EIPPM—The Executable Integrative Product-Production Model †

Abstract

1. Introduction

- Solution variants must be excluded at an early stage, as parallel development is not economically feasible.

- Decision-making is discipline-specific (mechanics, electronics, software), sequential and involves compromises, but often ignores cross-disciplinary couplings.

2. Fundamentals and Literature Review

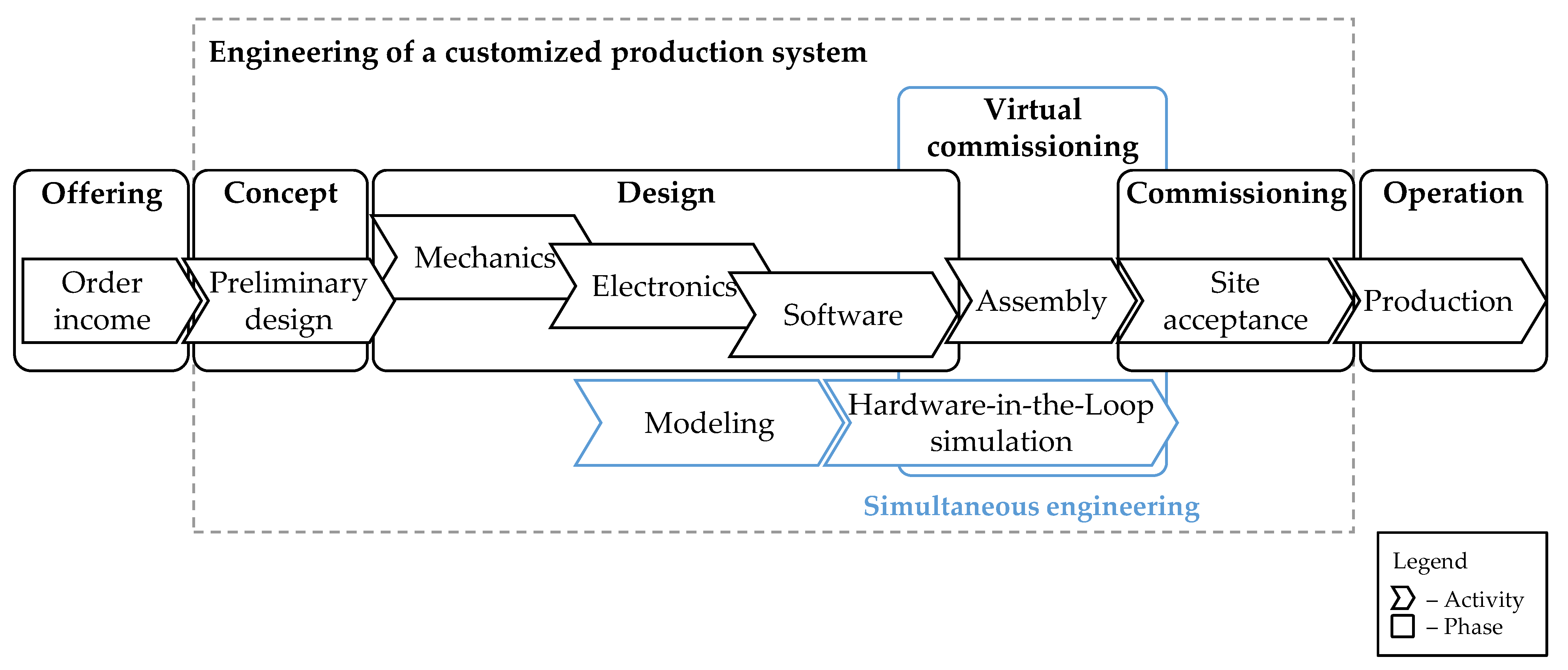

2.1. Methods for Virtual Commissioning of Production Systems

- The VCOM of control hardware and software

- Testing of the automation software and the human machine interface

- The optimization of the automation software

- Training of operators for the real production system

- Late time of model generation: Only final information from the individual mechatronic disciplines is included in the simulation models because the intended use is VCOM.

- Low frequency of model generation: The simulation is only generated and used for final acceptance, since data maintenance is still very time-consuming.

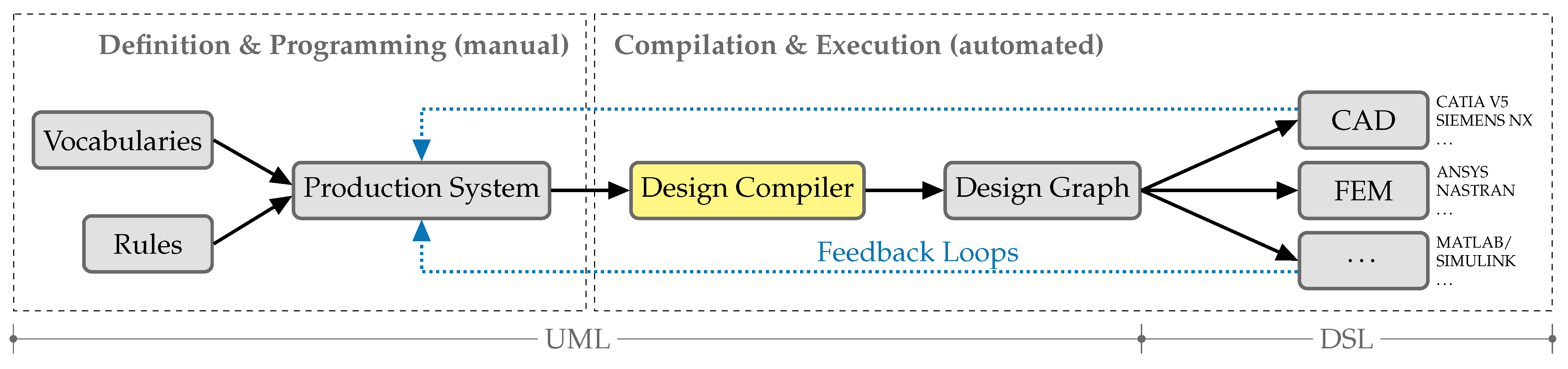

2.2. Graph-Based Design Languages based on Principles of Systems Engineering and Model-Based Systems Engineering

2.3. Literature Review of Model-Based Engineering for Production Systems

- /R1/

- Model-based description and coupling of a product and its associated PS (semantic interoperability)

- /R2/

- Automatic derivation of solution variants of the PS from the description

- /R3/

- Automatic generation of simulation models for the PS

- /R4/

- Feedback from simulation-based validation into system design

2.4. Interim Conclusions

- Formal storage of knowledge in the form of class diagrams and rules for simple know-how reuse

- Full semantic interoperability in the modeling of the product and the associated PS

- Fully automatic derivation of solution variants

- Fully automatic generation of simulation models for continuous virtual verification

- Feedback system of simulation-based validation and optimization back into system design model

