Monitoring of Non-Ferrous Wear Debris in Hydraulic Oil by Detecting the Equivalent Resistance of Inductive Sensors

Abstract

:1. Introduction

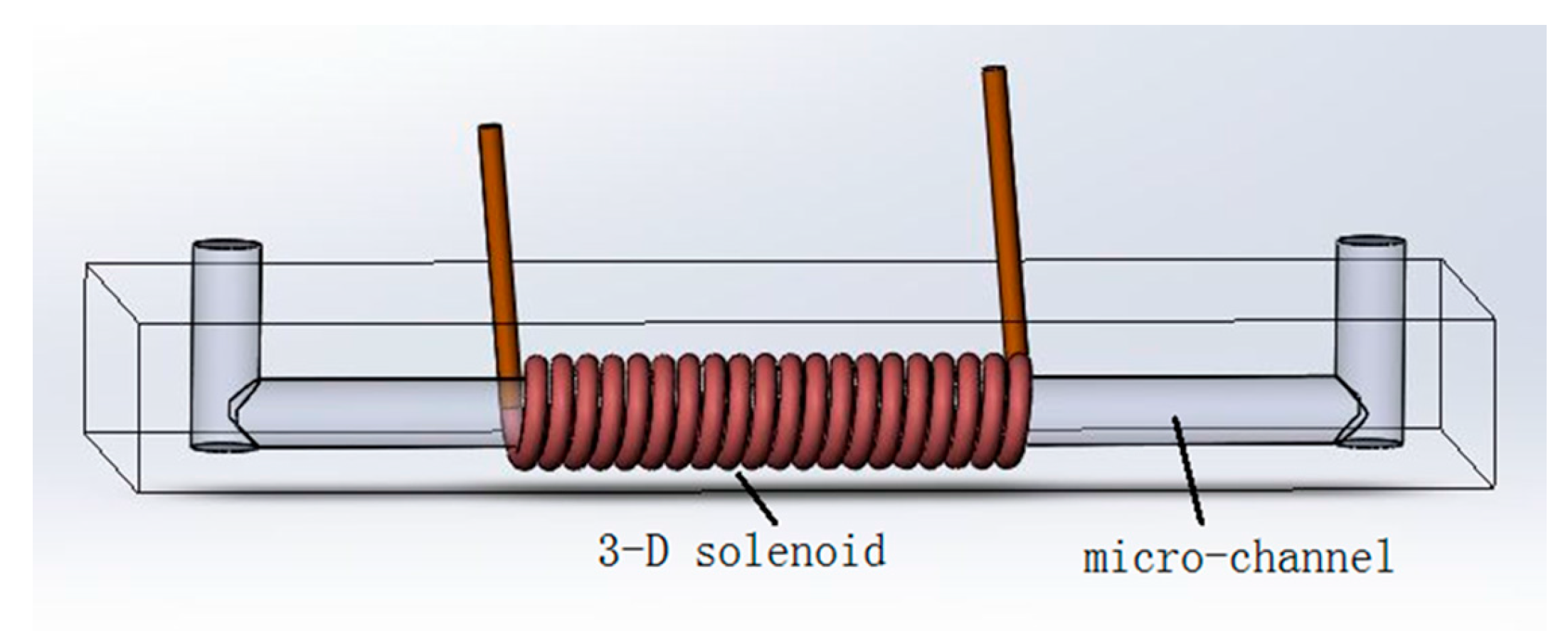

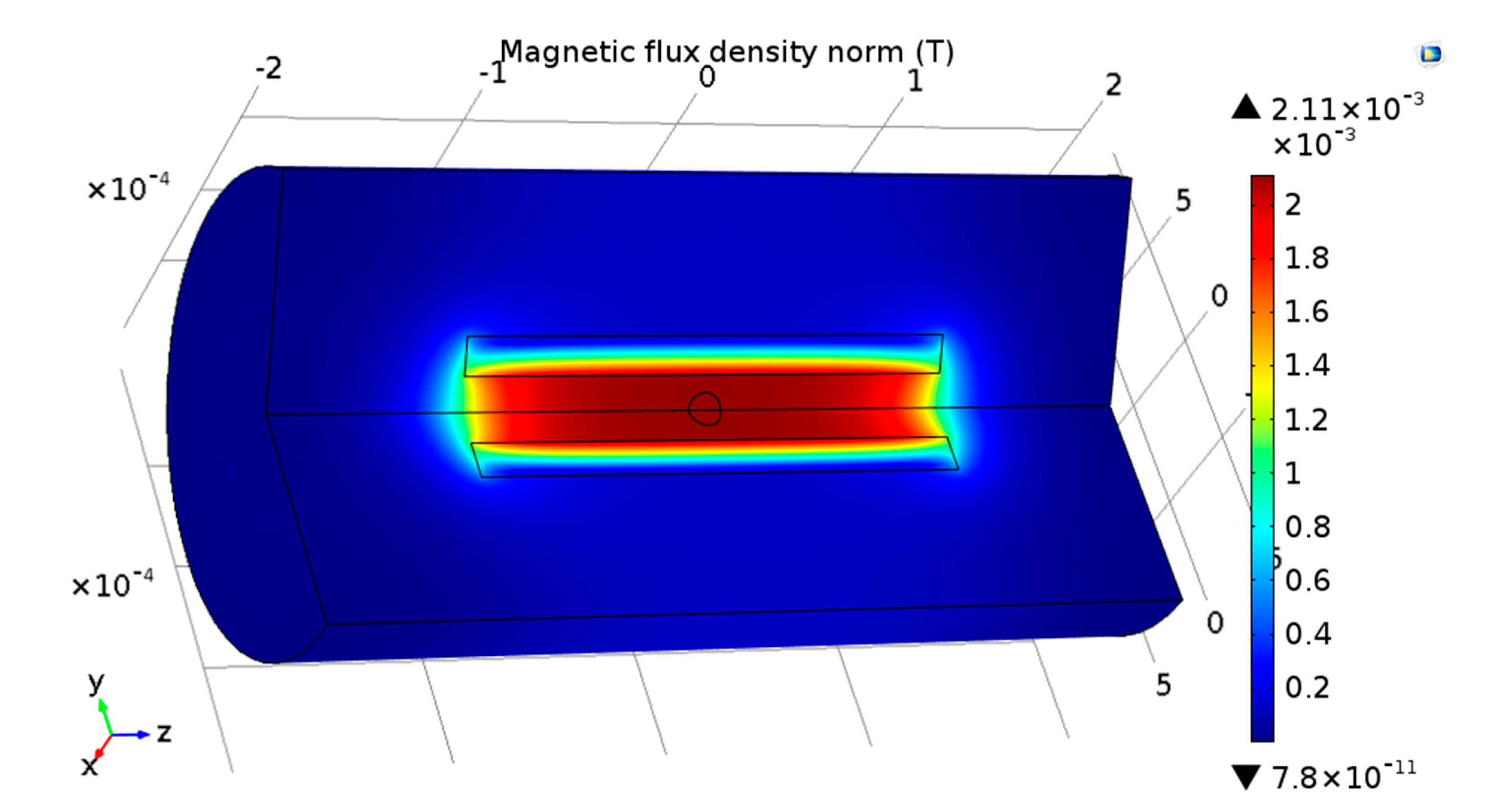

2. Sensor Design and Detection Principle

