From Lab on a Chip to Point of Care Devices: The Role of Open Source Microcontrollers

Abstract

1. Introduction

| Brief CV of the authors | |||

|  |  |  |

| Dang Duong Bang | Anders Wolff | Trieu Nguyen | Sune Z. Andreasen |

| Prof. Dang Duong Bang received his PhD in 1995 on Molecular biology from Leiden University, Leiden, and the Netherlands. In 2002, he was appointed as senior researcher and leaded the Laboratory of Applied Micro and Nanotechnology (LAMINATE) at National Veterinary Institute, Technical University of Denmark. In 2014, he was promoted as Professor MSO at National Food Institute, Technical University of Denmark. His research focuses on development of total integrated Lab on a chip systems for clinical diagnosis of infectious and food borne diseases. Professor Dang contributed more than 130 papers published in international peer review scientific journals and owned 5 patents. | Assoc. Prof. Anders Wolff received his M.Sc. in Chemical Engineering from Technical University of Denmark (DTU) in 1993 and his PhD in Biochemical and Engineering from Delft University of Technology, the Netherlands in Dec 1997. In 1998, Dr. Wolff joined the Department of Micro and Nanotechnology (now DTU Nanotech, DTU, Lyngby, Denmark). In 2000, he was appointed the associated professor and leaded the Cell Handling Group (now BioLabChip) at DTU. His research interests: PCR chip with integrated heaters and thermos sensor, integrated microsystem for sample preparation and DNA amplification. Dr. Wolff owned 7 patents, 80 papers published in international scientific journals. | Dr. Trieu Nguyen obtained his PhD (2015) on the microfluidic energy conversion with prof. Jan Eijkel and prof. Albert van den Berg (University of Twente, Netherlands). From November 2015 to January 2017, he worked as a postdoc on microfluidic mixers for protein folding studies in Michigan State University, USA. Currently he is a postdoc researcher at National Food Institute, Technical University of Denmark. His research interests stay on micro-, nanofluidics, Lab on a chip, microfabrication, physical chemistry, electrochemistry and rapid detection of food-borne diseases. | Dr. Sune Z. Andreasen received his M.Sc. in physics and nanotechnology from Technical University of Denmark (DTU) in 2013, and a PhD from the same place in 2017 on Lab-on-a-chip devices, specialized on centrifugal microfluidics, electrochemistry, and automated sample preparation. Since then, he has worked as a postdoc at DTU Nanotech developing sensing platforms for biochemical reactions, with emphasis on commercially viable solutions. His research interests include LoC applications, microfluidics, open-source electronics, instrument development and entrepreneurship. |

