tool is a game-changer… I could clearly see the piston-to-valve clearance”, was coded with labels like enhanced visualization, internal understanding, dynamic view, and better than CAD.

A comment on training, like, “This is the perfect tool for onboarding new engineers… significantly shortening their learning curve”, was coded with onboarding potential, reduced training time, and safe exploration.

A remark on usability, “This puts it one click away”, led to codes like one-click access, efficiency gain, and reduced search time.

These granular codes were then systematically reviewed and grouped based on their underlying concepts. All codes related to visual clarity and comprehension were consolidated into the ‘Enhanced Spatial Understanding’ theme. Similarly, codes related to training benefits formed the ‘High Potential for Training’ theme, and those related to ease of use were grouped under ‘Efficiency in Information Retrieval’.

To enhance the rigor and credibility of this single-analyst approach, the resulting codes and thematic map were then reviewed and discussed with a co-author. This peer debriefing process served to validate that the themes were a coherent and credible interpretation of the data, leading to the final four themes presented in the results.

Evaluation Tasks

While the framework is designed with engineering students as a primary audience, and a previous iteration has already been successfully evaluated in an academic setting [

41], the objective of the present study was to assess this enhanced version within a professional environment. By engaging with experienced engineers and technicians, we aimed to gather industry-relevant feedback on two fronts: first, to evaluate its potential as a tool for professional training and onboarding, and second, to gain expert perspective on how such a tool could best bridge the theory–practice gap for students entering the industry. This focus on professional evaluation provides a complementary and practice-oriented validation that is crucial for aligning educational technologies with the demands of Industry 4.0. The goal is to enrich learning software with interactive activities and motivational feedback, which are key to advancing users’ high-level cognitive skills and engagement.

Participants were guided through a series of five comprehensive tasks designed to test the full spectrum of the framework’s features, from complex 3D model navigation to data interpretation. For each task, participants were encouraged to use a “think-aloud” protocol to provide real-time qualitative feedback on their thought processes and user experience. The specific tasks were as follows:

Hierarchical Model Navigation: Participants were instructed to start with the main assembly view and navigate through the model’s hierarchical structure to locate the specific part named ‘Rocker Box Exhaust’. This required them to enter several sub-assembly levels (e.g., Crankcase Assembly, then Cylinder Assembly) and use the ‘Explode’ function on the final assembly to isolate the component. The objective of this task was to assess the intuitiveness and effectiveness of the multi-level navigation system, which mimics the exploration workflows of professional CAD systems.

Dual-Context Documentation Retrieval: This task was divided into two parts. First, participants were asked to open the main ‘Documents’ menu, find the ‘Engine Troubles’ manual, and identify the potential causes listed for ‘excessive oil temperature’. Second, they were instructed to return to the 3D model, select the ‘Crankcase Assembly’, and use the contextual action menu to open its specific assembly drawing. The objective was to evaluate the user’s ability to differentiate between and successfully retrieve information from both the centralized document library and the context-sensitive, part-specific links.

Information Retrieval from Animated Procedures: Participants were instructed to navigate to the ‘Procedures’ module and select the ‘Propeller Installation’ guide. They were then asked to follow the animated steps to find and state the correct tightening torque value for the propeller bolts. The objective of this task was to test the framework’s effectiveness in conveying precise technical data through animated instructions.

Internal Inspection and Comprehension: Participants were asked to activate the ‘Section’ view and slice through a cylinder and piston assembly. Once they had a clear view, they were instructed to verbally describe the spatial relationship between the top of the piston and the inner surface of the cylinder head. The objective was to determine if the dynamic cross-section feature provides users with a deeper comprehension of the internal geometry and mechanical relationships that are impossible to see from an external point of view.

Simulated Data Monitoring and Interaction: In the final task, participants were asked to open the ‘Dashboard’ module and start the engine simulation. After the readouts stabilized, they were instructed to use the ‘RPM Control’ slider to set the engine speed to approximately 2000 RPM and report the values displayed on the primary instrument gauges for Oil Pressure (PSI) and Cylinder Head Temperature (CHT). The objective was to evaluate the user’s ability to interact with simulated controls and correctly interpret data visualizations.