3. Experiments and Discussions

3.1. Experimental Procedure

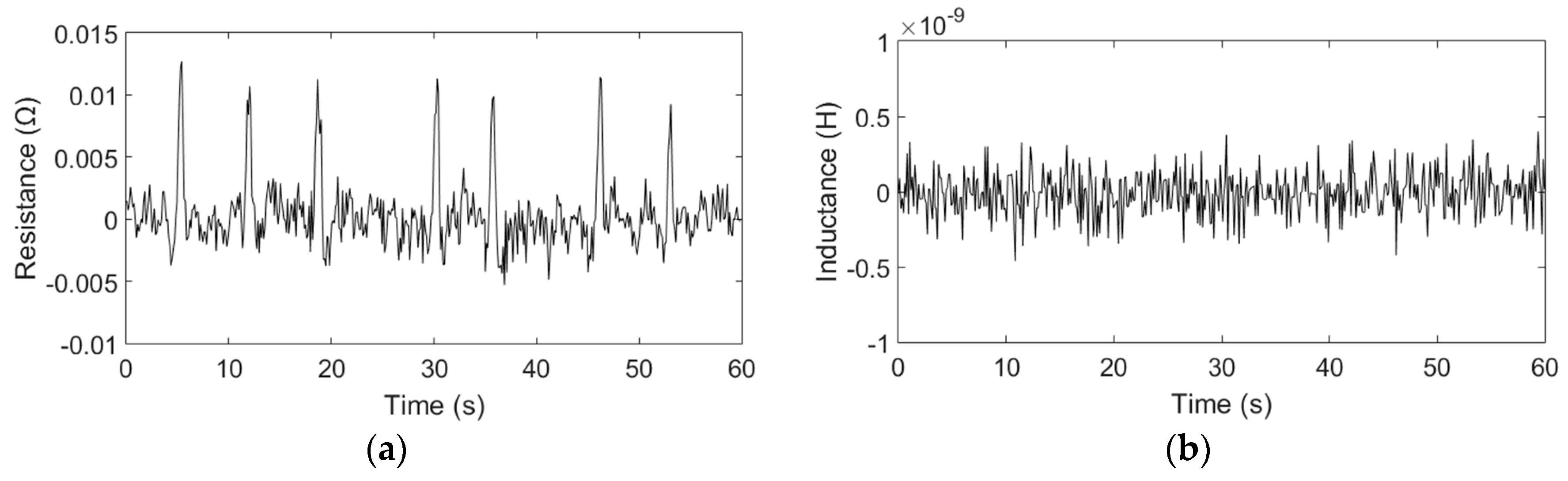

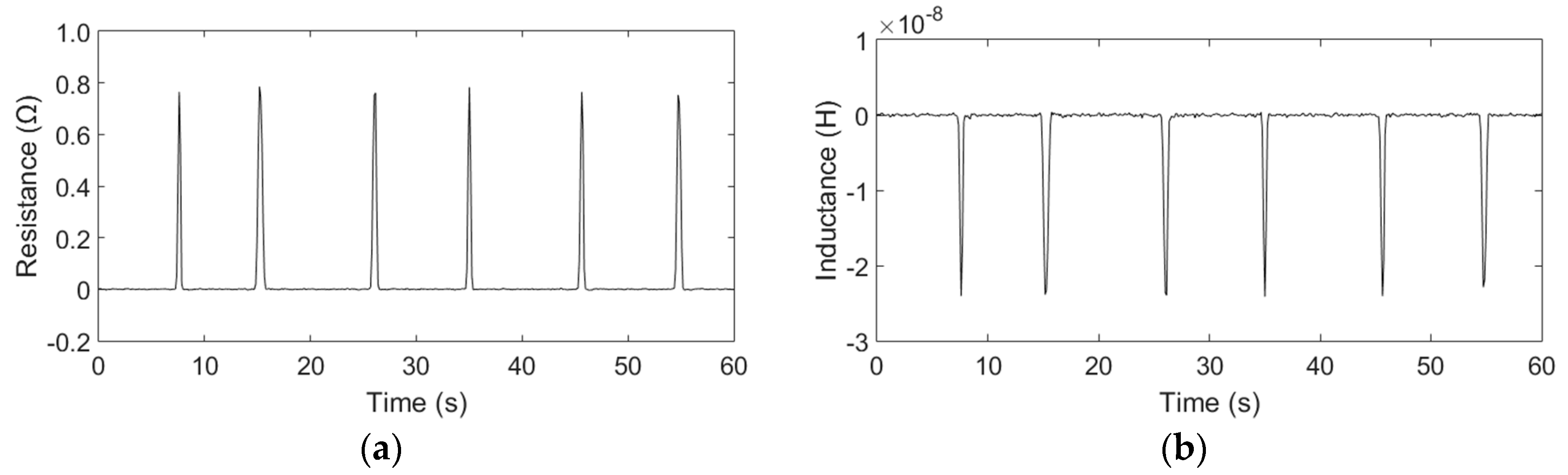

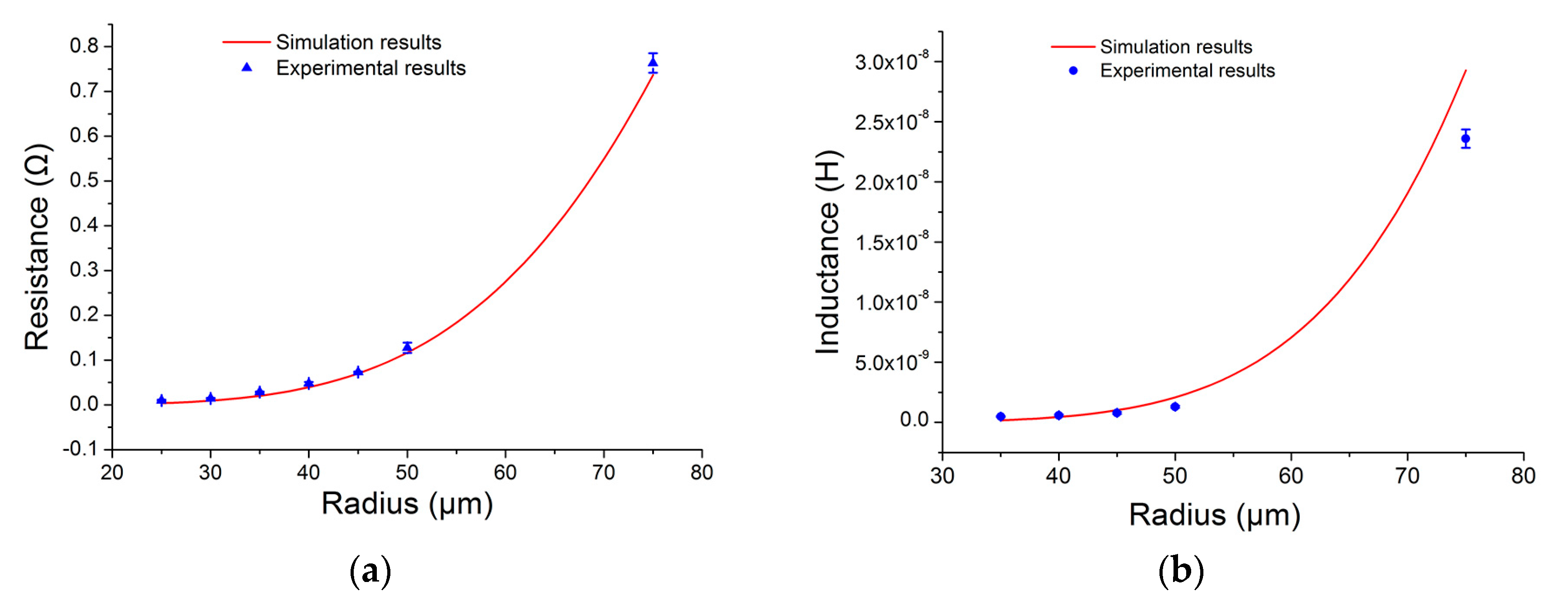

3.2. Results and Discussions

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhang, X.; Zhang, H.; Chen, H.; Zhang, Y.; Sun, Y. Study on the resolution-frequency characteristic of microfluidic oil detection chip. Chin. J. Sci. Instrum. 2014, 35, 427–433. [Google Scholar]

- Du, L.; Zhe, J.; Carletta, J.; Veillette, R.; Choy, F. Real-time monitoring of wear debris in lubrication oil using a microfluidic inductive Coulter counting device. Microfluid. Nanofluid. 2010, 9, 1241–1245. [Google Scholar] [CrossRef]

- Williams, J.A. Wear and wear particles—Some fundamentals. Tribol. Int. 2005, 38, 863–870. [Google Scholar] [CrossRef]

