A MEMS Variable Optical Attenuator with Ultra-Low Wavelength-Dependent Loss and Polarization-Dependent Loss

Abstract

1. Introduction

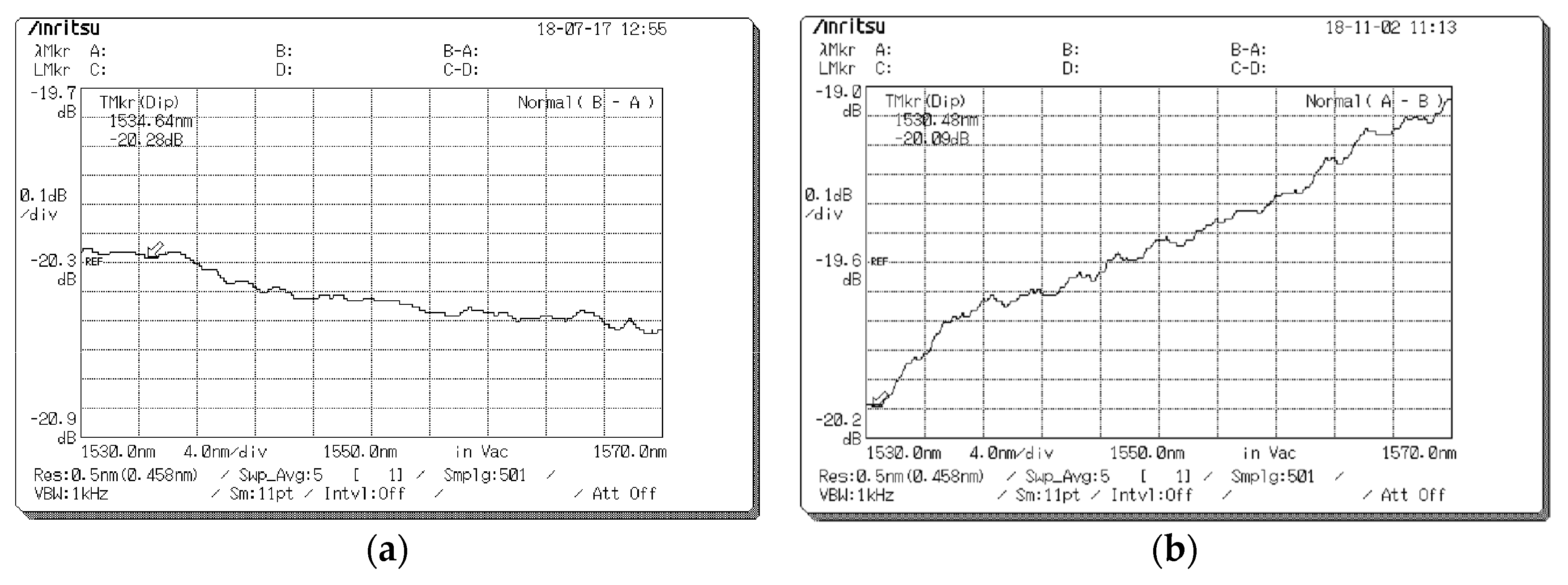

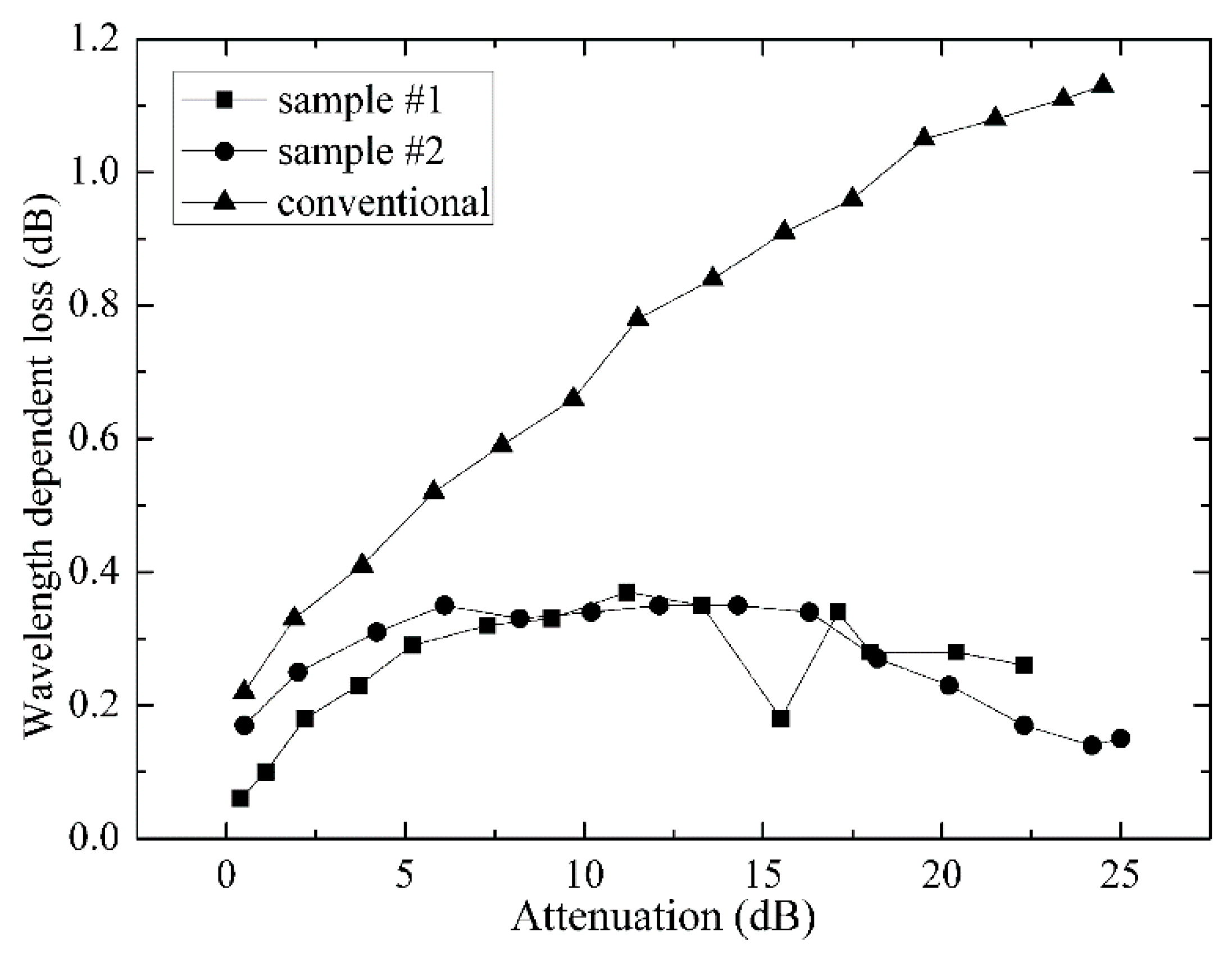

2. Theories

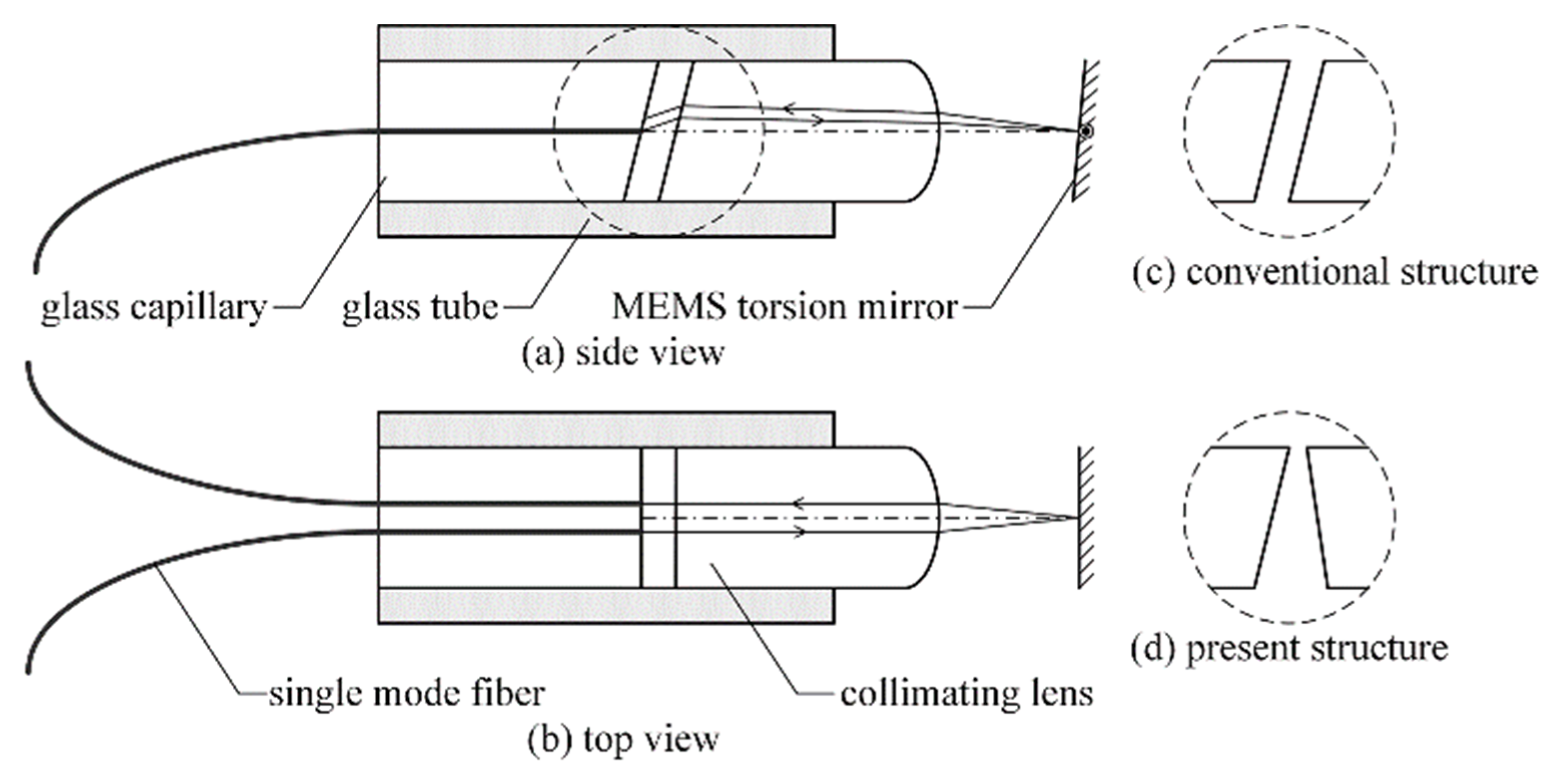

2.1. Structure of the VOA

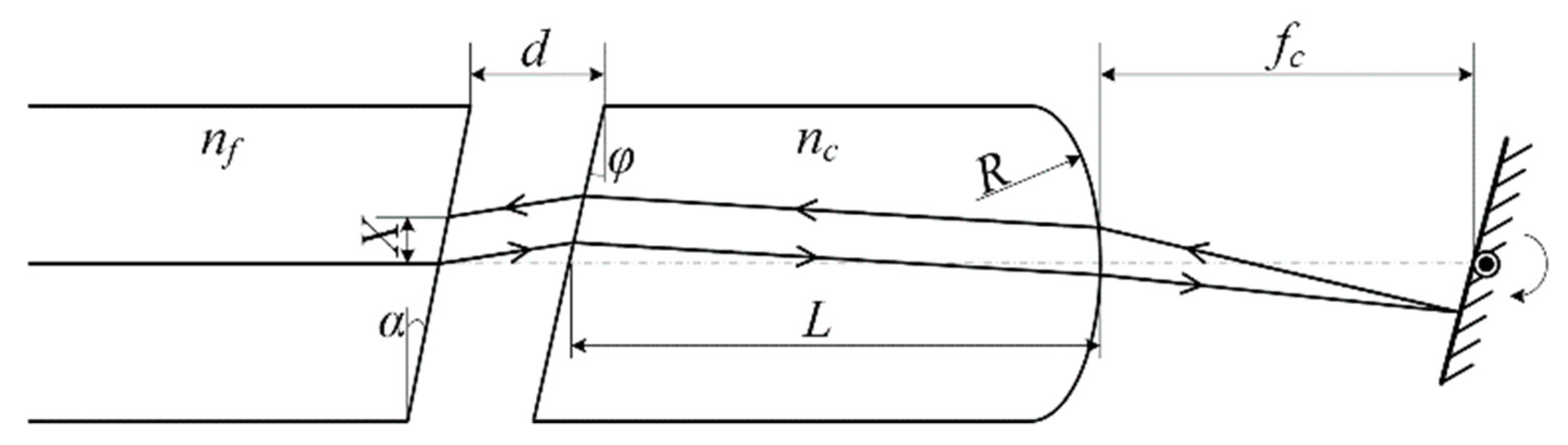