4. Results

This section presents the findings from the qualitative case study involving the seven engineering professionals. The data collected from the post-session survey and the “think-aloud” protocol are organized into quantitative and qualitative results to provide a comprehensive overview of the participants’ feedback.

The quantitative data gathered from the 5-point Likert questions reveals a highly positive reception of the Digital Twin framework. Participants gave consistently high ratings across all categories, indicating strong agreement with the application’s usability, educational impact, and professional relevance. The mean scores and standard deviations for the key survey statements are summarized in

Table 1.

The exceptionally high scores for understanding assemblies (4.86), training potential (4.86), and the clarity of the UI (4.86) indicate a strong consensus among the participants. The slightly lower, though still positive, score for daily work utility (4.29) with a higher standard deviation suggests that while the potential is clear, its direct integration into current workflows might vary by role.

Qualitative Results

The qualitative data gathered from open-ended questions and the “think-aloud” protocol were thematically analyzed. Four primary themes emerged from the participants’ feedback: enhanced spatial understanding, efficiency in information retrieval, high potential for training, and suggestions for professional features.

Enhanced Spatial Understanding and Visualization: All participants commented on the framework’s ability to clarify complex spatial relationships that are difficult to grasp from 2D drawings. The interactive cross-section and explode-view features were repeatedly highlighted as standout tools for comprehension. A mechanical engineer noted, “The cross-section tool is a game-changer. For the first time, I could clearly see the piston-to-valve clearance in a way that a CAD drawing just can’t show dynamically. You don’t just see it, you understand it.” Another participant, a service technician, added, “Being able to explode an assembly and then click on a part to isolate it would cut down diagnostic time significantly. You can see how things are supposed to fit together before you ever pick up a wrench.”

Efficiency in Information Retrieval: A recurring point of praise was the speed and intuitiveness of accessing technical documentation. Participants contrasted the application’s integrated approach with their current, often inefficient, methods of finding information. The technical manager stated, “The link between the physical part in the 3D model and its specific drawing is incredibly powerful. We spend a non-trivial amount of time hunting for the right revision of a drawing on our servers. This puts it one click away.”

High Potential for Training and Onboarding: The framework was unanimously recognized as a powerful tool for training and knowledge transfer. The animated procedures were seen as a major improvement over static manuals for teaching complex tasks. According to the technical manager, “This is the perfect tool for onboarding new engineers. It would allow them to explore and understand our products in a safe, interactive environment, significantly shortening their learning curve.” A service technician remarked, “Learning a new procedure from a paper manual is slow. Watching the animation for the propeller installation, I understood the sequence in under a minute.”

Suggestions for Professional Features: While the overall feedback was overwhelmingly positive, the expert users also provided constructive suggestions for future iterations that would enhance the tool’s utility in a professional engineering environment. A design engineer suggested, “This is almost perfect for design reviews. If it had a simple measurement tool and the ability to add annotations or markups, it would be indispensable.” Another common suggestion was related to data, “The simulated dashboard is a great proof-of-concept. The next logical step would be to integrate it with a real data feed from a test bench or a PLM system.”

5. Discussion

The results of this case study provide strong preliminary evidence for the effectiveness of the web-based Digital Twin framework as an e-learning and professional training tool in an engineering context. The overwhelmingly positive feedback, reflected in both the high quantitative scores and the rich qualitative comments, suggests that the application successfully addresses many of the pedagogical challenges associated with traditional technical education. This section interprets these findings, acknowledges the study’s limitations, and discusses the implications for the future of e-learning technologies.