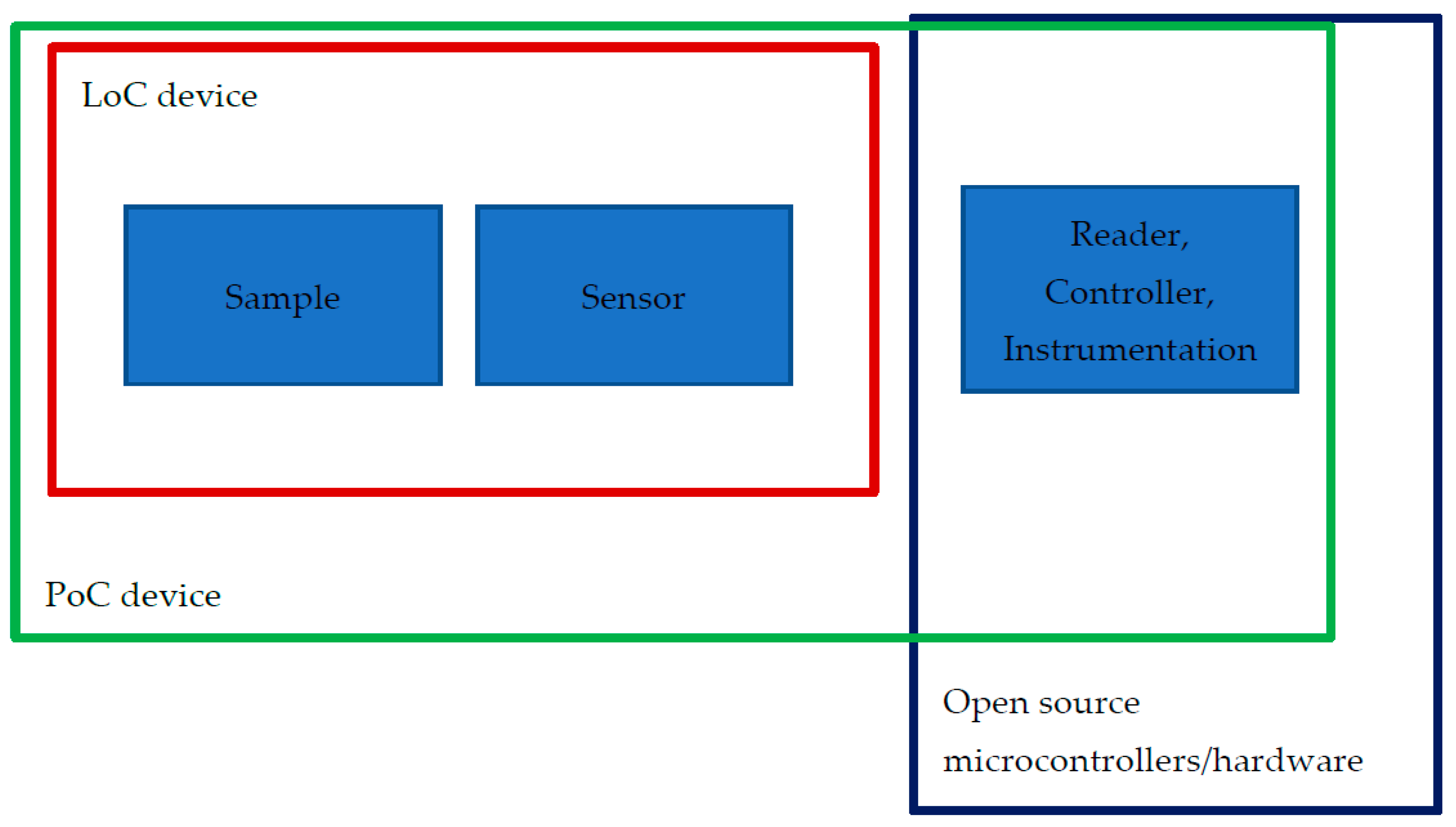

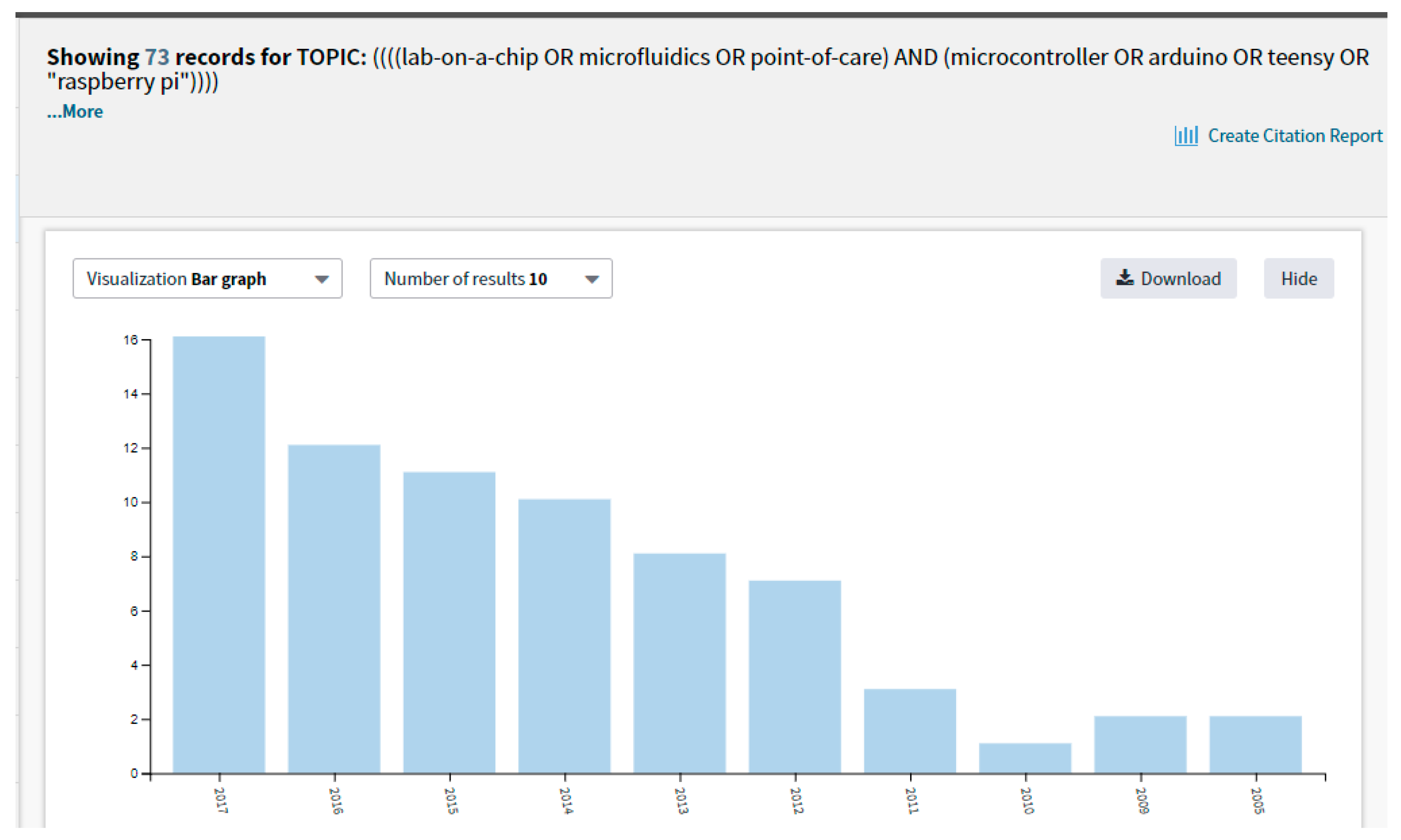

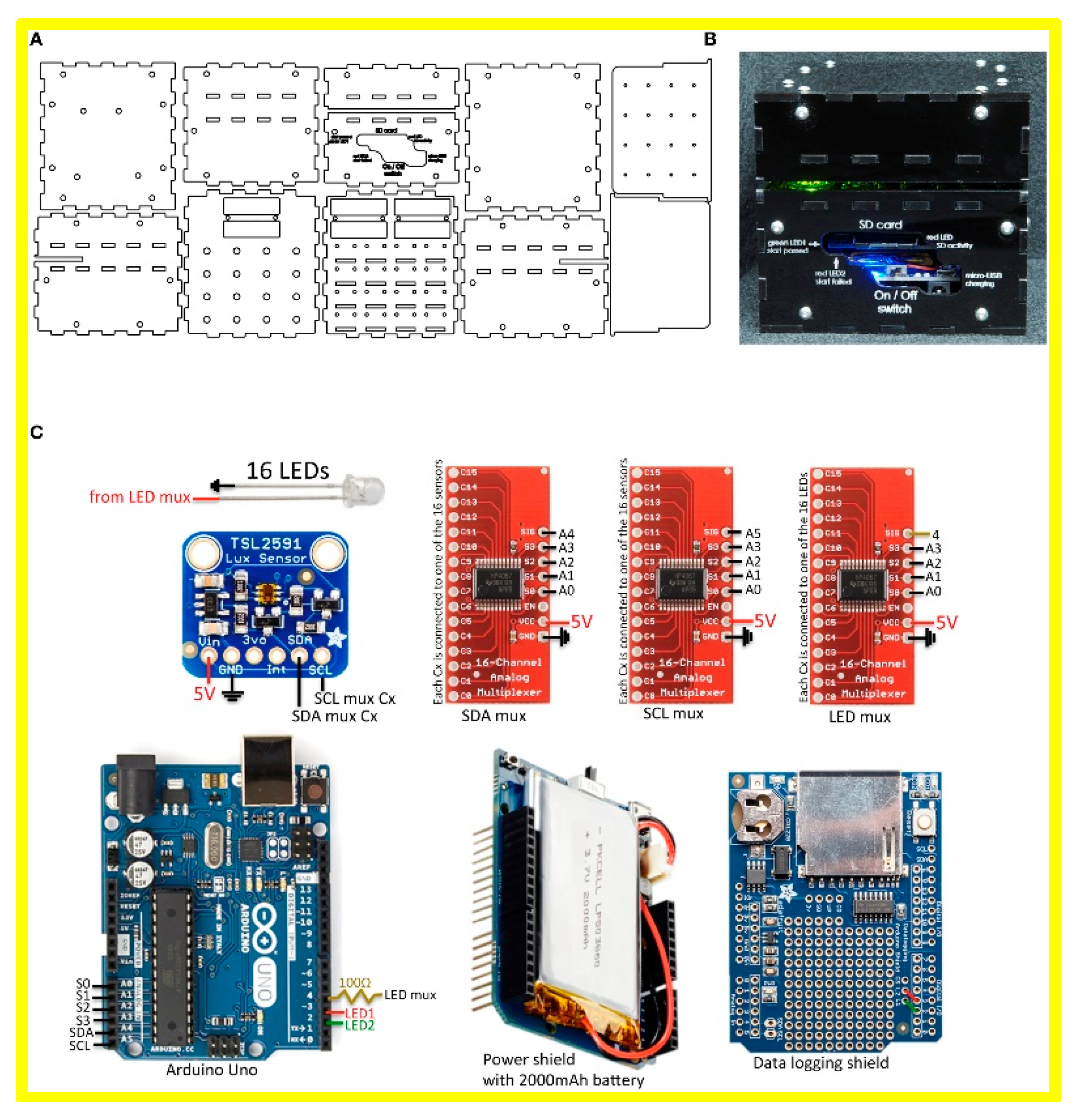

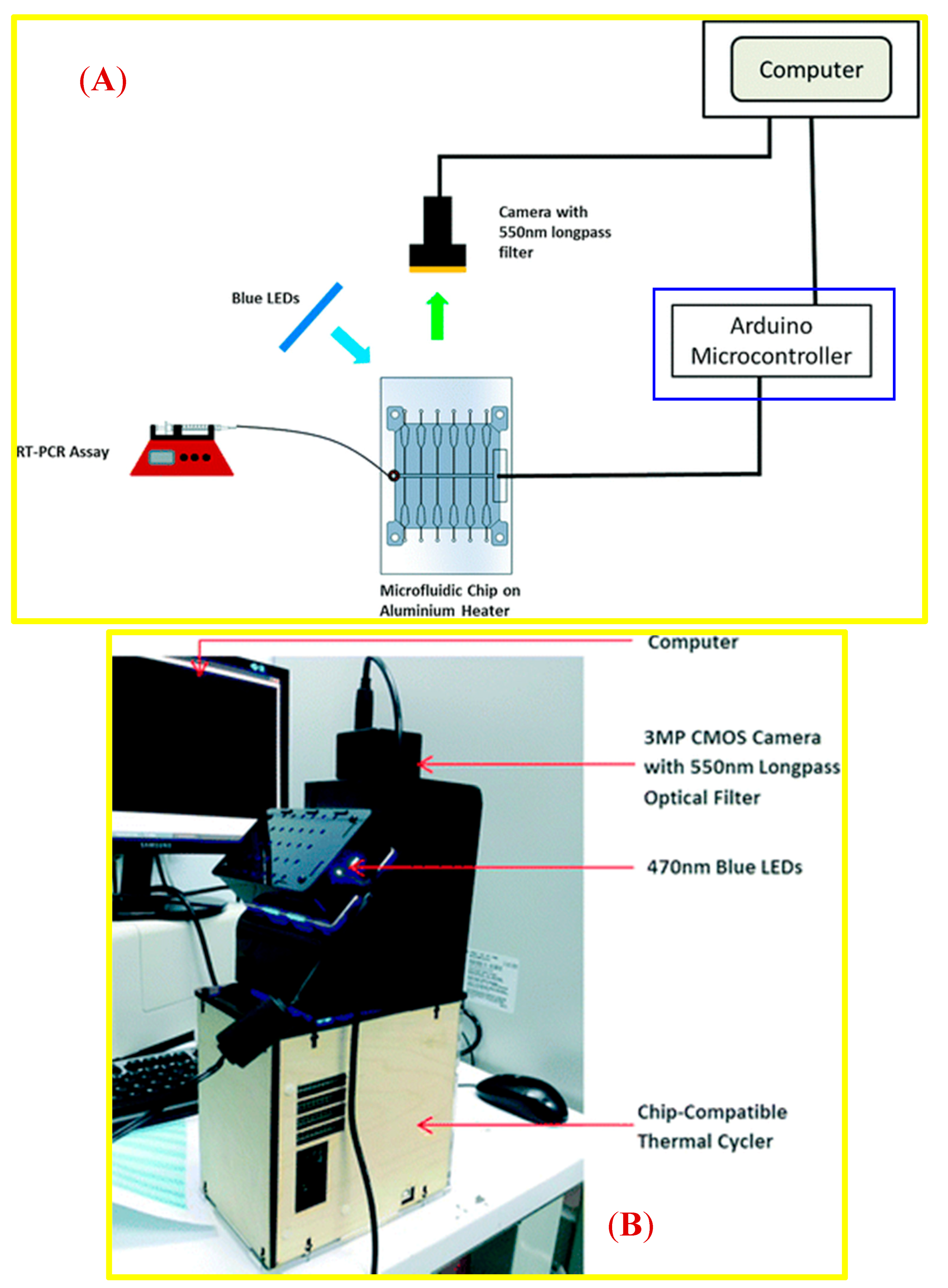

2. State-of-the-Art: The Role of Open Source Microcontroller-Based Platforms in Bridging LoC Technology and PoC Devices

3. How to Get Started

4. Challenges and Future Perspectives

Funding

Conflicts of Interest

References

- Manz, A.; Widmers, H.M.; Graber, N. Miniaturized total chemical analysis systems: A novel