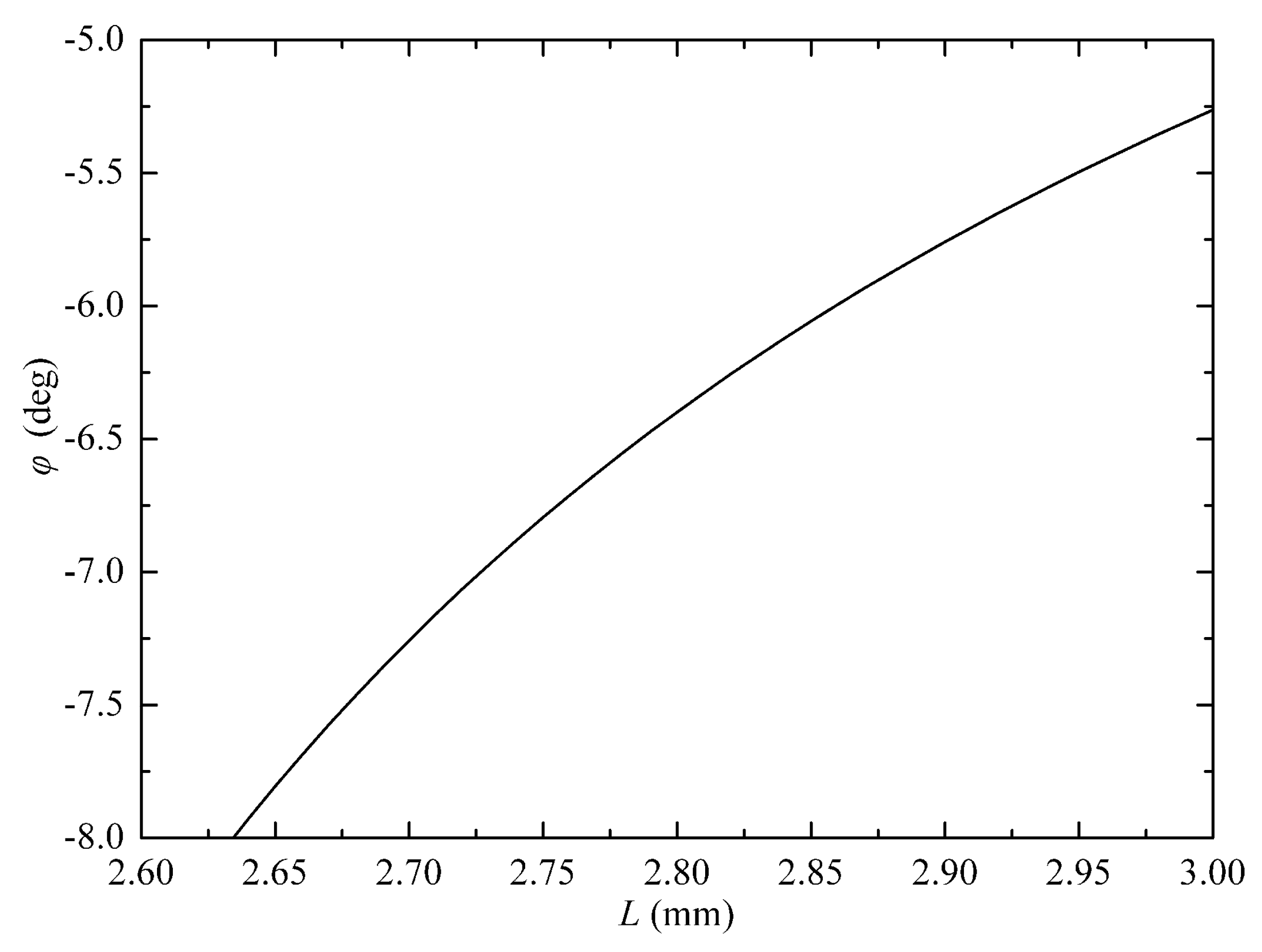

2.2. WDL Analysis and Optimization

2.3. Return Loss Consideration

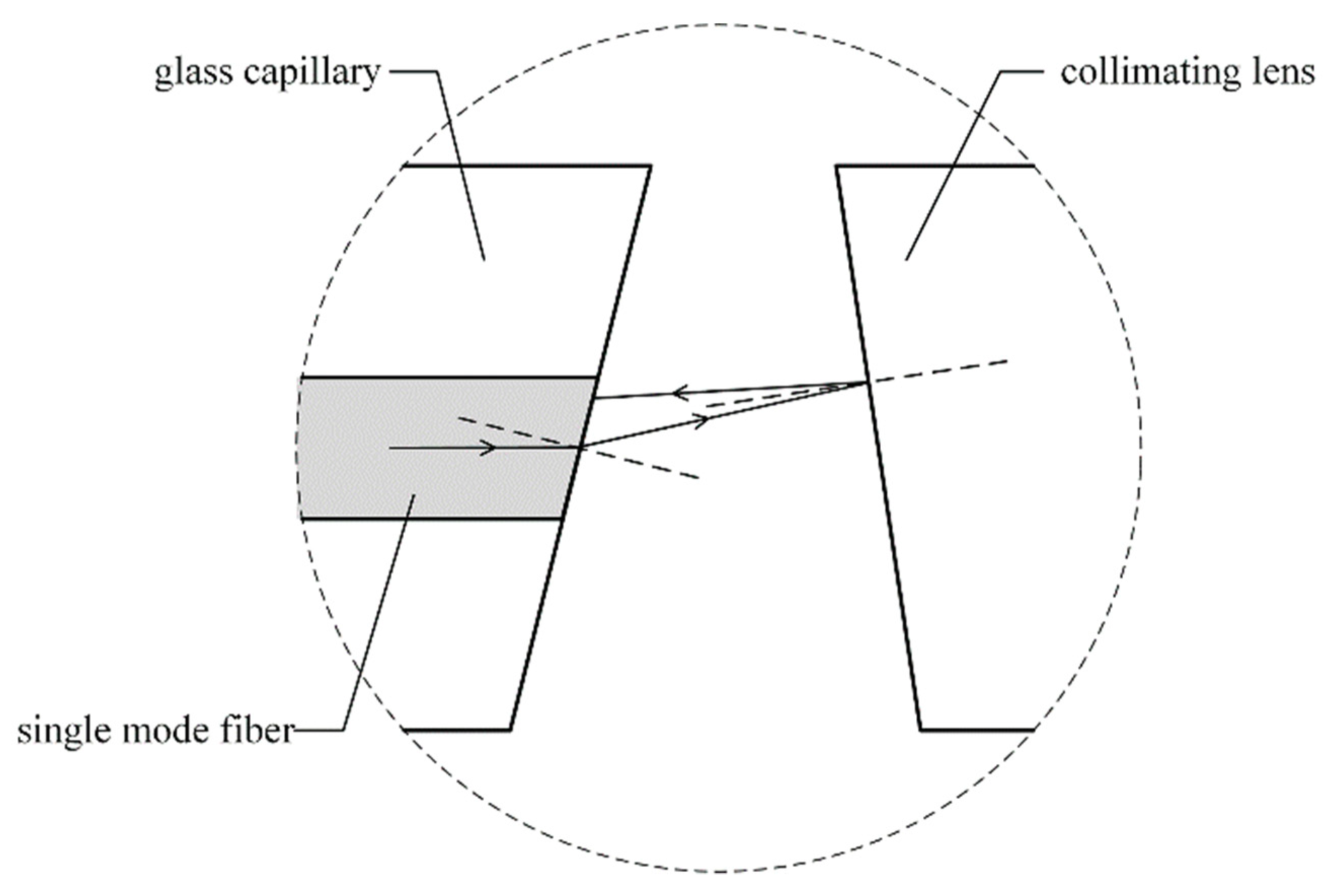

2.4. PDL Analysis

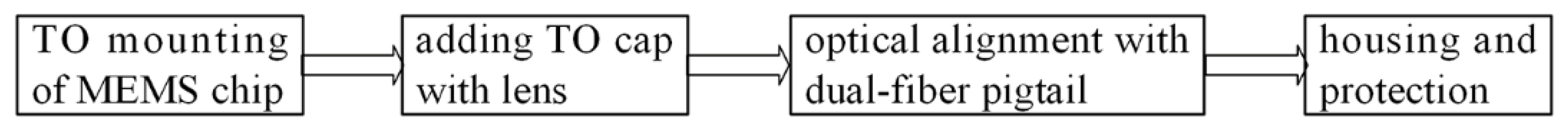

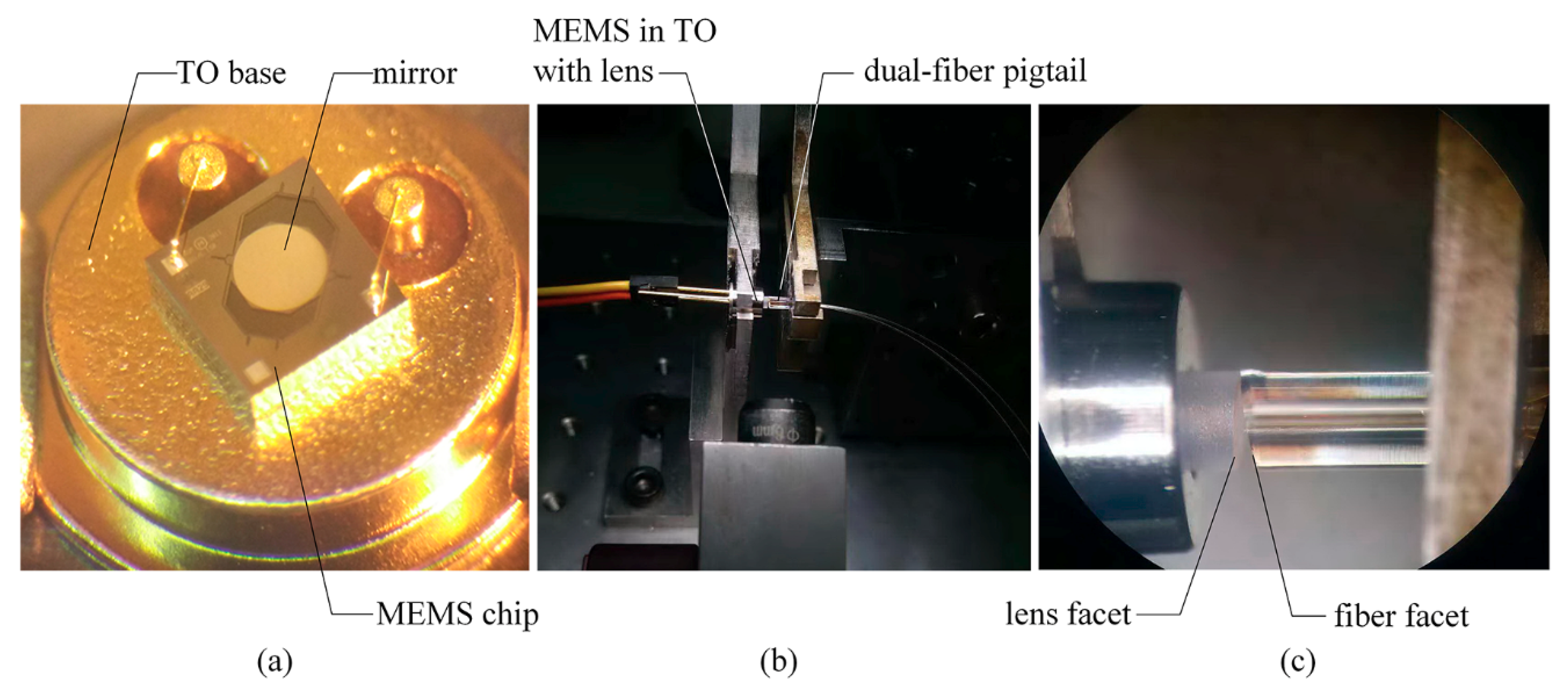

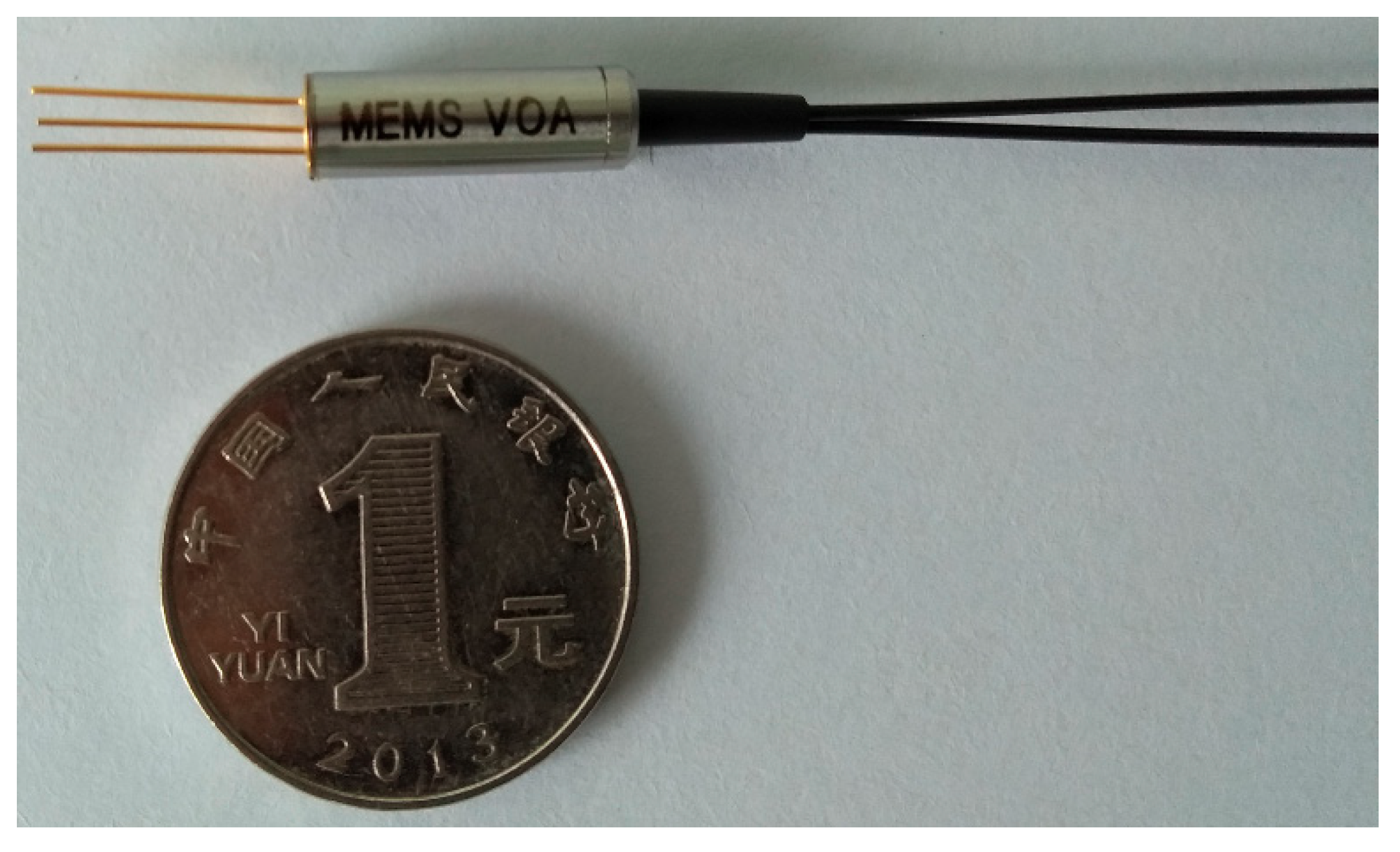