A central finding of this pilot study is the framework’s notable perceived impact on spatial understanding and the visualization of complex systems. The participants’ enthusiastic comments regarding the interactive cross-section and explode-view features directly support this. The sentiment that these tools allow users to not just “see” but to truly “understand” internal mechanics addresses the limitations of traditional 2D schematics, a finding consistent with studies that have shown interactive 3D visualizations to be superior for learning complex mechanical assemblies [

42]. By providing a dynamic and interactive representation, the framework appears to effectively bridge the gap between abstract engineering drawings and the tangible reality of a physical object, a cornerstone of effective technical education.

The exceptionally high usability ratings can be attributed to the user-centric design philosophy employed in the framework’s development. Participants, who are accustomed to the steep learning curves of professional CAD and PLM software, found the application’s non-intrusive overlay UI, contextual action menus, and direct-interaction model to be highly intuitive. The high mean score for the clarity of the link between the 3D model and its associated data (M = 4.86) indicates that the bidirectional connection was a success, reinforcing the value of a single, unified interface for complex information. This suggests that powerful engineering data can be made accessible to a wider audience without requiring extensive training.

Furthermore, the unanimous agreement on the framework’s potential for training and onboarding (M = 4.86) underscores its value beyond individual learning. The technical manager’s comment about shortening the learning curve for new engineers highlights significant potential for industrial application. The slightly more varied response regarding its utility in daily work (M = 4.29, SD = 0.76) is also insightful. It suggests that while the tool’s value is immediately apparent for learning and reference, its integration into the established, day-to-day workflows of experienced professionals may require additional features, such as the measurement and annotation tools suggested by the participants.

Despite the promising findings, the limitations of this study must be acknowledged to properly contextualize the results. The primary limitation is the small sample size (n = 7). This is, however, an inherent and accepted characteristic of a qualitative pilot study, which prioritizes depth of feedback over breadth. As such, the findings are intended to be indicative and to generate insights for future, larger-scale research, but they are not statistically generalizable. Furthermore, the study was not designed to include a control group to directly compare the framework’s effectiveness against traditional methods, such as 2D drawings or static manuals. This was an intentional choice, as the primary goal of this exploratory phase was to assess the tool’s usability and gather rich, qualitative feedback on its features from expert users, rather than to quantitatively measure learning outcomes. Therefore, while participant feedback strongly suggests the framework improves understanding, the current study cannot make a definitive, objective claim of superiority over conventional methods. A comparative study involving a control group is a critical next step for future research to formally validate these promising preliminary results. Secondly, the participants were all from a single company within the automotive technology sector. Finally, the “novelty effect,” a well-documented phenomenon where the initial enthusiasm for a new technology can temporarily boost engagement and perceived effectiveness, may have influenced the results [

43].

The implications of this work are significant and align with the growing body of literature on the “Pedagogical Digital Twin” as a transformative tool for experiential learning [

44]. This study demonstrates that it is possible to deliver a sophisticated, interactive, Digital Twin-like experience through a standard web browser, without the need for specialized software or high-end hardware. This “democratization” of advanced visualization tools has the potential to make high-quality, hands-on technical education more accessible and scalable.

Future work should first focus on validating these findings with a larger-scale study involving students. A key technical priority is to connect the framework to a physical asset to stream live operational data, transitioning the dashboard from an illustrative simulation to a true, real-time Digital Twin. In parallel with this, there is active, ongoing work to expand the framework’s capabilities. The next iteration will feature a more sophisticated implementation of Augmented and Virtual Reality (AR/VR). Additionally, an AI chatbot assistant is in development, which will be able to trigger in-app actions based on its responses. For example, if a user asks how to install the propeller, the chatbot will provide a text answer and simultaneously present a button to launch the corresponding interactive procedure, further blending instructional design with intelligent systems.

6. Conclusions

This paper addressed the challenge of enhancing technical education by presenting the development and evaluation of a novel, web-based Digital Twin framework designed to bridge the gap between abstract theory and practical application. By integrating an interactive 3D model with data-driven architecture and a suite of educational features, the application provides a universally accessible e-learning environment without the need for specialized software or hardware. The pilot case study with engineering professionals provided strong preliminary evidence for the framework’s effectiveness, suggesting that its intuitive interface and visualization tools the dynamic cross-section, significantly enhance spatial comprehension and hold strong potential for professional training. In conclusion, this work supports the potential of the use of accessible, web-based Digital Twins as a powerful and scalable solution for the present and future of e-learning technologies, laying a robust foundation for future enhancements such as real-time data integration and AI-driven assistance.