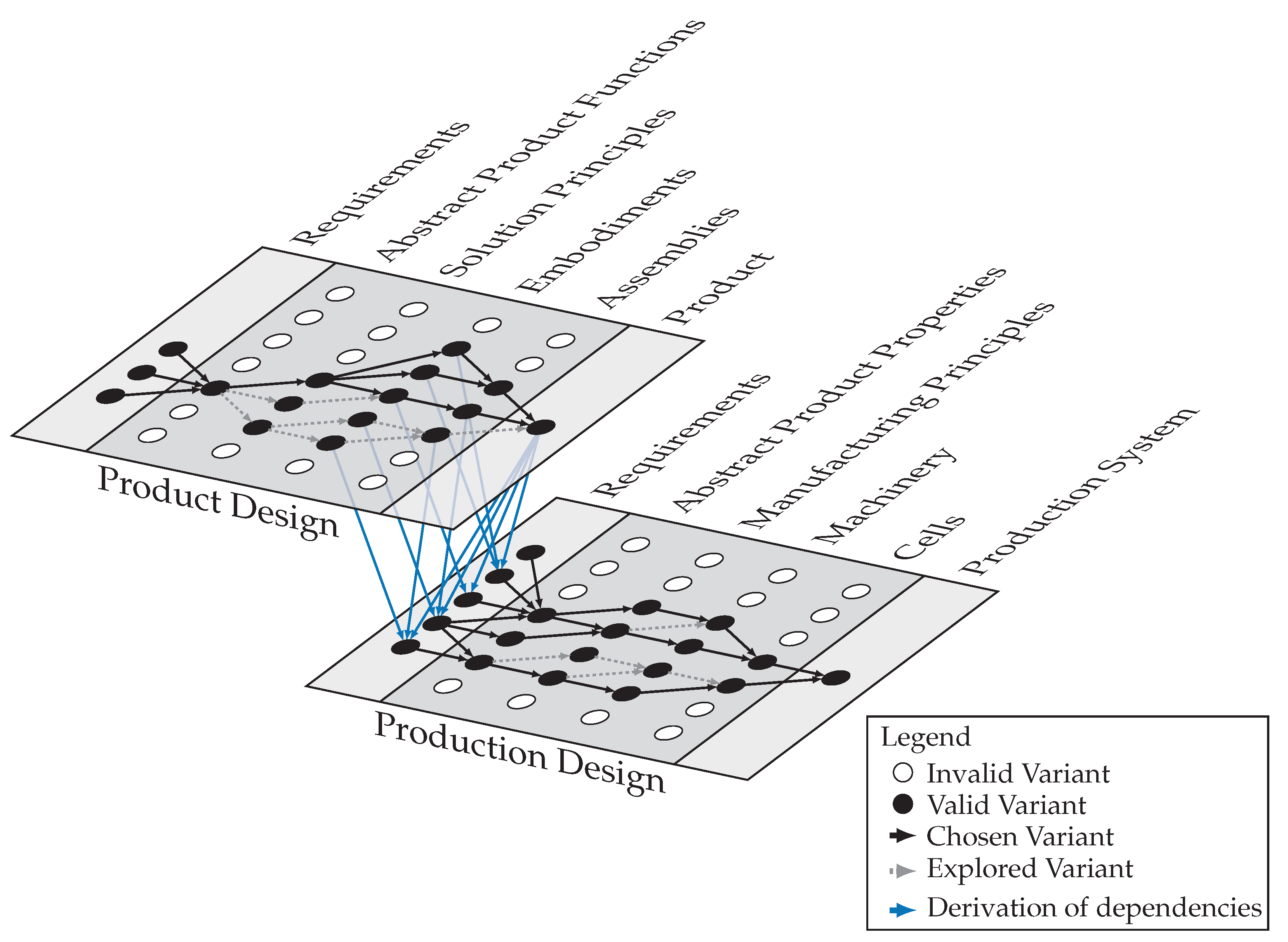

3. The Executable Integrative Product-Production Model (EIPPM)

Iterative Generation of the Product-Production Model, the Simulation Models and the Assessment

- Automated model-based system development for a complete and consistent description of the complex “product-production” system

- Iterative approach by automated expression and analysis of variants of the PS on VCOM simulation models

- Supporting methods for the optimization of the variants or for the optimal selection of a variant

- Simulative identification of weak points in the generated product-production system and transfer into improvement suggestions for the automated design process