3. Experimental Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tsunashima, S.; Nakajima, F.; Nasu, Y.; Kasahara, R.; Nakanishi, Y.; Saida, T.; Yamada, T.; Sano, K.; Hashimoto, T.; Fukuyama, H.; et al. Silica-based, compact and variable-opticalattenuator integrated coherent receiver with stable optoelectronic coupling system. Opt. Express 2012, 20, 27174–27179. [Google Scholar] [CrossRef] [PubMed]

- Ogawa, I.; Doi, Y.; Hashizume, Y.; Kamei, S.; Tamura, Y.; Ishii, M.; Kominato, T.; Yamazaki, H.; Kaneko, A. Packaging Technology for Ultra-Small Variable Optical Attenuator Multiplexer (V-AWG) With Multichip PLC Integration Structure Using Chip-Scale-Package PD Array. IEEE J. Sel. Top. Quant. 2006, 12, 1045–1053. [Google Scholar] [CrossRef]

- Maese-Novo, A.; Zhang, Z.Y.; Irmscher, G.; Polatynski, A.; Mueller, T.; Felipe, D.D.; Kleinert, M.; Brinker, W.; Zawadzki, C.; Keil, N. Thermally optimized variable optical attenuators on a polymer platform. Appl. Opt. 2015, 54, 569–575. [Google Scholar] [CrossRef]

- Wan, J.; Xue, F.L.; Wu, L.X.; Fu, Y.J.; Hu, J.; Zhang, W.; Hu, F.R. Extensible chip of optofluidic variable optical attenuator. Opt. Express 2016, 24, 9683–9692. [Google Scholar] [CrossRef] [PubMed]

- Duduś, A.; Blue, R.; Uttamchandani, D. Single-mode fiber variable optical attenuator based on a ferrofluid shutter. App. Opt. 2015, 54, 1952–1957. [Google Scholar] [CrossRef] [PubMed]

- Martincek, I.; Pudis, D. Variable Liquid-Core Fiber Optical Attenuator Based on Thermo-Optical Effect. J. Lightwave Technol. 2011, 29, 2647–2650. [Google Scholar] [CrossRef]

- Lee, C. A MEMS VOA Using Electrothermal Actuators. J. Lightwave Technol. 2007, 25, 490–498. [Google Scholar] [CrossRef]