Supplementary Materials

The interactive web application presented and evaluated in this study is publicly available online at:

https://v3d.net/1a2k (accessed on 1 August 2025).

Author Contributions

Conceptualization, P.W. and R.B.; methodology, P.W.; software, P.W.; validation, R.B. and M.V.; formal analysis, M.V.; investigation, R.B.; resources, P.W.; data curation, R.B.; writing—original draft preparation, P.W.; writing—review and editing, R.B.; visualization, M.V.; supervision, R.B.; project administration, M.V.; funding acquisition, P.W. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Scientific Grant Agency of the Ministry of Education, Science, Research and Sport of the Slovak Republic (VEGA), project no. 1/0568/24: Research in the field of loading and stress deformation states of rolling bearing cages. The authors gratefully acknowledge this support.

Data Availability Statement

The data presented in the case study are available from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Lee, J.; Bagheri, B.; Kao, H.A. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Raju, G.; Sorby, S. The role of spatial skills and sketching in engineering design problem solving. In Proceedings of the 2024 ASEE Annual Conference & Exposition, Portland, OR, USA, 23–26 June 2024; American Society for Engineering Education: Washington, DC, USA, 2024. [Google Scholar]

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Grandi, F.; Contini, G.; Peruzzini, M.; Raffaeli, R. A human-centric methodology for the co-evolution of operators’ skills, digital tools and user interfaces to support the Operator 4.0. Rob. Comput. Integr. Manuf. 2025, 91, 102854. [Google Scholar] [CrossRef]

- Cho, H.J.; Zhao, K.; Lee, C.R.; Runshe, D.; Krousgrill, C. Active learning through flipped classroom in mechanical engineering: Improving students’ perception of learning and performance. Int. J. STEM Educ. 2021, 8, 46. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Liang, W. Effectiveness of virtual laboratory in engineering education: A meta-analysis. PLoS ONE 2024, 19, e0316269. [Google Scholar] [CrossRef]

- Hagedorn, L.; Riedelsheimer, T.; Stark, R. Project-based learning in engineering education–developing digital twins in a case study. Proc. Des. Soc. 2023, 3, 2975–2984. [Google Scholar] [CrossRef]

- Kučera, Ľ.; Gajdošík, T.; Gajdáč, I.; Pompáš, L.; Smetanka, L.; Witkovský, V.; Wimmer, G. Design and Construction of Metrological Equipment for Torque Sensors with a Carbon-based Measuring Arm. Meas. Sci. Rev. 2023, 23, 163–167. [Google Scholar] [CrossRef]

- Čačo, M.; Kohár, R.; Hrček, S.; Tribula, R.; Ščerba, P. Use the Method of TRIZ in Optimizing Automated Machine for Ultrasonic Welding. Procedia Eng. 2017, 192, 80–85. [Google Scholar] [CrossRef]

- Ciolacu, M.I.; Mihailescu, B.; Rachbauer, T.; Hansen, C.; Amza, C.G.; Svasta, P. Fostering engineering education 4.0 paradigm facing the pandemic and VUCA world. Procedia Comput. Sci. 2023, 217, 177–186. [Google Scholar] [CrossRef]

- Sheharyar, A.; Srinivasa, A.R.; Masad, E. Enhancing 3-D spatial skills of engineering students using augmented reality. In Proceedings of the 2020 ASEE Virtual Annual Conference, Washington, DC, USA, 22–26 June 2020. [Google Scholar]

- Sharma, G.V.S.S. Spatial visualization for development of visual thinking and cognitive abilities among mechanical engineering students through tool design ideation. Int. J. Mech. Eng. Educ. 2023, 51, 227–242. [Google Scholar] [CrossRef]