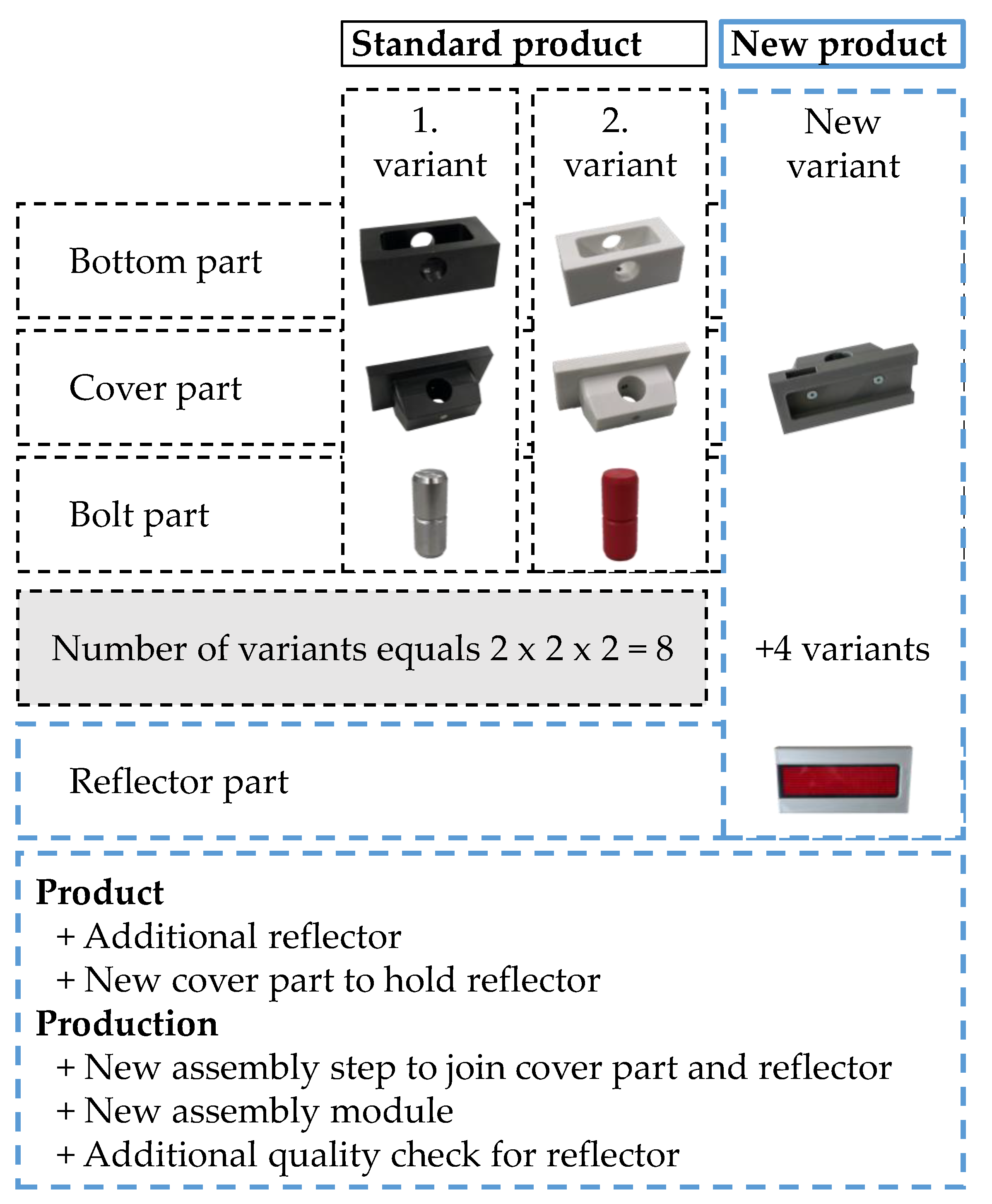

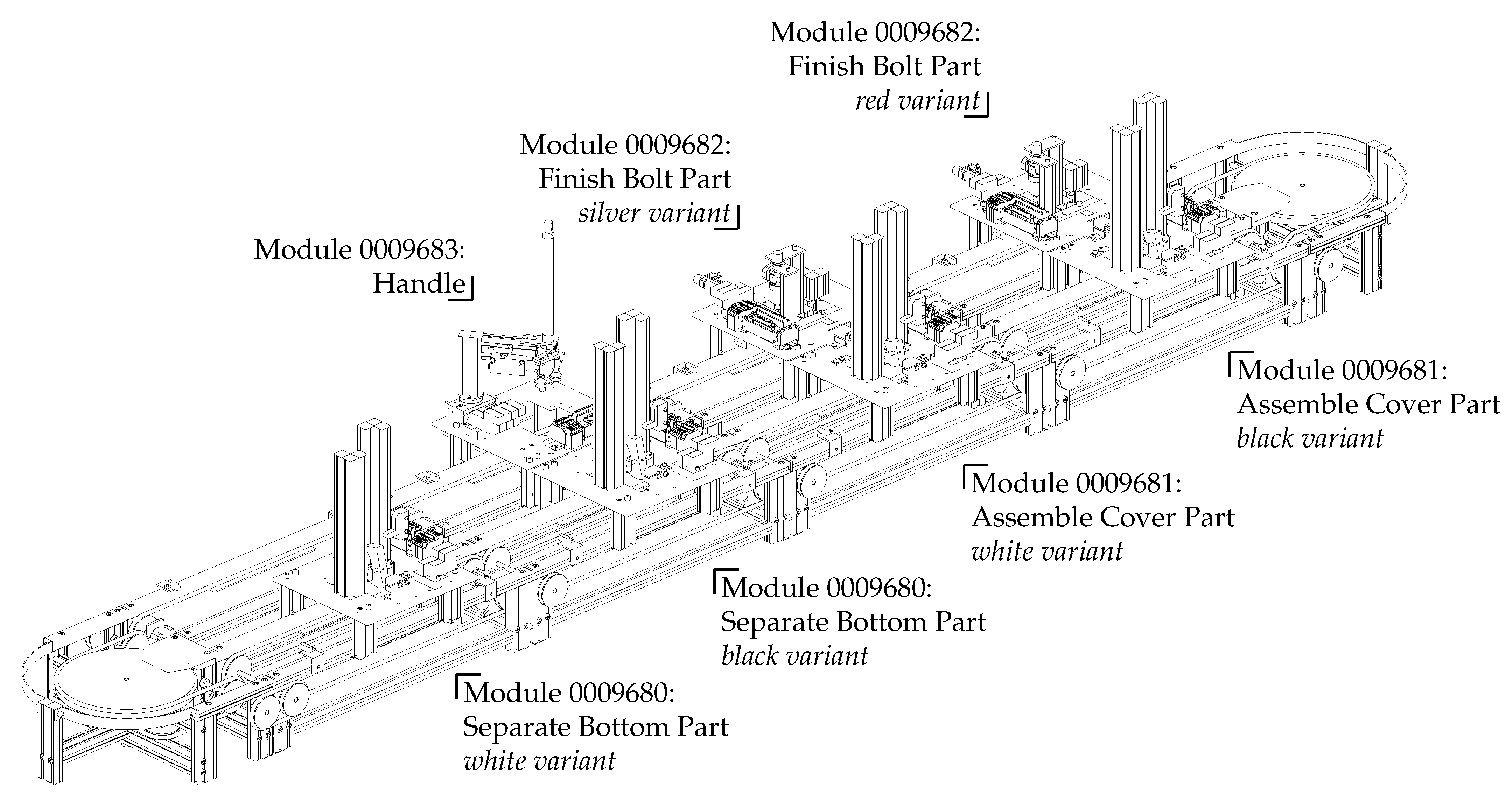

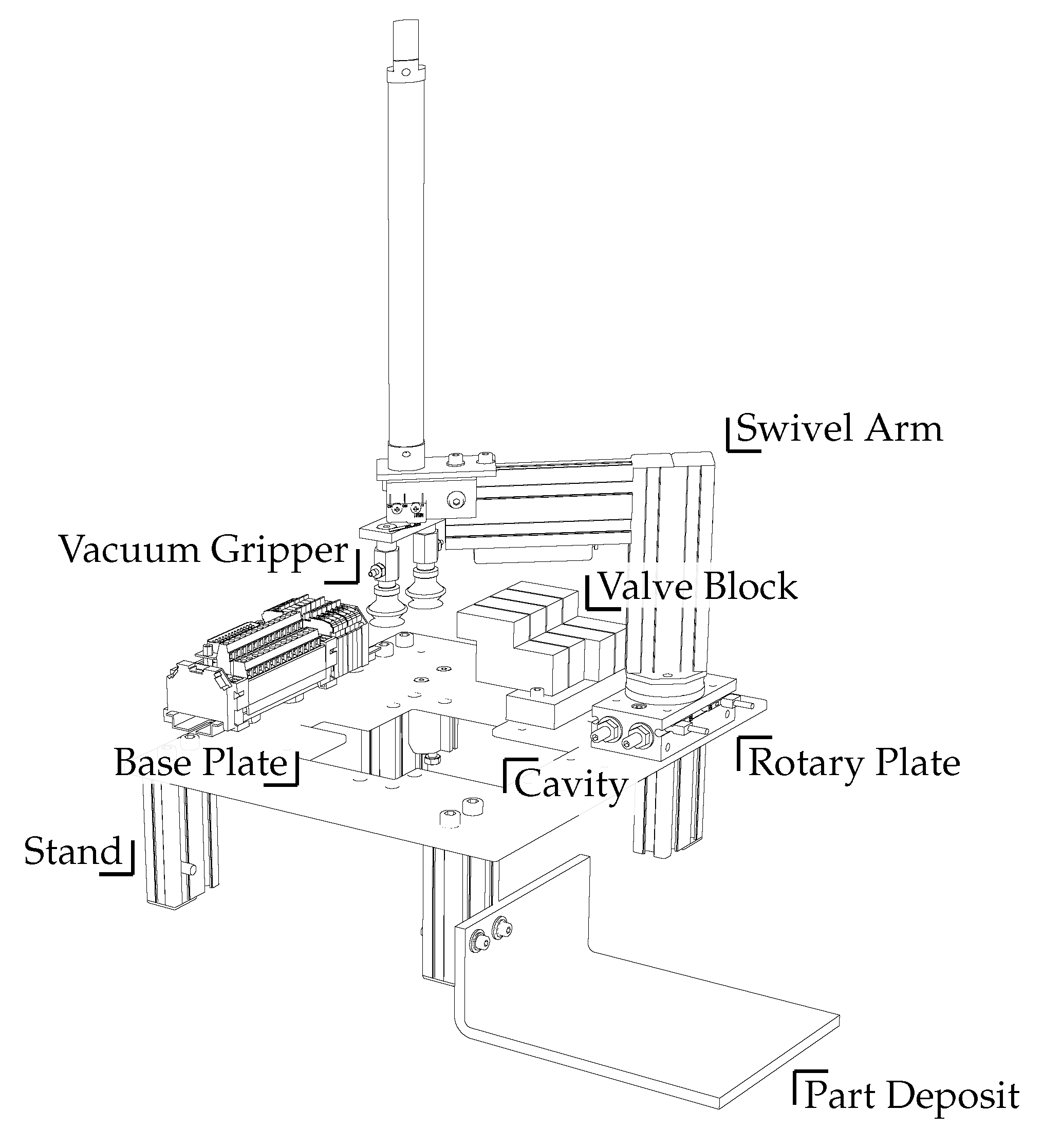

4. Application Example

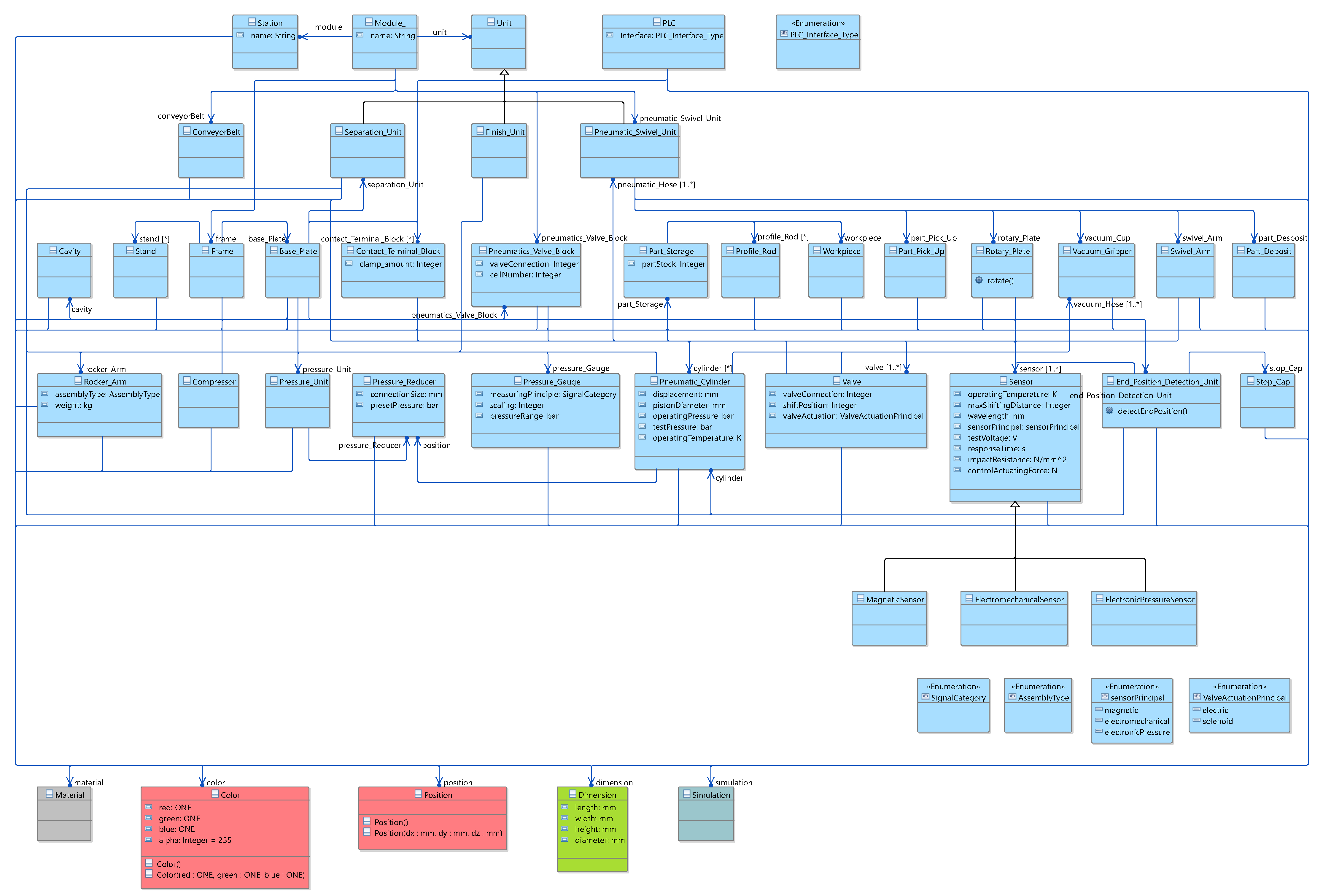

4.1. Modeling of the Class Diagram

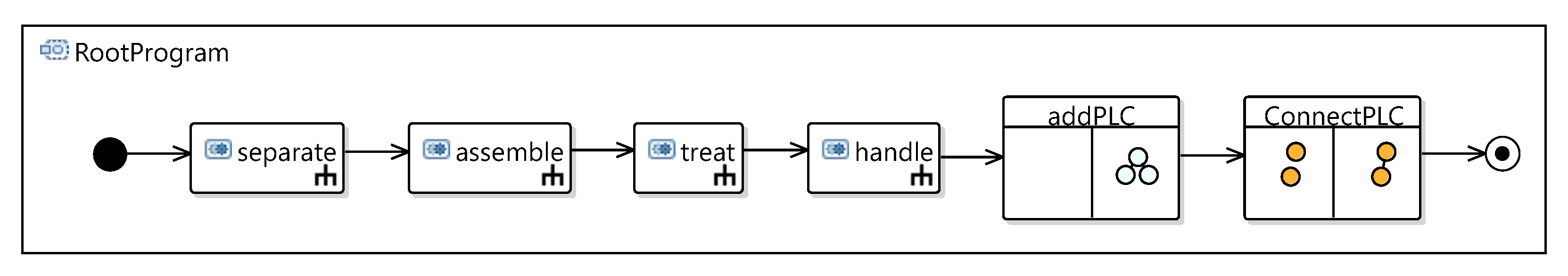

4.2. Modeling of the Activity Diagram and the Rules

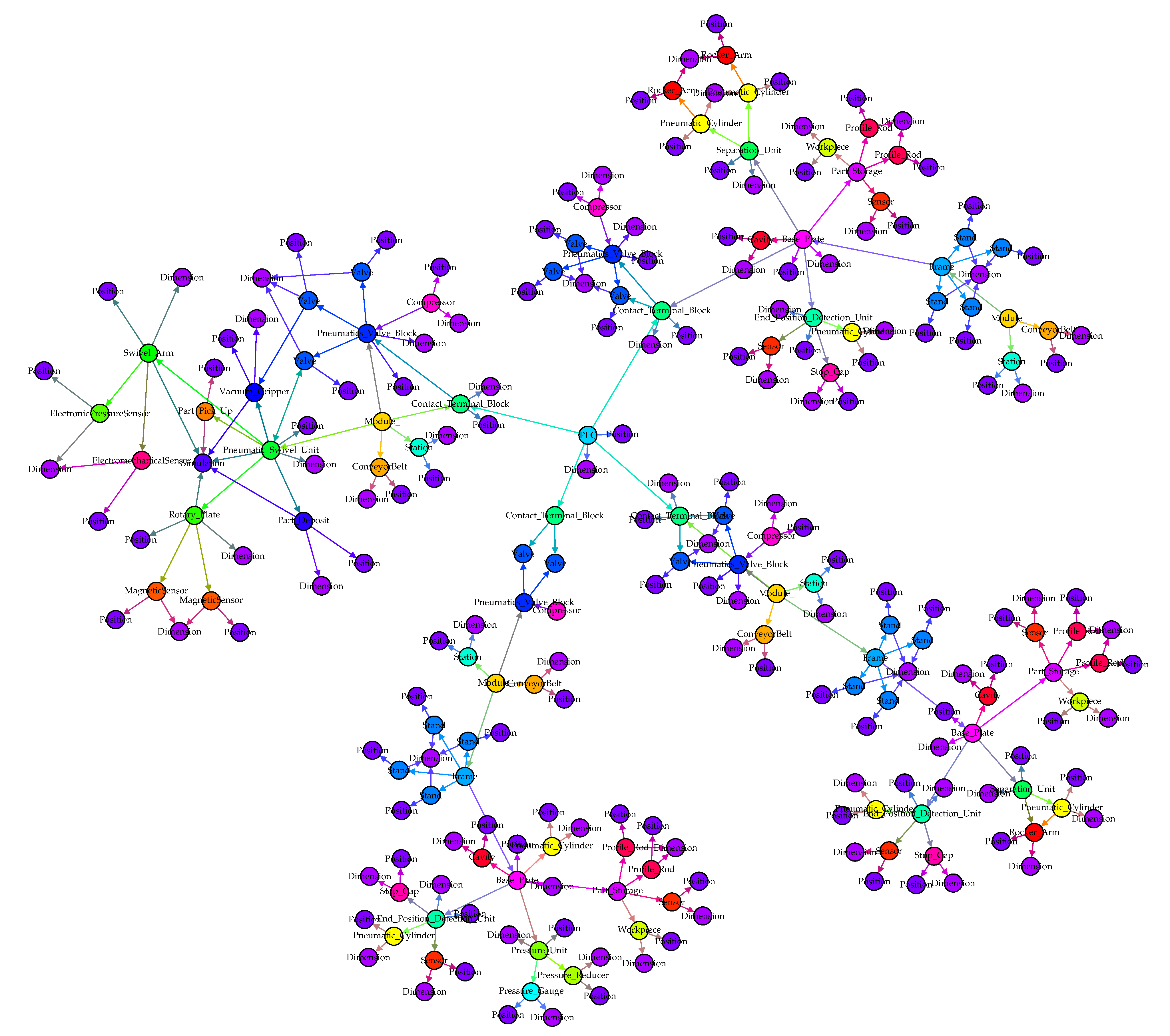

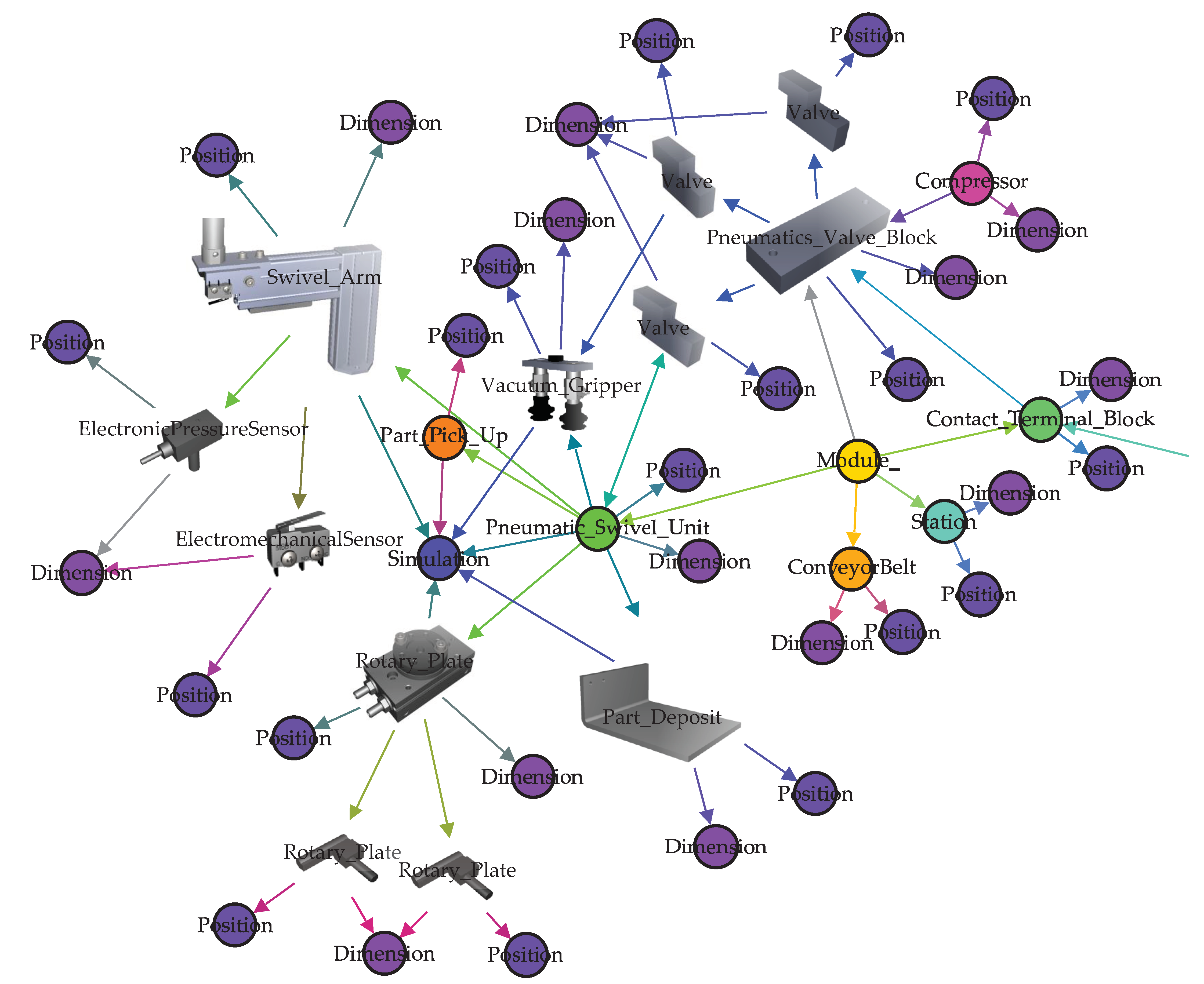

4.3. The Design Graph

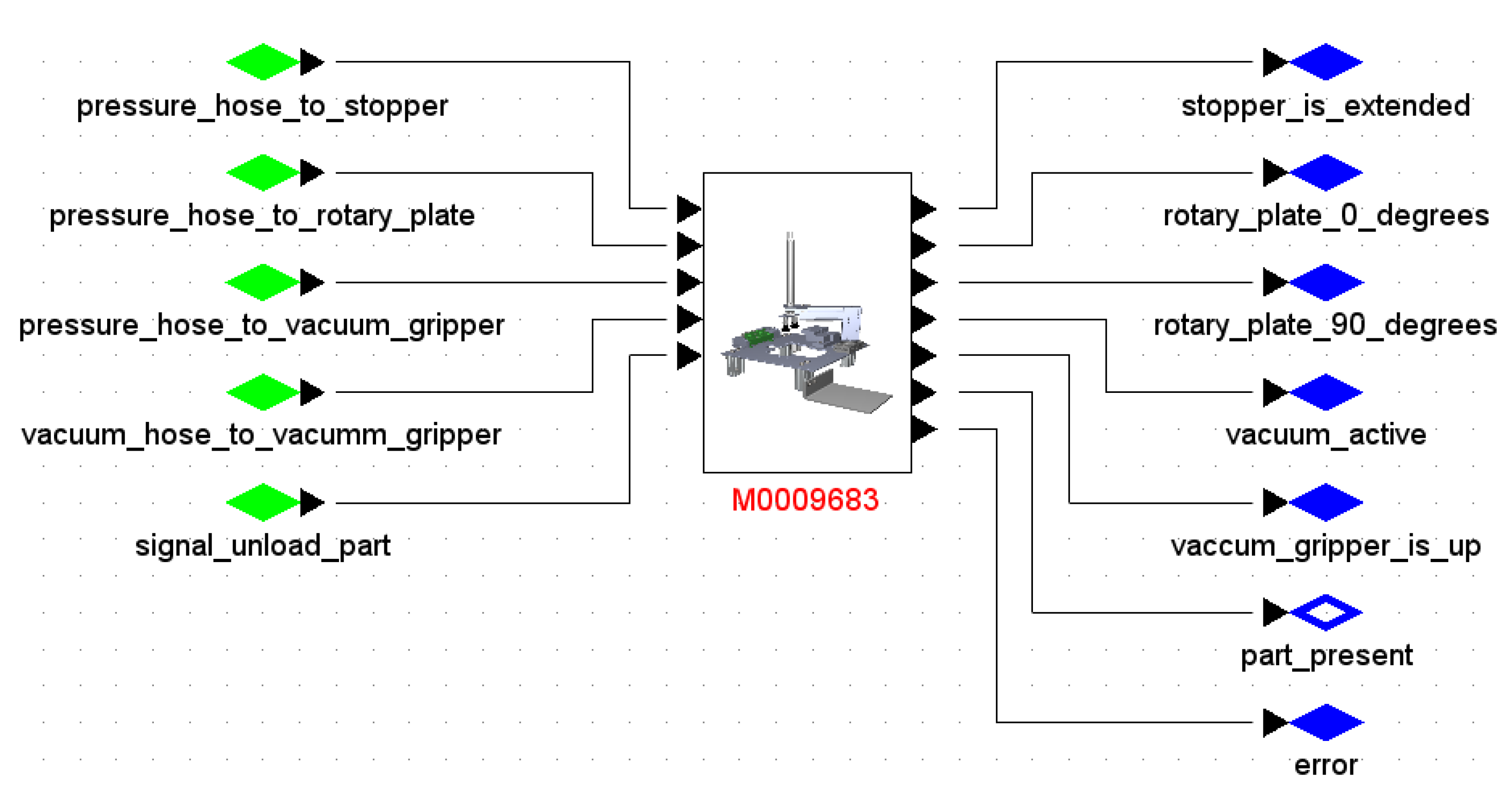

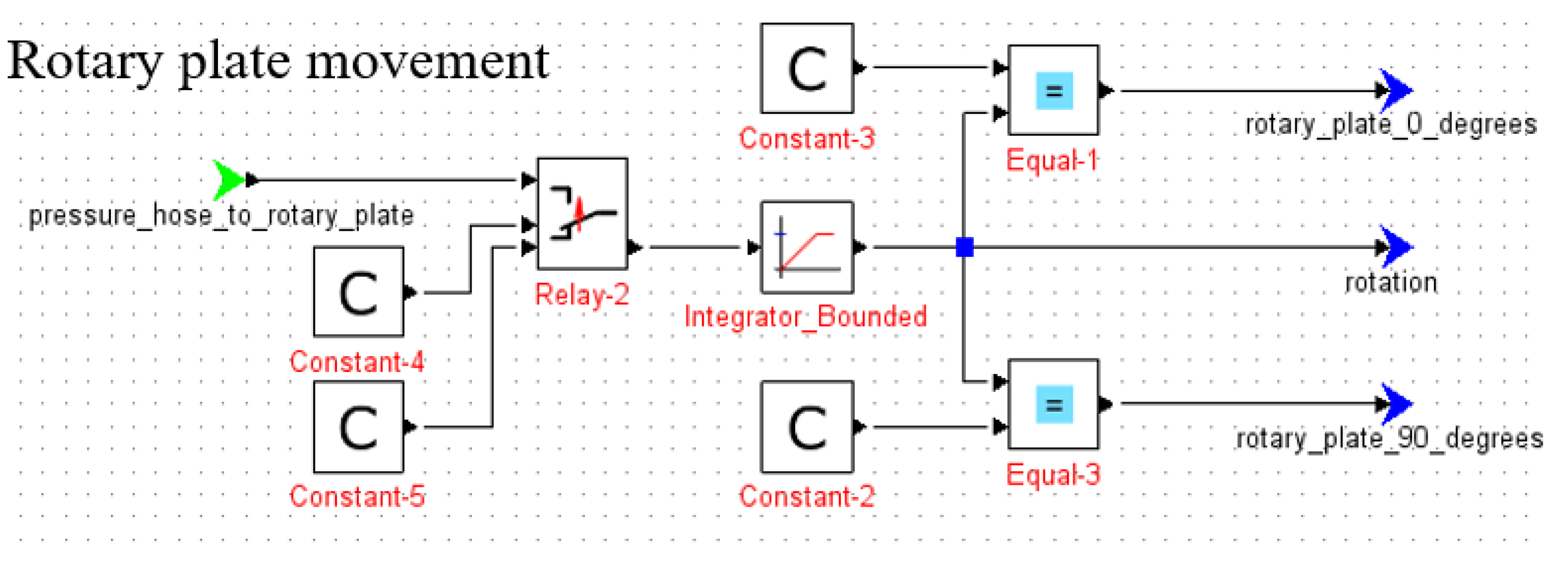

4.4. Generation of the Simulation Models

5. Discussion

6. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CAD | Computer-Aided Design |

| DSL | Domain Specific Language |

| EIPPM | Executable Integrative Product-Production Model |

| GBDL | Graph-based Design Language |

| HiL | Hardware-in-the-Loop |

| LHS | Left-Hand Side |

| IMS | Industrial Mechatronic System |

| MBE | Model-Based Engineering |

| MBSE | Model-Based Systems Engineering |

| MOF | Meta Object Facility |

| MiL | Model-in-the-Loop |

| PS | Production System |

| RHS | Right-Hand Side |

| SBE | Simulation-Based Engineering |

| SiL | Software-in-the-Loop |

| UML | Unified Modeling Language |

| VCOM | Virtual Commissioning |

References

- ElMaraghy, H.A. Flexible and reconfigurable manufacturing systems paradigms. Int. J. Flex. Manuf. Syst. 2005, 17, 261–276. [Google Scholar] [CrossRef]

- Acerbi, F.; Sassanelli, C.; Terzi, S.; Taisch, M. A Systematic Literature Review on Data and Information Required for Circular Manufacturing Strategies Adoption. Sustainability 2021, 13, 2047. [Google Scholar] [CrossRef]

- Royce, W.W. Managing the development of large software systems. In Proceedings of the IEEE WESCON 26, Los Angeles, CA, USA, 25–28 August 1970; TRW, Ed.; 1970; pp. 1–9. [Google Scholar]