- Hunt, T.M. Handbook of Wear Debris Analysis and Particle Detection in Liquids; Kluwer Academic Publishers Group: Berlin, Germany, 1993; ISBN 978-1-85-166962-2. [Google Scholar]

- Tucker, J.E.; Schultz, A.; Lu, C.; Sebok, T.; Holloway, C.; Tankersley, L.L.; Reintjes, J. Lasernet fines optical wear debris monitor. In Proceedings of the International Conference on Condition Monitoring, Swansea, UK, 12–15 April 1999; pp. 445–452. [Google Scholar]

- Edmonds, J.; Resner, M.S.; Shkarlet, K. Detection of precursor wear debris in lubrication systems. In Proceedings of the 2000 IEEE Aerospace Conference Proceedings, Big Sky, MT, USA, 25 March 2000; pp. 73–77. [Google Scholar]

- Rao, B. Handbook of Condition Monitoring; Elsevier Advanced Technology: Manchester, UK, 1996; ISBN 978-1-85-617234-9. [Google Scholar]

- Iwai, Y.; Honda, T.; Miyajima, T.; Yoshinaga, S.; Higashi, M.; Fuwa, Y. Quantitative estimation of wear amounts by real time measurement of wear debris in lubricating oil. Tribol. Int. 2010, 43, 388–394. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, W.; Jin, J.; Guo, L.; Li, D. Debris detection in hydraulic oil using a microfluidic inductive pulse device. In Proceedings of the ASME 2012 Third International Conference on Micro/Nanoscale Heat and Mass Transfer, Atlanta, GA, USA, 3–6 March 2012; pp. 51–57. [Google Scholar]

- Toms, A.; Toms, A. Oil analysis and condition monitoring. In Chemistry and Technology of Lubricants; Springer: Dordrecht, The Netherlands, 2010; pp. 459–495. [Google Scholar]

- Loutas, T.H.; Roulias, D.; Pauly, E.; Kostopoulos, V. The combined use of vibration, acoustic emission and oil debris on-line monitoring towards a more effective condition monitoring of rotating machinery. Mech. Syst. Signal Process. 2011, 25, 1339–1352. [Google Scholar] [CrossRef]

- Appleby, M.; Choy, F.K.; Du, L.; Zhe, J. Oil debris and viscosity monitoring using ultrasonic and capacitance/inductance measurements. Lubr. Sci. 2013, 25, 507–524. [Google Scholar] [CrossRef]

- Murali, S.; Jagtiani, A.V.; Xia, X.; Carletta, J.; Zhe, J. A microfluidic Coulter counting device for metal wear detection in lubrication oil. Rev. Sci. Instrum. 2009, 80, 016105. [Google Scholar] [CrossRef] [PubMed]

- Nicoli, D.F.; Toumbas, P. Sensors and Methods for High-Sensitivity Optical Particle Counting and Sizing. U.S. Patent US6794671 B2, 21 November 2004. [Google Scholar]

- Buttle, D.J.; Scruby, C.B. Characterization of particle impact by quantitative acoustic emission. Wear 1990, 137, 63–90. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Martin, B.; Bettscheider, S.; Gachot, C.; Kliem, H.; Mücklich, F. Correlation between solid–solid contact ratios and lubrication regimes measured by a refined electrical resistivity circuit. Wear 2014, 320, 51–61. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Heib, T.; Gachot, C.; Mücklich, F. Oil film lifetime and wear particle analysis of laser-patterned stainless steel surfaces. Wear 2015, 334, 1–12. [Google Scholar] [CrossRef]

- Murali, S.; Xia, X.; Jagtiani, A.V.; Carletta, J.; Zhe, J. Capacitive coulter counting: Detection of metal wear particles in lubricant using a microfluidic device. Smart Mater. Struct. 2009, 18, 037001. [Google Scholar] [CrossRef]

- Du, L.; Zhe, J.; Carletta, J.E.; Veillette, R.J. Inductive Coulter counting: Detection and differentiation of metal wear particles in lubricant. Smart Mater. Struct. 2010, 19, 057001. [Google Scholar] [CrossRef]