- Dhawan, S. Online Learning: A Panacea in the Time of COVID-19 Crisis. J. Educ. Technol. Syst. 2020, 49, 5–22. [Google Scholar] [CrossRef]

- Adedoyin, O.B.; Soykan, E. COVID-19 pandemic and online learning: The challenges and opportunities. Interact. Learn. Environ. 2023, 31, 863–875. [Google Scholar] [CrossRef]

- Bani Hani, A.; Hijazein, Y.; Hadadin, H.; Jarkas, A.K.; Al-Tamimi, Z.; Amarin, M.; Shatarat, A.; Abu Abeeleh, M.; Al-Taher, R. E-Learning during COVID-19 pandemic; Turning a crisis into opportunity: A cross-sectional study at The University of Jordan. Ann. Med. Surg. 2021, 70, 102882. [Google Scholar] [CrossRef]

- Akçayır, M.; Akçayır, G. Advantages and challenges associated with augmented reality for education: A systematic review of the literature. Educ. Res. Rev. 2017, 20, 1–11. [Google Scholar] [CrossRef]

- Lei, Z.; Zhou, H.; Hu, W.; Liu, G.P. Web-based digital twin online laboratories: Methodologies and implementation. Digit. Twin 2024, 1, 3. [Google Scholar] [CrossRef]

- Heradio, R.; de la Torre, L.; Galan, D.; Cabrerizo, F.J.; Herrera-Viedma, E.; Dormido, S. Virtual and remote labs in education: A bibliographic review. Comput. Educ. 2016, 98, 14–38. [Google Scholar] [CrossRef]

- Potkonjak, V.; Gardner, M.; Callaghan, V.; Mattila, P.; Guetl, C.; Petrović, V.M.; Jovanović, K. Virtual laboratories for education in science, technology, and engineering: A review. Comput. Educ. 2016, 95, 309–327. [Google Scholar] [CrossRef]

- Mamun, M.A.A.; Azad, M.A.K.; Mamun, M.A.A.; Boyle, M.; Hossain, M.B.; Islam, M.A. Review of flipped learning in engineering education: Scientific mapping and research horizon. Educ. Inf. Technol. 2022, 27, 1261–1286. [Google Scholar] [CrossRef]

- Teker, S.; Teker, D.; Tavman, E.B. Digital transformation and universities. In Proceedings of the 16th International Conference on Business, Finance & Economics (ICOBFE), Famagusta, Cyprus, 21 October 2022; pp. 171–174. [Google Scholar] [CrossRef]

- Sarasa-Cabezuelo, A.; Rodrigo, C. Development of an Educational Application for Software Engineering Learning. Computers 2021, 10, 106. [Google Scholar] [CrossRef]

- Vicente dos Anjos, F.E.; Rocha, L.A.O.; Oliveira da Silva, D.; Pacheco, R.; Pinheiro, D.M.B. Impacts of the Application of Virtual and Augmented Reality on Teaching-Learning Processes in Engineering Courses. Int. J. Virtual Pers. Learn. Environ. 2022, 12, 1–19. [Google Scholar] [CrossRef]

- Radianti, J.; Majchrzak, T.A.; Fromm, J.; Wohlgenannt, I. A systematic review of immersive virtual reality applications for higher education: Design elements, lessons learned, and research agenda. Comput. Educ. 2020, 147, 103778. [Google Scholar] [CrossRef]

- Merchant, Z.; Goetz, E.T.; Cifuentes, L.; Keeney-Kennicutt, W.; Davis, T.J. Effectiveness of virtual reality-based instruction on students’ learning outcomes in K-12 and higher education: A meta-analysis. Comput. Educ. 2014, 70, 29–40. [Google Scholar] [CrossRef]

- Remolar, I.; Rebollo, C.; Fernández-Moyano, J.A. Learning History Using Virtual and Augmented Reality. Computers 2021, 10, 146. [Google Scholar] [CrossRef]