- Verein Deutscher Ingenieure e.V. Digital Factory: Digital Factory Operations; VDI Guideline 4499, Sheet 2; Verlag des Vereins Deutscher Ingenieure: Dusseldorf, Germany, 2011. [Google Scholar]

- Kübler, K.; Scheifele, S.; Scheifele, C.; Riedel, O. Model-Based Systems Engineering for Machine Tools and Production Systems (Model-Based Production Engineering). Procedia Manuf. 2018, 24, 216–221. [Google Scholar] [CrossRef]

- Verein Deutscher Ingenieure e.V. Design of Technical Products and Systems: Model of Product Design; VDI Guideline 2221, Sheet 1; Verlag des Vereins Deutscher Ingenieure: Dusseldorf, Germany, 2019. [Google Scholar]

- Röck, S. Hardware in the loop simulation of production systems dynamics. Prod. Eng. 2011, 5, 329–337. [Google Scholar] [CrossRef]

- Stöppler, G.; Menzel, T.; Douglas, S. Hardware-in-the-loop simulation of machine tools and manufacturing systems. IEE Comput. Control Eng. 2005, 16, 10–15. [Google Scholar] [CrossRef]

- Reinhart, G.; Wünsch, G. Economic application of virtual commissioning to mechatronic production systems. Prod. Eng. 2007, 1, 371–379. [Google Scholar] [CrossRef]

- Verein Deutscher Ingenieure e.V. Digital Factory: Fundamentals; VDI Guideline 4499, Sheet 1; Verlag des Vereins Deutscher Ingenieure: Dusseldorf, Germany, 2008. [Google Scholar]

- Kühne, T. Matters of (Meta-) Modeling. Softw. Syst. Model. 2006, 5, 369–385. [Google Scholar] [CrossRef]

- Atkinson, C.; Kuhne, T. Model-driven development: A metamodeling foundation. IEEE Softw. 2003, 20, 36–41. [Google Scholar] [CrossRef]

- Caggiano, A.; Caiazzo, F.; Teti, R. Digital Factory Approach for Flexible and Efficient Manufacturing Systems in the Aerospace Industry. Procedia CIRP 2015, 37, 122–127. [Google Scholar] [CrossRef]

- Neyrinck, A.; Lechler, A.; Verl, A. Automatic Variant Configuration and Generation of Simulation Models for Comparison of Plant and Machinery Variants. Procedia CIRP 2015, 29, 62–67. [Google Scholar] [CrossRef]

- Yemenicioğlu, E. Data Exchange for the Physics-Based Simulation of Material Handling Systems in the Digital Factory. Ph.D. Thesis, Otto-von-Guericke-Universität, Magdeburg, Germany, 2016. [Google Scholar]

- Kübler, K.; Oberle, M.; Verl, A.; Riedel, O. Simulation-assisted run-to-run control for battery manufacturing in a cloud environment. In Proceedings of the 2017 24th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Auckland, New Zealand, 21–23 November 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Novák, P.; Ekaputra, F.J.; Biffl, S. Generation of Simulation Models in MATLAB-Simulink Based on AutomationML Plant Description. IFAC-PapersOnLine 2017, 50, 7613–7620. [Google Scholar] [CrossRef]

- Martinez, G.S.; Sierla, S.; Karhela, T.; Vyatkin, V. Automatic Generation of a Simulation-Based Digital Twin of an Industrial Process Plant. In Proceedings of the IECON 2018—44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018; pp. 3084–3089. [Google Scholar] [CrossRef]

- Scheifele, C.; Verl, A.; Riedel, O. Real-time co-simulation for the virtual commissioning of production systems. Procedia CIRP 2019, 79, 397–402. [Google Scholar] [CrossRef]

- Schopper, D.; Rudolph, S. From Model-Driven Architecture and Model-Based Systems Engineering via Formal Concept Analysis to Graph-Based Design Languages and Back: A Scientific Discourse. In Proceedings of the ASME 2018 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference IDETC/CIE 2018, Québec City, QC, Canada, 26–29 August 2018. [Google Scholar]

- Bajaj, M.; Backhaus, J.; Walden, T.; Waikar, M.; Zwemer, D.; Schreiber, C.; Issa, G.; Martin, L. Graph-Based Digital Blueprint for Model Based Engineering of Complex Systems. INCOSE Int. Symp. 2017, 27, 151–169. [Google Scholar] [CrossRef]

- Fricke, E.; Gebhard, B.; Negele, H.; Igenbergs, E. Coping with changes: Causes, findings, and strategies. Syst. Eng. 2000, 3, 169–179. [Google Scholar] [CrossRef]

- Verein Deutscher Ingenieure e.V.; Verband der Elektrotechnik Elektronik Informationstechnik e.V. Virtual Commissioning: Model Types and Glossary; VDI/VDE Guideline 3693, Sheet 1; Verlag des Vereins Deutscher Ingenieure: Dusseldorf, Germany, 2016. [Google Scholar]

- Rosen, R.; Jäkel, J.; Barth, M.; Stern, O.; Schmidt-Vollus, R.; Heinzerling, T.; Hoffmann, P.; Richter, C.; Puntel Schmidt, P.; Scheifele, C. Simulation und Digitaler Zwilling im Engineering und Betrieb Automatisierter Anlagen—Standpunkte und Thesen des GMA FA 6.11; VDI/VDE-Gesellschaft Mess- und Automatisierungstechnik, Ed.; Automation 2019; VDI Verlag GmbH: Düsseldorf, Germany, 2019; pp. 531–560. [Google Scholar]

- Oppelt, M.; Hoernicke, M.; Rosen, R.; Urbas, L.; Barth, M. Simulation 2025: Simulation im Lebenszyklus Industrieller Anlagen; VDI/VDE-Gesellschaft Mess- und Automatisierungstechnik, Ed.; Automation 2016; VDI Verlag GmbH: Düsseldorf, Germany, 2016. [Google Scholar]

- Scheifele, S.; Riedel, O.; Pritschow, G. Engineering of machine tools and plants using cyber-physical systems. In Proceedings of the 2017 Winter Simulation Conference, Las Vegas, NV, USA, 3–6 December 2017; IEEE Press: Piscataway, NJ, USA, 2017; pp. 1503–1514. [Google Scholar]

- Xu, L. Wiederverwendbare Modelle zur Maschinensimulation für den Steuerungstest. Ph.D. Thesis, Technische Universität München, München, Germany, 2003. [Google Scholar]

- Oppelt, M.; Wolf, G.; Drumm, O.; Lutz, B.; Baudisch, T.; Wehrstedt, J.C.; Krause, A.; Urbas, L. Automatische Generierung von Simulationsmodellen für die virtuelle Inbetriebnahme auf Basis von Planungsdaten; VDI/VDE-Gesellschaft Mess- und Automatisierungstechnik, Ed.; Automation 2014; VDI-Verlag: Düsseldorf, Germany, 2014. [Google Scholar]

- Barth, M. Automatisch Generierte Simulationsmodelle Verfahrenstechnischer Anlagen für den Steuerungstest: Zugl.: Hamburg, Univ. der Bundeswehr, Diss., 2011th ed.; Fortschritt-Berichte VDI Reihe 20, Rechnerunterstützte Verfahren; VDI-Verlag: Düsseldorf, Germany, 2011; Volume 438. [Google Scholar]

- Barth, M.; Fay, A. Automated generation of simulation models for control code tests. Control Eng. Pract. 2013, 21, 218–230. [Google Scholar] [CrossRef]

- Puntel Schmidt, P. Methoden zur Simulationsbasierten Absicherung von Steuerungscode Fertigungstechnischer Anlagen. Ph.D. Thesis, Helmut-Schmidt-Universität, Universität der Bundeswehr and Helmut-Schmidt-Universität, Hamburg, Germany, 2017. [Google Scholar]

- Kufner, A. Automatisierte Erstellung von Maschinenmodellen für die Hardware-in-the-Loop-Simulation von Montagemaschinen. Ph.D. Thesis, Universität Stuttgart, Stuttgart, Germany, 2012. [Google Scholar] [CrossRef]

- Weyrich, M.; Steden, F. Produktionssysteme modulbasiert simulieren: Methodische Identifikation wiederverwendbarer Simulationsmodule im Engineering-Prozess. Wt Werkstattstech. Online 2013, 103, 162–167. [Google Scholar]

- Lindworsky, A. Teilautomatische Generierung von Simulationsmodellen für den entwicklungsbegleitenden Steuerungstest. Ph.D. Thesis, Technische Universität München, München, Germany, 2011. [Google Scholar]

- Rudolph, S. Übertragung von Ähnlichkeitsbegriffen; Universität Stuttgart: Stuttgart, Germany, 2002. [Google Scholar]

- Rudolph, S.; Kröplin, B. Entwurfsgrammatiken—Ein Paradigmenwechsel. Prüfingenieur 2005, 26, 34–43. [Google Scholar]

- INCOSE Technical Operations. INCOSE Systems Engineering Vision 2020. Available online: http://www.ccose.org/media/upload/SEVision2020_20071003_v2_03.pdf (accessed on 25 May 2021).