concept for chemical sensing. Sens. Actuators B Chem. 1990, 1, 244–248. [Google Scholar] [CrossRef]

- Reyes, D.R.; Iossifidis, D.; Auroux, P.-A.; Manz, A. Micro Total Analysis Systems. 1. Introduction, Theory, and Technology. Anal. Chem. 2002, 74, 2623–2636. [Google Scholar] [CrossRef] [PubMed]

- Dincer, C.; Bruch, R.; Kling, A.; Dittrich, P.S.; Urban, G.A. Multiplexed Point-of-Care Testing—xPOCT. Trends Biotechnol. 2017, 35, 728–742. [Google Scholar] [CrossRef] [PubMed]

- Feng, C.; Mao, X.; Shi, H.; Bo, B.; Chen, X.; Chen, T.; Zhu, X.; Li, G. Detection of microRNA: A Point-of-Care Testing Method Based on a pH-Responsive and Highly Efficient Isothermal Amplification. Anal. Chem. 2017, 89, 6631–6636. [Google Scholar] [CrossRef] [PubMed]

- Syedmoradi, L.; Daneshpour, M.; Alvandipour, M.; Gomez, F.A.; Hajghassem, H.; Omidfar, K. Point of care testing: The impact of nanotechnology. Biosens. Bioelectron. 2017, 87, 373–387. [Google Scholar] [CrossRef] [PubMed]