- Henstrom, J.; De Amicis, R.; Sanchez, C.A.; Turkan, Y. Immersive learning in engineering: A comparative study of VR and traditional building inspection methods. In Proceedings of the 28th International ACM Conference on 3D Web Technology, San Sebastián, Spain, 9–11 October 2023; ACM: New York, NY, USA, 2023; pp. 1–11. [Google Scholar] [CrossRef]

- Iranshahi, K.; Brun, J.; Arnold, T.; Sergi, T.; Müller, U.C. Digital twins: Recent advances and future directions in engineering fields. Intell. Syst. Appl. 2025, 26, 200516. [Google Scholar] [CrossRef]

- Vlachopoulos, D.; Makri, A. The effect of games and simulations on higher education: A systematic literature review. Int. J. Educ. Technol. High. Educ. 2017, 14, 22. [Google Scholar] [CrossRef]

- Strazzeri, I.; Notebaert, A.; Barros, C.; Quinten, J.; Demarbaix, A. Virtual Reality Integration for Enhanced Engineering Education and Experimentation: A Focus on Active Thermography. Computers 2024, 13, 199. [Google Scholar] [CrossRef]

- Troussas, C.; Krouska, A.; Sgouropoulou, C. Enriching Mobile Learning Software with Interactive Activities and Motivational Feedback for Advancing Users’ High-Level Cognitive Skills. Computers 2022, 11, 18. [Google Scholar] [CrossRef]

- Dicheva, D.; Dichev, C.; Agre, G.; Angelova, G. Gamification in Education: A Systematic Mapping Study. Educ. Technol. Soc. 2015, 18, 75–88. [Google Scholar]

- Pàmies-Vilà, R.; Puig-Ortiz, J.; Jordi Nebot, L. Enhancing mechanical engineering education through augmented reality: A case study on mechanism and machine theory. Int. J. Mech. Eng. Educ. 2025, in press. [CrossRef]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges and Open Research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Barricelli, B.R.; Casiraghi, E.; Fogli, D. A Survey on Digital Twin: Definitions, Characteristics, Applications, and Design Implications. IEEE Access 2019, 7, 167653–167671. [Google Scholar] [CrossRef]

- Hananto, A.L.; Tirta, A.; Herawan, S.G.; Idris, M.; Soudagar, M.E.M.; Djamari, D.W.; Veza, I. Digital Twin and 3D Digital Twin: Concepts, Applications, and Challenges in Industry 4.0 for Digital Twin. Computers 2024, 13, 100. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of Digital Twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2021, 58, 346–361. [Google Scholar] [CrossRef]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Errandonea, I.; Beltrán, S.; Arrizabalaga, S. Digital Twin for maintenance: A literature review. Comput. Ind. 2020, 123, 103316. [Google Scholar] [CrossRef]

- Liu, Y.K.; Ong, S.K.; Nee, A.Y.C. State-of-the-art survey on digital twin implementations. Adv. Manuf. 2022, 10, 1–23. [Google Scholar] [CrossRef]

- Weis, P.; Smetanka, L.; Hrček, S.; Vereš, M. Interactive Application as a Teaching Aid in Mechanical Engineering. Computers 2024, 13, 170. [Google Scholar] [CrossRef]

- Gavish, N.; Gutiérrez, T.; Webel, S.; Rodríguez, J.; Peveri, M.; Bockholt, U.; Tecchia, F. Evaluating virtual reality and augmented reality training for industrial maintenance and assembly tasks. Interact. Learn. Environ. 2015, 23, 778–798. [Google Scholar] [CrossRef]

- Di Pietro, G.; Castaño Muñoz, J. A meta-analysis on the effect of technology on the achievement of less advantaged students. Comput. Educ. 2025, 226, 105197. [Google Scholar] [CrossRef]

- Karanam, S.A.K.; Hartman, N.W. A systematic review of Digital Twin (DT) and virtual learning environments (VLE) for smart manufacturing education. Manuf. Lett. 2025, 44, 1597–1608. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).