- Walter, B.; Martin, J.; Schmidt, J.; Dettki, H.; Rudolph, S. Executable State Machines Derived from Structured Textual Requirements—Connecting Requirements and Formal System Design. In Proceedings of the 7th International Conference on Model-Driven Engineering and Software Development, SCITEPRESS—Science and Technology Publications, Prague, Czech Republic, 20–22 February 2019; pp. 195–202. [Google Scholar] [CrossRef]

- Rudolph, S.; Beichter, J.; Eheim, M.; Hess, S.; Motzer, M.; Weil, R. On Multi-Disciplinary Architectural Synthesis and Analysis of Complex Systems with Graph-based Design Languages. In Proceedings of the 62th Deutscher Luft- und Raumfahrtkongress (DGLR 2013), Stuttgart, Germany, 10–12 September 2013. [Google Scholar]

- Groß, J.; Rudolph, S. Regelbasierte Analyse von Entscheidungen im Entwurf komplexer Systeme. In Tag des Systems Engineering; Maurer, M., Schulze, S.O., Eds.; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2013; pp. 175–183. [Google Scholar] [CrossRef]

- Groß, J.; Rudolph, S. Dependency Analysis in Complex System Design using the FireSat example. INCOSE Int. Symp. 2012, 22, 1856–1869. [Google Scholar] [CrossRef]

- Kiesel, M.; Klimant, P.; Beisheim, N.; Rudolph, S.; Putz, M. Using Graph-based Design Languages to Enhance the Creation of Virtual Commissioning Models. Procedia CIRP 2017, 60, 279–283. [Google Scholar] [CrossRef]

- Zech, A.; Stetter, R.; Till, M.; Rudolph, S. Automated generation of clamping concepts and assembly cells for car body parts for the digitalization of automobile production. In Proceedings of the Stuttgart Conference on Automotive Production (SCAP2020), Stuttgart, Germany, 9–10 November 2020. [Google Scholar]

- Feldhusen, J.; Grote, K.H. (Eds.) Pahl/Beitz Konstruktionslehre: Methoden und Anwendung Erfolgreicher Produktentwicklung, 8 Vollständig Überarbeitete Auflage ed.; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- BITKOM e.V.; VDMA e.V.; ZVEI e.V. (Eds.) Umsetzungsstrategie Industrie 4.0: Ergebnisbericht der Plattform Industrie 4.0. 2015. Available online: https://www.bitkom.org/sites/default/files/file/import/150410-Umsetzungsstrategie-0.pdf (accessed on 25 May 2021).

- Groß, J.; Rudolph, S. Modeling graph-based satellite design languages. Aerosp. Sci. Technol. 2016, 49, 63–72. [Google Scholar] [CrossRef]

- Groß, J.; Rudolph, S. Rule-based spacecraft design space exploration and sensitivity analysis. Aerosp. Sci. Technol. 2016, 59, 162–171. [Google Scholar] [CrossRef]

- Groß, J.; Rudolph, S. Geometry and simulation modeling in design languages. Aerosp. Sci. Technol. 2016, 54, 183–191. [Google Scholar] [CrossRef]

- Arnold, P.; Rudolph, S. Bridging the gap between product design and product manufacturing by means of graph-based design languages. In Proceedings of the TMCE 2012, Karlsruhe, Germany, 7–11 May 2012; Horváth, I., Ed.; Delft University of Technology: Delft, The Netherlands, 2012; pp. 985–998. [Google Scholar]

- Kübler, K.; Schopper, D.; Riedel, O.; Rudolph, S. Towards an Automated Product-Production System Design—Combining Simulation-based Engineering and Graph-based Design Languages. Procedia Manuf. 2020, 52, 258–265. [Google Scholar] [CrossRef]

- Ingenieurgesellschaft für Intelligente Lösungen und Systeme mbH (IILS). The Design Cockpit 43. 2021. Available online: https://www.iils.de/ (accessed on 25 May 2021).

- Rabe, M.; Anacker, H.; Westermann, T.; Dumitrescu, R. Potential of using model-based systems engineering to improve the development process of engineering-to-order products in the field of machinery and plant engineering. J. Teknol. 2015, 76. [Google Scholar] [CrossRef][Green Version]

- Bursac, N.; Albers, A.; Ölschläger, M. Baukastenentwicklung durch MBSE am Beispiel einer modularen Fertigungsanlage im Kontext der Industrie 4.0. In Tag des Systems Engineering, Herzogenaurach, 25–27 Oktober 2016; Schulze, S.O., Tschirner, C., Kaffenberger, R., Ackva, S., Eds.; Hanser: München, Germany, 2017; pp. 247–256. [Google Scholar]

- Wortmann, A.; Barais, O.; Combemale, B.; Wimmer, M. Modeling languages in Industry 4.0: An extended systematic mapping study. Softw. Syst. Model. 2019, 86, 997. [Google Scholar] [CrossRef]

- Dziwok, S.; Pohlmann, U.; Piskachev, G.; Schubert, D.; Thiele, S.; Gerking, C. The MechatronicUML Design Method: Process and Language for Platform-Independent Modeling. Available online: http://www.mechatronicuml.org/ (accessed on 25 May 2021).

- Pohlmann, U. A Model-Driven Software Construction Approach for Cyber-Physical Systems. Ph.D. Thesis, Universität Paderborn, Paderborn, Germany, 2018. [Google Scholar] [CrossRef]

- Alvarez Cabrera, A.A.; Foeken, M.J.; Tekin, O.A.; Woestenenk, K.; Erden, M.S.; de Schutter, B.; van Tooren, M.; Babuška, R.; van Houten, F.; Tomiyama, T. Towards automation of control software: A review of challenges in mechatronic design. Mechatronics 2010, 20, 876–886. [Google Scholar] [CrossRef]

- Hackenberg, G.; Richter, C.; Zäh, M. IMoMeSA—Abschlussbericht: Integrierte Modellbasierte Entwicklung Mechatronischer Systeme im Maschinen- und Anlagenbau; Abschlussbericht; Technische Universität München: München, Germany, 2015. [Google Scholar]

- Hackenberg, G. Test-Driven Conceptual Design of Cyber-Physical Manufacturing Systems. Ph.D. Thesis, Technische Universität München, München, Germany, 2018. [Google Scholar]

- Botaschanjan, J.; Hensel, T.; Hummel, B.; Lindworsky, A.; Zäh, M.F.; Reinhart, G.; Broy, M. AutoVIBN—Abschlussbericht: Automatische Generierung von Verhaltensmodellen aus CAD-Daten für die Qualitätsorientierte virtuelle Inbetriebnahme; Abschlussbericht; Technische Universität München: München, Germany, 2010. [Google Scholar]

- Albers, A. Five hypotheses about engineering processes and their consequences. In Proceedings of the TMCE, Ancona, Italy, 12–16 April 2010. [Google Scholar]

- Albers, A.; Muschik, S. The Role and Application of Activities in the Integrated Product Engineering Model (iPeM). In Proceedings of the International Design Conference—DESIGN 2010, Dubrovnik, Croatia, 17–20 May 2010; pp. 127–136. [Google Scholar]

- Albers, A.; Reiss, N.; Bursac, N.; Richter, T. iPeM—Integrated Product Engineering Model in Context of Product Generation Engineering. Procedia CIRP 2016, 50, 100–105. [Google Scholar] [CrossRef]

- Albers, A.; Fahl, J.; Hirschter, T.; Haag, S.; Hunemeyer, S.; Staiger, T. Defining, Formulating and Modeling Product Functions in the Early Phase in the Model of PGE—Product Generation Engineering. In Proceedings of the 2020 IEEE International Symposium on Systems Engineering (ISSE), Vienna, Austria, 12 October–12 November 2020; pp. 1–10. [Google Scholar] [CrossRef]

- Mandel, C.; Wolter, K.; Bause, K.; Behrendt, M.; Hanf, M.; Albers, A. Model-Based Systems Engineering methods to support the reuse of knowledge within the development of validation environments. In Proceedings of the 2020 IEEE International Systems Conference (SysCon), Montreal, QC, Canada, 24 August–20 September 2020; pp. 1–7. [Google Scholar] [CrossRef]

- Bursac, N. Model Based Systems Engineering zur Unterstützung der Baukastenentwicklung im Kontext der Frühen Phase der Produktgenerationsentwicklung. Ph.D. Thesis, Karlsruher Institut für Technologie, Karlsruhe, Germany, 2016. [Google Scholar]

- Object Management Group. OMG Meta Object Facility (MOF) Core Specification. Available online: https://www.omg.org/spec/MOF/2.5.1/PDF (accessed on 25 May 2021).