- Baryeh, K.; Takalkar, S.; Lund, M.; Liu, G. Introduction to medical biosensors for point of care applications. In Medical Biosensors for Point of Care (POC) Applications; Elsevier: Amsterdam, The Netherlands, 2017; pp. 3–25. [Google Scholar]

- Haney, K.; Tandon, P.; Divi, R.; Ossandon, M.R.; Baker, H.; Pearlman, P.C. The Role of Affordable, Point-of-Care Technologies for Cancer Care in Low- and Middle-Income Countries: A Review and Commentary. IEEE J. Transl. Eng. Health Med. 2017, 5, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Majors, C.E.; Smith, C.A.; Natoli, M.E.; Kundrod, K.A.; Richards-Kortum, R. Point-of-care diagnostics to improve maternal and neonatal health in low-resource settings. Lab Chip 2017, 17, 3351–3387. [Google Scholar] [CrossRef] [PubMed]

- Lopez-Barbosa, N.; Gamarra, J.D.; Osma, J.F. The future point-of-care detection of disease and its data capture and handling. Anal. Bioanal. Chem. 2016, 408, 2827–2837. [Google Scholar] [CrossRef] [PubMed]

- Hung, T.Q.; Chin, W.H.; Sun, Y.; Wolff, A.; Bang, D.D. A novel lab-on-chip platform with integrated solid phase PCR and Supercritical Angle Fluorescence (SAF) microlens array for highly sensitive and multiplexed pathogen detection. Biosens. Bioelectron. 2017, 90, 217–223. [Google Scholar] [CrossRef] [PubMed]

- Niezen, G.; Eslambolchilar, P.; Thimbleby, H. Open-source hardware for medical devices. BMJ Innov. 2016, 2, 78–83. [Google Scholar] [CrossRef] [PubMed]

- Pearce, J.M. Return on investment for open source scientific hardware development. Sci. Public Policy 2016, 43, 192–195. [Google Scholar] [CrossRef]

- Gibney, E. Open-hardware’ pioneers push for low-cost lab kit. Nature 2016, 531, 147–148. [Google Scholar] [CrossRef] [PubMed]

- Pearce, J.M. Maximizing returns for public funding of medical research with open-source hardware. Health Policy Technol. 2017, 6, 381–382. [Google Scholar] [CrossRef]

- Mesas-Carrascosa, J.F.; Santano, D.V.; Porras, F.P.; Meroño-Larriva, E.J.; García-Ferrer, A. The Development of an Open Hardware and Software System Onboard Unmanned Aerial Vehicles to Monitor Concentrated Solar Power Plants. Sensors 2017, 17, 1329. [Google Scholar] [CrossRef] [PubMed]

- Dryden, M.D.M.; Fobel, R.; Fobel, C.; Wheeler, A.R. Upon the Shoulders of Giants: Open-Source Hardware and Software in Analytical Chemistry. Anal. Chem. 2017, 89, 4330–4338. [Google Scholar] [CrossRef] [PubMed]

- Mary, P.; Jeebananda, P. Microprocessors and Microcontrollers; PHI Learning Pvt. Ltd.: Delhi, India, 2016. [Google Scholar]

- Galadima, A.A. Arduino as a learning tool. In Proceedings of the 11th International Conference on Electronics, Computer and Computation (ICECCO), Abuja, Nigeria, 28–30 September 2014. [Google Scholar]

- Kushner, D. The Making of Arduino. IEEE Spectrum—Article. Available online: http://spectrum.ieee.org/geek-life/hands-on/the-making-of-arduino (accessed on 16 July 2018).

- Leeuw, T.; Boss, E.; Wright, D. In situ Measurements of Phytoplankton Fluorescence Using Low Cost Electronics. Sensors 2013, 13, 7872–7883. [Google Scholar] [CrossRef] [PubMed]

- Skandarajah, A.; Sunny, S.P.; Gurpur, P.; Reber, C.D.; D’Ambrosio, M.V.; Raghavan, N.; James, B.L.; Ramanjinappa, R.D.; Suresh, A.; Kandasarma, U.; et al. Mobile microscopy as a screening tool for oral cancer in India: A pilot study. PLoS ONE 2017, 12, e0188440. [Google Scholar] [CrossRef] [PubMed]

- Adsul, N. Fluorescence Detection Based Point-of-Care Diagnostics Platforms: Bridging the Gap between Laboratory and Market; University of Basel: Basel, Switzerland, 2014. [Google Scholar]

- Pardee, K.; Green, A.A.; Takahashi, M.K.; Braff, D.; Lambert, G.; Lee, J.W.; Ferrante, T.; Ma, D.; Donghia, N.; Fan, M.; et al. Rapid, Low-Cost Detection of Zika Virus Using Programmable Biomolecular Components. Cell 2016, 165, 1255–1266. [Google Scholar] [CrossRef] [PubMed]