- Du, L.; Zhe, J. A high throughput inductive pulse sensor for online oil debris monitoring. Tribol. Int. 2011, 44, 175–179. [Google Scholar] [CrossRef]

- Du, L.; Zhu, X.; Han, Y.; Zhe, J. High throughput wear debris detection in lubricants using a resonance frequency division multiplexed sensor. Tribol. Lett. 2013, 51, 453–460. [Google Scholar] [CrossRef]

- Zeng, L.; Zhang, H.; Zhao, X.; Teng, H.; Yu, Z. Double coil multi-parameter impedance sensor for hydraulic oil pollutants detection. Chin. J. Sci. Instrum. 2017, 38, 1690–1697. [Google Scholar]

- Zhang, H.; Zeng, L.; Teng, H.; Zhang, X. A novel on-chip impedance sensor for the detection of particle contamination in hydraulic oil. Micromachines 2017, 8, 249. [Google Scholar] [CrossRef]

- Luo, J.; Yu, D.; Liang, M. Enhancement of oil particle sensor capability via resonance-based signal decomposition and fractional calculus. Measurement 2015, 76, 240–254. [Google Scholar] [CrossRef]

- Zhu, X.; Chong, Z.; Zhe, J. A high sensitivity wear debris sensor using ferrite cores for online oil condition monitoring. Meas. Sci. Technol. 2017, 28, 075102. [Google Scholar] [CrossRef]

- Wang, C.; Liu, X.; Chen, Z. Probe improvement of inductive sensor for online health monitoring of mechanical transmission systems. IEEE Trans. Magn. 2015, 51, 4004404. [Google Scholar] [CrossRef]

- Du, L.; Zhu, X.; Han, Y.; Zhan, L.; Zhe, J. Improving sensitivity of an inductive pulse sensor for detection of metallic wear debris in lubricants using parallel LC resonance method. Meas. Sci. Technol. 2013, 24, 075106. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, X.; Guo, L.; Zhang, Y.; Sun, Y. Design of the oil detection microfluidic chip. Chin. J. Sci. Instrum. 2013, 34, 762–767. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, H.; Zeng, L.; Chen, H.; Sun, Y. Determination of metal particles in oil using a microfluidic chip-based inductive sensor. Instrum. Sci. Technol. 2016, 44, 259–269. [Google Scholar] [CrossRef]

- Fan, H.; Zhang, Y.T.; Ren, G.Q.; Li, Z.N. Experimental study of an on-line monitoring sensor for wear particles in oil. Tribology 2010, 30, 338–343. [Google Scholar]

- Dziczkowski, L. Effect of eddy current frequency on measuring properties of devices used in non-destructive measurements of non-ferromagnetic metal plates. Arch. Mater. Sci. Eng. 2008, 32, 77–84. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, L.; Zhang, H.; Wang, Q.; Zhang, X. Monitoring of Non-Ferrous Wear Debris in Hydraulic Oil by Detecting the Equivalent Resistance of Inductive Sensors. Micromachines 2018, 9, 117. https://doi.org/10.3390/mi9030117

Zeng L, Zhang H, Wang Q, Zhang X. Monitoring of Non-Ferrous Wear Debris in Hydraulic Oil by Detecting the Equivalent Resistance of Inductive Sensors. Micromachines. 2018; 9(3):117. https://doi.org/10.3390/mi9030117

Chicago/Turabian StyleZeng, Lin, Hongpeng Zhang, Qiang Wang, and Xingming Zhang. 2018. "Monitoring of Non-Ferrous Wear Debris in Hydraulic Oil by Detecting the Equivalent Resistance of Inductive Sensors" Micromachines 9, no. 3: 117. https://doi.org/10.3390/mi9030117

APA StyleZeng, L., Zhang, H., Wang, Q., & Zhang, X. (2018). Monitoring of Non-Ferrous Wear Debris in Hydraulic Oil by Detecting the Equivalent Resistance of Inductive Sensors. Micromachines, 9(3), 117. https://doi.org/10.3390/mi9030117