- Kombination und Integration Etablierter Technologien mit additiven Fertigungsverfahren: Projekt-Abschlussbericht KitkAdd; Karlsruher Institut für Technologie (KIT) wbk Institut für Produktionstechnik, 2020; Available online: http://www.kitkadd.de/ (accessed on 25 May 2021).

- Jacob, A.; Windhuber, K.; Ranke, D.; Lanza, G. Planning, Evaluation and Optimization of Product Design and Manufacturing Technology Chains for New Product and Production Technologies on the Example of Additive Manufacturing. Procedia CIRP 2018, 108–113. [Google Scholar] [CrossRef]

- Jacob, A.; Steimer, S.; Stricker, N.; Häfner, B.; Lanza, G. Integrating product function design, production technology optimization and process equipment planning on the example of hybrid additive manufacturing. Procedia CIRP 2019, 86, 222–227. [Google Scholar] [CrossRef]

- Eigner, M.; Koch, W.; Muggeo, C. (Eds.) Modellbasierter Entwicklungsprozess Cybertronischer Systeme; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- Oestersötebier, F. Modellbasierter Entwurf Intelligenter Mechatronischer Systeme Mithilfe Semantischer Technologien. Ph.D. Thesis, Universität Paderborn, Paderborn, Germany, 2018. [Google Scholar]

- Stoffels, P.; Kaspar, J.; Bähre, D.; Vielhaber, M. Integrated Product and Production Engineering Approach—A Tool-Based Method for a Holistic Sustainable Design, Process and Material Selection. Procedia Manuf. 2018, 21, 790–797. [Google Scholar] [CrossRef]

- Verl, A.; Haubelt, A. Der Weg zur automatischen Generierung von Simulationsmodellen aus mechatronischen Baukästen. In Effiziente Methodiken und Durchgängige Werkzeuge zur Modellerstellung Digitaler Produktionseinrichtungen; Brecher, C., Ed.; Fortschritt-Berichte VDI Reihe 2, Fertigungstechnik 671; VDI Verlag: Düsseldorf, Germany, 2009; pp. 55–70. [Google Scholar]

- Verl, A.; Müller, V.; Haubelt, A. Baukastenbasiertes simulationsgestütztes Engineering. A&D-Kompendium 2009, 2009/2010, 72–74. [Google Scholar]

- Reuter, A.; Müller, V.; Verl, A. Disziplinübergreifendes Engineering: Integration von Simulationsdaten in mechatronische Komponentenmodelle. Wt Werkstattstech. Online 2010, 100, 399–406. [Google Scholar]

- Voß, V. Wiederverwendbare Simulationsmodelle für die domänen- und disziplinübergreifende Produktentwicklung. Ph.D. Thesis, Universität Stuttgart, Stuttgart, Germany, 2012. [Google Scholar] [CrossRef]

- Brovkina, D.; Kienzlen, A.; Riedel, O. Comparative Analysis of Factory Simulation Description Models for Comprehensive Description of Model Design. In Proceedings of the 2020 IEEE Eurasia Conference on IOT, Communication and Engineering (ECICE), Yunlin, Taiwan, 23–25 October 2020; pp. 318–321. [Google Scholar] [CrossRef]

- Verein Deutscher Ingenieure e.V.; Verband der Elektrotechnik Elektronik Informationstechnik e.V. Formalised Process Descriptions: Concept and Graphic Representation; VDI Guideline 3682 Sheet 1; Verlag des Vereins Deutscher Ingenieure: Dusseldorf, Germany, 2015. [Google Scholar]

- Verein Deutscher Ingenieure e.V. Design Methodology for Mechatronic Systems; VDI Guideline 2206; Verlag des Vereins Deutscher Ingenieure: Dusseldorf, Germany, 2004. [Google Scholar]

- Meta-Modeling and the OMG Meta Object Facility (MOF): A White Paper by the OCUP 2 Examination Team. Available online: https://www.omg.org/ocup-2/documents/Meta-ModelingAndtheMOF.pdf (accessed on 25 May 2021).

- Grönninger, H.; Krahn, H.; Pinkernell, C.; Rumpe, B. Modeling Variants of Automotive Systems using Views. In Tagungsband Modellierungs-Workshop MBEFF: Modellbasierte Entwicklung von Eingebetteten Fahrzeugfunktionen; TU Braunschweig: Braunschweig, Germany, 2008. [Google Scholar]

- Schmidt, J.P.; Zeller, A.; Weyrich, M. Modellgetriebene Entwicklung serviceorientierter Anlagensteuerungen. At-Automatisierungstechnik 2017, 65, 26–36. [Google Scholar] [CrossRef]

- Voss, C.; Petzold, F.; Rudolph, S. Linking Building Design with the Digital Factory by Graph-based Design Languages. In Proceedings of the TMCE 2020, Dublin, Ireland, 11–15 May 2020. [Google Scholar]

- Esanakula, J.; Sridhar, N.V.; Rangadu, V. Knowledge Based Engineering: Notion, Approaches and Future Trends. Am. J. Intell. Syst. 2015, 2015, 1–17. [Google Scholar] [CrossRef]

Short Biography of Authors

| Dominik Schopper (born 1989) is a PhD student and member of the research group “Design Theory and Similarity Mechanics” at the Institute of Aircraft Design (IFB) at the University of Stuttgart. His scientific work focuses on Graph-based Design Languages, round-trip engineering and design automation. Mr. Schopper received his diploma (M.Sc.) from the University of Stuttgart in the course of study Aeronautics and Space Engineering. |

| Karl Kübler (born 1988) is head of the research group for “Virtual Methods in Production Engineering” at the Institute for Control Engineering of Machine Tools and Manufacturing Units (ISW) of the University of Stuttgart. His scientific work focuses on virtual commissioning, simulation-based engineering and test automation. Mr. Kübler received his diploma (Dipl.-Ing.) from the University of Stuttgart in the course of study Automation Technology in Production. |

| Stephan Rudolph (born 1961) holds various academic engineering degrees (Dipl.-Ing.), (Dr.-Ing.) and (Priv.-Doz.) from the University of Stuttgart, Germany. Stephan Rudolph is Head of the research group “Design Theory and Similarity Mechanics” at the Institute of Aircraft Design (IFB) at the University of Stuttgart and teaches several courses on digital engineering. His research interests include formal methods in Model-Based System Engineering (MBSE) and formal engineering design synthesis methods, automatic model generation and design evaluation methods. The second research interest are applications of similarity mechanics in engineering and artificial intelligence. |

| Oliver Riedel (born 1965) is Full Professor and Head of the Institute for Control Engineering of Machine Tools and Manufacturing Units (ISW) at the University of Stuttgart and holds the chair of production information technologies. He is also the institute director at Fraunhofer Institute for Industrial Engineering IAO in Stuttgart, where he focuses on digital engineering. Previously, he held several senior management positions in the IT and automotive industries. For more than 20 years, he has been working on the fundamentals and practical application of methods for virtual assurance in product development and production. |

| Reference | /R1/ | /R2/ | /R3/ | /R4/ |

|---|---|---|---|---|

| MechatronicUML and Pohlmann [55,56] |  either of them either of them |  |  |  |

| Alvarez Cabrera et al. [57] |  production production |  |  |  |

| Project AutoVIBN [60] |  production production |  |  |  |

| Project IMoMeSA and Hackenberg [58,59] |  either of them either of them |  |  |  |

| Project KitkAdd, Jacob et al. [68,69,70] |  both both |  |  |  |

| Project mecPro2 [71] |  both both |  |  |  |

| Albers et al. [61,62,63] |  product product |  |  |  |

| Bursac [66] |  product product |  |  |  |

| Oestersötebier [72] |  product product |  |  |  |

| Stoffels et al. [73] |  both both |  |  |  |

| Project WieMod and Voß [74,75,76,77] |  production production |  |  |  |

not fulfilled;

not fulfilled;  partly fulfilled;

partly fulfilled;  fully fulfilled.

fully fulfilled.Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schopper, D.; Kübler, K.; Rudolph, S.; Riedel, O. EIPPM—The Executable Integrative Product-Production Model. Computers 2021, 10, 72. https://doi.org/10.3390/computers10060072

Schopper D, Kübler K, Rudolph S, Riedel O. EIPPM—The Executable Integrative Product-Production Model. Computers. 2021; 10(6):72. https://doi.org/10.3390/computers10060072

Chicago/Turabian StyleSchopper, Dominik, Karl Kübler, Stephan Rudolph, and Oliver Riedel. 2021. "EIPPM—The Executable Integrative Product-Production Model" Computers 10, no. 6: 72. https://doi.org/10.3390/computers10060072

APA StyleSchopper, D., Kübler, K., Rudolph, S., & Riedel, O. (2021). EIPPM—The Executable Integrative Product-Production Model. Computers, 10(6), 72. https://doi.org/10.3390/computers10060072