- Lim, G.S.; Chang, J.S.; Lei, Z.; Wu, R.; Wang, Z.; Cui, K.; Wong, S. A lab-on-a-chip system integrating tissue sample preparation and multiplex RT-qPCR for gene expression analysis in point-of-care hepatotoxicity assessment. Lab Chip 2015, 15, 4032–4043. [Google Scholar] [CrossRef] [PubMed]

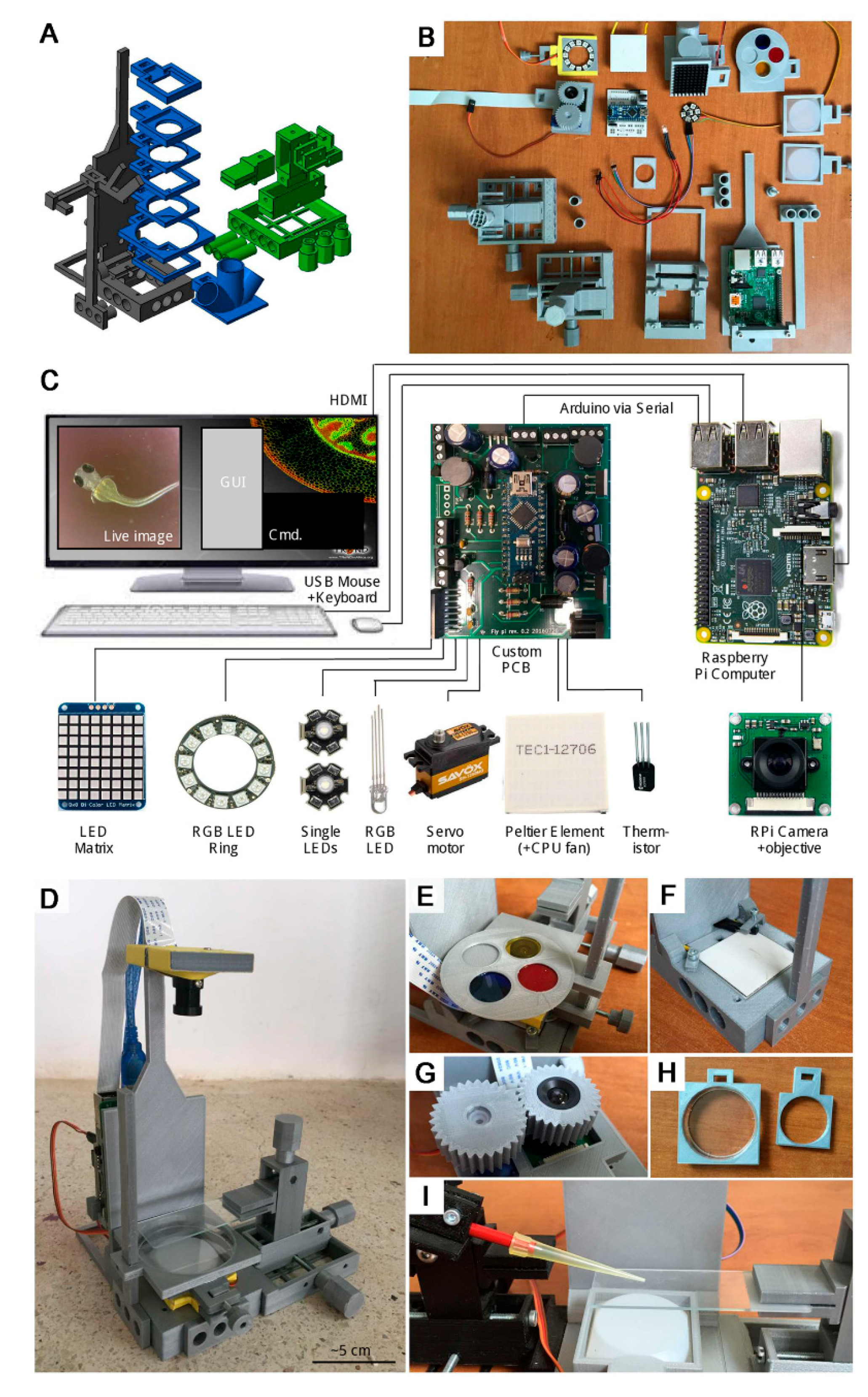

- Chagas, A.M.; Prieto-Godino, L.L.; Arrenberg, A.B.; Baden, T. The €100 lab: A 3D-printable open-source platform for fluorescence microscopy, optogenetics, and accurate temperature control during behaviour of zebrafish, Drosophila, and Caenorhabditis elegans. PLoS Biol. 2017, 15, e2002702. [Google Scholar] [CrossRef] [PubMed]