- Andrew, Y.J.; Jiang, S.S.; Lee, C. MOEMS variable optical attenuators using rotary comb drive actuators. IEEE Photonics Technol. Lett. 2006, 18, 1170–1172. [Google Scholar]

- Lee, C. Monolithic-integrated 8CH MEMS variable optical attenuator. Sens. Actuators A 2005, 123, 596–601. [Google Scholar] [CrossRef]

- Unamuno, A.; Blue, R.; Uttamchandani, D. Modeling and Characterization of a Vernier Latching MEMS Variable Optical Attenuator. J. Microelectromech. Syst. 2013, 22, 1229–1241. [Google Scholar] [CrossRef]

- Isamoto, K.; Kato, K.; Morosawa, A.; Chong, C.H.; Fujita, H.; Toshiyoshi, H. A 5-V Operated MEMS Variable Optical Attenuator by SOI Bulk Micromachining. IEEE J. Sel. Top. Quant. 2004, 10, 570–578. [Google Scholar] [CrossRef]

- Chu, C.; Belov, N.; Hout, S.I.; Vanganov, V. Method and Apparatus of Optical Components Having Improved Optical Properties. U.S. Patent 2004/0008967 A1, 15 January 2004. [Google Scholar]

- Chen, B.; Liu, X.S.; Yang, Y.T.; Cai, B. Variable Optical Attenuator with Wavelength Dependent Loss Compensation. U.S. Patent 7,295,748 B2, 13 November 2007. [Google Scholar]

- Godil, A.A.; Honer, K.; Lawrence, M.; Gustafson, E. Optical Attenuator. U.S. Patent 8,280,218 B2, 2 October 2012. [Google Scholar]

- Yuan, S.F.; Riza, N.A. General formula for coupling-loss characterization of single-mode fiber collimators by use of gradient-index rod lenses. App. Opt. 1999, 38, 3214–3222. [Google Scholar] [CrossRef]

- Liu, H.Z.; Liu, L.R.; Xu, R.W.; Luan, Z. ABCD matrix for reflection and refraction of Gaussian beams at the surface of a parabola of revolution. App. Opt. 2005, 44, 4809–4813. [Google Scholar] [CrossRef]

| Optical Fiber | Refractive Index | Mode Radius | Mode Dispersion | Facet Angle |

|---|---|---|---|---|

| Corning SMF-28 | nf = 1.4682 | ωc = 5.2 μm | Δω = 0.0622 μm | α = 8˚ |

| Material | Refractive Index | Length | Curvature Radius | Facet Angle |

|---|---|---|---|---|

| Schott N-SF11 | nc = 1.7434 | L = 2.72 mm | R = 1.419 mm | φ = −7° |

| MEMS Mirror | Clear Aperture | Maximum Tilting Angle |

|---|---|---|

| Preciseley LV-VOA | Ф0.85 mm | 0.35° @5 V |

| No. | IL | RL | PDL (dB) | ||||

|---|---|---|---|---|---|---|---|

| (dB) | (dB) | @IL | @5 dB | @10 dB | @15 dB | @20 dB | |

| #1 | 0.55 | 52.2 | 0.02 | 0.05 | 0.07 | 0.10 | 0.10 |

| #2 | 0.58 | 51.5 | 0.01 | 0.04 | 0.05 | 0.07 | 0.12 |

| Conventional | 0.44 | 56.3 | 0.04 | 0.07 | 0.13 | 0.19 | 0.26 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, H.; Zhou, W.; Zhang, Z.; Wan, Z. A MEMS Variable Optical Attenuator with Ultra-Low Wavelength-Dependent Loss and Polarization-Dependent Loss. Micromachines 2018, 9, 632. https://doi.org/10.3390/mi9120632

Sun H, Zhou W, Zhang Z, Wan Z. A MEMS Variable Optical Attenuator with Ultra-Low Wavelength-Dependent Loss and Polarization-Dependent Loss. Micromachines. 2018; 9(12):632. https://doi.org/10.3390/mi9120632

Chicago/Turabian StyleSun, Huangqingbo, Wei Zhou, Zijing Zhang, and Zhujun Wan. 2018. "A MEMS Variable Optical Attenuator with Ultra-Low Wavelength-Dependent Loss and Polarization-Dependent Loss" Micromachines 9, no. 12: 632. https://doi.org/10.3390/mi9120632

APA StyleSun, H., Zhou, W., Zhang, Z., & Wan, Z. (2018). A MEMS Variable Optical Attenuator with Ultra-Low Wavelength-Dependent Loss and Polarization-Dependent Loss. Micromachines, 9(12), 632. https://doi.org/10.3390/mi9120632