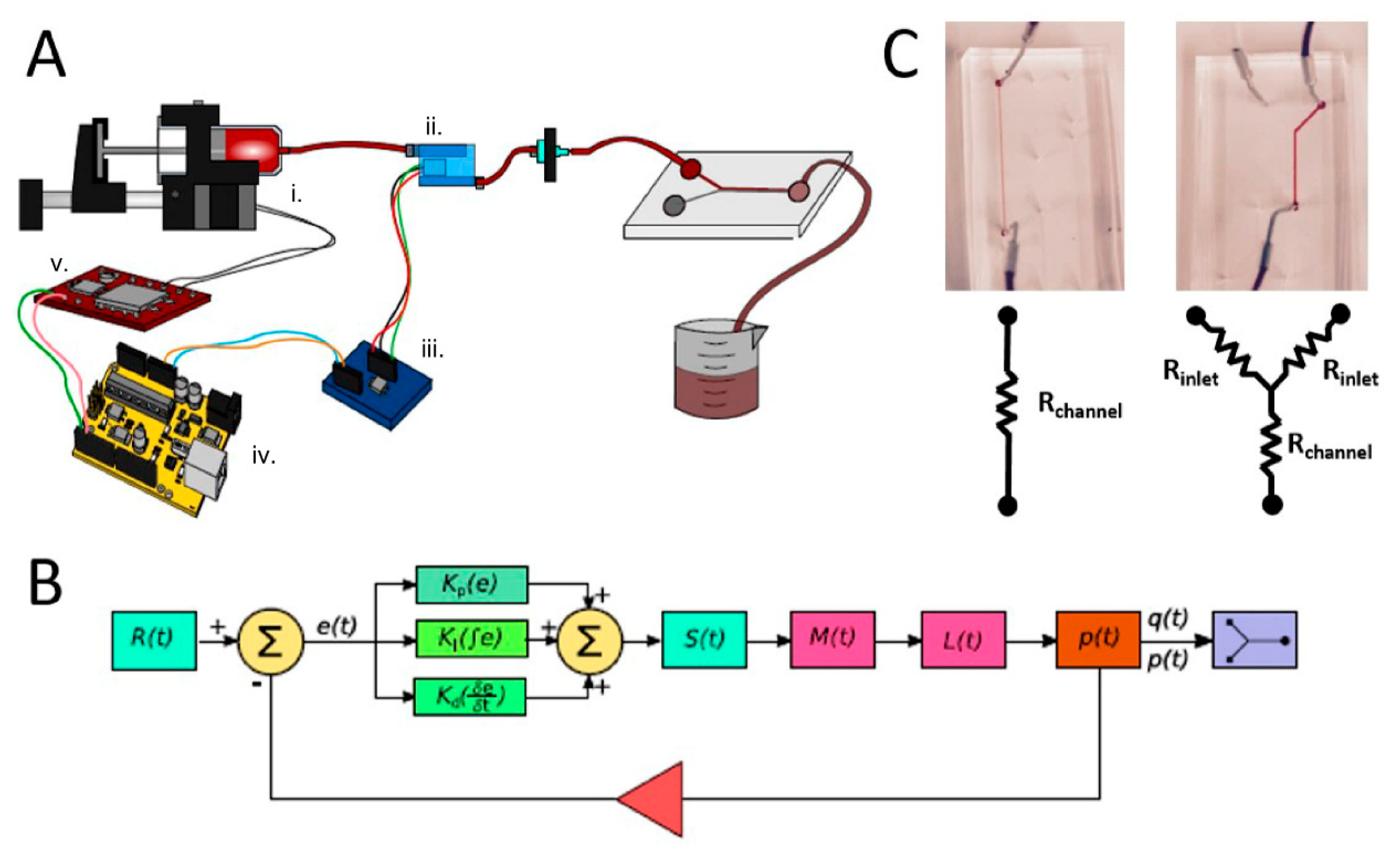

- Lake, J.R.; Heyde, K.C.; Ruder, W.C. Low-cost feedback-controlled syringe pressure pumps for microfluidics applications. PLoS ONE 2017, 12, e0175089. [Google Scholar] [CrossRef] [PubMed]

- Aminondin, A.A.; Chia, K.S. A temperature control system for near infrared spectroscopic analysis using proportional controller. Int. J. Integr. Eng. 2017, 9, 24–28. [Google Scholar]

- Pardy, T.; Rang, T.; Tulp, I. Finite Element Modelling for the Optimization of Microheating in Disposable Molecular Diagnostics. Int. J. Comput. Methods Exp. Meas. 2017, 5, 13–22. [Google Scholar] [CrossRef]

- Pardy, T.; Rang, T.; Tulp, I. Development of temperature control solutions for non-instrumented nucleic acid amplification tests (NINAAT). Micromachines 2017, 8, 180. [Google Scholar] [CrossRef]

- Pardy, T.; Rang, T.; Tulp, I. Modelling and experimental characterisation of thermoelectric heating for molecular diagnostics devices. In Proceedings of the Biennial Baltic Electronics Conference (BEC), Tallinn, Estonia, 3–5 October 2016. [Google Scholar]

- Bayram, A.; Mohammed, S.; Kara, F. Design of Heating System Controlled by Arduino. In Proceedings of the 4th International Symposium on Innovative Technologies in Engineering and Science (ISITES2016), Alanya, Turkey, 3–5 November 2016. [Google Scholar]

- Bista, D. Understanding and Design of an Arduino-Based PID Controller. Master’s Thesis, Virginia Commonwealth University, Richmond, VA, USA, 2016; p. 59. [Google Scholar]

- Boxall, J. Arduino Worskhop—A Hands-On Introduction with 65 Projects. No Starch Press, 2013. Available online: https://nostarch.com/arduino (accessed on 16 July 2018).

- Pardy, T.; Rang, T.; Tulp, I. Thermal analysis of a disposable, instrument-free DNA amplification lab-on-a-chip platform. Sensors 2018, 18, 1812. [Google Scholar] [CrossRef] [PubMed]

- Urrios, A.; Parra-Cabrera, C.; Bhattacharjee, N.; Gonzalez-Suarez, A.M.; Rigat-Brugarolas, L.G.; Nallapatti, U.; Samitier, J.; DeForest, C.A.; Posas, F.; Garcia-Cordero, J.L.; et al. 3D-printing of transparent bio-microfluidic devices in PEG-DA. Lab Chip 2016, 16, 2287–2294. [Google Scholar] [CrossRef] [PubMed]

- Seder, I.; Kim, D.-M.; Hwang, S.-H.; Sung, H.; Kim, D.-E.; Kim, S.-J. Microfluidic chip with movable layers for the manipulation of biochemicals. Lab Chip 2018, 13, 1867–1874. [Google Scholar] [CrossRef] [PubMed]

- Kong, T.; Brien, R.; Njus, Z.; Kalwa, U.; Pandey, S. Motorized actuation system to perform droplet operations on printed plastic sheets. Lab Chip 2016, 16, 1861–1872. [Google Scholar] [CrossRef] [PubMed]

- Virtanen, J.; Kallio, P.; Tuukkanen, S. Dispenser System for Nanocellulose 3D Printing. 2018. Available online: https://tutcris.tut.fi/portal/files/11033114/Automation_days_full_paper_FINAL.pdf (accessed on 16 July 2018).

- Kornuta, J.A.; Nipper, M.E.; Dixon, J.B. Low-cost microcontroller platform for studying lymphatic biomechanics in vitro. J. Biomech. 2013, 46, 183–186. [Google Scholar] [CrossRef] [PubMed]

- Chen, C. Mapping Scientific Frontiers: The Quest for Knowledge Visualization; Springer Science & Business Media: Berlin, Germany, 2013. [Google Scholar]

| Point of Care Devices | Open-Source Microcontrollers (Arduino Platform) | |

|---|---|---|

| Low cost | √ | √ |

| Easily accessible | √ | √ |

| Easy to use | √ | √ |

| Type of Resource | Company’s Name | Webpage | Remarks |

|---|---|---|---|

| Books and Video lessons | Safari Books Online | safaribooksonline.com | One can create a trial account in order to download books and video lessons on Arduino, Raspberry Pi in 10 days. This is a great source of information. |

| Tutorial | Udemy instructors Programming electronics academy | https://www.udemy.com https://programmingelectronics.com/arduino-tutorials-all/ | Plenty of Tutorials on Do-It-Yourself (DIY) using Arduino, Raspberry Pi, Python… |

| Forum and code library | https://github.com/ https://forum.arduino.cc/ www.instructables.com | ||

| Where to buy | |||

| RS Components | www.rs-online.com | ||

| Sparkfun Electronics | https://www.sparkfun.com/ | ||

| Adafruit Industries | https://www.adafruit.com/ | ||

| Farnell element14 | https://farnell.com | ||

| Mouser Electronics | www.mouser.com | ||

| DigiKey Electronics | www.digikey.com | ||

| Conrad Electronics | https://www.conrad.com |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, T.; Zoëga Andreasen, S.; Wolff, A.; Duong Bang, D. From Lab on a Chip to Point of Care Devices: The Role of Open Source Microcontrollers. Micromachines 2018, 9, 403. https://doi.org/10.3390/mi9080403

Nguyen T, Zoëga Andreasen S, Wolff A, Duong Bang D. From Lab on a Chip to Point of Care Devices: The Role of Open Source Microcontrollers. Micromachines. 2018; 9(8):403. https://doi.org/10.3390/mi9080403

Chicago/Turabian StyleNguyen, Trieu, Sune Zoëga Andreasen, Anders Wolff, and Dang Duong Bang. 2018. "From Lab on a Chip to Point of Care Devices: The Role of Open Source Microcontrollers" Micromachines 9, no. 8: 403. https://doi.org/10.3390/mi9080403

APA StyleNguyen, T., Zoëga Andreasen, S., Wolff, A., & Duong Bang, D. (2018). From Lab on a Chip to Point of Care Devices: The Role of Open Source Microcontrollers. Micromachines, 9(8), 403. https://doi.org/10.3390/mi9080403